Honeycomb paperboard all-paper tray and manufacturing method thereof

A technology of honeycomb cardboard and its production method, which is applied to cardboard items, rigid containers, containers, etc., can solve the problems of cumbersome and increased packaging and transportation costs, and achieve the effects of eliminating high costs, good social benefits, and increasing the scale of tax payment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

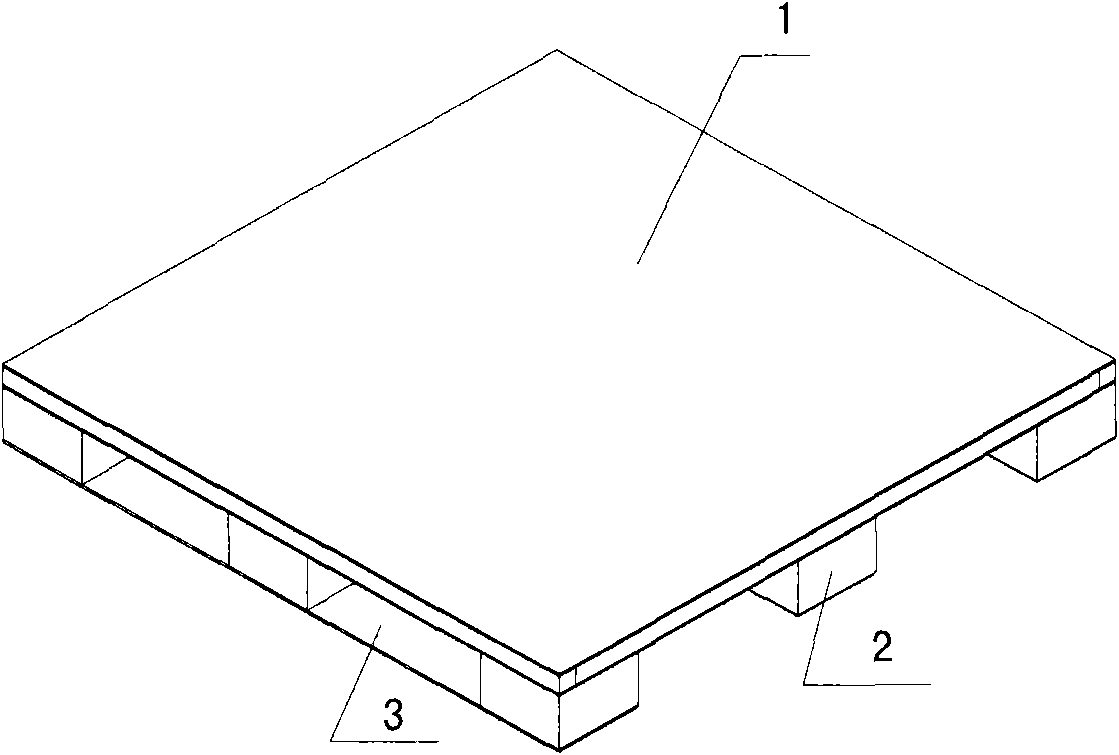

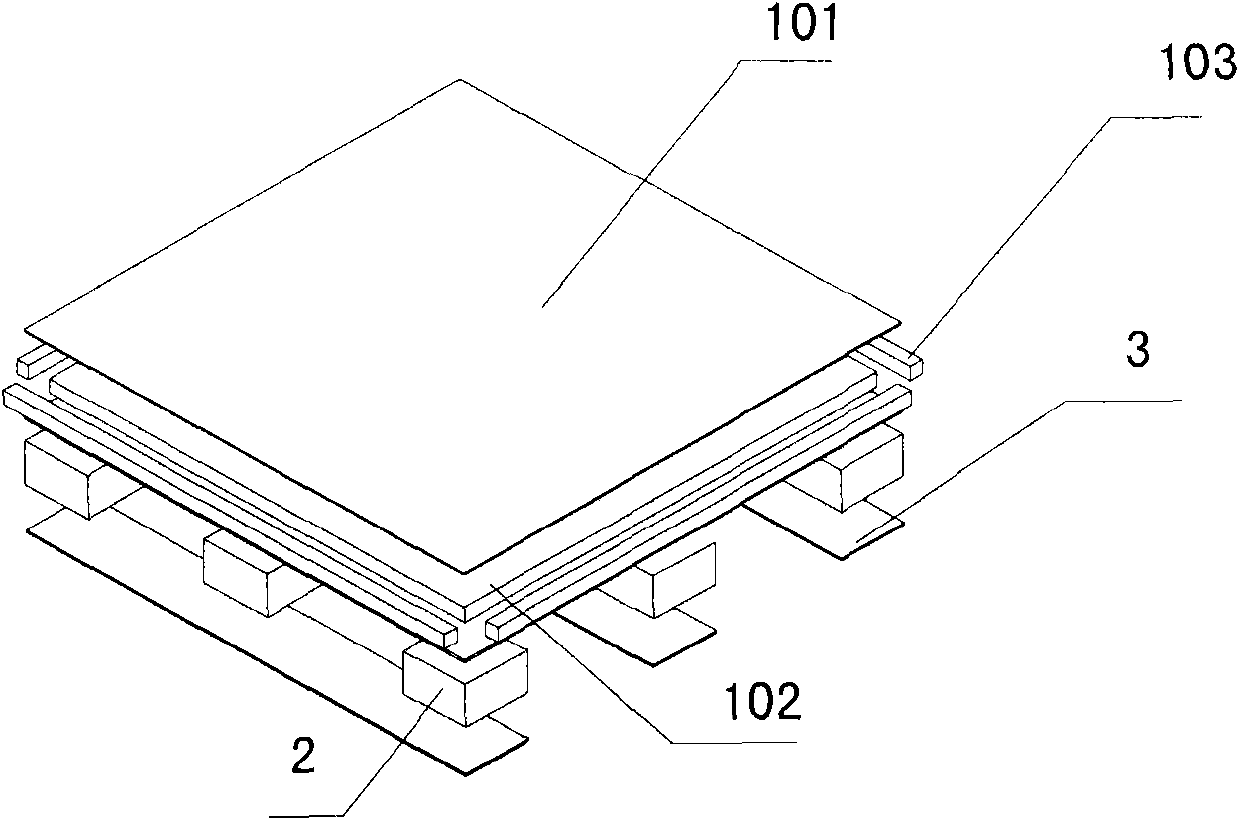

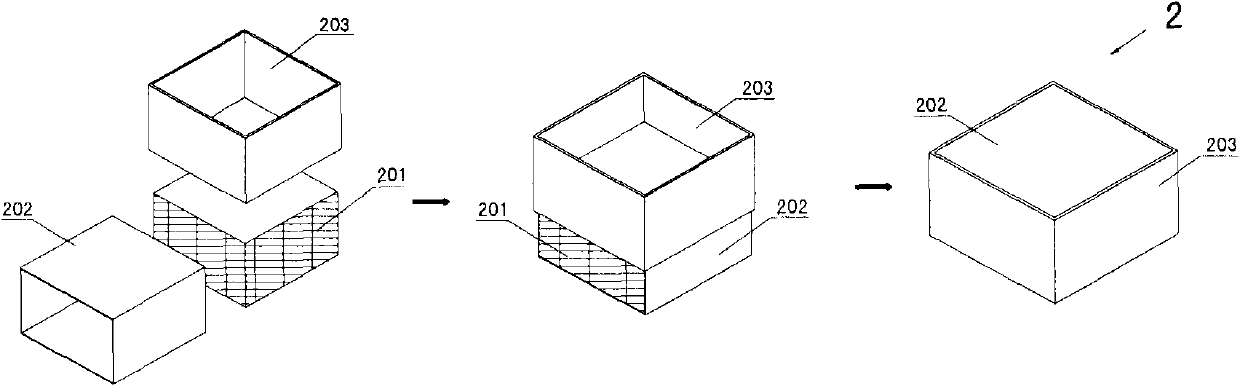

[0046] Such as figure 1 , figure 2 As shown, the honeycomb paperboard all-paper pallet of the present invention includes a top decking board 1, a bottom pier 2 for supporting the top decking board 1 and a bottom belt 3 connecting the bottom pier 2, and the top decking board 1 includes a honeycomb paperboard substrate 102, which is composited on the honeycomb paperboard The paper cardboard 101 on the upper and lower surfaces of the base material 102 is compounded on the paper square tube 103 around the honeycomb cardboard base material 102; image 3 As shown, the bottom pier 2 includes a honeycomb cardboard filling block 201, a paper square tube inner cover 202 and a paper square tube outer cover 203, the paper square tube inner cover 202 is set outside the honeycomb cardboard filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com