End part local elongation type anti-buckling support-beam-column connecting node

A technology of anti-buckling support and connecting nodes, which is applied in the direction of architecture and building structure, can solve the problems of adverse effects on the seismic performance of building structures, easy cracking of beam ends and column end flanges, and difficulties in repairing structures after earthquakes, and achieves easy Post-earthquake repair, detachable post-earthquake repair, and good stability of nodes out of plane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

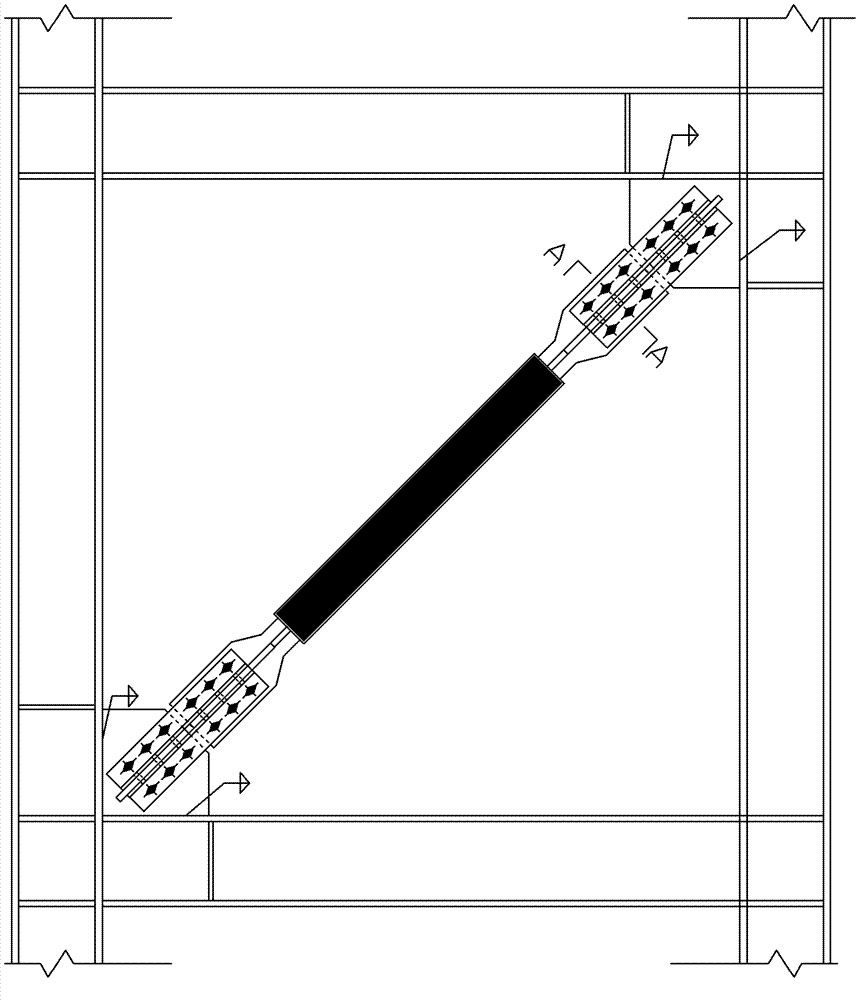

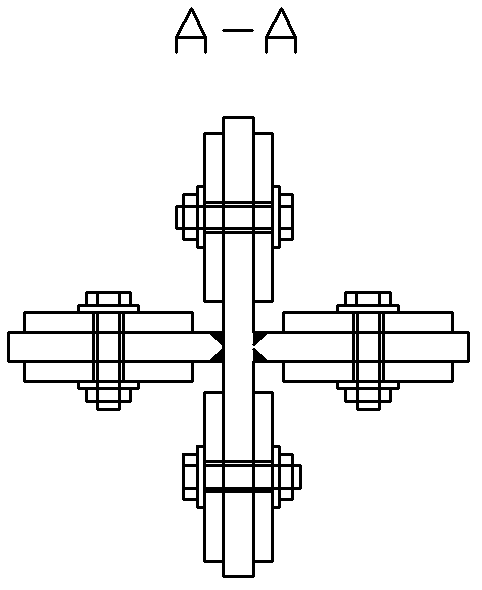

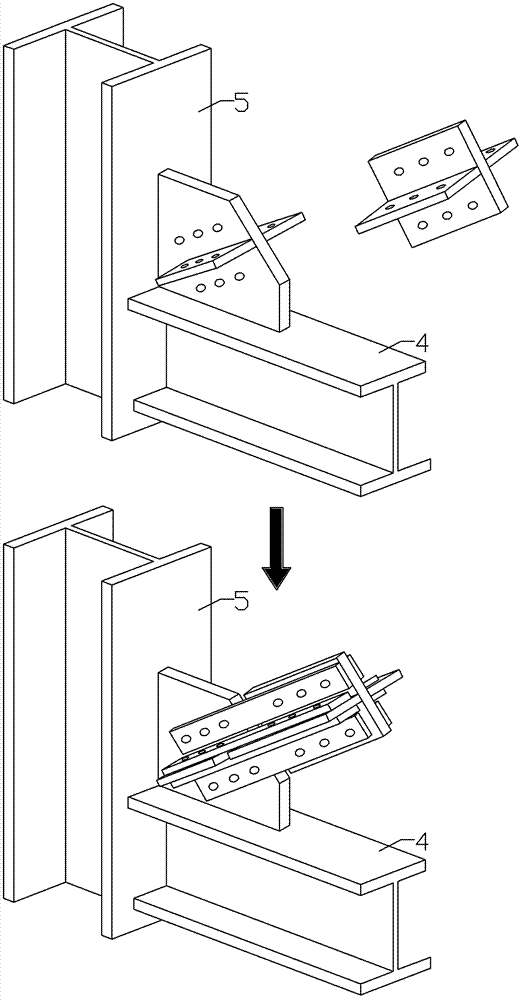

[0017] Specific implementation mode one: combine Figure 4 ~ Figure 14 Illustrate, the local elongation type buckling-resistant brace-beam-column connecting node of the present embodiment, described connecting node comprises I-shaped steel beam 4 and H-shaped steel column 5, and one end of I-shaped steel beam 4 and H-shaped steel column 5 The outer surface of one side of the flange 5-1 is attached to each other; the connection node also includes a frame gusset plate 6, a local elongated node 7 at the end (buckling-resistant support), a plurality of first high-strength bolts 10 and a plurality of second High strength bolt 11;

[0018] The middle gusset plate 6-1 of the frame gusset plate 6 is inserted into the open slot 7-5 on the end part elongated node 7, and the two local elongated stiffening parts of the end part elongated node 7 Ribs or partially elongated core plates 7-2 are symmetrically arranged on both sides of the intermediate gusset plate 6-1, and the inclined plane...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination Figure 4 ~ Figure 10 and Figure 14 Note that the frame gusset 6 in this embodiment includes an intermediate gusset 6-1, a vertical end plate 6-2, a horizontal end plate 6-3, a horizontal stiffening rib 6-4 and a vertical stiffening rib 6-5 ;

