Patents

Literature

751results about How to "Guarantee the quality of work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

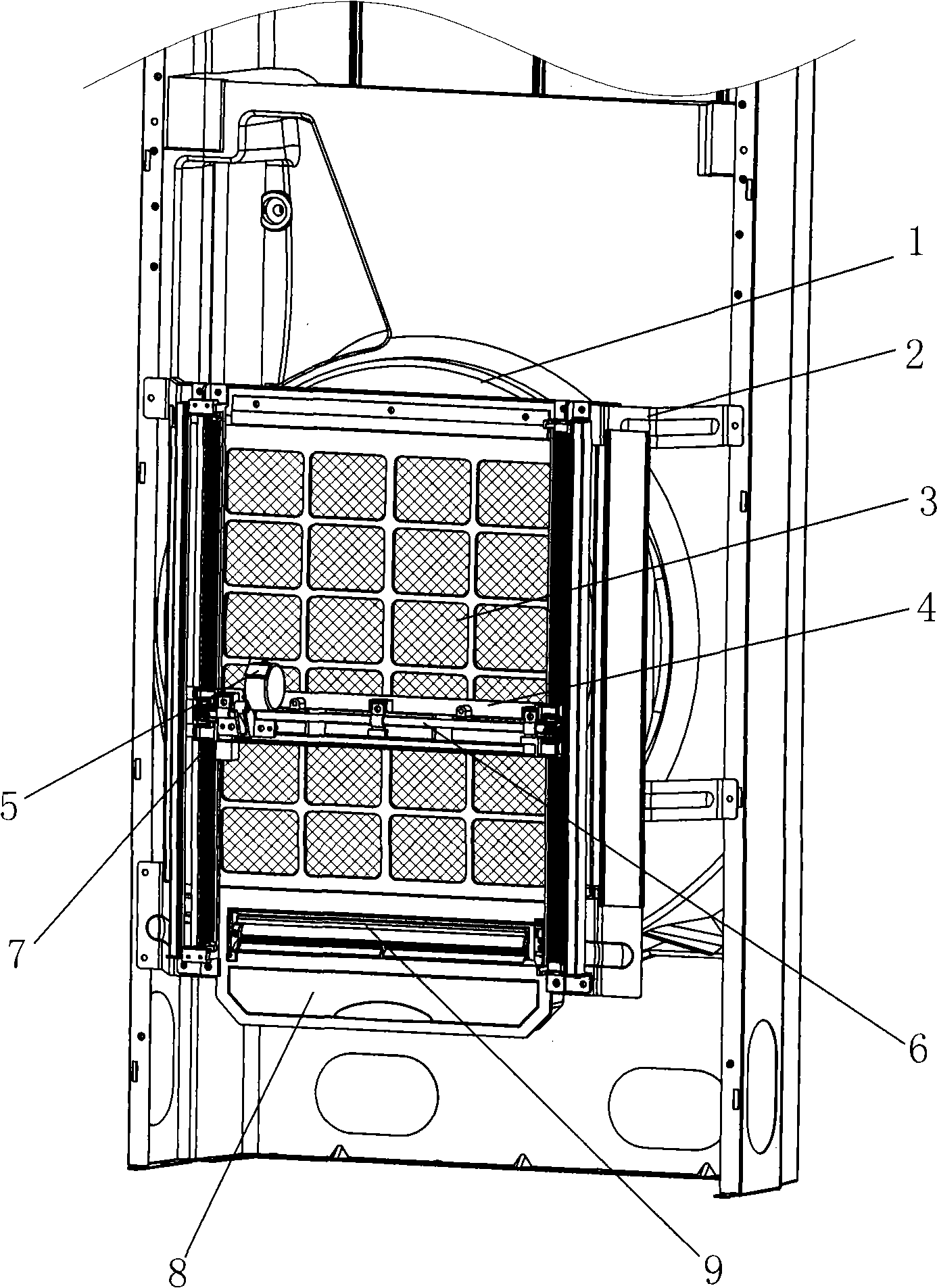

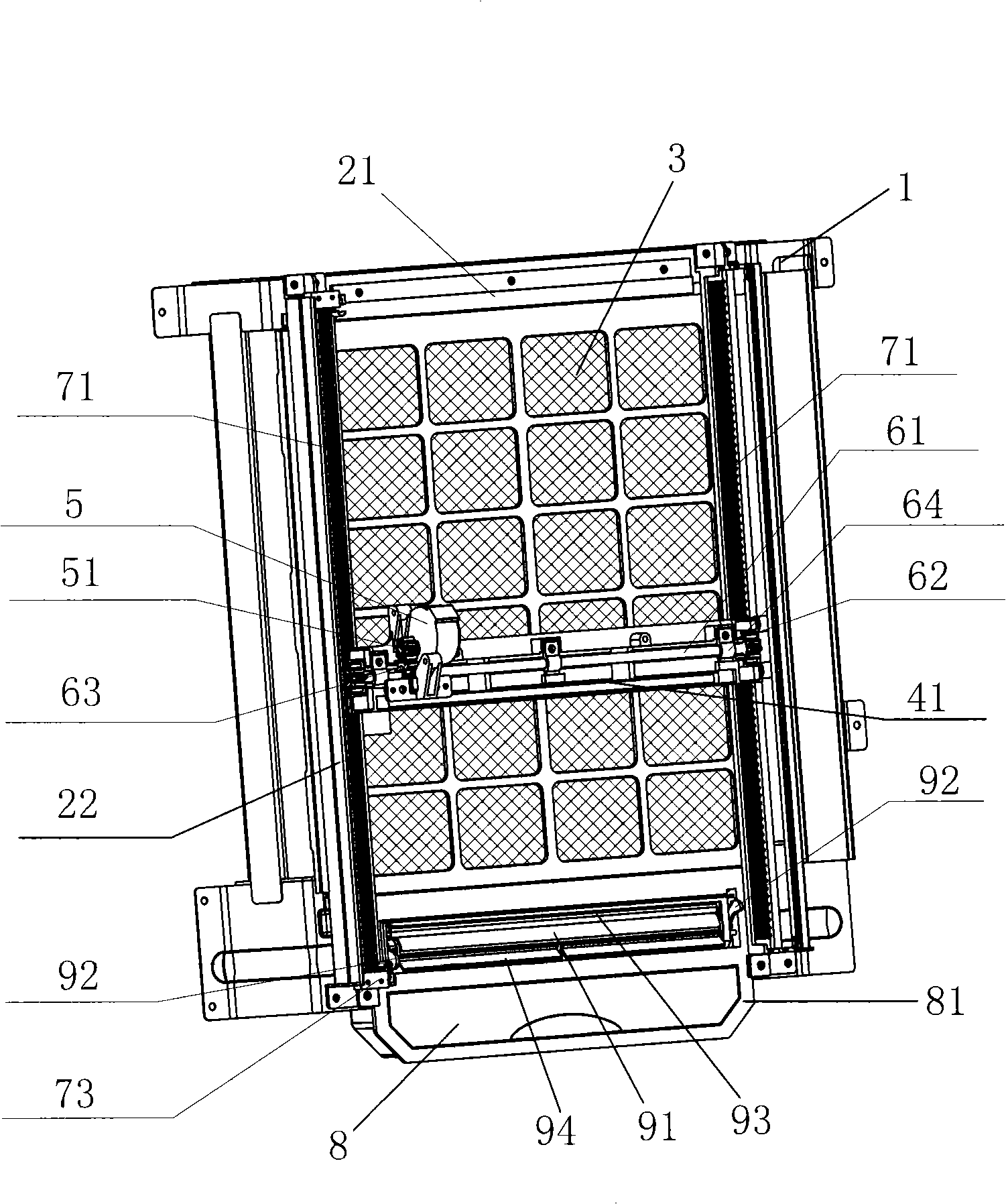

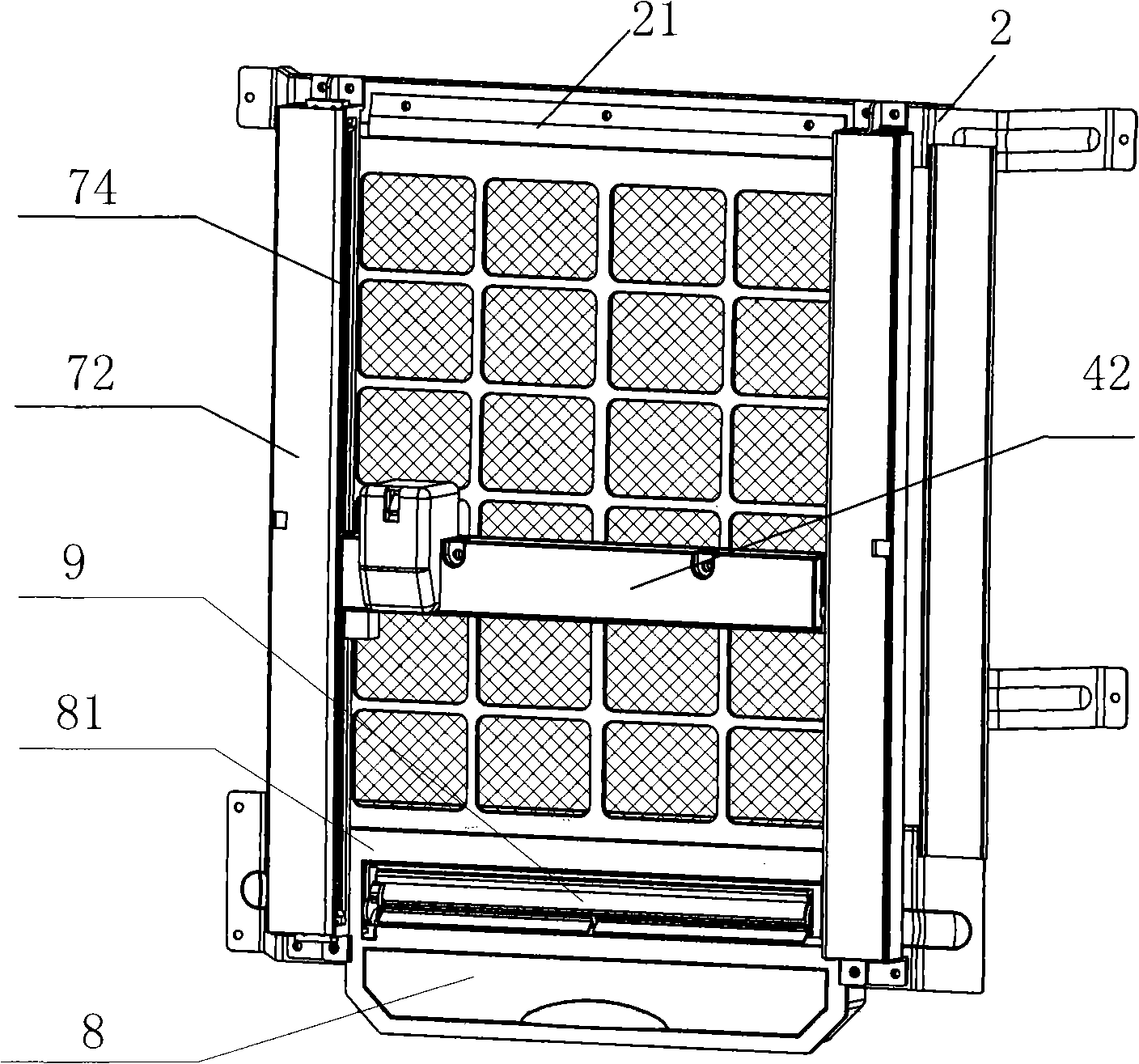

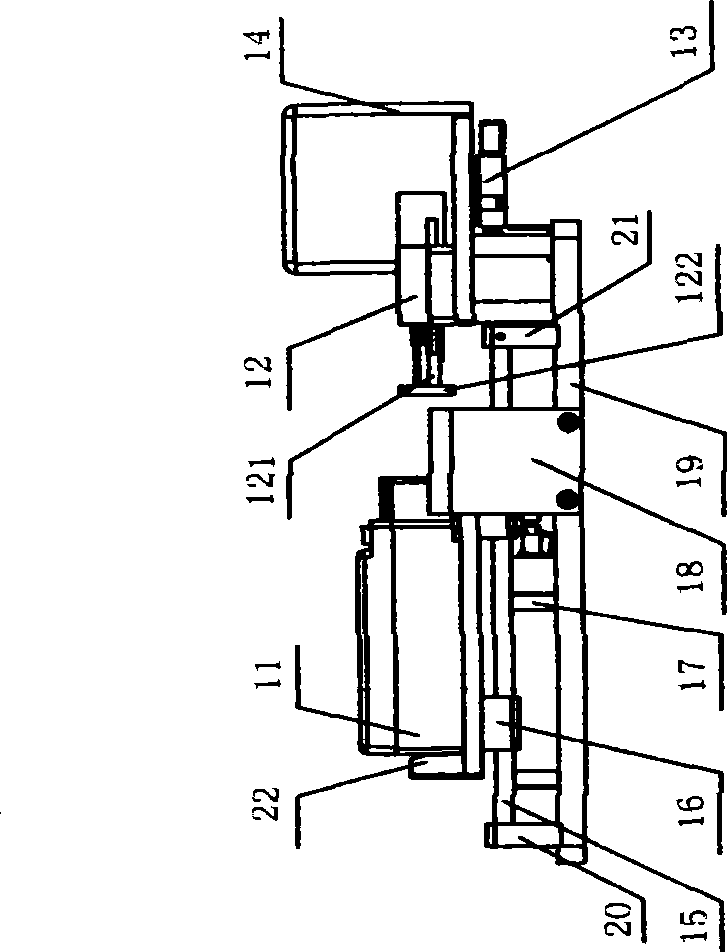

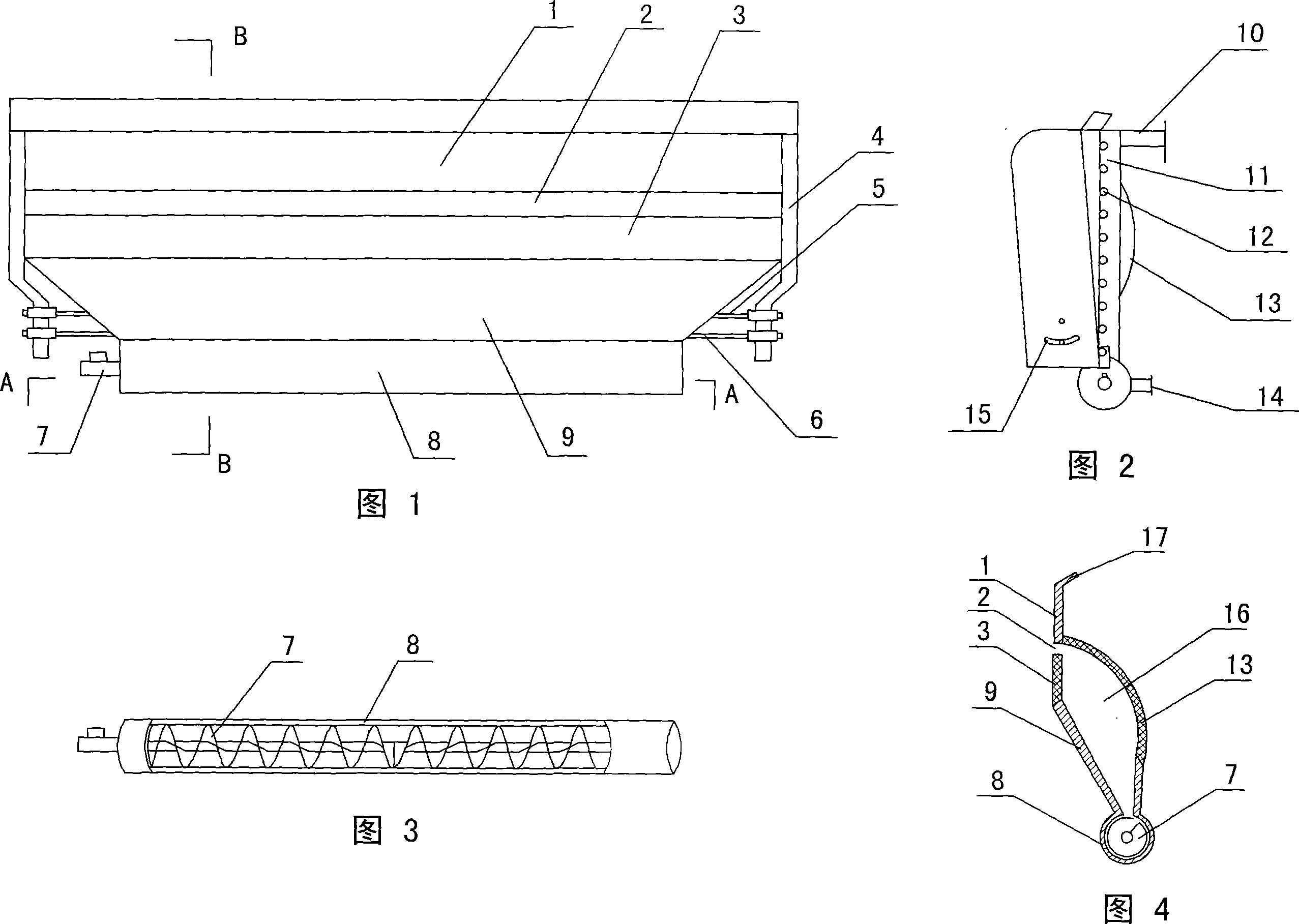

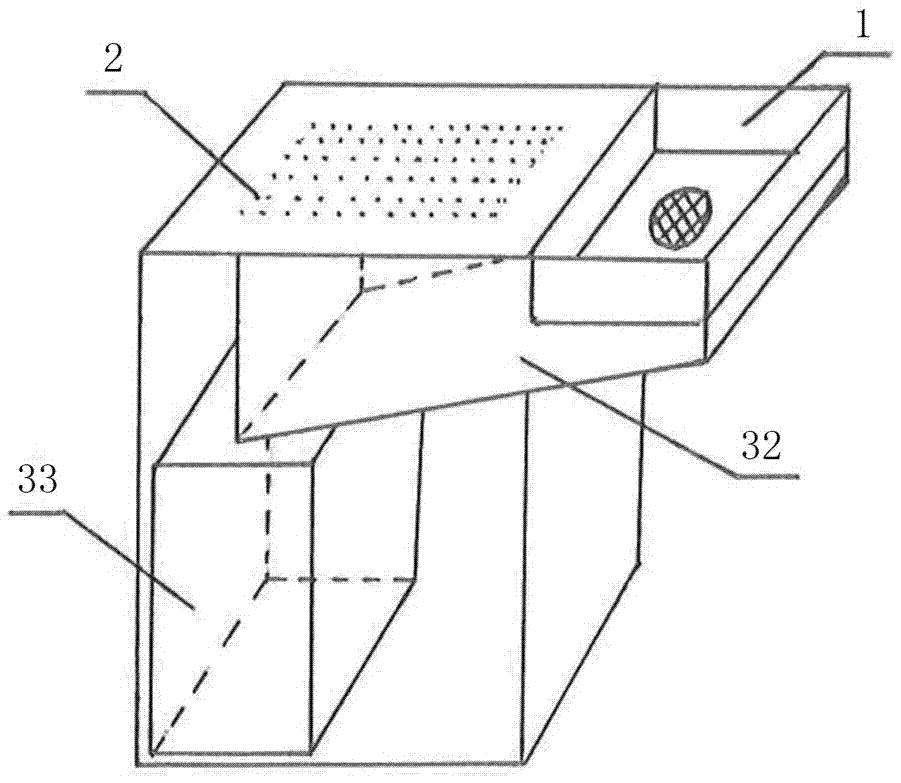

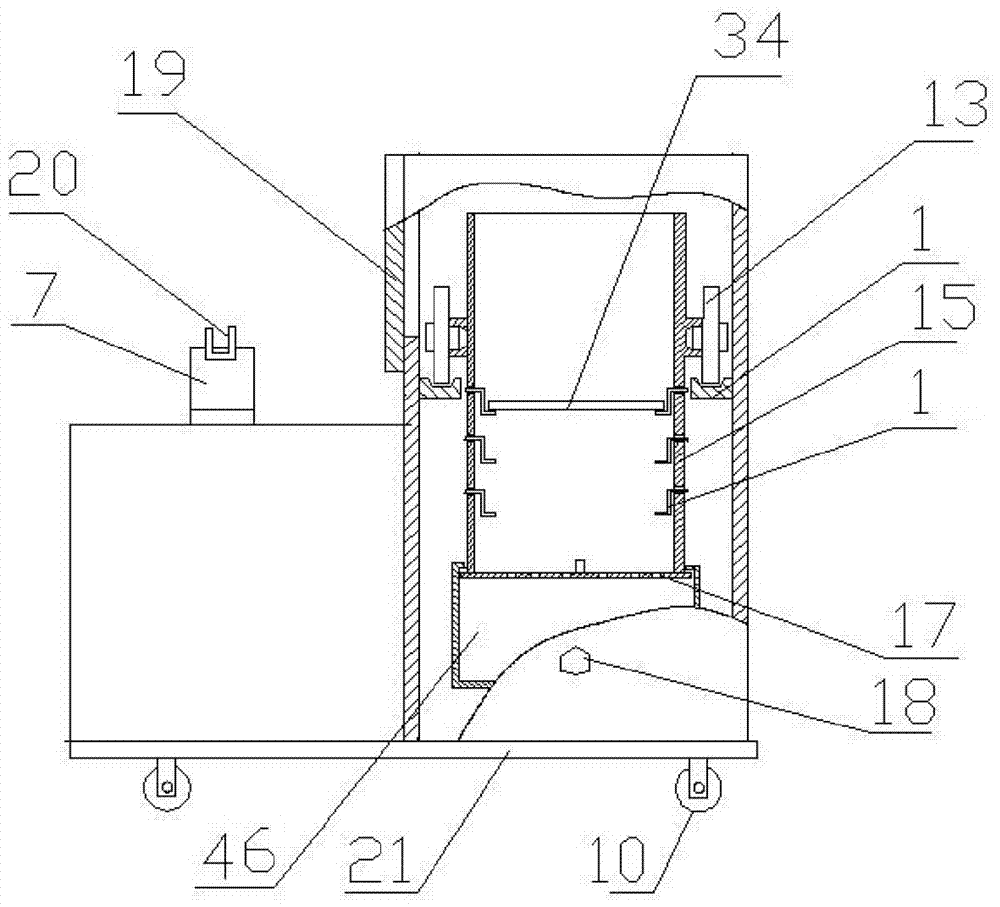

Air conditioner filter screen self-cleaning device

ActiveCN101290151AGuaranteed cleanlinessGuarantee the quality of workMechanical apparatusDispersed particle filtrationDrive motorSelf cleaning

The invention discloses a self-cleaning device for an air conditioner filter screen, which is arranged on filter screen brackets at an air passage spiral casing air inlet of a cabinet air conditioner and is arranged outside the filter screen, an upper bracket and a lower bracket are provided with filter screen guide rails with slots, the filter screen is fixed on the filter screen brackets through the slots of the guide rails, a filter screen cleaning device comprises a cleaning component with a brush, a drive motor fixed on the cleaning component, a driving mechanism connected with the drive motor, a rack set arranged at the left side part and the right side part of the filter screen and a dust box arranged under the filter screen and used for collecting dust; a dust exchange device is arranged between the dust box and the filter screen; the drive motor connected with the driving mechanism drives the cleaning component to slide up and down along the rack set adhering to the filter screen in order to enable the brush to clean dust down; the cleaning component slides down to pass through the dust exchange device and cleans the dust down in the dust exchange device, and then the dust exchange device pours the dust to the dust box. The self-cleaning device for air conditioner filter screen saves time and labor and can be cleaned at any time without disassembling.

