Patents

Literature

91results about How to "Avoid torsional deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

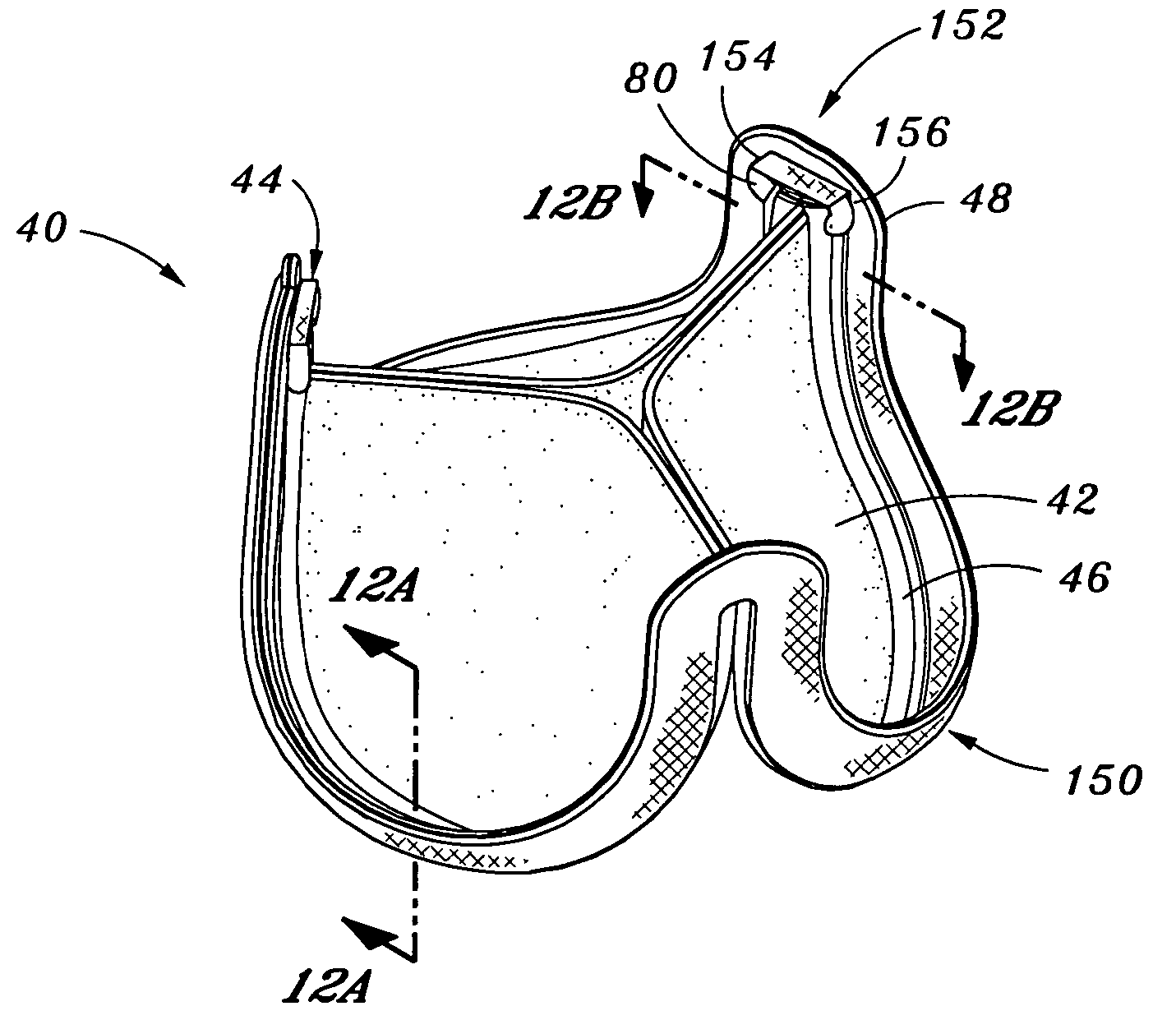

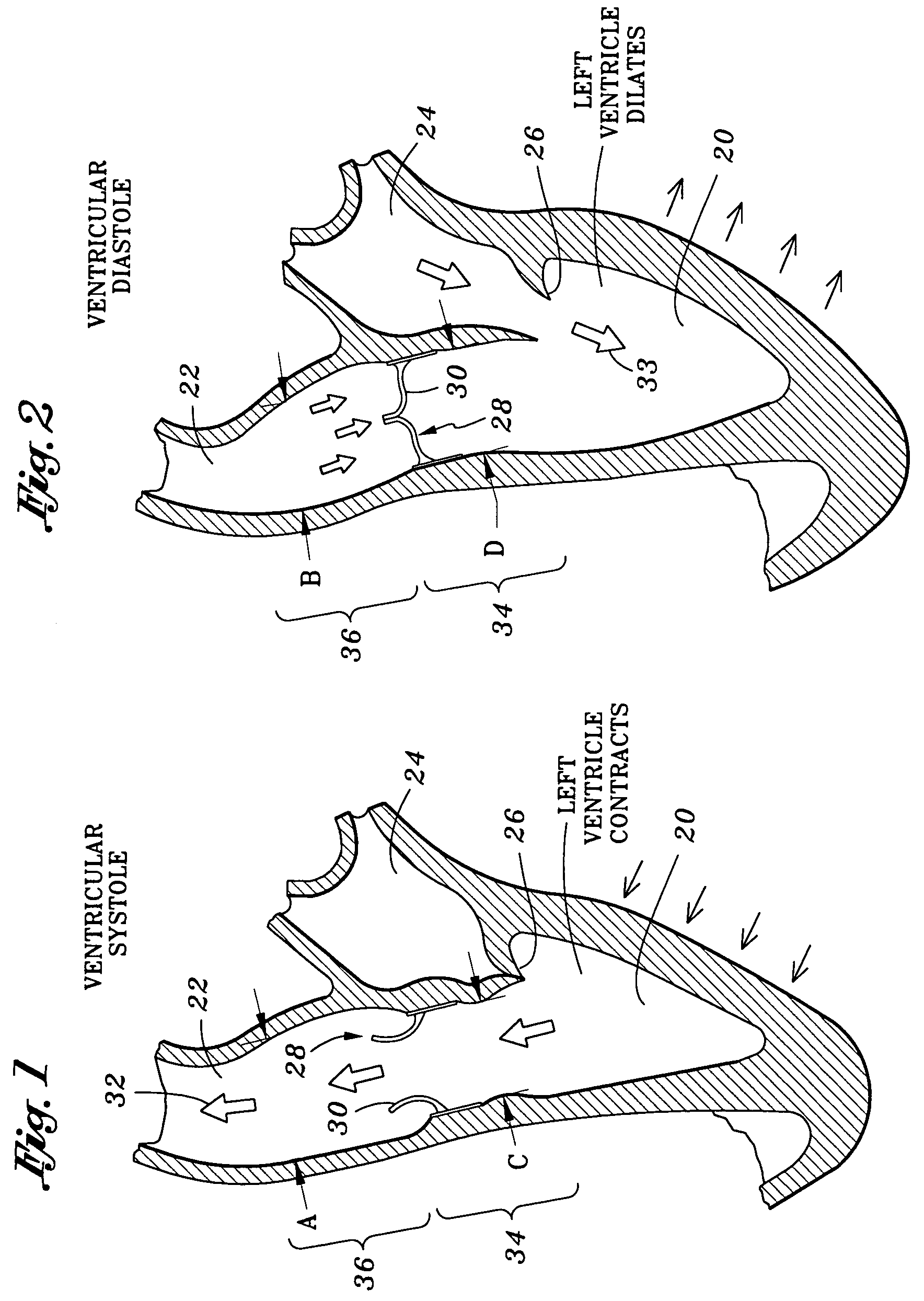

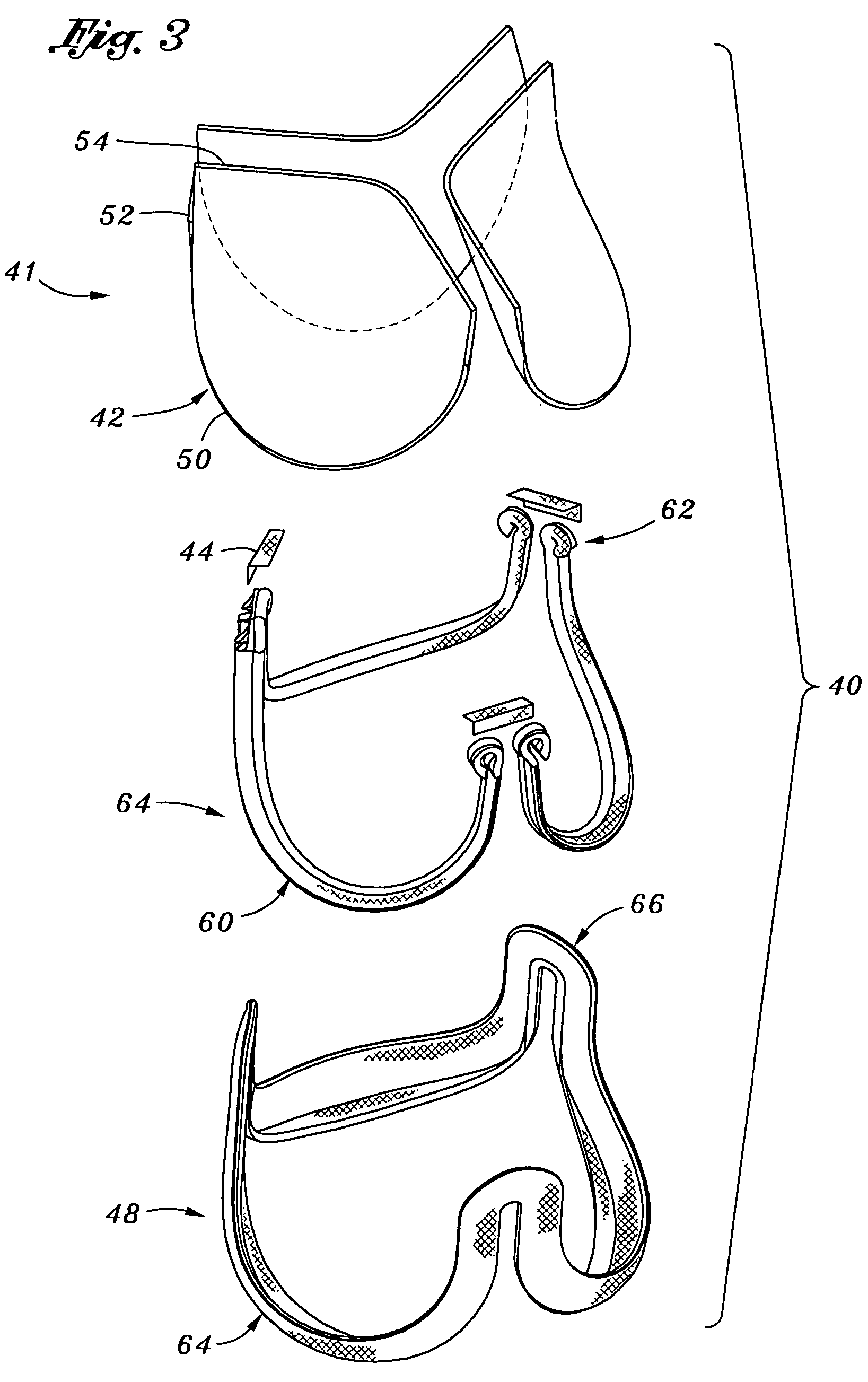

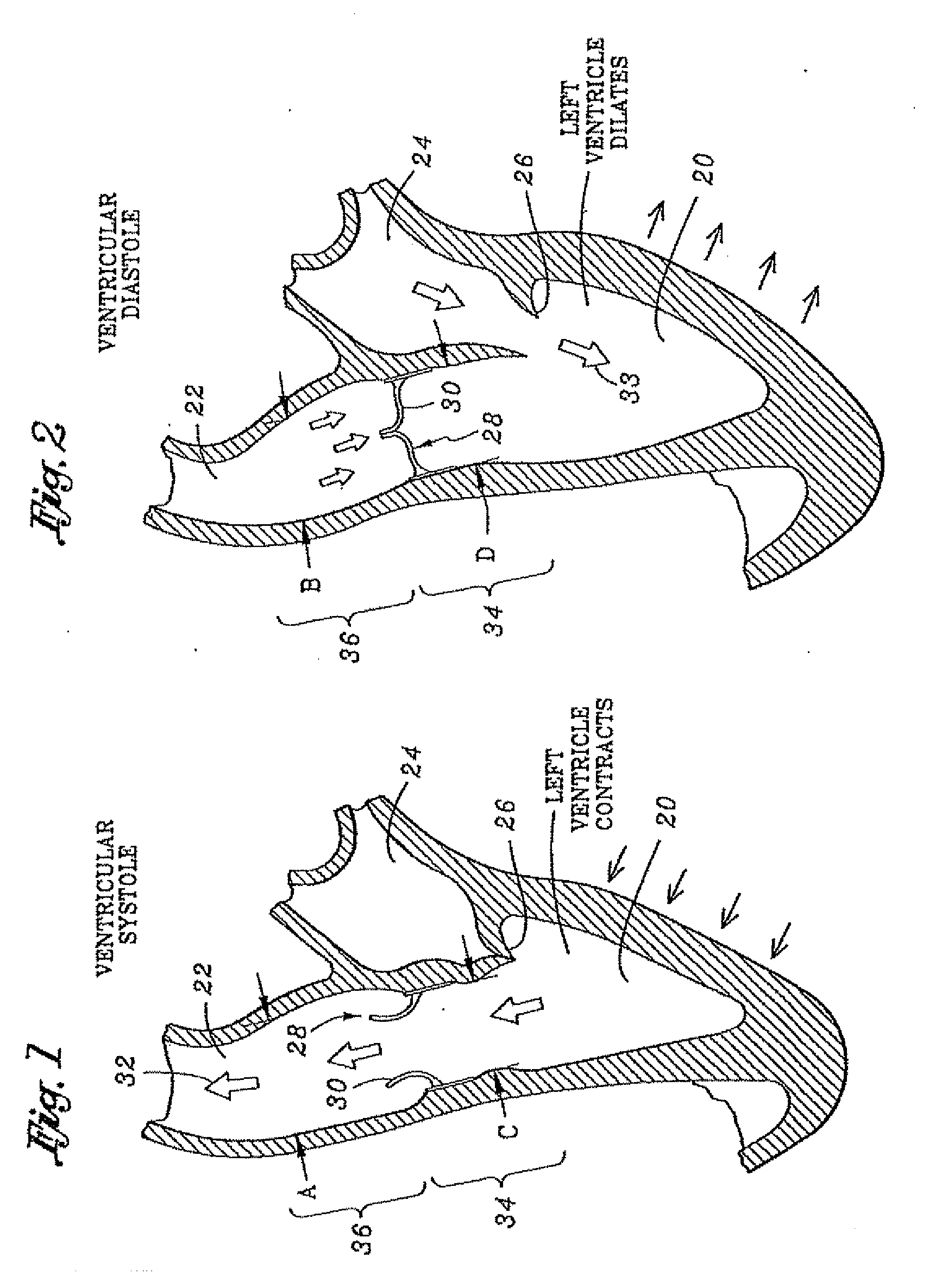

Flexible heart valve and associated connecting band

A highly flexible tissue-type heart valve is disclosed having a structural stent in a generally cylindrical configuration with cusps and commissures that are permitted to move radially. The stent commissures are constructed so that the cusps are pivotably or flexibly coupled together at the commissures to permit relative movement therebetween.

Owner:EDWARDS LIFESCIENCES CORP

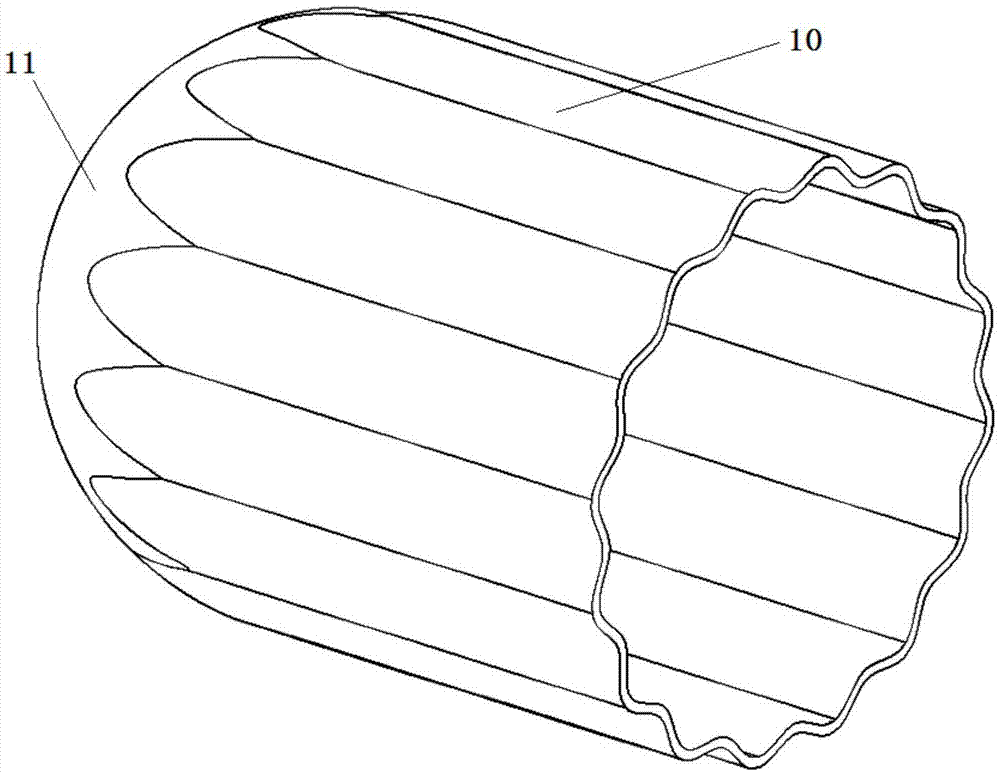

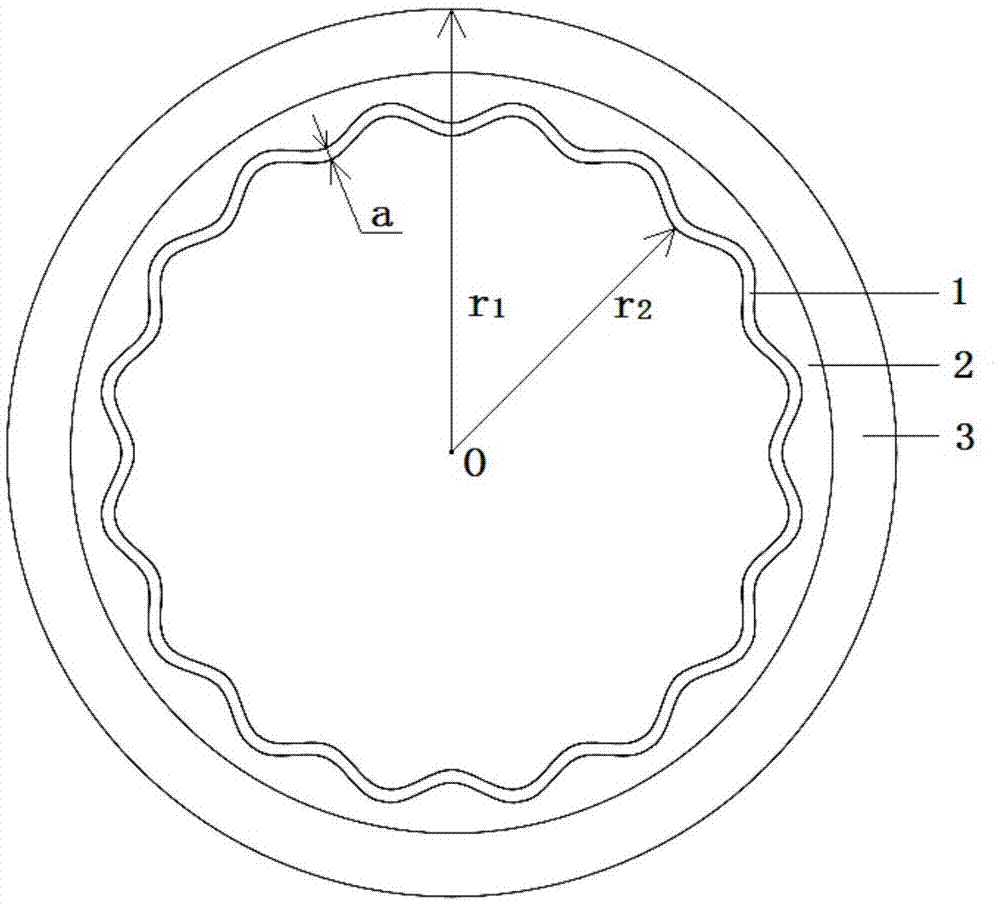

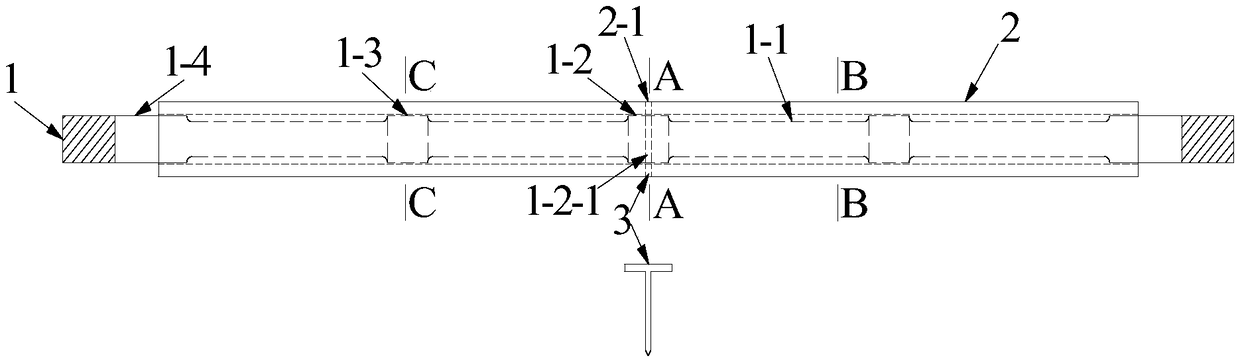

Fibrous-composite-wound pressure container with thin-walled metal lining and manufacturing process thereof

InactiveCN105443973AFull sealing effectIncrease the allowable loadVessel geometry/arrangement/sizeVessel wallsThin walledFibrous composites

The invention discloses a fibrous-composite-wound pressure container with a thin-walled metal lining and a manufacturing process thereof. The pressure container is characterized in that a lining barrel body section is of a thin-walled metal tube structure, and the wall face of the lining barrel body section is corrugated; the pressure container further comprises an elastic material filling layer wrapped outside the lining barrel body section; a fibrous composite winding layer is wrapped outside the elastic material filling layer and a lining end closure section. The manufacturing process of the pressure container includes the steps of S1, manufacturing the lining through a thin-walled metal material, S2, wrapping elastic materials outside the lining barrel body section and S3, winding fibrous composites varnished in resin on the outer surface of the elastic material filling layer in a layered mode and carrying out curing molding. According to the pressure container and the manufacturing process thereof, the lining, the fibrous composite winding layer and the adjacent layers are not prone to debonding or failures.

