Bamboo-shaped round rod energy consumption rod

A technology of bamboo-shaped and energy-dissipating rods, which is applied in the direction of building components, building types, and earthquake resistance, can solve the difficulties in setting up dense concrete and unbonded materials, the bamboo-shaped buckling restraint support is prone to torsional deformation, and the hysteresis curve is not good. Symmetry and other issues, to achieve the effect of simple structure, small yield force, and improved low cycle fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

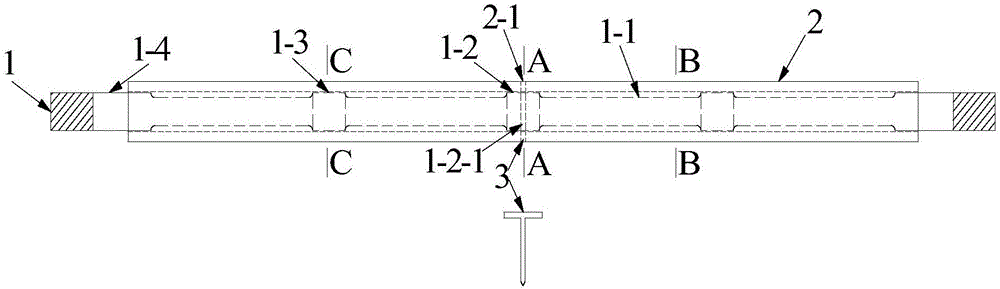

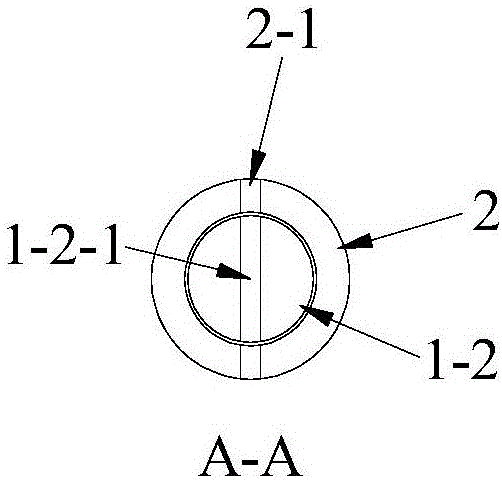

[0050] Such as Figure 1-9 Shown: a bamboo-shaped round rod energy-dissipating rod includes a core component 1, an outer constraint component 2 and a positioning pin 3;

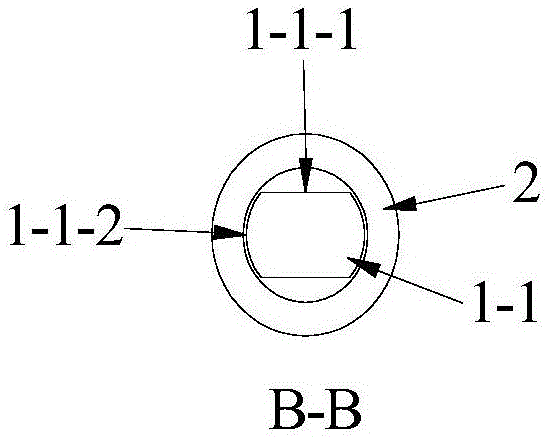

[0051] The core component 1 is composed of a plurality of energy dissipation sections 1-1, a middle limiting section 1-2, a bamboo section 1-3 and two end connecting sections 1-4 connected along a longitudinal coaxial line, and the middle limiting section 1 -2 is located in the middle of the core component 1, the bamboo section 1-3 is spaced apart from the energy dissipation section 1-1, arranged on both sides of the middle limiting section 1-2, and forms a whole with the middle limiting section 1-2 , the outer two ends are fixedly connected to the connecting sections 1-4 at both ends to jointly form the core component 1; the cross-sections of the middle limiting section 1-2, the bamboo section 1-3 and the connecting sections 1-4 at both ends are all circular , the middle of the middle limit section 1-2 has ...

Embodiment 2

[0056] Such as Figure 10-20 Shown: this embodiment is the same as the rest of embodiment 1, the difference is that the distance between the two parallel opposite sides 1-1-1 of the plurality of energy dissipation sections 1-1 of the core component 1 is changed from the distance between the two sides of the core component 1 tapering off toward the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com