Patents

Literature

37results about How to "Efficient energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

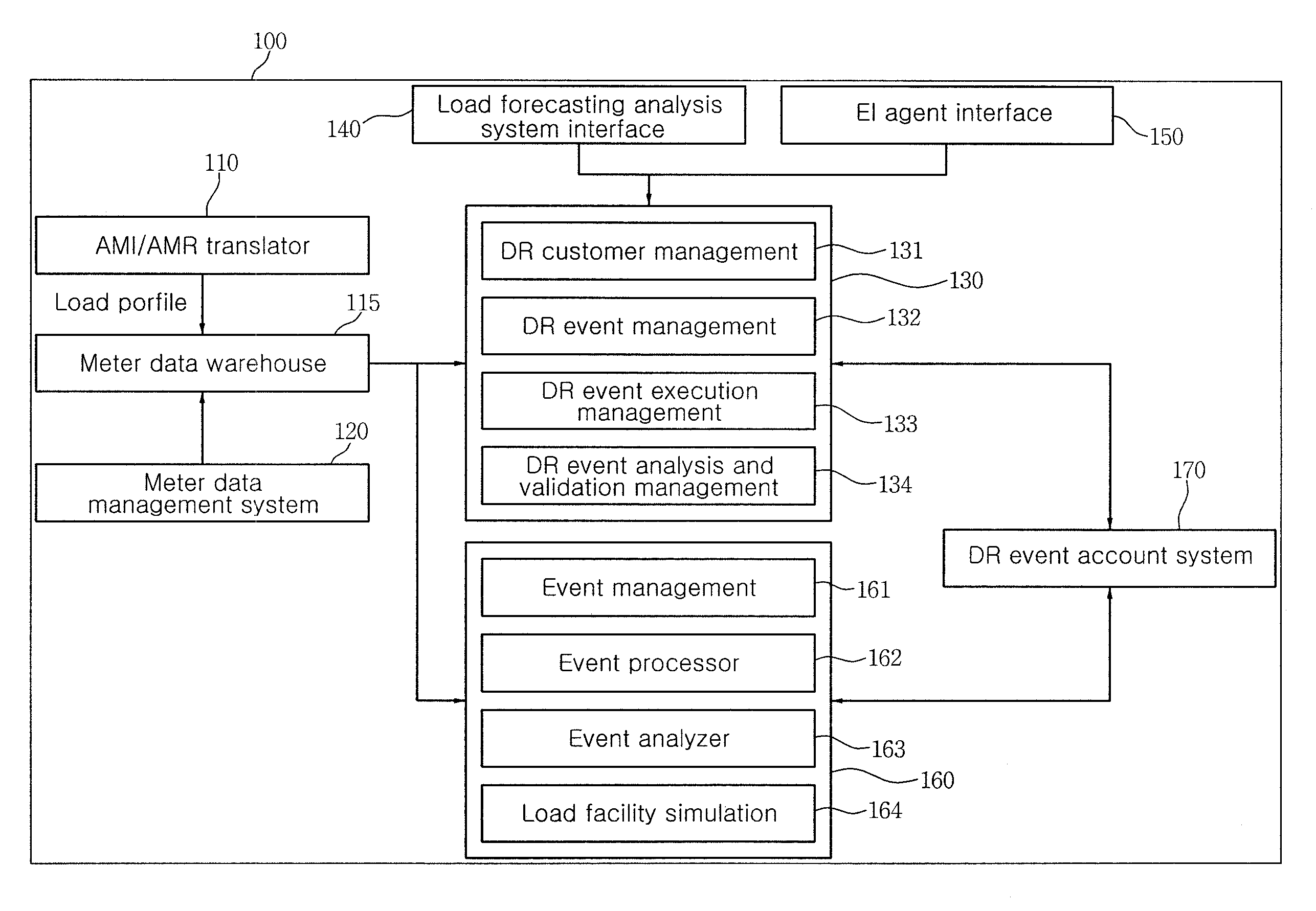

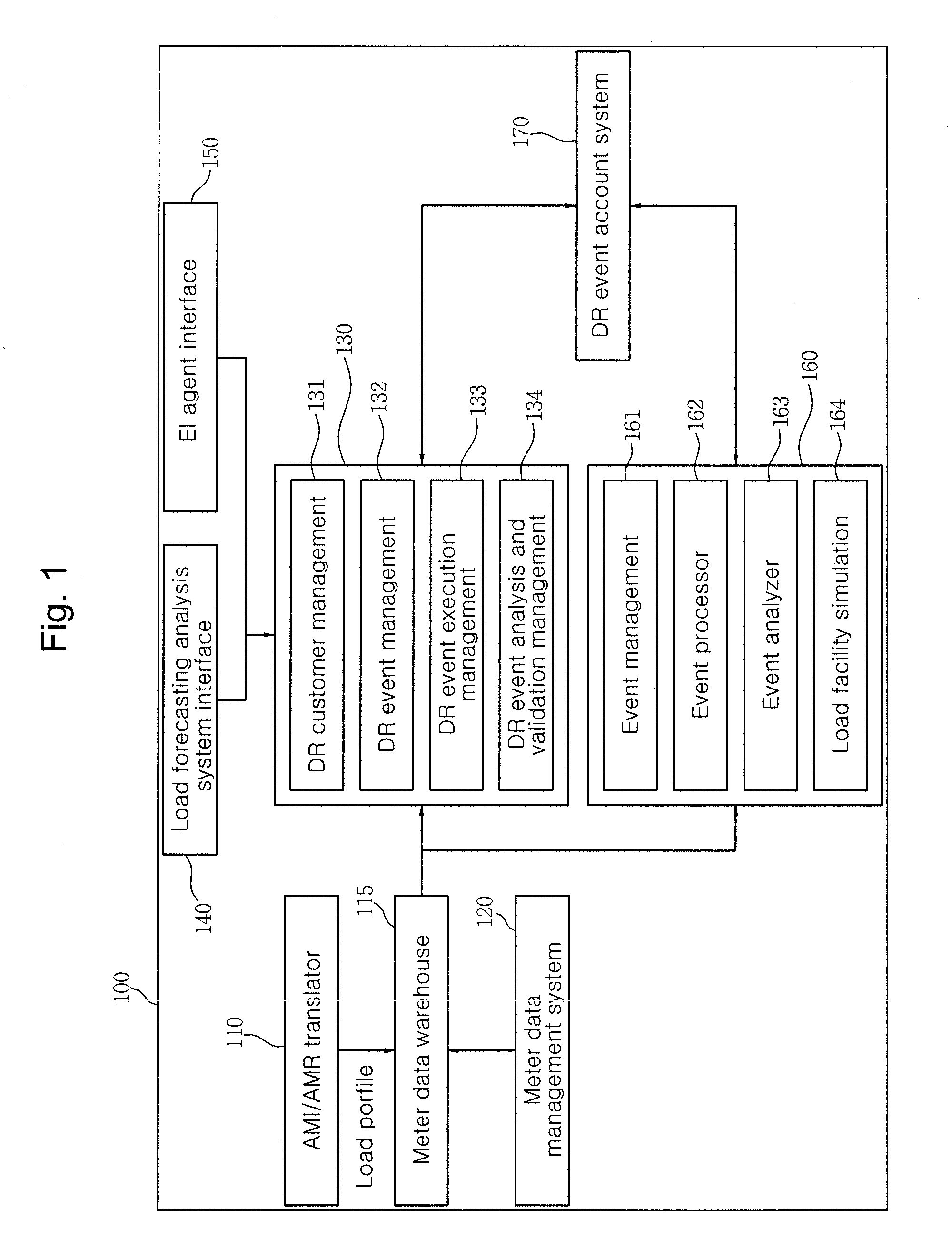

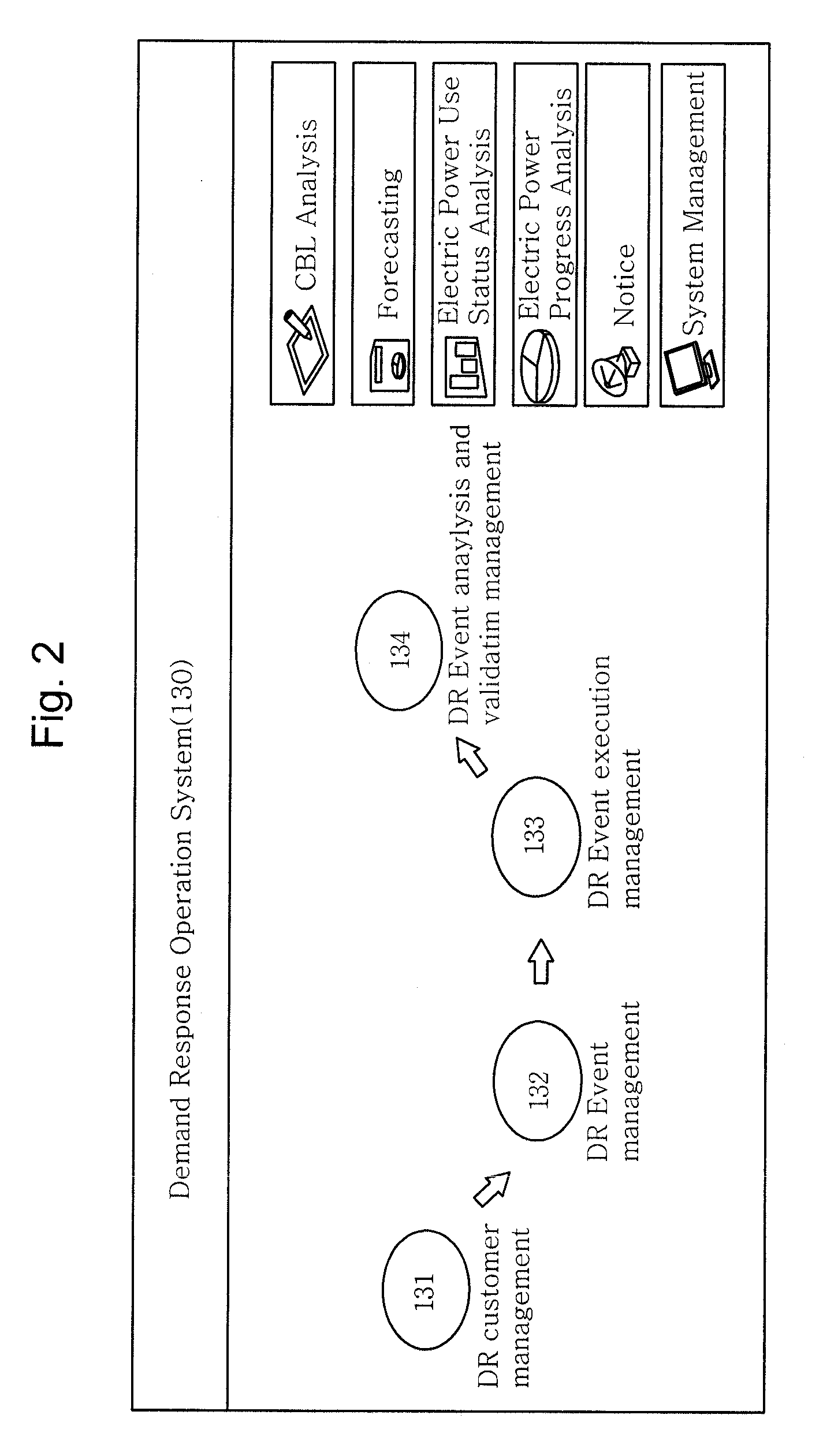

Day-ahead load reduction system based on customer baseline load

InactiveUS20100106342A1Efficient energy consumptionAddress rising pricesLevel controlLoad forecast in ac networkOperational systemData warehouse

Provided is a day-ahead load reduction system based on a customer baseline load for inducing a user to efficiently manage energy consumption by applying an incentive (user compensation according to load reduction) to achieve load reduction and load decentralization. The day-ahead load reduction system based on a customer baseline load operates in connection with a provider terminal and a user terminal through a network to induce a reduction in the load of a user and includes an AMI / AMR translator collecting load profile data of the user in real time, converting the load profile data and storing the load profile data in a meter data warehouse; a meter data management system monitoring and analyzing the load profile data stored in the meter data warehouse in real time; a demand response operation system managing the demand of the user by using the load profile data and performing overall management, analysis and verification of a day-ahead load reduction event; a customer energy management system operating in connection with the demand response operation system and providing information on the load to the user through the user terminal in real time to allow the user to control the load; and an account system operating in connection with the demand response operation system and the customer energy management system, calculating an incentive for the day-ahead load reduction event and notifying a provider and the user of the incentive through the provider terminal and the user terminal.

Owner:KOREA ELECTRIC POWER CORP

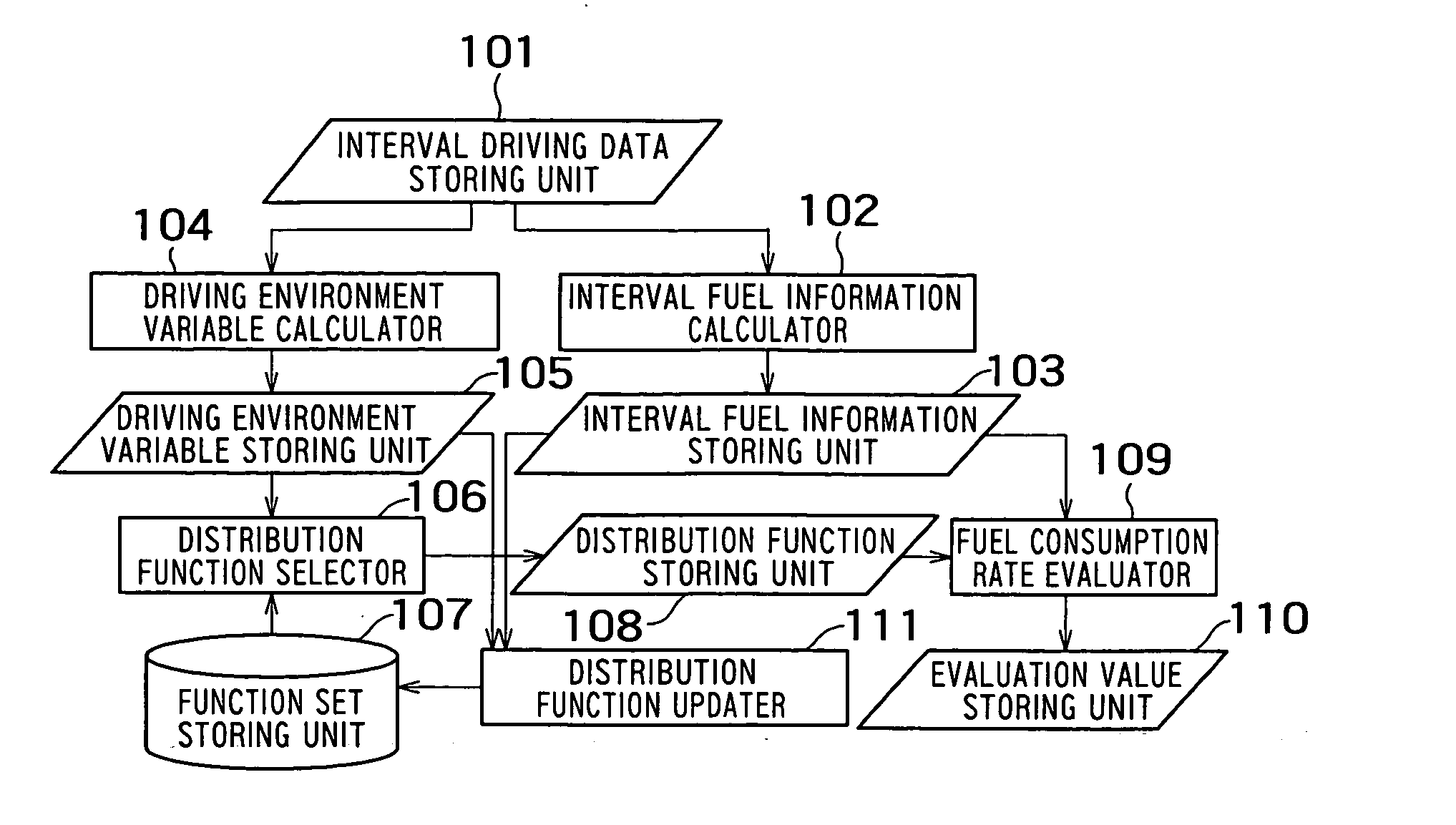

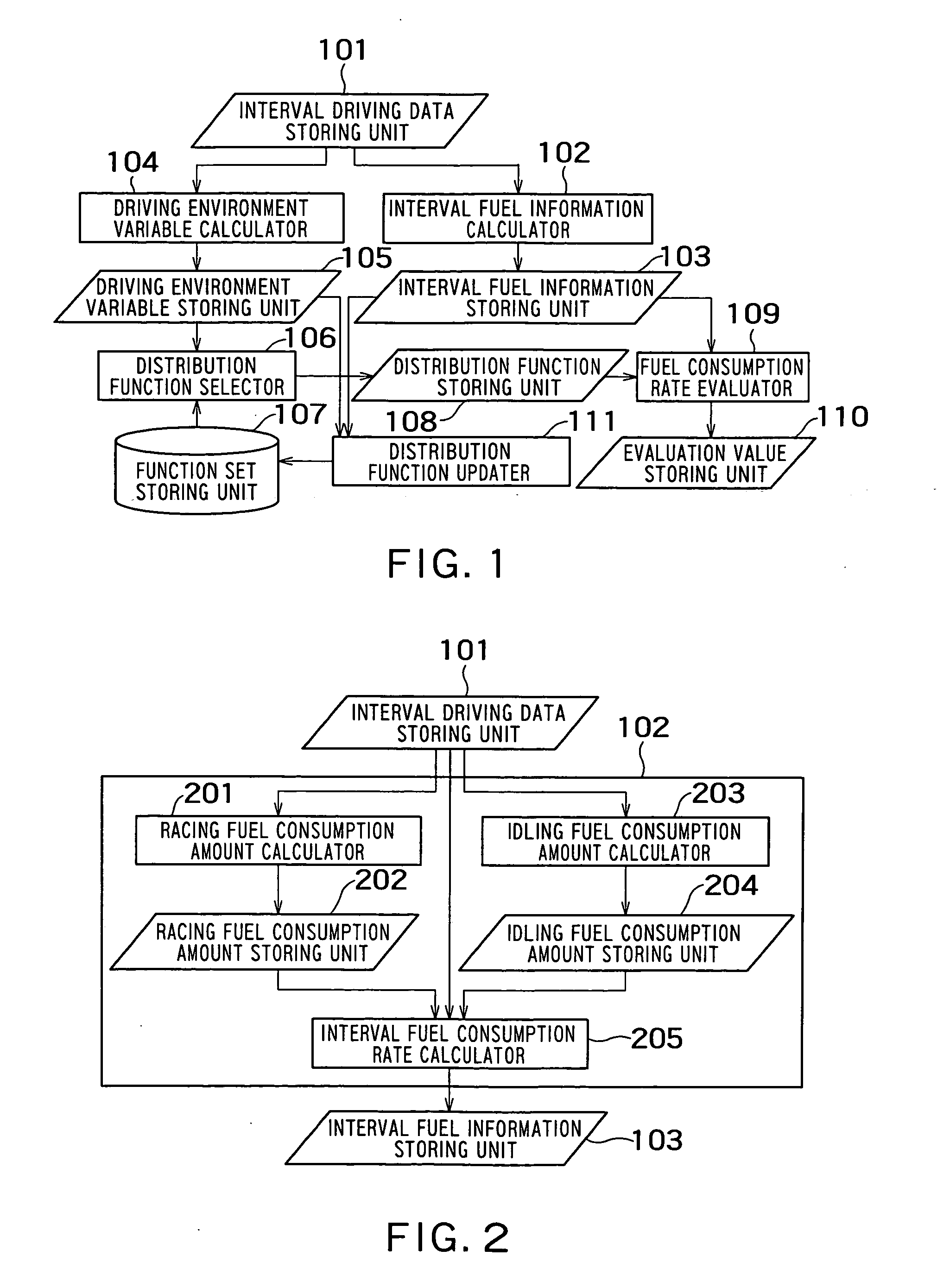

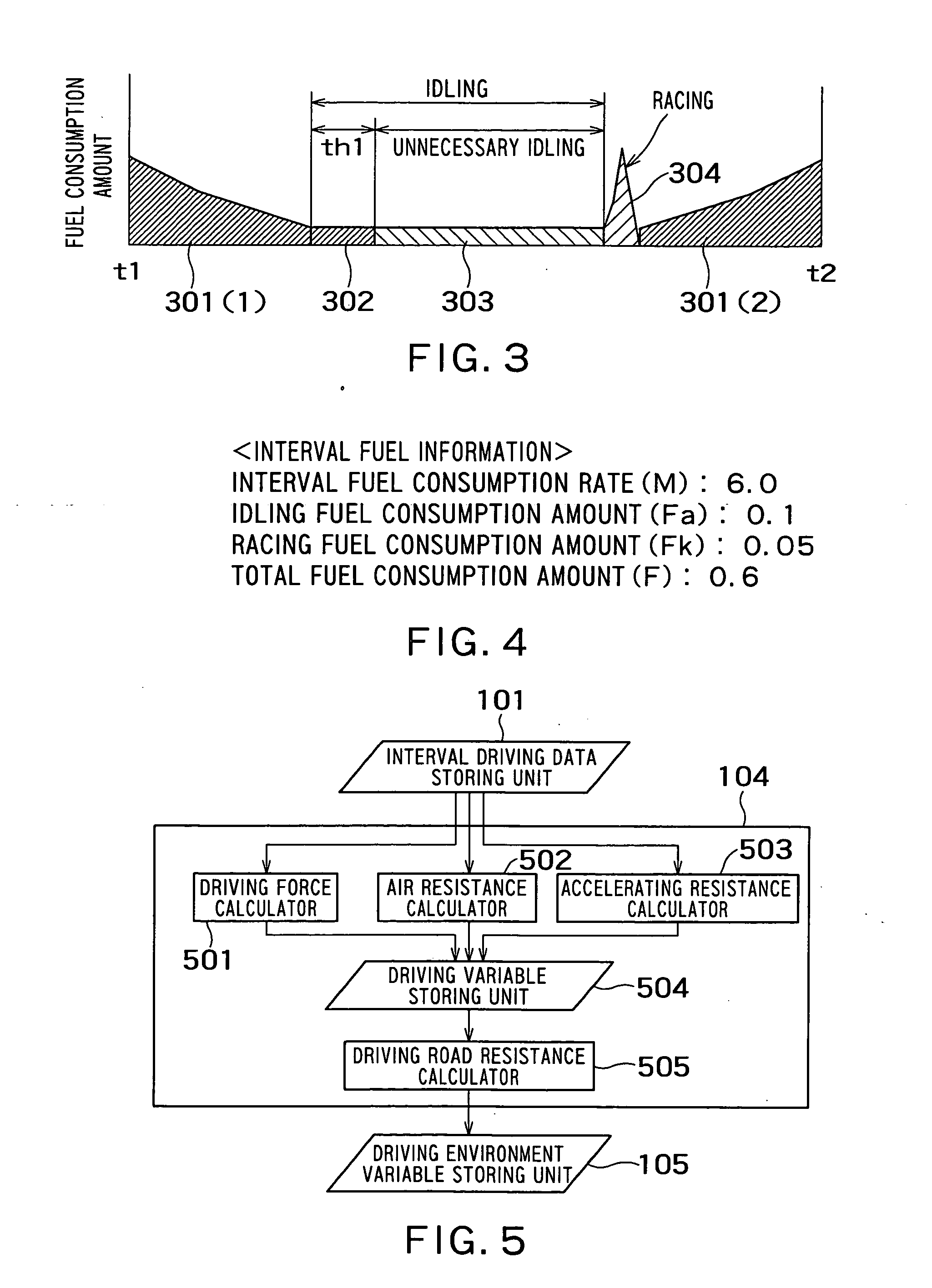

Driving evaluation apparatus, driving evaluation program, and driving evaluation method

InactiveUS20050288850A1Efficient energy consumptionHybrid vehiclesAnalogue computers for vehiclesAssessment methodsAutomotive engineering

There are provided a driving evaluation method for evaluating a fuel consumption rate of driving a vehicle in certain driving interval on the basis of driving data acquired at time of driving in the driving interval, including: calculating an energy consumption efficiency in the driving interval; calculating a driving environment variable indicative of an environment factor which exerts an influence on energy consumption by driving in the driving interval; selecting a probability density function or a cumulative distribution function corresponding to the calculated driving environment variable from a plurality of probability density functions or cumulative distribution functions having the energy consumption efficiency as a probability variable; and calculating an evaluation value for evaluating a fuel consumption rate of driving in the driving interval by using the selected probability density function or the selected cumulative distribution function and the calculated energy consumption efficiency.