Owner:HAIER GRP CORP +1

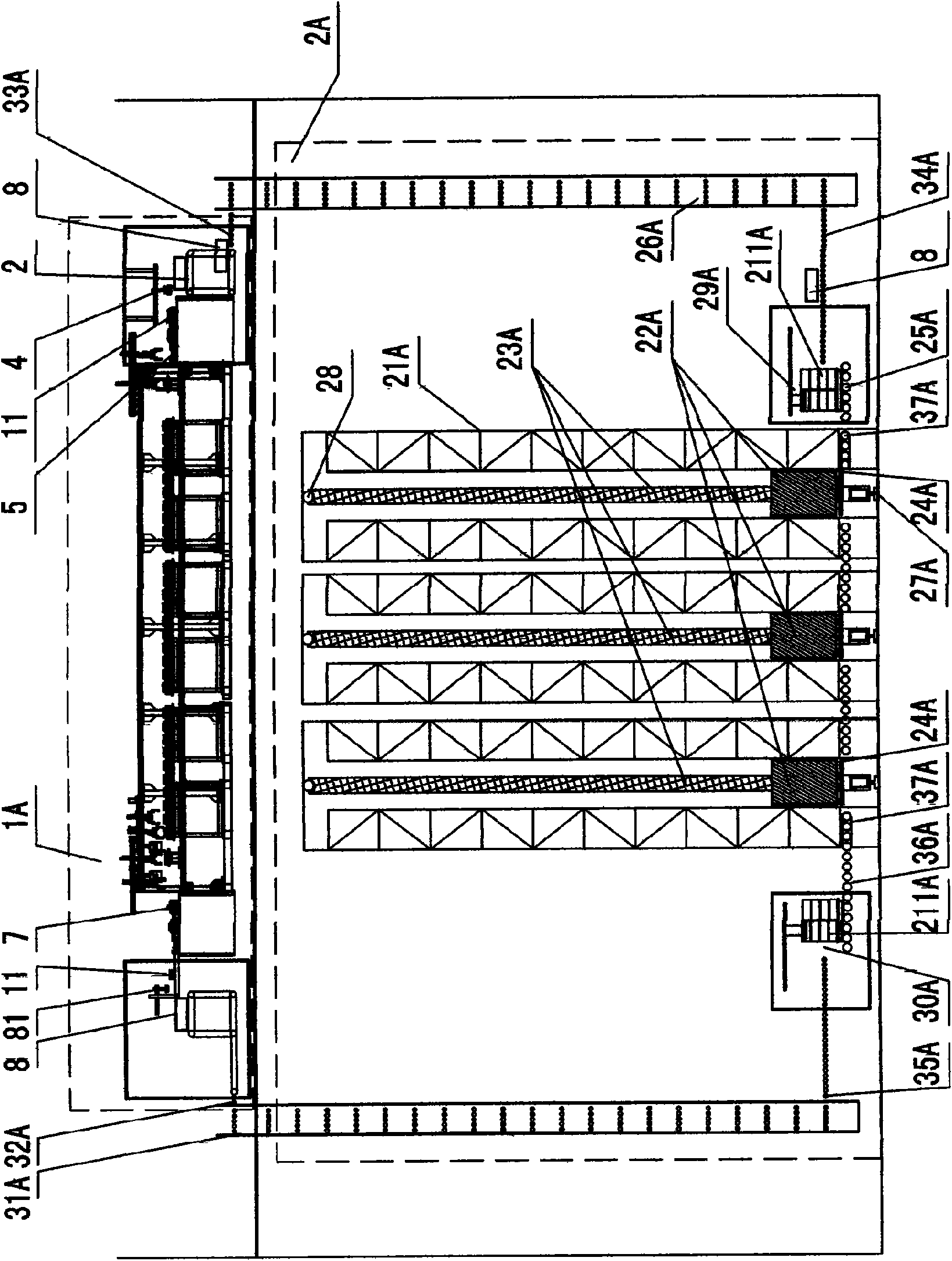

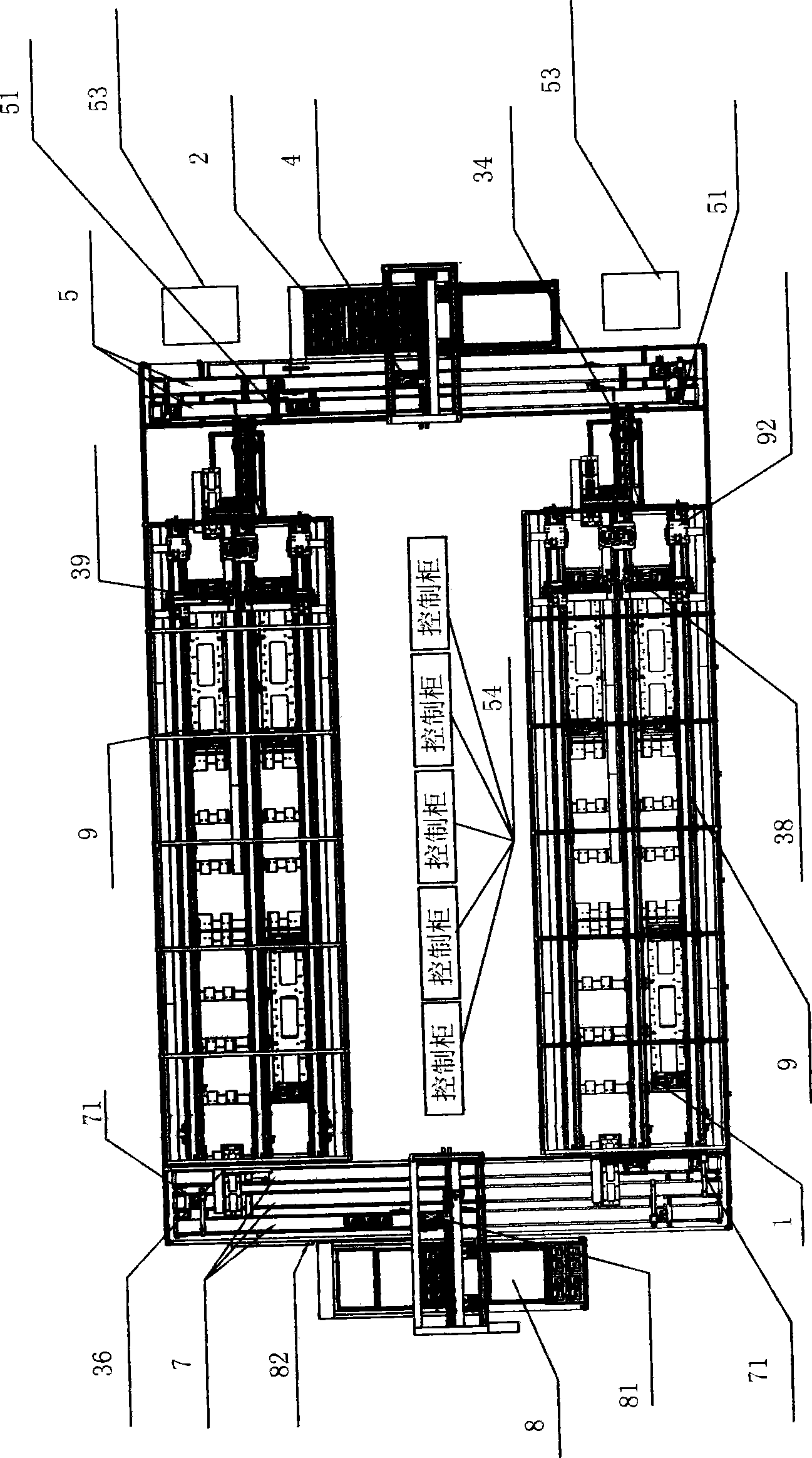

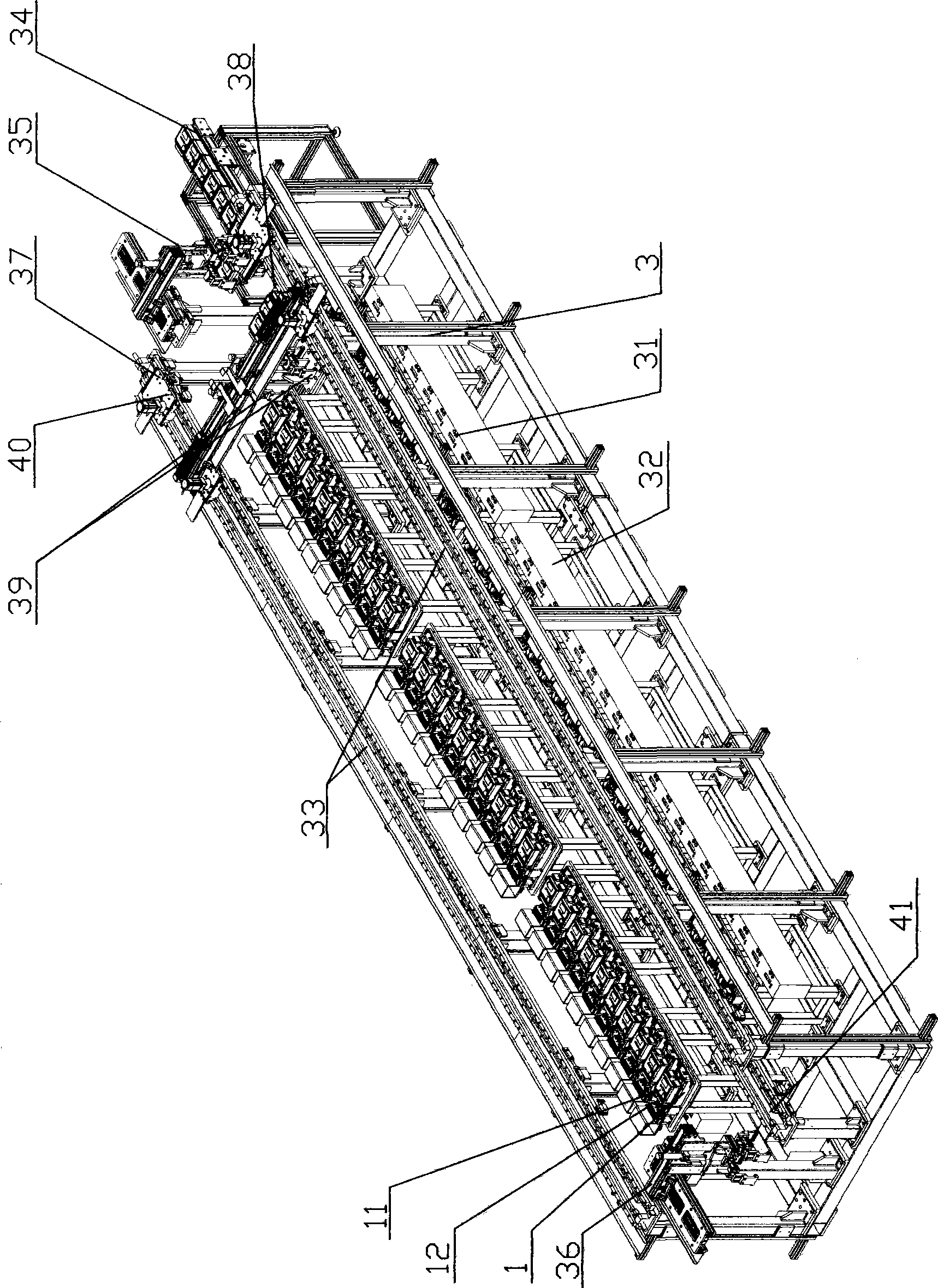

Automatic holographic management system integrating detection of electric energy meter and warehousing management

ActiveCN101539617ARealize automatic feeding processAchieve contactRadiation pyrometryElectrical measurementsTemperature monitoringEngineering

The invention discloses an automatic holographic management system integrating detection of an electric energy meter and warehousing management, comprising an automatic pipelining standard device for detection of the electric energy meter, an unboxing machine, a boxing machine and a three-dimensional table library; wherein the three-dimensional table library is respectively connected with the boxing machine and the unboxing machine; and the boxing machine and the unboxing machine are respectively connected with the automatic pipelining standard device for detection of the electric energy meter by a conveying belt. The system changes large amount of repeated and mechanical manual modes in the whole process of the operation of the electric energy meter, and has the automatic functions of automatic delivery from the warehouse, automatic distribution, automatic feeding, automatic positioning, automatic wire connection, automatic image recognition, automatic temperature monitoring, automatic wire disconnection, automatic discharging, automatic boxing, automatic disc packing and automatic warehouse entry.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +1

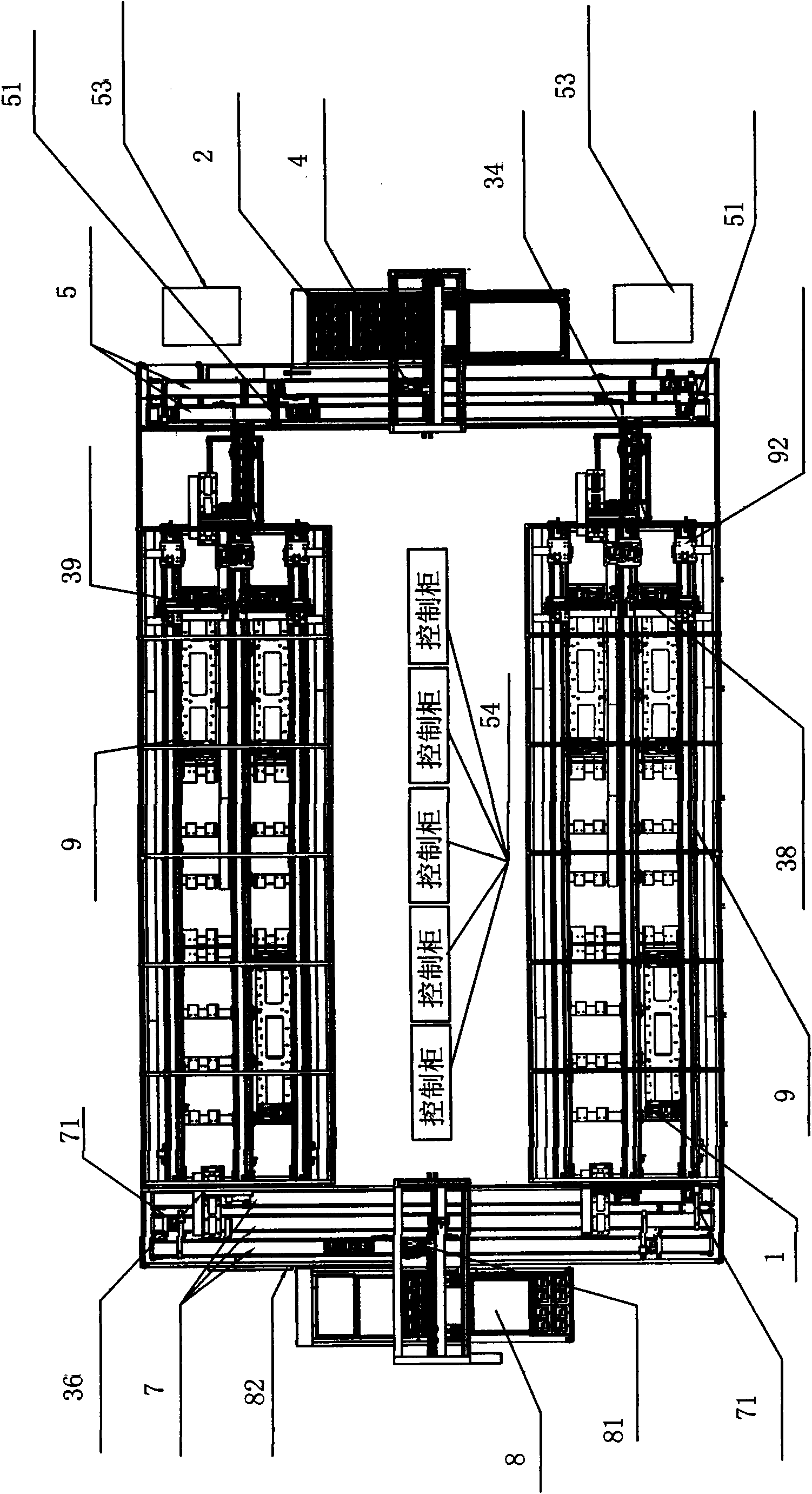

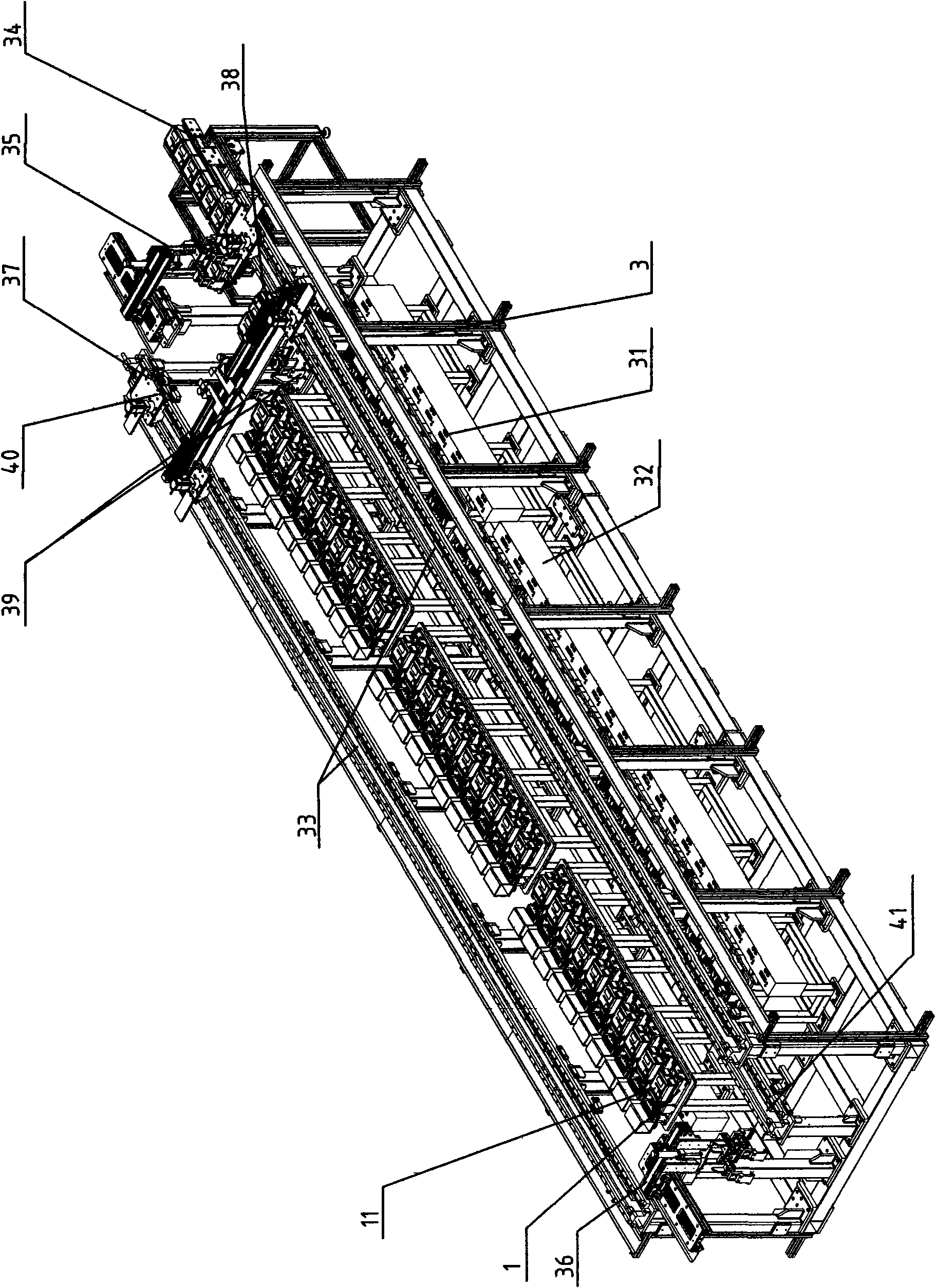

Automatic assembly line standard apparatus for electric energy meter calibration

ActiveCN101464504ARealize automatic feeding processAchieve contactElectrical measurementsProduction lineElectrical connection

The invention discloses an automatic production line standard device detected by an electric energy meter, which comprises a loading platform, a feeding loop line belt and an electric energy meter automatic standard device. The loading platform is connected with the feeding loop line belt; a material taking manipulator and a bar code reader are mounted on the feeding loop line belt; the feeding loop line belt is connected with the electric energy meter automatic standard device; the electric energy meter automatic standard device is simultaneously connected with a blanking conveying loop line belt; a loading manipulator and another bar code reader are mounted on the blanking conveying loop line belt; the loading manipulator is connected with an electric energy meter feeding box; an unqualified product outlet is formed on the blanking conveying loop line belt; the working process of the whole production line in the whole device is controlled by a computer program through a production line control cabinet; and the calibration / detection of the electric energy meter is controlled by a computer calibrating procedure through a calibrating control cabinet. The invention has the advantages of completely improving the calibrating / detecting work efficiency, reducing the labor intensity, improving the work quality, achieving the reliability and the safety of electrical connection, etc.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +1