Owner:DALIAN UNIV OF TECH

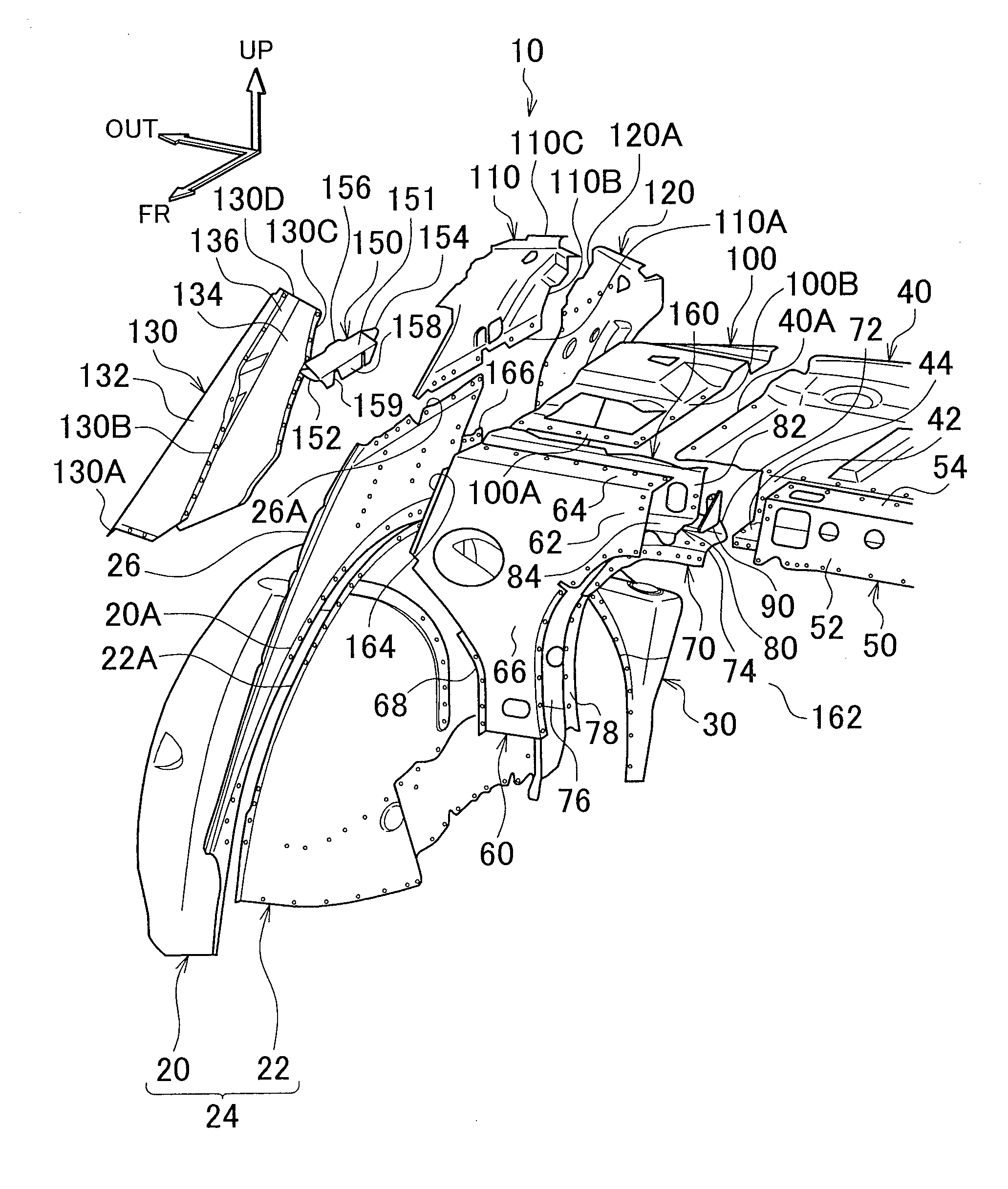

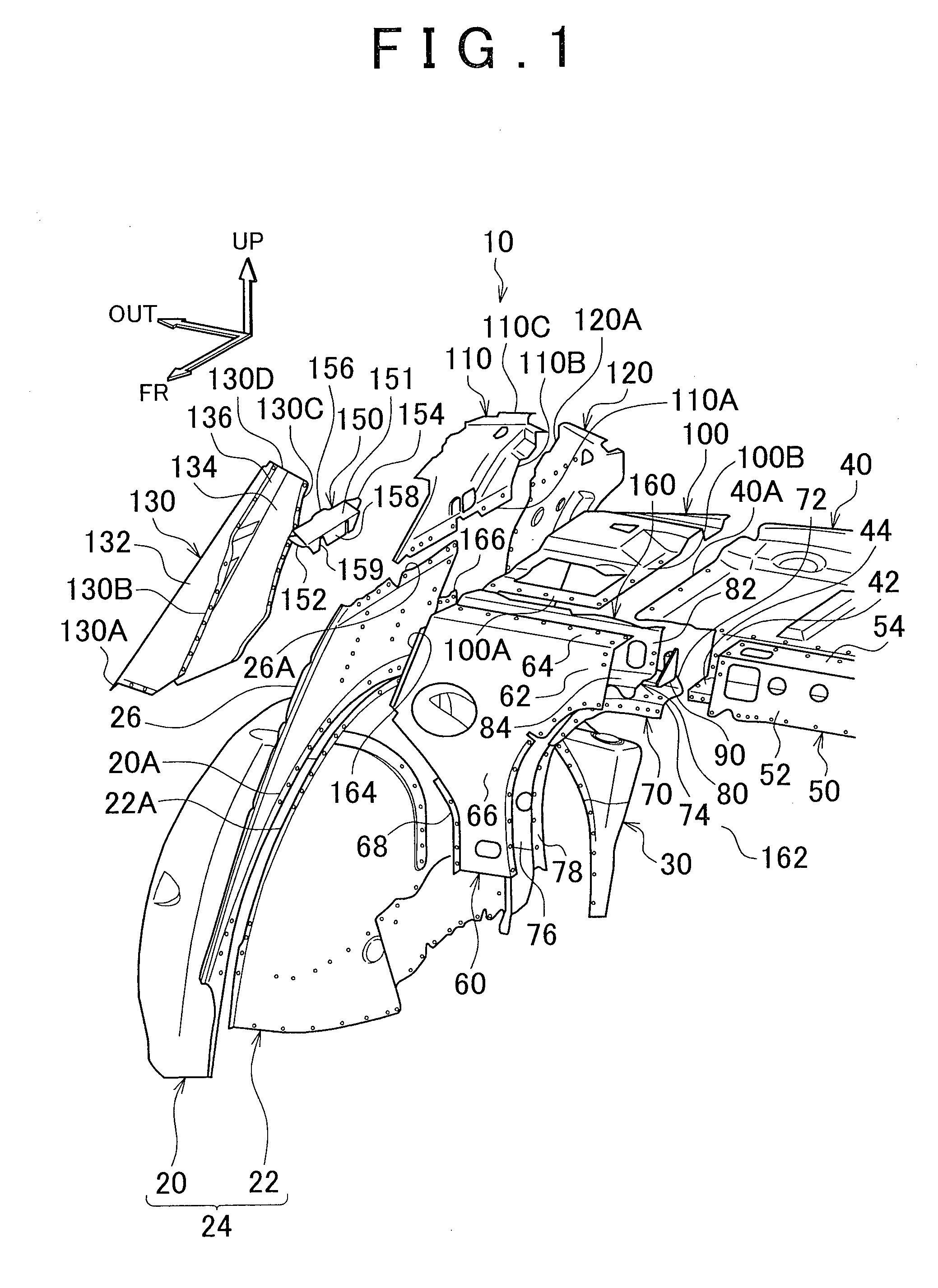

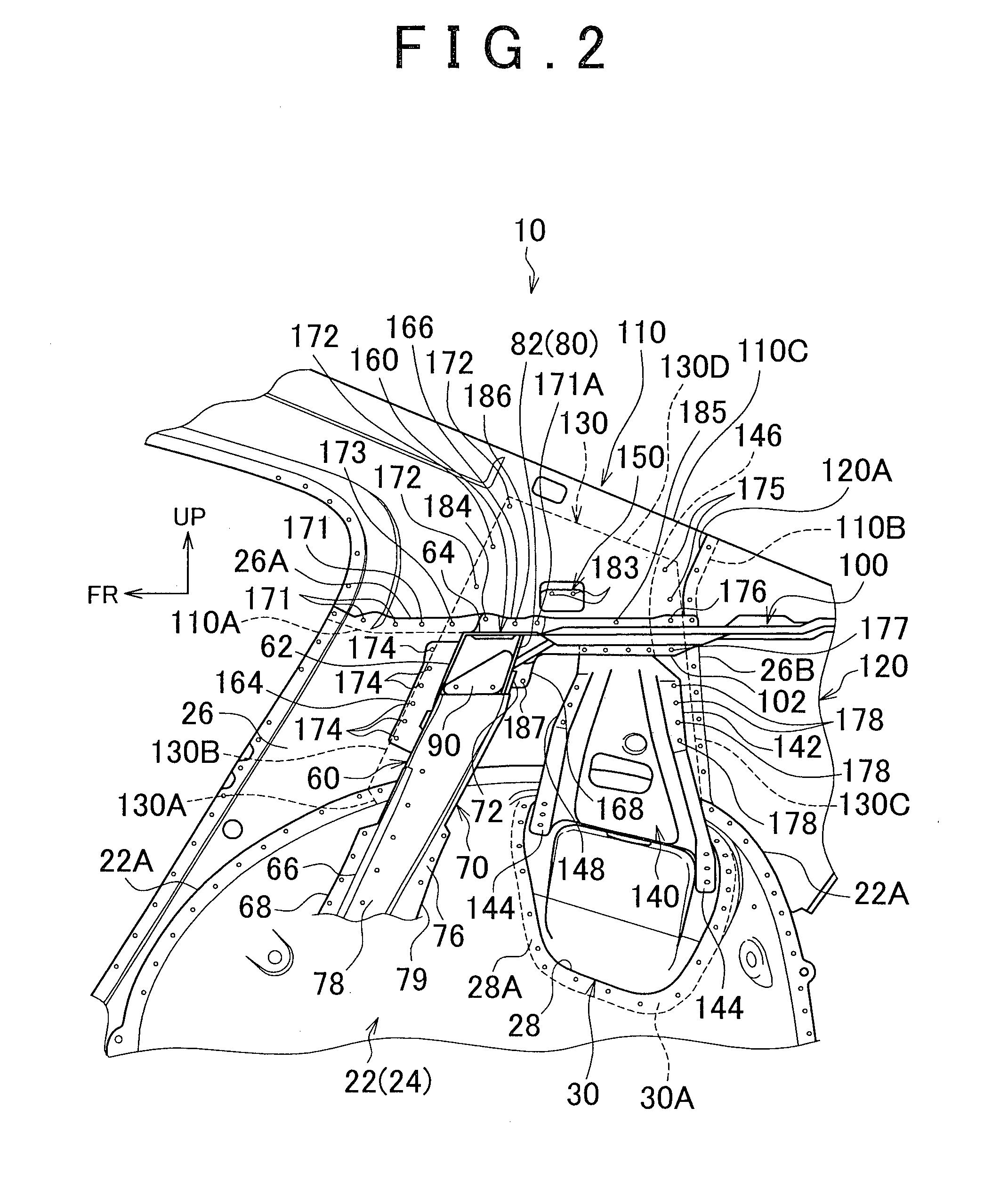

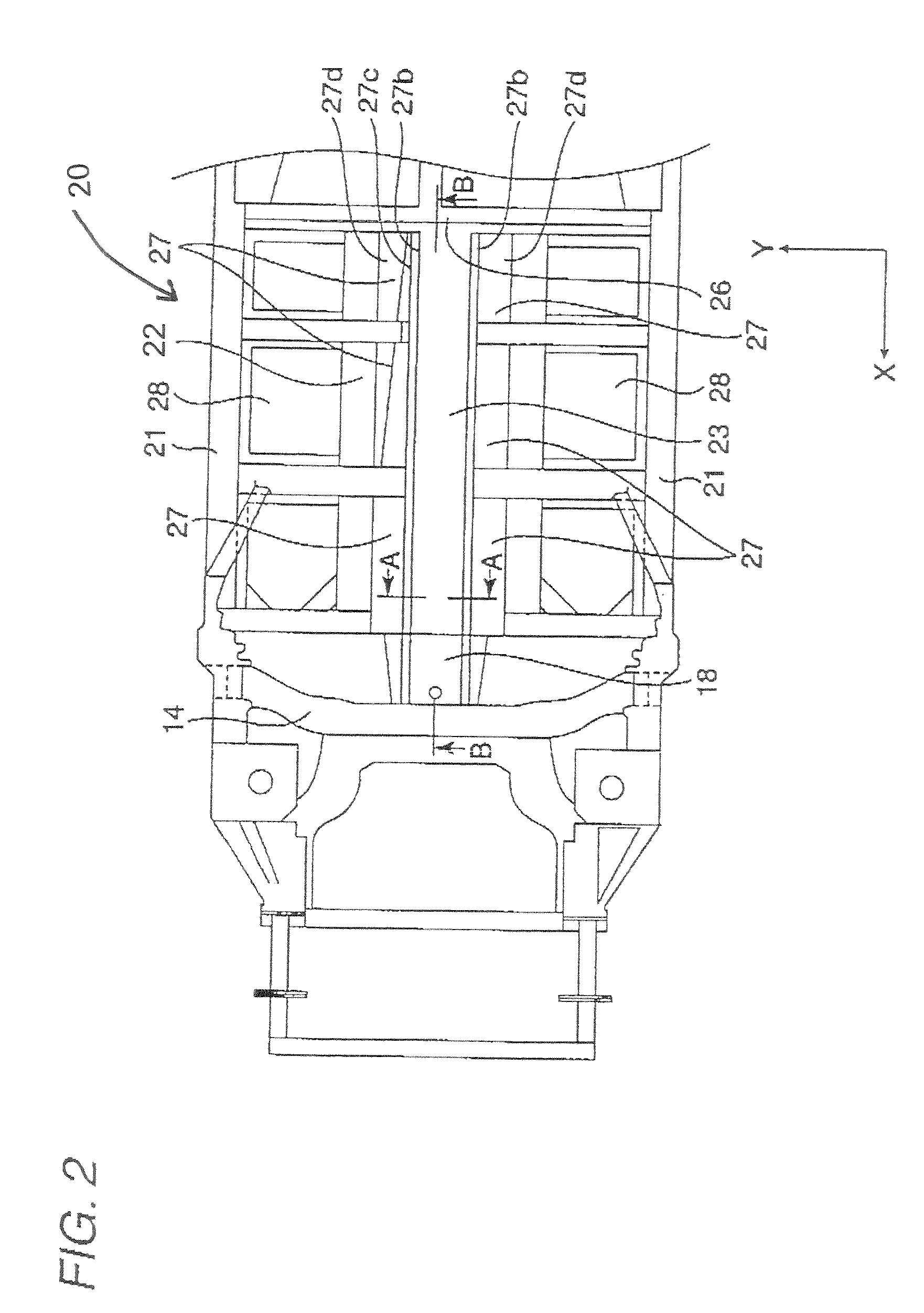

Vehicle body rear structure

ActiveUS20140152054A1Efficient separationAvoid torsional deformationVehicle seatsSuperstructure subunitsEngineeringMechanical engineering

A vehicle body rear structure includes an upper back cross-sectional portion which forms a skeleton that is elongated in a vehicle width direction, a bracket package tray which is located on a vehicle rear side of the upper back cross-sectional portion and joined to the upper back cross-sectional portion, a roof side inner which is located on a vehicle top side of a wheel house, a roof side outer which is located outside an extended portion and the roof side inner in a vehicle width direction and which has a front end portion which is joined to the upper back cross-sectional portion and a rear end portion which is joined to a bracket package tray, and a bulk which couples the roof side outer and the upper back cross-sectional portion.

Owner:TOYOTA JIDOSHA KK

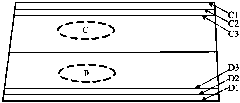

Two-way allowance-variable milling method for blade

ActiveCN103990840AHigh precisionImprove positionMilling equipment detailsEngineeringDimensional modeling

The invention discloses a two-way allowance-variable milling method for a blade. The method is used for solving the technical problem that an existing allowance-variable milling method for the blade is low in accuracy. According to the technical scheme, firstly, a three-dimensional blade model is established in three-dimensional modeling software UG; both the two end faces of the blade are made deflect towards a blade body in the three-dimensional blade model, so that two deflection faces, namely, the blade root edge interface and the blade tip edge interface, are obtained; a driving face is determined by means of a section line lofting method; then, machining routes on the driving face are determined; allowance of each machining route is determined by means of a lever allowance fine tuning method; finally, circulation machining is conducted on the blade according to the set allowance, so that machining accuracy is improved for the blade. According to the method, when the blade with the length which is about 70 mm is machined, the surface tolerance of the blade can be controlled within the range of 0.06 mm to 0.1 mm.

Owner:西安三航动力科技有限公司

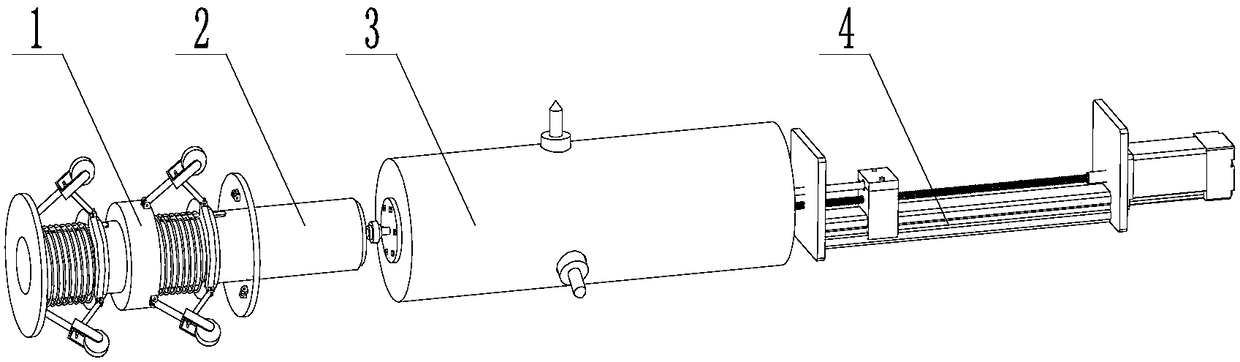

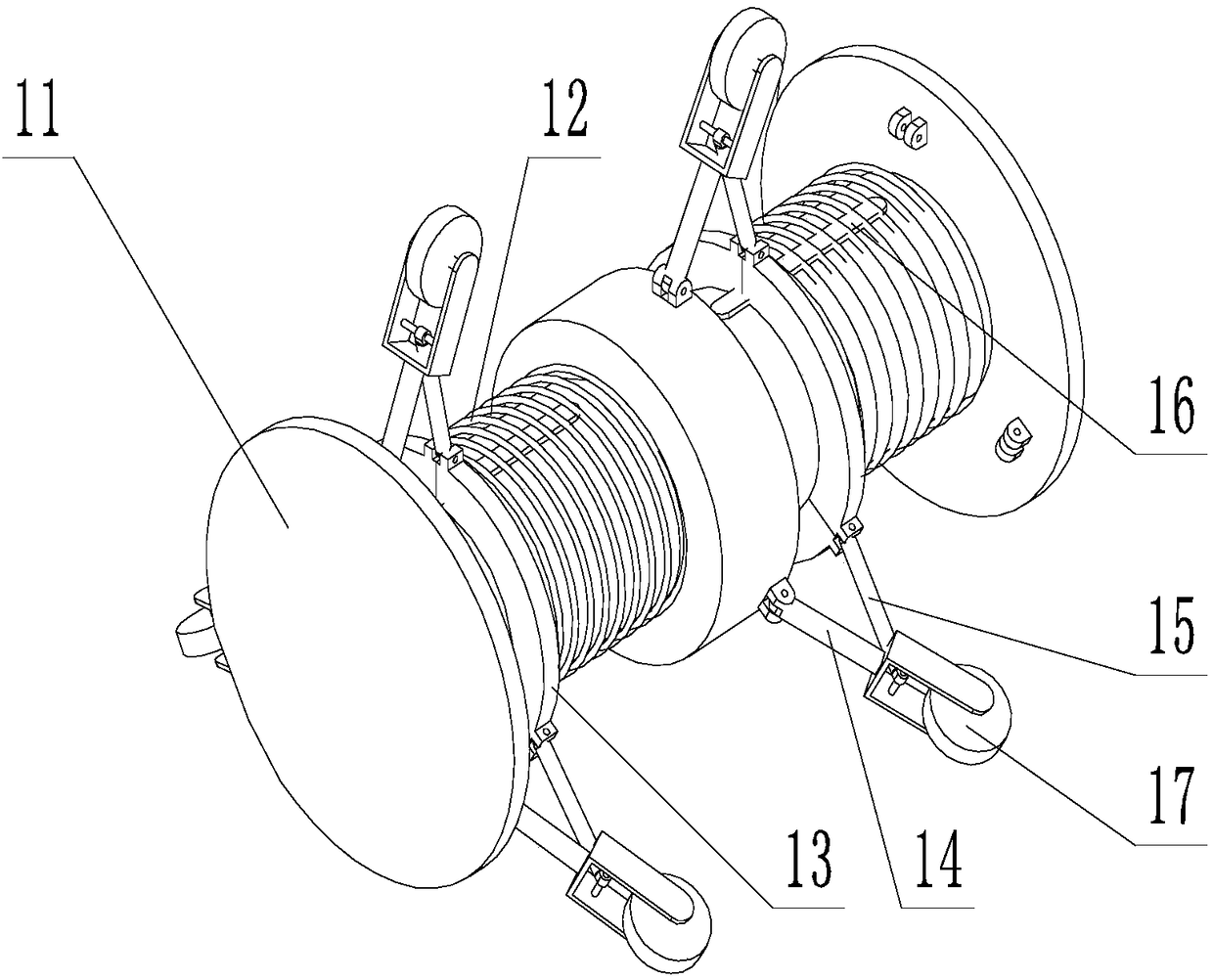

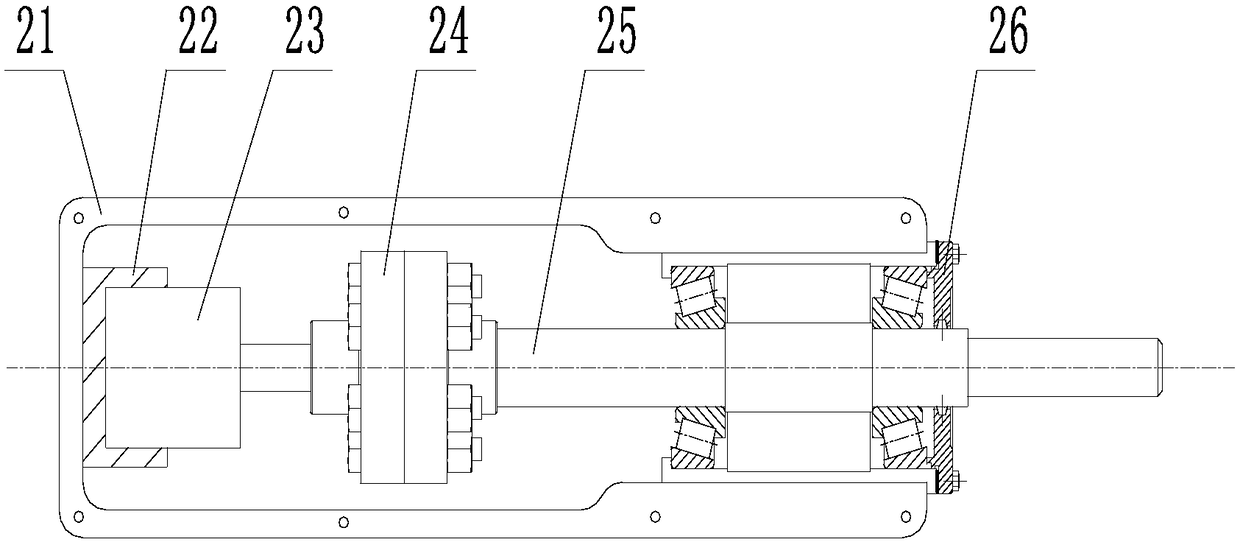

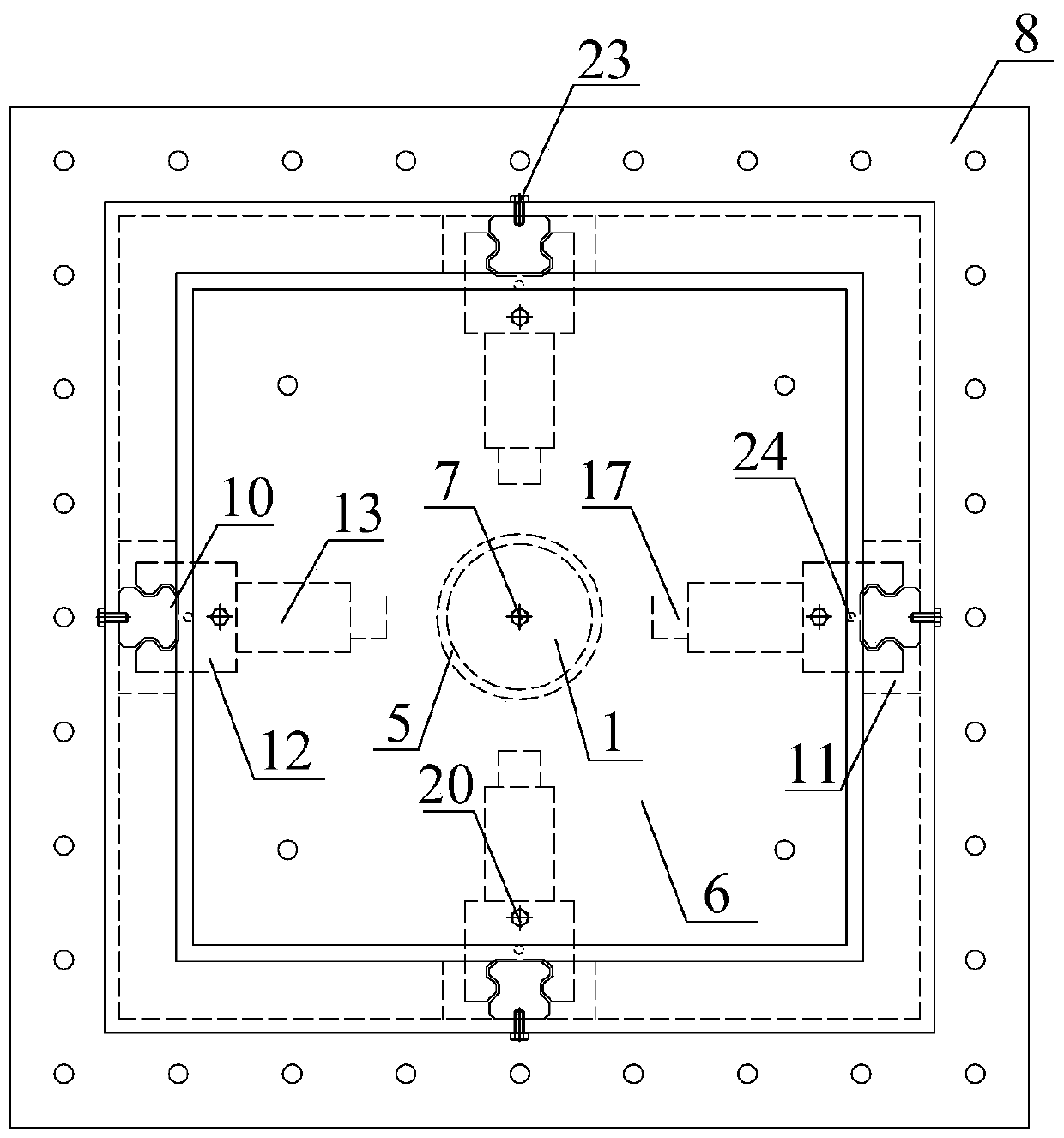

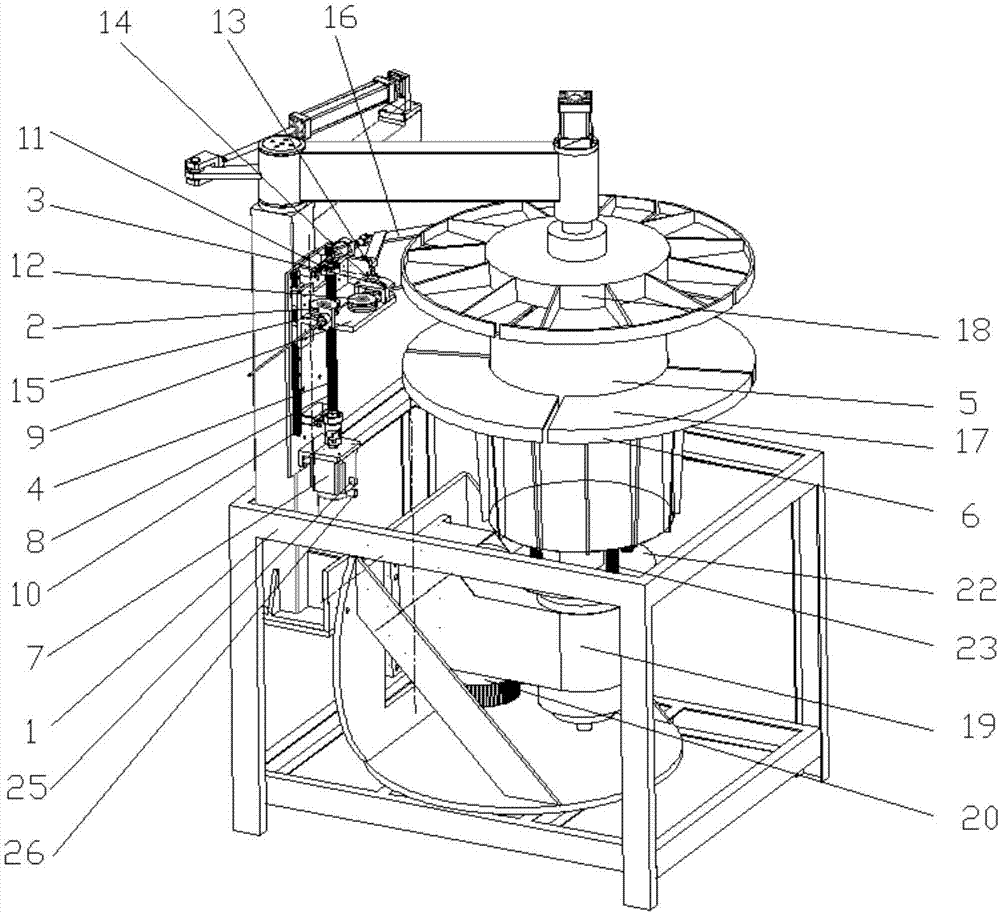

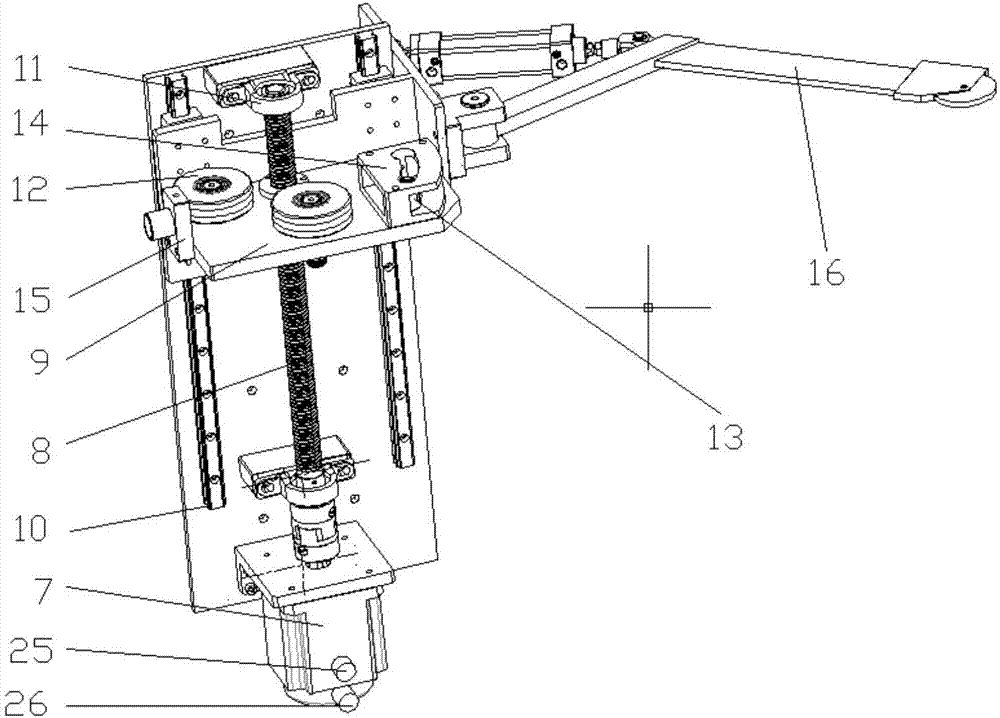

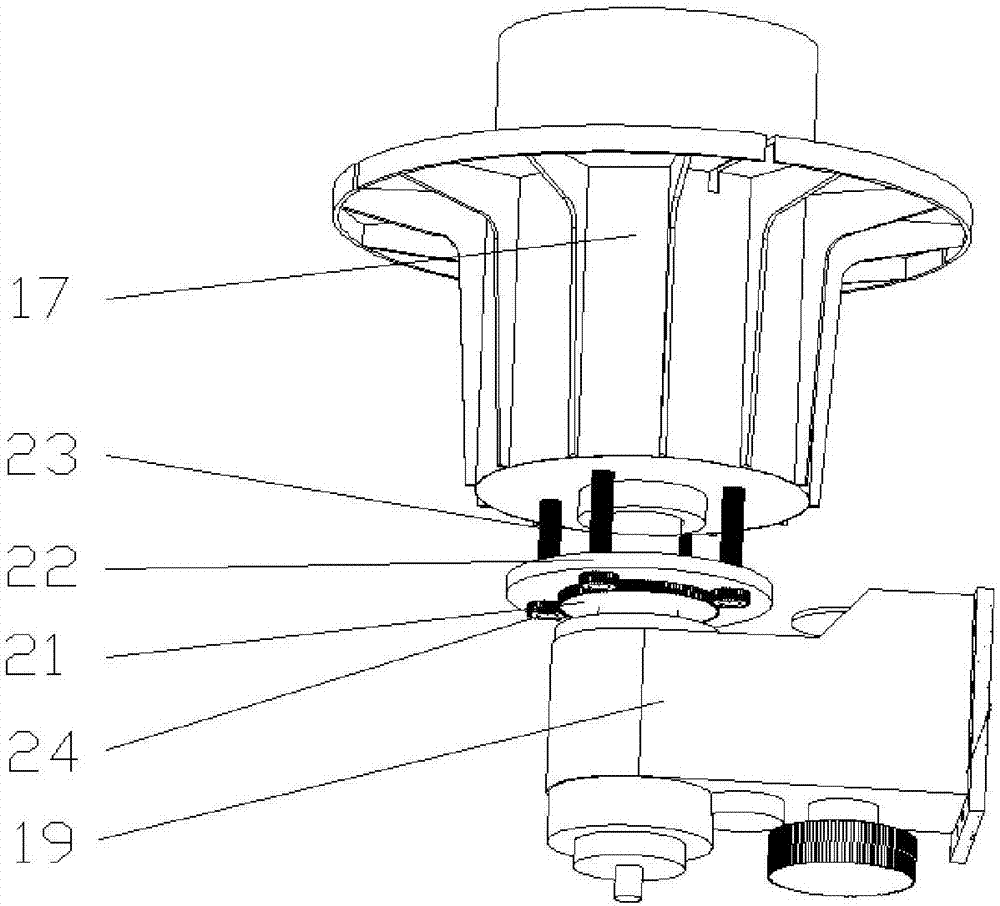

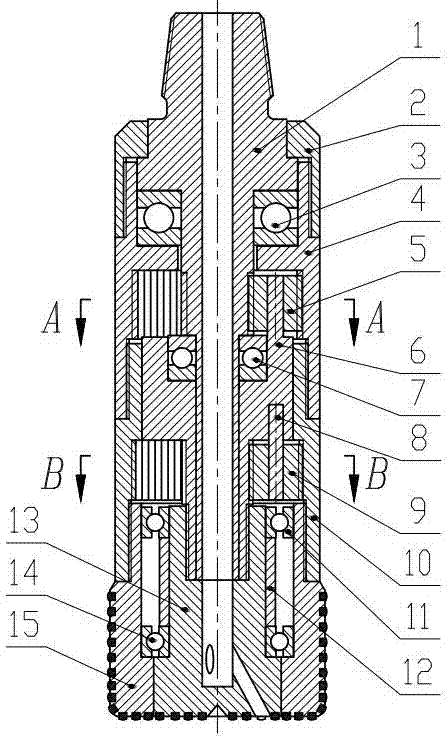

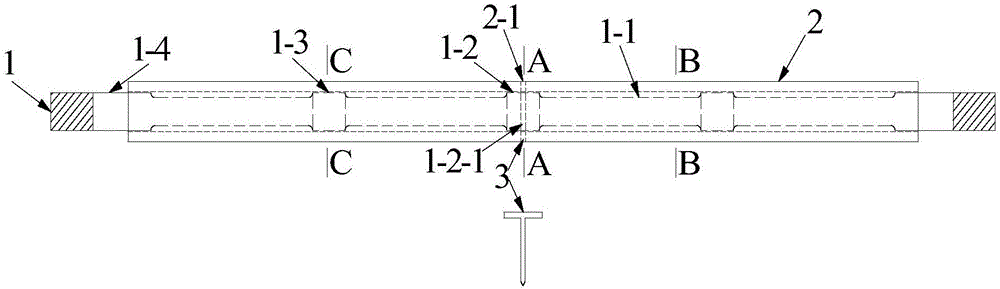

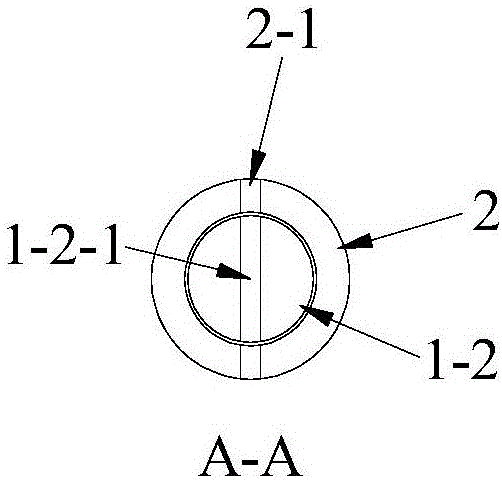

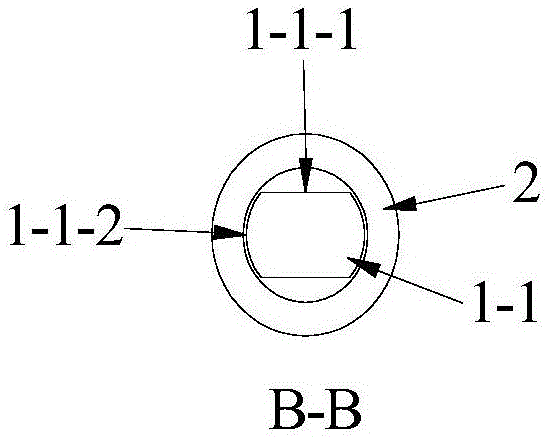

Processing device and processing method of simulated groove in inner wall of conical water inlet pipe of water pump

PendingCN108213534ARealize continuous processingSelf-lockingMilling equipment detailsSelf lockingEngineering

The invention discloses a processing device and a processing method of a simulated groove in the inner wall of a conical water inlet pipe of a water pump. The processing device comprises a supportingmechanism, a processing mechanism, a rotating mechanism and a feeding machine, wherein the supporting mechanism is arranged at the outer part of the rotating mechanism; an output end of the rotating mechanism is connected with one end of the processing mechanism; the other end of the processing mechanism is connected with an action end of the feeding mechanism; one end of the supporting mechanismis defined as a front part, and one end of the feeding mechanism is defined as a rear part. The processing method comprises the following steps: fixing well a pipeline requiring to be processed, and regulating the feeding mechanism until a cutting tool assembly arrives a to-be-processed position; regulating the shape of a supporting frame, and enabling the supporting frame to press the inner wallof the pipeline; regulating a cutting blade of a cutting tool to be in contact with the inner wall of a to-be-processed pipeline; starting a rotating part, and starting to process a groove in the inner wall of the pipeline; repeating the operation, thus realizing continuous processing of the simulated groove in the to-be-processed pipeline. The processing device and the processing method, disclosed by the invention, have the beneficial effects that an application range is extremely wide, and the processing device and the processing method are not influenced by the size of a pipe wall; a self-locking function is obtained, and the accuracy is higher; the processing quality is high.

