High-torque drilling tool for unconventional hyper-tight rock stratums

A high-torque, compact technology, applied to drill bits, drilling equipment, directional drilling, etc., can solve problems such as insufficient drilling torque, avoid torsional deformation, and ensure drilling safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

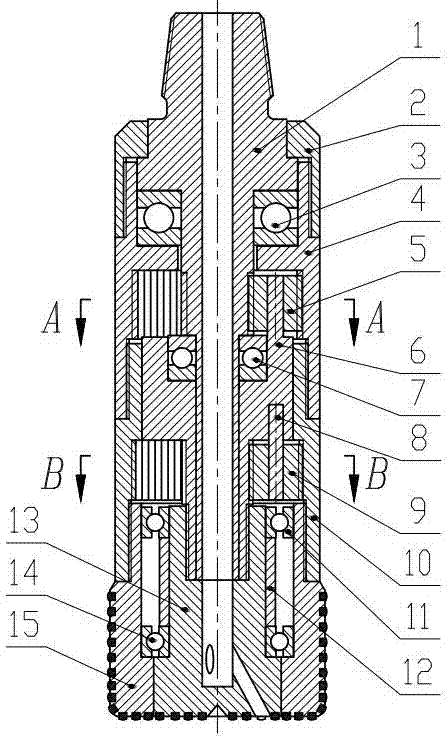

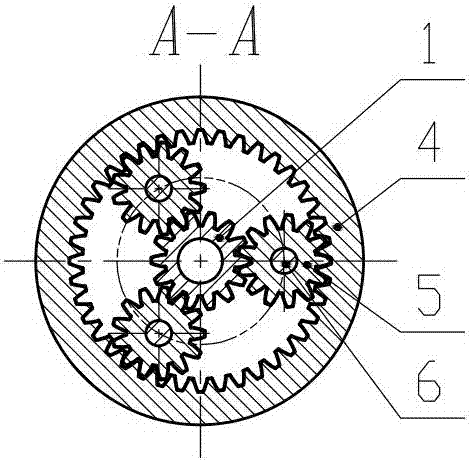

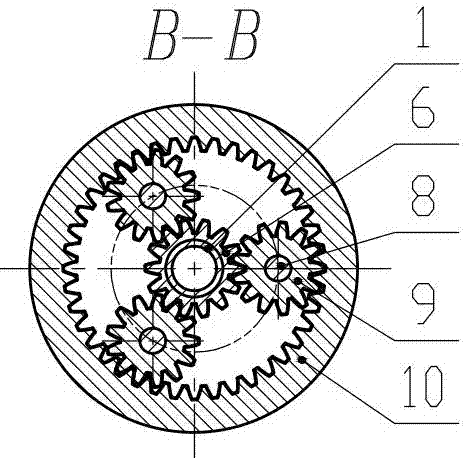

[0012] like figure 1 As shown, a high-torque drilling tool for unconventional ultra-dense rock formations of the present invention is composed of a power joint 1, an anti-drop end cover 2, an upper thrust bearing 3, a deceleration outer cylinder 4, a first-stage planetary wheel 5, and an output mandrel 6 , lower thrust bearing 7, pin shaft 8, secondary planetary wheel 9, output outer cylinder 10, upper radial bearing 11, axle sleeve 12, mandrel drill bit 13, lower radial bearing 14 and outer cylinder drill bit 15; its structure The characteristics are: the upper end of the power joint 1 is connected with the downhole power drilling tool with a screw thread; the inner cavity of the power joint 1 is set as a through hole, the upper part of the outer circle of the power joint 1 is set with a circle of steps, and the middle part of the outer circle of the power joint 1 is set as a gear shaft; The thrust bearing 3 is installed on the stepped surface of the upper part of the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com