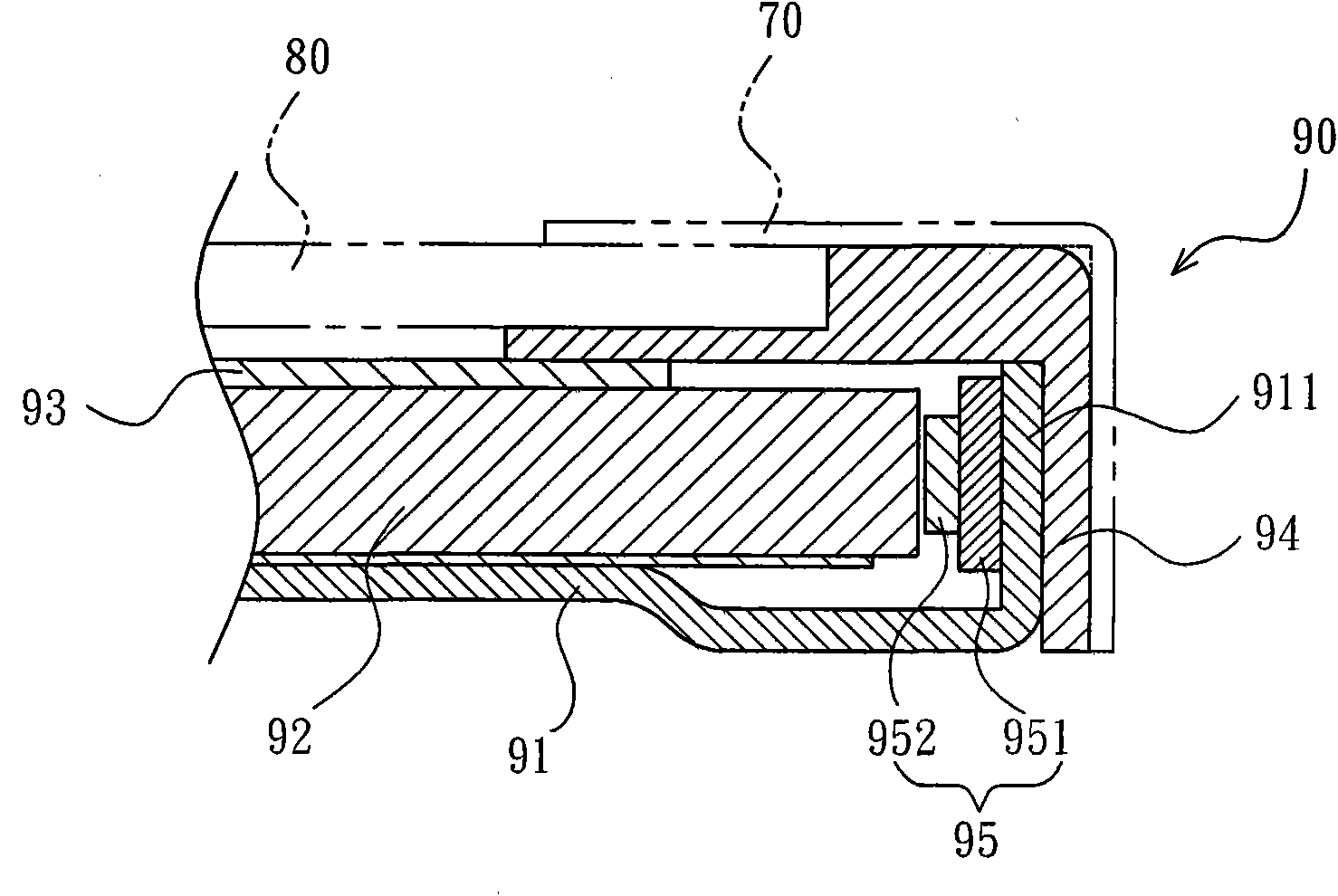

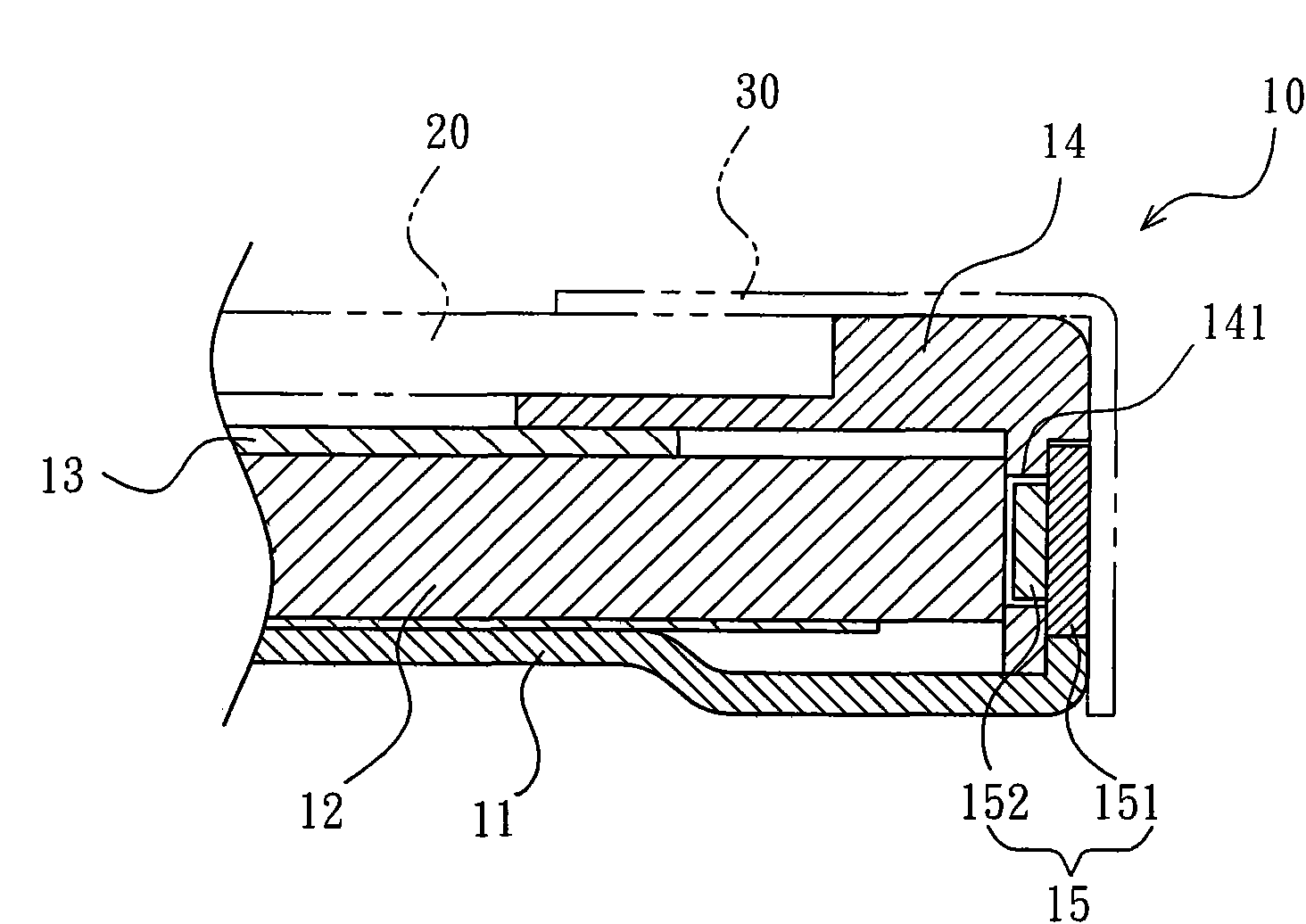

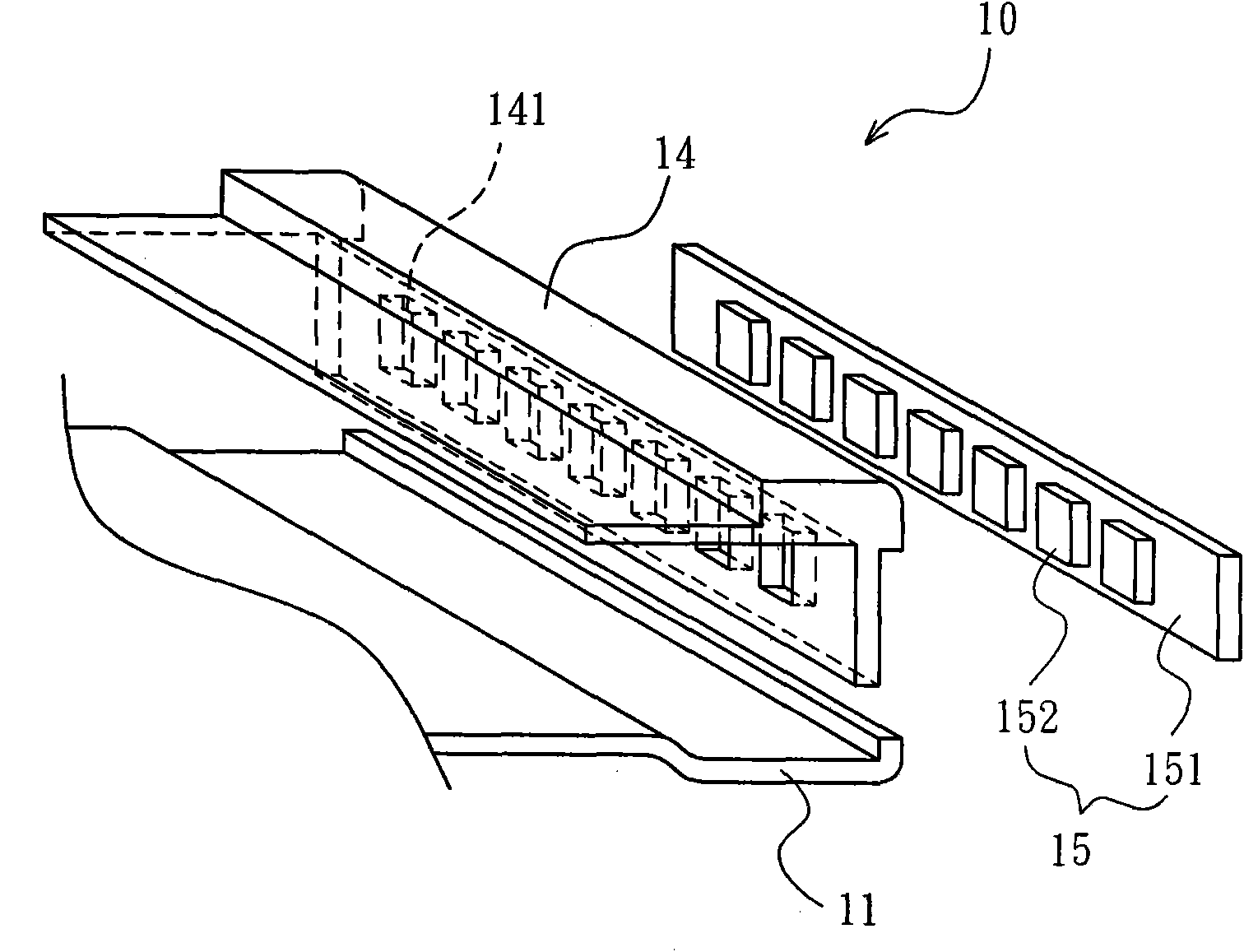

Edge-type backlight module and liquid crystal display

InactiveCN102003661AGuarantee the quality of workLighting heating/cooling arrangementsLight fasteningsLiquid-crystal displayLight guide

The invention discloses an edge-type backlight module and a liquid crystal display. The edge-type backlight module comprises a back plate, a light guide plate, a fixing frame and a light-emitting device, wherein the fixing frame encases and fixes the light guide plate on the back plate, a circuit board of the light-emitting device is arranged at the outer side of the fixing frame, and the fixing frame is provided with at least one light inlet opening corresponding to at least one light-emitting element of the light-emitting device. In the invention, a lateral light source required by the light guide plate can be provided through the light inlet onpenging, but most of heat energy generated by the light-emitting device can be isolated.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

