Inertial-type shock-absorbing layer system

A shock-absorbing layer and inertial capacity technology, applied in the direction of earthquake resistance, building types, building components, etc., can solve the problems of structural shock resistance, change of force flow path, and uneven stiffness, so as to ensure the overall deformation and reduce the sudden change of internal force , amplify the effect of harmful deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions provided by the present invention will be further described below in conjunction with specific embodiments and accompanying drawings. The advantages and features of the present invention will become clearer in conjunction with the following description.

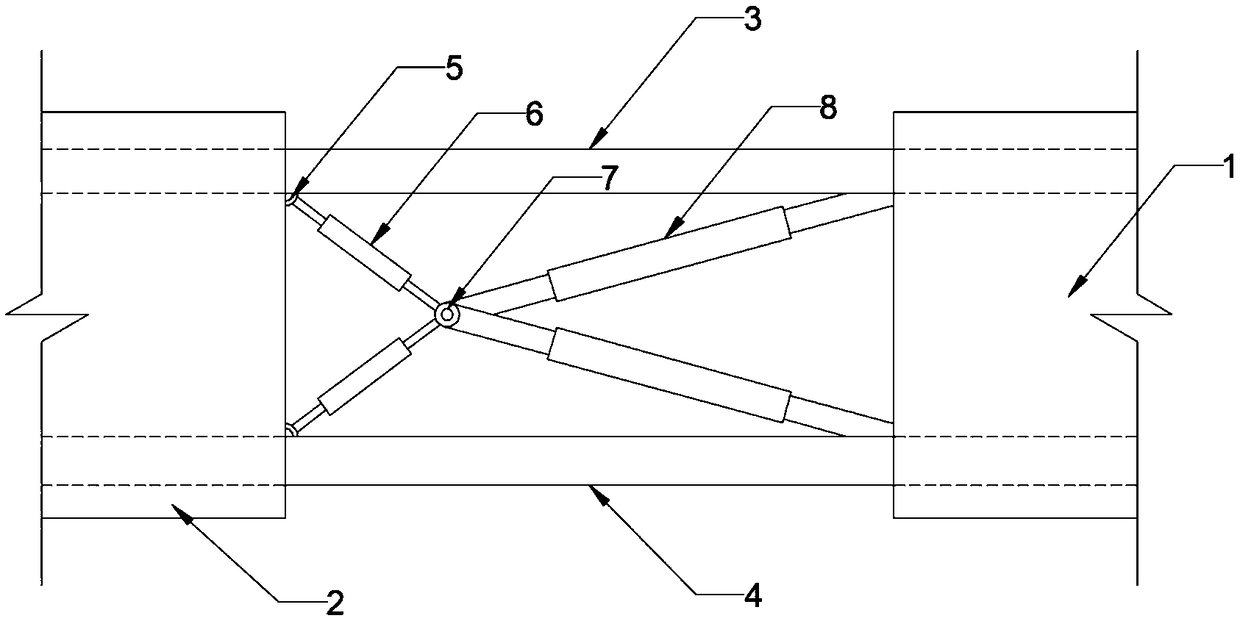

[0022] Such as figure 1 As shown, an inertial type shock-absorbing layer system includes a core tube 1, an outer frame structure 2, an upper truss group 3, a lower truss group 4, connecting earrings 5, a friction-limited viscous inertial system 6, and connecting rings 7. Anti-buckling restraint support 8; friction-limited viscous inertial system 6 is used to improve the energy dissipation efficiency of the shock-absorbing layer, and establish a multi-level stiffness change mechanism and energy dissipation mechanism of the shock-absorbing layer.

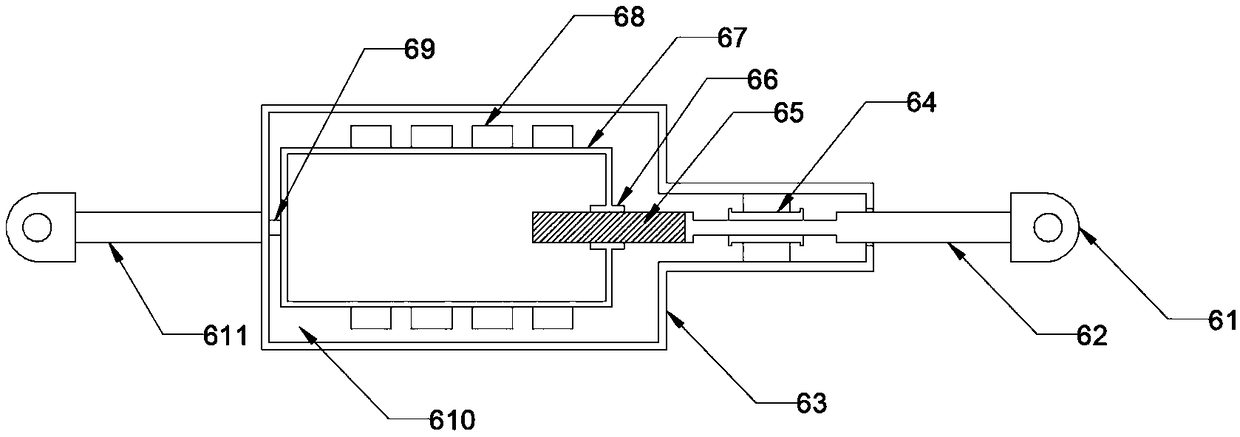

[0023] Such as figure 2 As shown, the friction-limited viscous inertia system 6 includes an inertia system earring 61, a ball screw 62, an inertia o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com