Owner:KK TOSHIBA

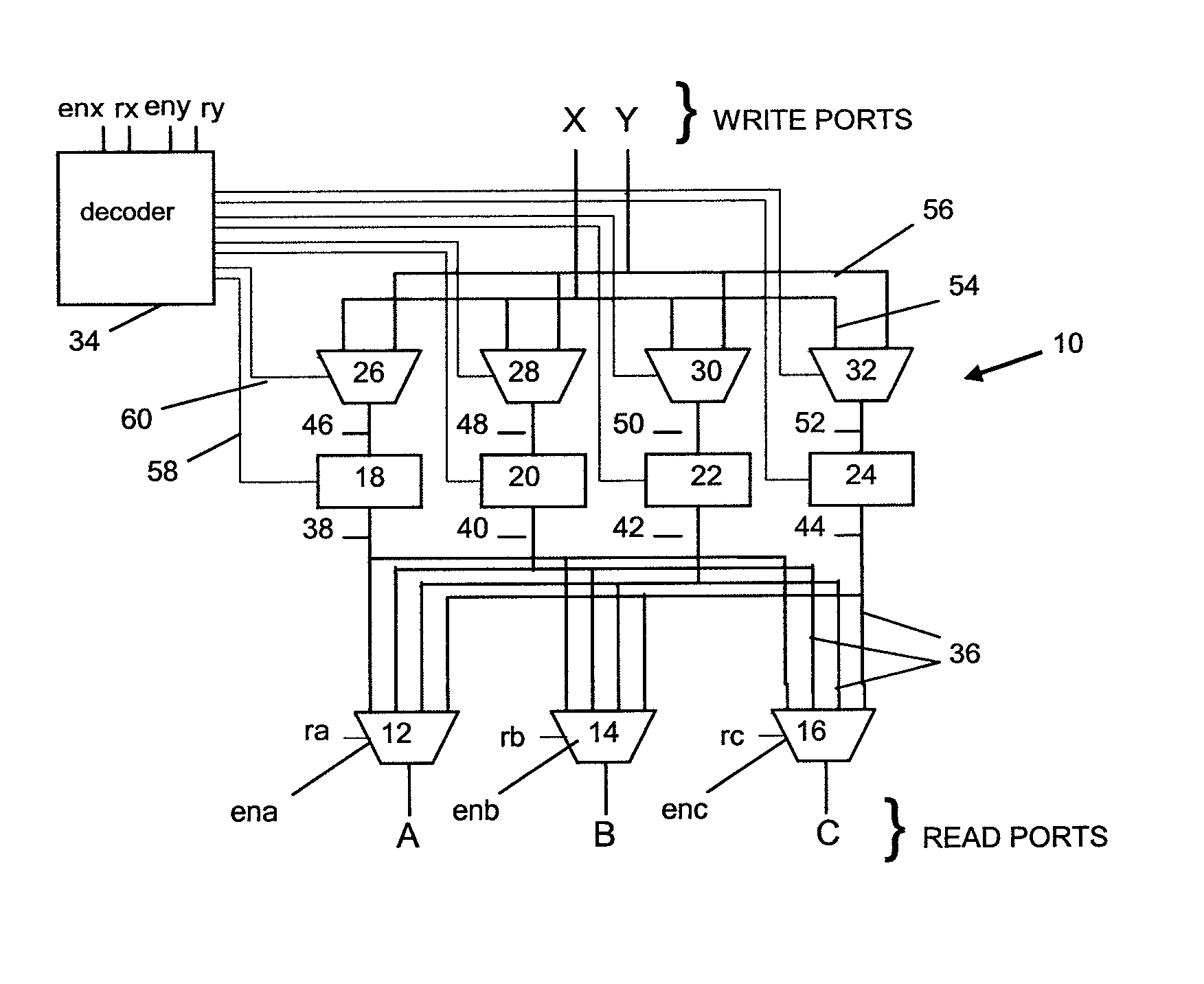

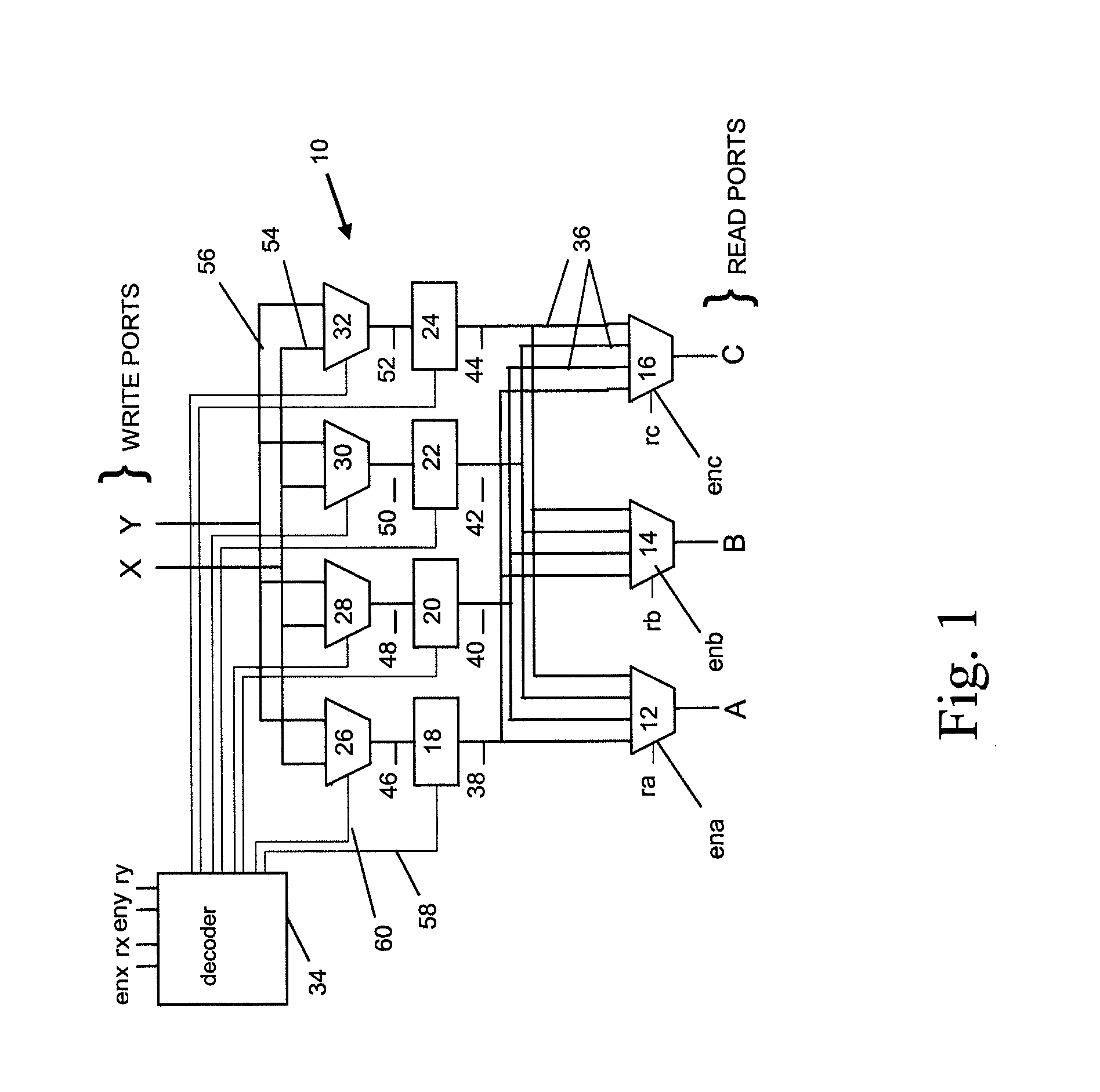

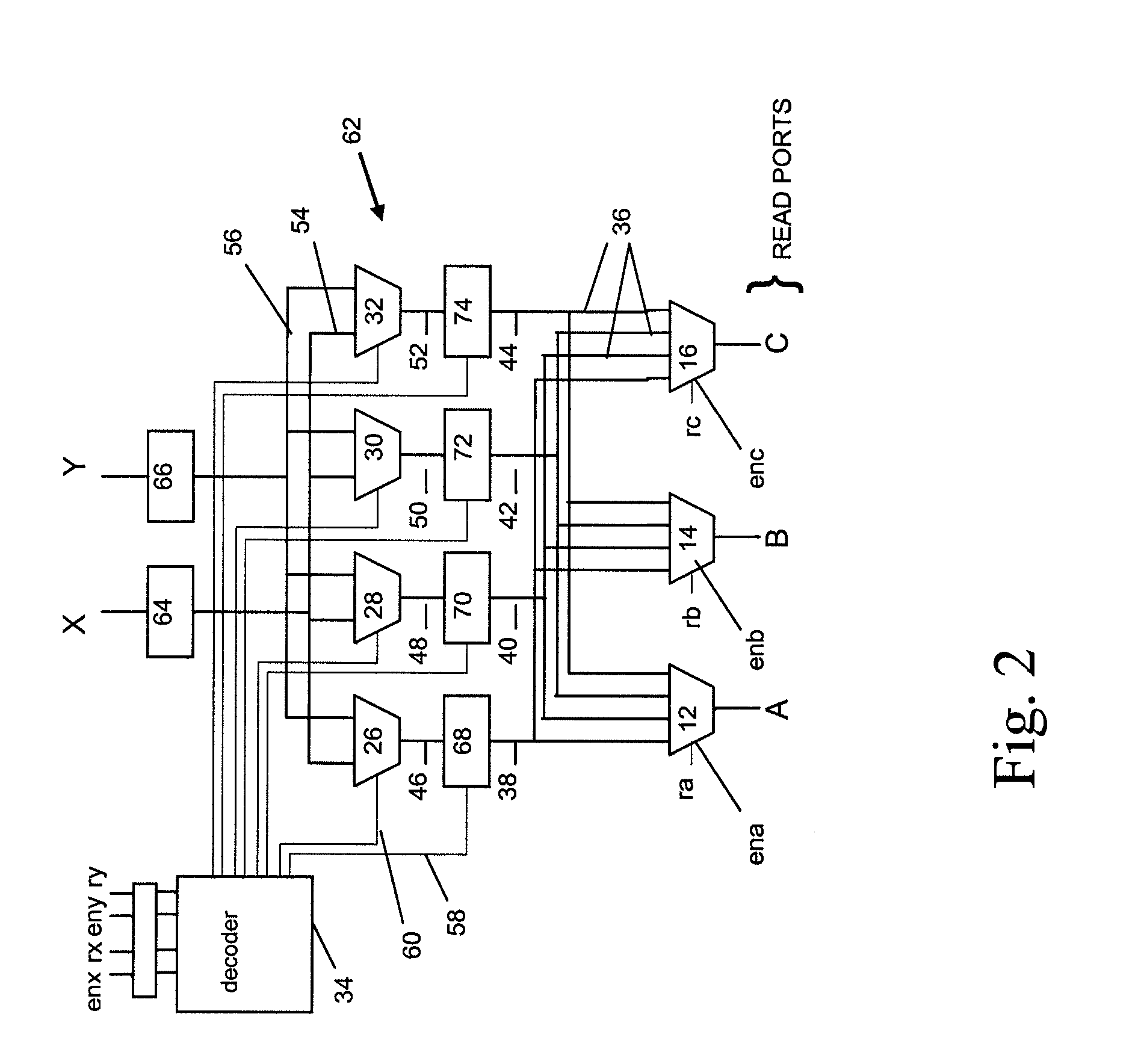

Latch-based implementation of a register file for a multi-threaded processor

InactiveUS20110241744A1Efficient energy consumptionRegister arrangementsElectric pulse generatorRegister fileProcessor register

A processor register file for a multi-threaded processor is described. The processore register file includes, in one embodiment, T threads, having N b-bit wide registers. Each of the registers includes a b-bit master latch, T b-bit slave latches connected to the master latch, and a slave latch write enable connected to the slave latches. The master latch is not opened at the same time as the slave latches. In addition, only one of the slave latches is enabled at any given time. As should be apparent to those skilled in the art, T, N, and b are all integers. Other embodiments and variations are also provided.

Owner:QUALCOMM INC

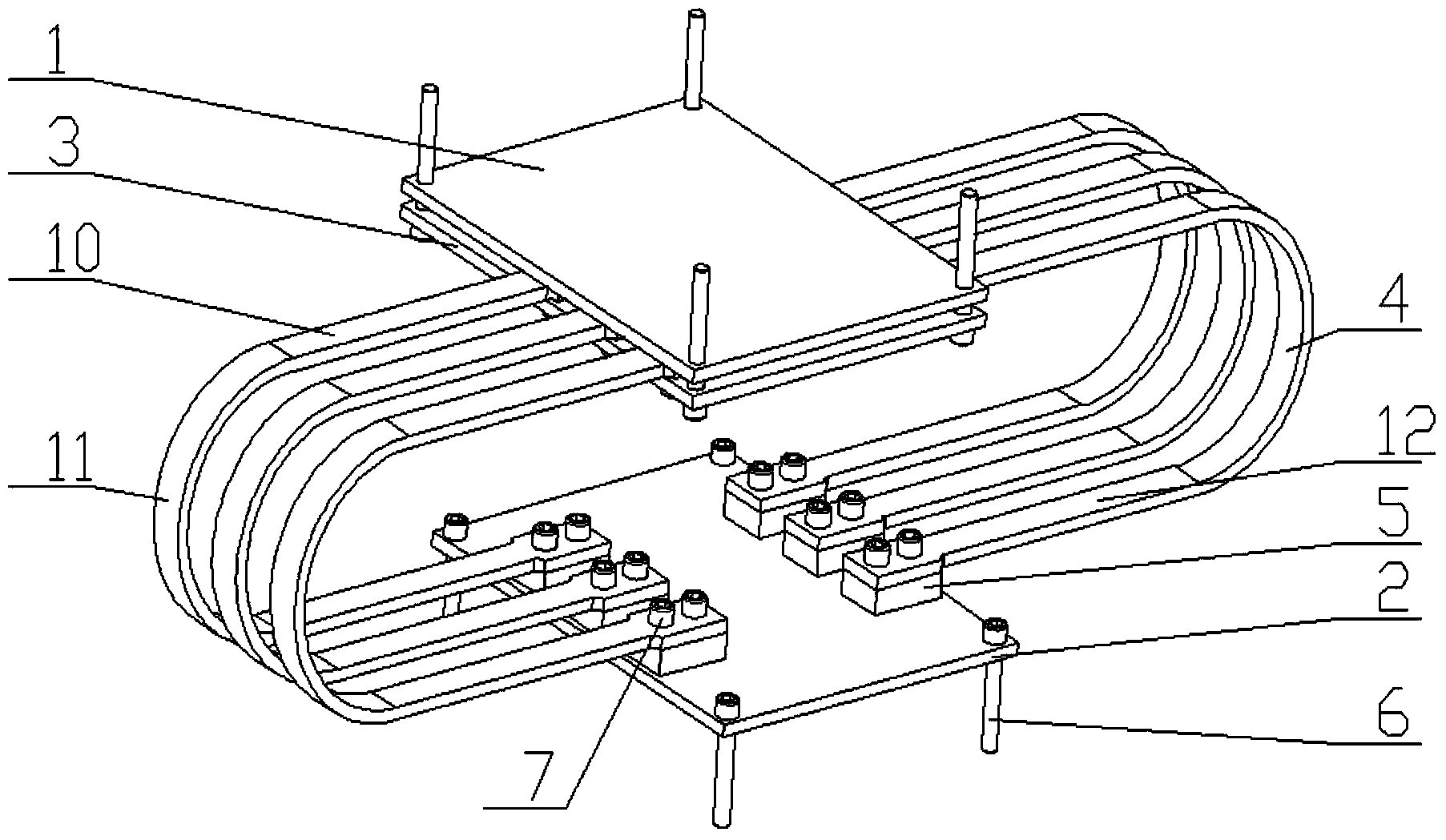

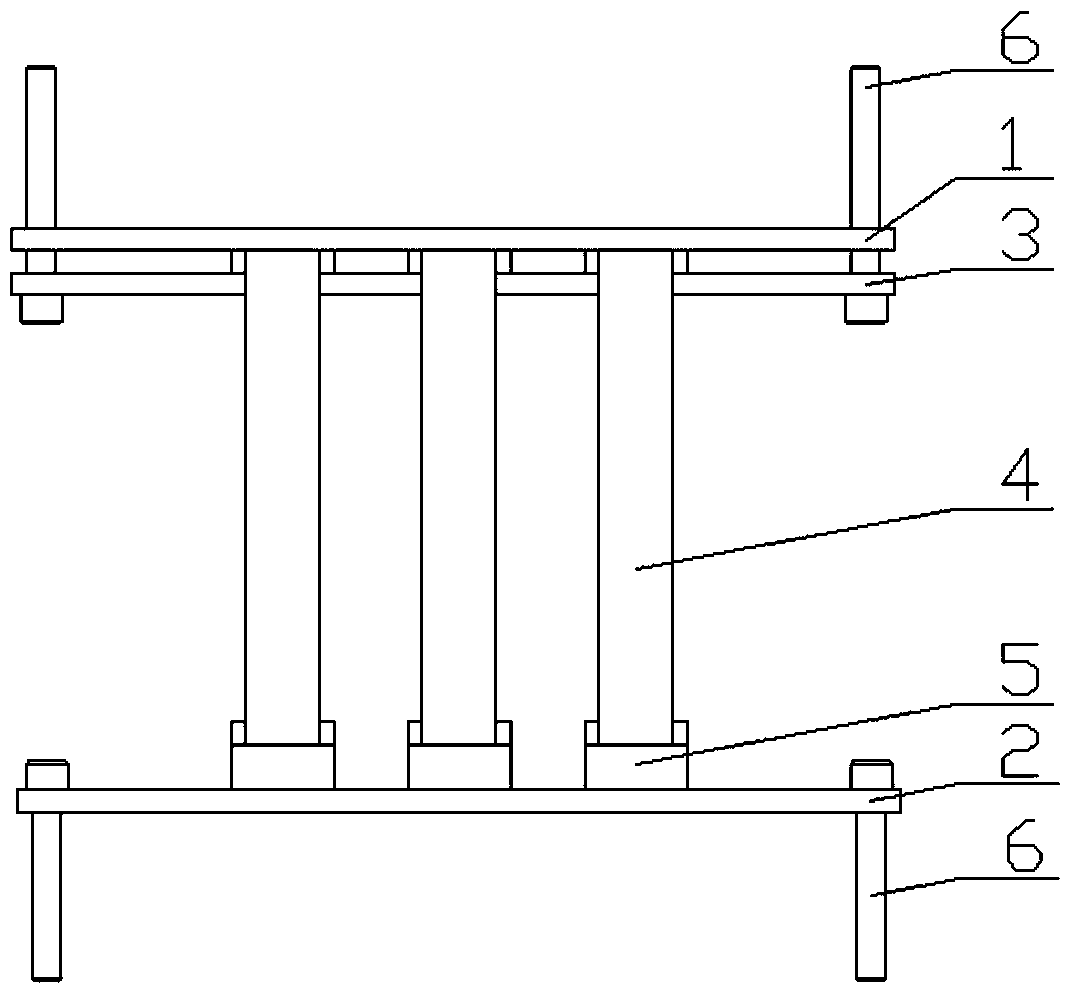

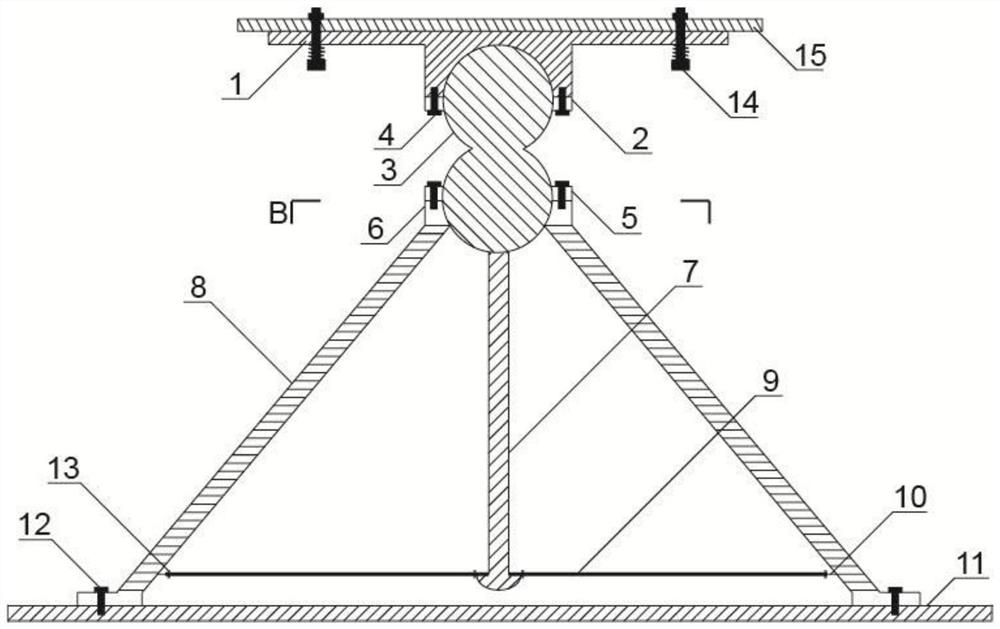

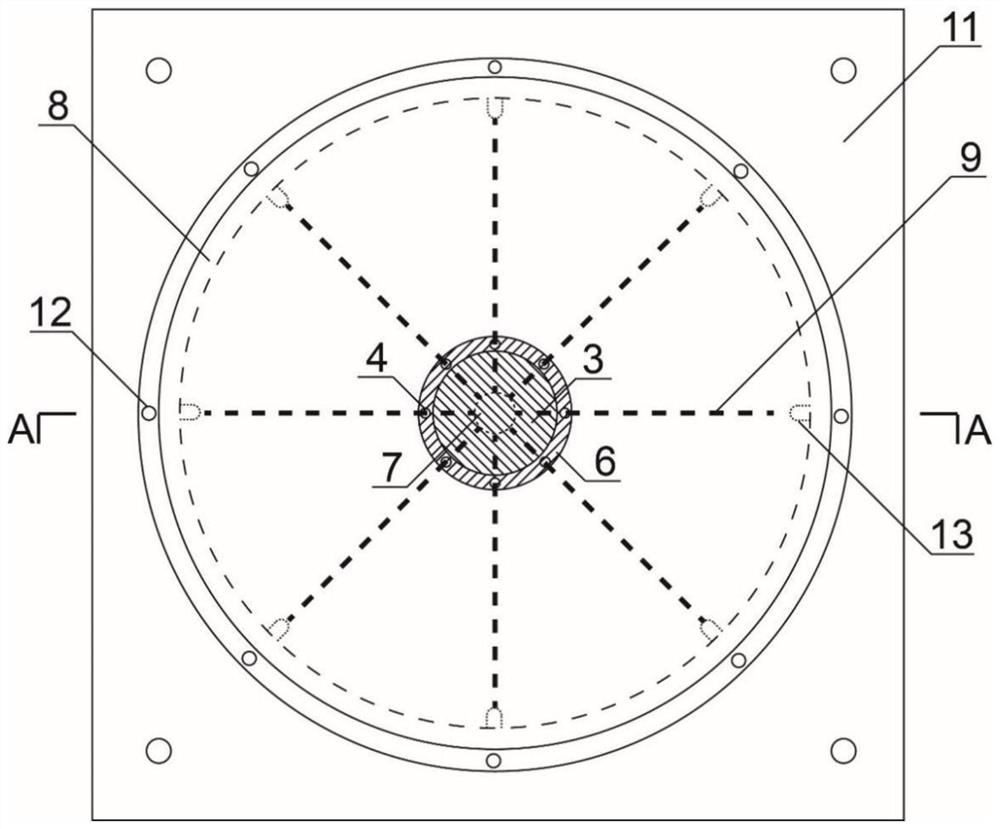

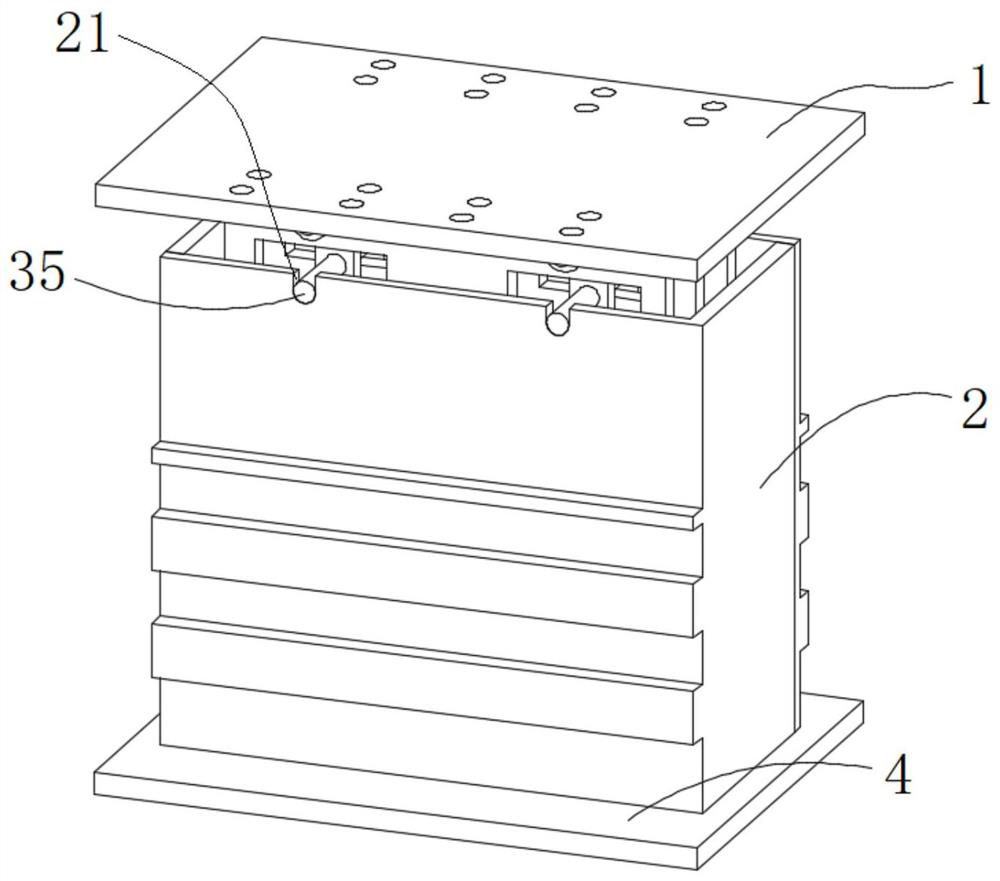

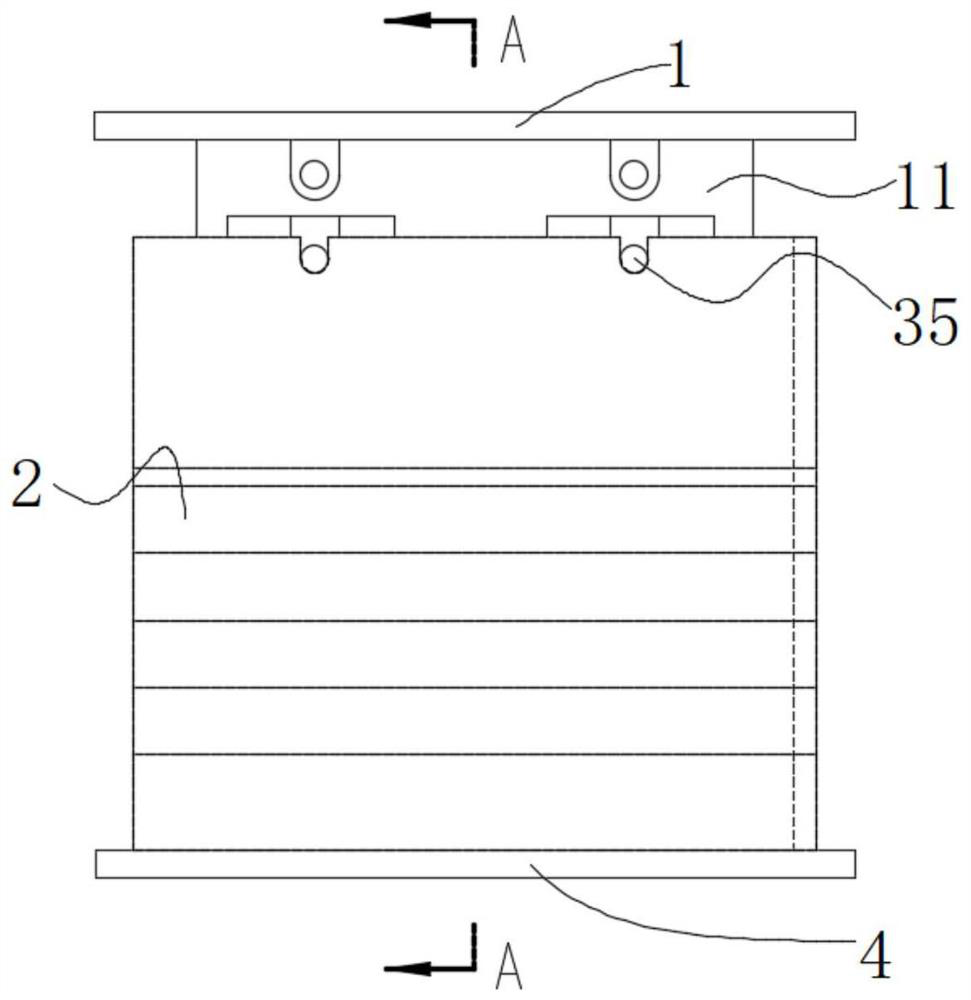

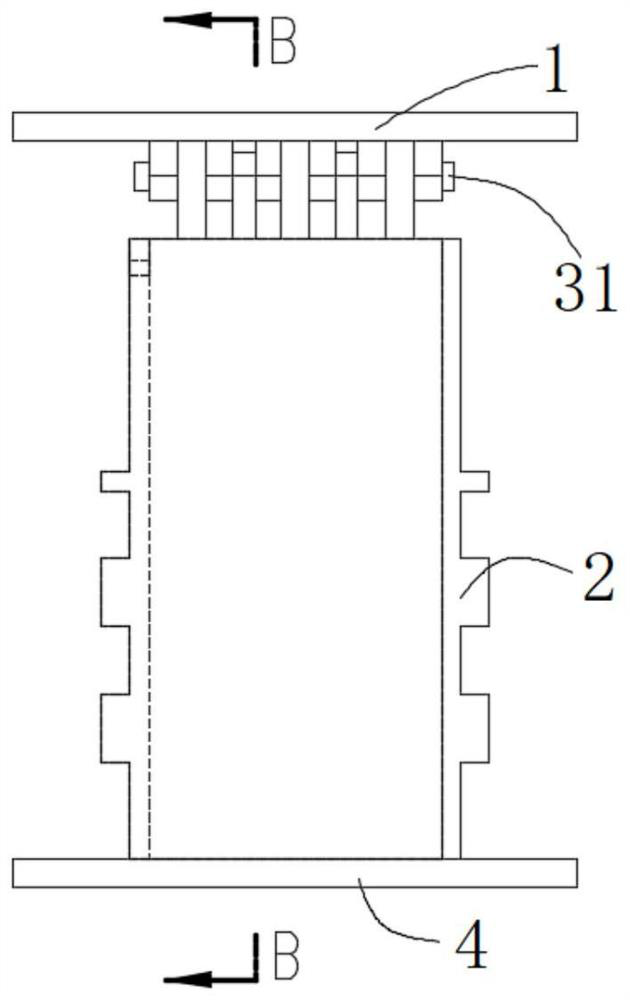

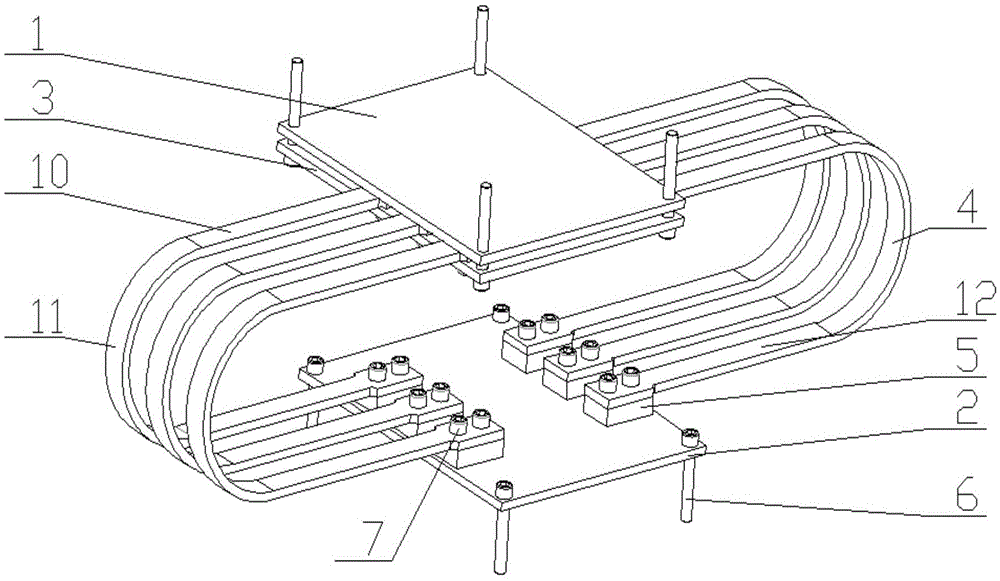

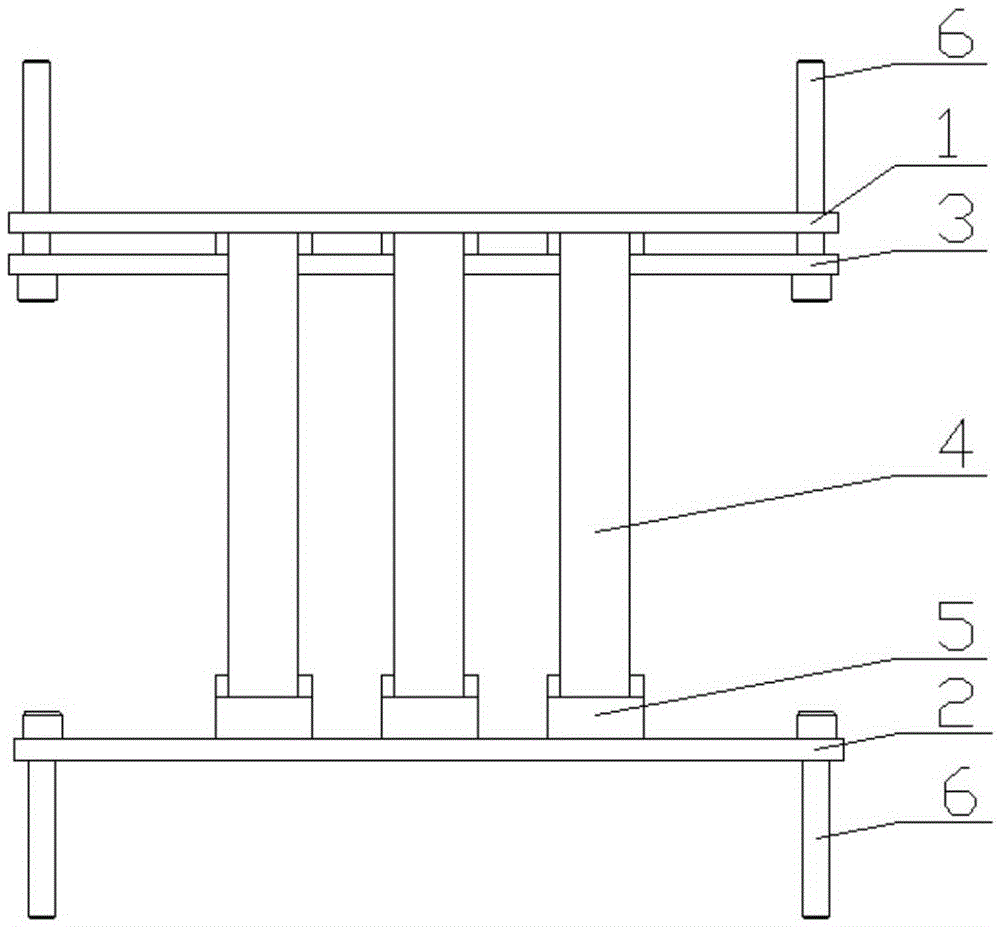

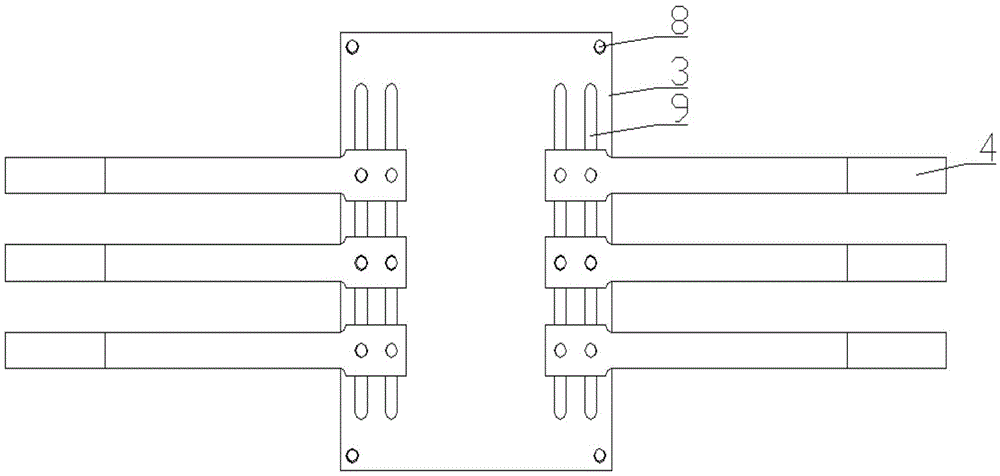

Transverse damping device applicable to large-span bridge

ActiveCN104313998AStrong designabilityMeet serialization needsBridge structural detailsBridge materialsEngineeringTower

The invention discloses a transverse damping device applicable to a large-span bridge. The damping device comprises an upper top plate, a lower bottom plate, an upper connecting plate, a U-shaped steel plate, a cushion block, an anchor bolt, a high-strength bolt, bolt holes and a slotting hole, wherein the bolt holes are reserved in the upper top plate and the lower bottom plate, and the upper top plate and the lower bottom plate are respectively and firmly connected with a bridge girder and a bridge tower; the U-shaped steel plate is an energy-consumption element, and is arranged between the upper top plate and the lower bottom plate; the upper connecting plate is reserved with the bolt holes and is fixed below the upper top plate through the anchor bolt; a straight section on the upper part of the U-shaped steel plate is arranged between the upper top plate and the upper connecting plate and is not in contact with the upper top plate; a straight section on the upper part of the U-shaped steel plate is reserved with the bolt hole, the slotting hole is reserved in the upper connecting plate, and the straight section at the upper part of the U-shaped steel plate is connected with the upper connecting plate through the high-strength bolt capable of freely sliding in the slotting hole. According to the damping device provided by the invention, the instant impact force generated in the process of converting the transverse structural system of the large-span bridge can be resisted, and the anti-seismic property of the large-span bridge can be improved.