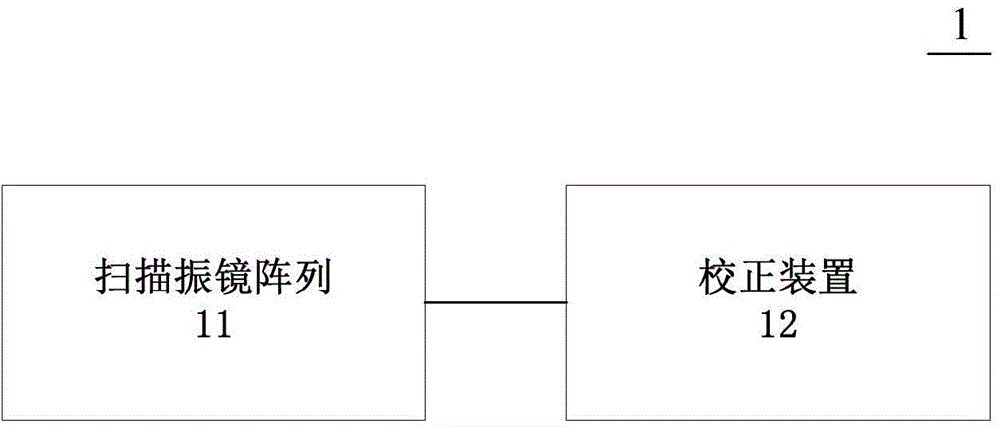

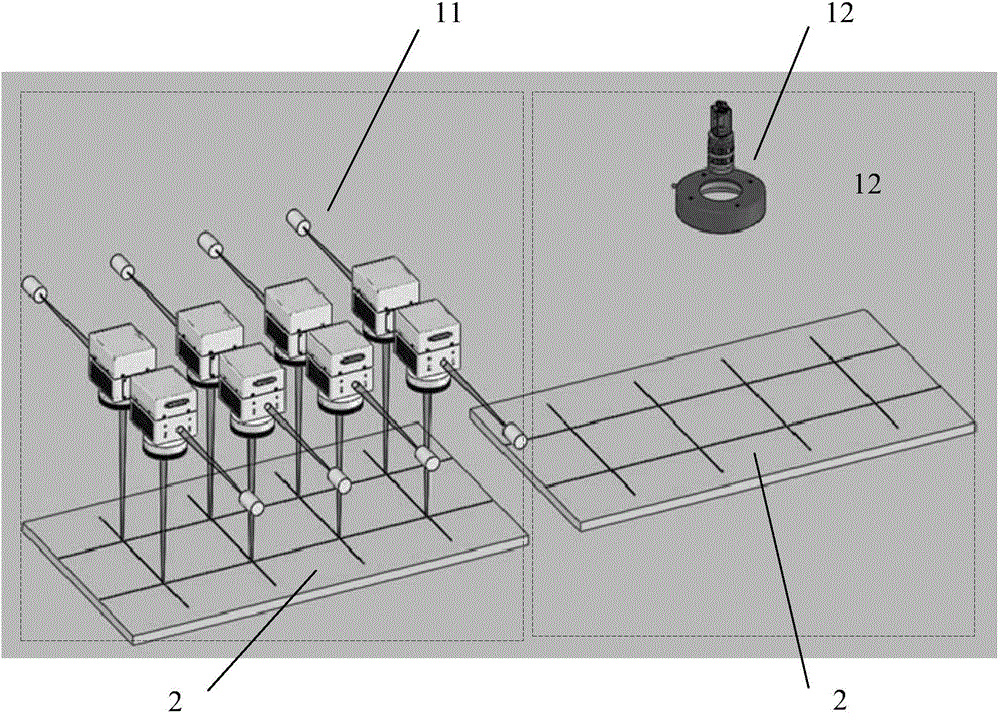

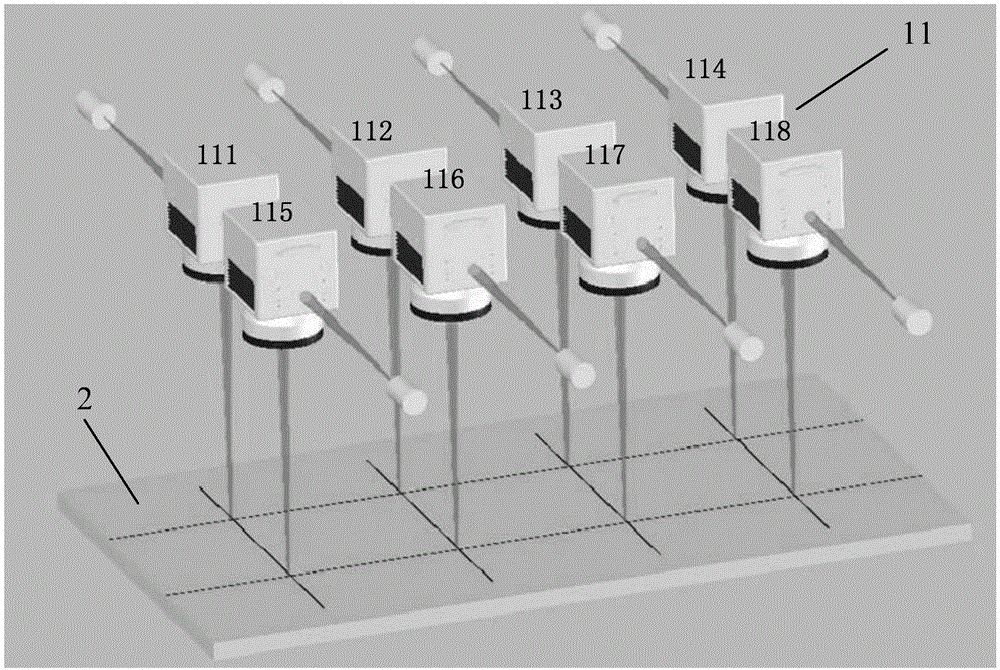

Laser equipment and laser scanning galvanometer array calibrating method

ActiveCN104475970AAchieve correctionManufacturing precision requirements are lowLaser beam welding apparatusLaser scanningGalvanometer

The invention relates to the field of laser equipment, in particular to laser equipment and a laser scanning galvanometer array calibrating method. The laser scanning galvanometer array calibrating method includes steps of acquiring images corresponding to operations of a laser scanning galvanometer array by a calibrator, processing the images by the calibrator so as to obtain calibration values of various scanning galvanometer; generating actual scanning positions by the scanning galvanometer so as to scan according to the calibration values. By the laser equipment and the laser scanning galvanometer array calibrating method, operation quality in a large operation area is ensured under the condition that manufacturing accuracy requirement of the equipment can be reduced.