Owner:ZHEJIANG UNIV OF TECH

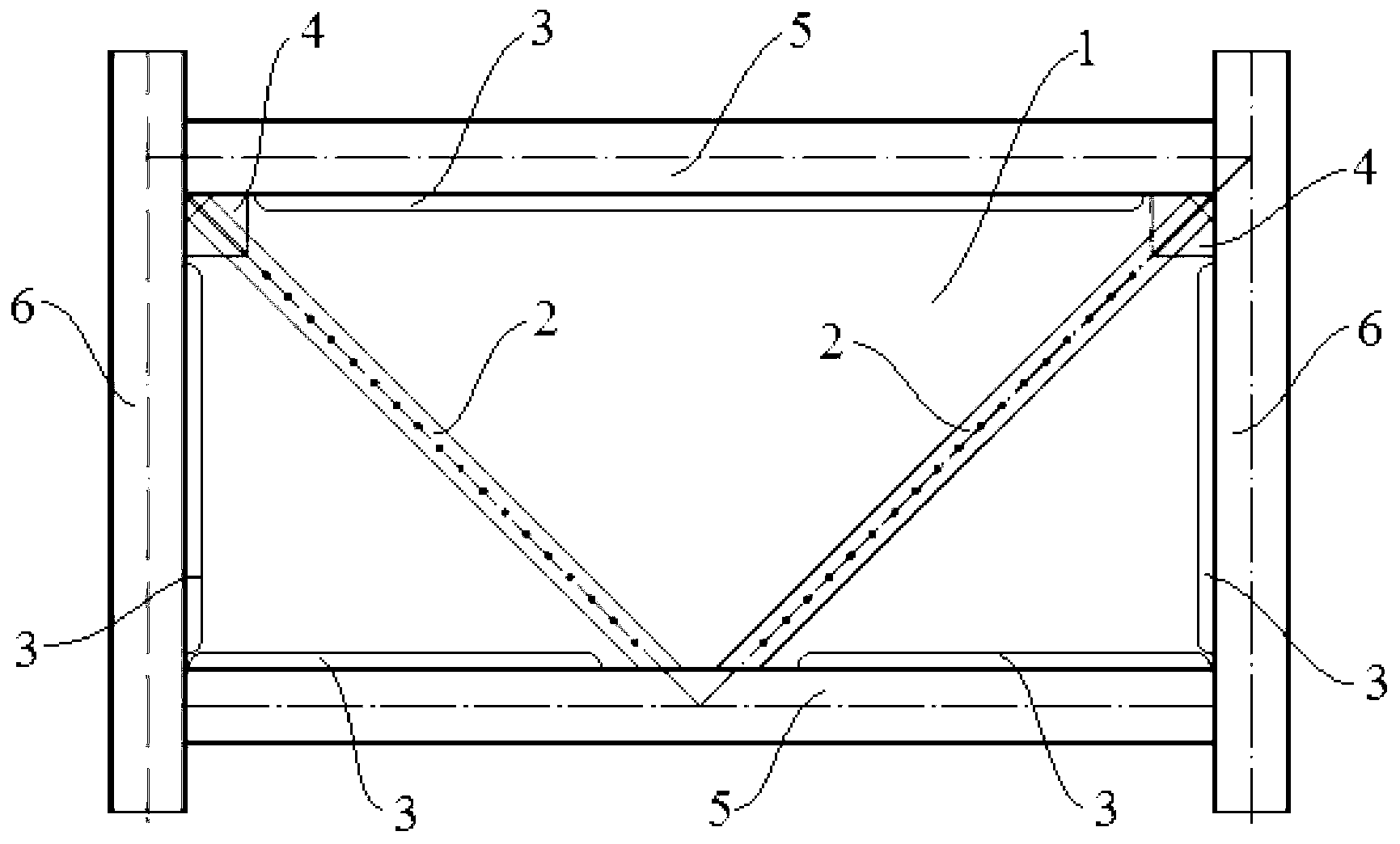

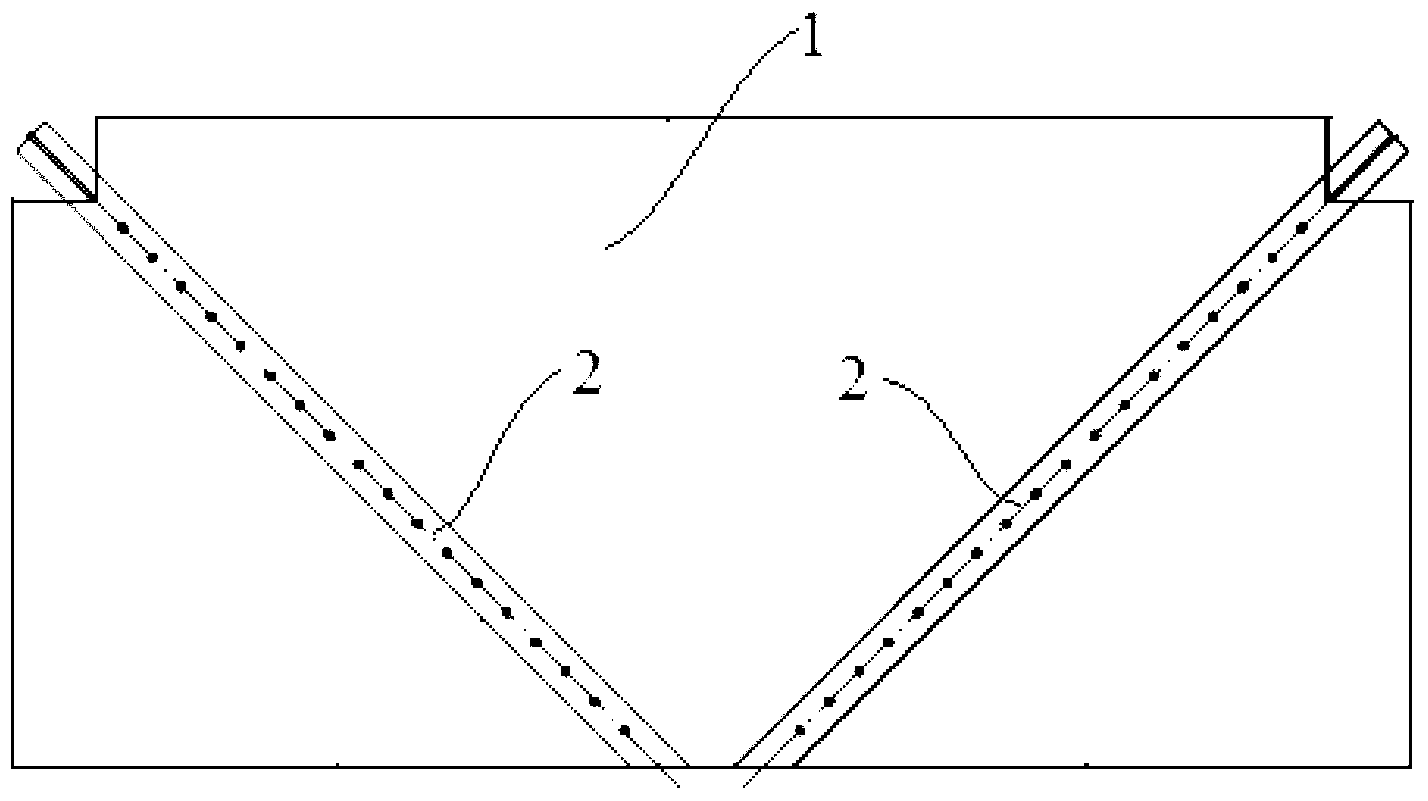

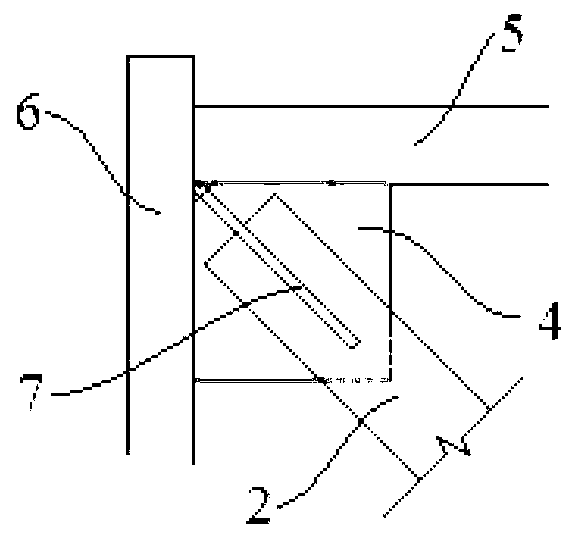

Steel plate-steel support combined lateral force resisting member and beam column structure applying same

ActiveCN103243836AImproved plastic hysteresis energy dissipation capacityReduce the shock effectWallsShock proofingSteel platesPull force

The invention discloses a steel plate-steel support combined lateral force resisting member and a beam column structure applying the same and belongs to the technical field of lateral force resisting members in structural engineering. The steel plate-steel support combined lateral force resisting member comprises a steel plate, a steel support integrally connected with the steel plate, wherein the steel plate is in a shape like a Chinese character 'tu', the steel support comprises two portions respectively arranged on two sides of the steel plate, bolt holes are arranged on the steel support at intervals, bolt holes are also arranged at corresponding positions of the steel plate, the two portions of the steel support are respectively connected with the steel plates through high-strength bolts, the steel support is arranged in a V-shaped mode and used for providing a part of axial tension resisting and compression resisting capacity of the lateral force resisting member. The main purpose is that the steel support is utilized to constrain deformation outside a plane of the steel plate so as to avoid 'pinch' effect of a hysteretic curve, a pulling force field of the steel plate is utilized to constrain a phenomenon that an extreme point of the compressed steel support in a structural plane is often unstable, and accordingly the lateral force resisting member with excellent anti-seismic property is obtained.

