Porcelain plate blank powder and preparation technology thereof

A preparation process and a technology for ceramic slabs, which are applied in the field of ceramic slab body powder and its preparation, can solve the problems of difficulty in drying and crushing, low water absorption and high moisture content, and achieve improved dry blank strength and low raw material moisture. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

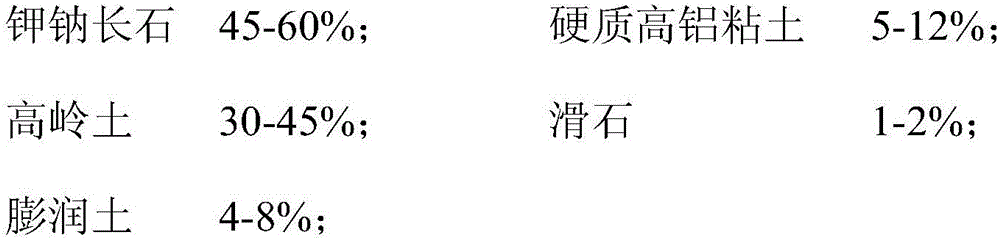

Method used

Image

Examples

Embodiment 1

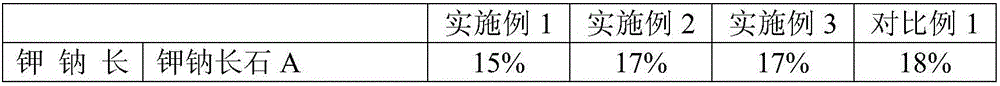

[0050] Each component of embodiment 1 and the ratio of each component are recorded in Table 1.

[0051] A preparation process of porcelain plate body powder, comprising the following steps:

[0052] 1) Raw material crushing; use a jaw crusher to coarsely, mediumly and finely crush each component in the formula to obtain the first crushed material with a crushing fineness of 12 meshes;

[0053] 2) drying for the first time; drying the first crushed material respectively to obtain the second crushed material with a moisture content of 6%;

[0054] 3) batching; respectively weigh the second crushed material according to the formula amount, and mix uniformly to obtain the first mixed material; when weighing the second crushed material, various raw materials are continuously weighed by electronic belt;

[0055] 4) fine grinding; finely grinding and winnowing the first mixture to obtain a second mixture with a fineness of 325 mesh;

[0056] 5) Humidification and granulation: put t...

Embodiment 2

[0062] Embodiment 2 each component and the proportioning ratio of each component are recorded in Table 1.

[0063] A preparation process of porcelain plate body powder, comprising the following steps:

[0064] 1) Raw material crushing; use dry grinding equipment to carry out coarse, medium and fine crushing of each component in the formula respectively to obtain the first crushed material with a crushing fineness of 12 meshes;

[0065] 2) drying for the first time; drying the first crushed material respectively to obtain the second crushed material with a moisture content of 7%;

[0066] 3) batching; respectively weigh the second crushed material according to the formula amount, and mix uniformly to obtain the first mixed material; when weighing the second crushed material, various raw materials are continuously weighed by electronic belt;

[0067] 4) fine grinding; finely grinding and winnowing the first mixture to obtain a second mixture with a fineness of 325 mesh;

[006...

Embodiment 3

[0074] Embodiment 3 each component and the proportioning ratio of each component are recorded in Table 1.

[0075] A preparation process of porcelain plate body powder, comprising the following steps:

[0076] 1) Raw material crushing; use a jaw crusher to coarsely, mediumly and finely crush each component in the formula to obtain the first crushed material with a crushing fineness of 12 meshes;

[0077] 2) drying for the first time; drying the first crushed material respectively to obtain the second crushed material with a moisture content of 8%;

[0078] 3) batching; respectively weigh the second crushed material according to the formula amount, and mix uniformly to obtain the first mixed material; when weighing the second crushed material, various raw materials are continuously weighed by electronic belt;

[0079] 4) fine grinding; finely grinding and winnowing the first mixture to obtain a second mixture with a fineness of 325 mesh;

[0080] 5) Humidification and granula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com