Owner:HANS LASER TECH IND GRP CO LTD +1

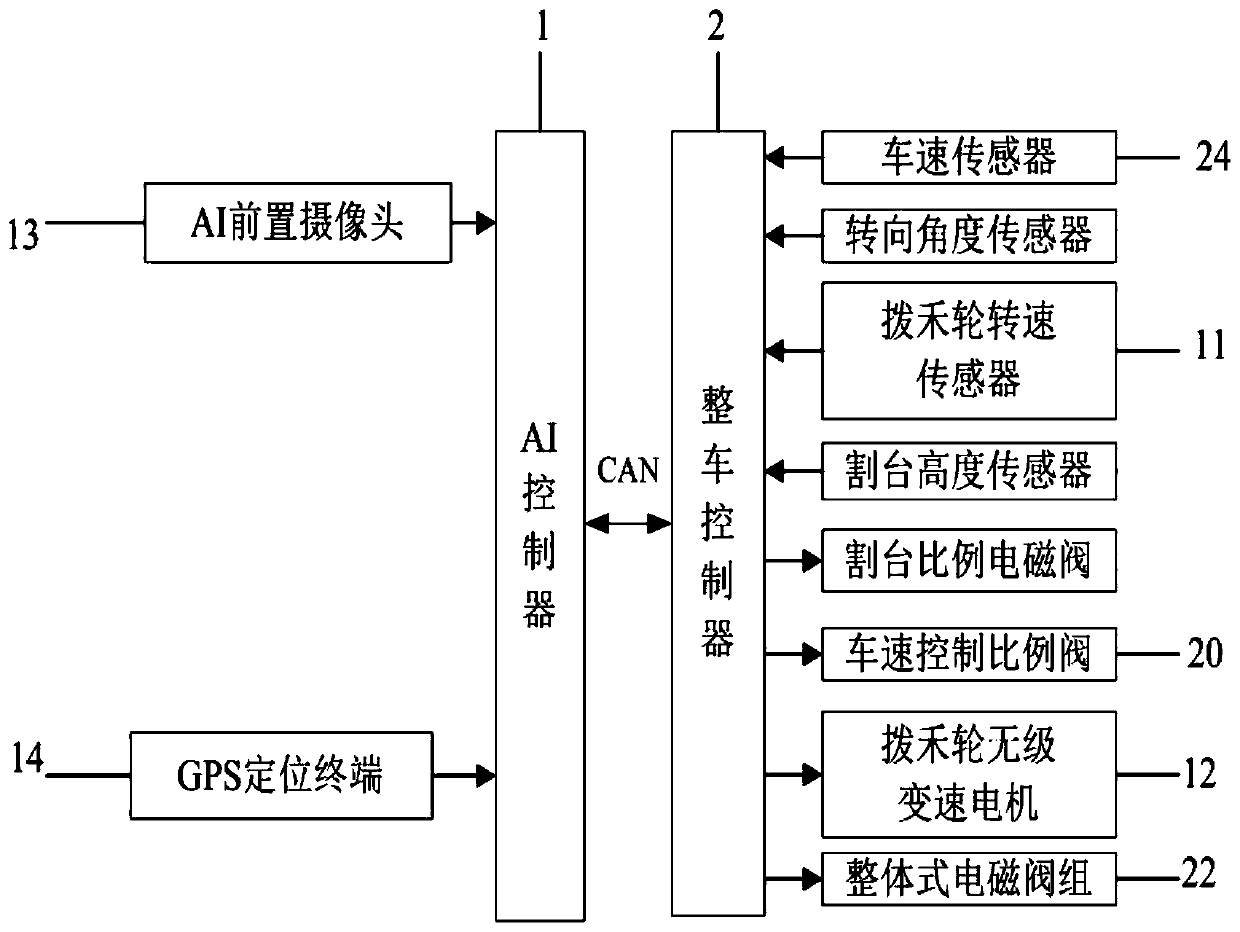

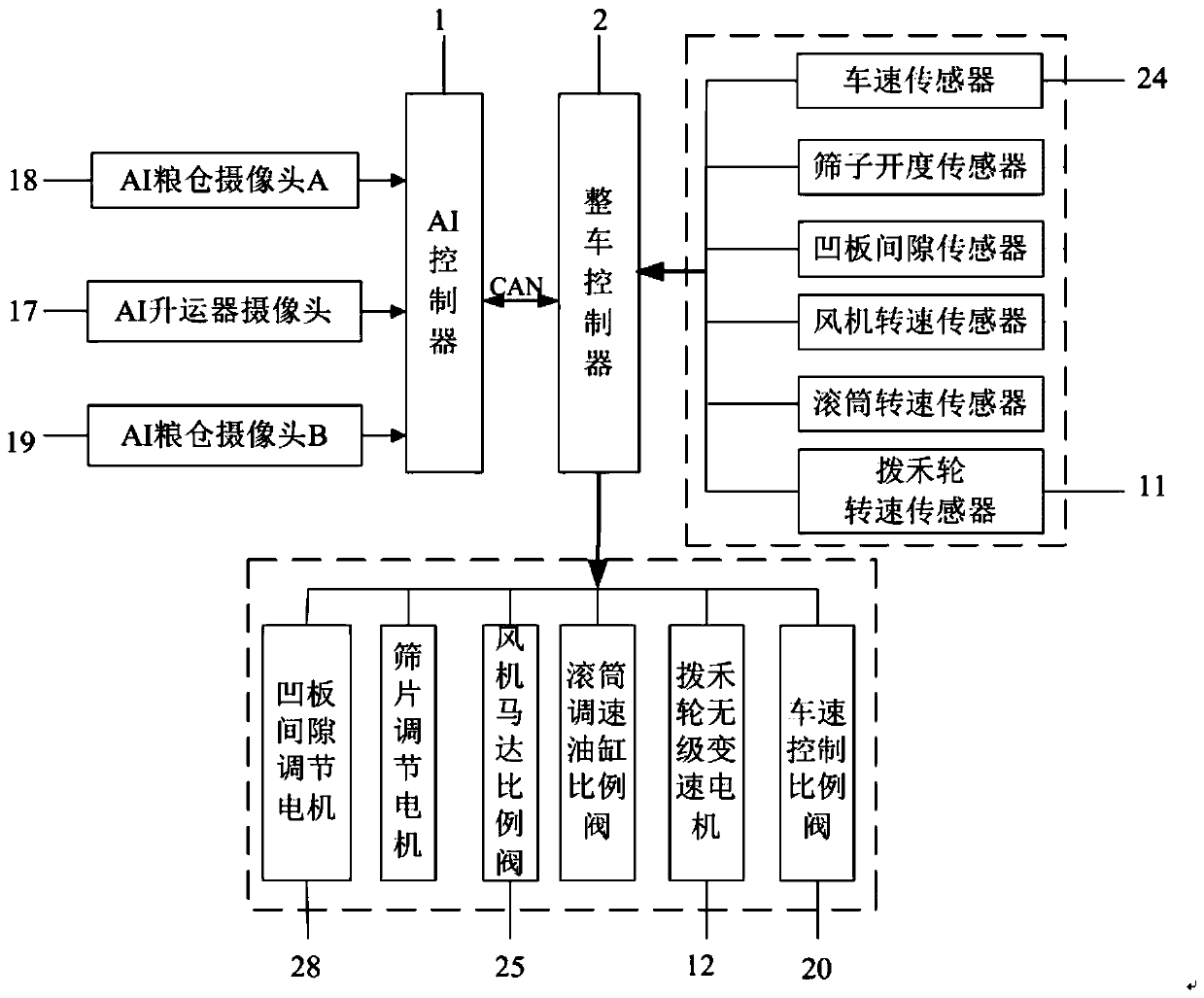

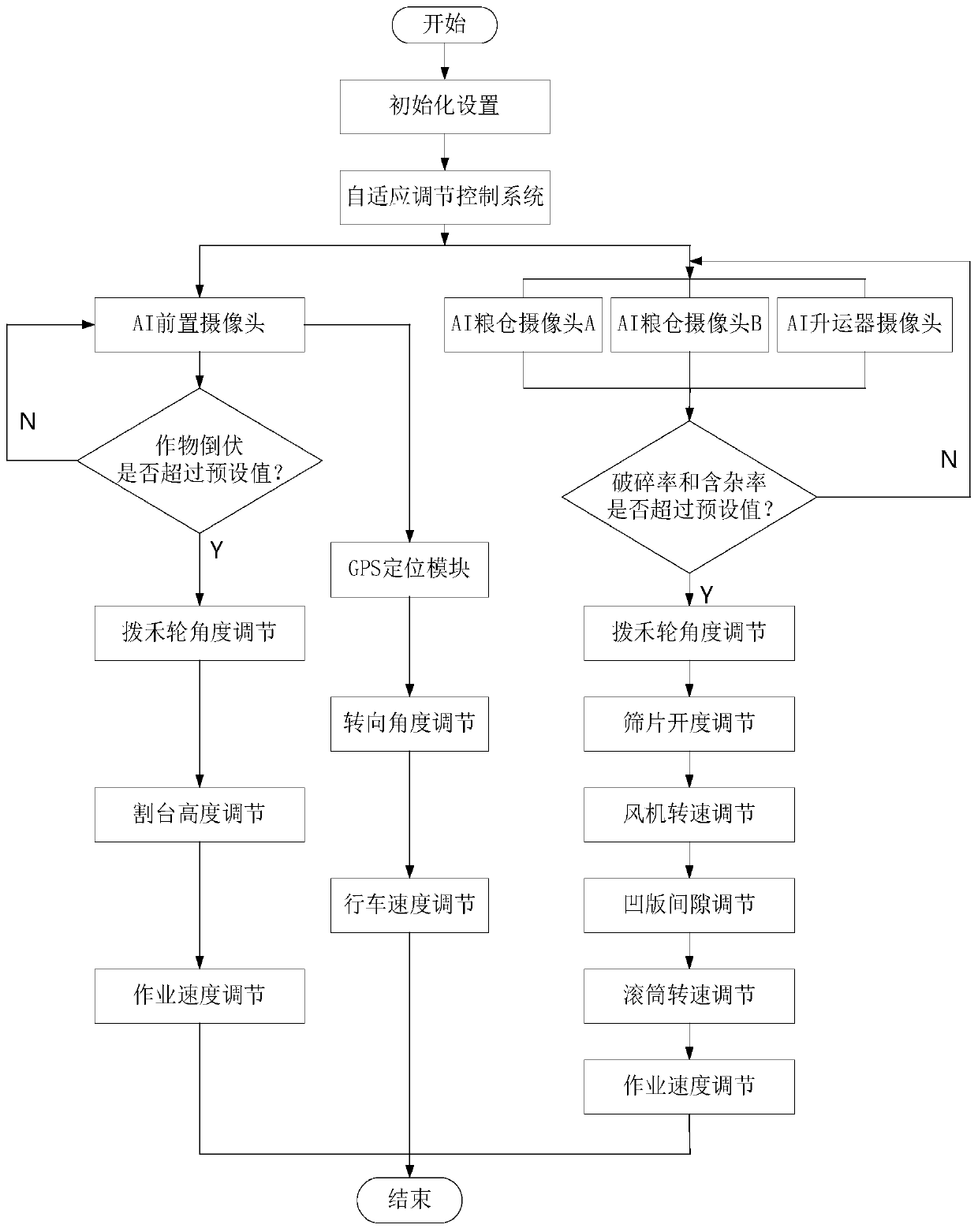

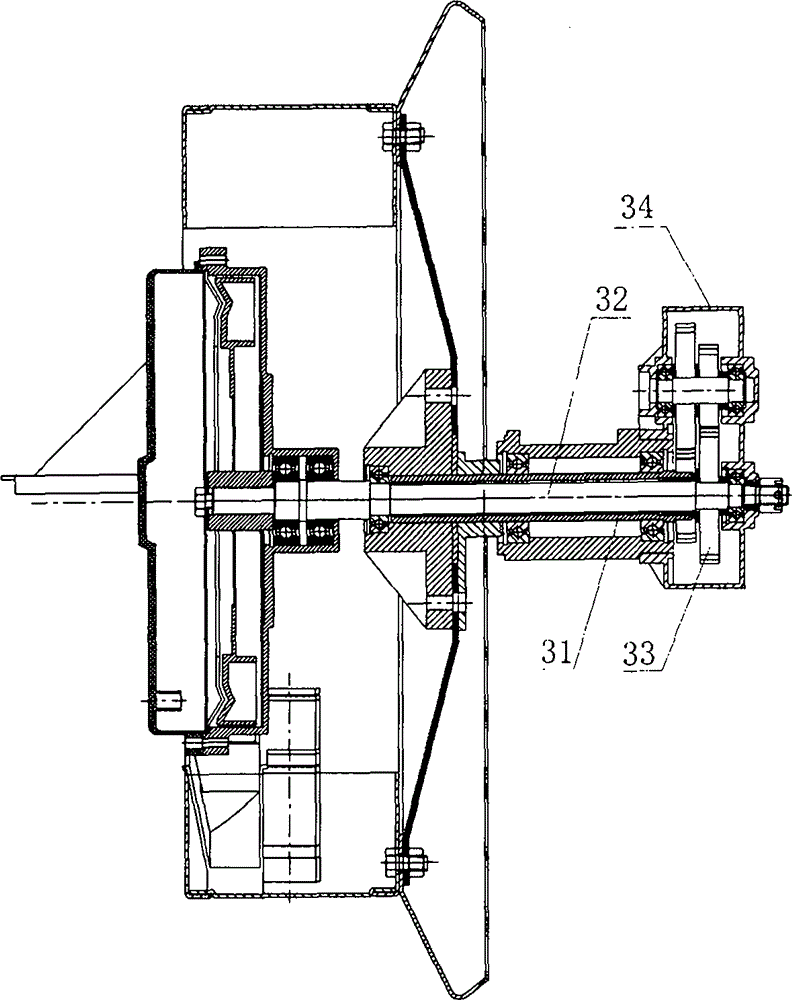

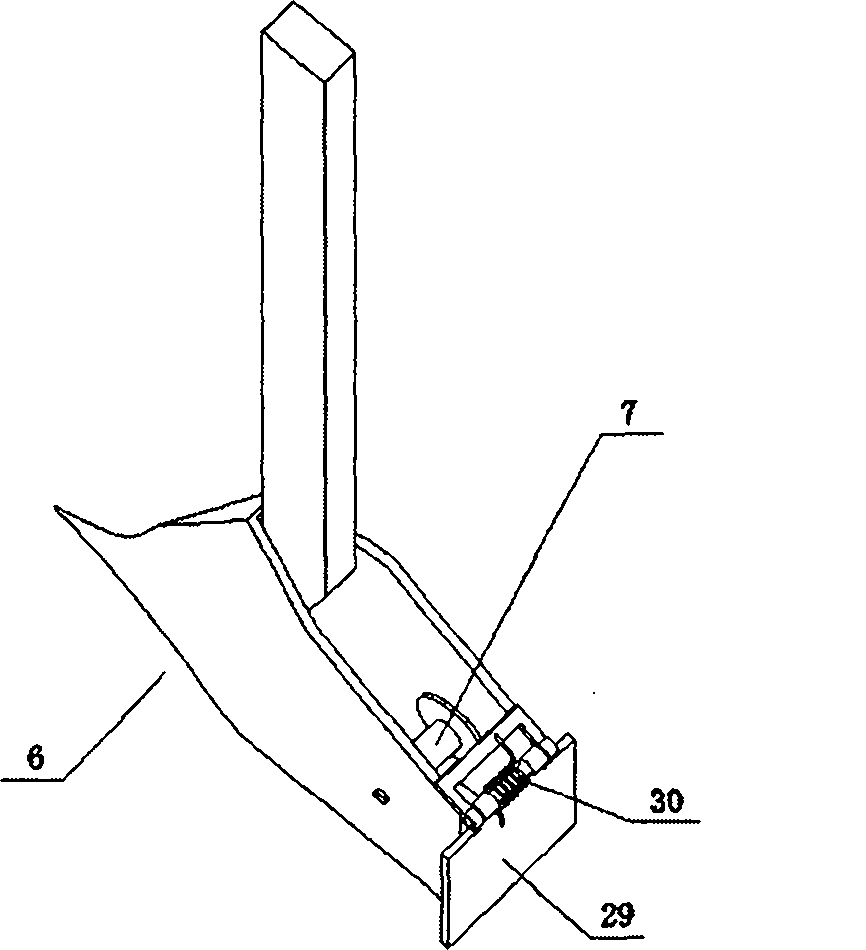

Intelligent regulating system for grain harvesters and control method thereof

PendingCN110720302AGuarantee the quality of workImprove work efficiencyMowersControl cellBreakage rate

The invention relates to an intelligent regulating system for grain harvesters and a control method thereof; an AI (artificial intelligence) control unit calculates grain impurity rate and breakage rate according to image information acquired by a grain bin camera and an elevator camera; when the impurity rate and the breakage rate exceed a set threshold, required matching values, including opening of a screen, gaps of a concave plate, rotating speed of a roller, rotating speed of a fan, rotating speed of a reel and operating speed are judged, and the required matching values are sent to a vehicle control unit; the vehicle control unit correspondingly adjusts the opening of the screen, the gaps of the concave plate, the rotating speed of the roller, the rotating speed of the fan, the rotating speed of the reel and the operating speed to arrive at the required matching values. The intelligent regulating system for grain harvesters is simple in structure and convenient to operate, and the operation quality and efficiency of the harvesters are effectively guaranteed.

Owner:ZOOMLION HEAVY MASCH CO LTD

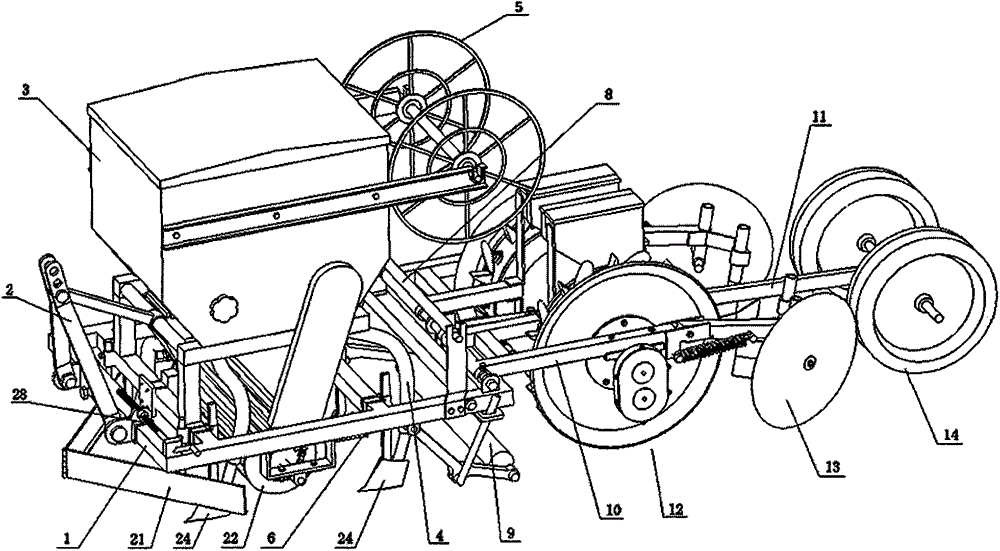

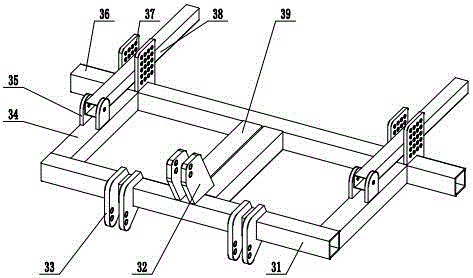

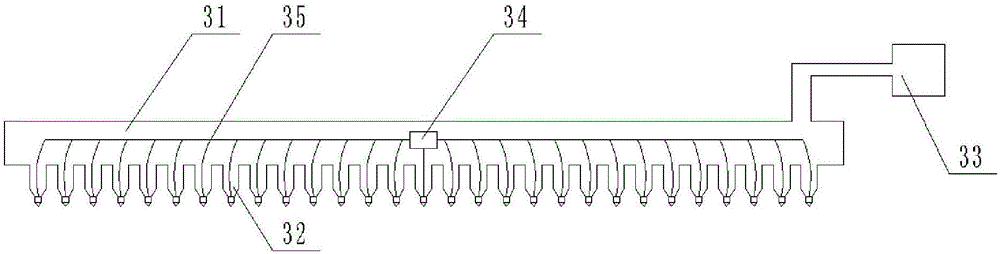

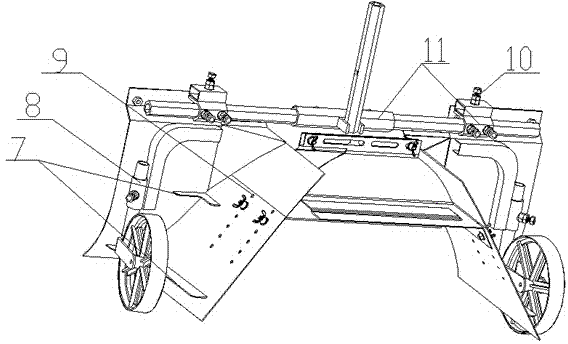

Fertilizer-applying tape-laying film-coating multifunctional seeder

The invention discloses a fertilizer-applying tape-laying film-coating multifunctional seeder which comprises a frame, a fertilizer-applying device, a tape-laying device, a film-coating device, and a seeding device. The fertilizer-applying device has a fertilizer-applying box comprising a base fertilizer box and a seeding fertilizer box, wherein the base fertilizer box is provided with a deep fertilizer-applying fertilizer-discharging device comprising a fertilizer-discharging chamber and a stirrer, the upper part of the fertilizer-discharging chamber is communicated with the base fertilizer box, and the lower part of the fertilizer-discharging chamber is provided with a fertilizer-discharging port and a fertilizer-controlling plugboard. The seeder of the invention has a simple structure, and complete functions, is a seeding machinery integrating soil preparation, fertilizer application, tape laying, film coating, seeding, soil casing, and pressing as a whole, and is a crop seeder suitable for crop plantation by the technology of drip irrigation under plastic films. Especially, the seeder is further provided with the deep fertilizer-applying fertilizer-discharging device, which realizes discharge of large amount of fertilizer, is applicable to ammonium bicarbonate deep fertilization and application of biomass fertilizer, realizes large fertilizer applying amount and uniform fertilizer application, and has no obstruction phenomenon.