Owner:常州东吉路国际贸易有限公司

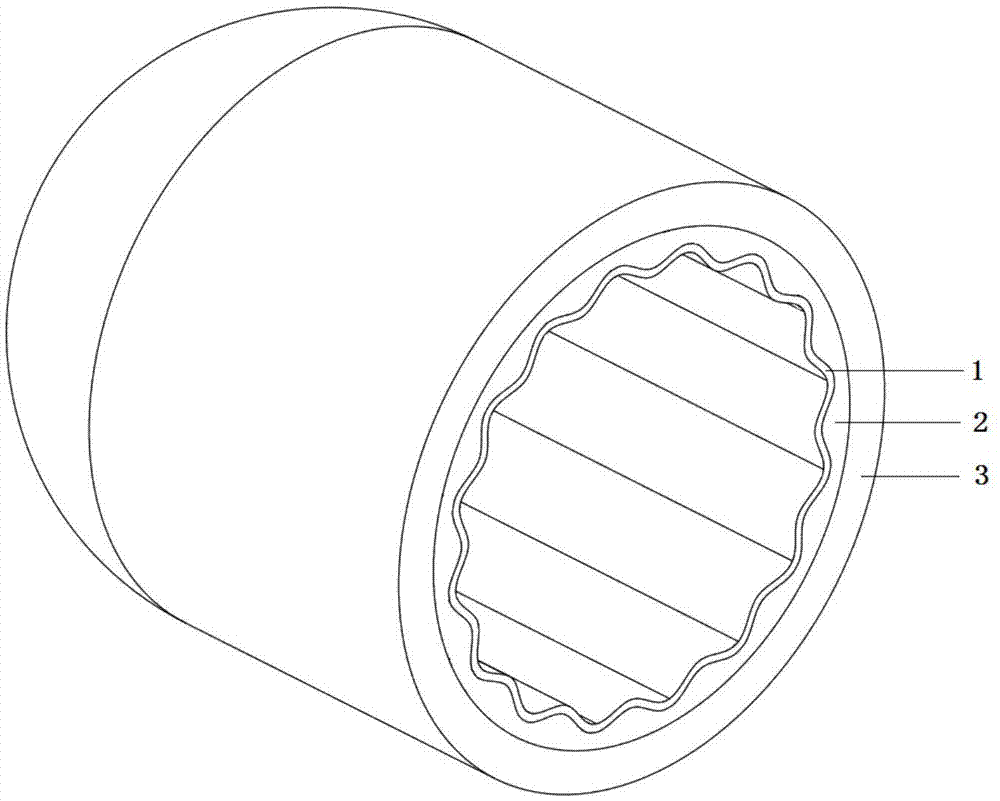

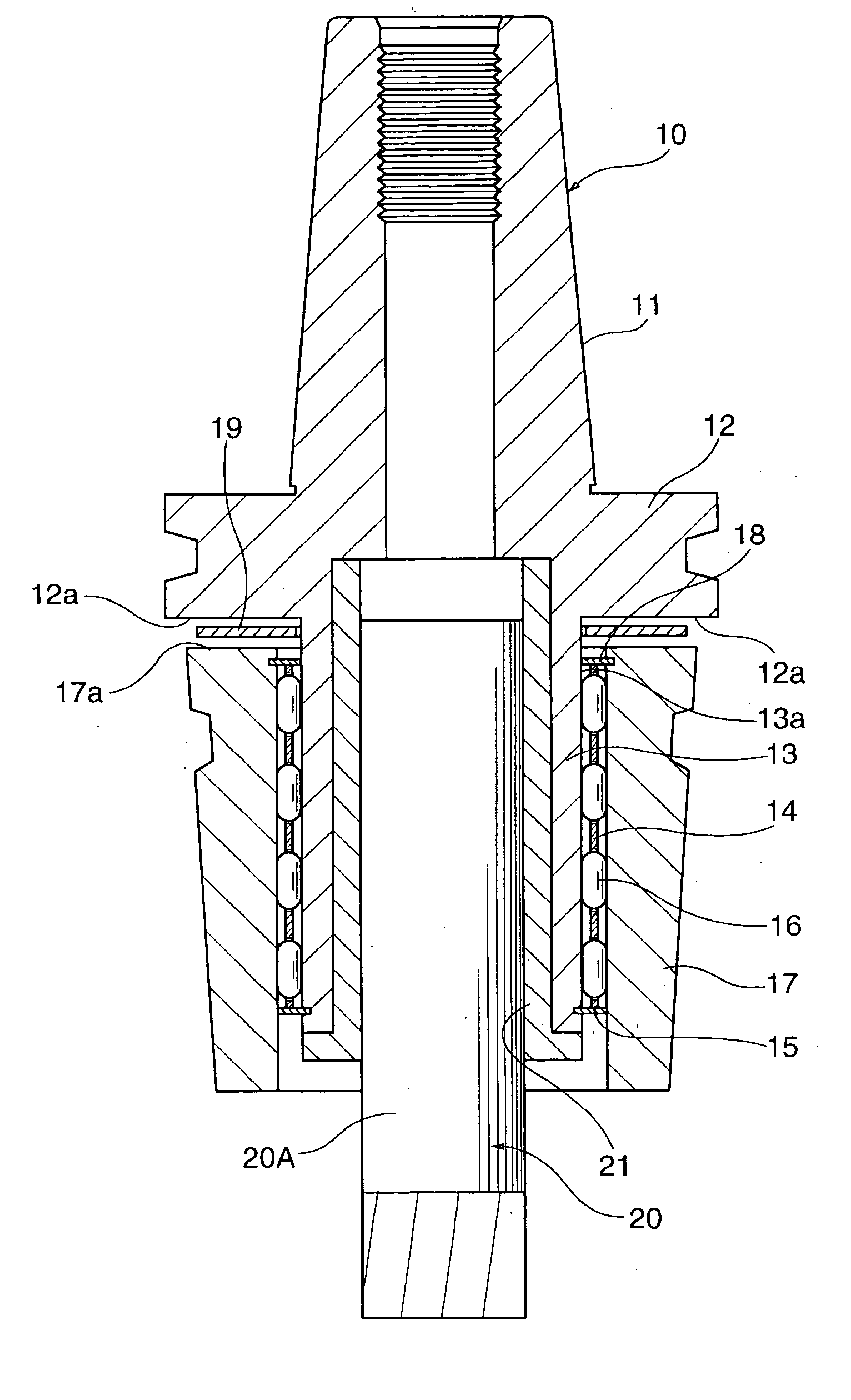

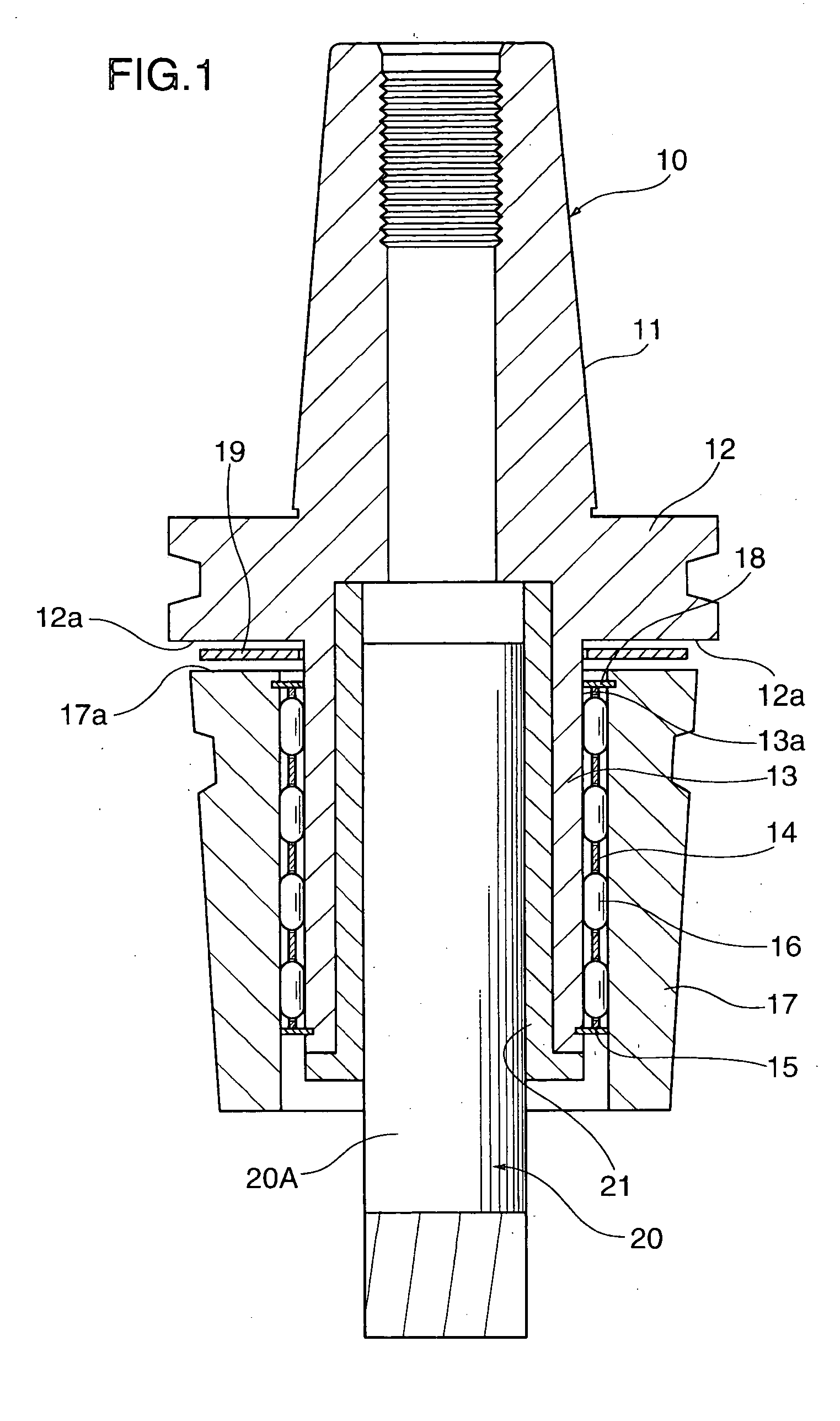

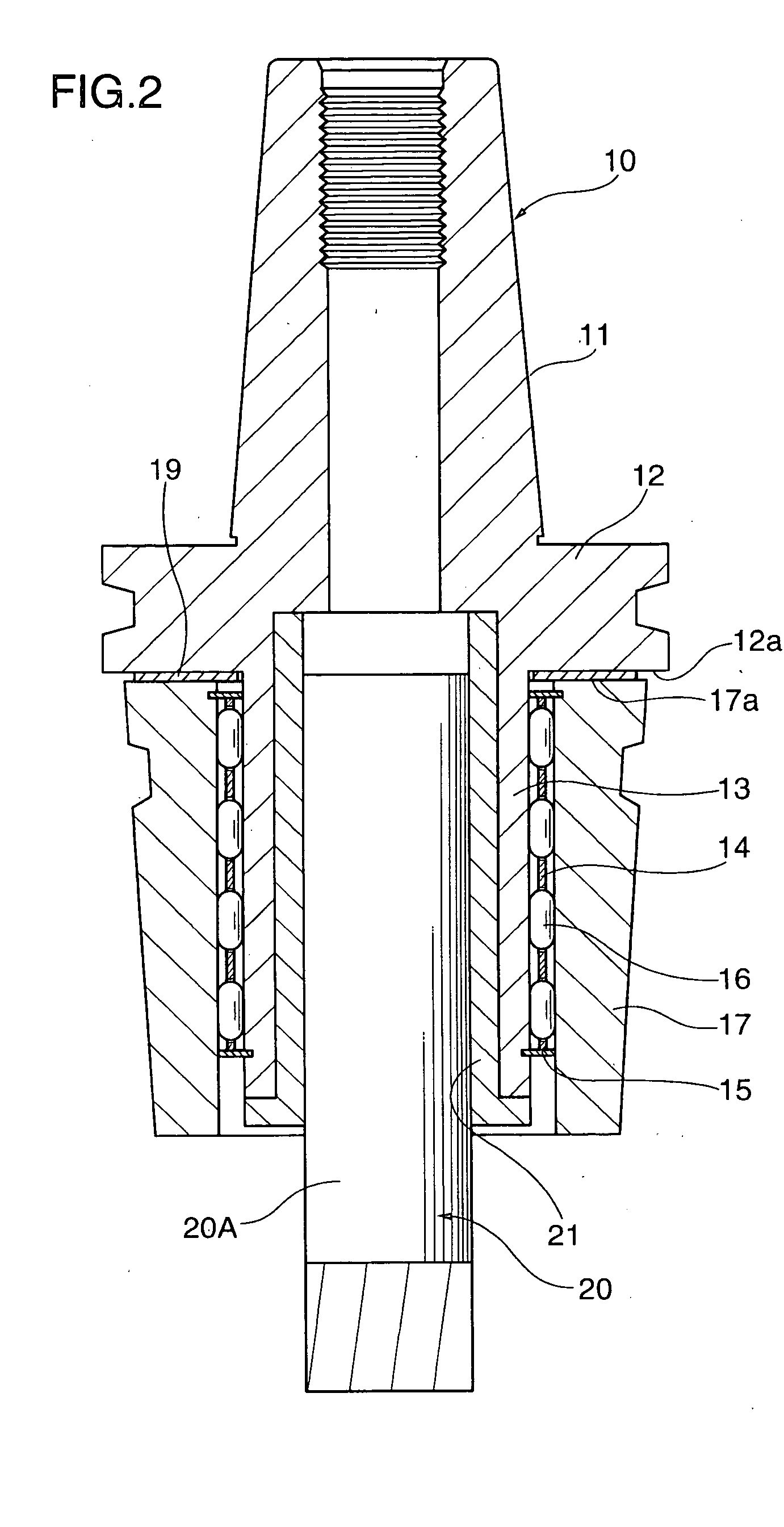

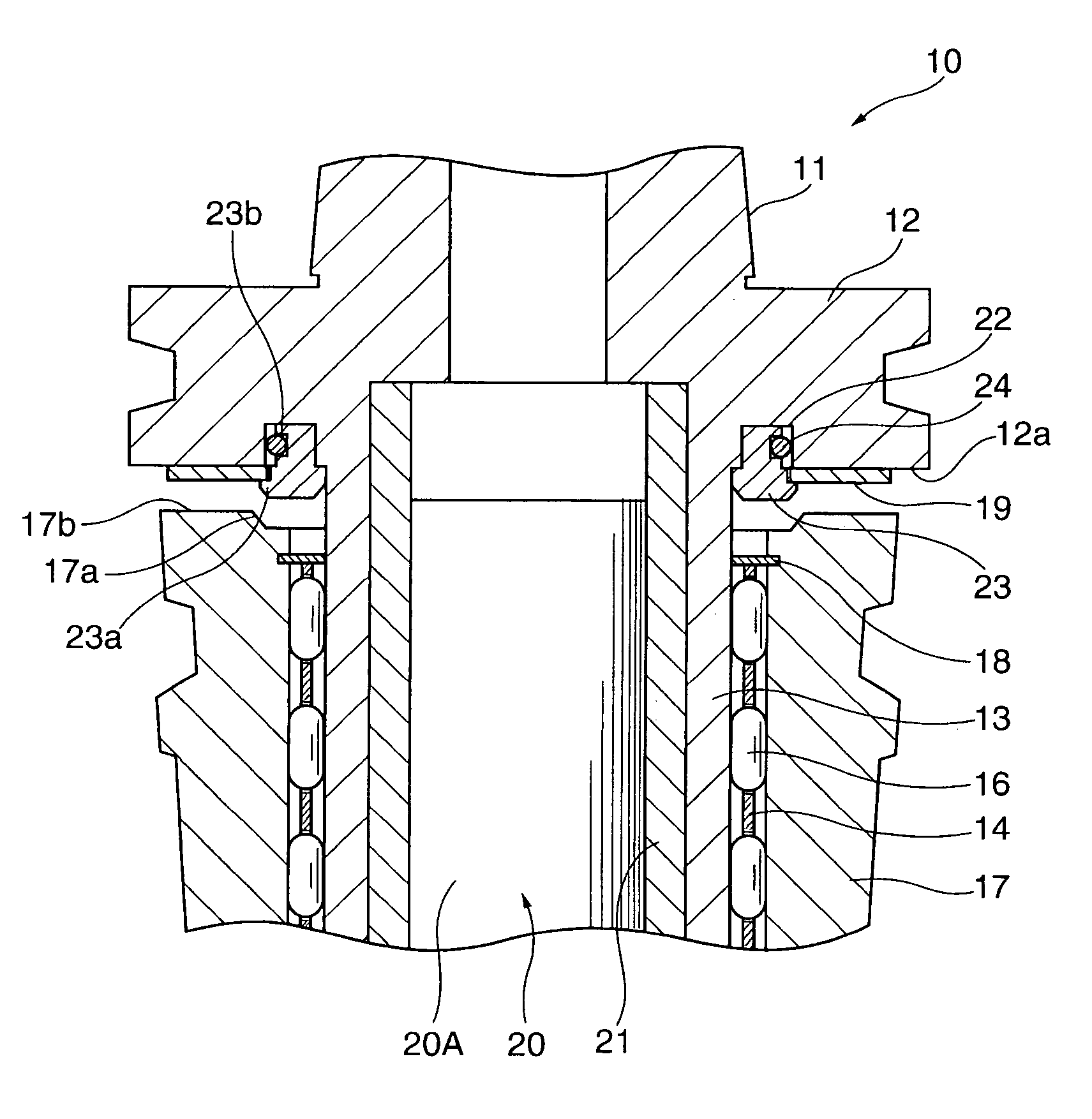

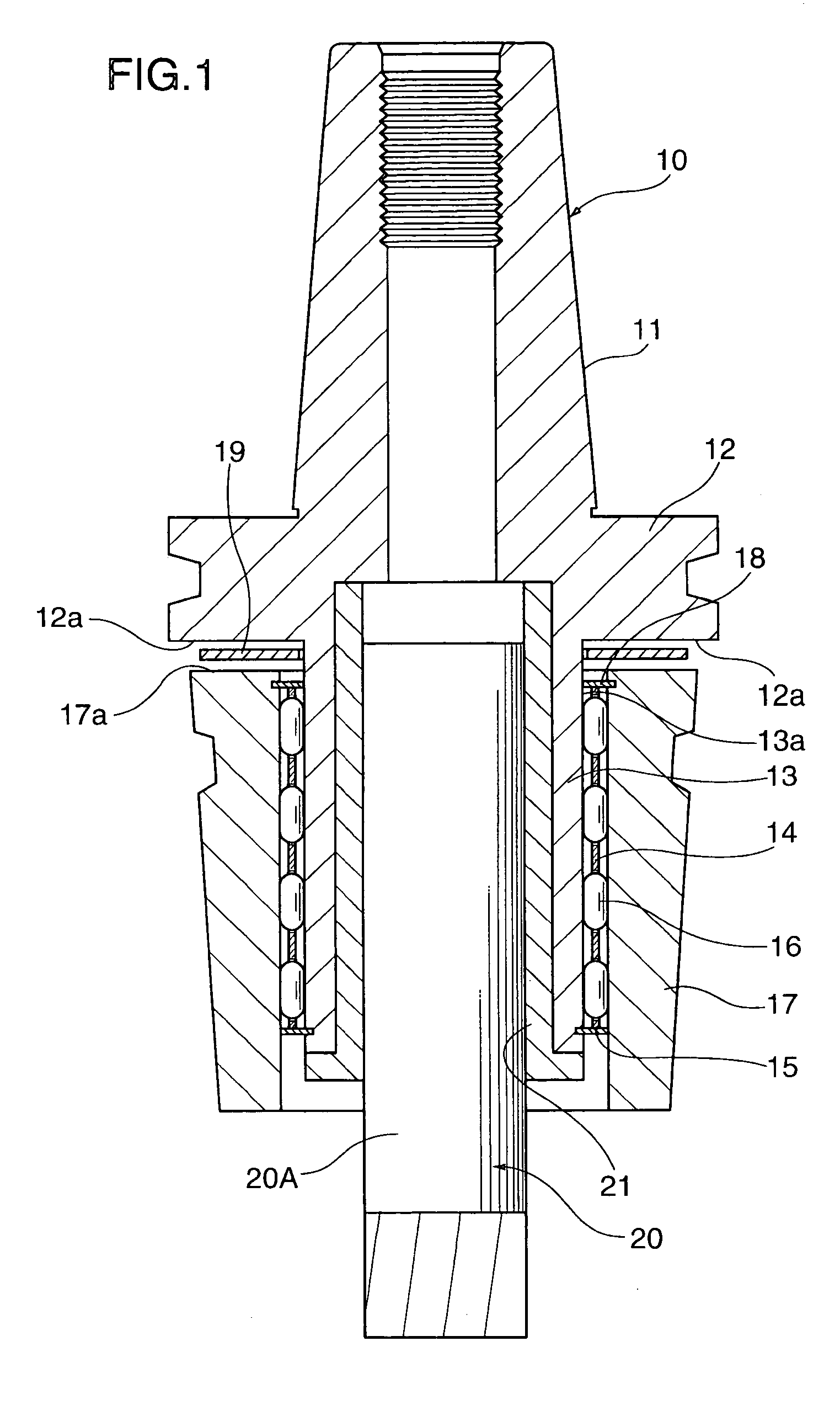

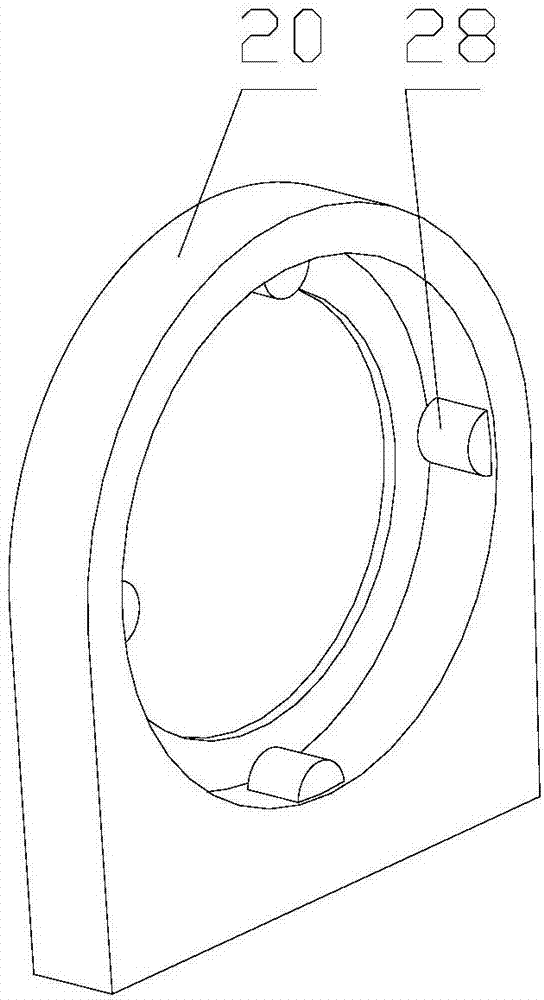

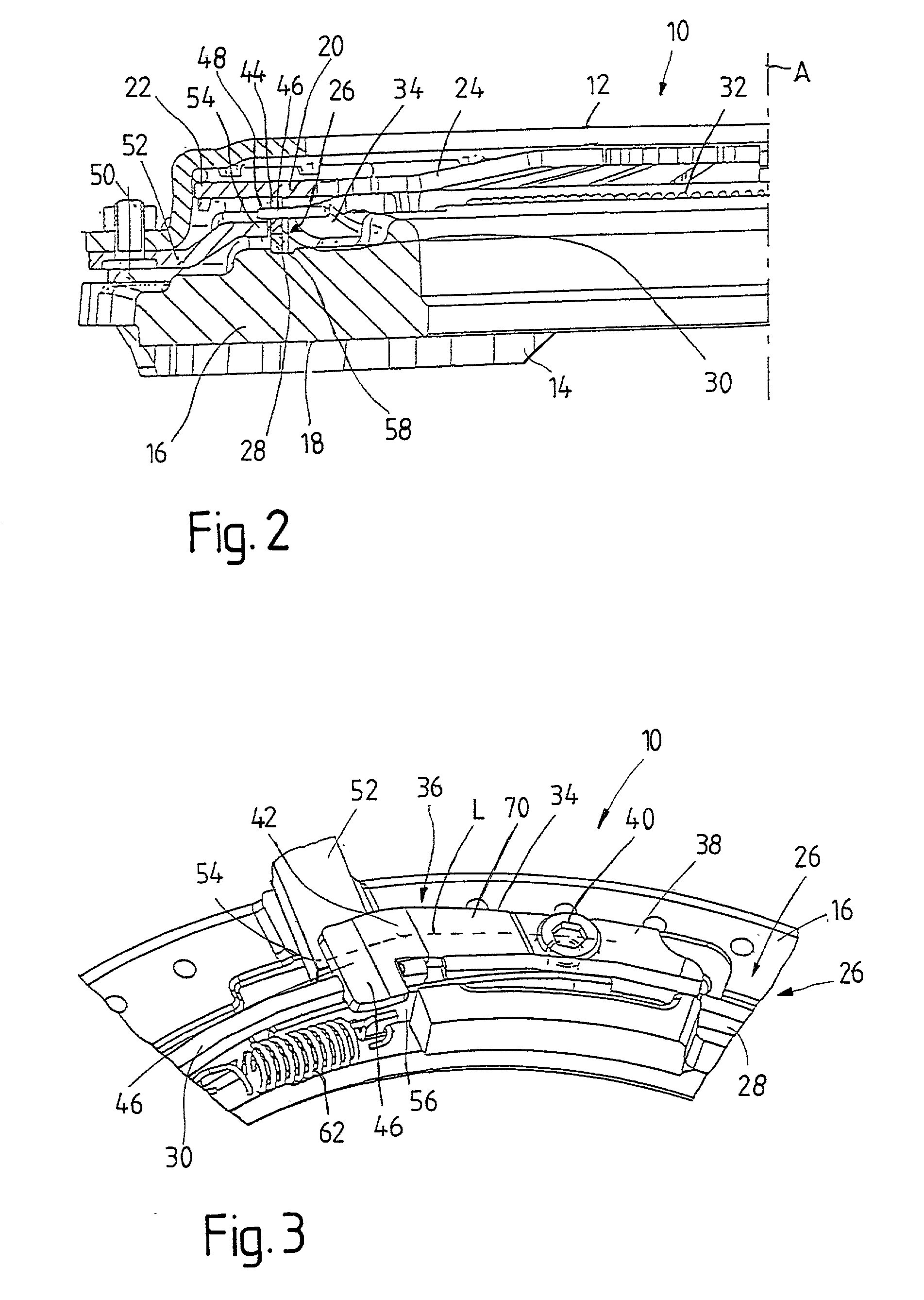

Chuck

ActiveUS20050073115A1Avoid torsional deformationReduce adverse effectsSleeve/socket jointsChucksFlangeEngineering

A chuck includes a holder body, a clamp sleeve, and a large number of needle rollers. The holder body has a shank portion, a flange, and a chuck sleeve. The clamp sleeve is fitted onto the outer circumference of the chuck sleeve such that the clamp sleeve is rotatable and axially movable relative to the chuck sleeve. The needle rollers are disposed between the chuck sleeve and the clamp sleeve over the entire circumference. The clamp sleeve is rotated to cause the needle rollers to revolve spirally along the outer circumferential surface of the chuck sleeve while rotating about their own axes in order to decrease and restore the diameter of the chuck sleeve. A thrust member is disposed between the end surface of the flange opposite the shank portion and a corresponding end surface of the clamp sleeve.

Owner:NIKKEN KOSAKUSHO WORKS LTD

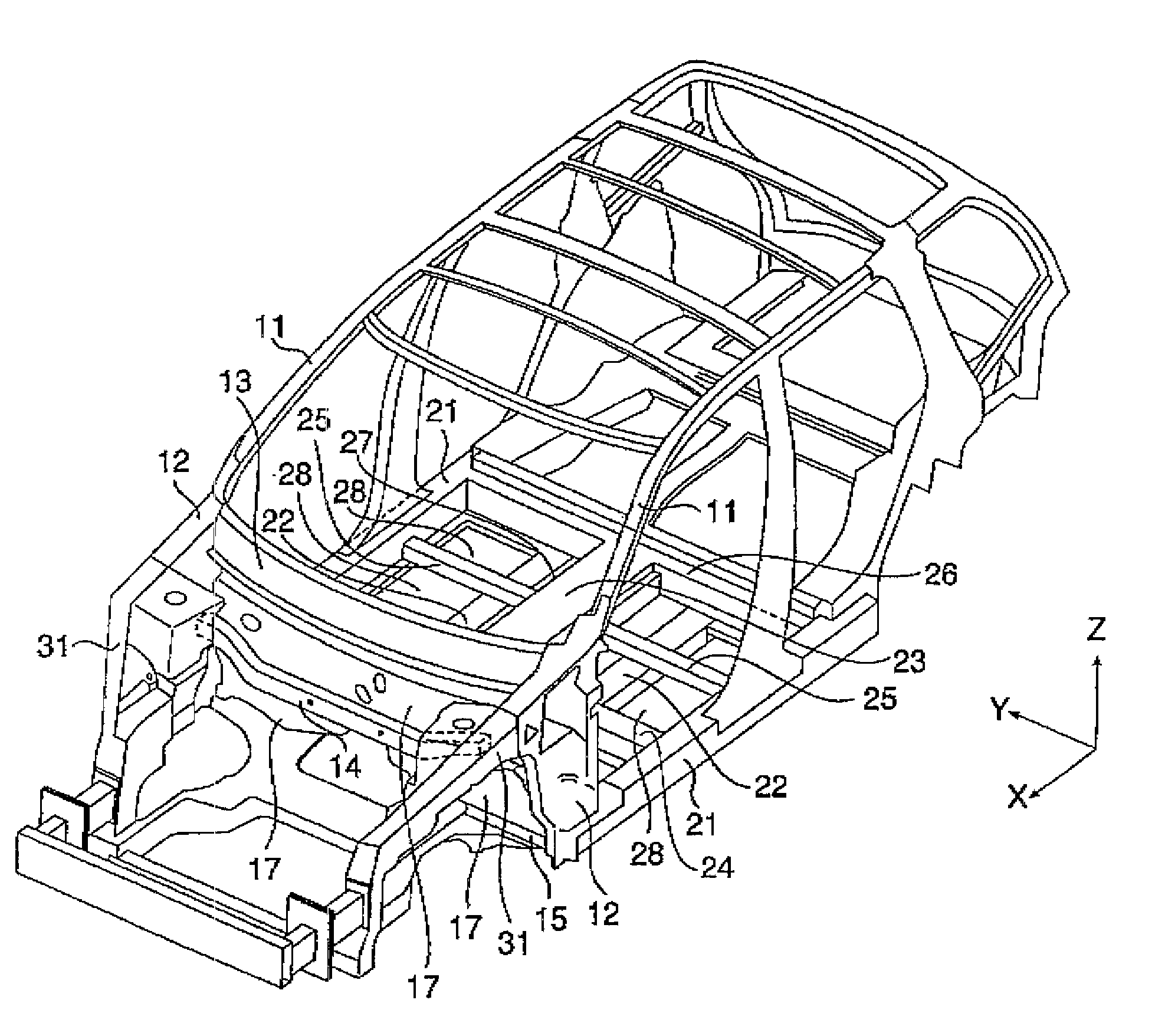

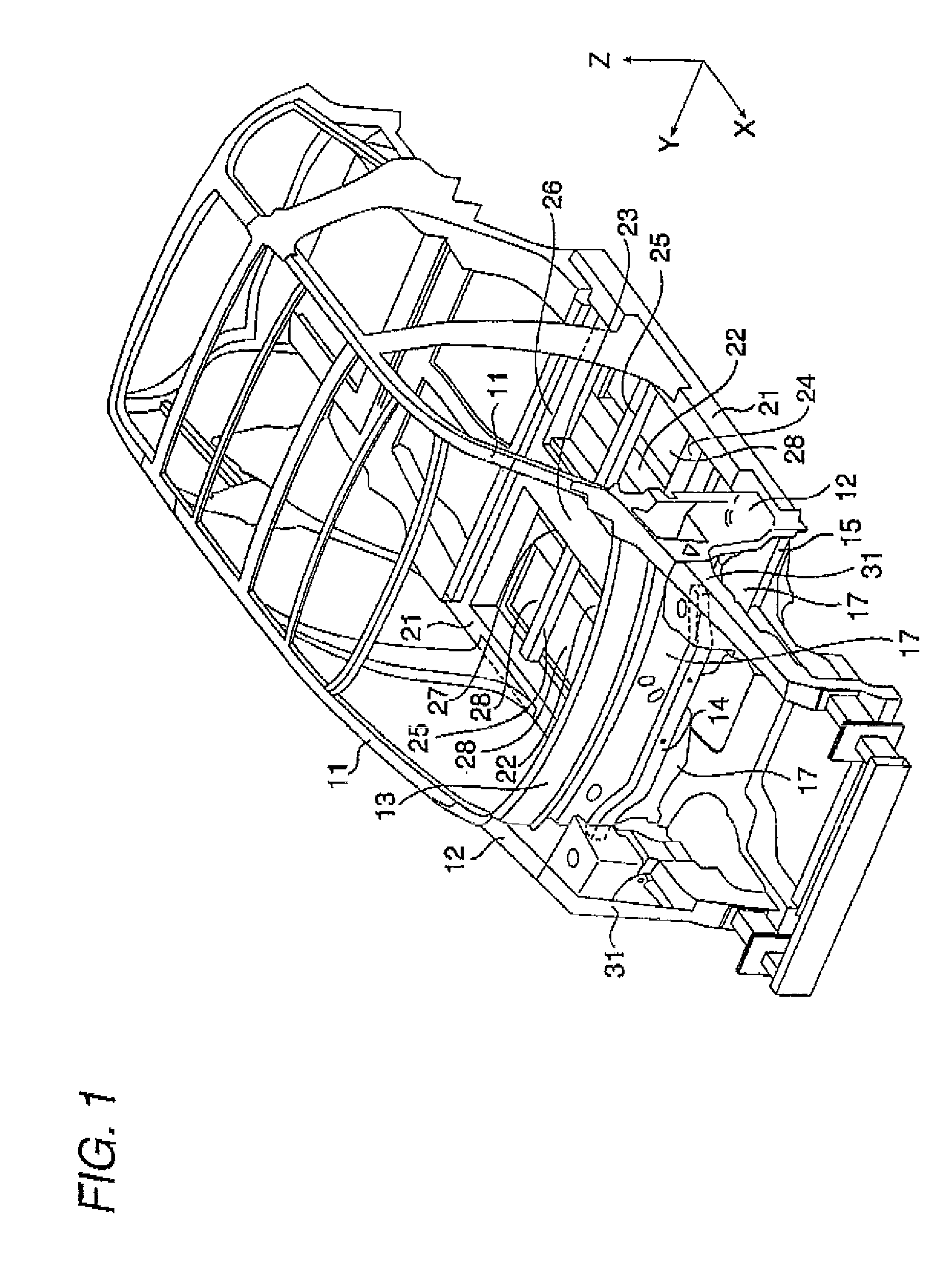

Body framework construction

InactiveUS7677643B2Avoid torsional deformationHigh strengthVehicle seatsSuperstructure subunitsGusset plateBuilding construction

Owner:MITSUBISHI MOTORS CORP +1

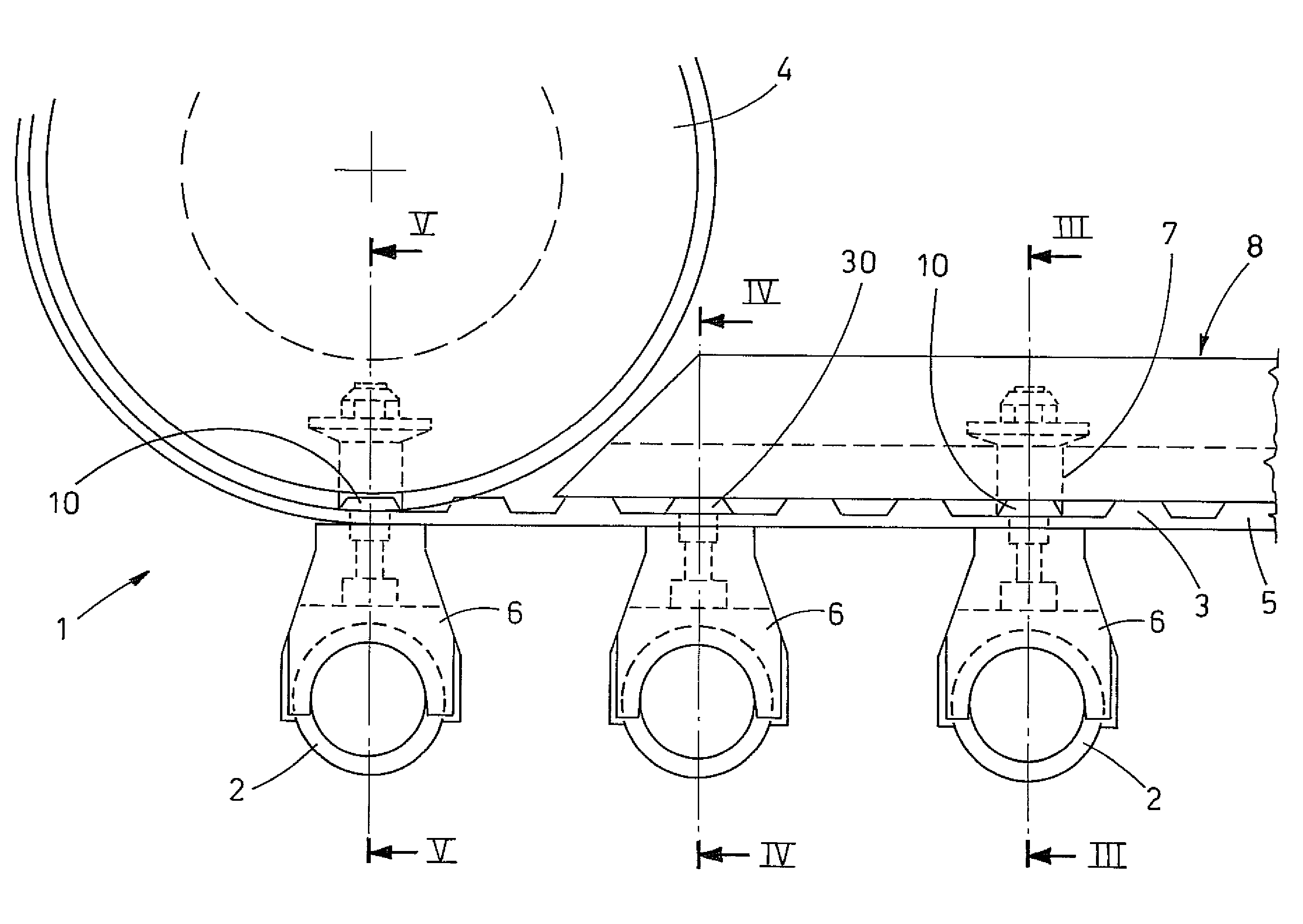

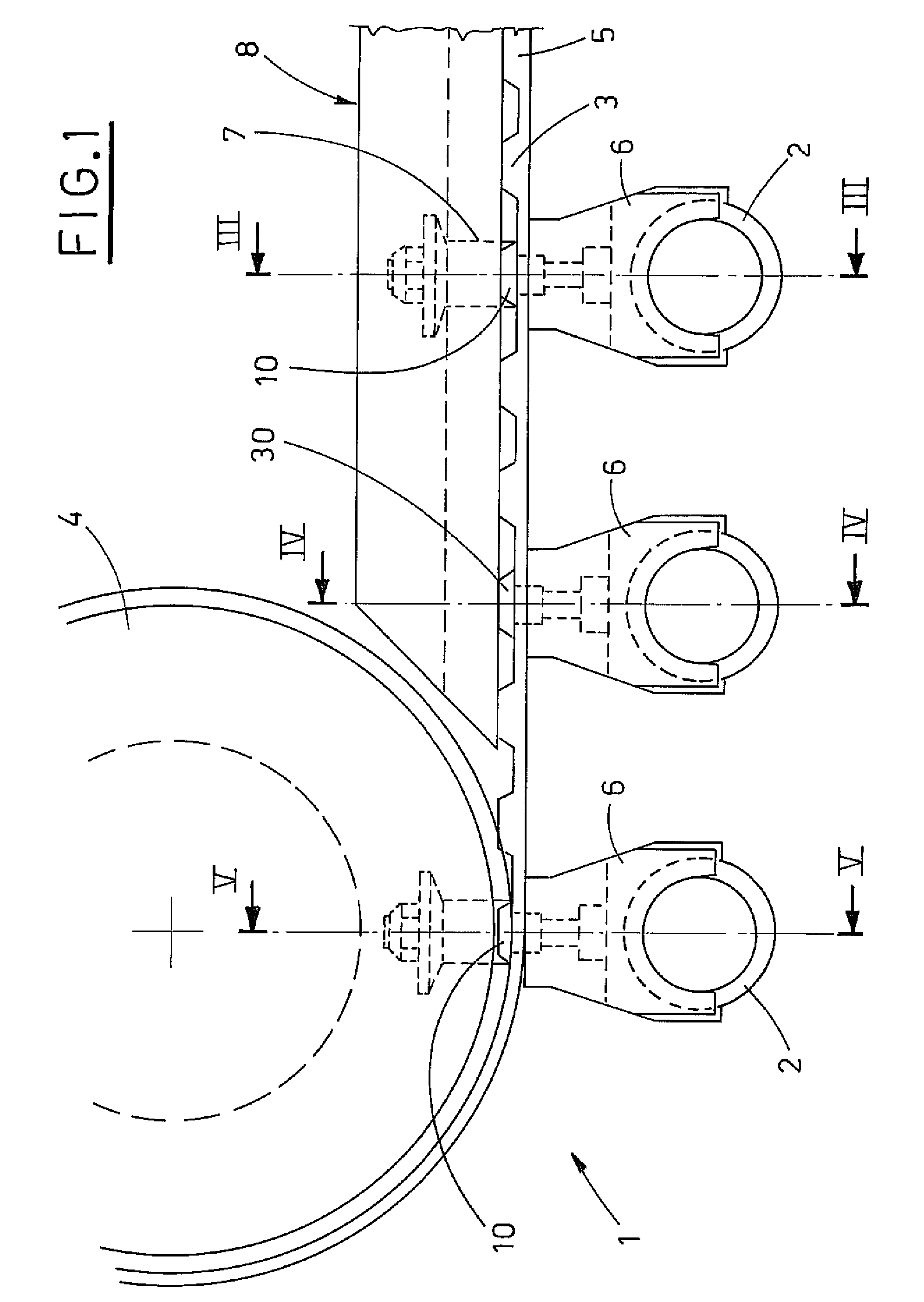

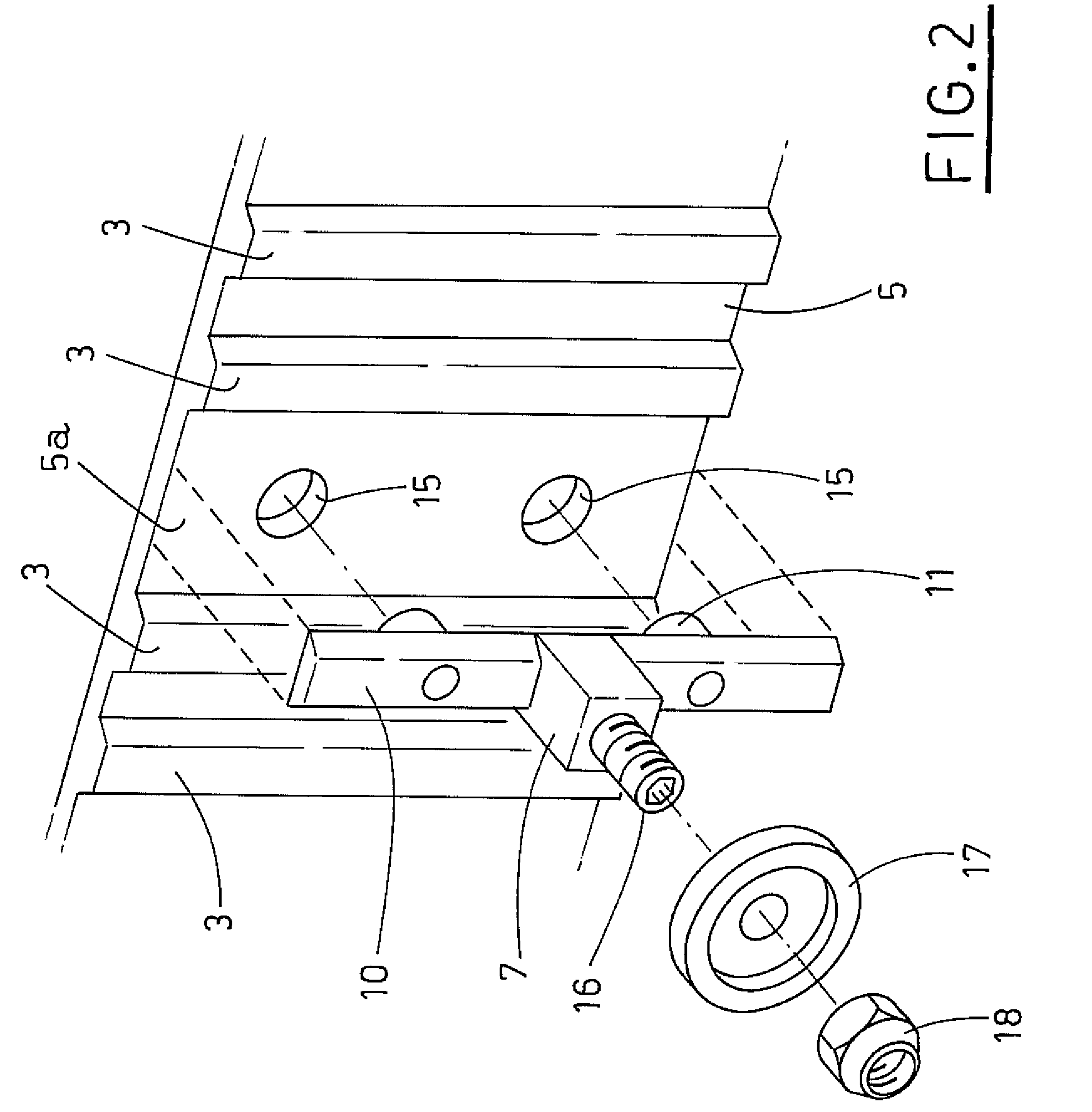

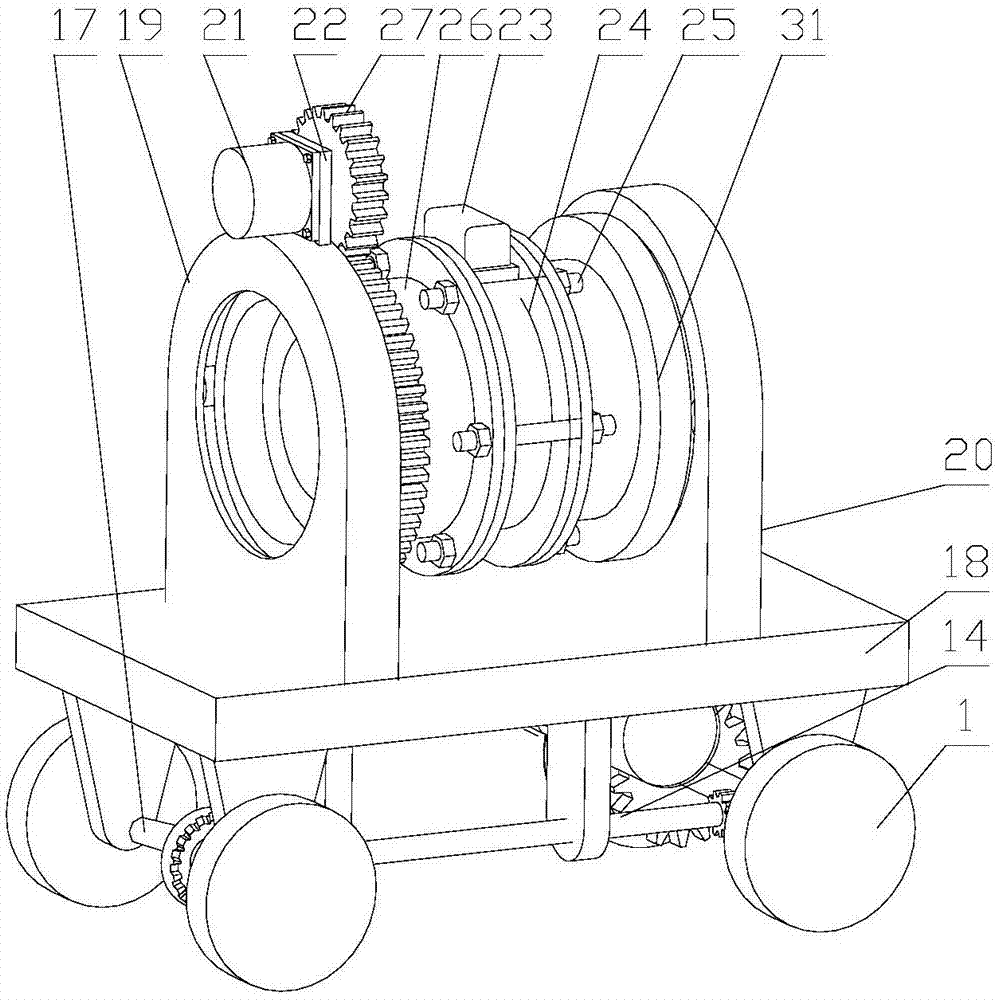

Device for transporting containers

ActiveUS7681720B2Avoid torsional deformationHighly reliable in operationConveyor partsMechanical conveyorsGear wheelEngineering

Owner:MARCHESINI GROUP SPA

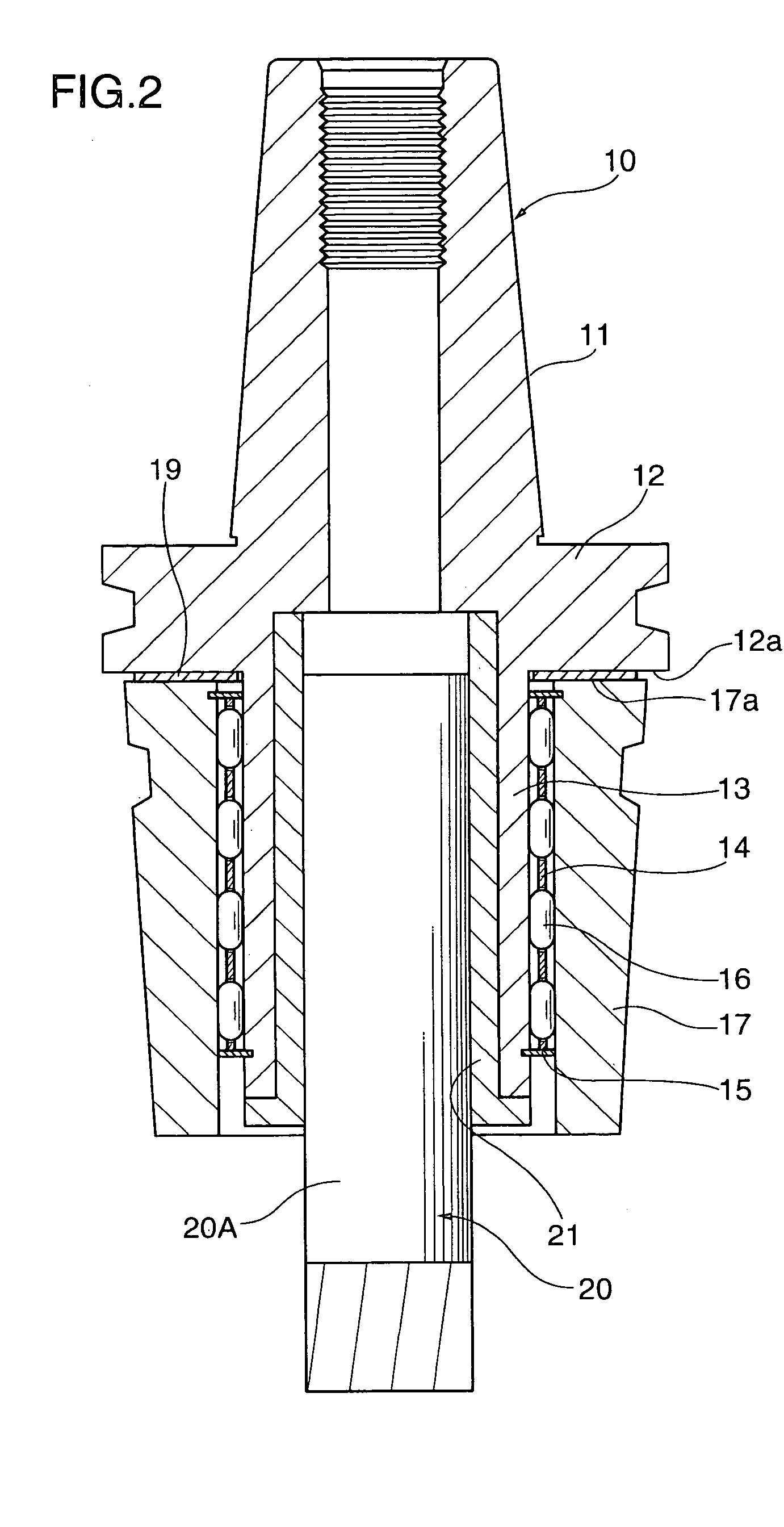

Chuck

ActiveUS7017919B2Avoid torsional deformationReduce adverse effectsSleeve/socket jointsChucksEngineeringFlange

A chuck includes a holder body, a clamp sleeve, and a large number of needle rollers. The holder body has a shank portion, a flange, and a chuck sleeve. The clamp sleeve is fitted onto the outer circumference of the chuck sleeve such that the clamp sleeve is rotatable and axially movable relative to the chuck sleeve. The needle rollers are disposed between the chuck sleeve and the clamp sleeve over the entire circumference. The clamp sleeve is rotated to cause the needle rollers to revolve spirally along the outer circumferential surface of the chuck sleeve while rotating about their own axes in order to decrease and restore the diameter of the chuck sleeve. A thrust member is disposed between the end surface of the flange opposite the shank portion and a corresponding end surface of the clamp sleeve.