[0020]The middle gusset plate 6-1 is arranged vertically, the upper end face and the lower end face of the middle gusset plate 6-1 are both horizontal planes, the length of the upper end face of the middle gusset plate 6-1 is less than the length of the lower end face, and the middle gusset plate 6-1 One end of the upper end face of the middle gusset plate is flush with one end of the lower end face, the other end of the upper end face of the middle gusset plate 6-1 is connected with the other end of the lower end face through the inclined plane 6-6 and the vertical plane 6-7 in turn, and the middle gusset plate 6 -1 has a first positioning bolt hole 6-8, the lower end surface of t...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination Figure 11 to Figure 14 Note that the locally elongated end node 7 (buckling-resistant support) in this embodiment includes an intermediate core plate 7-1 and two locally elongated stiffeners or locally elongated core plates 7-2 (used to support the end part); two partially elongated stiffeners or partially elongated core plates 7-2 are symmetrically arranged on both sides of the middle core plate 7-1 in the thickness direction and are perpendicular to the middle core plate 7-1, and the local elongated stiffeners Or the length of the partially elongated core board 7-2 is longer than the board length of the middle core board 7-1, and one side of the middle core board 7-1 in the length direction is connected with two partially elongated stiffeners or the partially elongated core board 7 One side of the length direction of -2 is arranged flush, the middle core plate 7-1 is welded with two partially elongated stiffeners or par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com