Owner:NANJING UNIV OF TECH

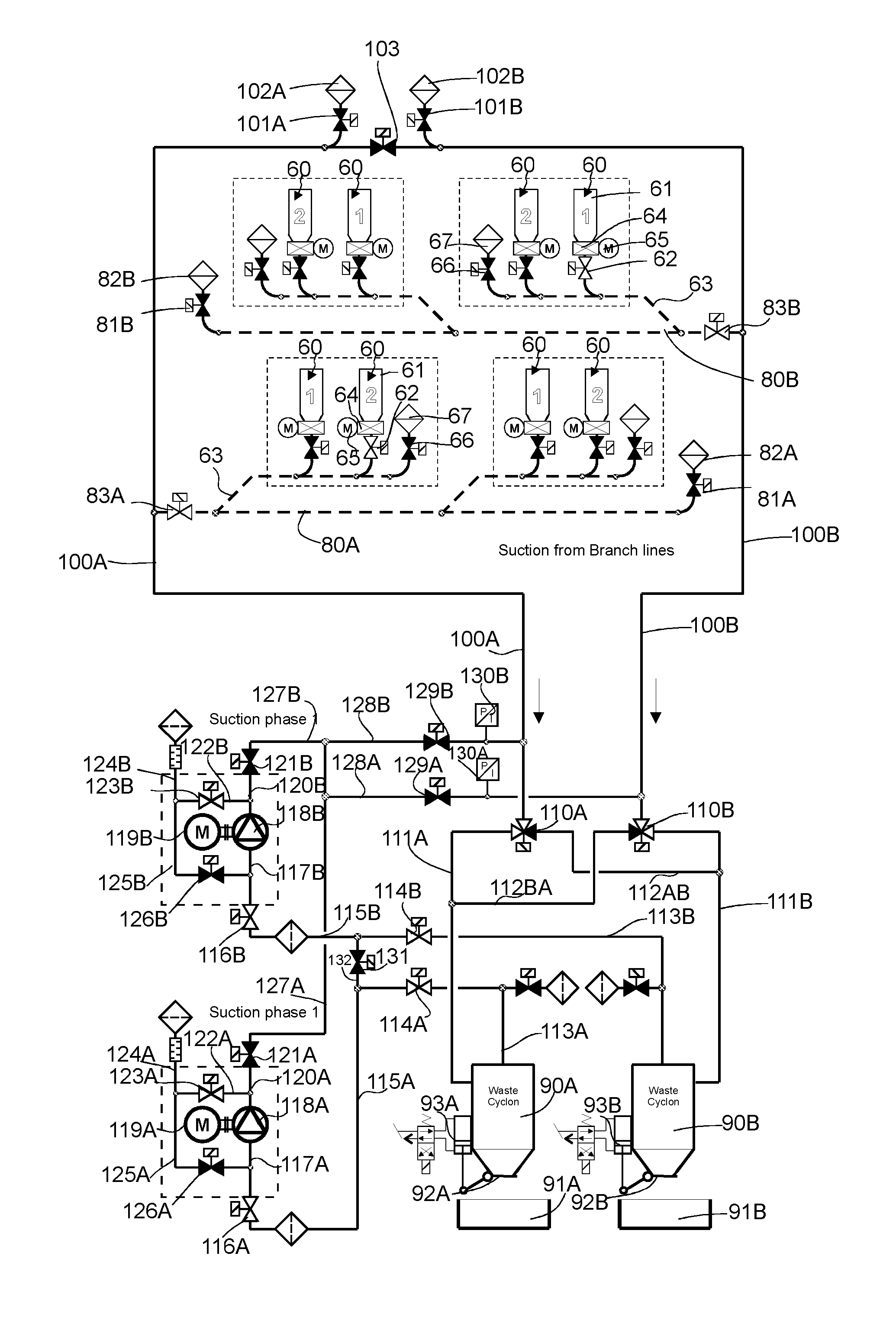

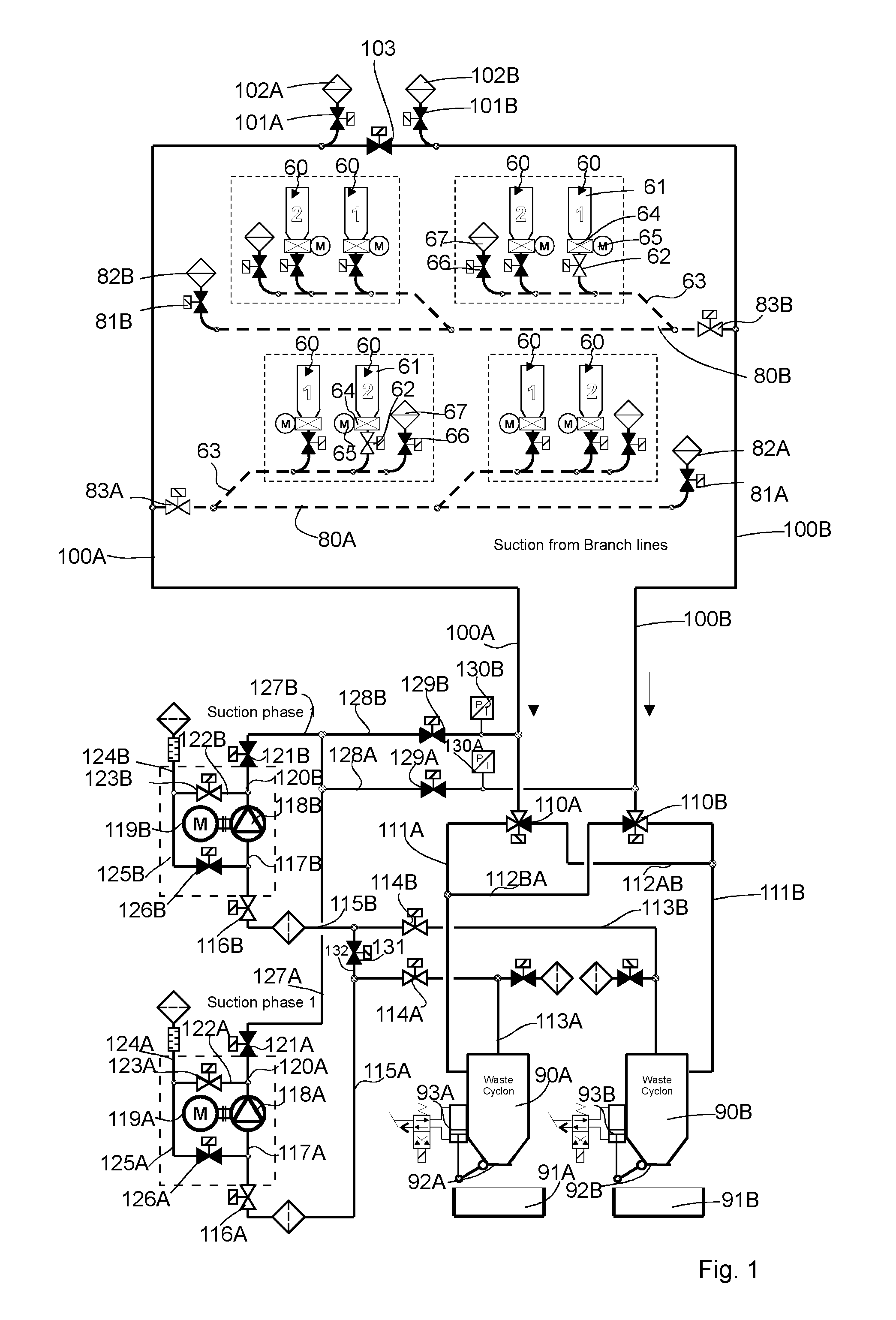

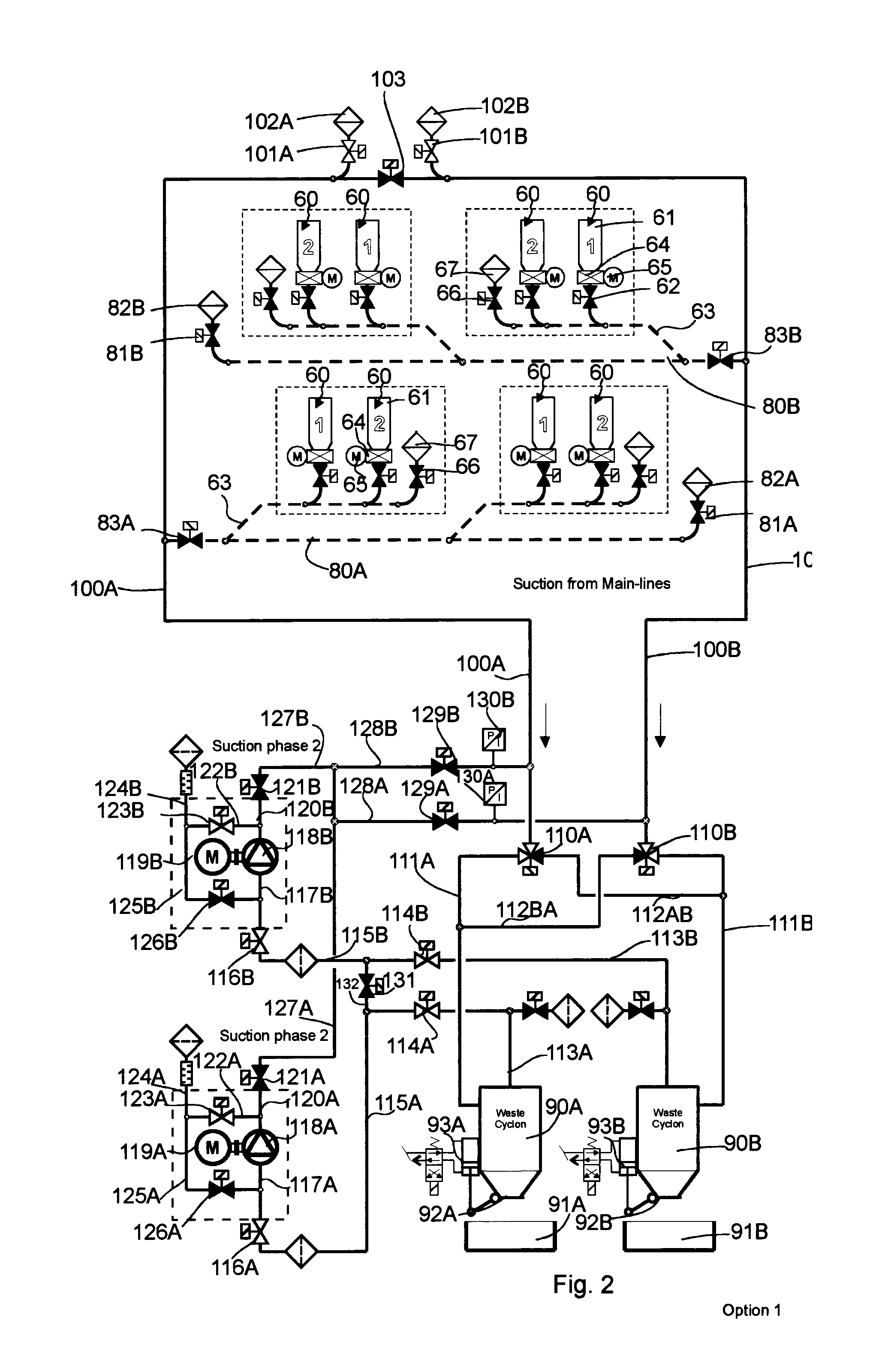

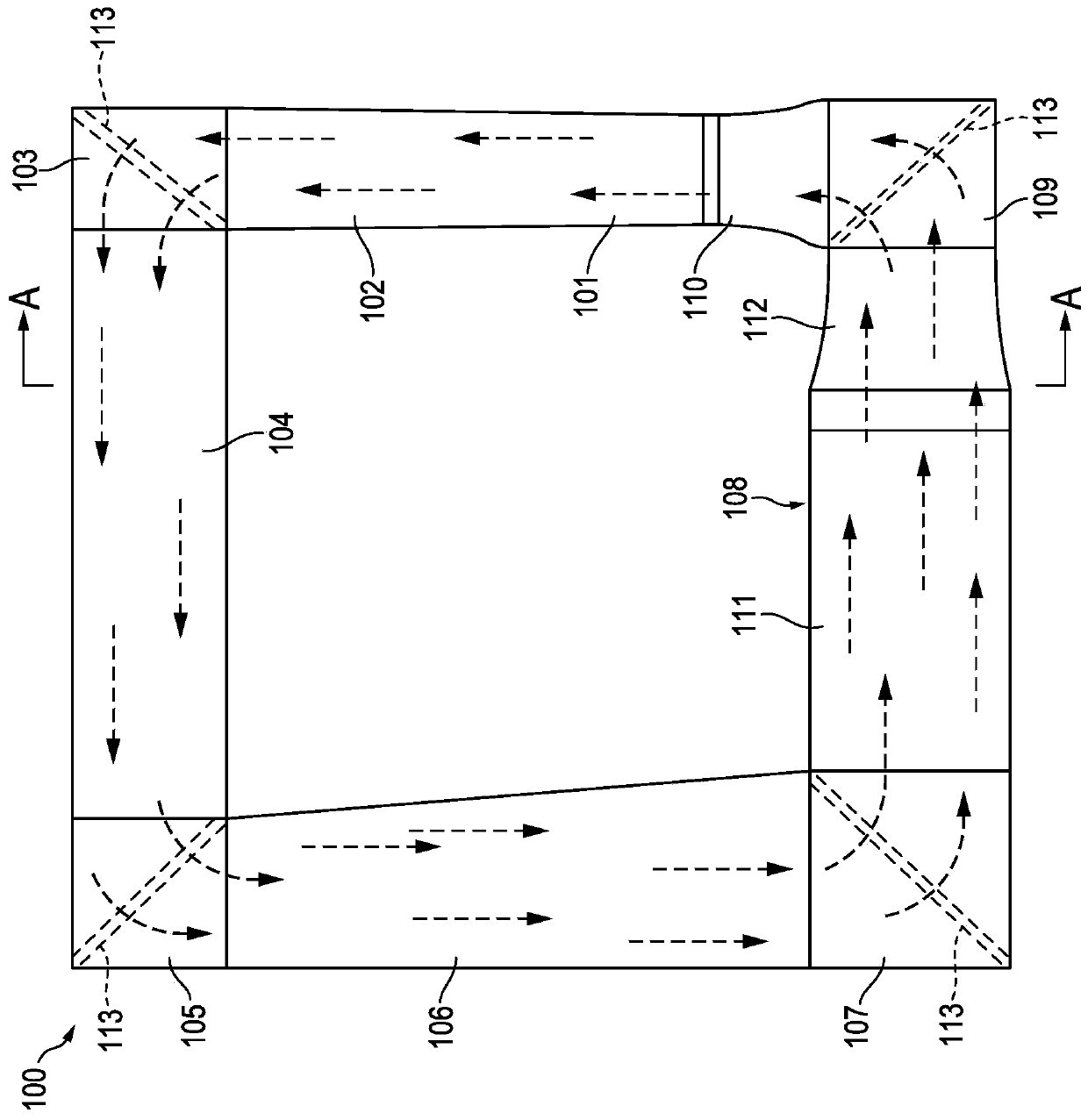

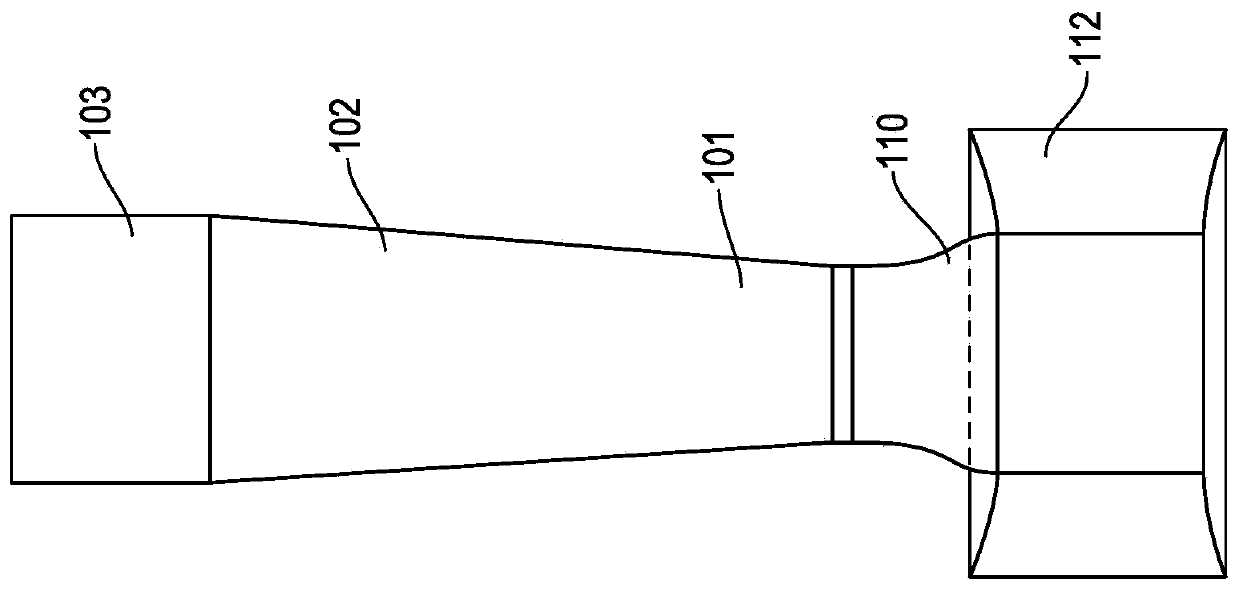

Method and pneumatic material conveying system

ActiveUS20130195563A1Efficient dryingEfficient rinseRefuse gatheringBulk conveyorsEngineeringPressure difference

Method in a pneumatic material conveying system, such as a waste conveying system, which conveying system comprises at least one input point (60) of material, more particularly of waste material, a material conveying pipe, which can be connected to the input point (60), and at least one separating device (90, 90A, 90B), in which the material to be conveyed is separated from the conveying air, and also means for achieving a pressure difference and / or a conveying air current in the conveying pipe at least during conveyance of the material, which means for achieving a pressure difference and / or a conveying air current comprise at least one pump unit, which comprises at least one pump device (118A, 118B). In the method the conveying piping comprises at least one main conveying pipe section (100A, 100B) and also at least one branch conveying pipe section (80A, 80B), which can be connected to the main conveying pipe section (100A, 100B), and in that an input point (60) can be connected to a branch conveying pipe section (80A, 80B), in which method material is transferred initially from an input point (60) via a branch conveying pipe (80A, 80B) into a main conveying pipe section (100A, 100B) by means of the suction / pressure difference and / or the conveying air flow achieved by at least one pump device (118A, 118B) and in which method a main conveying pipe section (100A, 100B) is used as a material reservoir and in that in a second phase the material transferred into a main conveying pipe section is transferred by means of the suction / pressure difference and / or the conveying air flow achieved by at least one pump device into a separating means (90A,

Owner:MARICAP OY

Electrochlorination method for above-ground swimming pools

InactiveUS20120318748A1Efficient energy consumptionTechnology being suitableWater/sewage treatment by magnetic/electric fieldsWaste water treatment from bathing facilitiesAbove groundSodium bisulfate

The invention relate to the addition of mixture of non-halide salts to the water of above-ground swimming pools to allow sterilisation by in-situ electrochlorination with a modest sodium chloride content. A limitation of sodium chloride concentration in above-ground pools is necessary to prevent corrosion of the relevant steel supporting structure. The salt mixture additive contains sodium bisulphate and other salts of low toxicity.