Owner:NIKKEN KOSAKUSHO WORKS LTD

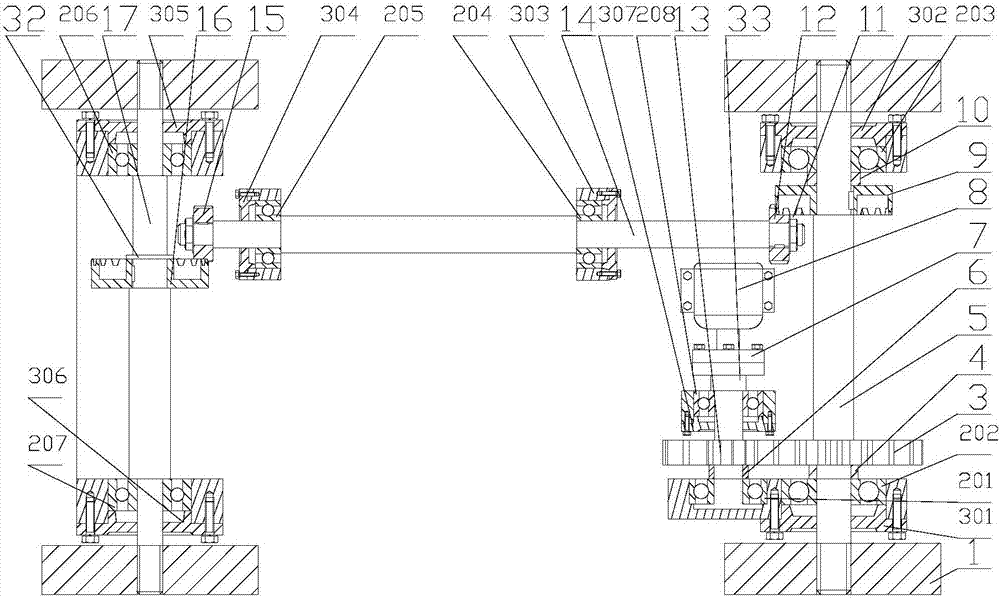

Pipeline outer wall bionic groove surface machining device and machining method thereof

ActiveCN107020409AImprove athletic abilityImprove stabilityFeeding apparatusLarge fixed membersEngineeringDrive motor

The invention relates to a pipeline outer wall bionic groove surface machining device and a machining method thereof. The pipeline outer wall bionic groove surface machining device comprises a driving mechanism used for providing driving force, a supporting base used for being connected with the driving mechanism and supporting a machining mechanism, the machining mechanism used for machining bionic grooves in a pipeline outer wall and a controller; a first supporting table and a second supporting table are installed above the supporting base and are coaxially and symmetrically arranged at the two ends of the supporting base; the driving mechanism is installed below the supporting base; the machining mechanism is installed between the first supporting table and the second supporting table in a clamped manner; the driving mechanism and the machining mechanism are both electrically connected with the corresponding control ends of the controller; and the machining method includes the steps that the devices are firstly placed, the positions of the device are adjusted, a driving motor is started, and the driving motor is stopped after the devices are adjusted to the appropriate positions; and the position of a cutter is adjusted through an adjusting pressure control device, and cutting is started. The pipeline outer wall bionic groove surface machining device has the beneficial effects that the structure is simple, operation is easy, and bionic groove structures can be machined on the pipeline outer wall protection coating surface.

Owner:ZHEJIANG UNIV OF TECH

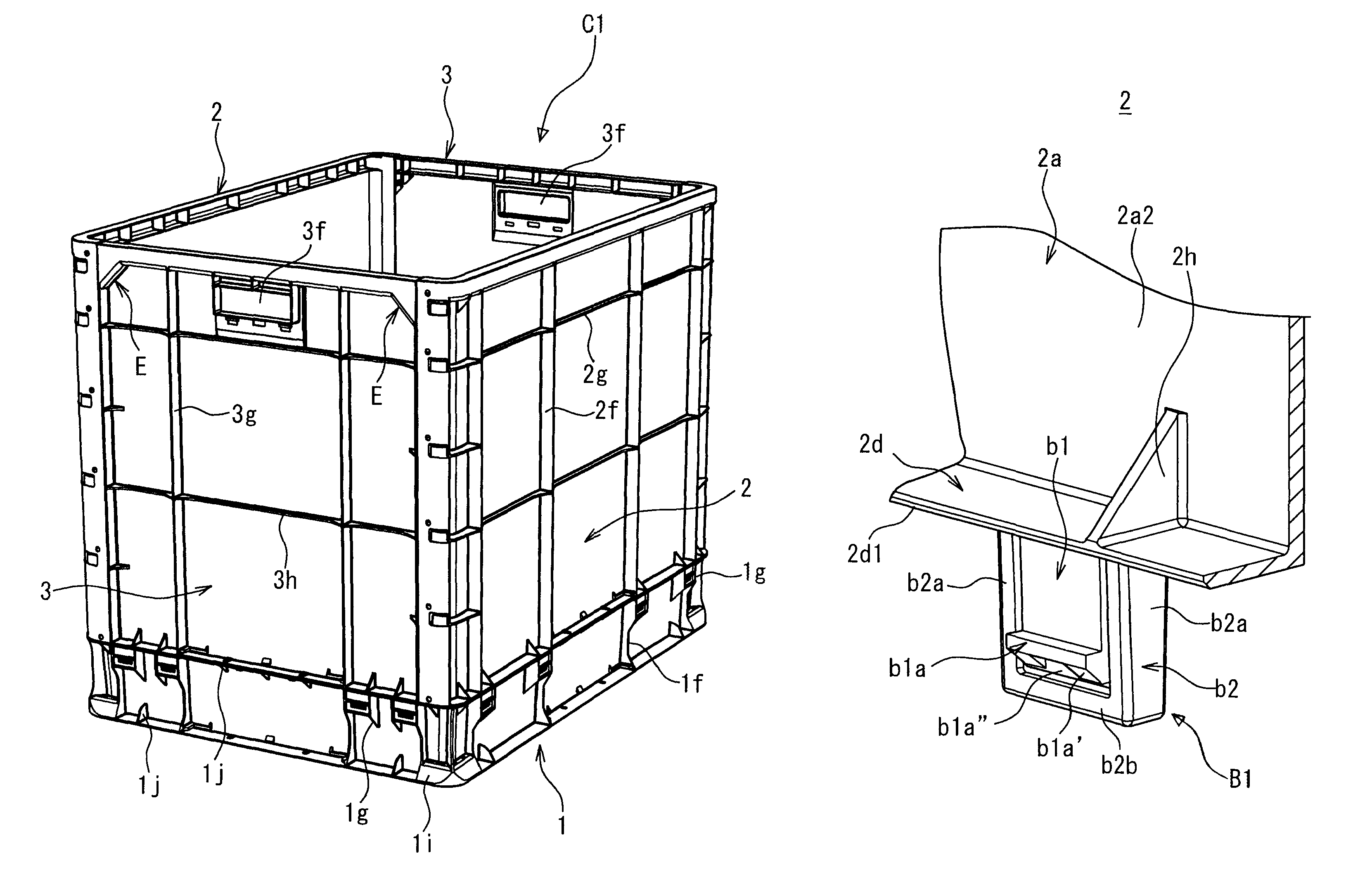

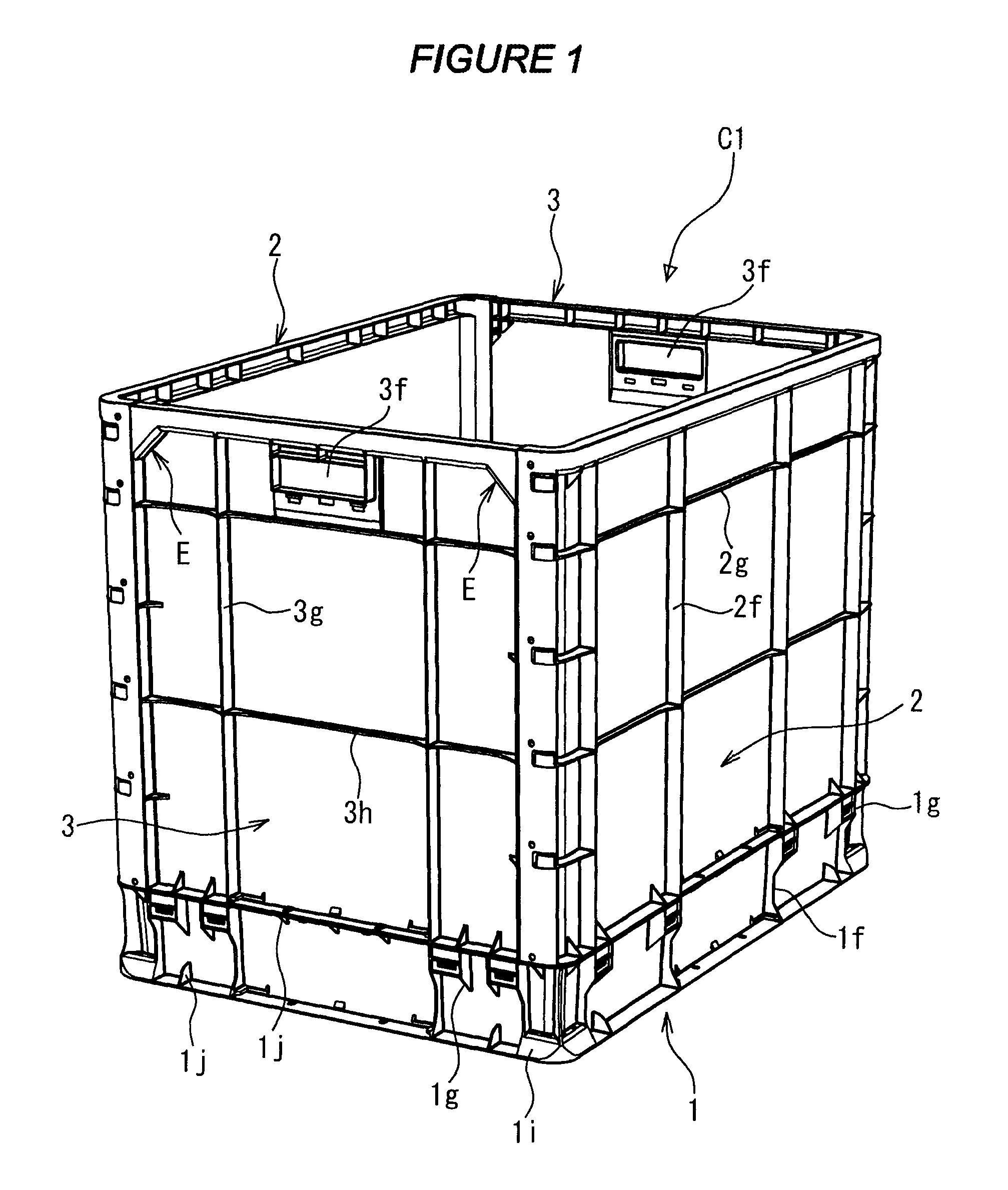

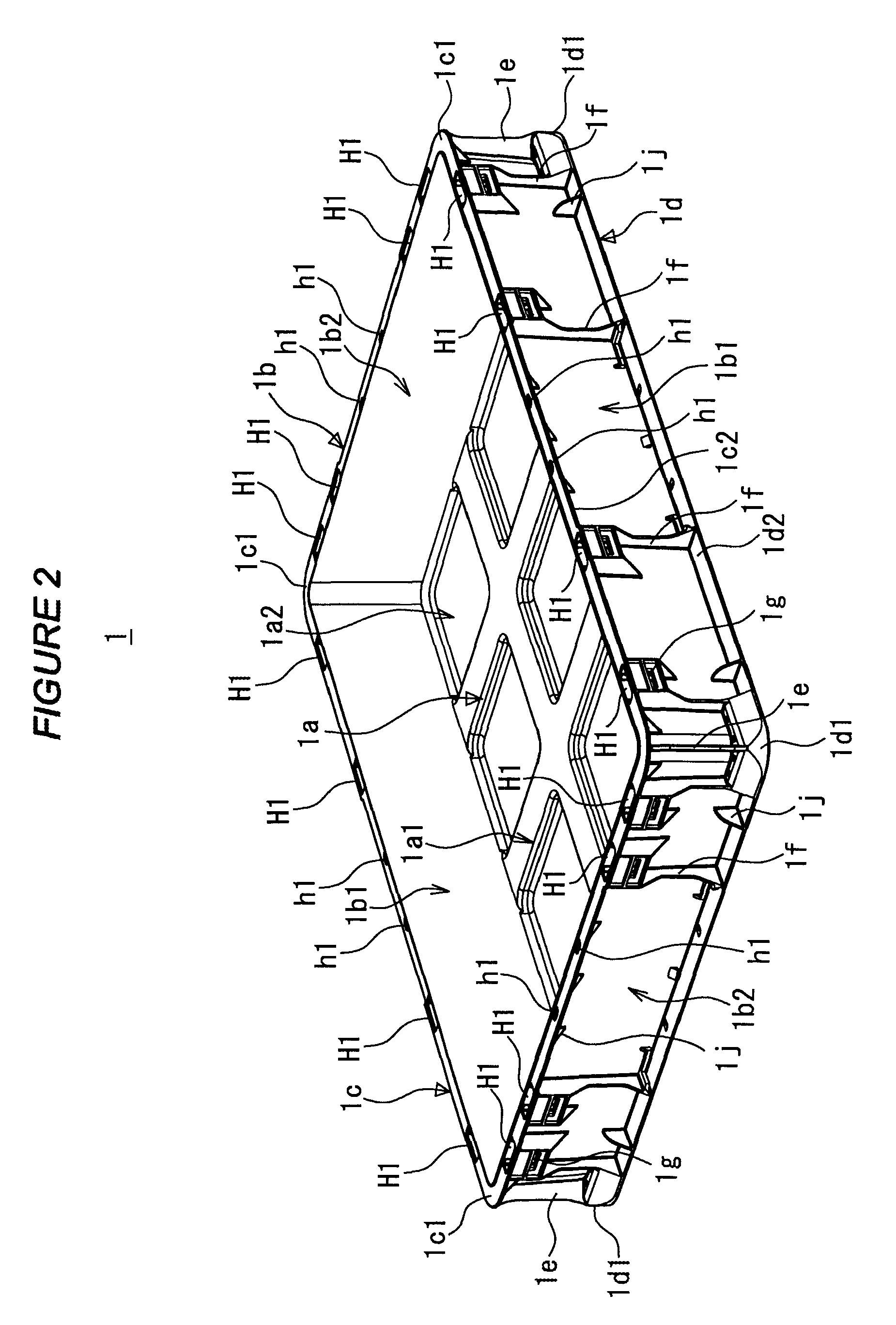

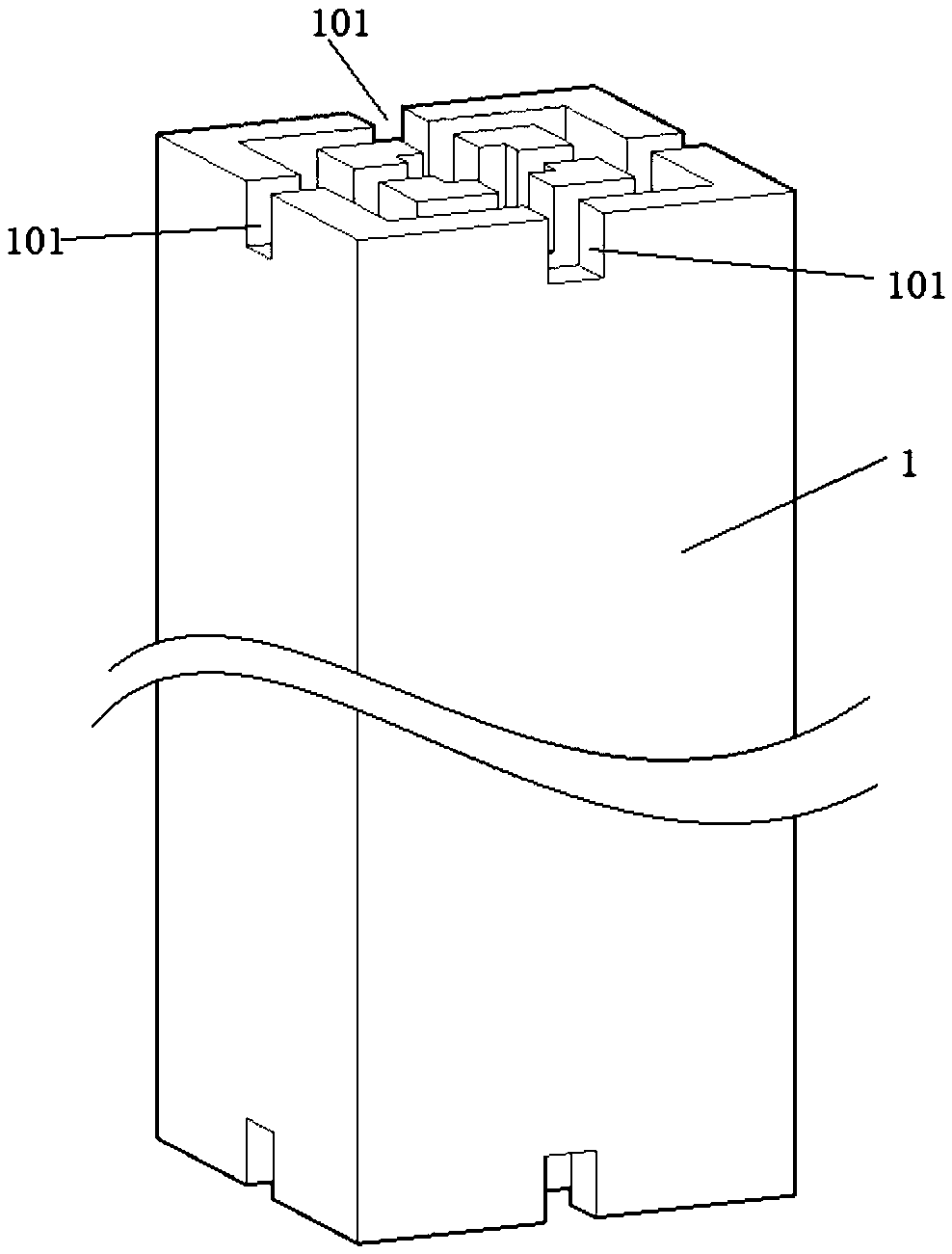

Assemblable and disassemblable container

An assemblable and disassemblable container is disclosed wherein a short wall member includes upper corner reinforcing members each formed at a corresponding corner formed by an upper horizontal flange and an endwise vertical side plate portion of the short wall member, and the upper corner reinforcing member includes an inclined coupling rib coupling the vicinity of the end of the upper horizontal flange to the vicinity of the upper end of the endwise vertical side plate portion, and wherein the lower end of the inclined coupling rib is positioned close to an endwise vertical side plate portion side of a lower horizontal rib of a horizontal portion included in a fitting block member. This configuration allows the short wall members and thus the container formed into a box shape to be increased in strength and rigidity, and can be prevented from undergoing torsional deformation.

Owner:SANKO CO LTD

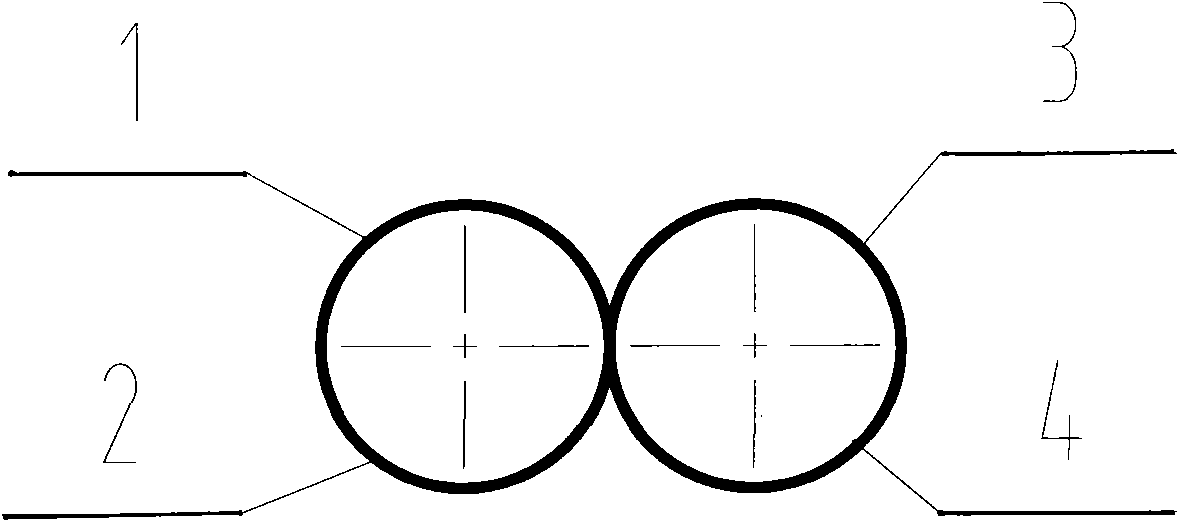

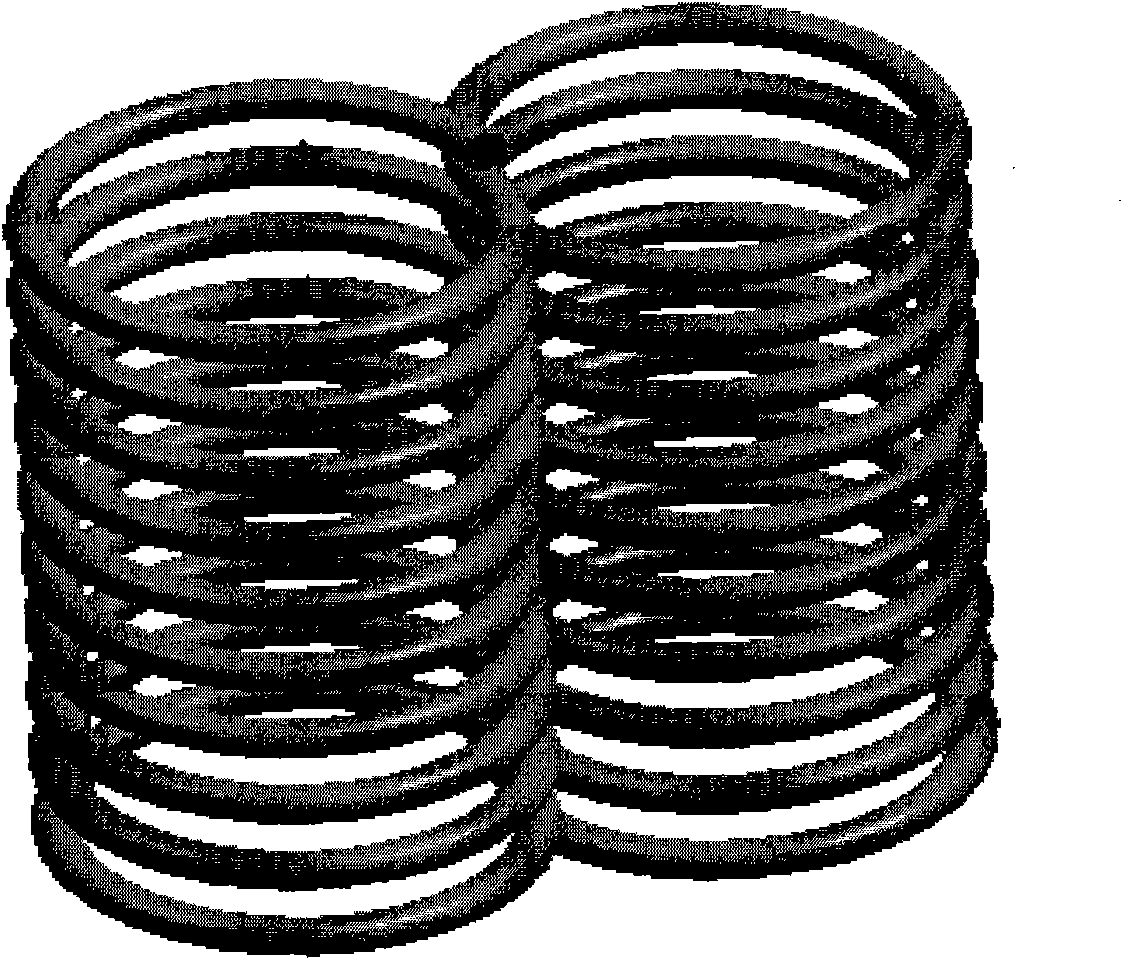

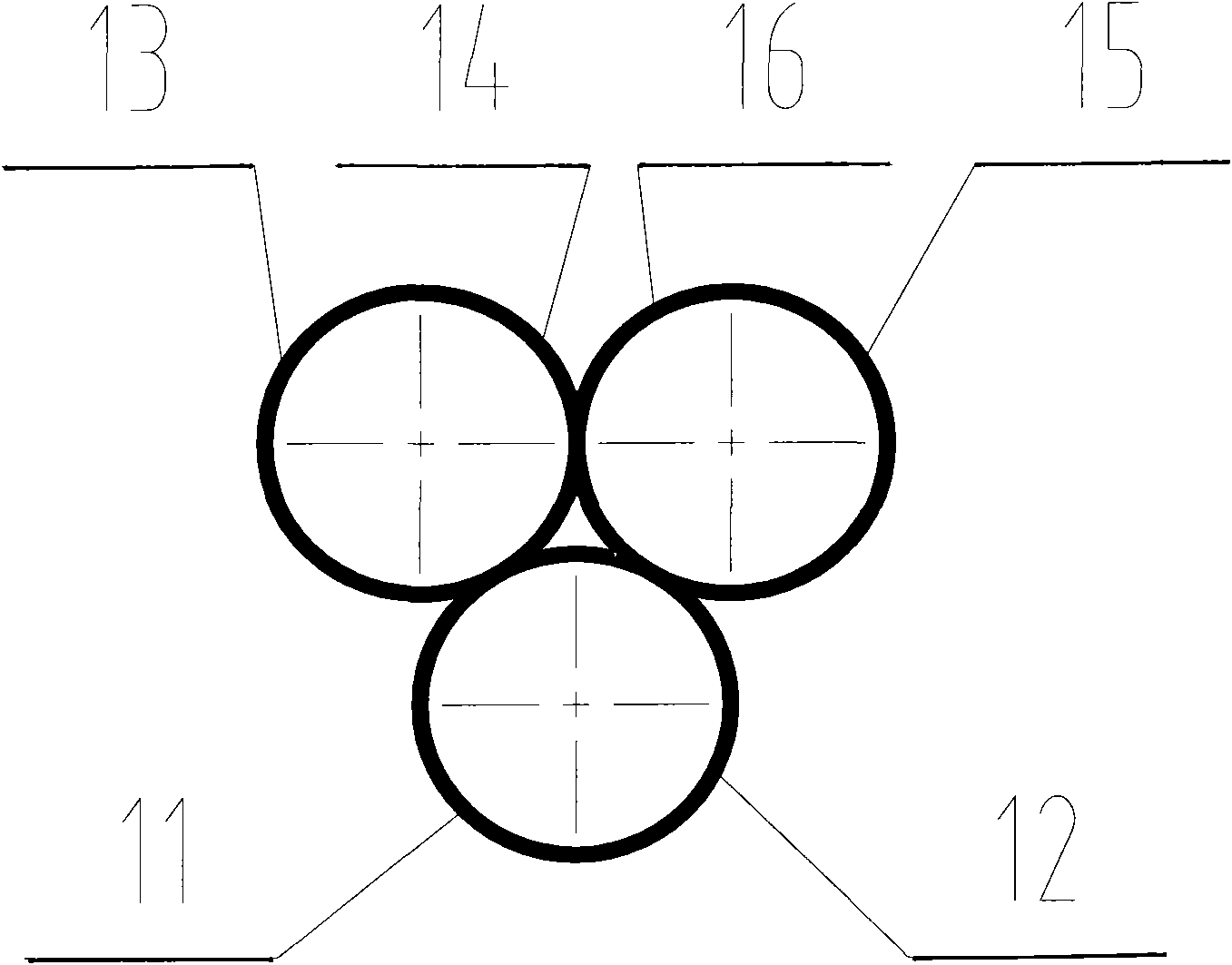

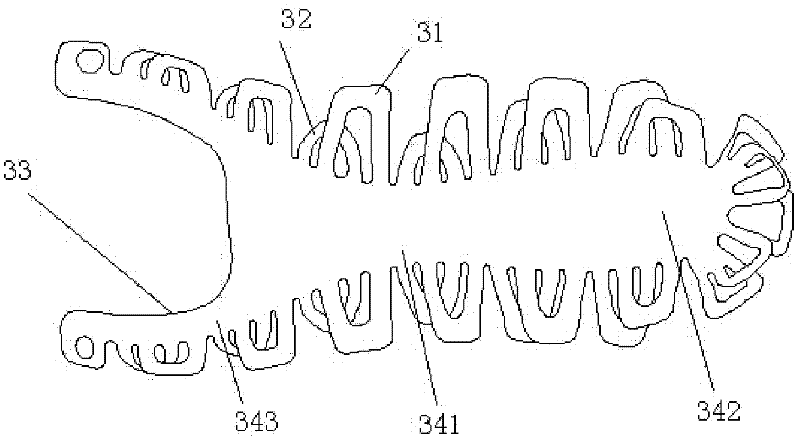

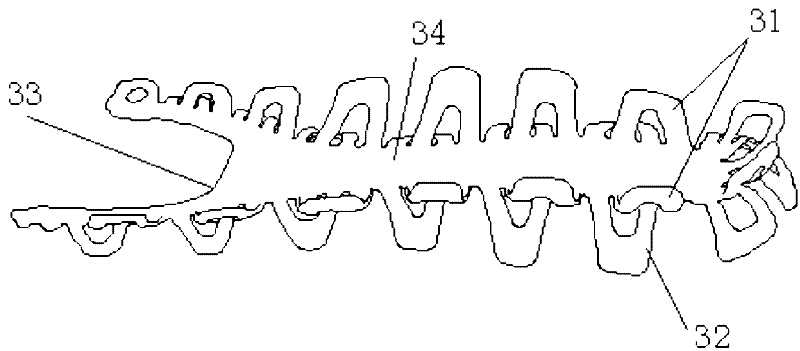

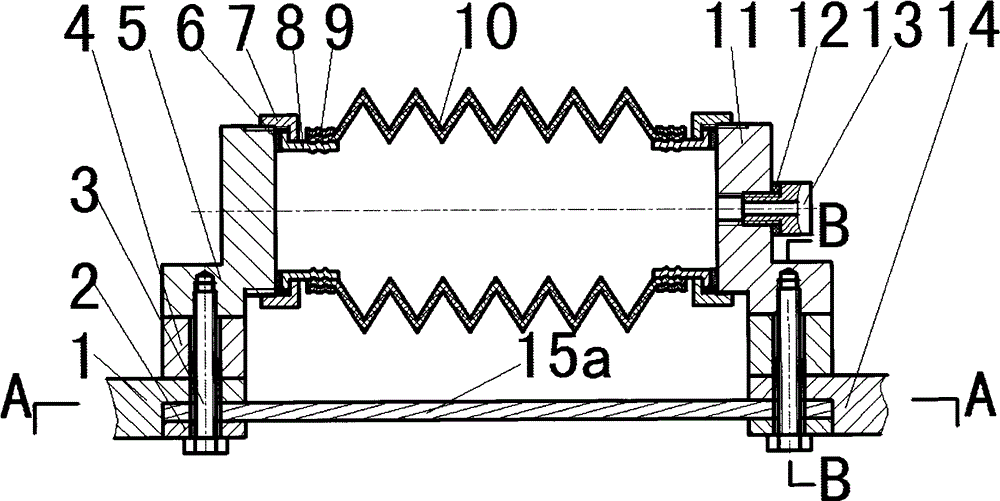

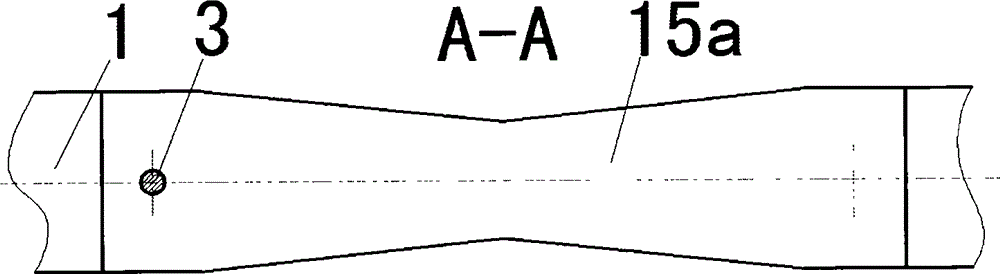

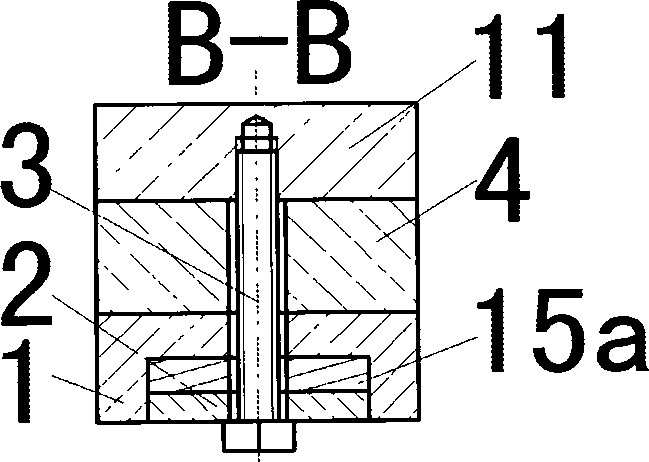

Multi-connection helical spring

InactiveCN101832351AAvoid torsional deformationPrevent internal forceWound springsMarket potentialStructural stability