Owner:赵玉茹

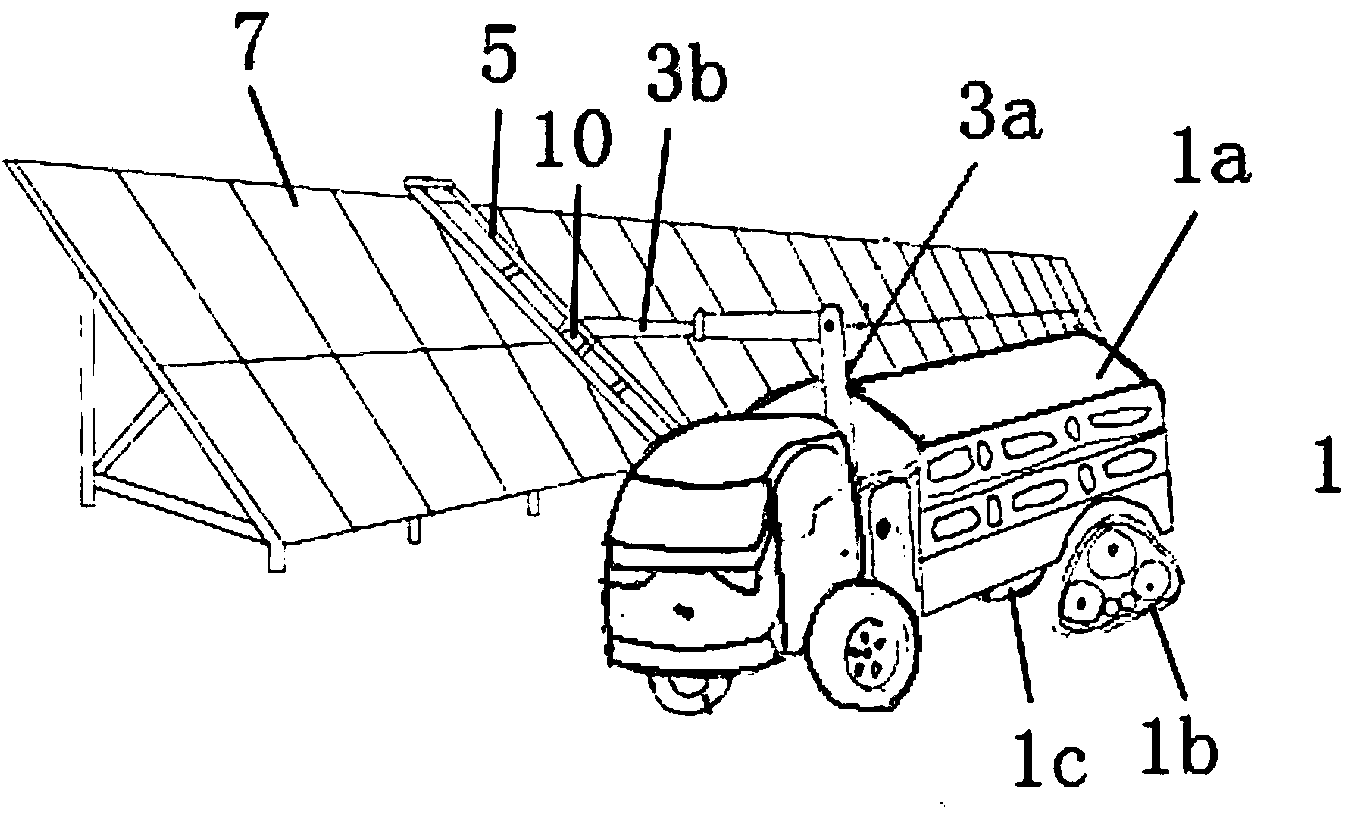

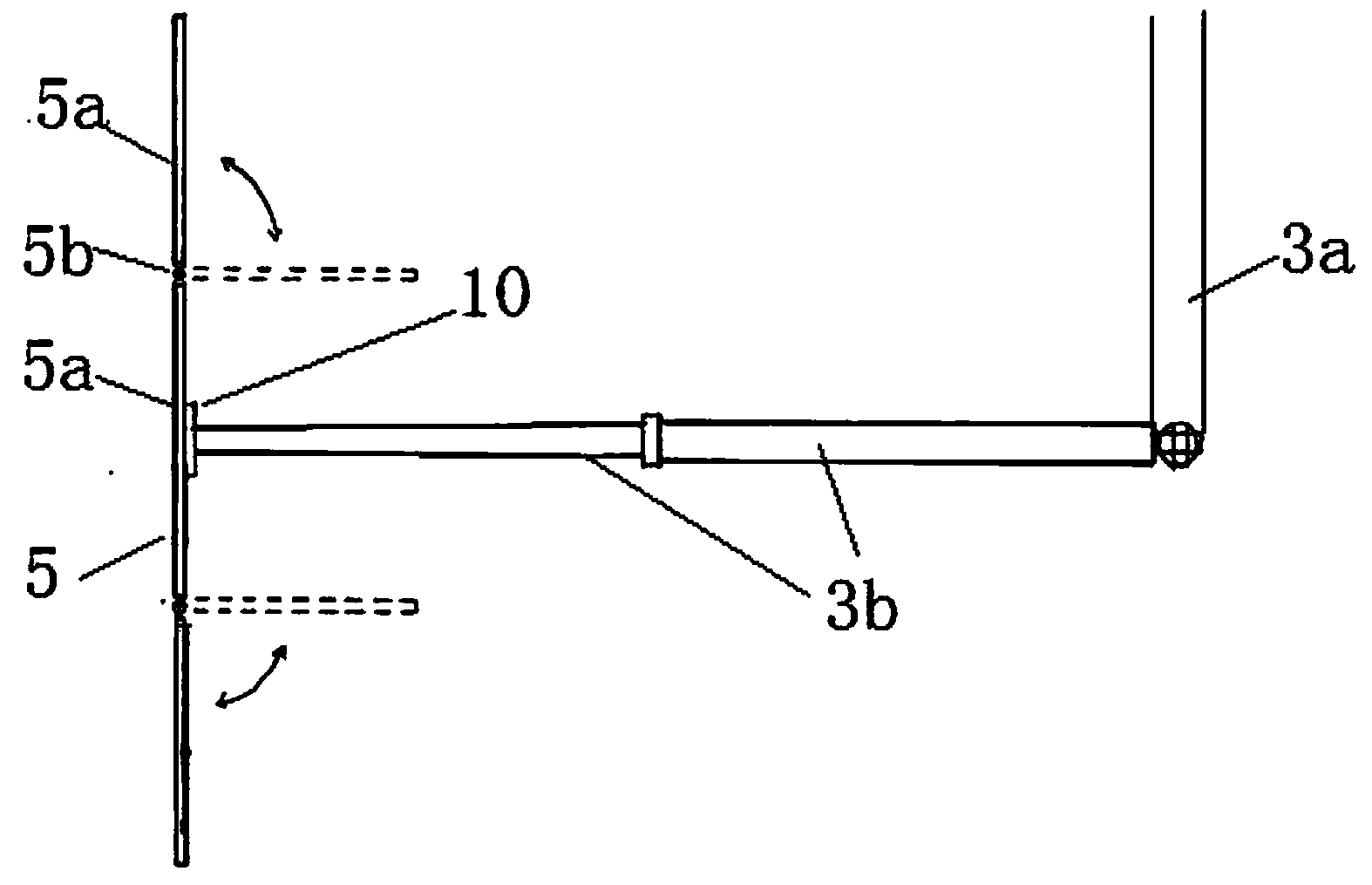

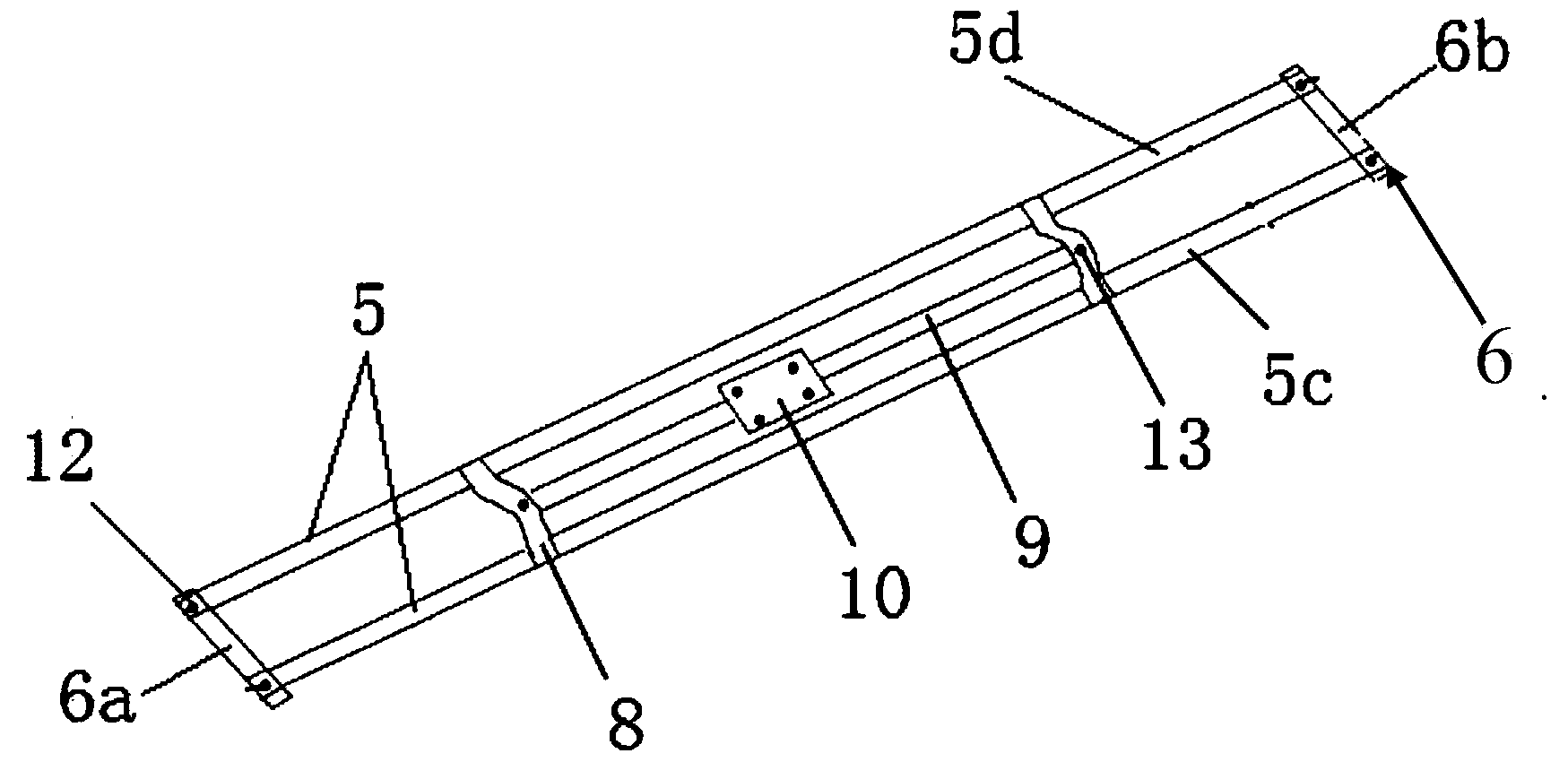

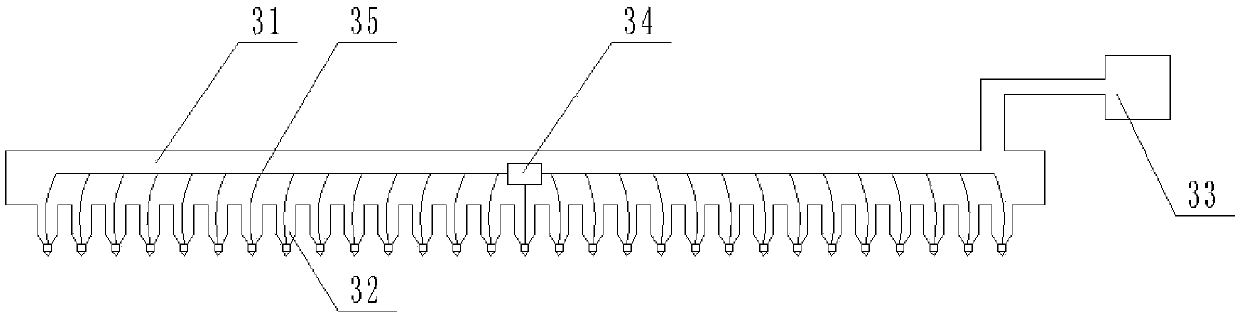

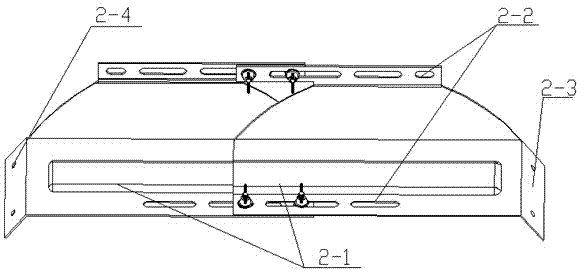

Non-contact solar cell panel cleaning device

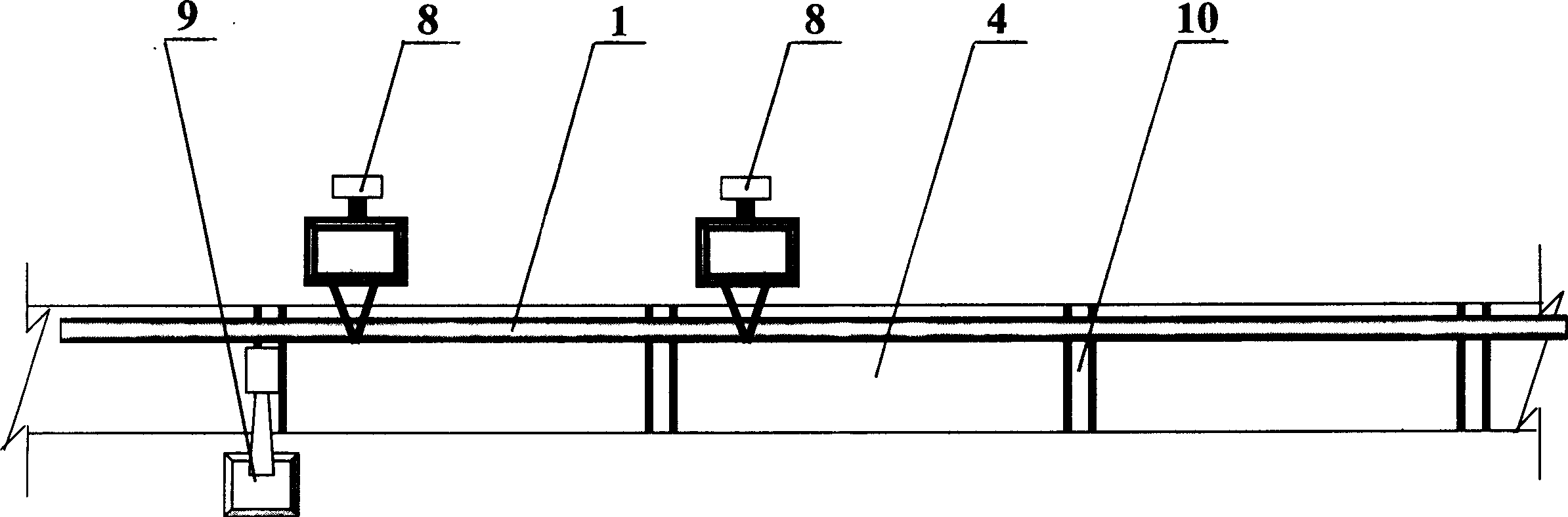

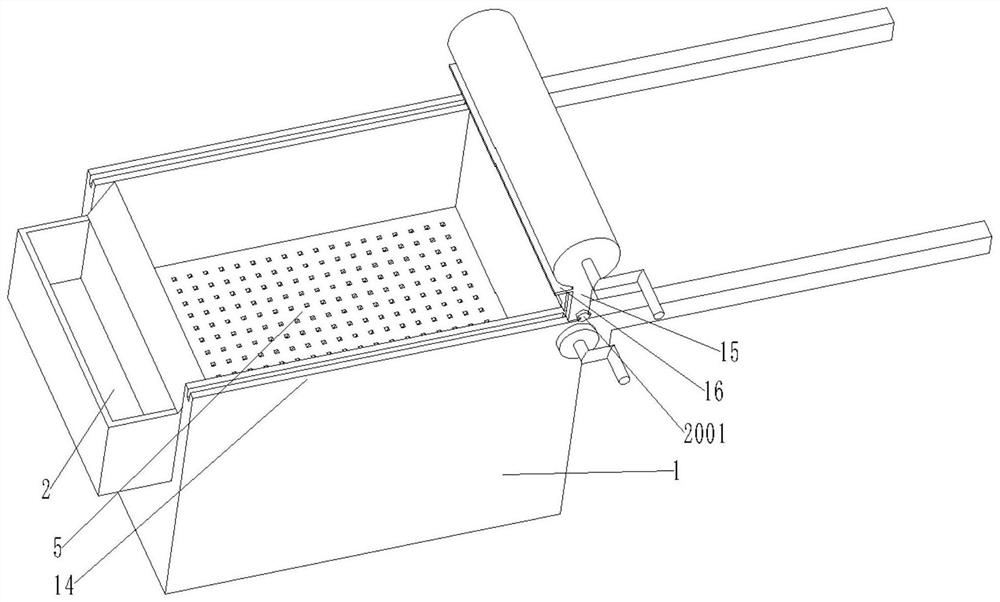

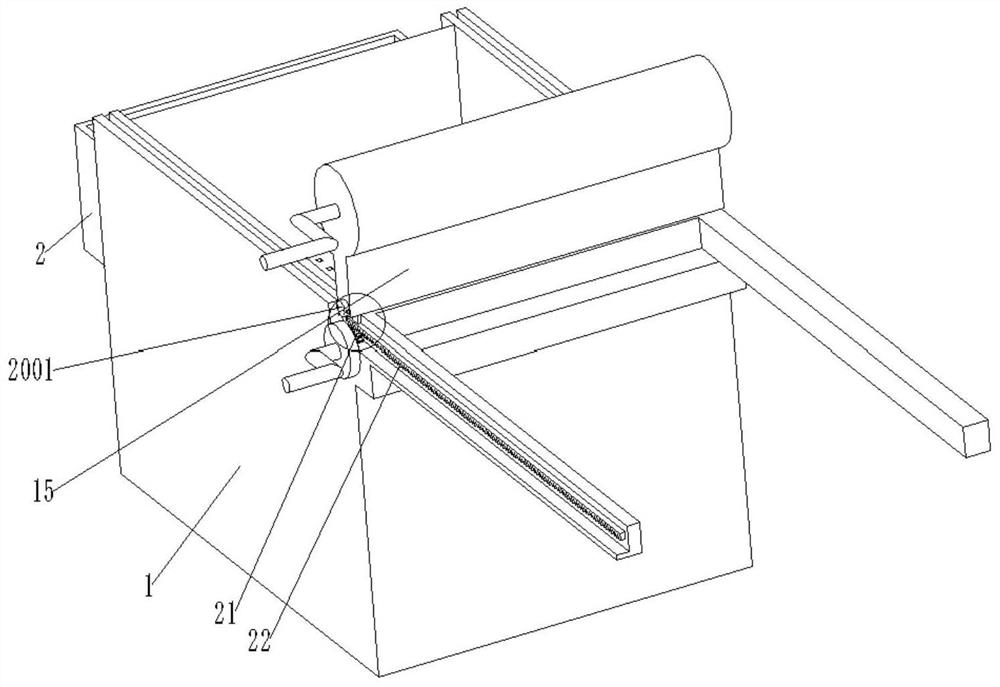

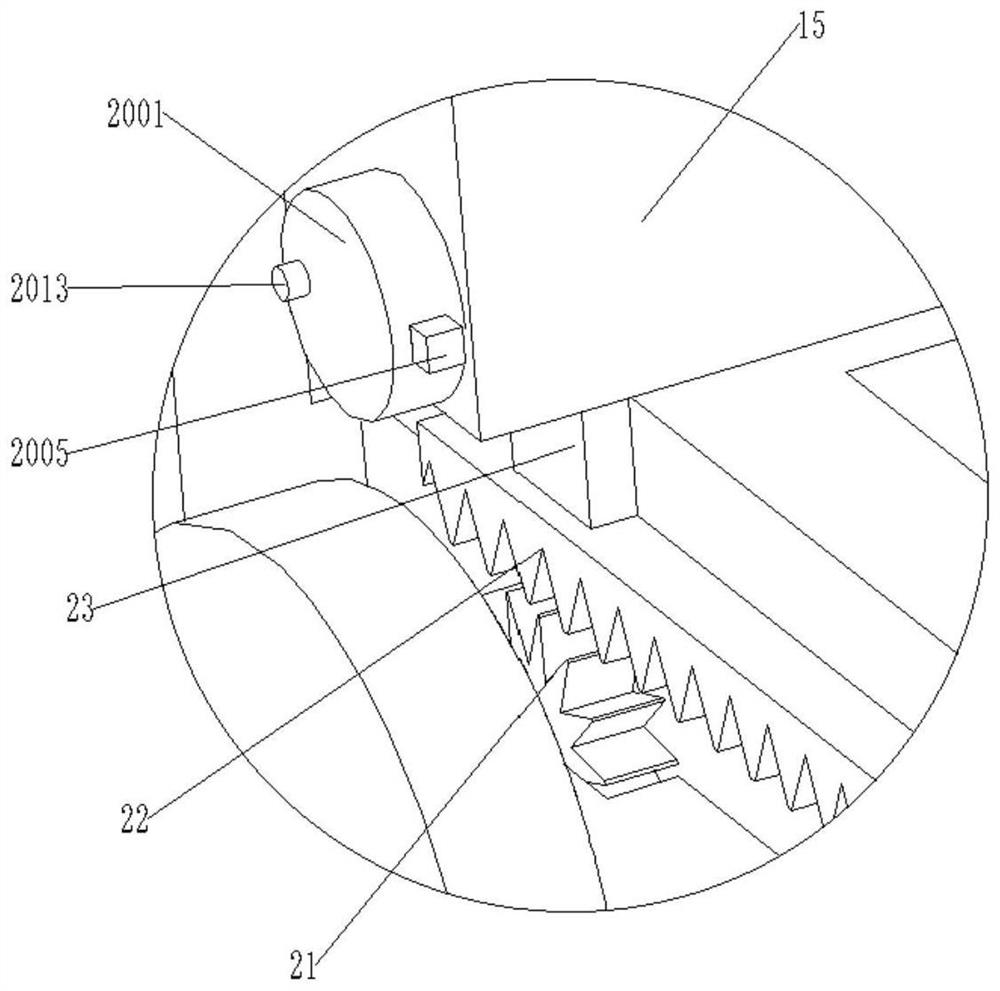

InactiveCN103658116ASmooth rideGuarantee the quality of workCleaning using gasesCleaning using liquidsSpray nozzleSolar cell

The invention discloses a non-contact solar cell panel cleaning device, and relates to solar cell panel cleaning devices. The non-contact solar cell panel cleaning device comprises a movable device (1) and a cleaning device (2) arranged on the movable device (1). The cleaning device (2) comprises a supporting mechanism (3) and a cleaning mechanism (4) connected with the supporting mechanism (3). The cleaning mechanism (4) comprises a plurality of spray pipe supports (5) arranged at intervals and a fixing mechanism (6) which connects the spray pipe supports (5) into a whole, high pressure spray pipes (14) are arranged on the spray pipe supports (5), cleaning agents used for cleaning a solar cell panel (7) are contained in the high pressure spray pipes (14), spray holes (15) which are formed at intervals are formed in each high pressure spray pipe (14), each spray hole (15) is connected with a spray nozzle (16), and the cleaning agents are sprayed onto the solar cell panel (7) through the spray nozzles (16). When the solar cell panel is cleaned through the non-contact solar cell panel cleaning device, the cleaning mechanism does not need to make contact with the solar cell panel, and therefore the solar cell panel can be effectively protected.