Owner:IND DE NORA SPA

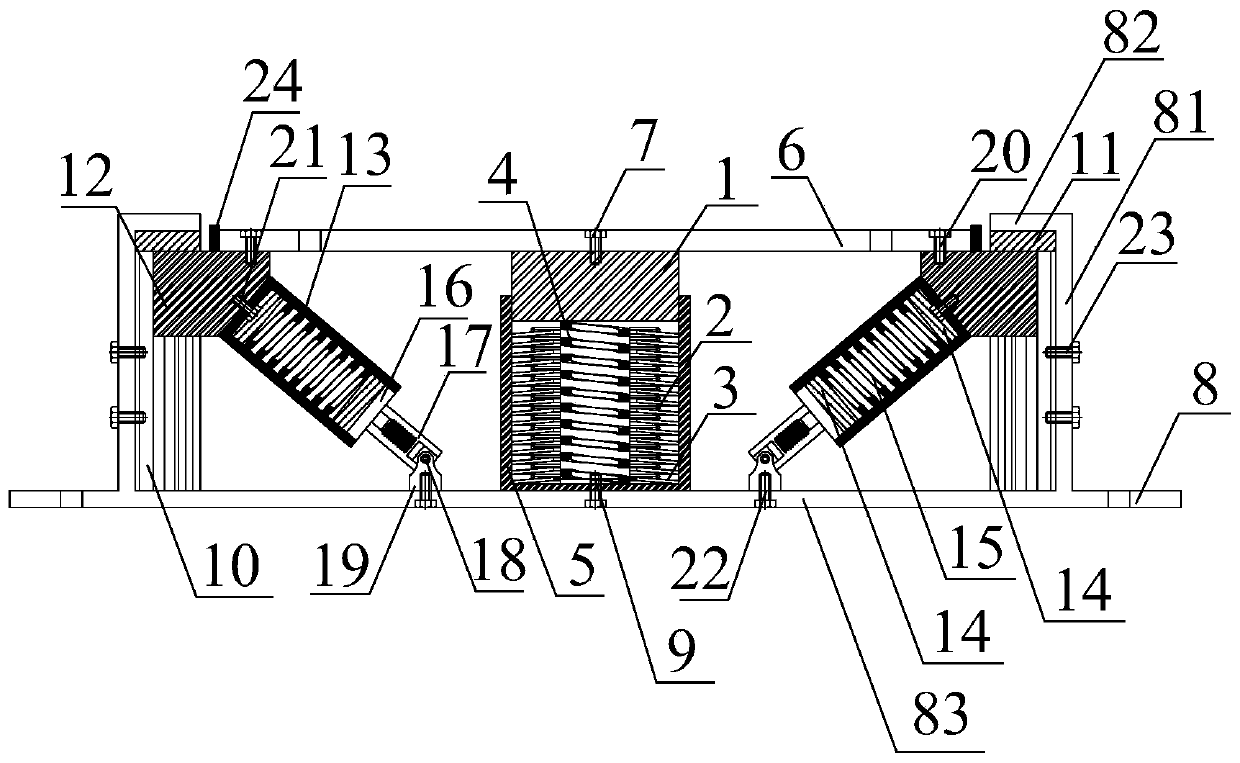

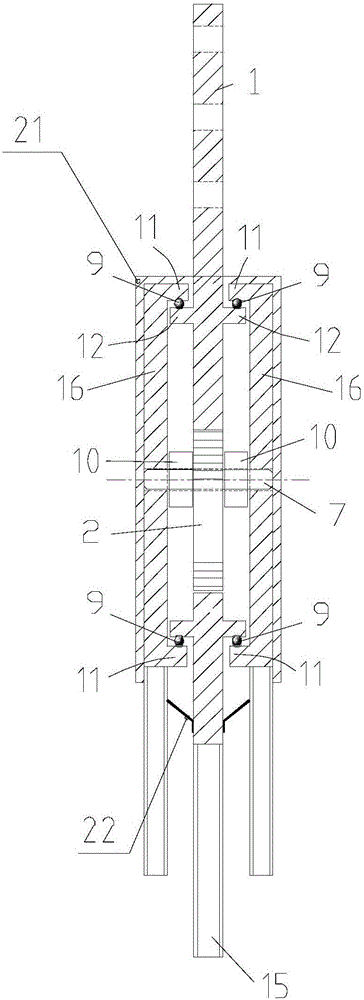

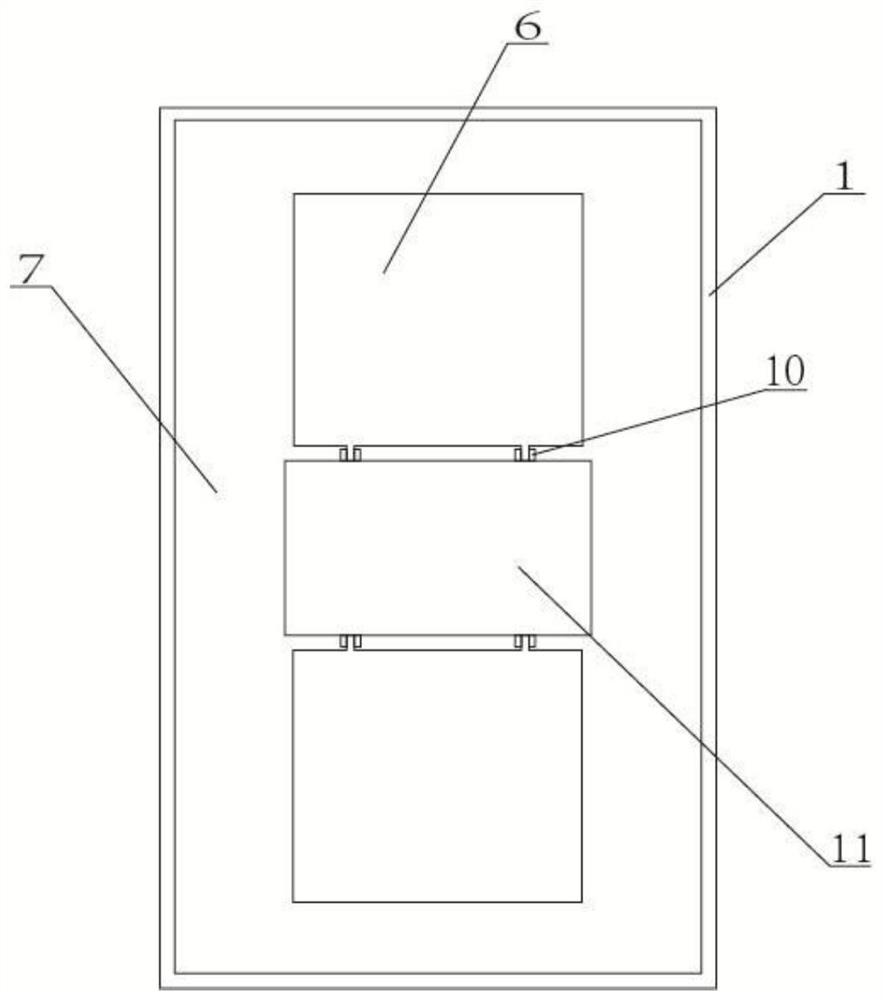

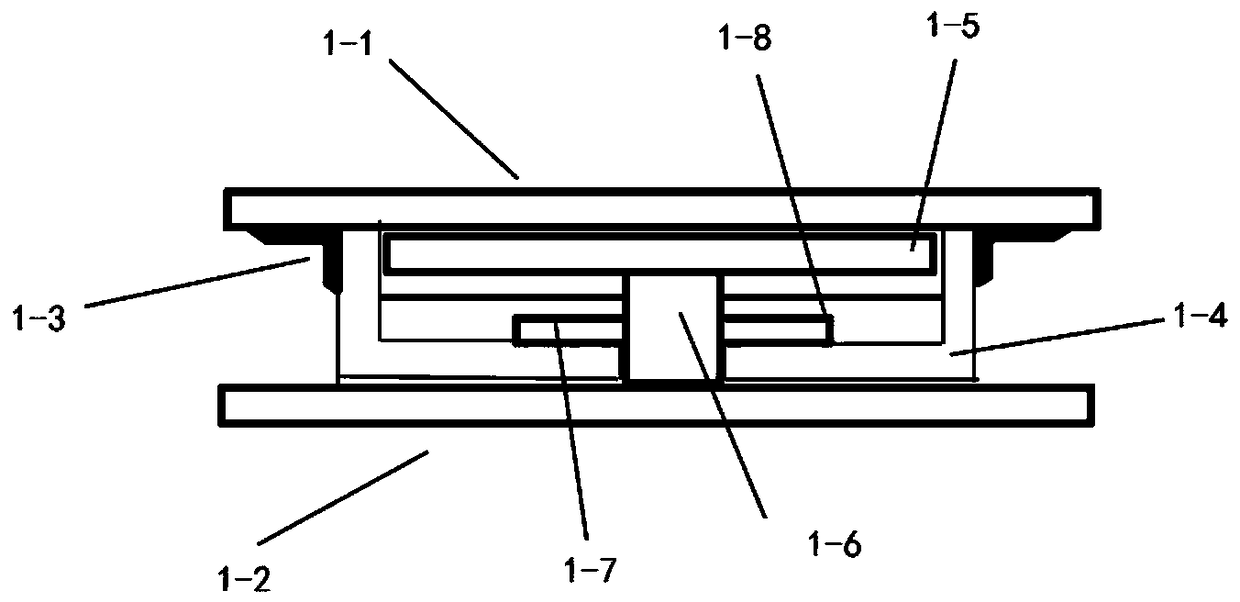

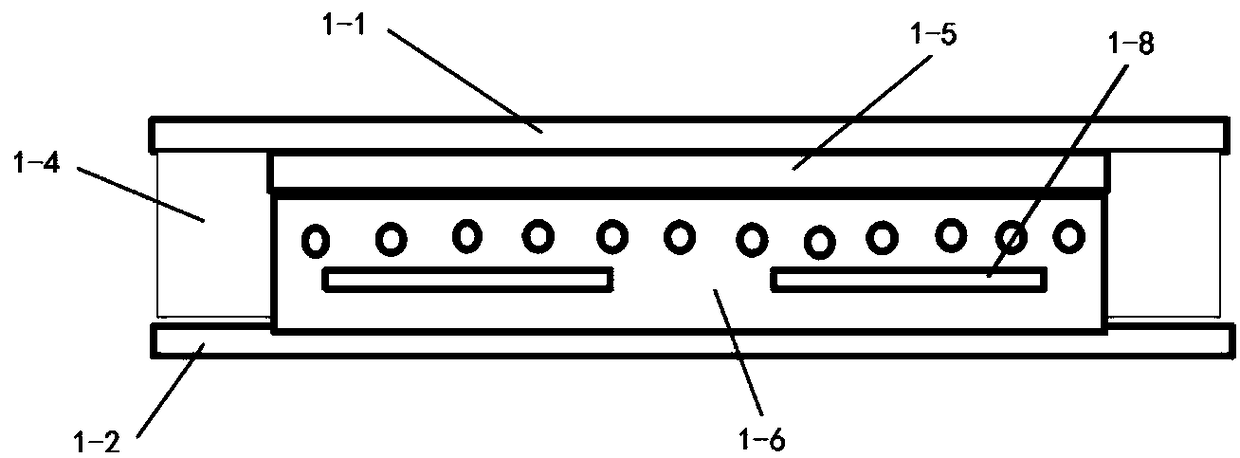

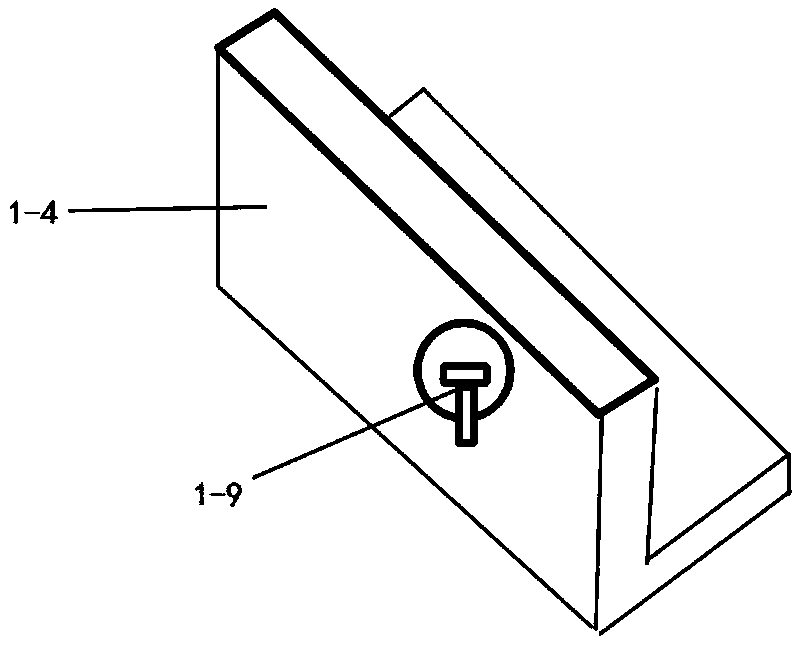

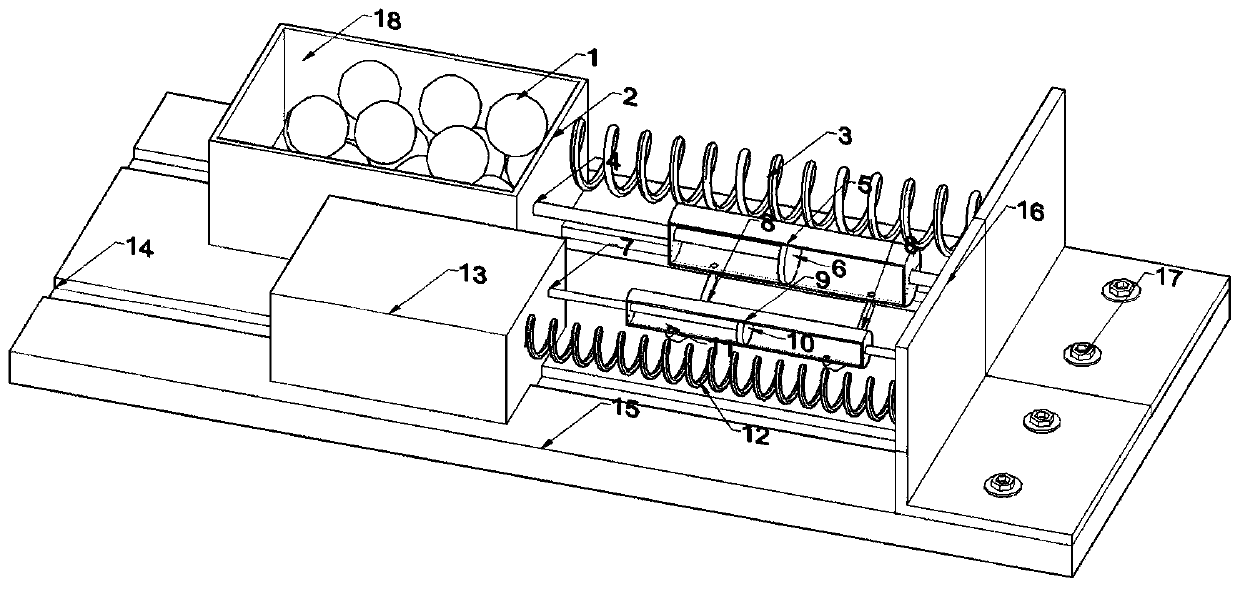

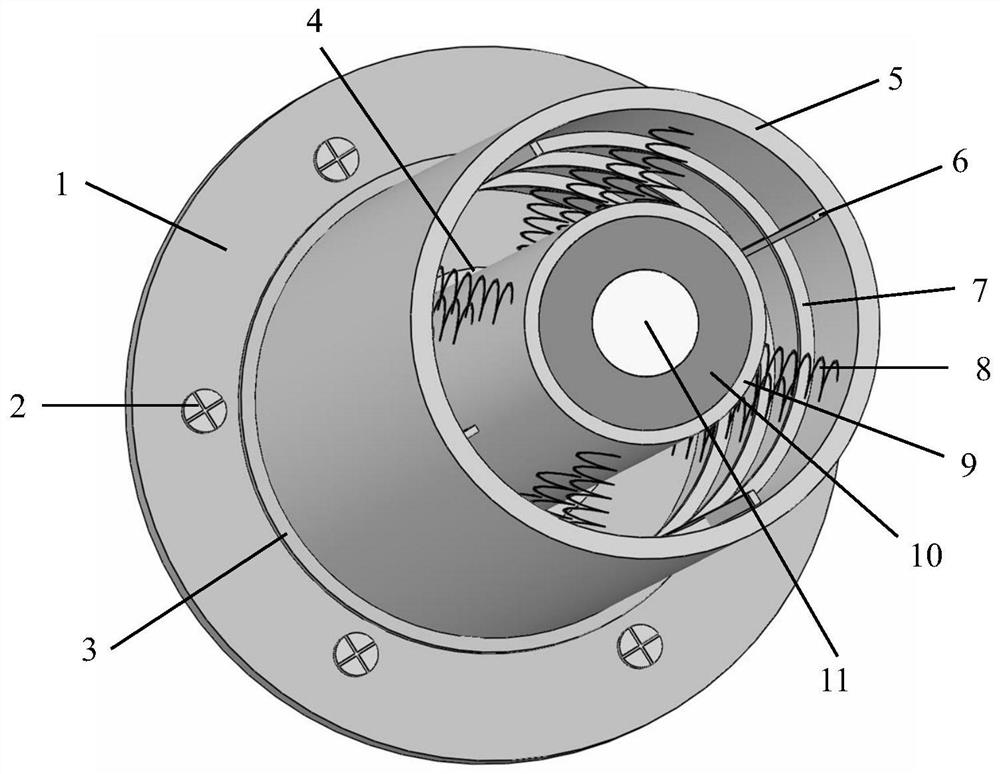

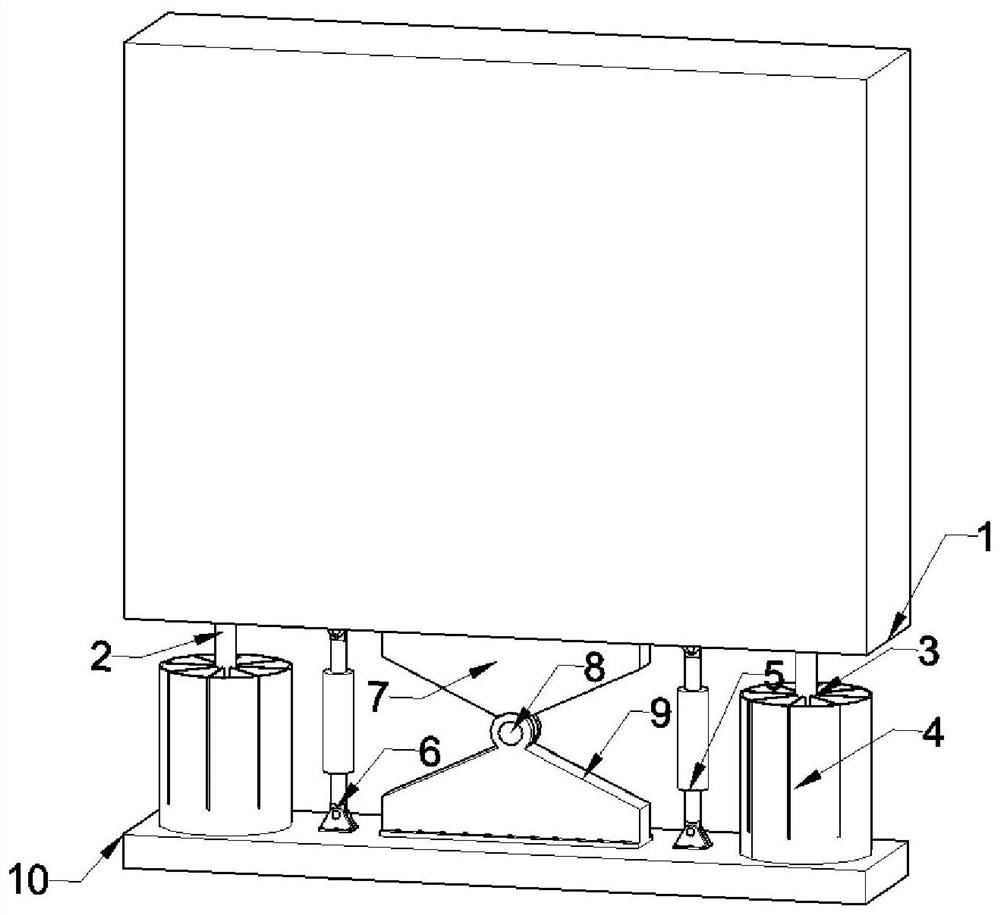

Vertical vibration isolation device

InactiveCN111336204AEasy to assembleEfficient energy consumptionHigh internal friction springsProtective buildings/sheltersVertical vibrationUniversal joint

The invention discloses a vertical vibration isolation device. The vertical vibration isolation device mainly comprises an upper connecting plate, an adaptive stiffness unit, slidable oblique rectangular compression spring units and a lower connecting plate. The adaptive stiffness unit is mainly composed of a positioning loading ring, a belleville spring and a pre-compressed rectangular spring, wherein the positioning loading ring and the belleville spring work in parallel to provide vertical negative stiffness, the pre-compressed rectangular spring provides vertical positive stiffness, and the positioning loading ring, the belleville spring and the pre-compressed rectangular spring work together to generate adaptive stiffness; and the slidable oblique rectangular compression spring unitsare each composed of a directional linear guide rail, an oblique rectangular compression spring and a universal joint, vertical sliding blocks move down along the directional linear guide rails to cause axial compression deformation of the oblique rectangular springs, and energy is dissipated through the mutual conversion of elastic potential energy and kinetic energy. The adaptive stiffness unitand the slidable oblique rectangular compression spring units work in parallel, collaboratively deform and jointly achieve vertical vibration isolation. The vertical vibration isolation device can bewidely applied to buildings or large and medium-sized mechanical equipment with high requirements for vibration reduction and near rail transit.

Owner:TONGJI UNIV

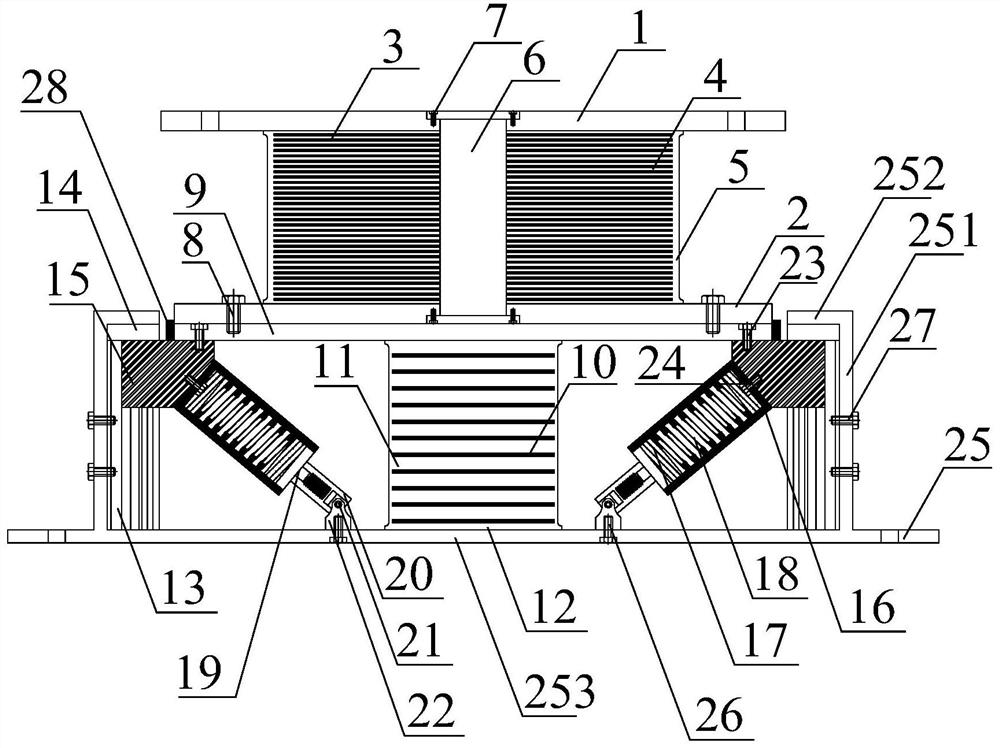

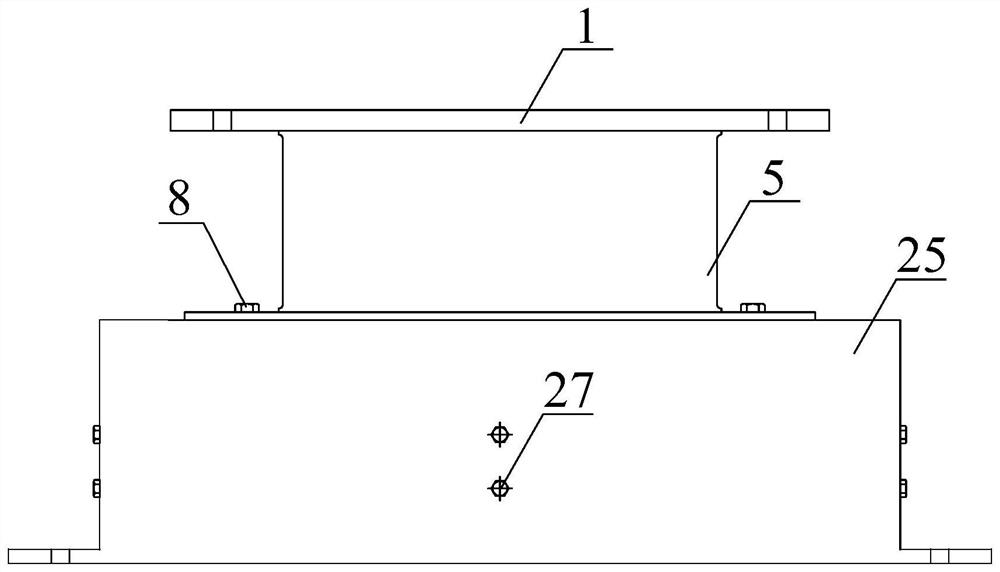

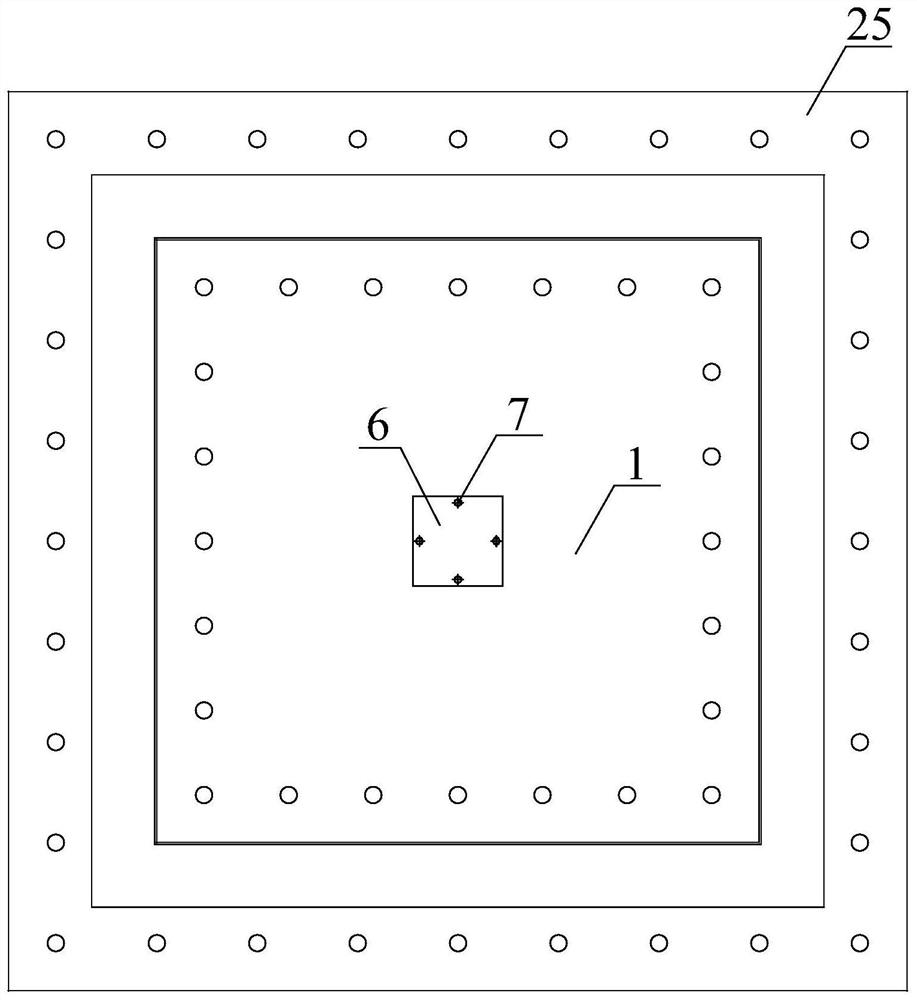

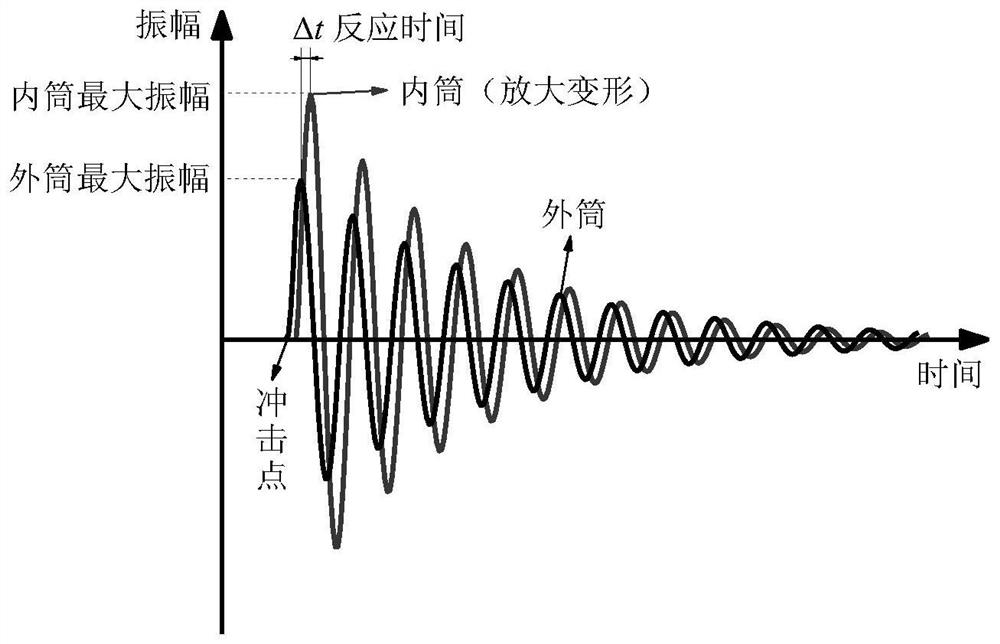

Inertial-type shock-absorbing layer system

ActiveCN109267810AAvoid destructionReduce internal force mutationProtective buildings/sheltersExtraordinary structuresHysteresisViscous damping

The invention relates to an inertial type shock-absorbing layer system used in the fields of civil engineering and energy infrastructure, which comprises an upper truss and a lower truss, an anti-buckling restrained brace energy consumption unit and a friction limit type viscous inertial system. The system provides the basic rigidity of the shock-absorbing layer through the upper truss group and the lower truss group, and limits the sliding of a lead screw through the friction limit unit of the inertial system under the action of wind load and small earthquake. When the external loading actionis enhanced, by relaxing the restraint with the friction limit unit of the inertial system, the energy of the shock-absorbing layer is dissipated by utilizing the friction damping, the viscous damping and an anti-buckling restrained brace hysteresis unit. The shock-absorbing layer establishes a systematically complete energy consumption path and a two-stage rigidity adjusting mechanism. The designed anti-buckling restrained brace meets the energy consumption requirement of the multi-stage support. The friction limit type viscous inertial system improves the energy consumption efficiency of the shock-absorbing layer. The inertial type shock-absorbing layer system is convenient and flexible, can effectively absorb and dissipate earthquake energy, has the advantages of high energy consumption efficiency, strong robustness, easy repair after earthquake and the like, and has good popularization and application value.