The invention discloses a spring member, in particular a constraint spring for artificial muscles, i.e. a multiconnection helical spring which is characterized by being provided with a spring wire; the spring is in multilayer distribution along the axial direction to form a stereoscopic shape which is just like being formed by connecting a plurality of cylinders; and the axis of each cylinder is independent, and the section shape is similar to a whole connected by a plurality of rings. The invention provides a spring with a new structure for the mechanical manufacture industry, which has larger support surface than a single helical spring when used as an elastic element for axial stretching and bending, can carry out multishaft guide and be mutually supported, has good structural stability, can prevent torsion deformation or internal force generated when the single helical structure is loaded by being used for radial constraint of the artificial muscles, can adopt parallel connection of two, three, four or more integrated columnar helical springs wound by one spring wire in structure, and has high popularization and application values and favorable market potential.

Owner:BEIHUA UNIV

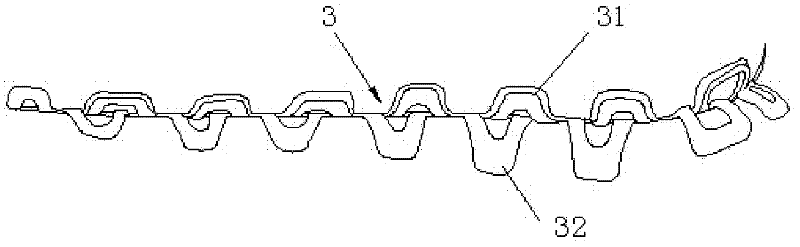

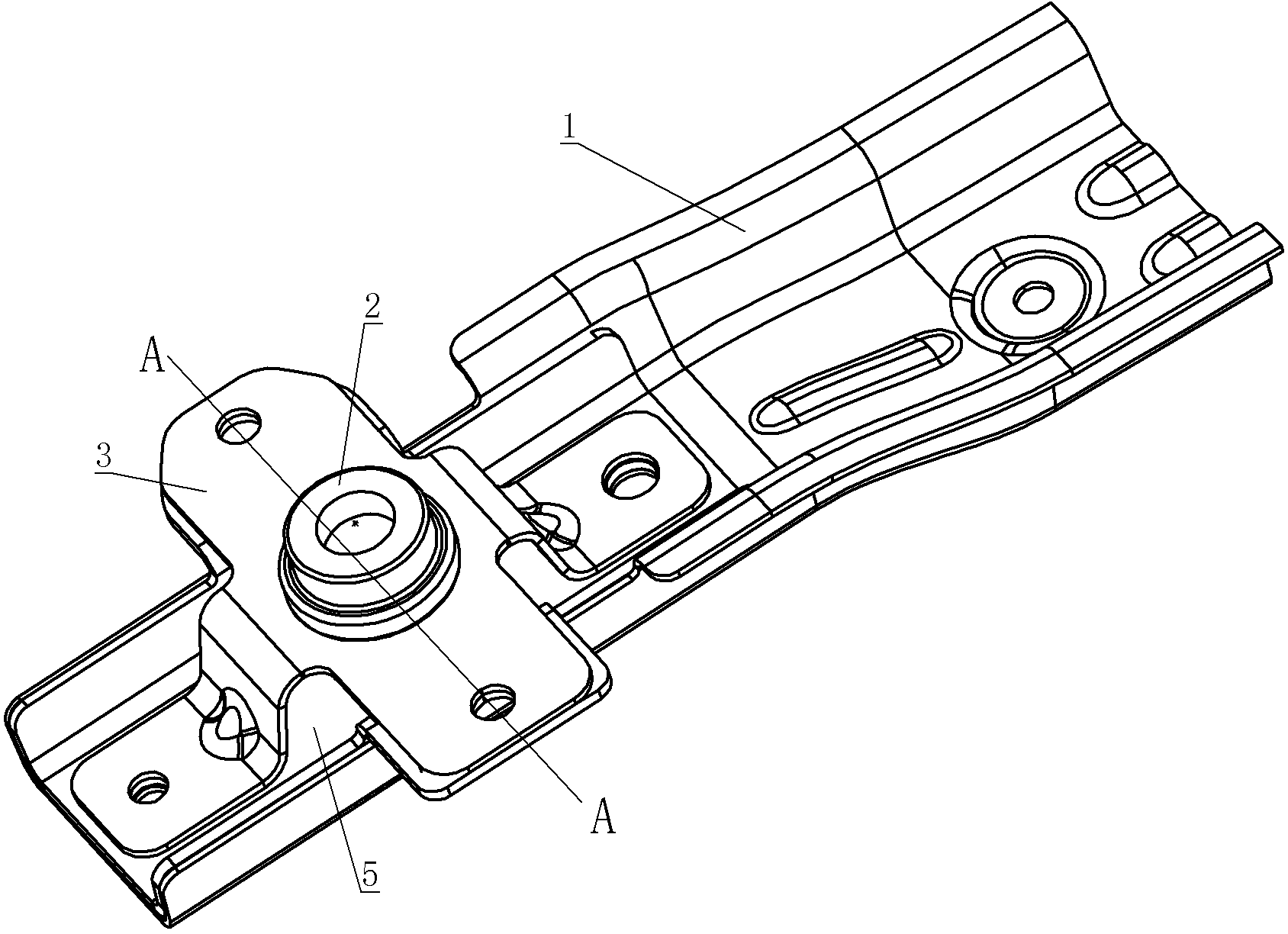

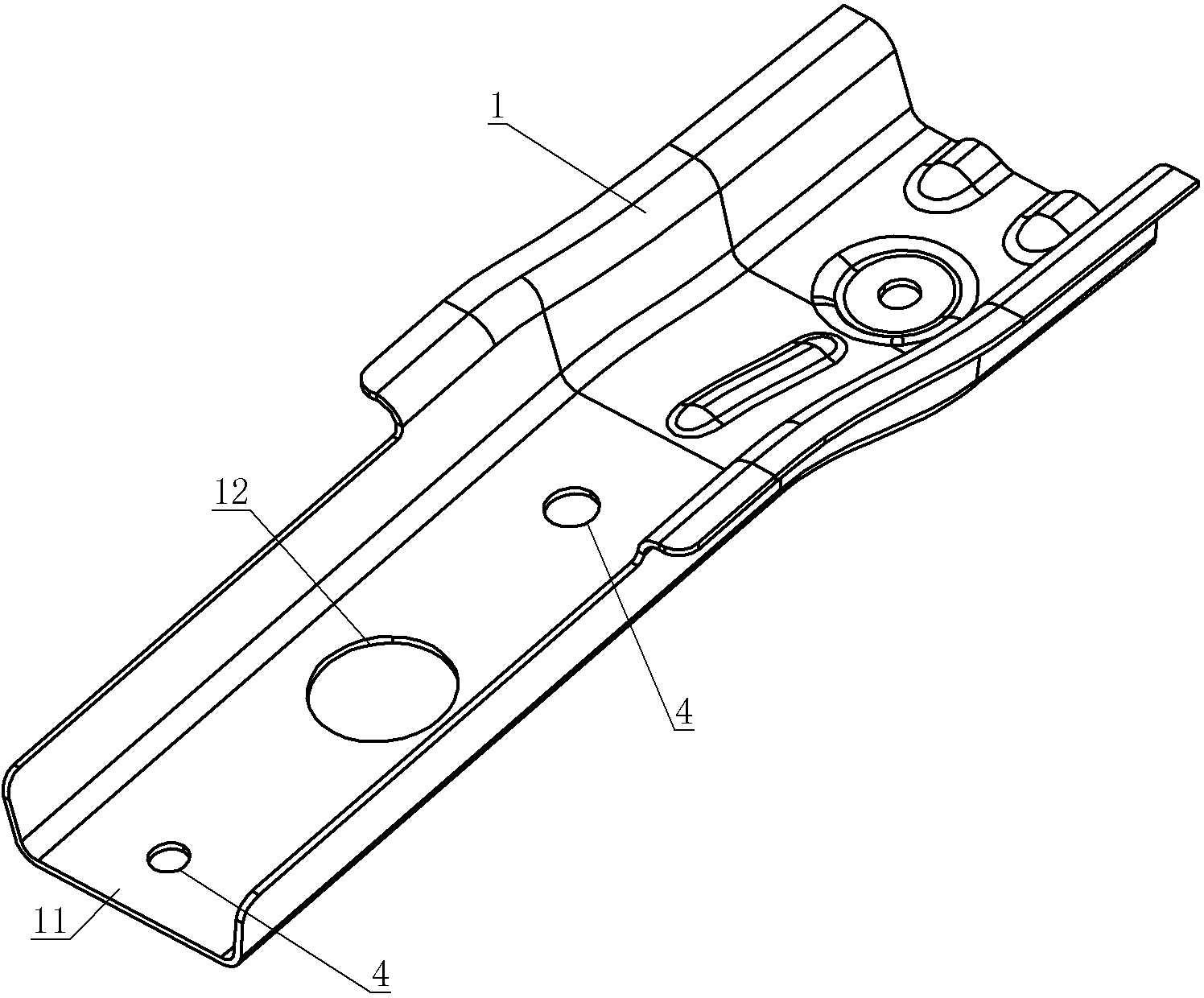

Damping and torsion-resisting element for shoe sole

The invention provides a damping and torsion-resisting element for a shoe sole. The damping and torsion-resisting element comprises a substrate, wherein positioning sheets extend from both sides of the substrate along the width direction of the substrate respectively, and are divided into an upper positioning sheet and a lower positioning sheet; the upper positioning sheet obliquely extends upwards, and then extends upwards in a bending way; the lower positioning sheet obliquely extends downwards, and then extends downwards in a bending way; bending positions are in circular transition; the middle parts of the upper positioning sheet and the lower positioning sheet are hollowed; the upper positioning sheet and the lower positioning sheet are distributed in a staggered way; and the middle part and the end part of the upper positioning sheet and the lower positioning sheet cling to the two outer side walls of a middle sole and an inner sole, so that the peripheries of shoe waists of themiddle sole and the inner sole are supported in a jointing way. The damping and torsion-resisting element has damping, supporting, shaping, rebounding and stabilizing functions, can be taken as a damping element applied to a thin position on the shoe sole for effectively absorbing and eliminating front face and side face impact force of the ground on feet, and can automatically restore to the original shape to prevent the shoe sole from being deformed excessively in a torsional way and prevent the feet from being wrenched.

Owner:MAOTAI FUJIAN SOLES CO LTD

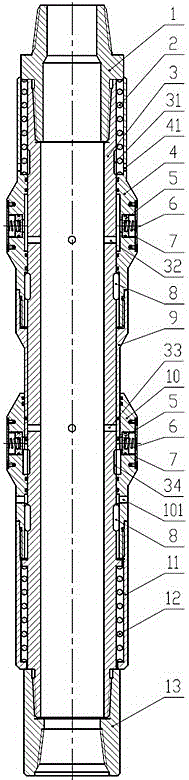

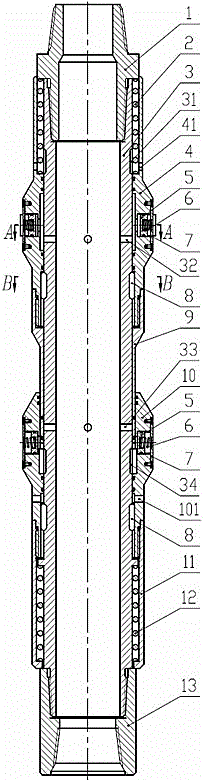

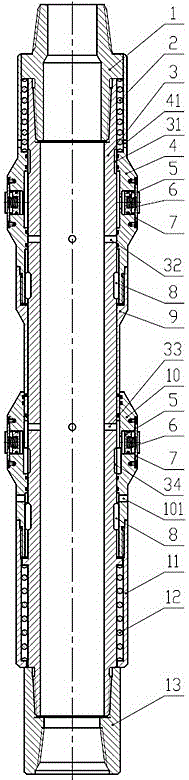

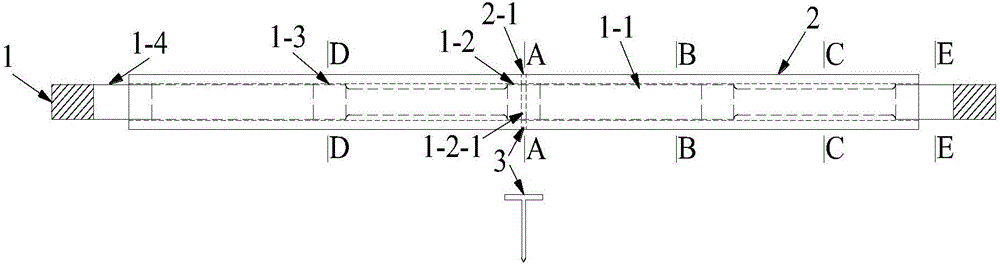

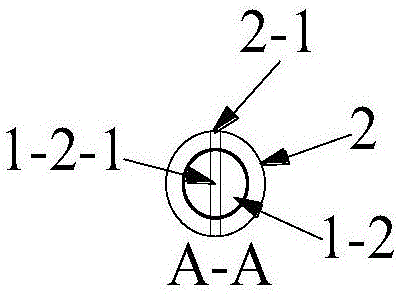

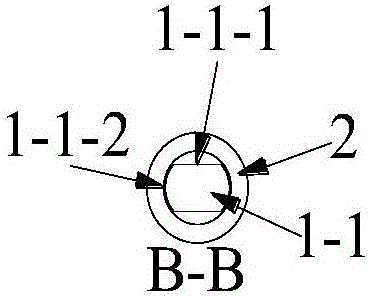

Linkage type drill stem anti-twist tool

InactiveCN105840113AAvoid torsional deformationImprove Steering Drilling EfficiencyDrilling rodsDrilling casingsUpper jointWell drilling

The invention relates to a linkage type drill stem anti-twist tool capable of preventing twist deformation of a drill stem in the oil and gas industry, and solves the drill stem twist deformation problems in an oil and gas drilling process; the technical scheme is that a main barrel top and an upper joint bottom are in screwed connection; a main barrel bottom and a lower joint top are in screwed connection; anti-twist pins are respectively arranged in a pin slot below a main barrel upper fluid inlet and a pin slot below a main barrel lower unloading groove; an upper anchoring casing is sleeved on the upper portion of the main barrel excircle; a lower anchoring casing is sleeved on the lower portion of the main barrel excircle; an anchor palm is arranged in a step hole of an upper anchoring casing centralizer rib, and an anchor palm is arranged in a step hole of a lower anchoring casing centralizer rib. The linkage type drill stem anti-twist tool can realize contentiously drilling, and at least the upper anchoring casing, the lower anchoring casing, or both of the two are anchored with the well wall, thus effectively preventing drill stem from having twist deformation; the linkage type drill stem anti-twist tool can be applied in the drill tool face and coiled-tubing drilling technical field.

Owner:SOUTHWEST PETROLEUM UNIV

Vertical type bamboo-shaped round rod energy consumption rod

ActiveCN106760854AAvoid torsional deformationConstrained Lateral DeformationProtective buildings/sheltersShock proofingEnergy consumption

The invention discloses a vertical type bamboo-shaped round rod energy consumption rod comprising a core part, an outer restraint part and a locating pin. The core part is composed by connecting a plurality of mutually-perpendicular energy dissipation sections, intermediate limiting sections, bamboo sections and two-end connecting sections along the longitudinal coaxial axis. The intermediate limiting sections are located in the middle of the core part. The bamboo sections and the energy dissipation sections are distributed at intervals, arranged on the two sides of the intermediate limiting sections and form a whole together with the intermediate limiting sections, and the two ends of the outer sides of the bamboo sections and the energy dissipation sections are fixedly connected with the two-end connecting sections to form the core part. The cross sections of the intermediate limiting sections, the bamboo sections and the two-end connecting sections are all circular. First holes are formed in the middles of the intermediate limiting sections in the diameter direction. The energy dissipation sections are cut and manufactured in the length direction, so that the cross sections of the energy dissipation sections are two parallel opposite sides, the other two short sides are original arc lines, under the effect of the axial tensile pressure, the energy dissipation sections of the core part enter yielding through the formed new cross section areas, while the intermediate limiting sections, the bamboo sections and the two-end connecting sections always remain elastic.

Owner:SOUTHEAST UNIV

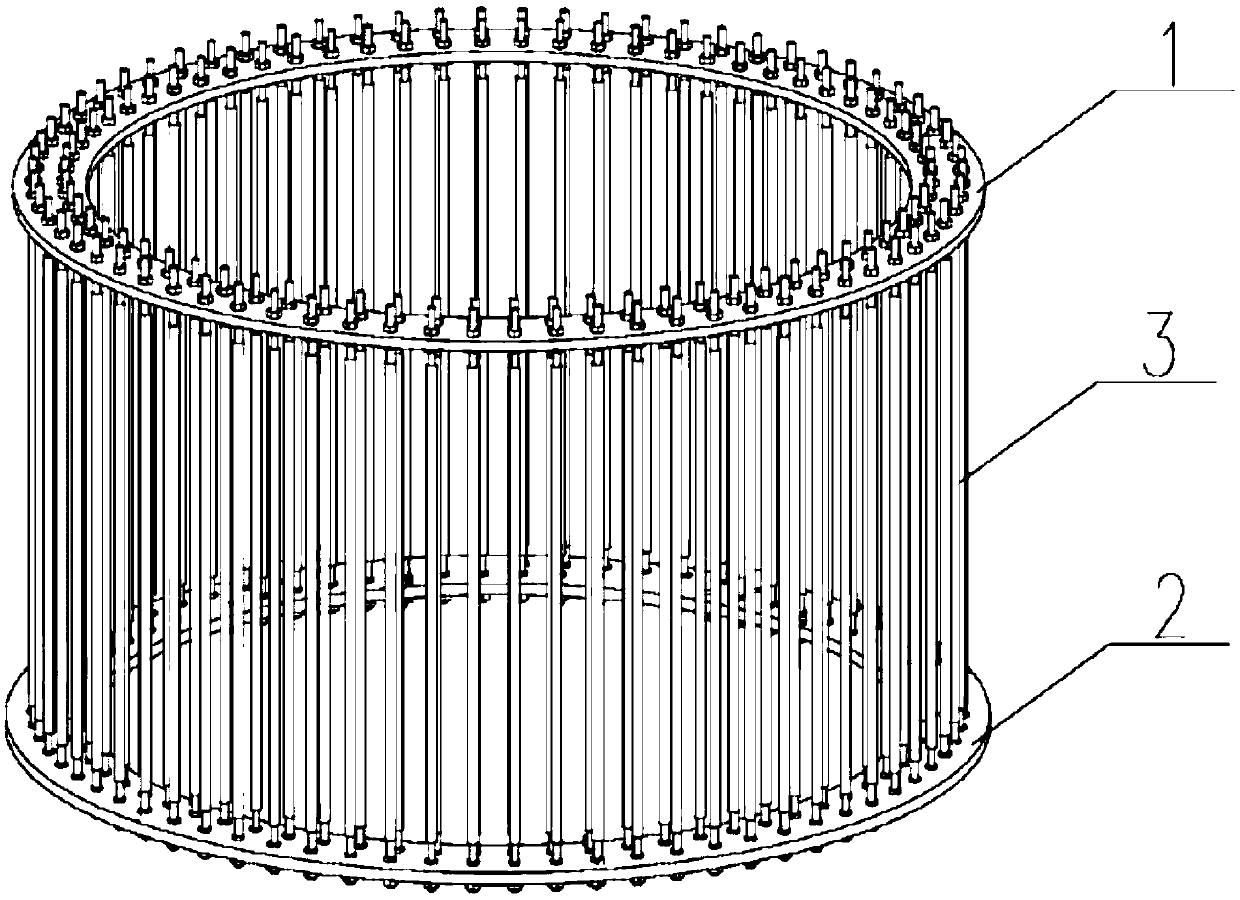

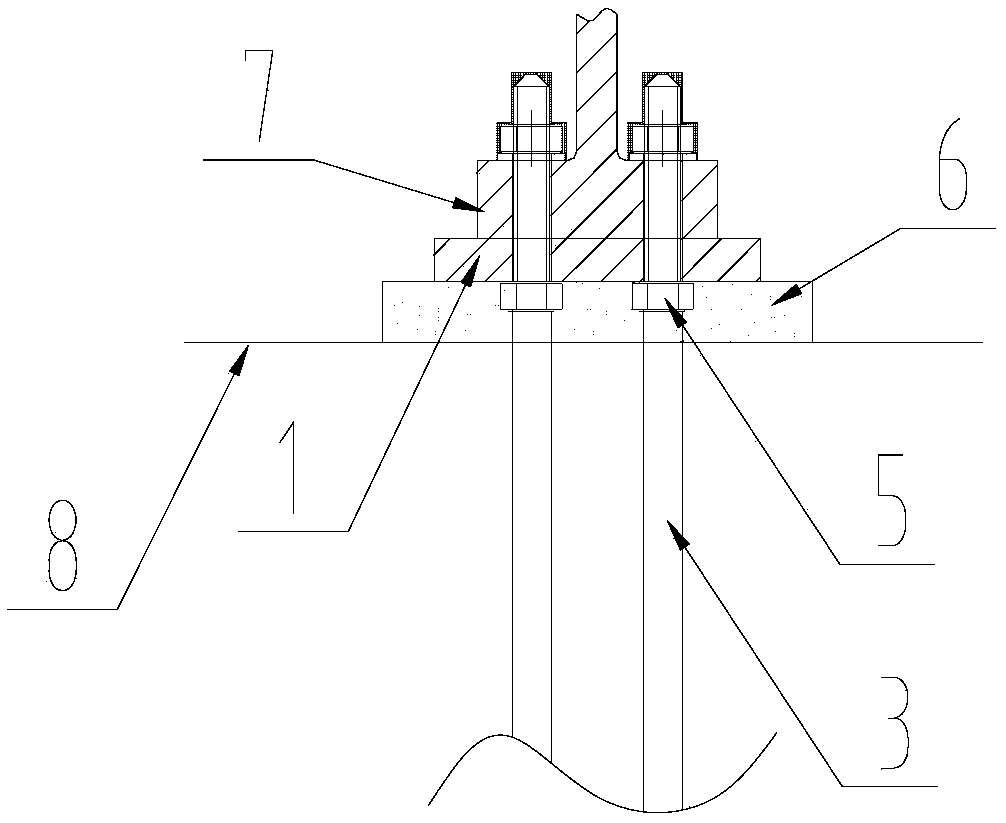

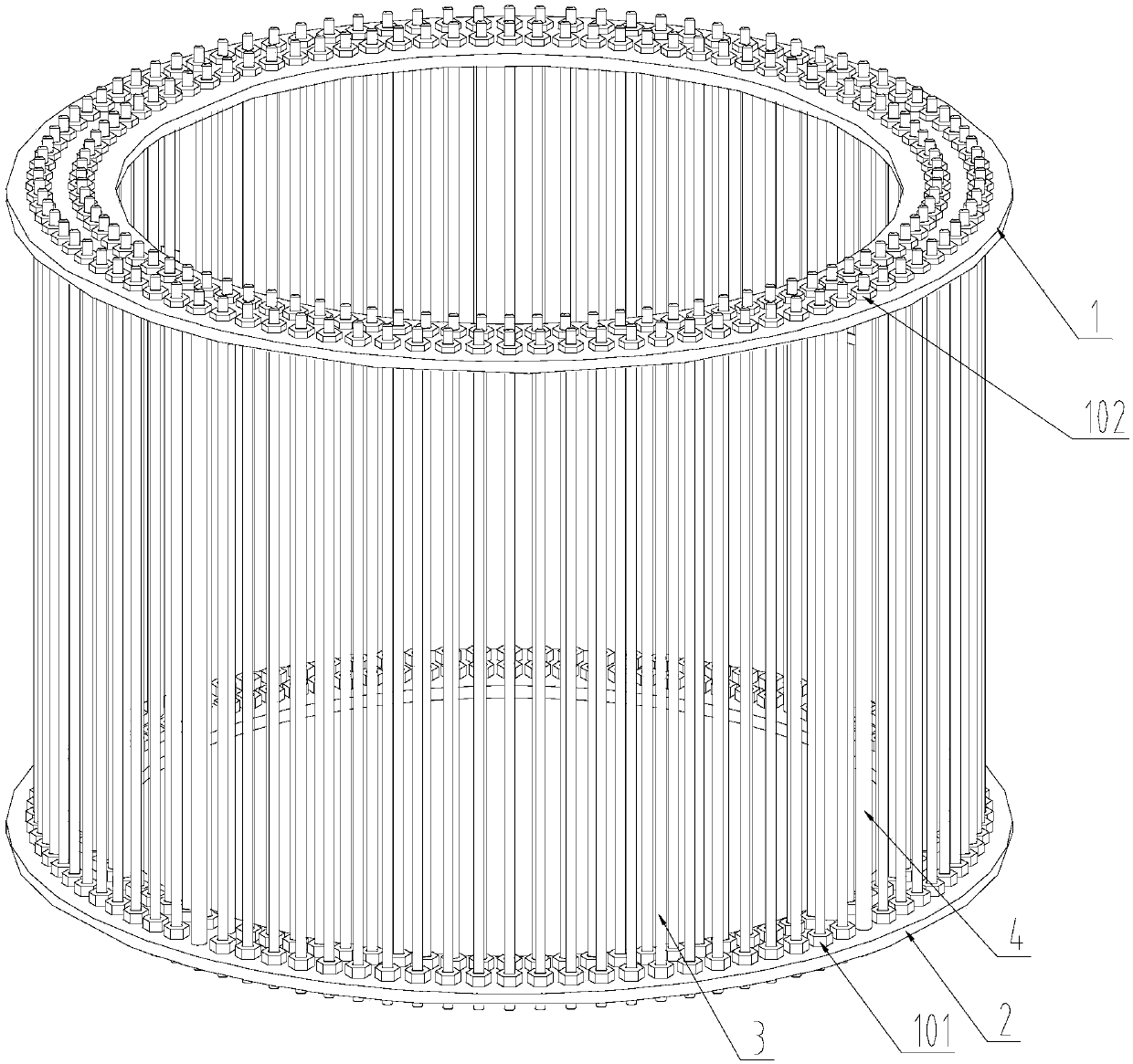

Wind generating set foundation anchor bolt assembly and construction method of connecting tower cylinder thereof

ActiveCN109595126AHigh precisionQuality improvementWind motor supports/mountsWind energy generationTowerWind force

The invention relates to a wind generating set foundation anchor bolt assembly and a construction method of a connecting tower cylinder thereof. The wind generating set foundation anchor bolt assemblycomprises an upper anchor plate, a lower anchor plate, multiple anchor bolts, a supporting casing pipe set and a protecting casing pipe; the anchor bolts are connected with the upper anchor plate andthe lower anchor plate, the supporting casing pipe set comprises a first supporting pipe, a second supporting pipe and a connecting pipe fixedly connected with the first supporting pipe and the second supporting pipe, two adjacent anchor bolts are sleeved with the first supporting pipe and the second supporting pipe correspondingly, the upper anchor plate is supported by the first supporting pipeand the second supporting pipe, the protecting casing pipe is arranged on remaining anchor bolts in a sleeving manner, two adjacent anchor bolts are sleeved with the integrated supporting casing pipeset, deviation of the anchor bolts in the horizontal direction after the anchor bolts are arranged on the upper anchor plate and the lower anchor plate can be limited, whole torsion deforming of theanchor bolts around a vertical shaft of the foundation anchor bolt assembly is avoided, whole precision of the wind generating set foundation anchor bolt assembly is improved, the quality of the windgenerating set foundation anchor bolt assembly is improved, and the tower cylinder lifting difficulty is reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Mounting device for tow hook

The invention discloses a mounting device for a tow hook. The mounting device comprises an anti-collision beam body, a connecting post and a stiffening plate, wherein the connecting post is connected with the tow hook, the stiffening plate is fixed on the anti-collision beam body, a protruding connecting surface separated from the surface of the anti-collision beam body and at least two connecting lugs positioned on two sides of the connecting surface are arranged on the stiffening plate, two ends of the connecting post are fixedly connected with the anti-collision beam body and the connecting surface respectively, and each connecting lug is fixedly connected on the anti-collision beam body. According to the mounting device, the stiffening plate is arranged additionally, so that the stability of the anti-collision beam body and the connecting post can be improved, when the tow hook is under the action of bending moment, the stiffening plate can provide opposite moment for the anti-collision beam body, and torsional deflection of the anti-collision beam body cannot occur easily. The mounting device is applicable to various automobiles and used for mounting front or back tow hooks.

