160MPa earthquake-proof low yield strength steel, steel plate and manufacturing method thereof

A technology with low yield strength and manufacturing method, which is applied in the field of iron and steel materials, can solve the problems that are not conducive to steel plate welding and low-temperature impact performance, increase manufacturing difficulty and cost, and fail to provide low-temperature impact performance, and achieve simple and economical composition design. The effect of earthquake resistance and excellent plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following examples describe the present invention in more detail. These examples are merely descriptions of the best embodiments of the present invention, and do not limit the scope of the present invention in any way.

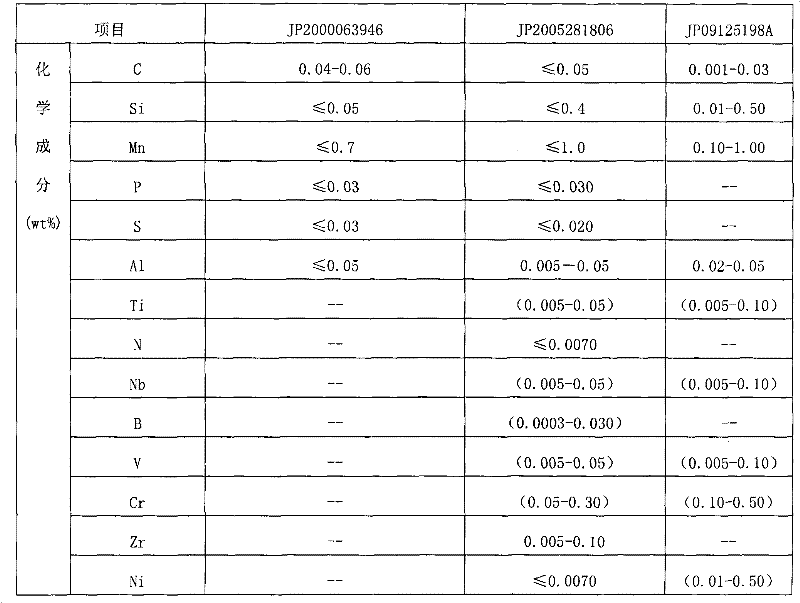

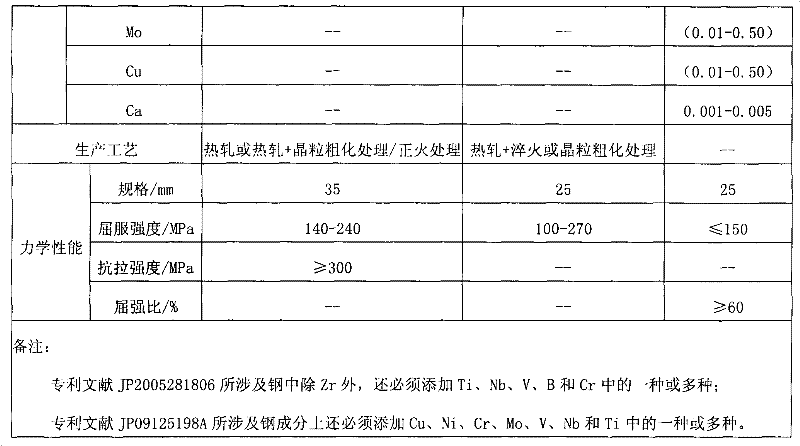

[0037] The steel slab produced in each embodiment of the present invention has the chemical composition shown in Table 2. The obtained steel slab is heated to 1100-1250°C, and the final rolling temperature is 850-950°C. After rolling, it is air-cooled or water-cooled to room temperature, and the rolling thickness is 30-50mm. , The mechanical properties of the obtained steel plate are shown in Table 3.

[0038] Table 2 The chemical composition (wt%) of the steel billet produced in each embodiment of the present invention

[0039] Example

C

Si

Mn

P

S

Al

Nb

V

Ti

B

N

A

0.016

0.064

0.34

0.0050

0.0047

0.034

--

--

0.033

0.0002

0.0019

B

0.005

0.035

1.08

0.008

0.0038

0.042

--

--

0.035

--

0.00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com