Owner:TONGJI UNIV

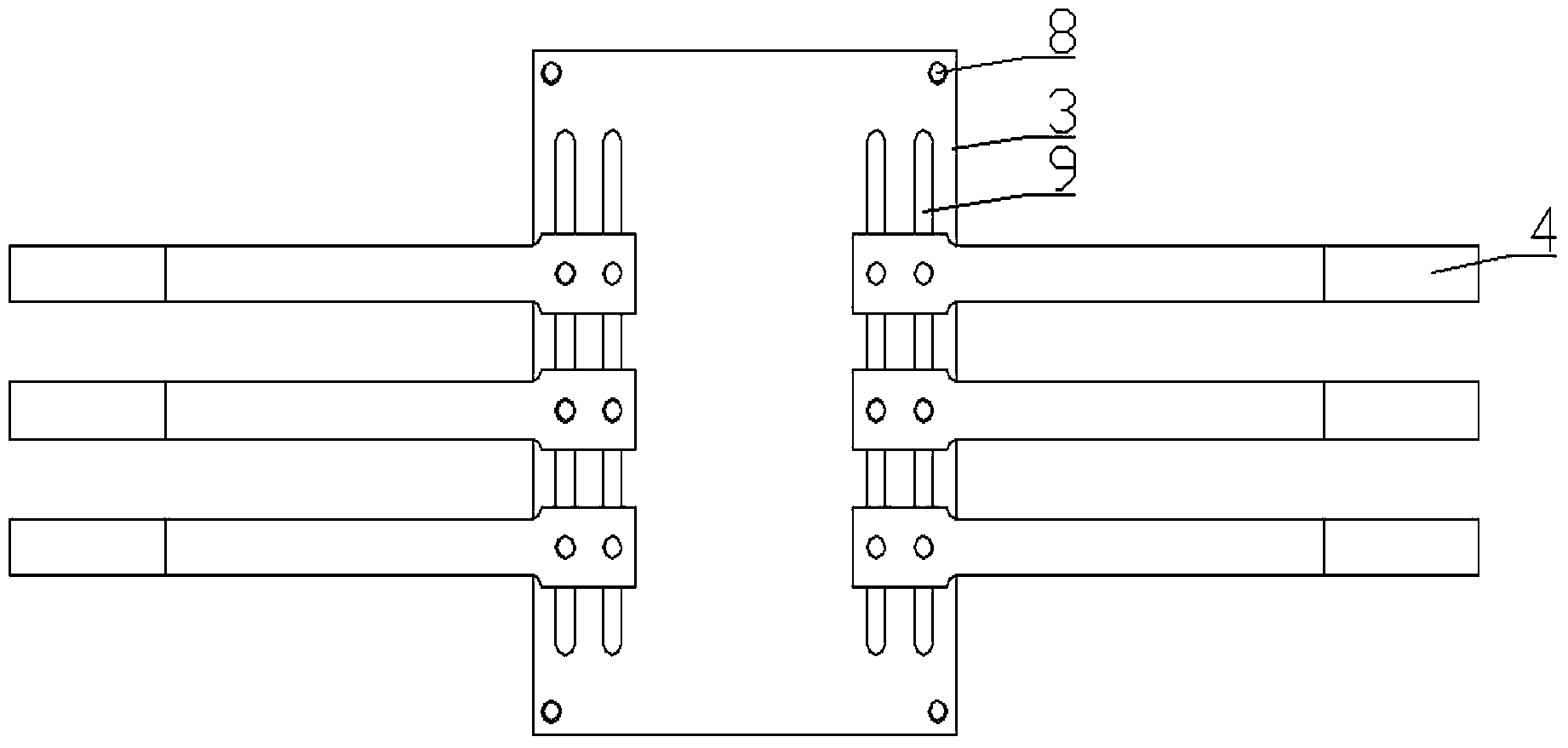

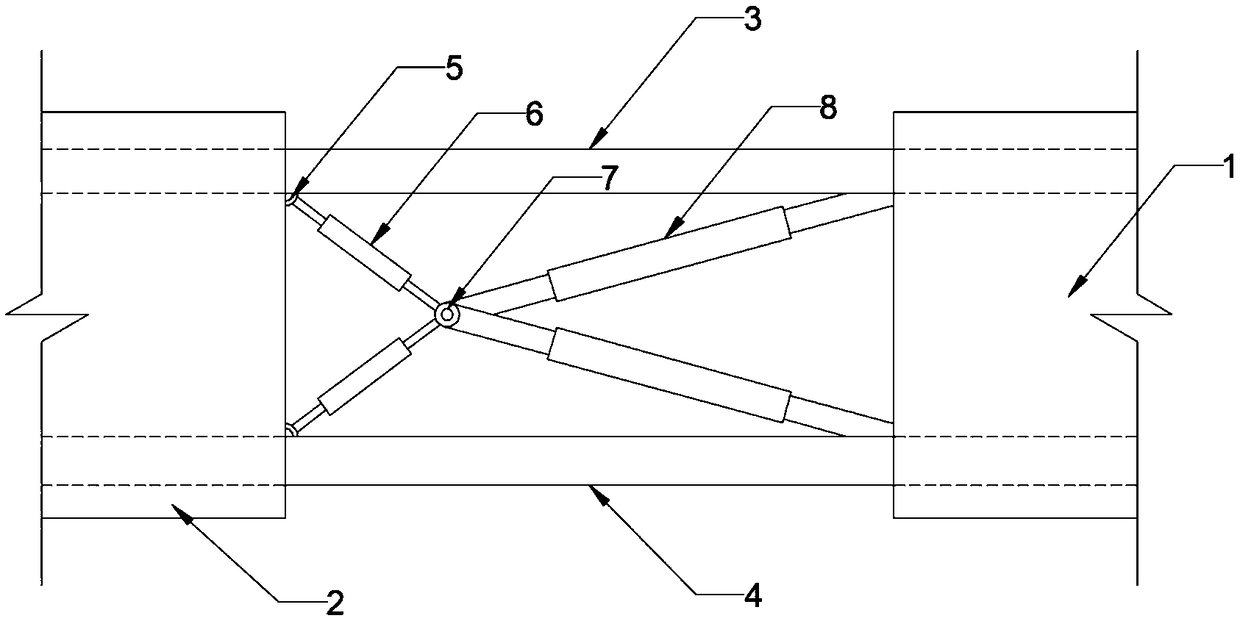

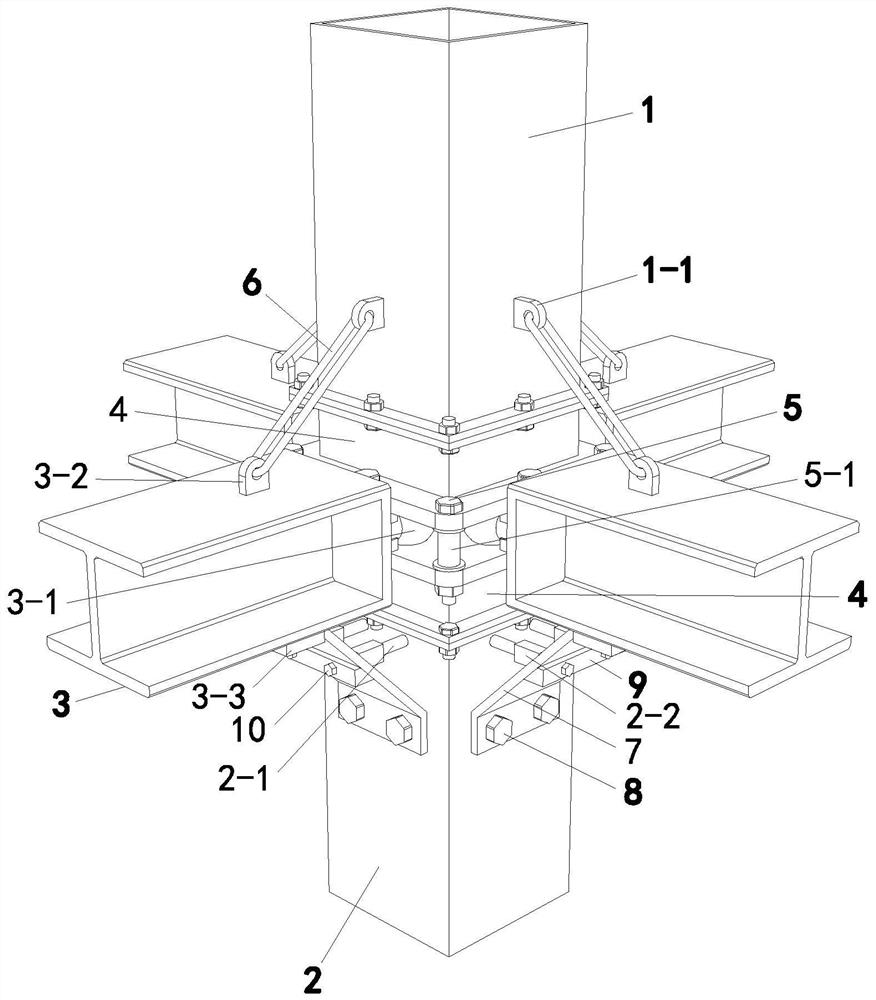

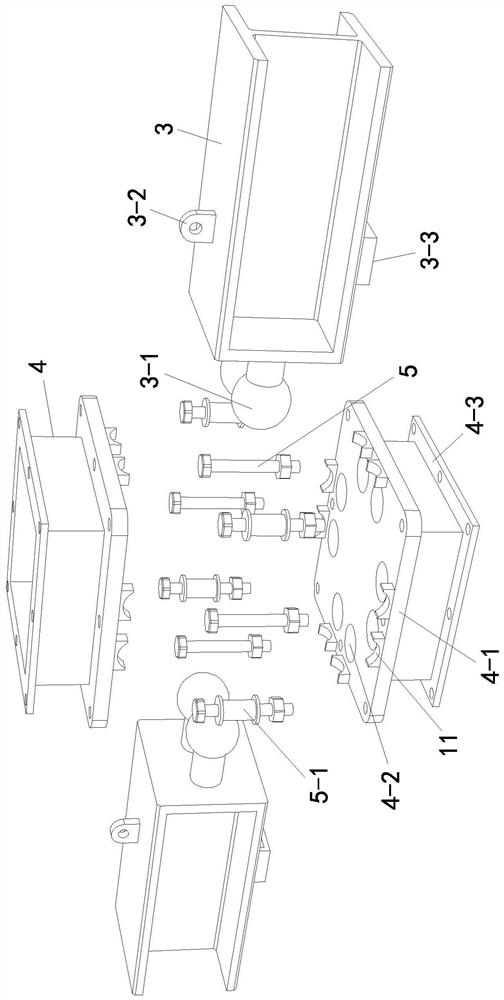

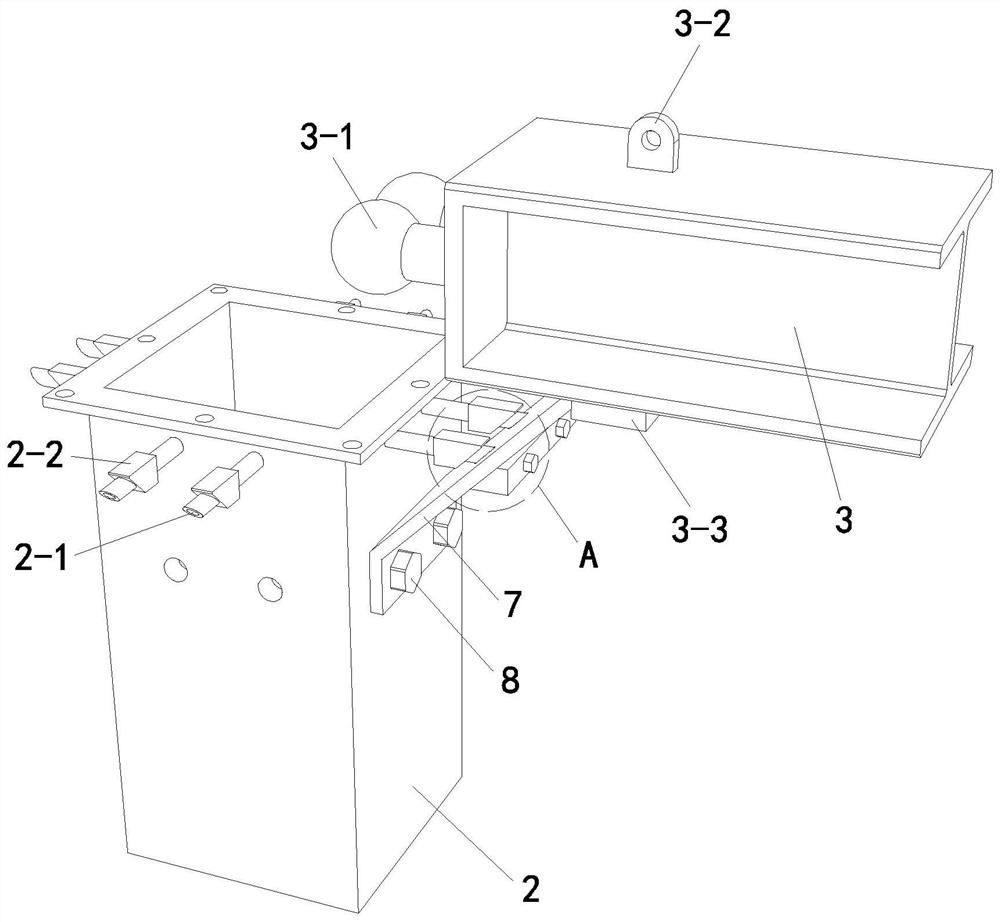

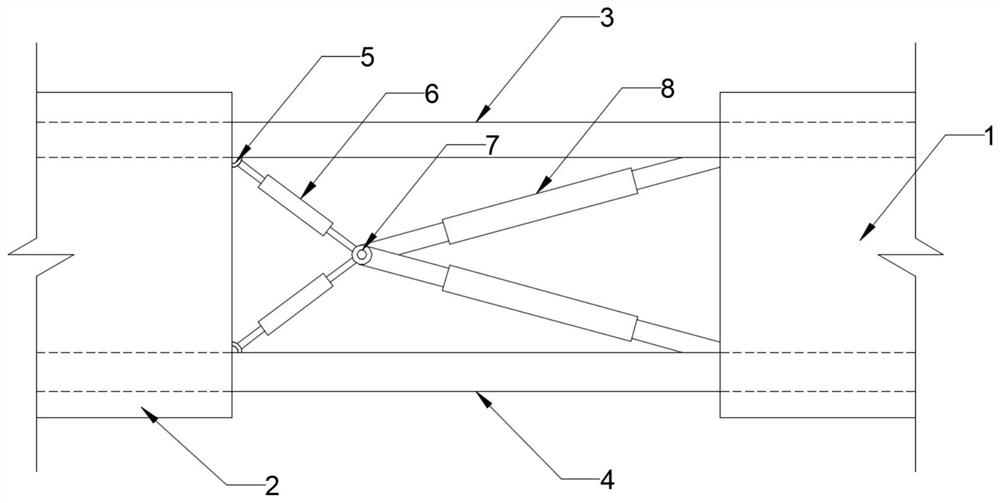

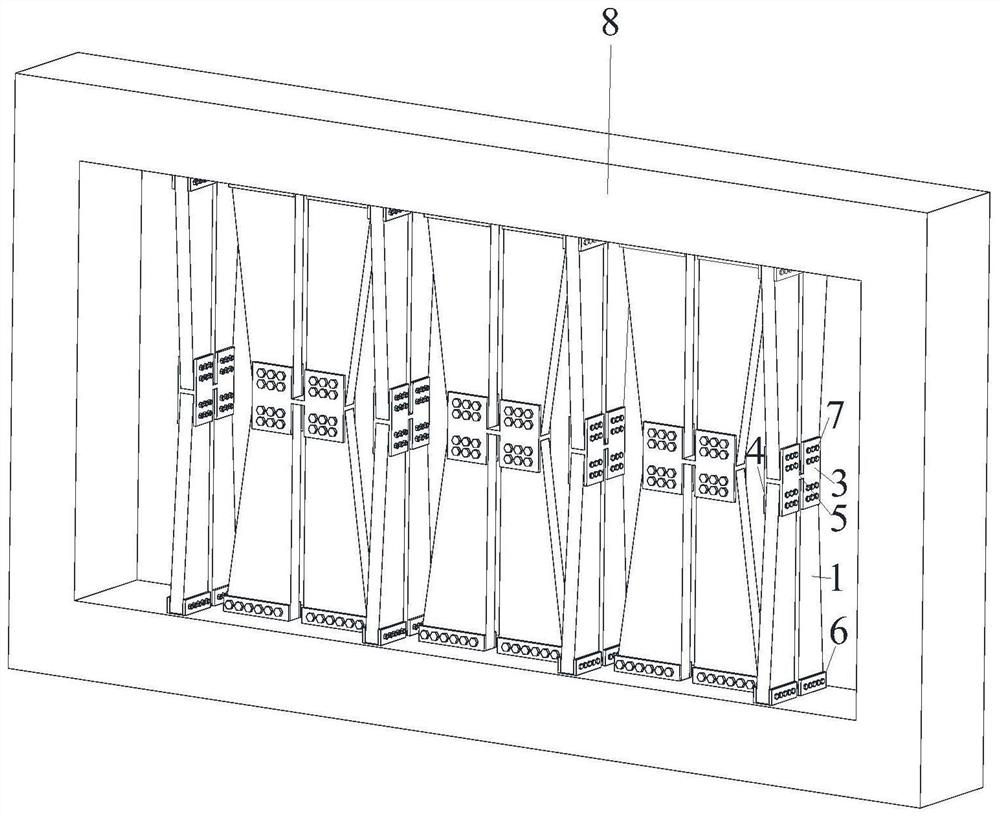

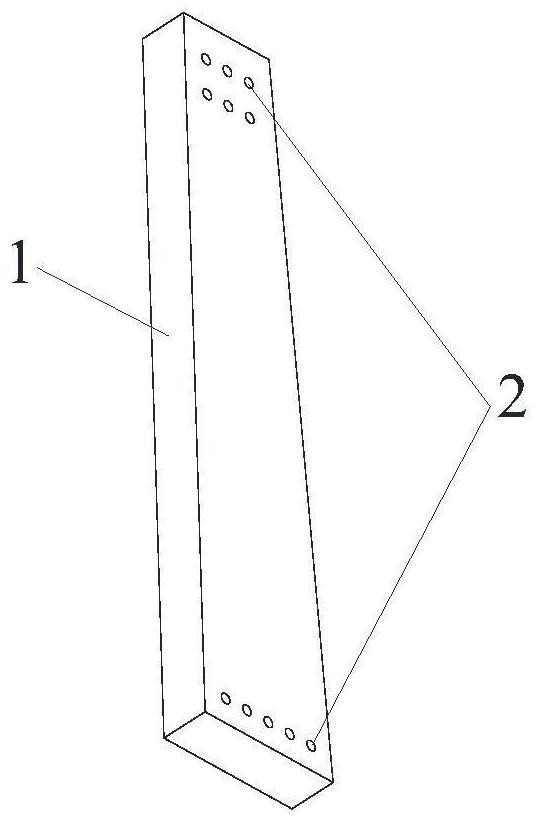

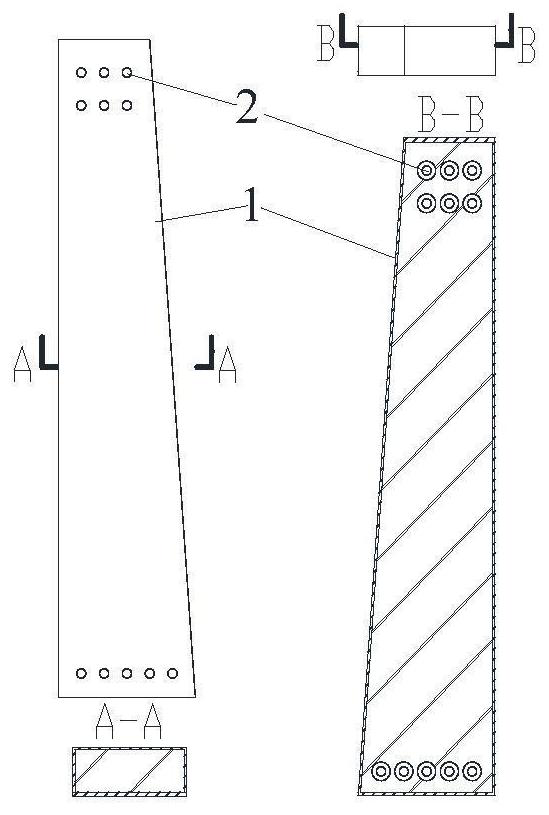

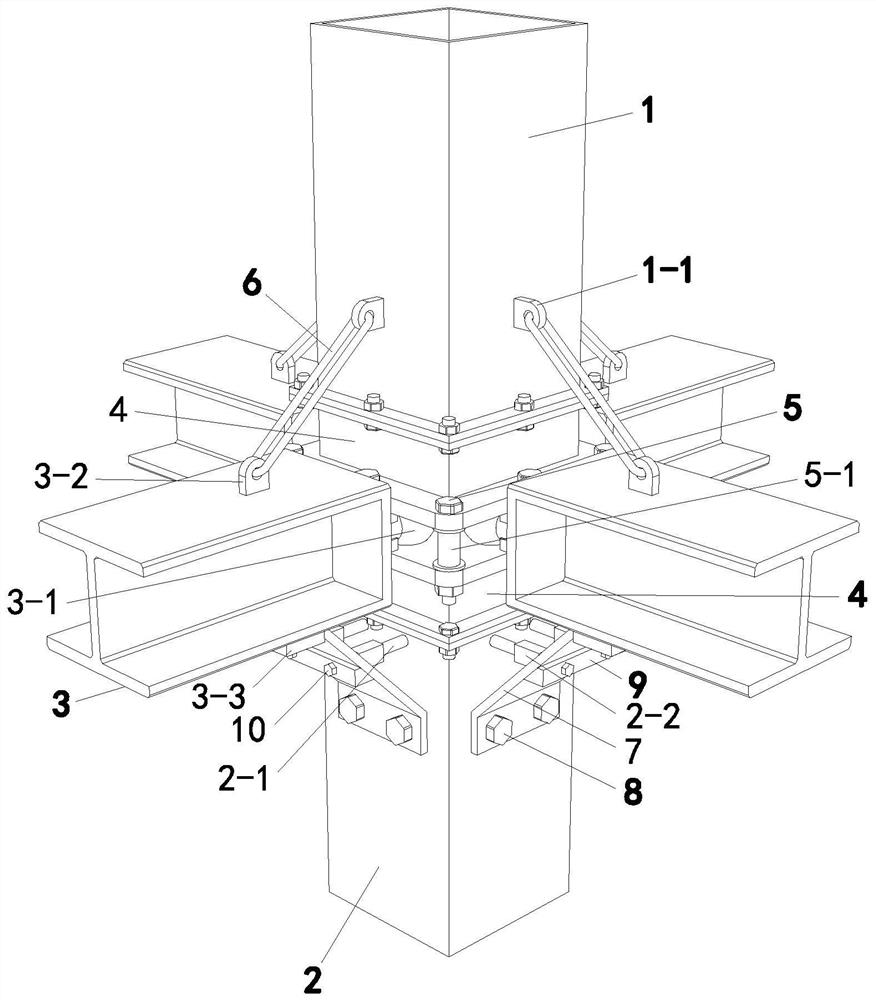

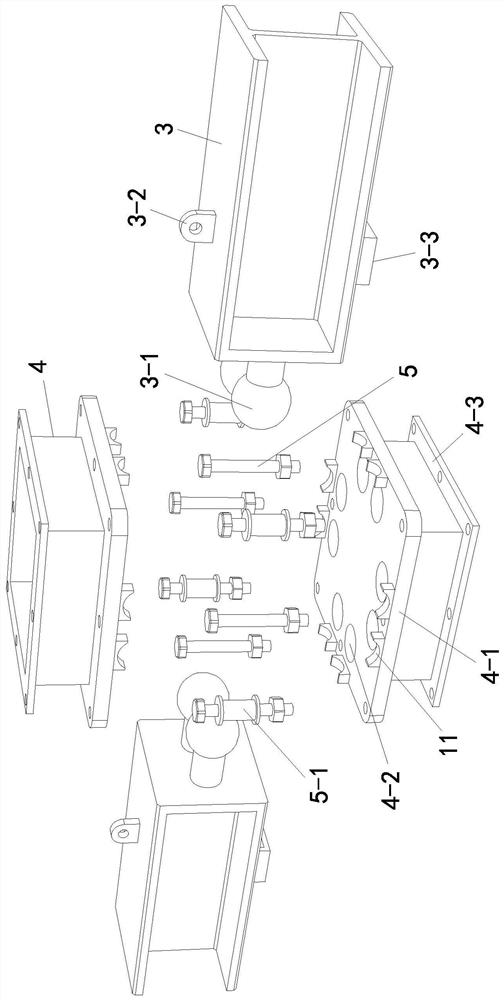

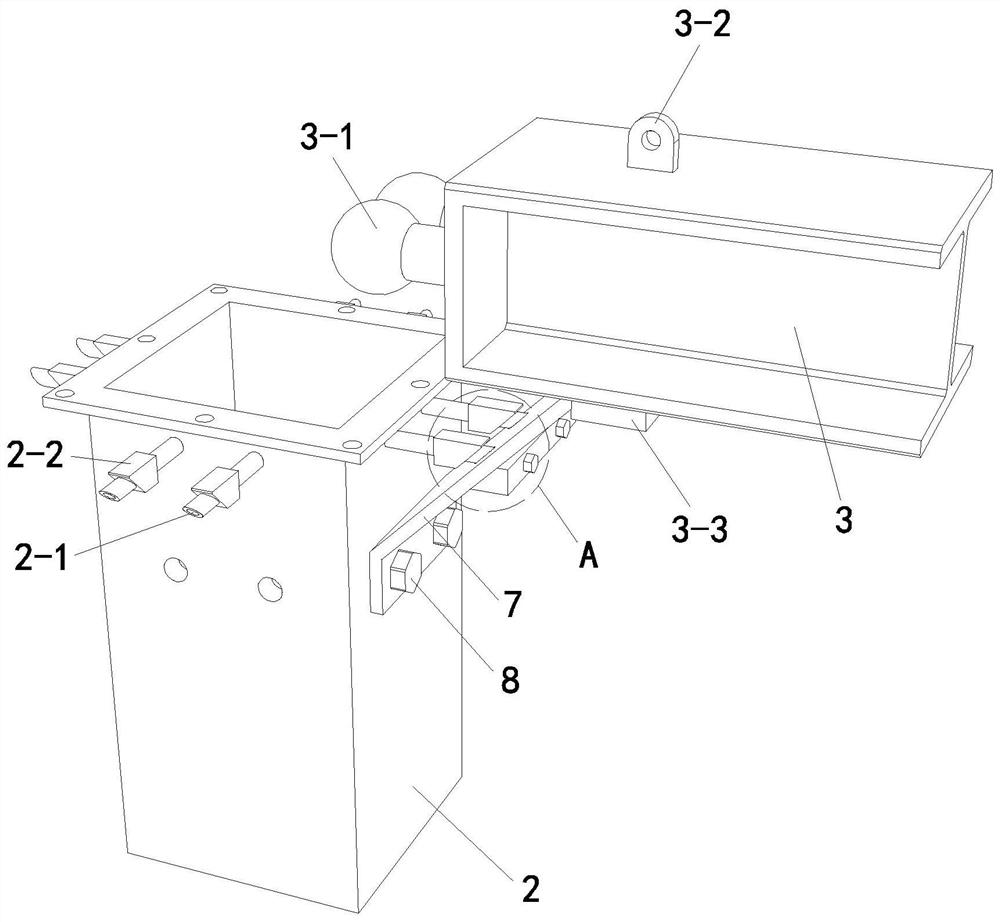

Assembly type building beam column joint structure and construction method thereof

ActiveCN112900626AGood transmission shearEfficient energy consumptionProtective buildings/sheltersBuilding material handlingLap jointBeam column

The invention provides an assembly type building beam column joint structure and a construction method thereof, and relates to a beam column joint and a construction method. Two to four steel beams are connected between an upper steel pipe column and a lower steel pipe column; flat plates and flange plates are arranged at the two ends of joint connecting seats respectively; the two joint connecting seats are fixed to the lower end of the upper steel pipe column and the upper end of the lower steel pipe column respectively; two spherical positioning grooves are concavely formed in each side of the periphery of the surface of each flat plate; two ball head lap joint rods are arranged at the connecting ends of the steel beams and clamped between the spherical positioning grooves corresponding to the two flat plates; the edges of the two flat plates are connected and fixed through fastening bolts and nuts; the upper portions of the steel beams are connected with the upper steel pipe column in a suspended mode through steel wire ropes; and energy dissipation steel plates are obliquely supported between the lower portions of the steel beams and the lower steel pipe column. A connecting structure similar to a spherical hinge is adopted between the beam columns, the upper portion is suspended through the steel wire ropes, the energy dissipation steel plates are obliquely supported and installed on the lower portion, the efficient energy dissipation effect is achieved through mutual cooperation, the structure is stable, and assembly and damage repair are facilitated.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