Owner:GREAT WALL MOTOR CO LTD

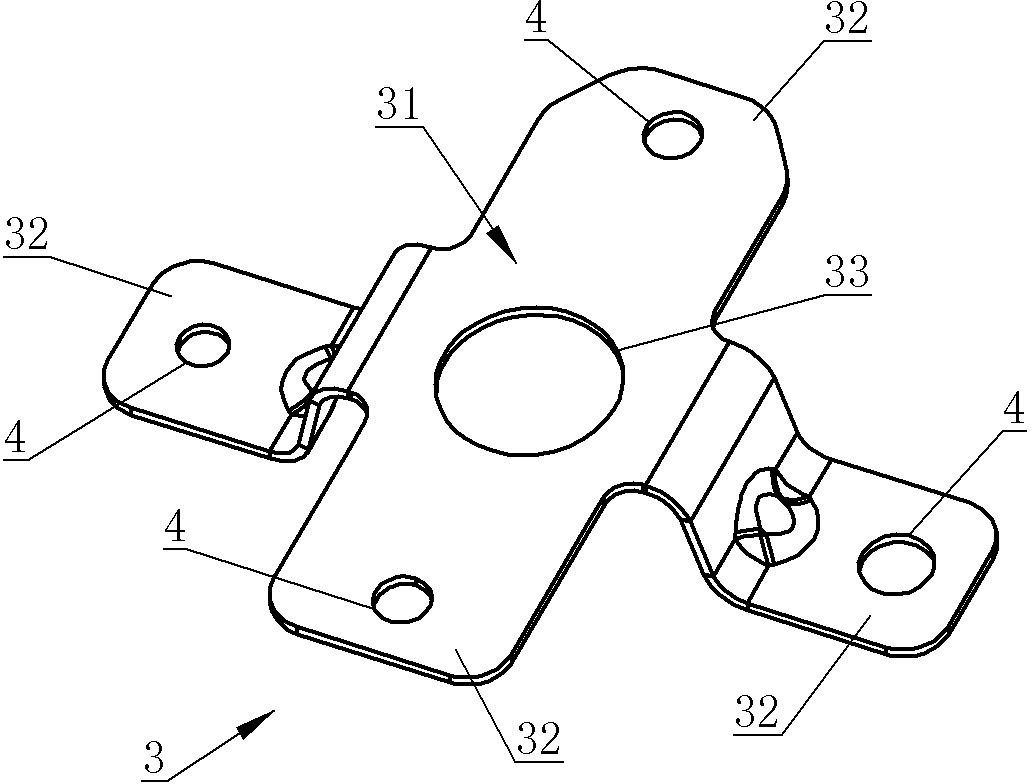

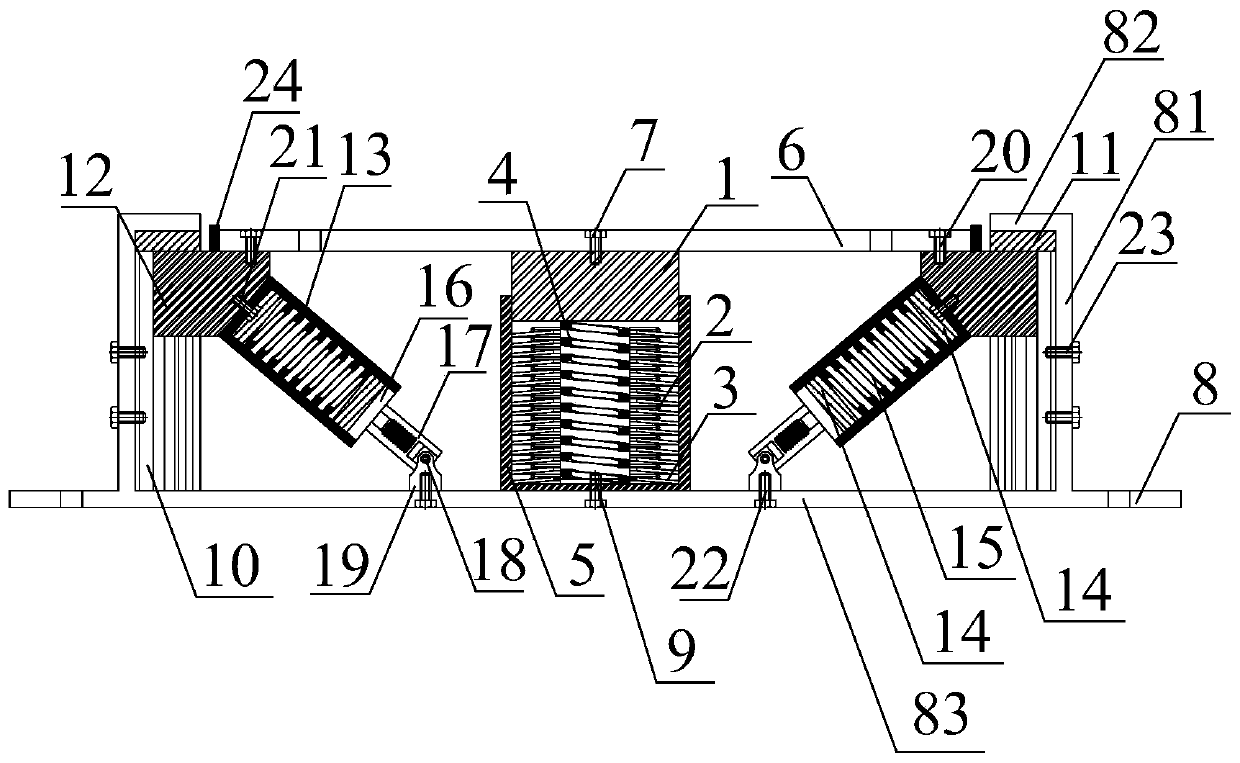

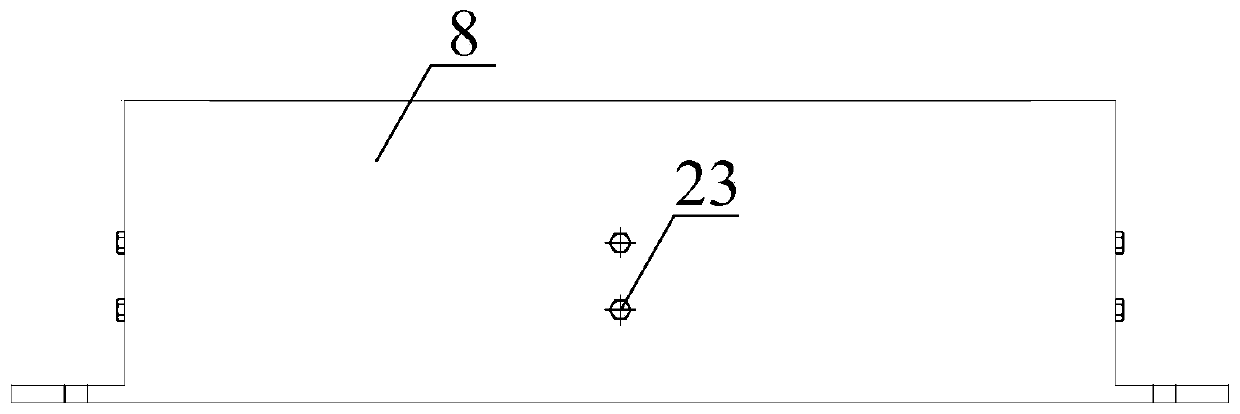

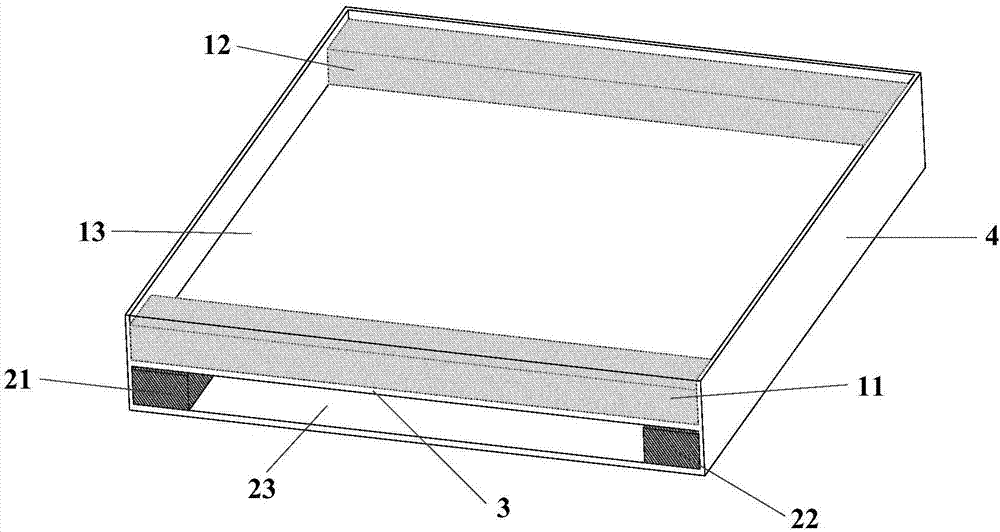

Vertical vibration isolation device

InactiveCN111336204AEasy to assembleEfficient energy consumptionHigh internal friction springsProtective buildings/sheltersVertical vibrationUniversal joint

The invention discloses a vertical vibration isolation device. The vertical vibration isolation device mainly comprises an upper connecting plate, an adaptive stiffness unit, slidable oblique rectangular compression spring units and a lower connecting plate. The adaptive stiffness unit is mainly composed of a positioning loading ring, a belleville spring and a pre-compressed rectangular spring, wherein the positioning loading ring and the belleville spring work in parallel to provide vertical negative stiffness, the pre-compressed rectangular spring provides vertical positive stiffness, and the positioning loading ring, the belleville spring and the pre-compressed rectangular spring work together to generate adaptive stiffness; and the slidable oblique rectangular compression spring unitsare each composed of a directional linear guide rail, an oblique rectangular compression spring and a universal joint, vertical sliding blocks move down along the directional linear guide rails to cause axial compression deformation of the oblique rectangular springs, and energy is dissipated through the mutual conversion of elastic potential energy and kinetic energy. The adaptive stiffness unitand the slidable oblique rectangular compression spring units work in parallel, collaboratively deform and jointly achieve vertical vibration isolation. The vertical vibration isolation device can bewidely applied to buildings or large and medium-sized mechanical equipment with high requirements for vibration reduction and near rail transit.

Owner:TONGJI UNIV

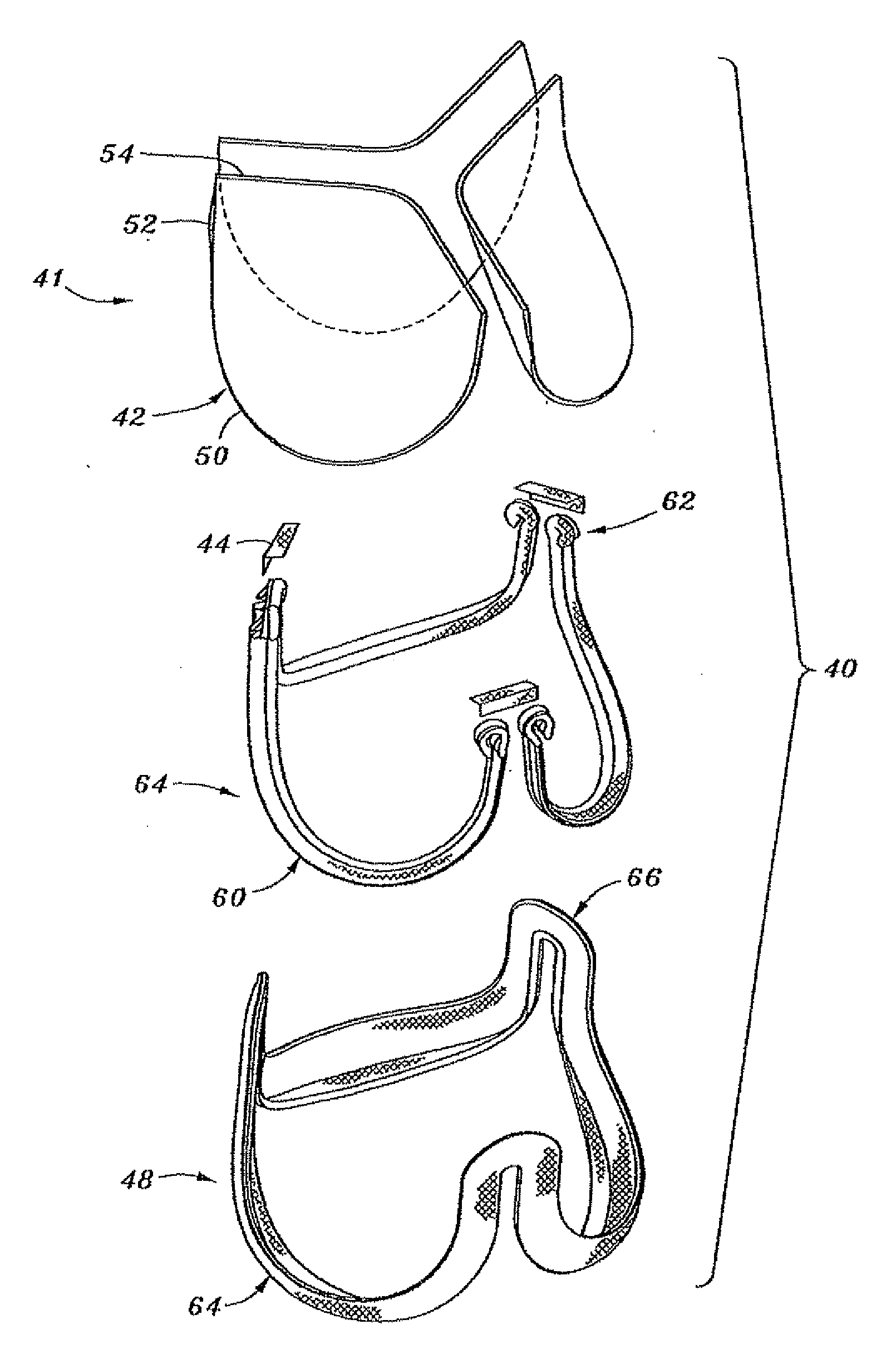

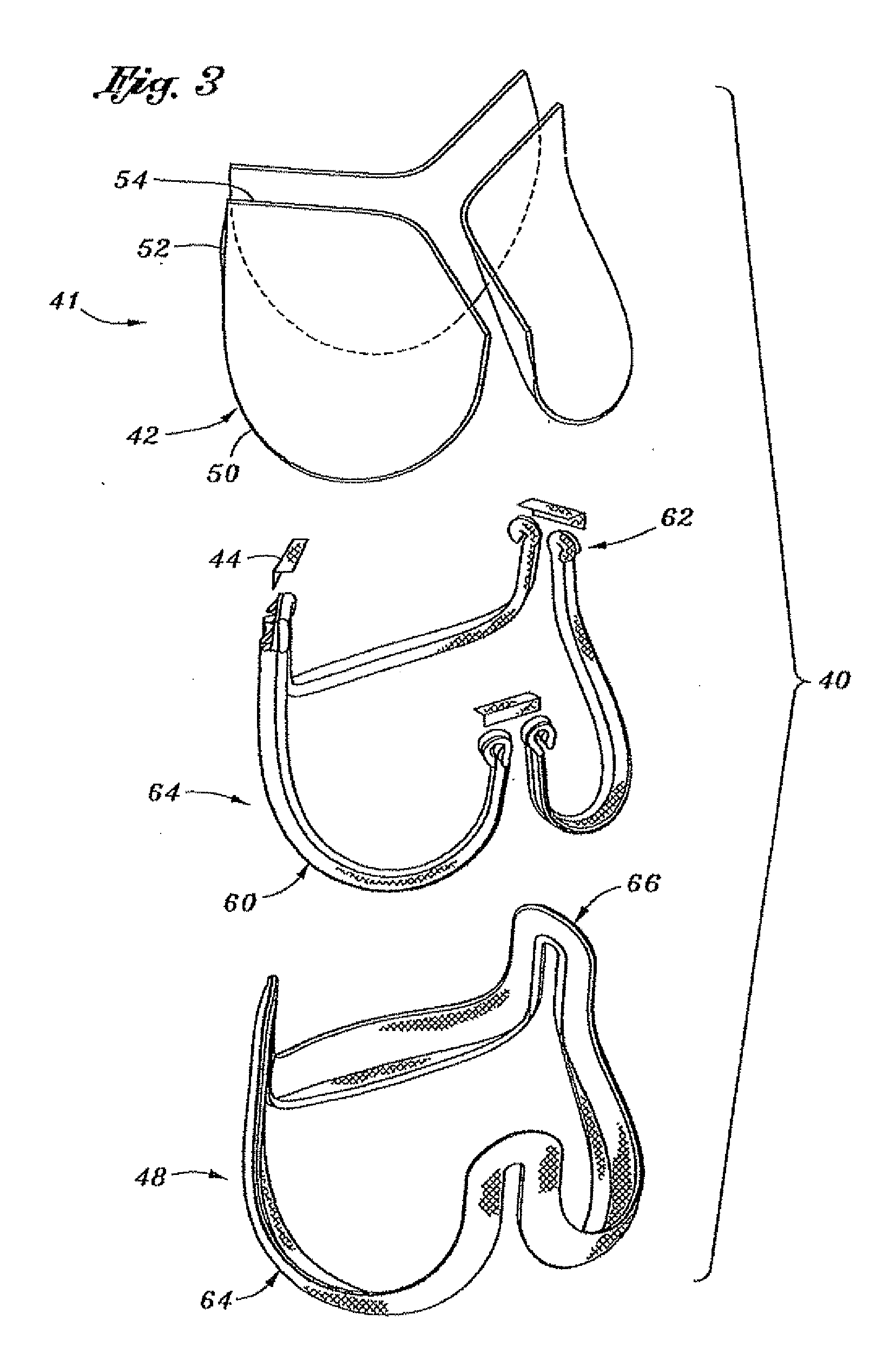

Flexible heart valve and associated connecting band

InactiveUS20100057193A1Pressure lossProvide durabilityHeart valvesBlood vesselsSingle elementTissues types

A highly flexible tissue-type heart valve is disclosed having a structural stent in a generally cylindrical configuration with cusps and commissures that are permitted to move radially. The stent commissures are constructed so that the cusps are pivotably or flexibly coupled together at the commissures to permit relative movement therebetween. The stent may be cloth-covered and may be a single element or may be made in three separate elements for a three cusp valve, each element having a cusp portion and two commissure portions; adjacent commissure portions for each pair of adjacent stent element combining to form the stent commissures. If the stent has separate elements their commissure portions may be pivotably or flexible coupled, or may be designed to completely separate into independent leaflets at bioresorbable couples. The cloth covering may have an outwardly projecting flap that mates with valve leaflets (e.g., pericardial leaflets) along the cusps and commissures. A connecting band may be provided that follows the cusps and commissures and extends outwardly. The valve is connected to the natural tissue along the undulating connecting band using conventional techniques, such as sutures. The connecting band may be a cloth-covered silicon member and attaches to the underside of the valve at the cusps to provide support to the stent and to the outer side of the valve at the commissures. The connecting band includes commissure portions defining generally axial gaps that help permit flexing of the valve.

Owner:EDWARDS LIFESCIENCES CORP

Flexible parabola-shaped abnormal plate spring framework joint

InactiveCN104608143AAccording to the distribution of stressEasy to transformJointsEngineeringAbnormal shaped

The invention relates to a flexible parabola-shaped abnormal plate spring framework joint, and belongs to the technical field of application of robots and mechanical arms. According to the joint, an abnormal plate spring is used as a framework, the joint is bent through the drive of fluid, and the joint can be used as various joints of a robot. When an elastic corrugated pipe is inflated, the elastic corrugated pipe extends and is restrained by the plate spring to be bent towards one side of the plate spring. When gas in the elastic corrugated pipe is released, the joint is restored to be in an extension state under the effect of the plate spring. The pressure in the elastic corrugated pipe is controlled to enable the joint to be bent and to be kept at a certain angle. The elastic corrugated pipe has good flexibility, the plate spring has good elasticity, and therefore the joint has good flexibility. Through the improvement of the cross section of the plate spring, the bending space can be increased, the strength demand can be met, the flexibility is improved, and plate spring materials are saved. The flexible parabola-shaped abnormal plate spring framework joint is flexible in bending action, small in energy consumption, convenient to control and has a good flexible adaptability effect.

Owner:JIANGNAN UNIV

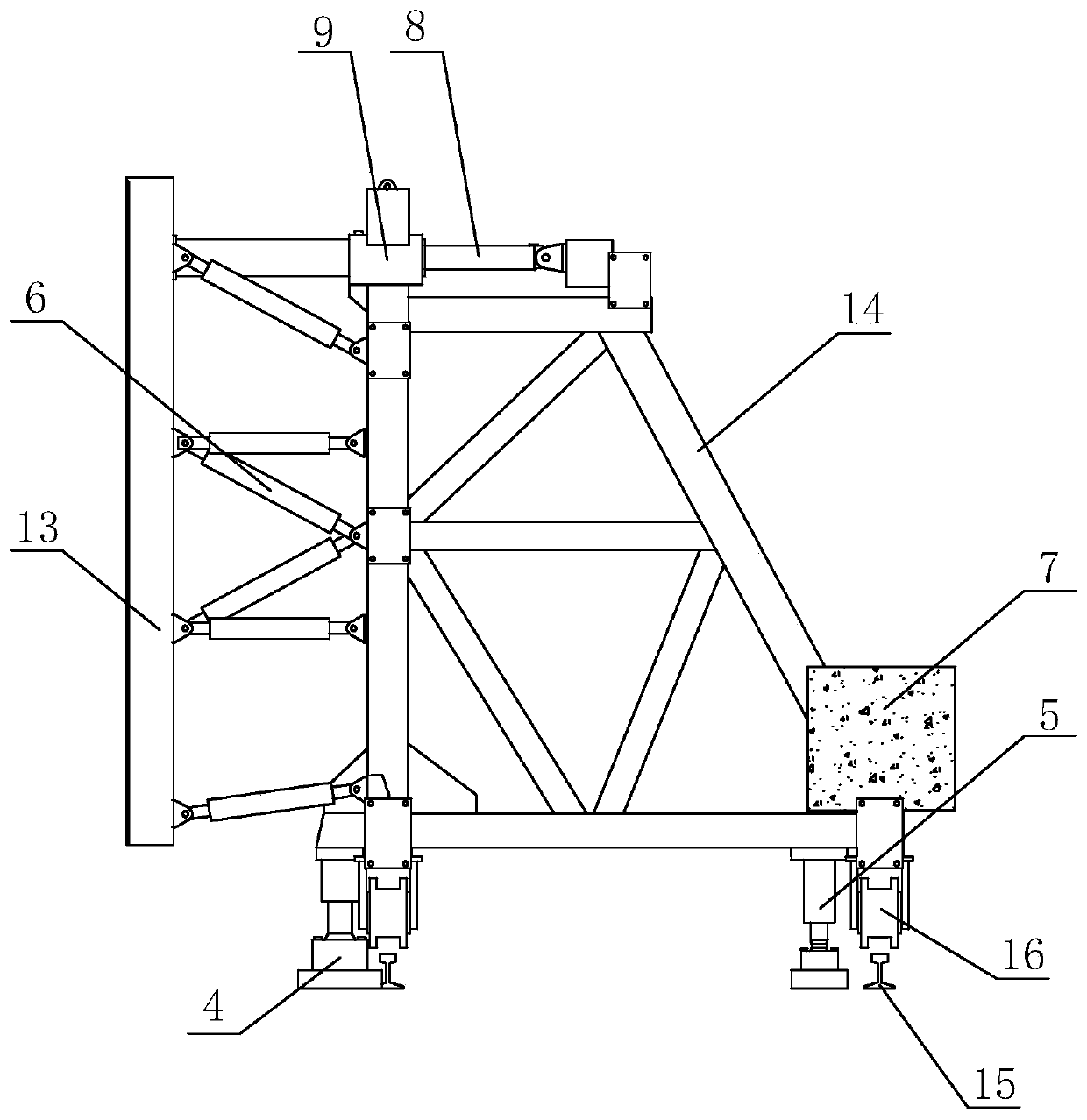

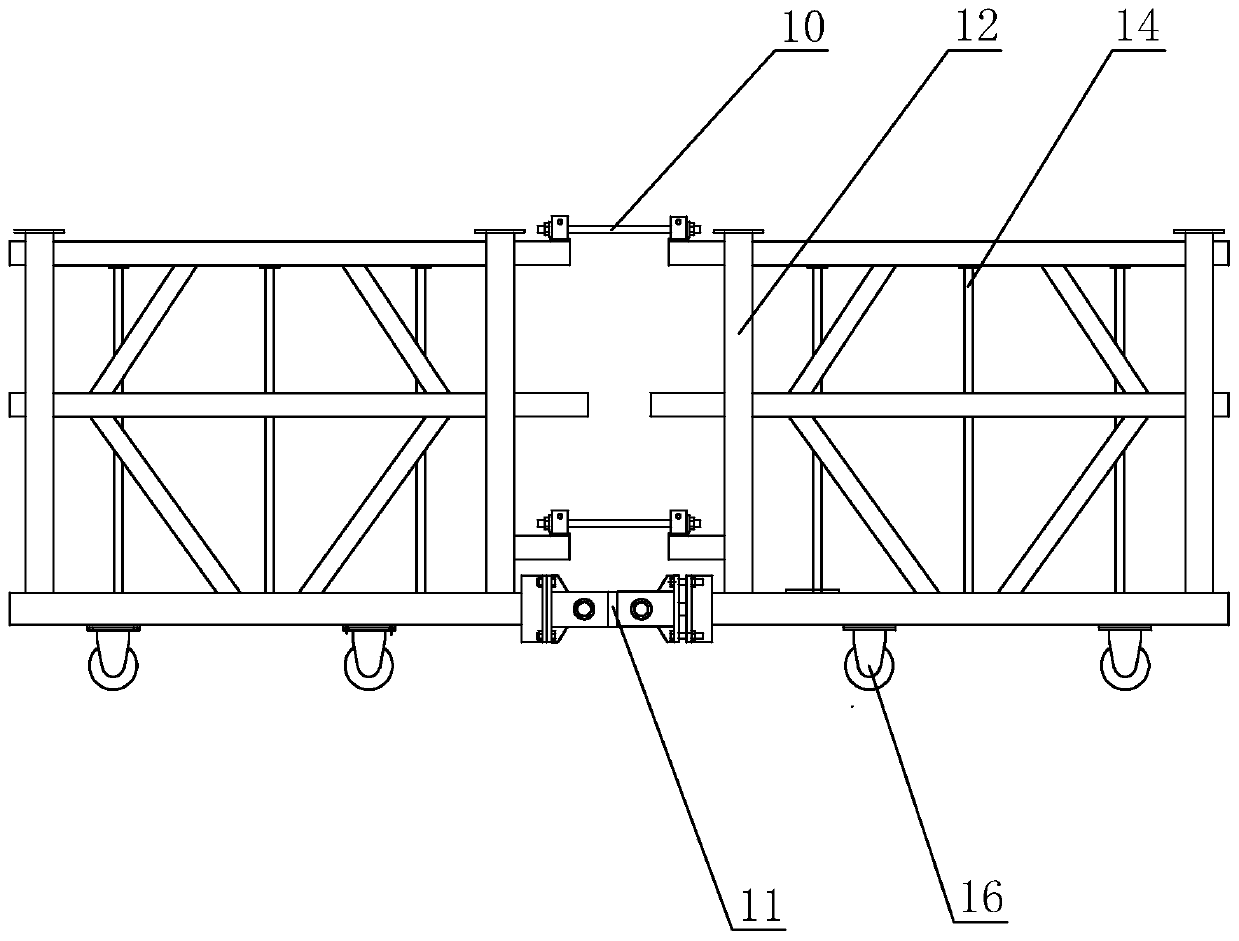

Self-inclined side wall formwork trolley, device and application method of device

PendingCN111075480ASimple demoulding methodReduced need for operating technologyUnderground chambersTunnel liningVehicle frameMechanism (engineering)

The invention discloses a self-inclined side wall formwork trolley, and relates to the technical field of building engineering construction. The self-inclined side wall formwork trolley comprises a vehicle frame, a formwork is arranged on one side of the vehicle frame in an adjustable mode, and an adjusting device for adjusting the position of the formwork is arranged between the formwork and thevehicle frame, a wheel walking device which is convenient for moving the position of the vehicle frame is arranged at the bottom of the vehicle frame, and a self-inclined demoulding device for pushingthe vehicle frame to incline is further arranged at the bottom of the vehicle frame; and the self-inclined demoulding device comprises a rotating mechanism and a pushing gear, and the rotating mechanism and a pushing gear are separately arranged on two sides of the vehicle frame. In order to solve the problem of difficulty in demoulding in the prior art, the vehicle frame is arranged in an inclined mode, and then the self weight of the vehicle frame is used for restoring the horizontal placement position to achieve demoulding, the demolding efficiency is improved, and the operation requirement is low.

