Vertical vibration isolation device

A vibration damping device, vertical technology, applied to building components, high internal friction springs, shockproof, etc., can solve the problems of small vertical stiffness, harsh working environment, easy resonance and high-frequency vibration transmission, etc., to avoid torsion Deformation, broad application prospects, and the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

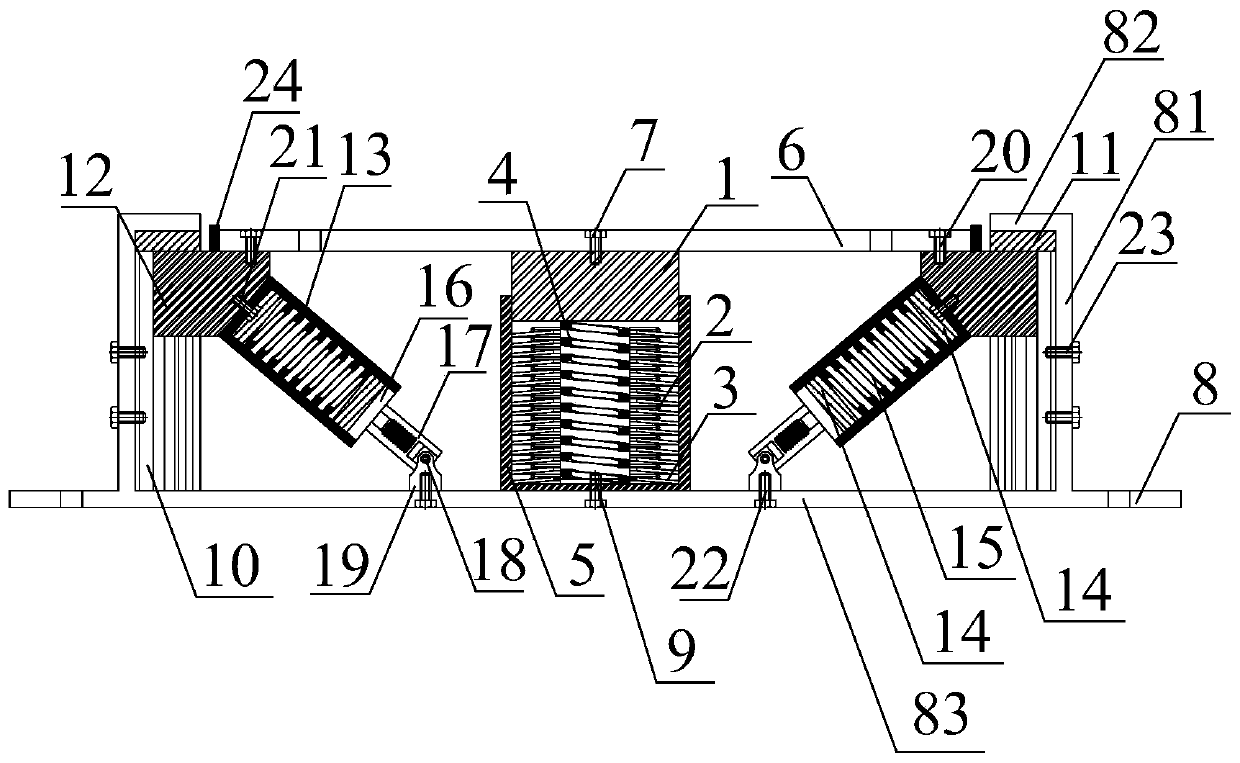

[0052] Embodiment 1: see figure 1 and figure 2

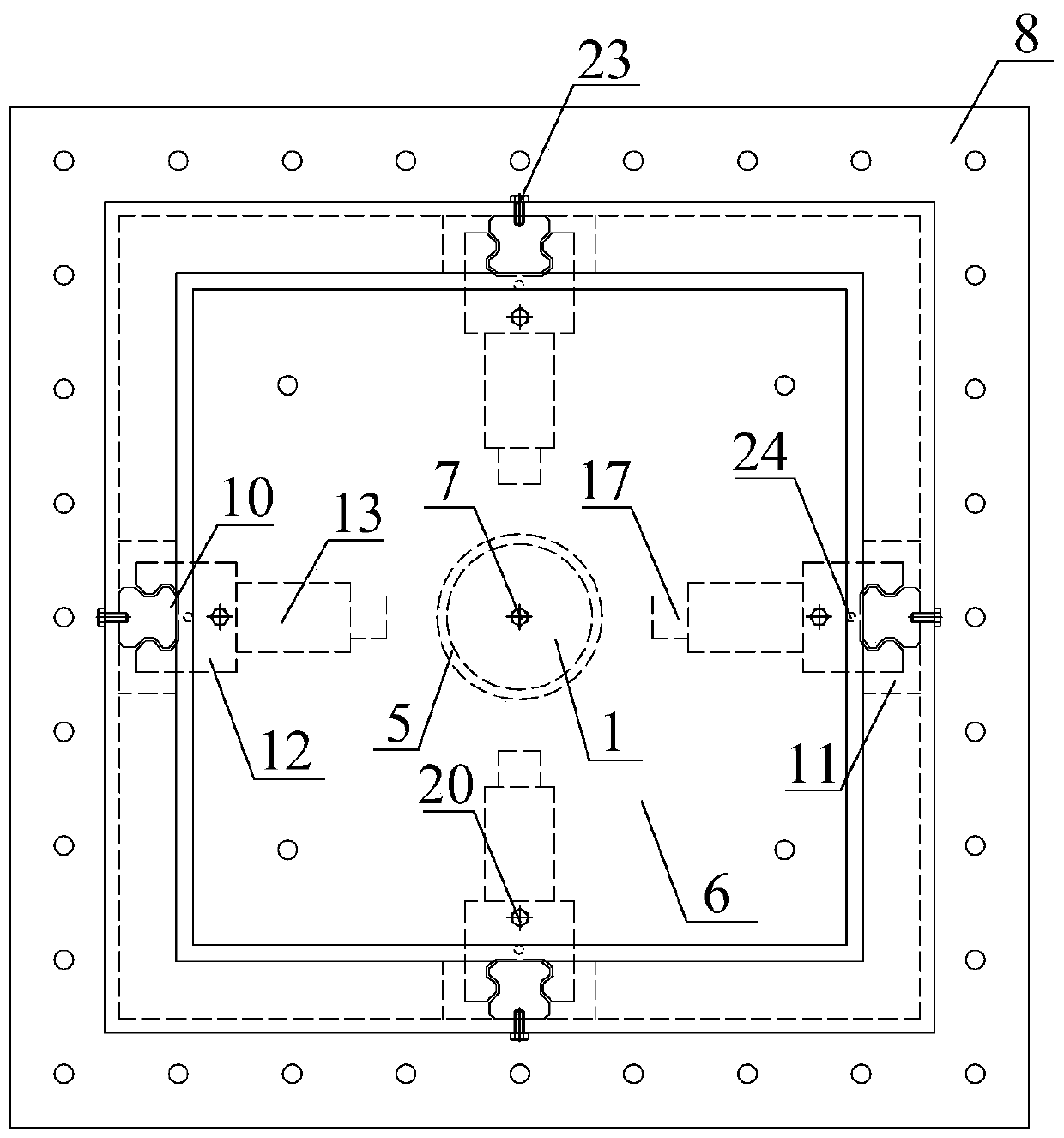

[0053] see image 3 , as an example, this embodiment is provided with 4 sets of damping devices. Under the action of vertical vibration, the 4 sets of damping devices are linked together to reduce the vertical vibration. The 4 sets of devices are placed symmetrically to prevent the structure or equipment Unsteady.

[0054] Figure 4 It is a schematic diagram of the construction of an adaptive stiffness element, and a schematic diagram of the construction of a disc spring group, see Figure 5 , see the three-dimensional view of the preloaded rectangular spring Figure 6 . The positioning loading ring 2 and the disc spring 3 work in parallel to provide vertical negative stiffness, the pre-compressed rectangular spring 4 is in contact with the actuating block 1, and the disc spring group and the actuating block 1 reserve a gap of 5-8mm to ensure the pre-compressed rectangular The larger positive stiffness provided by the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com