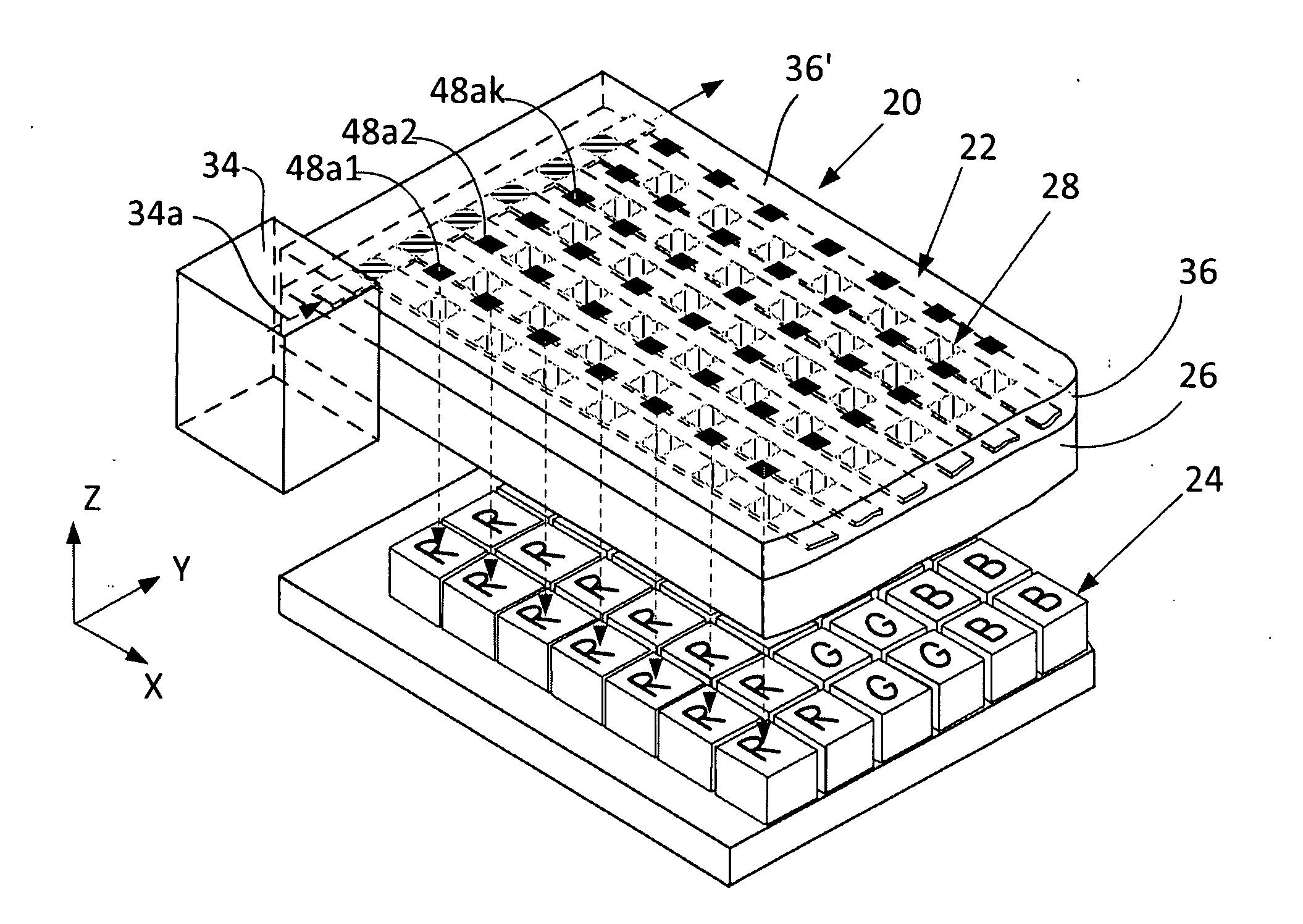

Frontlight unit for reflective displays

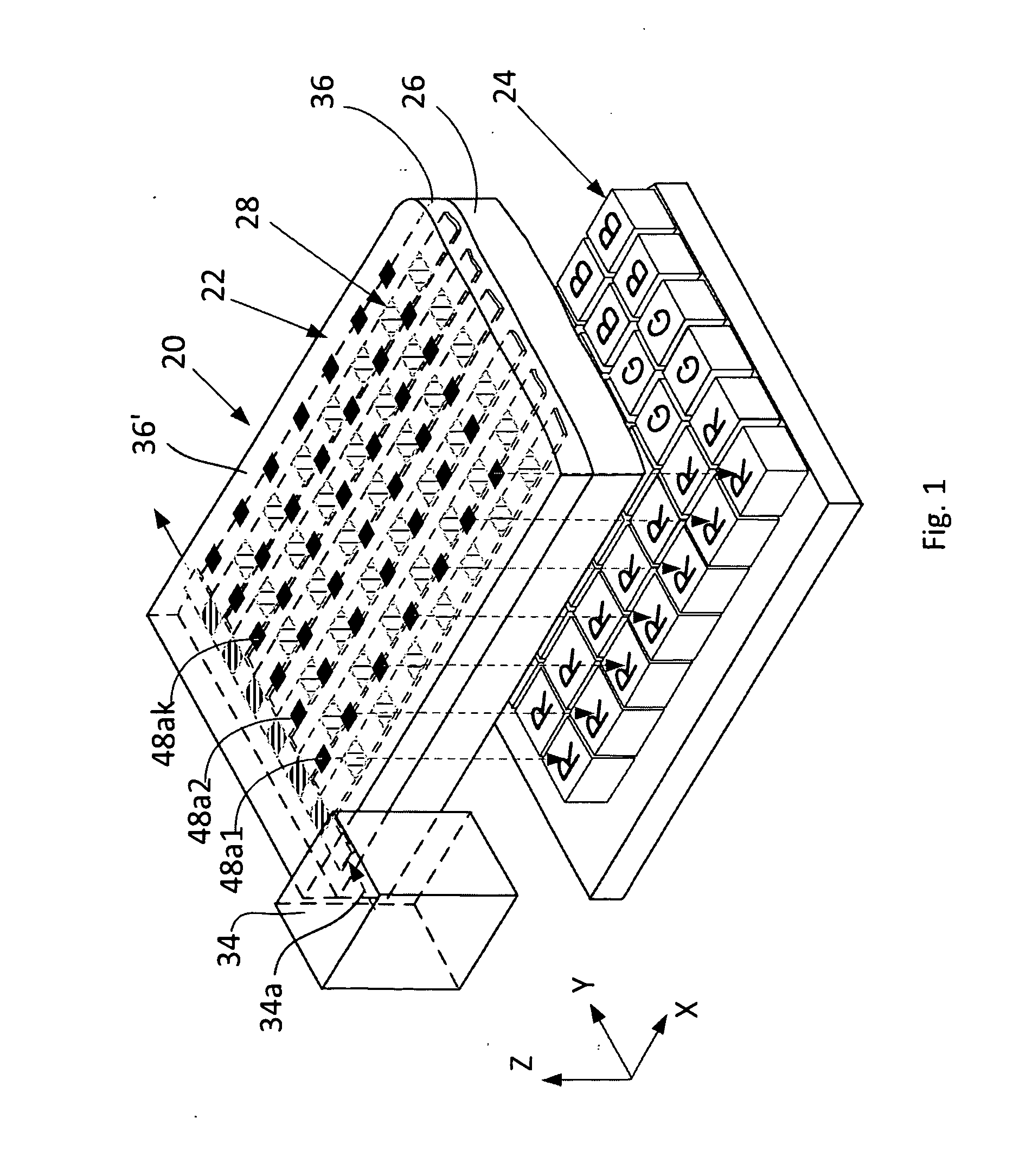

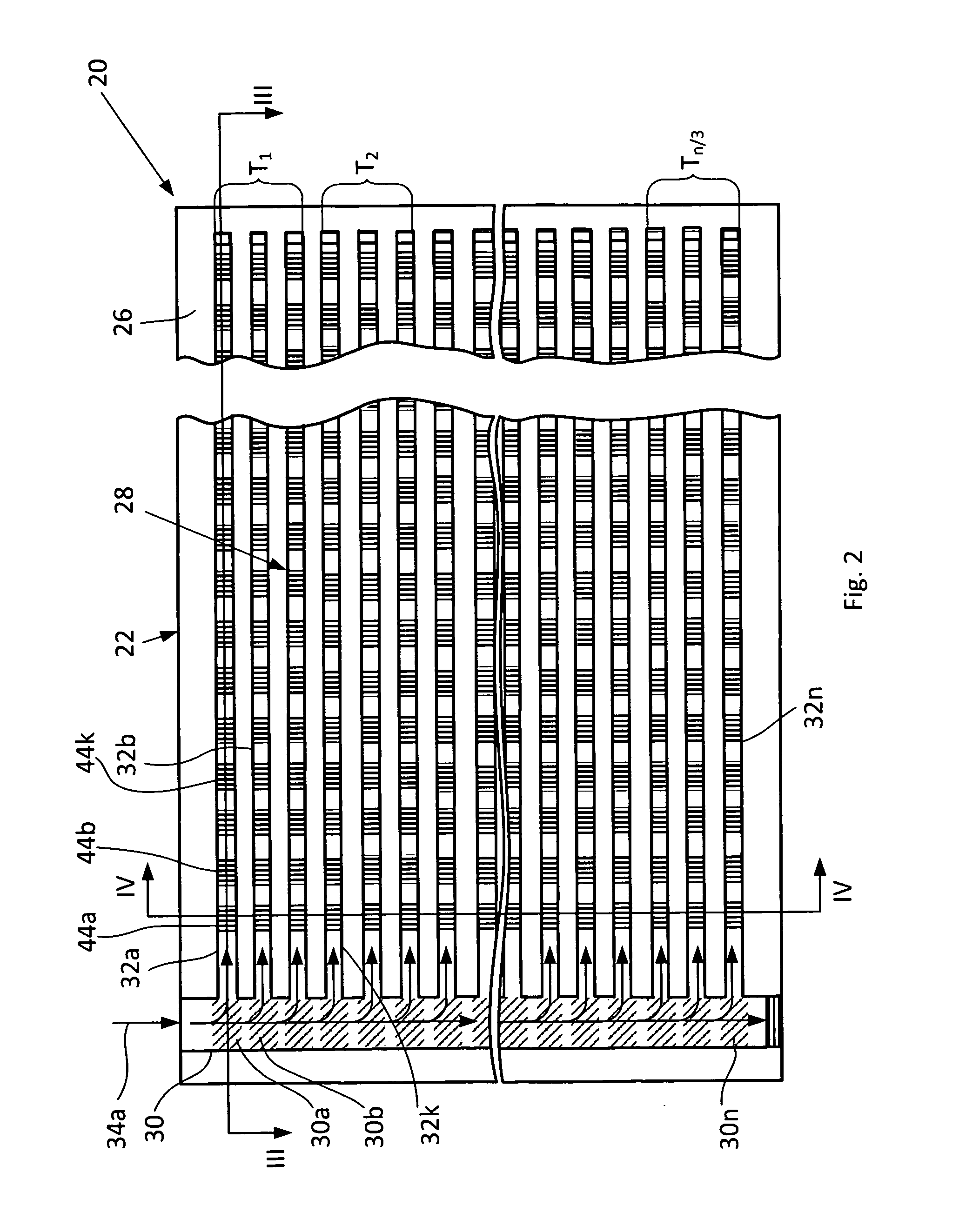

ActiveUS20130121019A1Improve image qualityEfficient energy consumptionMechanical apparatusLight guides for lighting systemsRidge waveguidesDisplay device

The frontlight unit is intended for enhancing illumination of a reflective display having pixels arranged in a matrix pattern and using monochromatic laser lights as light sources. The unit contains a network of light-distribution planar ridge waveguides with holograms arranged in a matrix pattern that corresponds to the matrix pattern of the reflective display when it is applied onto this display and emits light in the downward direction in the form of diverging beams that fall onto the pixels of the reflective display and in the upward direction onto mirrors wherefrom light is reflected also in the form of diverging beams onto the reflective display. Thus, all of the light reflected from the holograms of the light-distribution planar ridge waveguides is not lost and is used entirely for illumination of the reflective display. The mirrors occupy no more than 5% of the display surface area.

Owner:YANKOV VLADIMIR +1

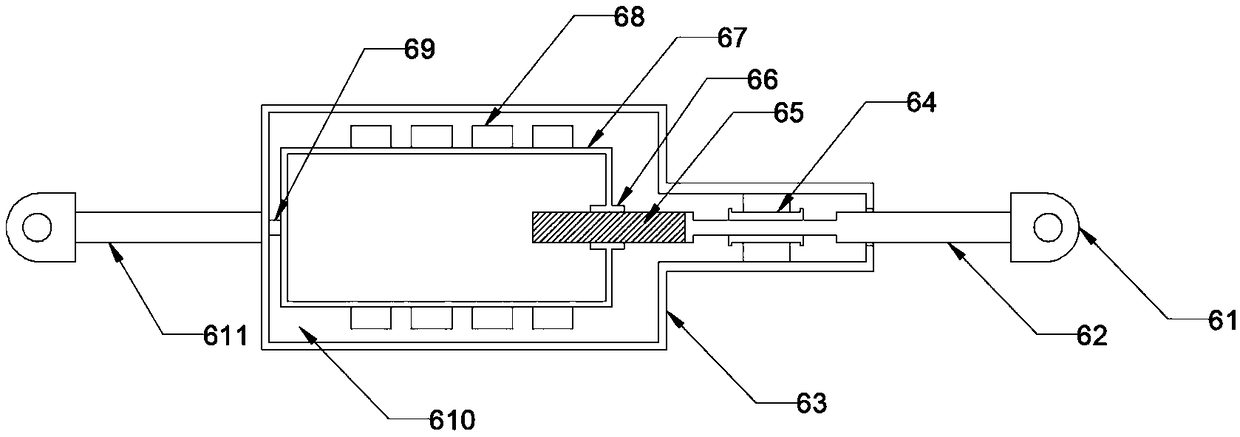

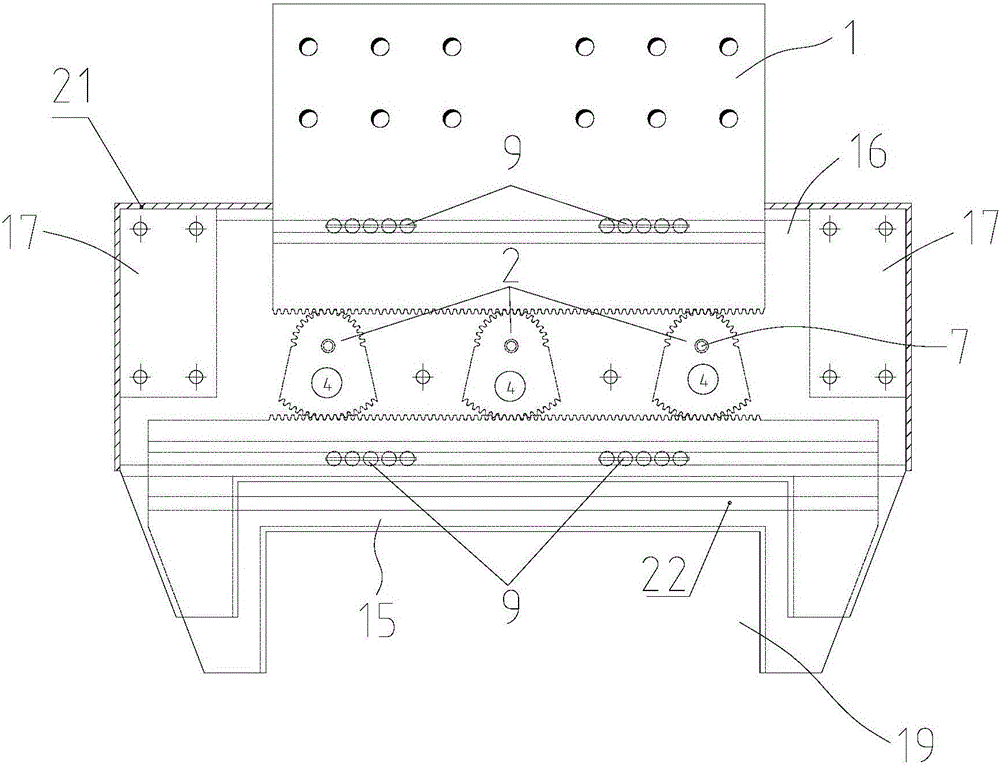

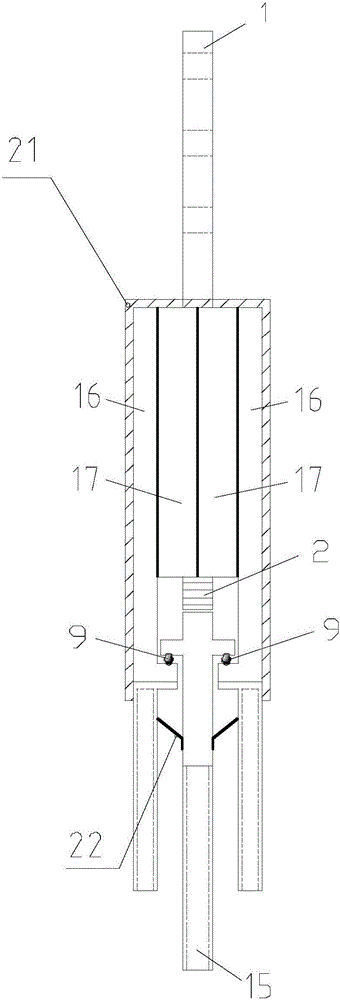

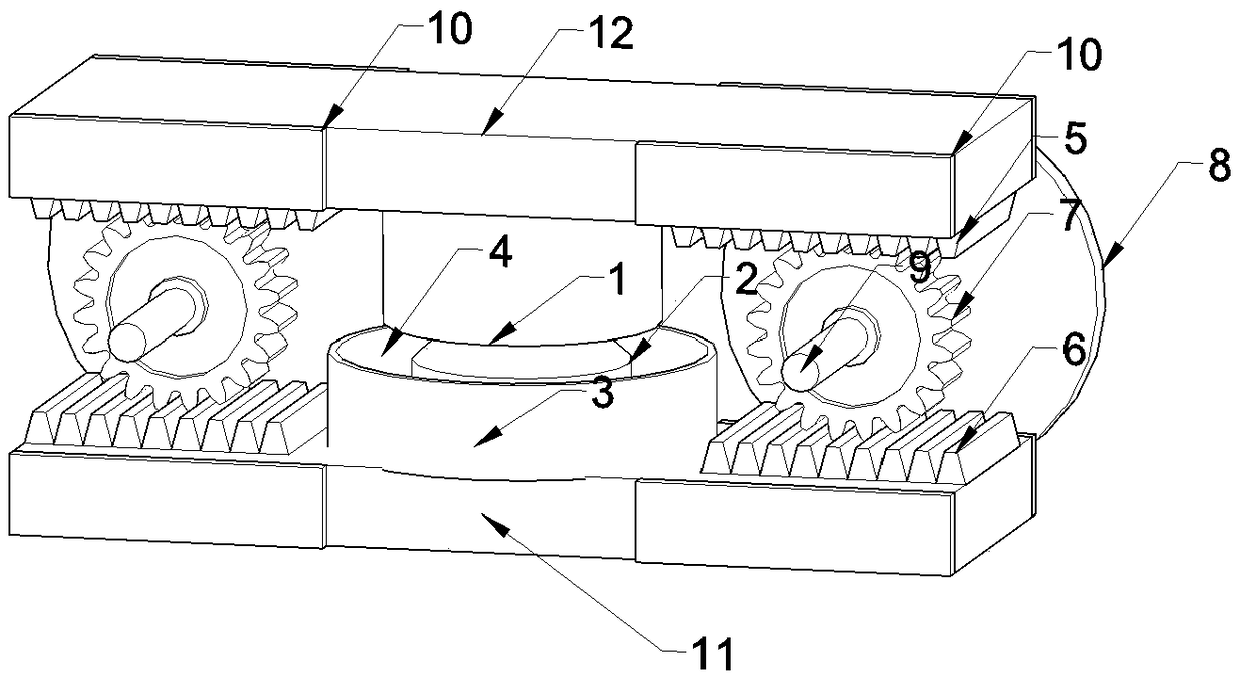

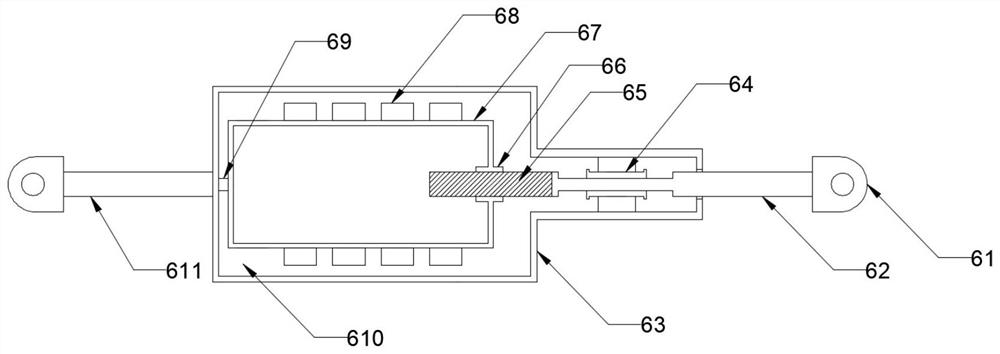

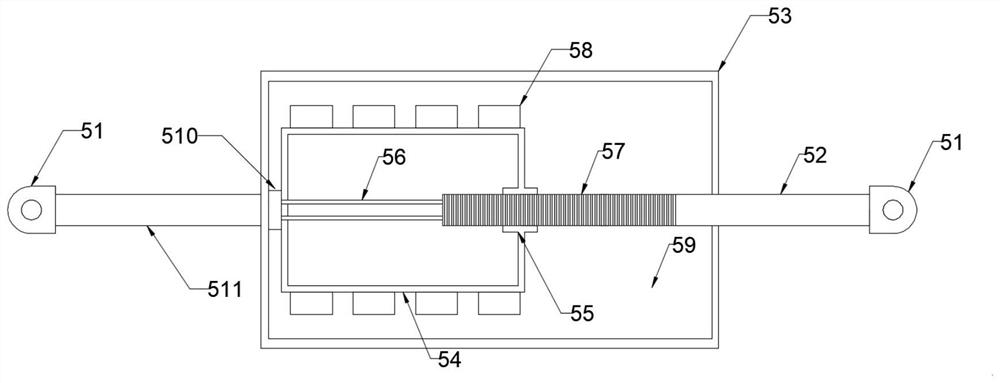

Strain increasing device and damper

ActiveCN105133741AImprove efficiencyImprove competitive advantageShock proofingSteel platesUltrasound attenuation

The invention discloses a strain increasing device and a damper. The strain increasing device comprises a first connecting steel plate, outer sandwich steel plates, an eccentric sector gear, and a second connecting steel plate. The lower part of the first connecting steel plate is disposed in the upper part between the two outer sandwich steel plates. The eccentric sector gear is arranged between the two outer sandwich steel plates. The second connecting steel plate is arranged in the lower part between the two outer sandwich steel plates. The lower side face of the first connecting steel plate is meshed with the upper teeth of the eccentric sector gear through teeth. The energy efficiency is enhanced by increasing the strain of the damper. Energy can be consumed efficiently from tiny vibration. Once the strain is beyond the designed strain of the damper, limiters are triggered to consume energy. Therefore, the overall performance of the damper tends to be stable, and excessive damping attenuation is not generated due to large deformation. The number of dampers used and the installation workload are reduced, and the overall cost is lowered.

Owner:四川三树银城科技有限公司

Friction pendulum type inerter shock isolation system

InactiveCN109296244AReduce energy inputEfficient isolation systemProtective buildings/sheltersShock proofingKinetic energyPendulum

The invention relates to a friction pendulum type inerter shock isolation system used in the field of civil engineering and energy infrastructures. The friction pendulum type inerter shock isolation system comprises a friction pendulum unit, an inerter subsystem unit and an installation unit. According to the friction pendulum type inerter shock isolation system, an energy disposal mechanism of the system is established for a structural system subjected to an external action; firstly, external energy input is reduced by isolating the structure from the ground through the friction pendulum unit; secondly, energy is stored in the form of kinetic energy through the rotation of an inerter in the inerter subsystem unit; and the energy is dissipated through a friction pendulum friction sliding mechanism and an eddy current unit. The friction pendulum type inerter shock isolation system utilizes the arrangement of the inerter subsystem unit, the energy absorption efficiency and energy consumption efficiency of the friction pendulum type inerter shock isolation system are improved while the physical quality of the shock isolation system is not significantly increased, the displacement of ashock isolation layer can be effectively controlled, and the inertial characteristics of an upper structure can further be effectively adjusted, so that the control over high-order vibration of the structure is realized, and the dynamic response of the structure is significantly reduced. The friction pendulum type inerter shock isolation system has the characteristics of high energy consumption efficiency, high robustness and the like, and has wide application prospects.

Owner:TONGJI UNIV

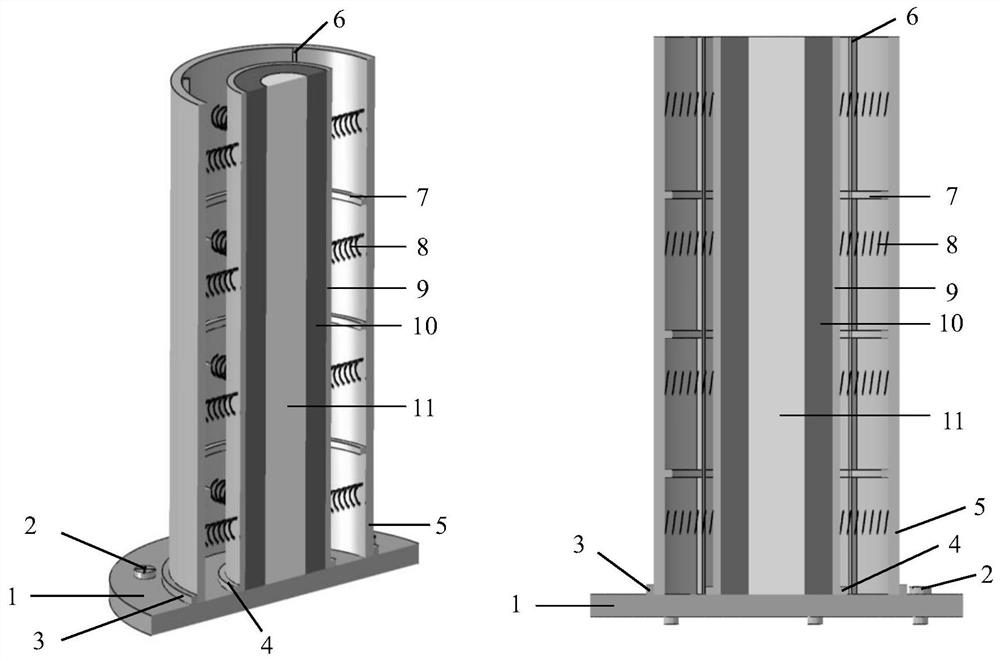

Double-tuned inertance system

ActiveCN109138567AIncreased bandwidthImprove energy absorptionProtective buildings/sheltersShock proofingFrequency bandEnergy infrastructure

The invention relates to a double-tuned inertance system in the civil engineering and energy infrastructure field. The system comprises a first-grade collision friction type tuning mass unit, a second-grade tuning mass unit, a liquid inertance damping unit and an installation unit. In the invention, a double damping tuning mechanism is established to adjust a system frequency and carry out dampingcontrol, and the frequency bandwidth of the effective damping control of the damping system is increased. The two grade tuning mass units and the liquid inertance unit are used to store energy. The nonlinear collision of a collision friction block and a liquid inertance damping dissipation structure are used to vibrate energy. Based on the quality synergy effect of the liquid inertance unit, additional mass required for the first-grade collision friction type tuning mass unit is greatly reduced, and a light-weight tuning damping device is provided. In addition, the inertance unit effectivelycontrols the deformation of the entire first-grade collision friction type tuning mass unit, the installation space of the device is saved, the efficiency of the internal damping energy consumption of collision friction block damping is improved, and the system has a wide application prospect.

Owner:TONGJI UNIV

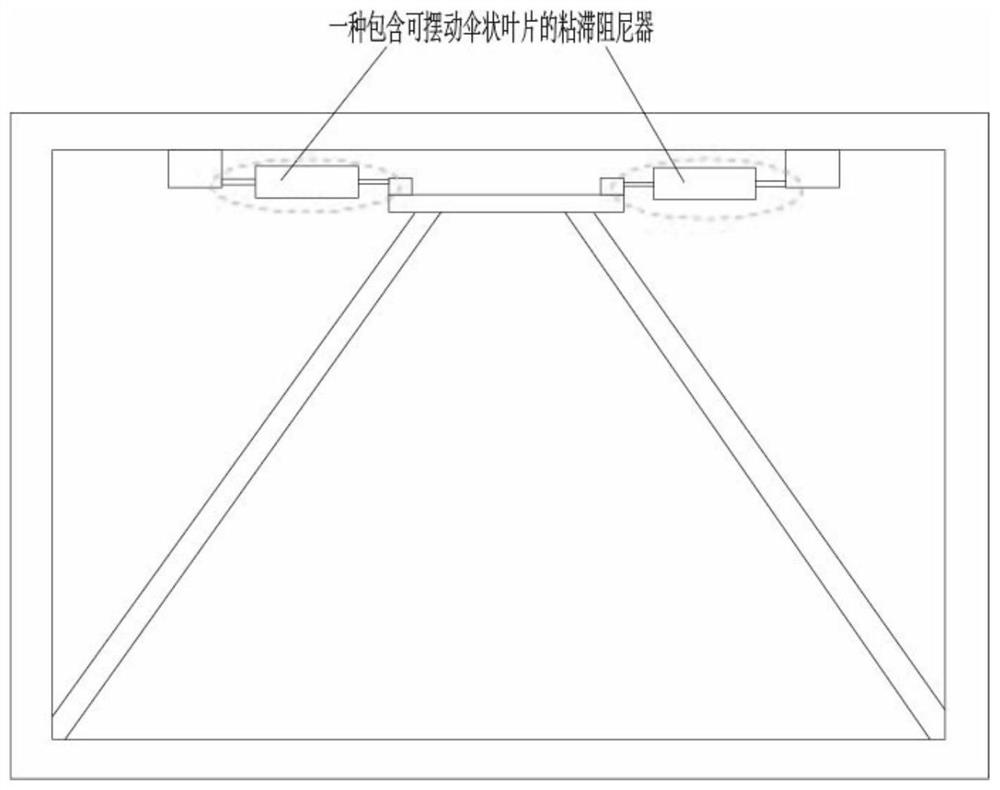

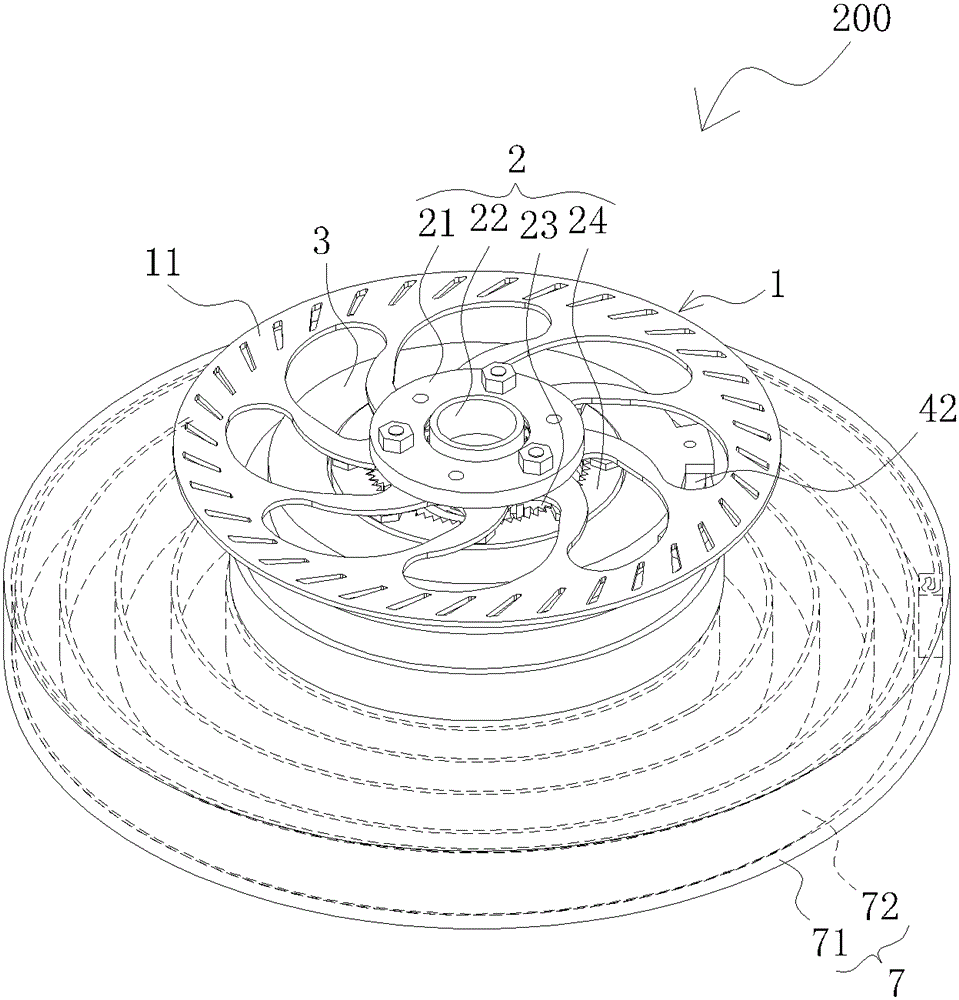

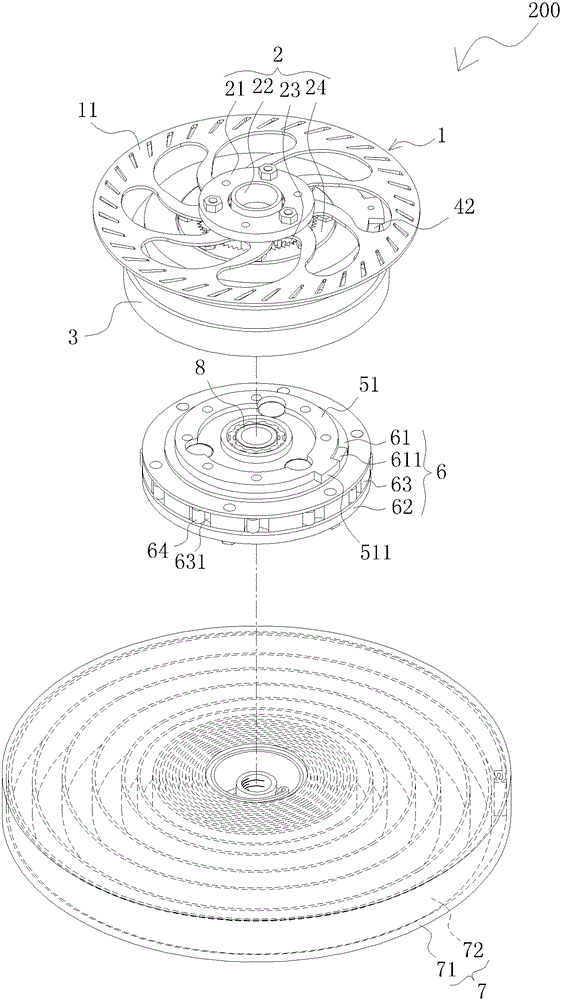

Viscous damper comprising swingable umbrella type blades

PendingCN112267592AAchieving shock absorption and energy dissipation capacityStable shock absorption and energy dissipation capacityProtective buildings/sheltersShock proofingBlade plateVibration control

The invention provides a viscous damper comprising swingable umbrella type blades, the viscous damper is mainly applied to vibration control of building structures, and belongs to the technical fieldof structural vibration control. The viscous damper comprises a damping cylinder body, a cover plate, a dowel bar, a supporting rod fixing device, a supporting rod, a square blade plate, damping liquid, a hinge device A, a hinge device B, a hinge device C, a blade plate fixing device and a connecting device. When an external structure connected with the damper vibrates, the dowel bar is driven tomove axially, due to the fact that the supporting rod fixing device is fixed to the cover plate and the blade plate fixing device is fixed to the dowel bar, the dowel bar drives the blade plate fixingdevice to move together, and then the square blade plate paddles in the damping liquid under the action of the supporting rod, so that vibration reduction and energy dissipation are achieved throughcounter-acting force given by the damping liquid in the paddling process. The viscous damper is novel and clear in structure and is a safe and efficient damper.