Owner:SHANGHAI MECHANIZED CONSTR GRP

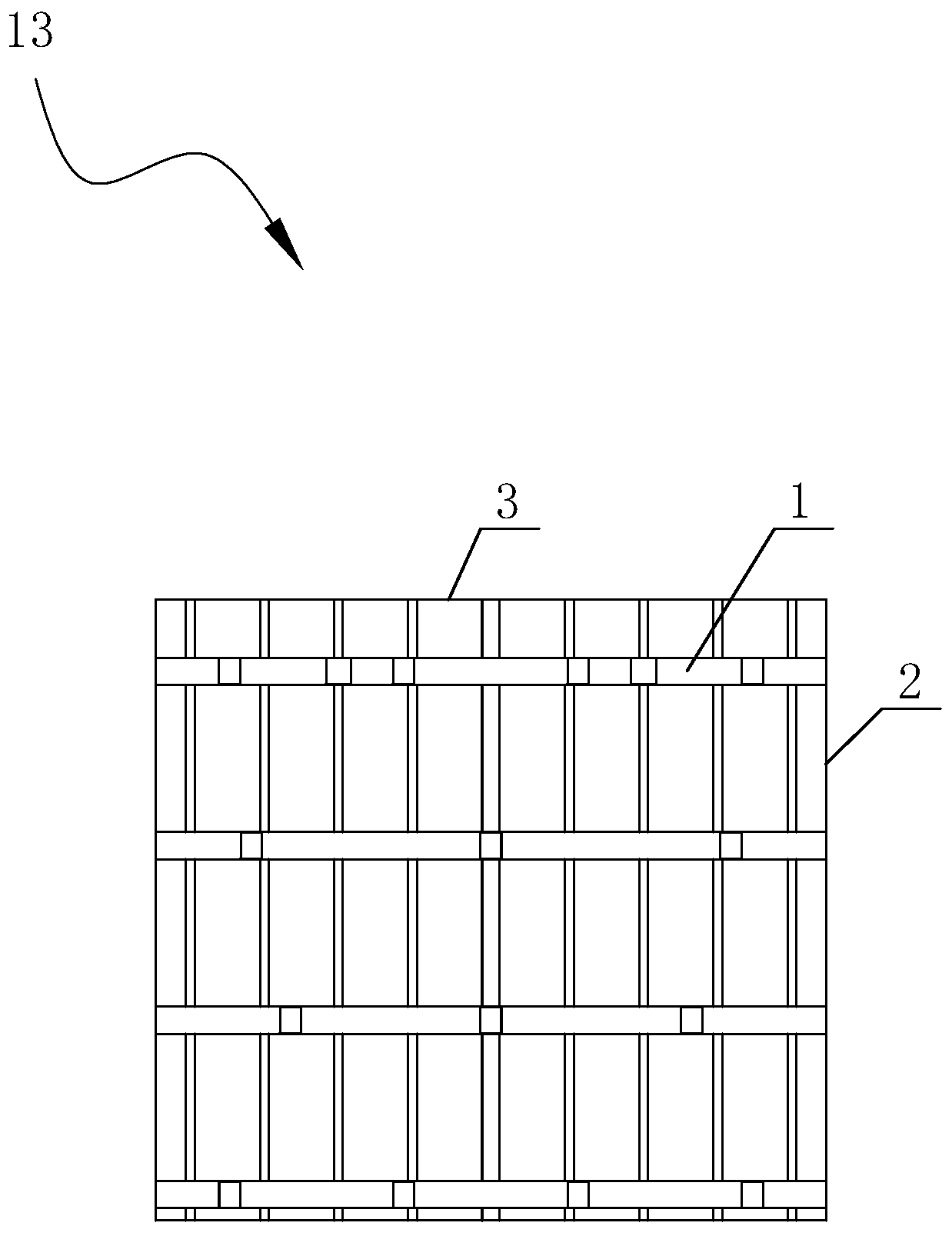

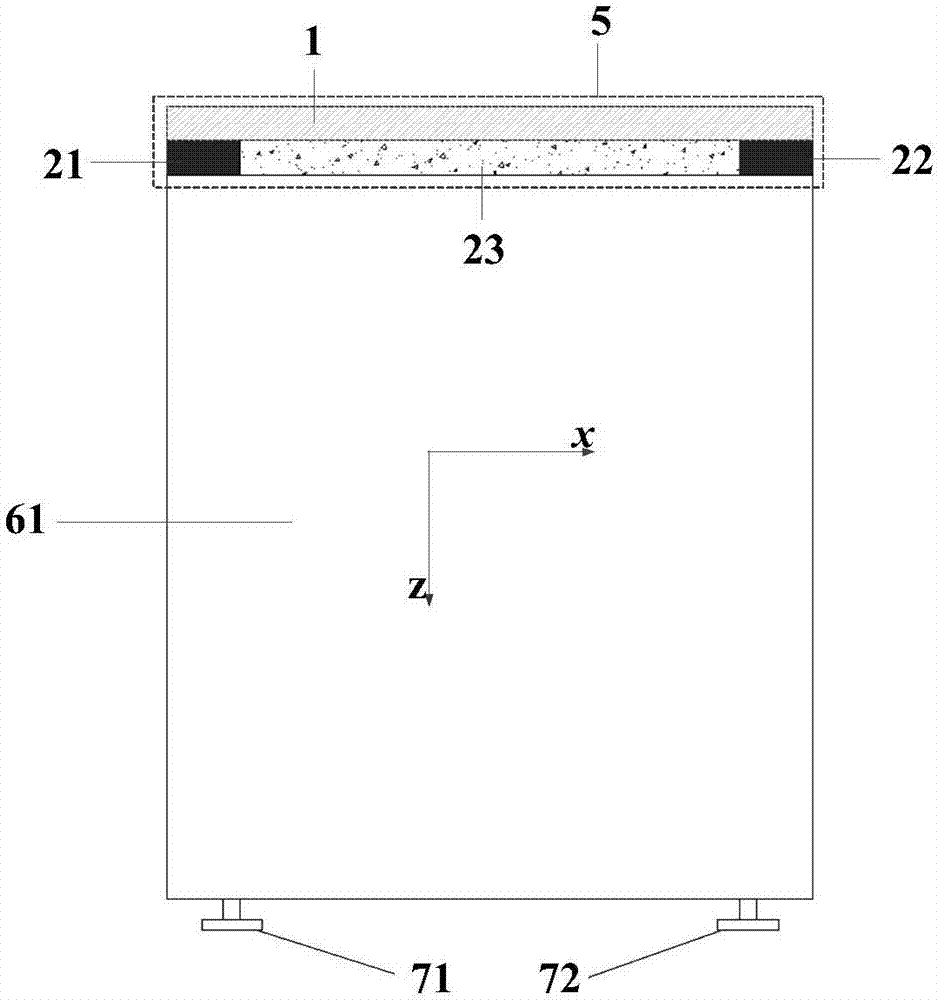

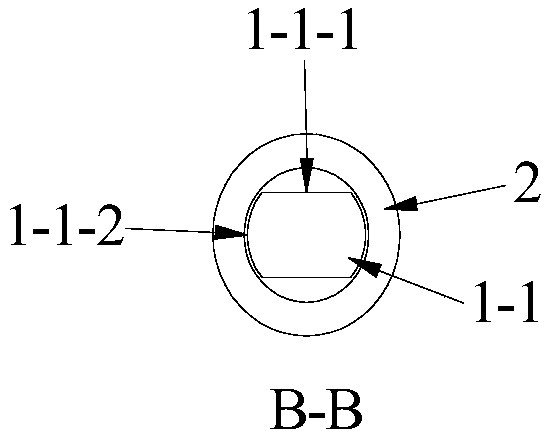

Vibration attenuation structure, washing machine and vibration attenuation method thereof

ActiveCN107974805ASolve the "walking" problemSolve the torsion problemOther washing machinesTextiles and paperVibration attenuationUltrasound attenuation

The invention discloses a vibration attenuation structure, a washing machine and a vibration attenuation method thereof. The vibration attenuation structure comprises a first direction electromagneticvibration attenuation layer (1) and a second direction electromagnetic vibration attenuation layer (2). The first direction electromagnetic vibration attenuation layer (1) is used for carrying out first-direction active vibration attenuation processing on first-direction vibration when equipment to be subjected to vibration attenuation generates the first-direction vibration in the operation process; the second direction electromagnetic vibration attenuation layer (2) is used for carrying out second-direction active vibration attenuation processing on second-direction vibration when equipmentto be subjected to vibration attenuation generates the second-direction vibration in the operation process. According to the scheme, the defects that in the prior art, vibration noises are high, overall swing vibration is likely to happen, are the user experience is poor can be overcome, and the advantages of being low in vibration noise, free of overall swing vibration and good in user experience are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

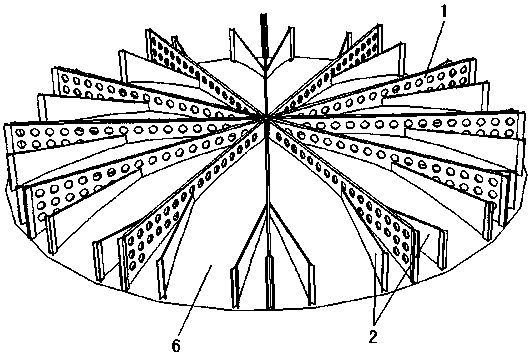

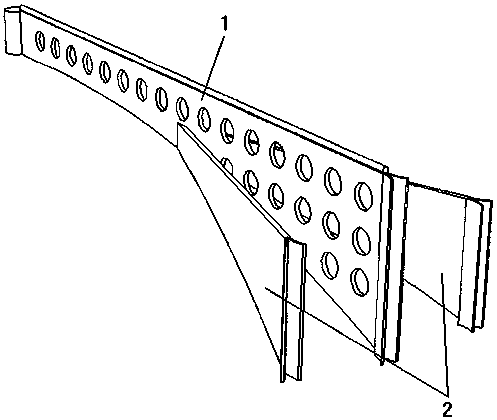

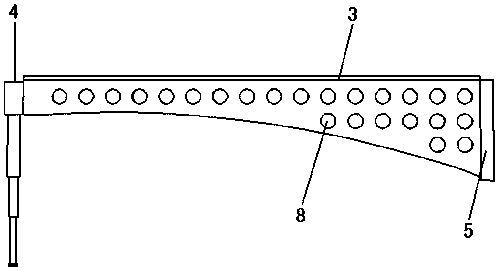

Expandable branching rib plate high-precision reflecting plane

ActiveCN107275795AIncreased out-of-plane bending stiffnessReduce local bucklingCollapsable antennas meansEngineeringParaboloid

The invention discloses an expandable branching rib plate high-precision reflecting plane, which comprises a center hub, main rib plates, auxiliary rib plates, positioning sheet-pressing springs, a paraboloid, a compressing belt, a waveguide rod and a feed source, and is characterized in that the upper side edge of each main rib plate is designed with dual straight pipes with an omega shape after being expanded, so that the out-plane bending rigidity is improved, and local buckling is substantially reduced. Each main rib plate is designed with the branched auxiliary rib plates, so that a defect of not satisfying an ideal paraboloid equation because of being away from a middle region is compensated, and the profile precision of a radial radiation rib plate antenna is improved. The lower side of the dual omega-shaped straight pipes is provided with the main rib plate with uniformly distributed circular holes, so that the structure mass can be effectively reduced, and the specific rigidity is improved. The positioning sheet-pressing springs drive expansion of the auxiliary rib plates and realize in-place expansion of the auxiliary rib plates at the same time.

Owner:HARBIN INST OF TECH

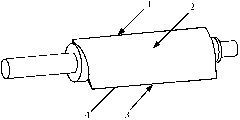

Metal-tube sectional material rewinder

The invention discloses a metal-tube sectional material rewinder. The metal-tube sectional material rewinder comprises a machine table machine frame. A metal tube guiding device and a sizing and prebending mechanism are arranged on the upper left side of the machine frame, an automatic tube-bank control mechanism is arranged on the left side of the machine frame, a tube winding rotating shaft driven by a motor and an unwinding mechanism are arranged in the middle of the machine frame, a to-be-rewound metal-tube sectional material is put into the guiding device, a metal tube output through guiding is bent to a certain degree through the sizing and prebending mechanism, and then rewinding tube winding is carried out at the tube winding rotating shaft under controlling of the automatic tube-bank control mechanism, and after rewinding are carried out, unwinding is carried out through the unwinding mechanism. The metal-tube sectional material rewinder has the advantages that the metal-tube sectional material can be automatically rewound, and the whole device is simple in structure; a winding tube bank is controlled by the automatic tube-bank control system, real-time monitoring is carried out through a motor-running-state sensor, and the quality of a rewinding tube bank is guaranteed; as unwinding is carried out through a horizontal tube winding and unwinding mechanism, the working efficiency of winding is improved.

Owner:佛山市顺德区精艺万希铜业有限公司

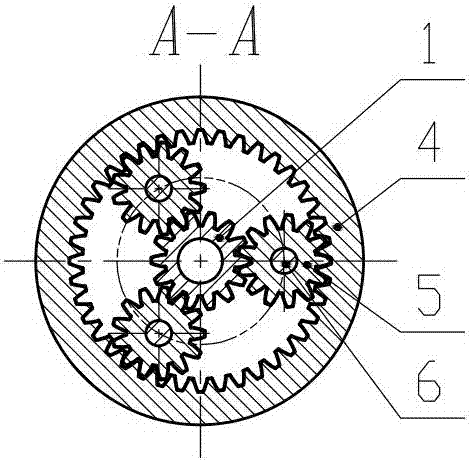

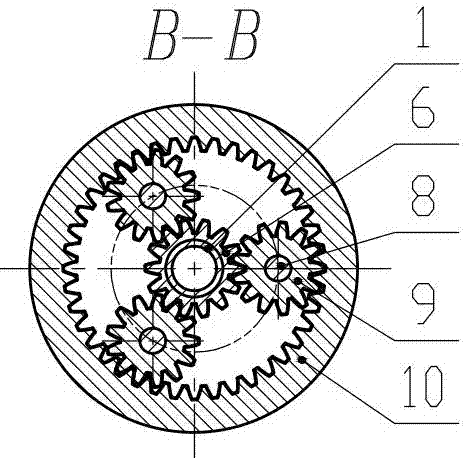

High-torque drilling tool for unconventional hyper-tight rock stratums

InactiveCN106968598AAvoid torsional deformationEnsure drilling safetyDrill bitsDirectional drillingGas industryTorsional deformation

The invention relates to a high-torque drilling tool for unconventional hyper-tight rock stratums. The high-torque drilling tool is suitable for the petroleum and natural gas industry and geological drilling operation, and solves the problems that drilling torque for the unconventional hyper-tight rock stratums is not high enough and reaction torque is difficult to overcome. According to the technical scheme, the upper end of a deceleration outer barrel is in screwed connection with an anti-falling end cap, and the lower end of the deceleration outer barrel is in screwed connection with the upper end of an output outer barrel; three primary planetary wheels are installed on three cylinders at the upper end of an output mandrel, three pins are installed in three counterbores in the stepped face of the middle of the outer circle of the output mandrel, and three secondary planetary wheels are installed on the three pins; and an upper radial bearing, a shaft sleeve and a lower radial bearing are sequentially sleeved with a stepped shaft at the outer circle of a mandrel drill bit; and the upper end of the mandrel drill bit is in screwed connection with the lower end of the output mandrel. The high-torque drilling tool provides a great torque and meets the requirement of extremely hard stratums for cutting torque; and the cutting direction of the mandrel drill bit is opposite to that of an outer barrel drill bit, cutting torques offset mutually, a drill stem is effectively protected against torsional deformation, and drilling safety is ensured.

Owner:SOUTHWEST PETROLEUM UNIV

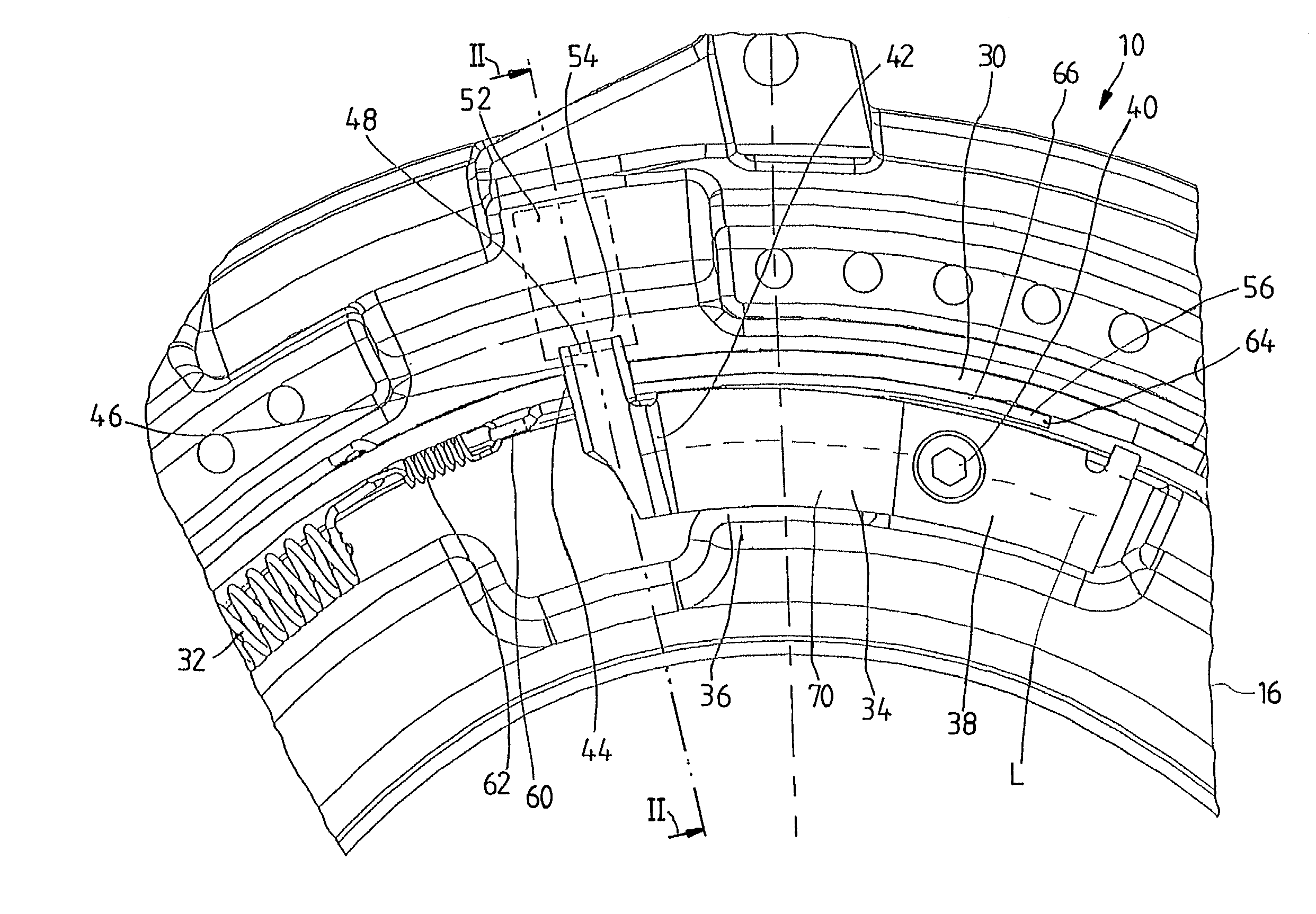

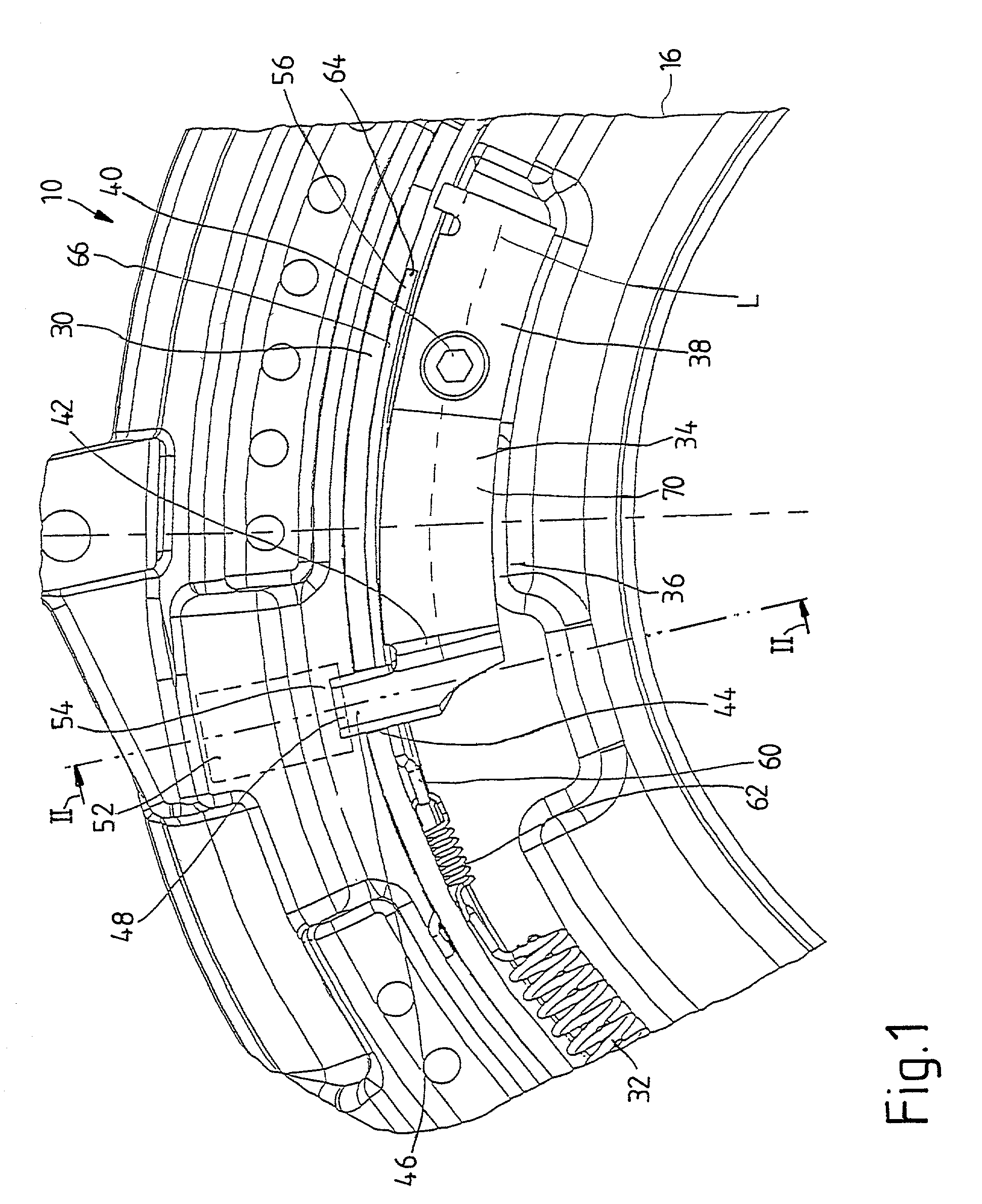

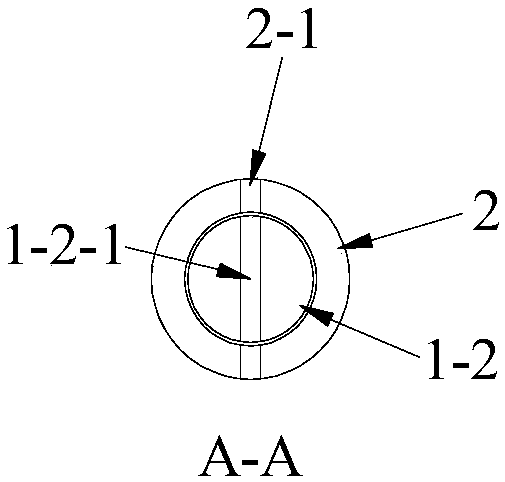

Pressure plate assembly

InactiveUS20020043439A1Avoid torsional deformationPrevent movementFriction clutchesRotational axisStored energy

A pressure plate assembly for a friction clutch includes a housing; a pressure plate held in the housing with freedom to move in the same direction as that in which a rotational axis (A) extends; a stored-energy element; and a wear-compensating device acting in the path of force transmission between the stored-energy element and the pressure plate and / or between the stored-energy element and the housing arrangement, where the wear-compensating device has at least one adjusting element able to move in an adjusting direction to compensate for wear. A clearance-producing arrangement includes at least one gripping element, where the minimum of one gripping element has a body section, one end of which is attached to the assembly consisting of the pressure plate and the housing, between which assembly and the stored-energy element the wear-compensating device acts. The other end of the body section is designed with a blocking section projecting laterally from the body section to act on the wear-compensating device and to interact with a blocking element, which is able to shift position relative to at least part of the gripping element when wear occurs. It is in the area of its body section that the minimum of one gripping element interacts with the blocking element.

Owner:ZF FRIEDRICHSHAFEN AG

Bamboo-shaped round bar energy-dissipating rod

ActiveCN106760855BAvoid torsional deformationReduce surface strainProtective buildings/sheltersShock proofingRound barEnergy consumption

The invention discloses a bamboo-shaped round rod energy consumption rod comprising a core part, an outer restraint part and a locating pin. The core part is composed by connecting a plurality of energy dissipation sections, intermediate limiting sections, bamboo sections and two-end connecting sections along the longitudinal coaxial axis. The intermediate limiting sections are located in the middle of the core part. The bamboo sections and the energy dissipation sections are distributed at intervals, arranged on the two sides of the intermediate limiting sections and form a whole together with the intermediate limiting sections, and the two ends of the outer sides of the bamboo sections and the energy dissipation sections are fixedly connected with the two-end connecting sections to form the core part. The cross sections of the intermediate limiting sections, the bamboo sections and the two-end connecting sections are all circular. First holes are formed in the middles of the intermediate limiting sections in the diameter direction. The energy dissipation sections are manufactured by cutting of round rods in the length direction, so that the cross sections of the energy dissipation sections are two parallel opposite sides, the other two short sides are original arc lines, under the effect of the axial tensile pressure, the energy dissipation sections of the core part enter yielding through the formed new cross section areas, while the intermediate limiting sections, the bamboo sections and the two-end connecting sections always remain elastic.

Owner:SOUTHEAST UNIV

Bamboo-shaped round rod energy consumption rod

ActiveCN106760855AAvoid torsional deformationReduce surface strainProtective buildings/sheltersShock proofingRound barEnergy consumption

The invention discloses a bamboo-shaped round rod energy consumption rod comprising a core part, an outer restraint part and a locating pin. The core part is composed by connecting a plurality of energy dissipation sections, intermediate limiting sections, bamboo sections and two-end connecting sections along the longitudinal coaxial axis. The intermediate limiting sections are located in the middle of the core part. The bamboo sections and the energy dissipation sections are distributed at intervals, arranged on the two sides of the intermediate limiting sections and form a whole together with the intermediate limiting sections, and the two ends of the outer sides of the bamboo sections and the energy dissipation sections are fixedly connected with the two-end connecting sections to form the core part. The cross sections of the intermediate limiting sections, the bamboo sections and the two-end connecting sections are all circular. First holes are formed in the middles of the intermediate limiting sections in the diameter direction. The energy dissipation sections are manufactured by cutting of round rods in the length direction, so that the cross sections of the energy dissipation sections are two parallel opposite sides, the other two short sides are original arc lines, under the effect of the axial tensile pressure, the energy dissipation sections of the core part enter yielding through the formed new cross section areas, while the intermediate limiting sections, the bamboo sections and the two-end connecting sections always remain elastic.

Owner:SOUTHEAST UNIV

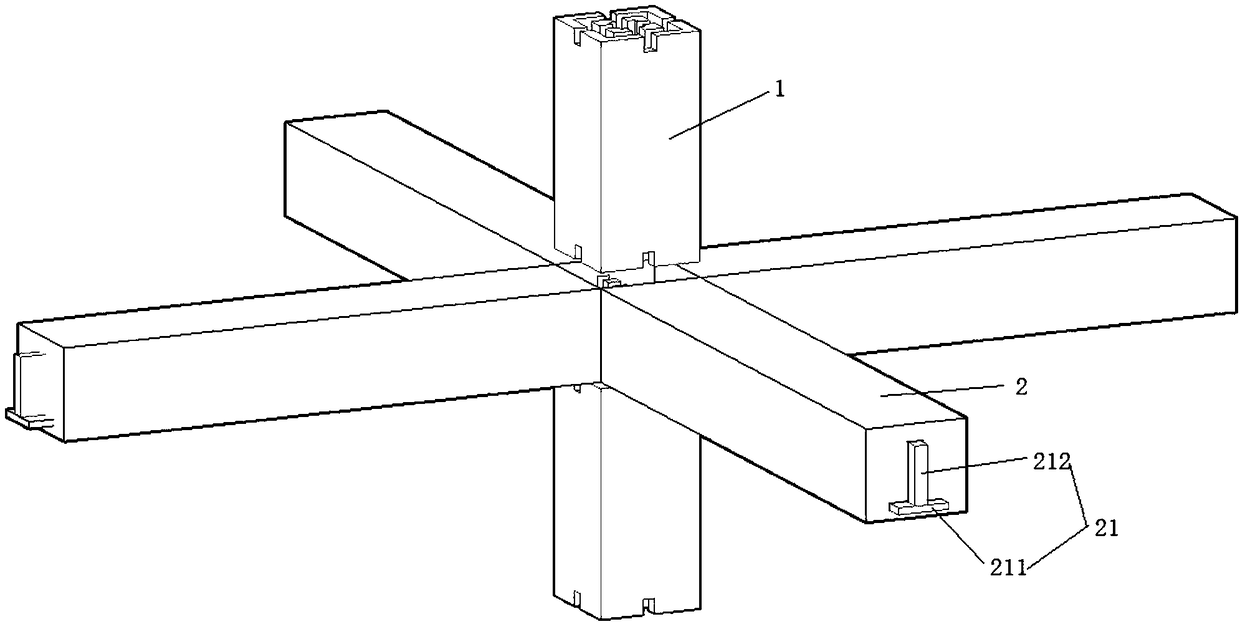

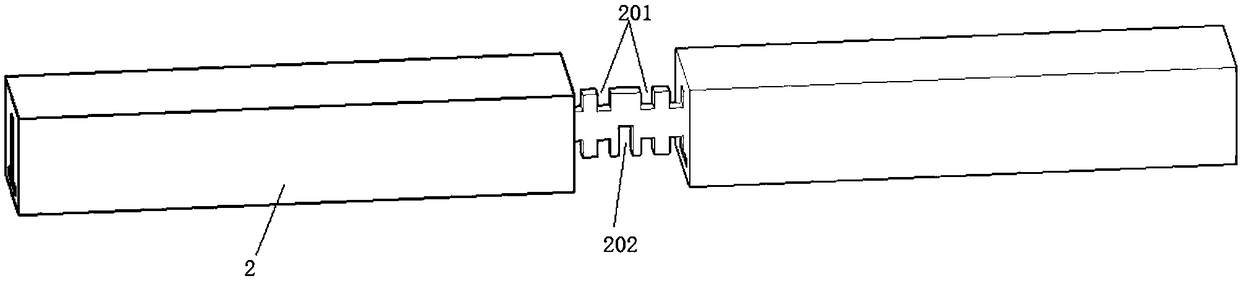

Joint tenon-mortise structure of square steel tube structures and steel reinforced concrete beams and method

InactiveCN108755936AEnsure stabilityImprove flexural strengthBuilding constructionsMortise and tenonReinforced concrete

The invention discloses a joint tenon-mortise structure of square steel tube structures and steel reinforced concrete beams and a method. The two steel reinforced concrete beams are connected in an upper-and-lower vertical butting mode through a butting groove to form a steel reinforced concrete beam connecting body. Two square steel tube structures are separately connected to the steel reinforcedconcrete beam connecting body in an upper-and-lower butting mode, and square steel grooves of the upper and lower steel tubes and profile steel grooves of the upper and lower sides of profile steel are correspondingly arranged in a butting mode to form the joint tenon-mortise structure. Through ingenious lapping joint of the joint tenon-mortise structure, the connection between the steel reinforced concrete structural beams and square steel tube concrete columns is realized, the bending resistance and torsional strength of a joint connecting member are improved, and the joint connecting member is prevented from bending and torsional deformation. Meanwhile, rectangular mold cavities of the upper and lower square steel tube structures communicate with each other to form an integrated rectangular mold cavity, concrete is poured into the integrated rectangular mold cavity to form a square steel tube confined concrete column which is used for wrapping the joint tenon-mortise structure in the concrete, a concrete column joint with high bending resistance and high torsional strength is formed, and the stability of the joint tenon-mortise structure is ensured.

Owner:YANGTZE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com