Processing device and processing method of simulated groove in inner wall of conical water inlet pipe of water pump

A processing device and water inlet pipe technology, which is applied to metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve problems such as pipes that are not suitable for taper-shaped water pump inlet pipes, and achieve operation quality assurance, high precision, and scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

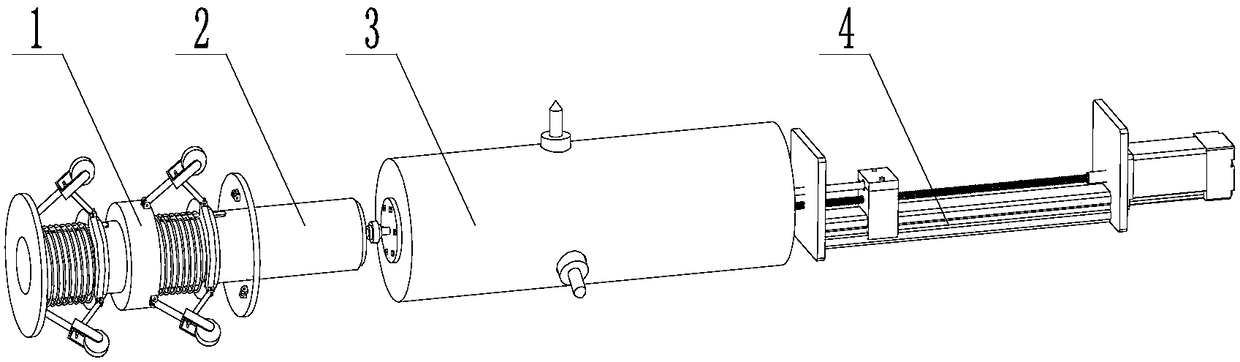

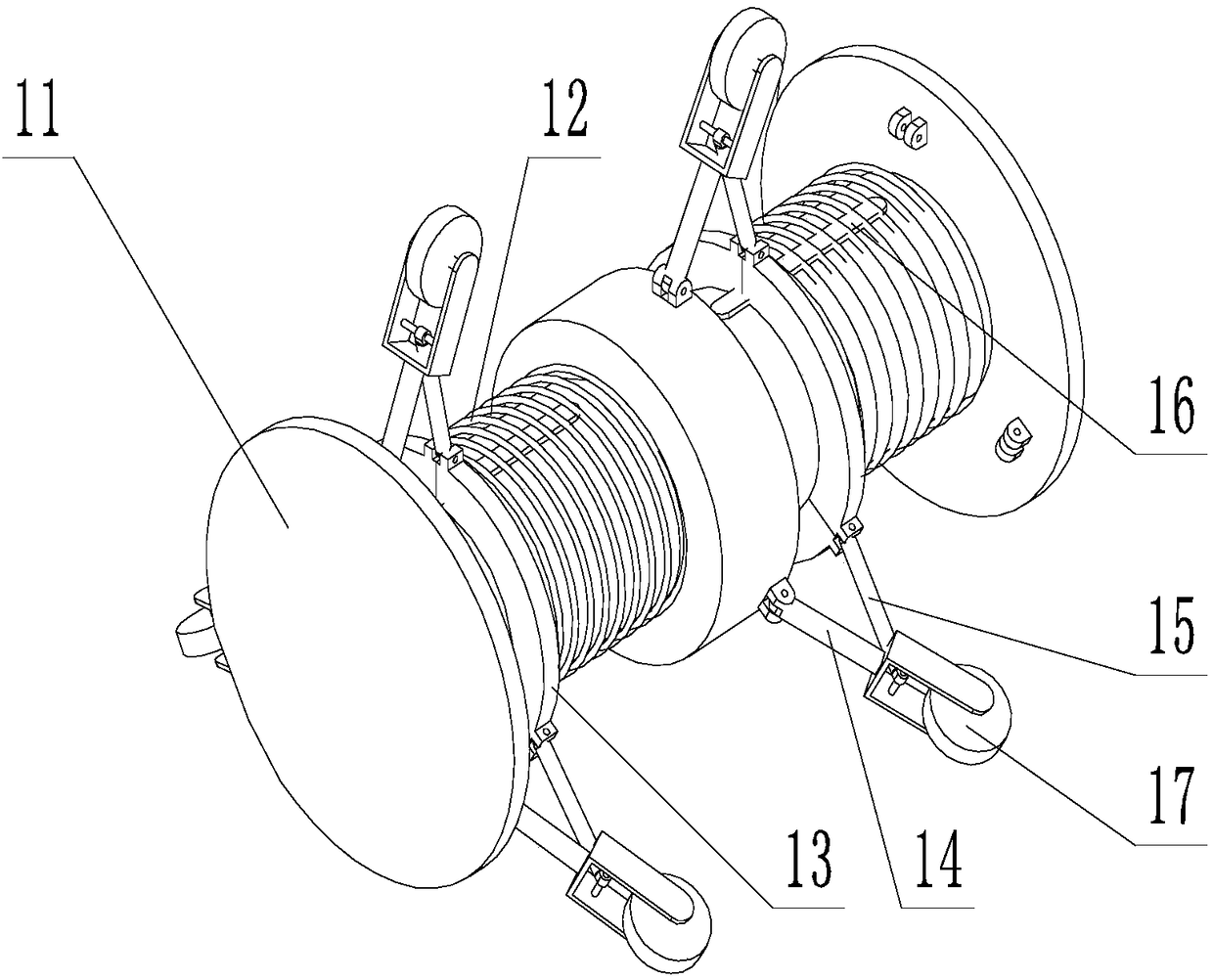

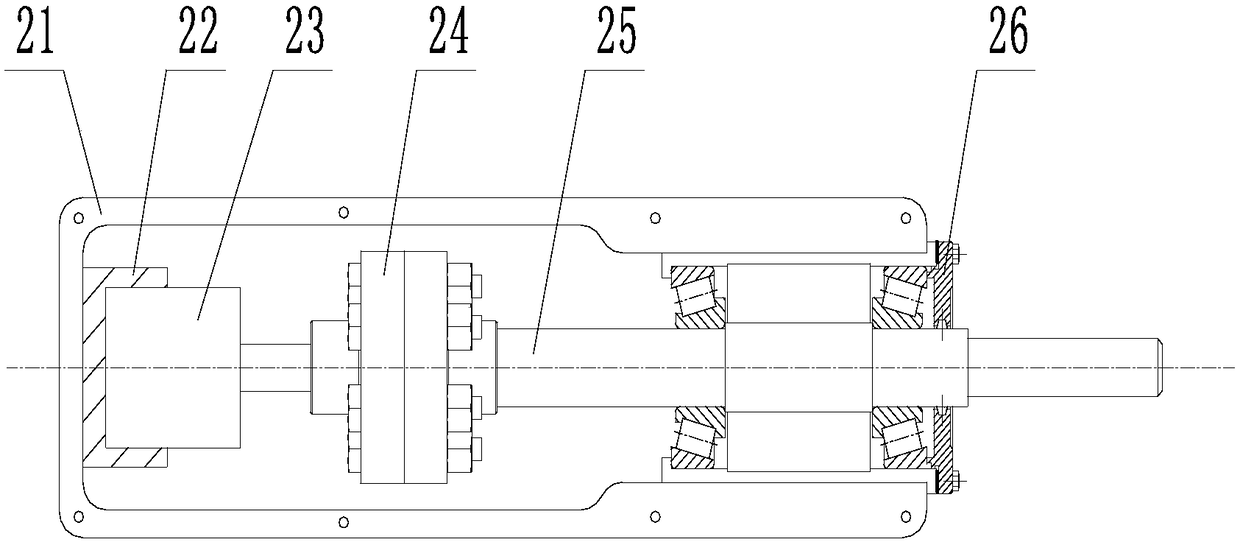

[0040] Embodiment 1 A processing device for bionic grooves on the inner wall of a conical water inlet pipe of a water pump according to the present invention includes an auxiliary support mechanism 1 for supporting the whole processing device to snap into the conical water inlet pipe of the water pump, and an auxiliary support mechanism 1 for driving the processing mechanism around Rotating rotary mechanism 2, a processing mechanism 3 for processing bionic grooves on the inner wall of the conical water inlet pipe of the water pump, and a feeding mechanism 4 for driving the entire processing device to advance axially along the inner wall of the pipe, the auxiliary support mechanism 1 and The rotating mechanism 2 is fixedly connected by bolts; the output end of the rotating mechanism 2 is connected to one of the shaft ends of the processing mechanism 3; the other shaft end of the processing mechanism 3 is connected to the action end of the feeding mechanism 4 , to realize the adv...

Embodiment 2

[0053] Embodiment 2 The processing method of using the processing device for the bionic groove on the inner wall of the conical water inlet pipe of a water pump described in Embodiment 1 includes the following steps:

[0054] (1) Fix the pipeline to be processed, start the third servo motor of the feed mechanism, push the whole device into the pipeline along the axial direction of the pipeline, compress the spring of the auxiliary support device, and press the six support wheels on the inner wall of the pipeline, Make the cutting tool assembly come to the position to be processed, and turn off the third servo motor at this time;

[0055] (2) Start the first servo motor of the rotating mechanism, the rotation of the first servo motor drives the gear to rotate, thereby driving the shell of the processing mechanism meshed with the gear to rotate, so that the cutter rotates, and the groove on the inner wall of the pipeline is started to be processed;

[0056] (3) Start the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com