Owner:DALIAN UNIV OF TECH

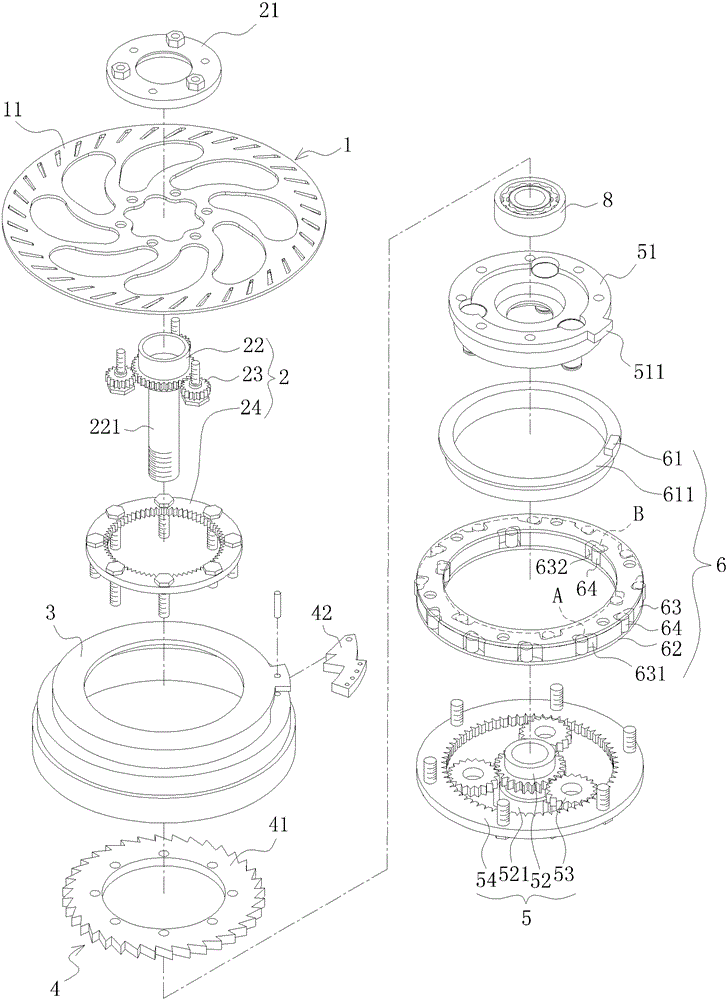

accumulator

The invention aims at providing an energy accumulator which can store originally useless kinetic energy and convert the kinetic energy into auxiliary power. The energy accumulator comprises a braking part, a first planetary gear group, a gearbox, a ratchet device, a second planetary gear group, a compound ratchet and an energy accumulation part. The compound ratchet is composed of a sliding ring, a locating piece and a main ring. The external diameter of the main ring is smaller than the internal diameter of the corresponding position of an accommodating space, the internal diameter of the main ring is larger than the external diameter of the sliding ring, a plurality of outer grooves are annularly arranged at the position of the ring edge of the outer side of the main ring, and a plurality of inner grooves are also annularly arranged at the position of the ring edge of the inner side of the main ring. The outer grooves and the inner grooves are oppositely arranged, the higher side ends of and the lower side ends of both a first inclined plane and a second inclined plane are same in direction, and rolling columns capable of rolling in the outer grooves and the inner grooves are respectively movably embedded in the outer grooves and the inner grooves. In addition, a one-way bearing is further arranged at the joint of a first sun gear and a second planet carrier.

Owner:游大庆

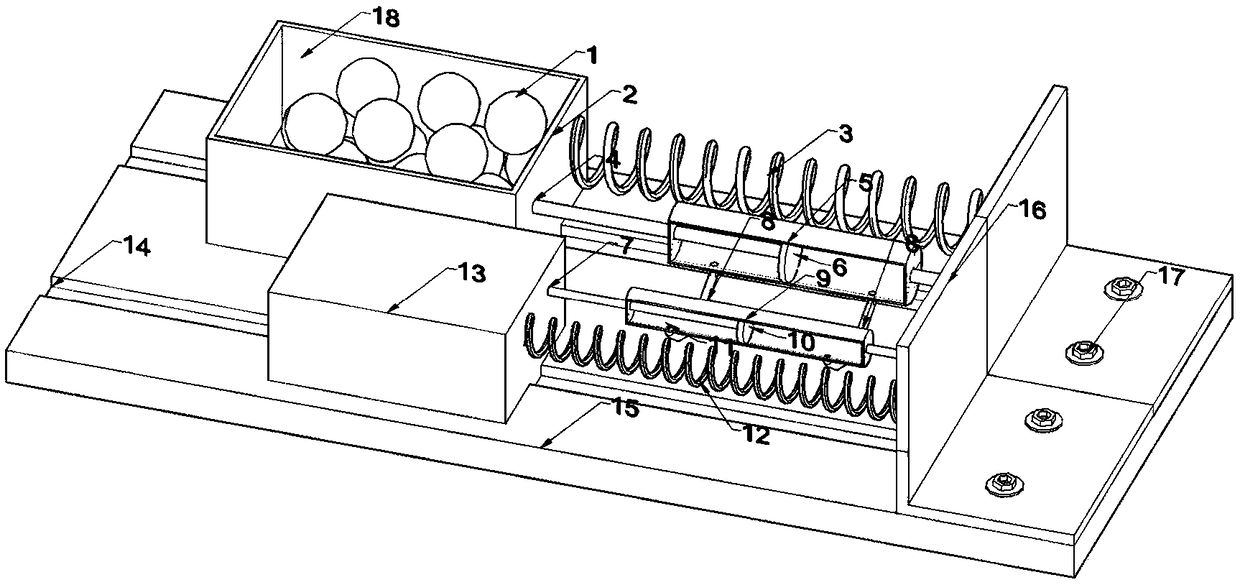

Assembly, energy consumption and self-resetting method for shape memory alloy spring buckling restrained brace

ActiveCN109296103AEasy to moveImprove energy consumptionProtective buildings/sheltersShock proofingBuckling-restrained braceShape-memory alloy

The invention discloses an assembly, energy consumption andself-resetting method for a shape memory alloy spring buckling restrained brace, and belongs to the field of construction damping. In order to solve the problems that an inner core has low bracing capacity in an earthquake due to the fact thatan existing brace mainly relies on inner core deformation to consume energy, the replacing and maintaining cost of the brace is high, and the brace has no self-resetting capacity. A plurality of shape memory alloy springs are connected to the outer peripheries of round steel pipes in a coating mode, and thetwo round steel pipes and an upper steel plate are fixedly connected by vertical steel strips; and two first steel blocks are clamped at the positions, on the end portions of the two shape memory alloy springs,on the round steel pipes correspondingly, second steel blocks of cross-shaped long steel strip concave groove inner cores are clampedat the positions,between the two shape memory alloy springs, on the round steel pipes correspondingly,and a steel plate set is connected with the upper steel plate by bolts. The assembly, energy consumption andself-resetting method for the shape memory alloy spring buckling restrained braceis of an assembly type, most parts are connected by bolts, disassembly is convenient and rapid, and routine maintenance and renovation after the earthquakeare easy.

Owner:DALIAN UNIV

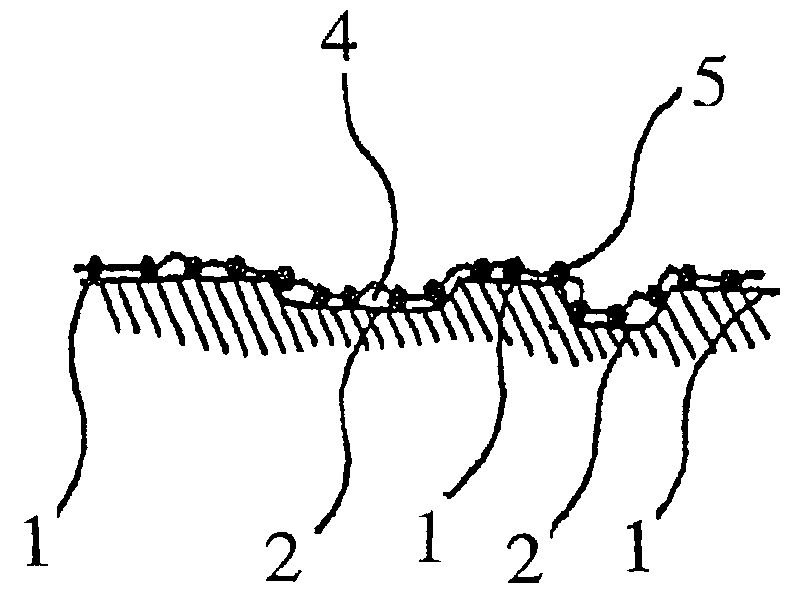

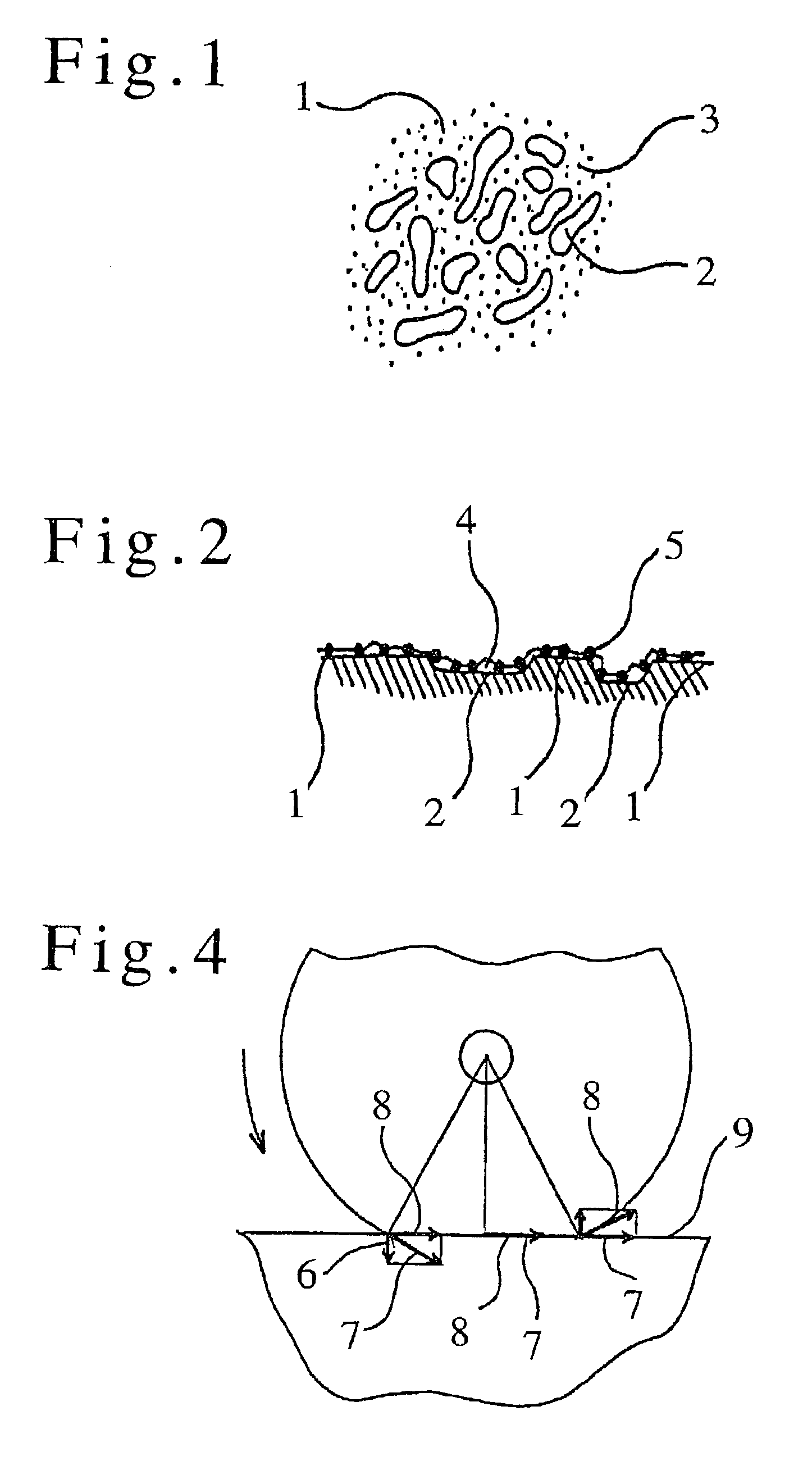

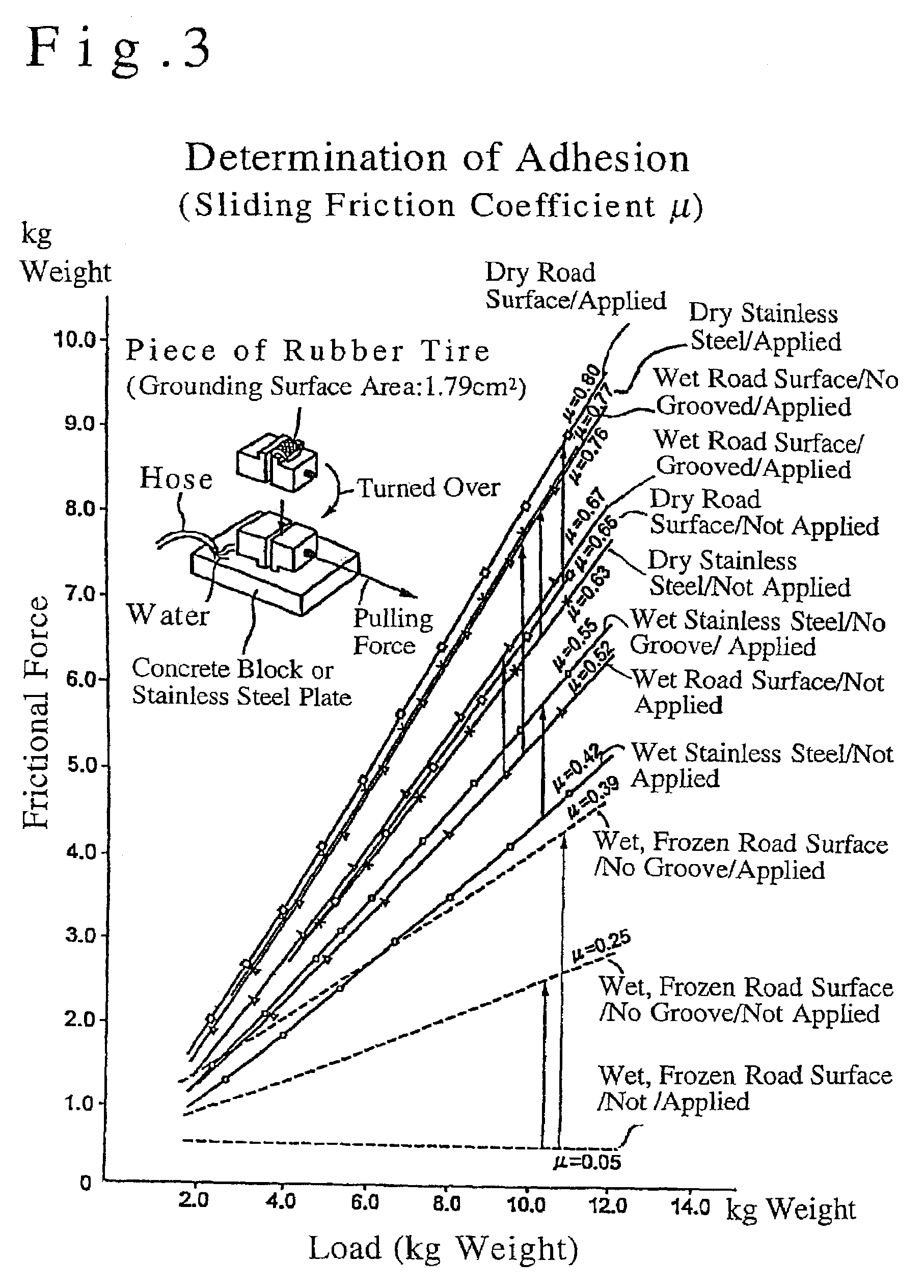

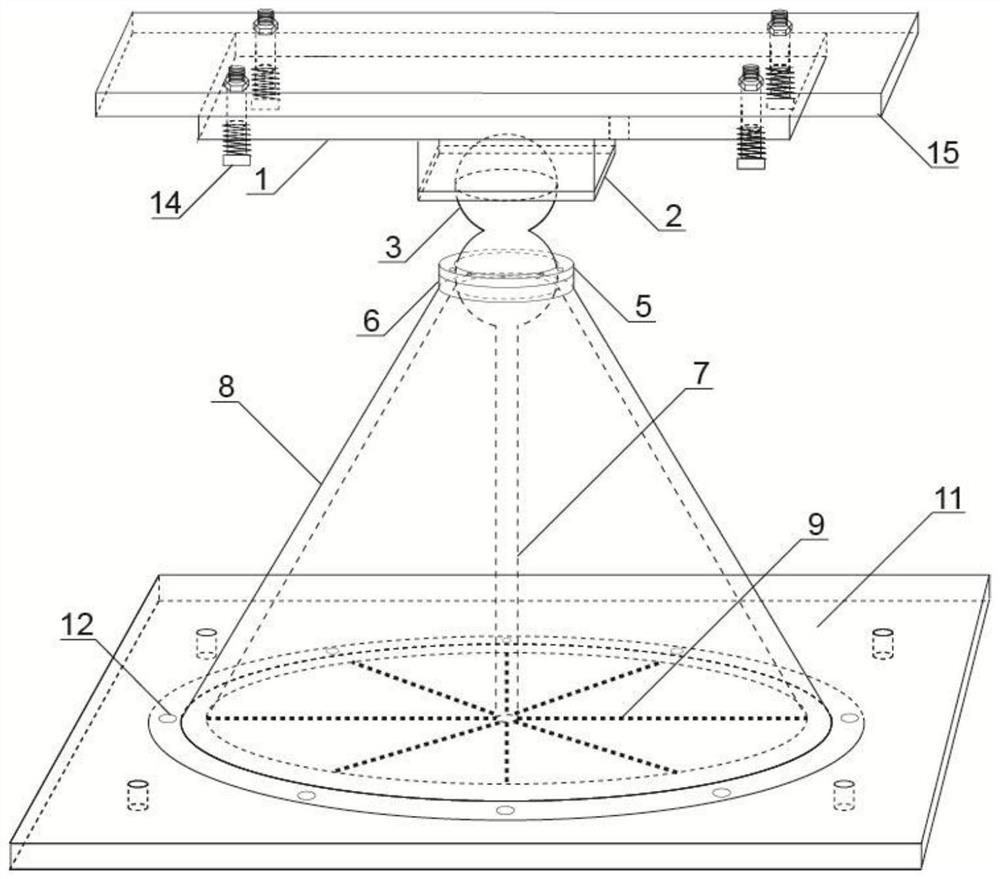

Energy consumption efficiency improving agent and method, and article having improved energy consumption efficiency

InactiveUS7398807B2High energy consumption efficiencyEfficient energy consumptionSolesOther chemical processesEngineeringEnergy expenditure

An energy consumption efficiency improving agent is disclosed which forms a substance having a large adherability to an applying object and a high adherence to a contacting object and greatly reduces energy loss, and attains improvement of an energy consumption efficiency substantially equal to three powers of adhesion improving rate under ordinary use conditions.

Owner:COSMOS CHEM

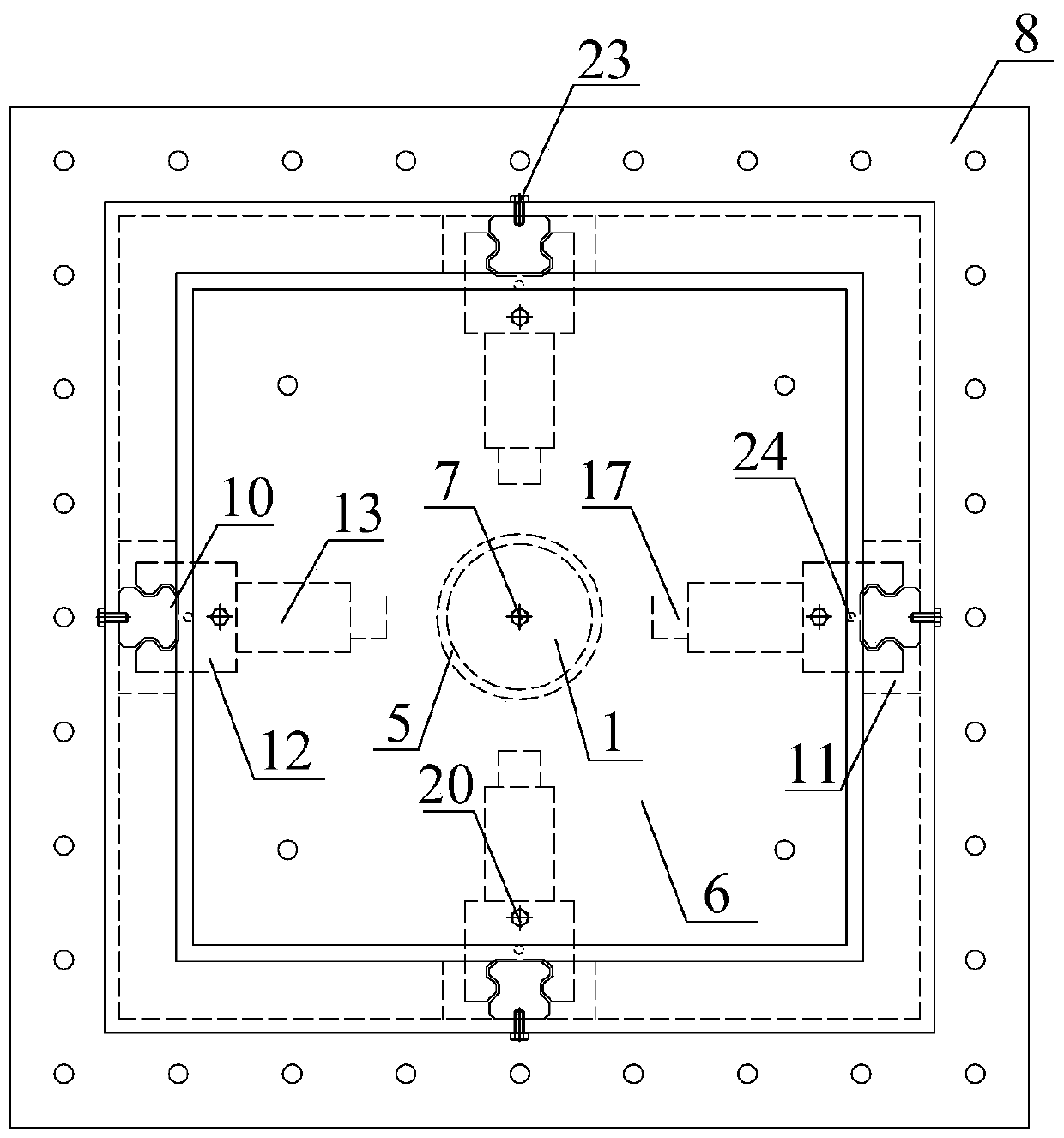

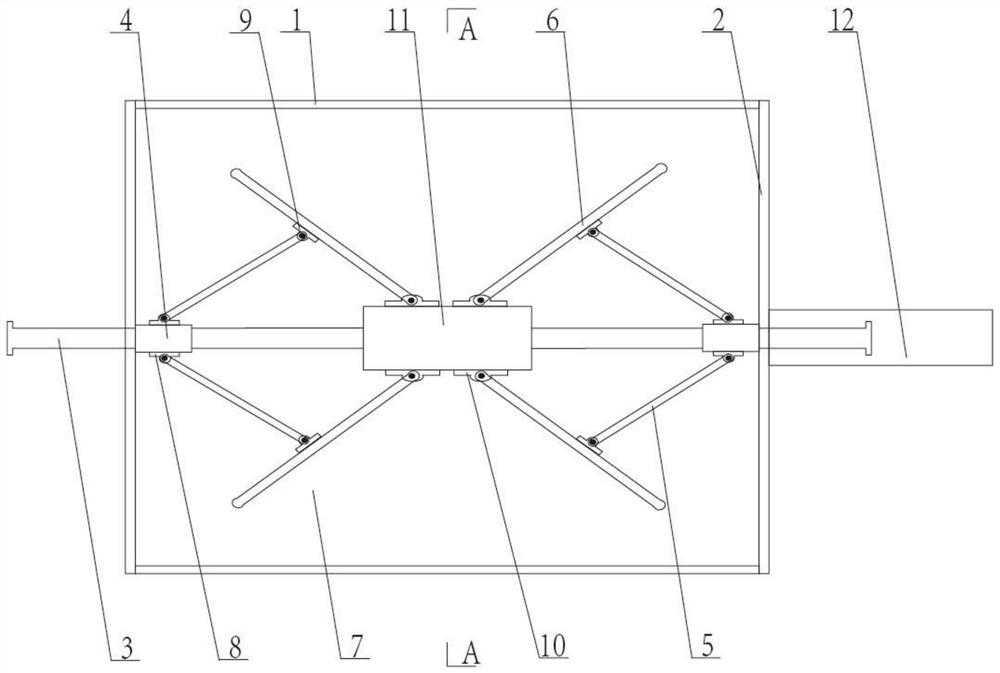

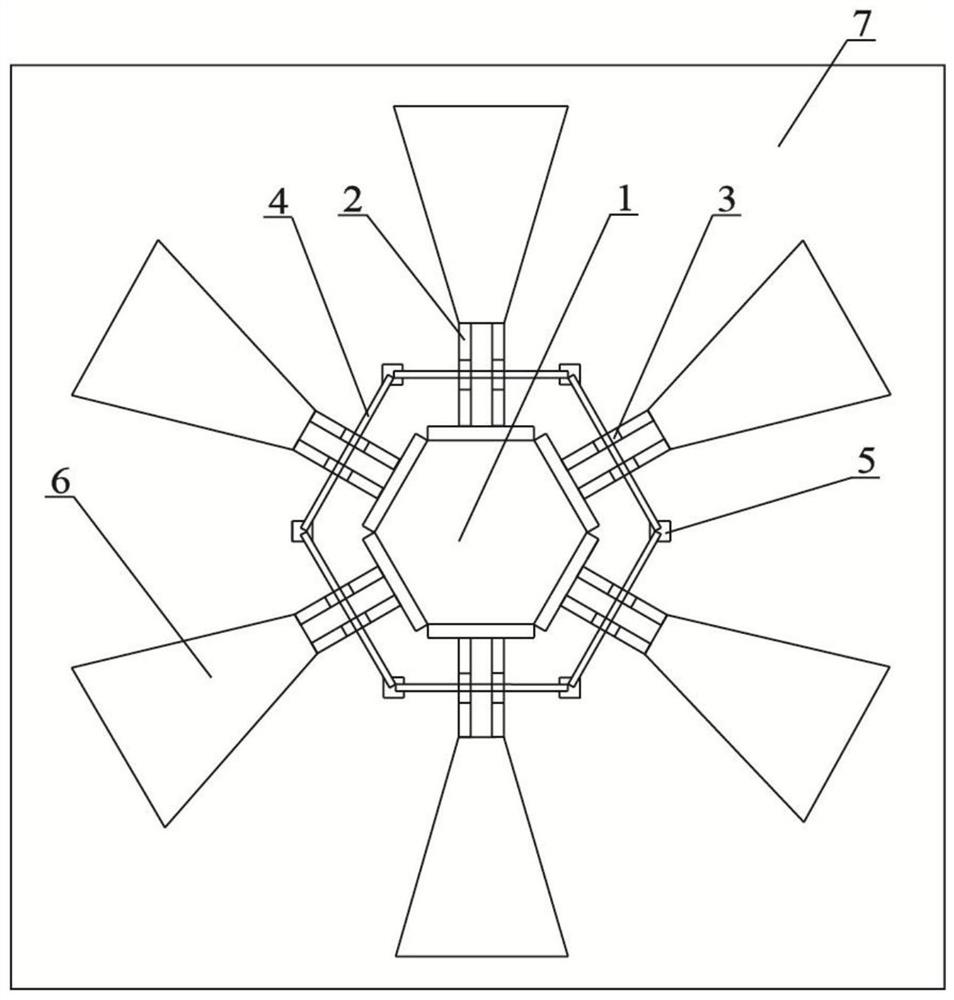

Horizontal omnidirectional displacement amplification type SMA energy dissipation and seismic mitigation device

PendingCN112301879AHas rotational symmetryReduced seismic responseBridge structural detailsProtective buildings/sheltersRelative displacementClassical mechanics

The invention provides a horizontal omnidirectional displacement amplification type SMA energy dissipation and seismic mitigation device, and belongs to the technical field of structural vibration control. The device is composed of a top plate, a spherical ring, a gourd-shaped rotating ball body, a high-strength bolt, a lever arm, a hollow circular truncated cone, an SMA stranded wire, a U-shapedlocking ring, a bottom plate, a fastening clamp, a spring bolt and the like. According to the device, through the omnidirectional rotation capacity of the gourd-shaped rotating ball body, the device can still utilize hysteretic deformation of the SMA stranded wire to consume energy under the effect of random and unpredictable multidirectional earthquake, and therefore 360-degree omnidirectional effective damping is provided. Meanwhile, the device amplifies the relative displacement of a pier beam of a bridge structure through a lever spherical hinge rotating mechanism, so that the displacement, speed and other responses of the series energy dissipation material are amplified, and the device can play a good energy dissipation role under the effect of large, medium and small earthquakes. Thedevice is clear in structure and high in applicability, and is a safe and efficient energy dissipation and seismic mitigation device.

Owner:DALIAN UNIV OF TECH

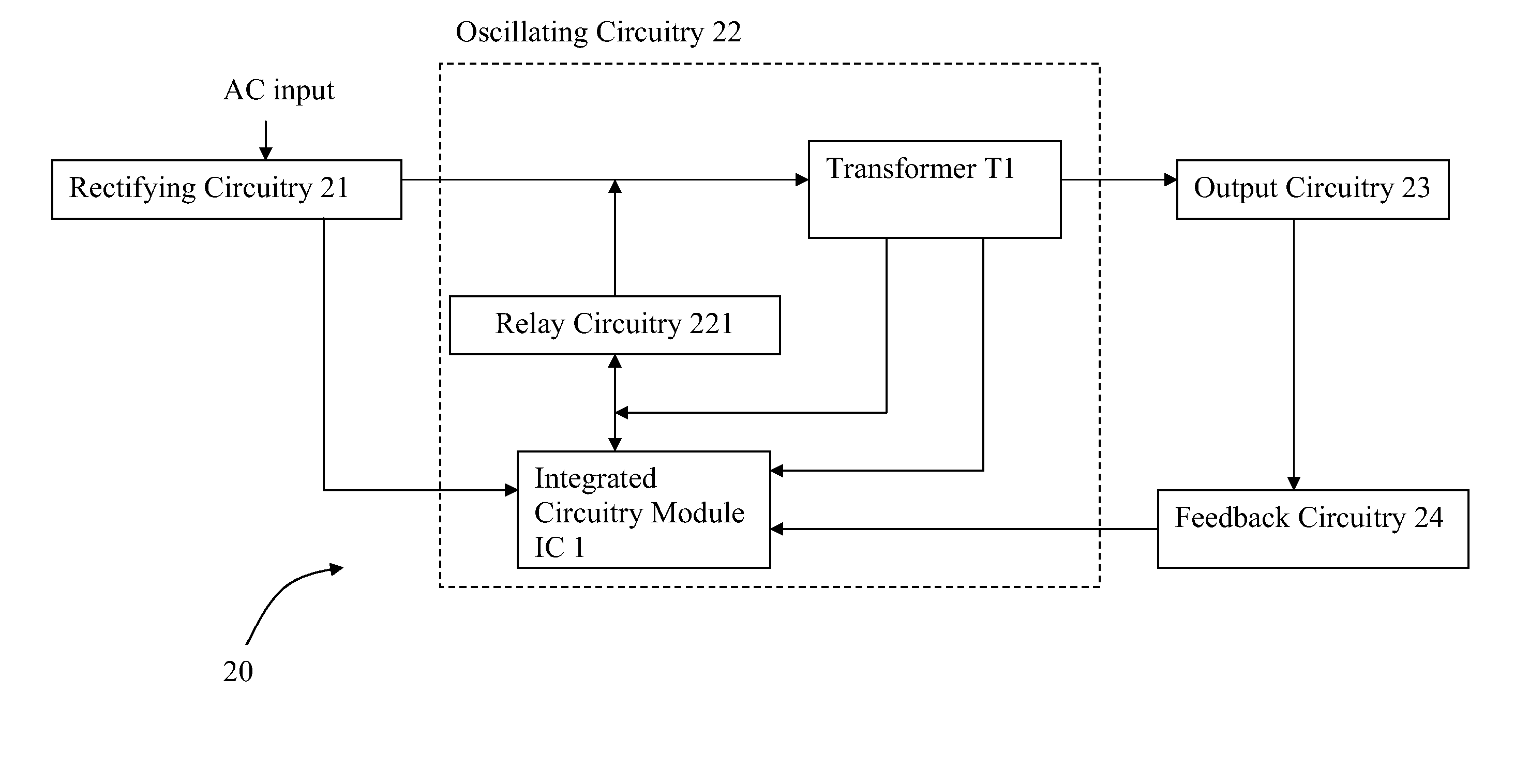

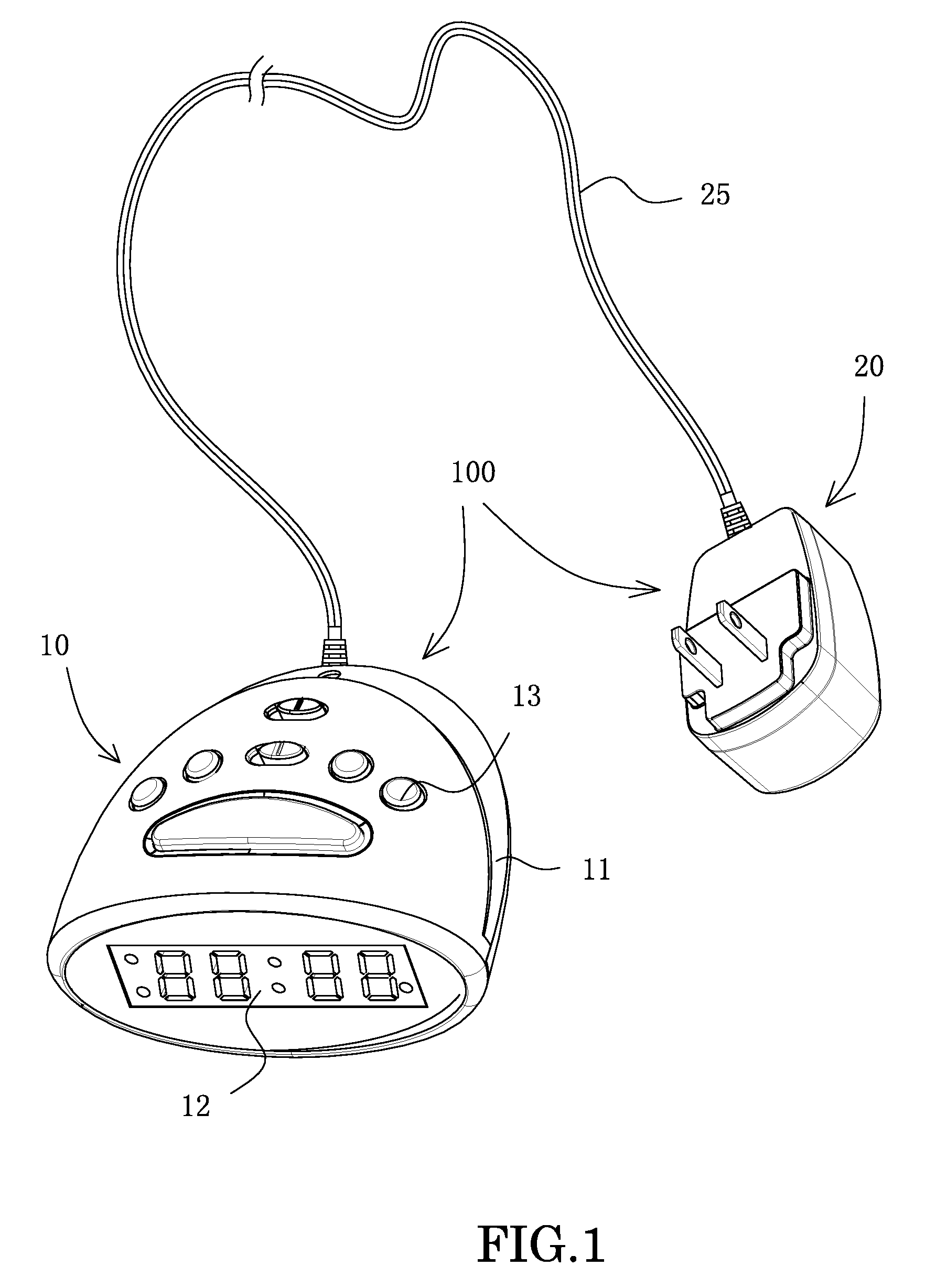

Energy Saving Digital Timepiece

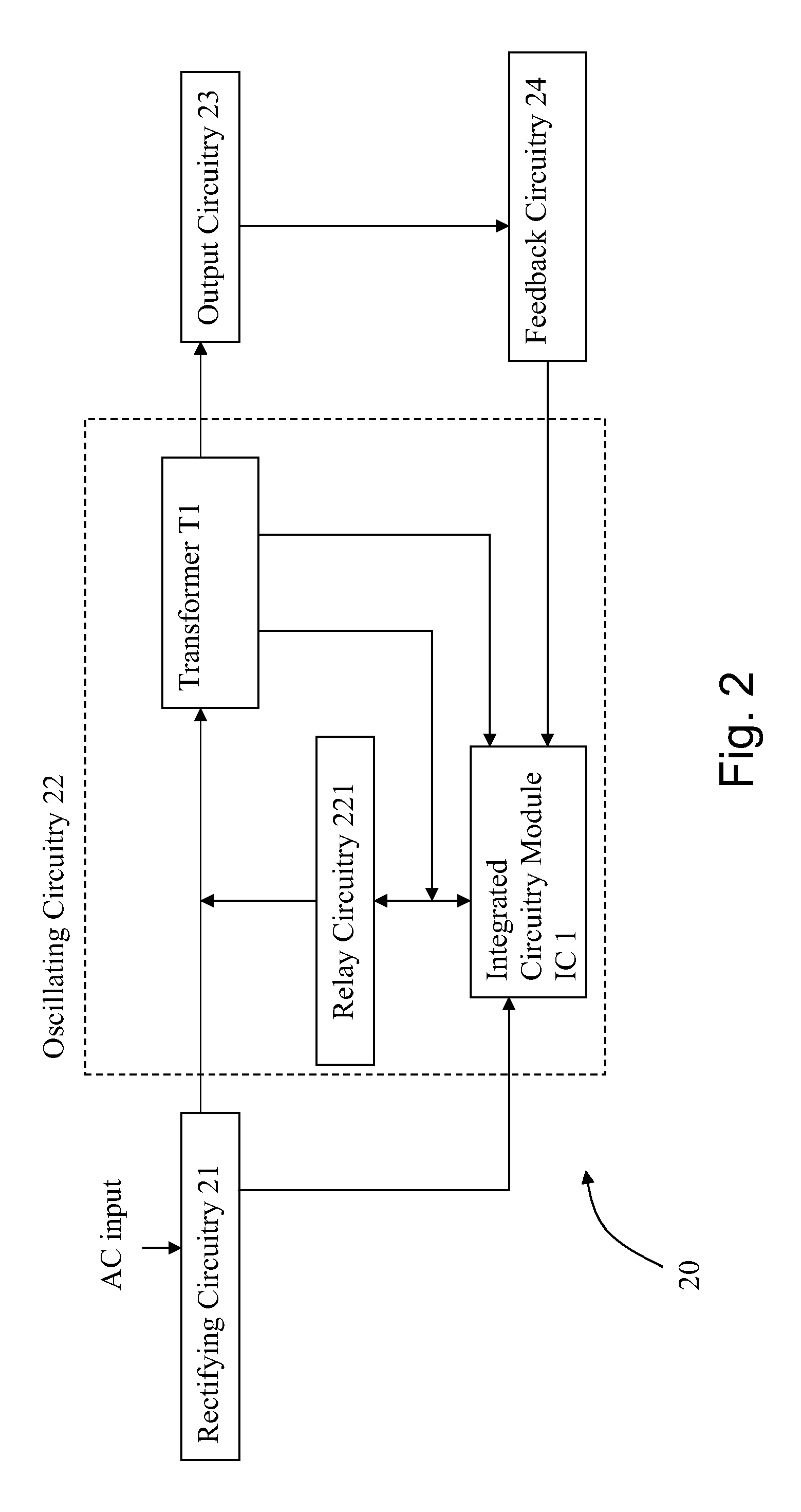

InactiveUS20110051563A1Efficient energy consumptionEnergy efficiencyElectric indicationSynchronous motors for clocksAC powerCurrent time

A timepiece includes a casing, a display, a timepiece core unit, and a current processing circuitry. The current processing circuitry includes a rectifying circuitry, an oscillating circuitry, and an output circuitry. The rectifying circuitry is adapted for electrically connected with an AC power source, and arranged to rectify the AC. The oscillating circuitry is electrically connected with the rectifying circuitry, and is arranged to transform the DC outputted from the rectifying circuitry back into AC having a predetermined voltage and a frequency. The output circuitry is electrically connected with the oscillating circuitry, and is arranged to rectifying the AC output from the oscillating circuitry into a DC pulses output, wherein the DC output from the output circuitry is electrically transmitted to the timepiece circuitry for triggering an operation thereof so as to allow the signal generator to generate accurate time signal to display the current time by the display.

Owner:SHENZHEN GREAT POWER INNOVATION & TECH ENTERPRISE CO LTD

Shear type damping wall with reverse displacement amplification

PendingCN112780002ASimple structureImprove energy consumptionProtective buildings/sheltersShock proofingRelative displacementClassical mechanics

The invention provides a shear type damping wall with reverse displacement amplification. The shear type damping wall comprises an upper connecting plate, at least one displacement amplification mechanism and a lower connecting plate, wherein the upper connecting plate is arranged on an upper floor beam, and at least two fixed shear plates are arranged on the lower surface of the upper connecting plate; and the displacement amplification mechanisms are arranged in a damper outer steel box, each displacement amplification mechanism is located between the two fixed shear plates, the upper ends of the displacement amplification mechanisms are hinged to the upper ends of the fixed shear plates through first rotating shafts, and the damper outer steel box is filled with shear energy dissipation materials. The shear type damping wall with reverse displacement amplification is simple in structure, when the upper floor beam moves horizontally, interlayer displacement acts on reverse shear plates through displacement amplification levers, the reverse shear plates and the fixed shear plates move reversely to shear the shear energy dissipation materials in the damper outer steel box, so that the relative displacement and speed of the damping wall are increased, and the energy consumption of the damping wall is improved.

Owner:SHANGHAI UNIV

Inertia-type shock-absorbing layer system

ActiveCN109267810BAvoid destructionReduce internal force mutationProtective buildings/sheltersExtraordinary structuresEnergy infrastructureViscous damping

The invention relates to an inertial type shock-absorbing layer system used in the fields of civil engineering and energy infrastructure, which comprises an upper truss and a lower truss, an anti-buckling restrained brace energy consumption unit and a friction limit type viscous inertial system. The system provides the basic rigidity of the shock-absorbing layer through the upper truss group and the lower truss group, and limits the sliding of a lead screw through the friction limit unit of the inertial system under the action of wind load and small earthquake. When the external loading actionis enhanced, by relaxing the restraint with the friction limit unit of the inertial system, the energy of the shock-absorbing layer is dissipated by utilizing the friction damping, the viscous damping and an anti-buckling restrained brace hysteresis unit. The shock-absorbing layer establishes a systematically complete energy consumption path and a two-stage rigidity adjusting mechanism. The designed anti-buckling restrained brace meets the energy consumption requirement of the multi-stage support. The friction limit type viscous inertial system improves the energy consumption efficiency of the shock-absorbing layer. The inertial type shock-absorbing layer system is convenient and flexible, can effectively absorb and dissipate earthquake energy, has the advantages of high energy consumption efficiency, strong robustness, easy repair after earthquake and the like, and has good popularization and application value.

Owner:TONGJI UNIV

Double tuned inertial system

ActiveCN109138567BIncreased bandwidthImprove energy absorptionProtective buildings/sheltersShock proofingEnergy infrastructureEngineering

The invention relates to a double-tuned inertance system in the civil engineering and energy infrastructure field. The system comprises a first-grade collision friction type tuning mass unit, a second-grade tuning mass unit, a liquid inertance damping unit and an installation unit. In the invention, a double damping tuning mechanism is established to adjust a system frequency and carry out dampingcontrol, and the frequency bandwidth of the effective damping control of the damping system is increased. The two grade tuning mass units and the liquid inertance unit are used to store energy. The nonlinear collision of a collision friction block and a liquid inertance damping dissipation structure are used to vibrate energy. Based on the quality synergy effect of the liquid inertance unit, additional mass required for the first-grade collision friction type tuning mass unit is greatly reduced, and a light-weight tuning damping device is provided. In addition, the inertance unit effectivelycontrols the deformation of the entire first-grade collision friction type tuning mass unit, the installation space of the device is saved, the efficiency of the internal damping energy consumption of collision friction block damping is improved, and the system has a wide application prospect.

Owner:TONGJI UNIV

A three-dimensional vibration isolation device with sliding inclined spring

ActiveCN111305632BEasy to assembleEfficient energy consumptionProtective buildings/sheltersShock absorbersVertical vibrationStiffness coefficient

The invention discloses a three-dimensional shock isolation / vibration device with a sliding inclined spring, which is composed of horizontal and vertical shock isolation / vibration units connected in series up and down. The horizontal vibration isolation / vibration unit is a thin laminated rubber bearing with a large first shape factor, which contains a high-purity lead core energy dissipation unit; the vertical vibration isolation / vibration unit is supported by a thick laminated rubber bearing with a small first shape factor. The seat and the oblique rectangular compression spring connected to the vertical heavy-duty linear guide rail are connected in parallel. Through the elastic deformation of the low-hardness high-damping rubber and the linear guide rail-linked oblique rectangular spring tension-compression deformation, the vertical shock / vibration can be isolated together, and it can also be changed. The first shape coefficient of the thick laminated rubber bearing and the stiffness coefficient of the rectangular spring reduce vertical vibrations of different frequencies and amplitudes and realize three-dimensional vibration isolation / vibration. The invention belongs to a passive shock / vibration control means, which can be widely used in the shock-isolation layer of the upper cover structure of urban rail transit and the bottom of important large and medium-sized mechanical equipment.

Owner:TONGJI UNIV

Transverse Damping Device Applicable to Long-span Bridges

ActiveCN104313998BStrong designabilityMeet serialization needsBridge structural detailsBridge materialsSheet steelEngineering

Owner:NANJING TECH UNIV

Negative Stiffness Adaptive Energy Storage Shock Resistant Column

ActiveCN112554096BImprove energy consumptionIncreased Dissipated Impact EnergyRoadway safety arrangementsEngineeringNegative stiffness

Owner:ROCKET FORCE UNIV OF ENG

Shear wall system with hysteretic inertia

ActiveCN109267675BControl deformationImprove seismic performanceWallsProtective buildings/sheltersEnergy infrastructureVibration control

The invention belongs to the field of civil engineering and energy infrastructure and provides a shear wall system with a hysteretic inerter, comprising a shear wall structure, a hysteretic inerter structure, and a mounting base. The hysteretic inerter structure includes a plurality of groups of hysteretic energy-dissipating support units and a plurality of groups of viscous self-resetting inerterunits. A double self-resetting mechanism and a multiple energy-absorbing energy-dissipating means are established; structural vibrational energy is absorbed and dissipated via hysteretic shear platesand the viscous inerter units; rotational effect of a rocking shear wall helps decrease horizontal action that a rocking device bears; the inerter units enable system inertial characteristics to be effectively adjusted and overall deformation of the shear wall to be effectively controlled at the premise of not improving deformation rigidity of the shear wall; a rocking shear wall vibration-damping energy-dissipating system suitable for effective structural multimodal vibration control is provided; multiple aseismic lines are provided; the shear wall system herein has the advantages of energy-dissipating synergy, good robustness, good convenience of post-quake restoration and the like, and is well worthy of popularization and application.

Owner:TONGJI UNIV

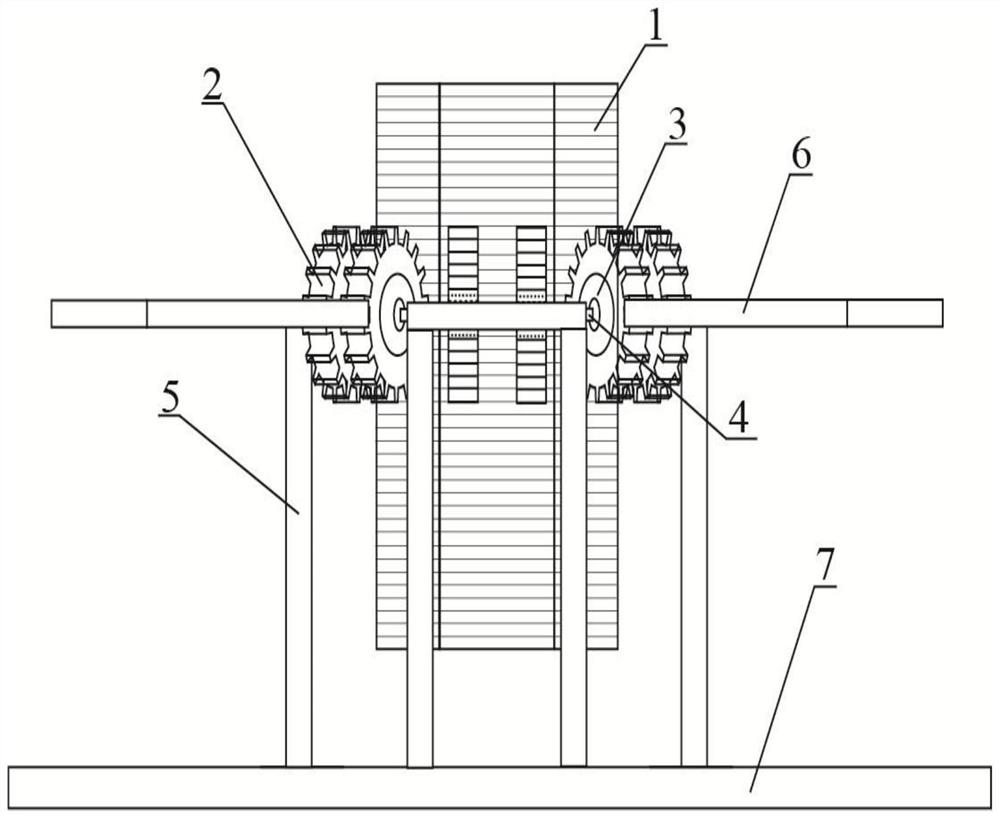

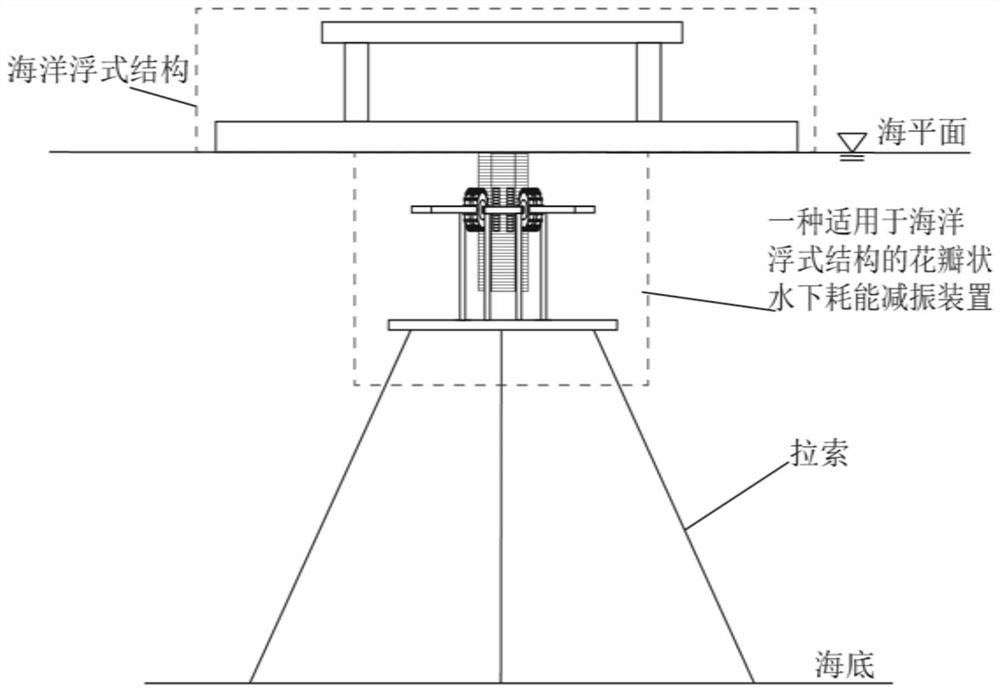

Petal-shaped underwater energy dissipation and vibration reduction device suitable for ocean floating structure

PendingCN112519970AFlexible energy consumptionEfficient energy consumptionNon-rotating vibration suppressionFloating buildingsBall (bearing)Engineering

The invention provides a petal-shaped underwater energy dissipation and vibration reduction device suitable for an ocean floating structure, and belongs to the technical field of structural vibrationcontrol. The energy dissipation and vibration reduction device comprises a rack rod, a gear, a ball bearing, a rod shaft, a stand column, a blade plate and a bottom floating plate. A rack rod of the device is connected to an upper ocean floating structure, and when the structure vibrates up and down, the rack rod also axially moves along with the structure to drive gears arranged on the peripheryto rotate; due to the fact that each gear is connected with the corresponding blade plate, when the gears rotate, the blade plates distributed in the petal shape start to slide in water, the energy dissipation and vibration reduction effects are achieved through counter-acting force given by water, and vibration of an upper structure is reduced. Meanwhile, different energy consumption effects canbe achieved by adjusting the sizes of the gears and the areas of the blade plates, and then different working environments and design requirements are met. The underwater energy dissipation and vibration reduction device is novel in structure, safe and flexible, and is an efficient underwater energy dissipation and vibration reduction device.

Owner:DALIAN UNIV OF TECH

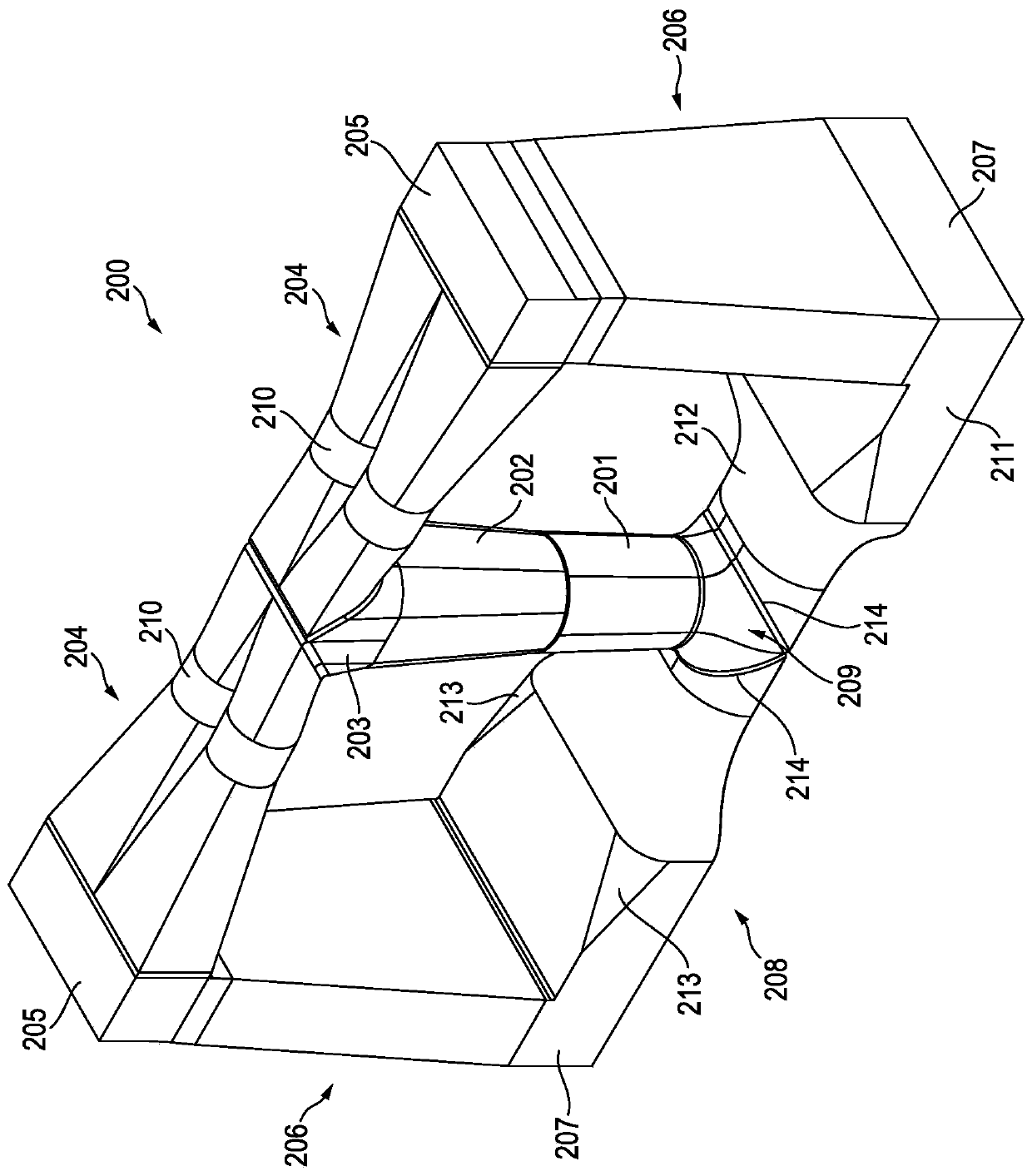

Recirculating vertical wind tunnel

PendingCN111196368AReduce operating costsShorten the vertical distanceAmusementsParachutes training apparatusEngineeringMechanics

A vertical wind tunnel for indoor skydiving has at least one recirculating airflow plenum. The airflow plenum includes a first vertical member housing a flight chamber, a top horizontal member, a second vertical member, and a bottom horizontal member. The bottom horizontal member has a first section and a second section. A corner section connects the second section of the bottom horizontal memberwith the first vertical member. The second section of the bottom horizontal member contracts the airflow travelling through the bottom horizontal member between the first section and its exit to the corner section. The corner section further contracts the airflow exiting the second section of the bottom horizontal member towards the first vertical member.

Owner:SKYVENTURE INTERNATIONAL (UK) LIMITED

A Modular Steel Tube Concrete Multidimensional Energy Dissipative Wall with Uniform Stress Distribution Under Earthquake

ActiveCN112982729BReduce wasteEasy constructionWallsProtective buildings/sheltersArchitectural engineeringBeam direction

Owner:BEIJING UNIV OF TECH

A prefabricated building beam-column joint structure and its construction method

ActiveCN112900626BGood transmission shearEfficient energy consumptionProtective buildings/sheltersBuilding material handlingArchitectural engineeringDamage repair

A prefabricated building beam-column joint structure and a construction method thereof relate to a beam-column joint and a construction method. Two to four steel beams are connected between the upper steel pipe column and the lower steel pipe column. Flat plates and flanges are respectively arranged at both ends of the joint connection seat. The two joint connection seats are respectively fixed on the lower end of the upper steel pipe column and the upper end of the lower steel pipe column. Two spherical positioning grooves are recessed on each side of the periphery, and two ball-joint lap rods are set at the steel beam connection end to be clamped between the corresponding spherical positioning grooves of the two flat plates. The edges of the two flat plates are connected and fixed by fastening bolts and nuts. The upper part of the beam is suspended and connected with the upper steel pipe column by a steel wire rope, and the energy-dissipating steel plate is diagonally braced between the lower part of the steel beam and the lower steel pipe column. A connection structure similar to a spherical hinge is adopted between the beams and columns, and the upper part is suspended by wire ropes, and the lower part is installed with energy-dissipating steel plates, which cooperate with each other to play an efficient energy-dissipating effect. The structure is stable and easy to assemble and repair damage.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com