Owner:WUHAN ZHUOCHENG PHOTOVOLTAIC NEW ENERGY CO LTD

A method and device for precisely controlling voltage

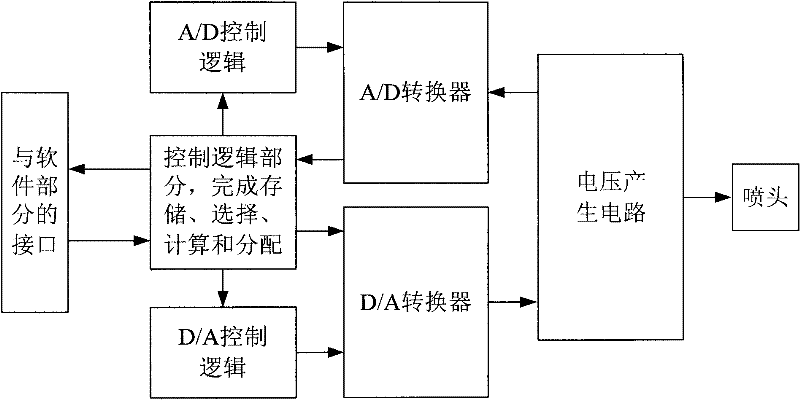

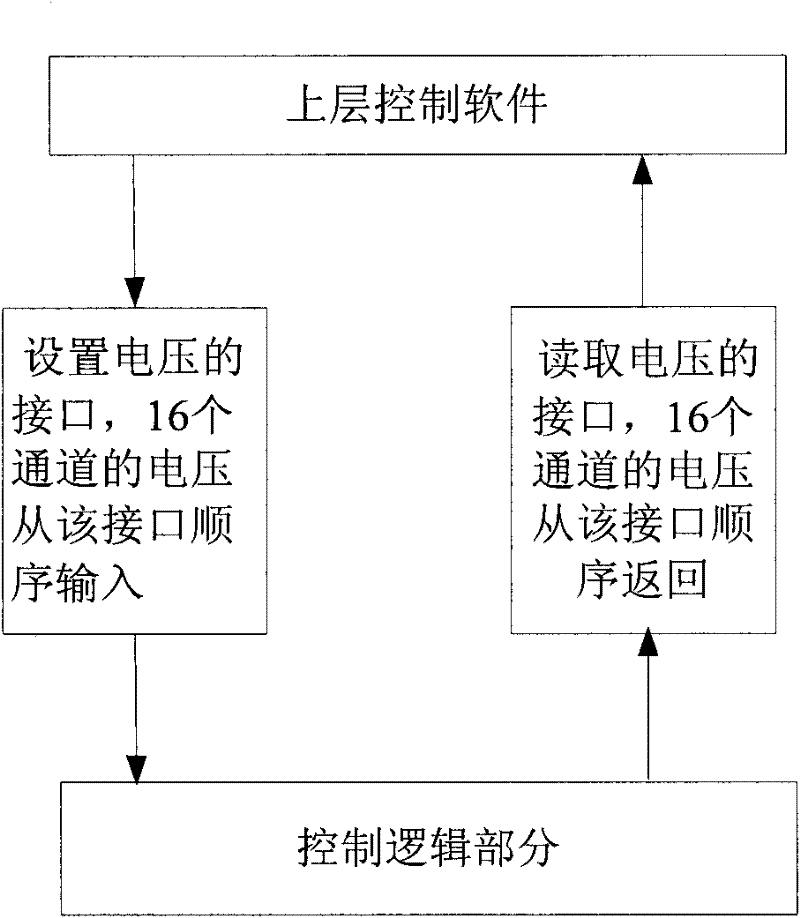

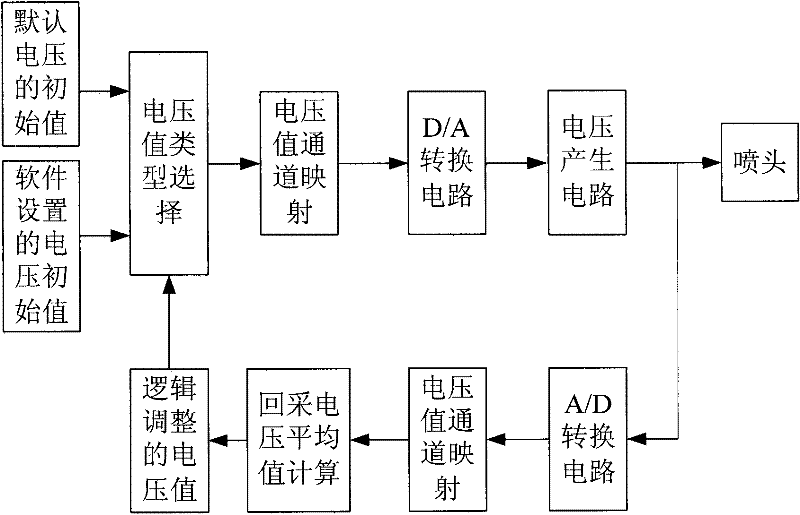

InactiveCN102262411AThe voltage value is accurateGuarantee the quality of workPrintingElectric variable regulationComputer moduleEngineering

The invention discloses a method and a device of accurately controlling voltage. In the method of accurately controlling voltage of the invention, a voltage control logic component, a D / A converter, a voltage generation circuit and an A / D converter are arranged to process real time adjustment to an output voltage on a working component so as to realize the accurate control of the output voltage on the working component. The aim of adopting the set is to combine the digital television with the analog television to accurately adjust the real time voltage on the working component so as to solve the problem that the big error between the ideal voltage and the real voltage which is generated by using the voltage generation module or circuit in the prior art.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

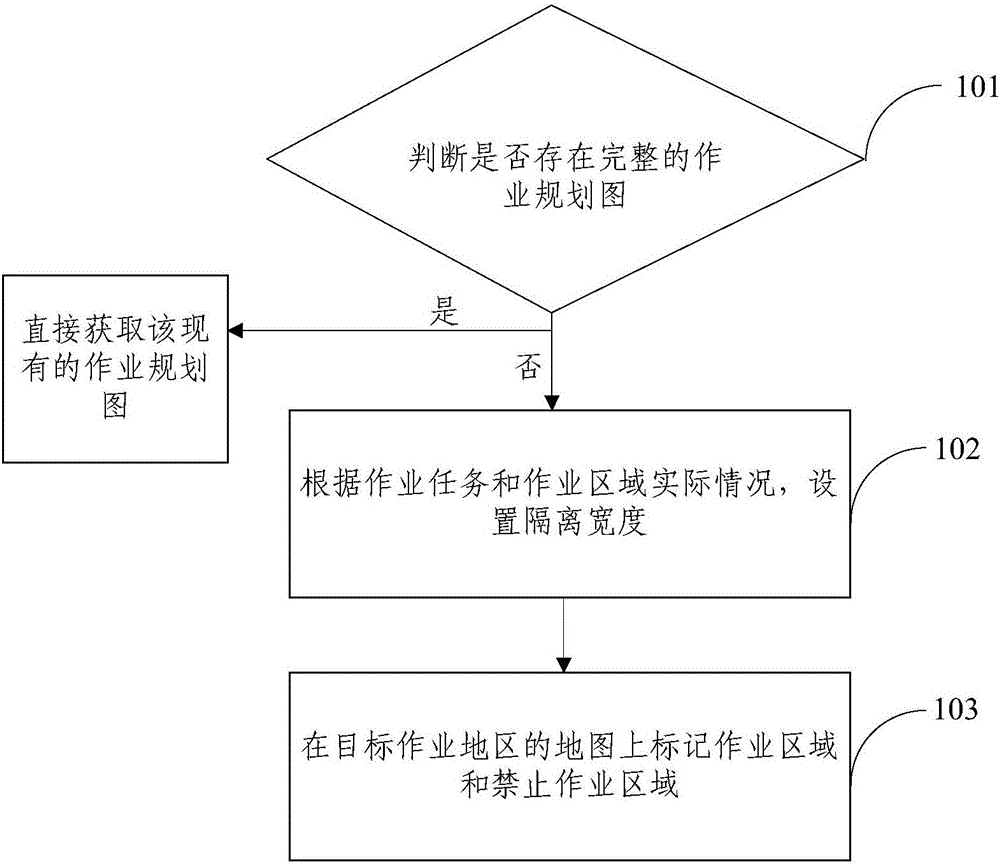

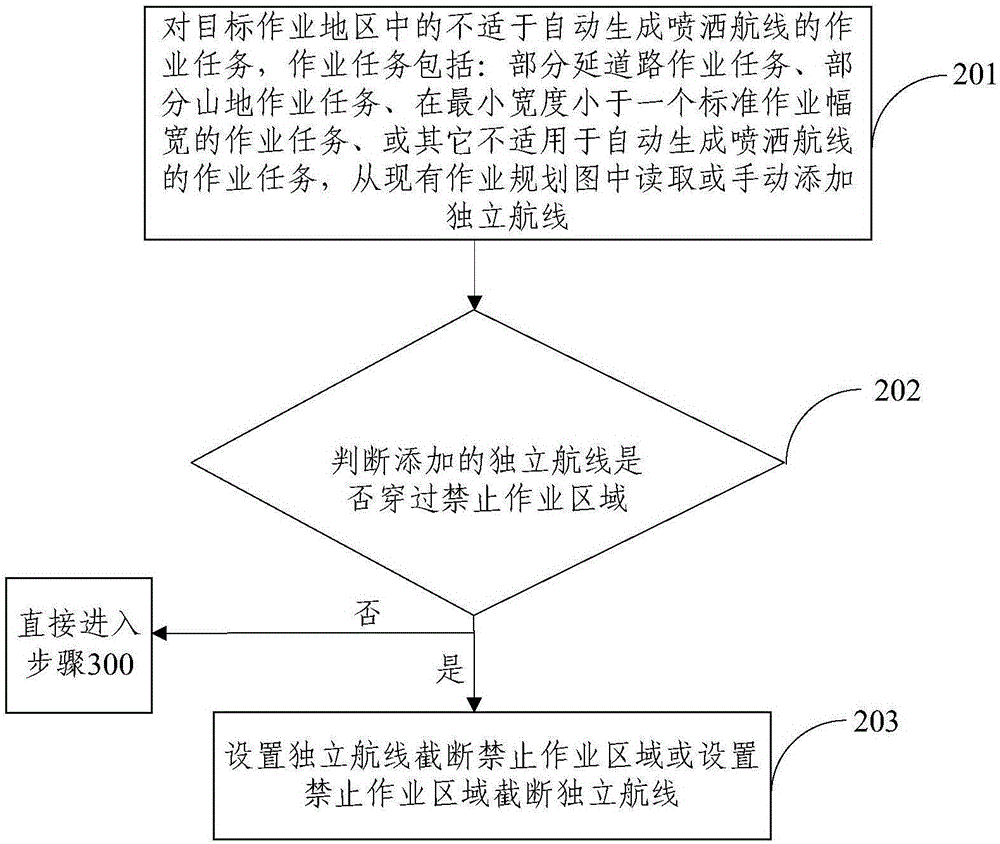

Operation air route acquiring method and system for aviation plant protection aircraft

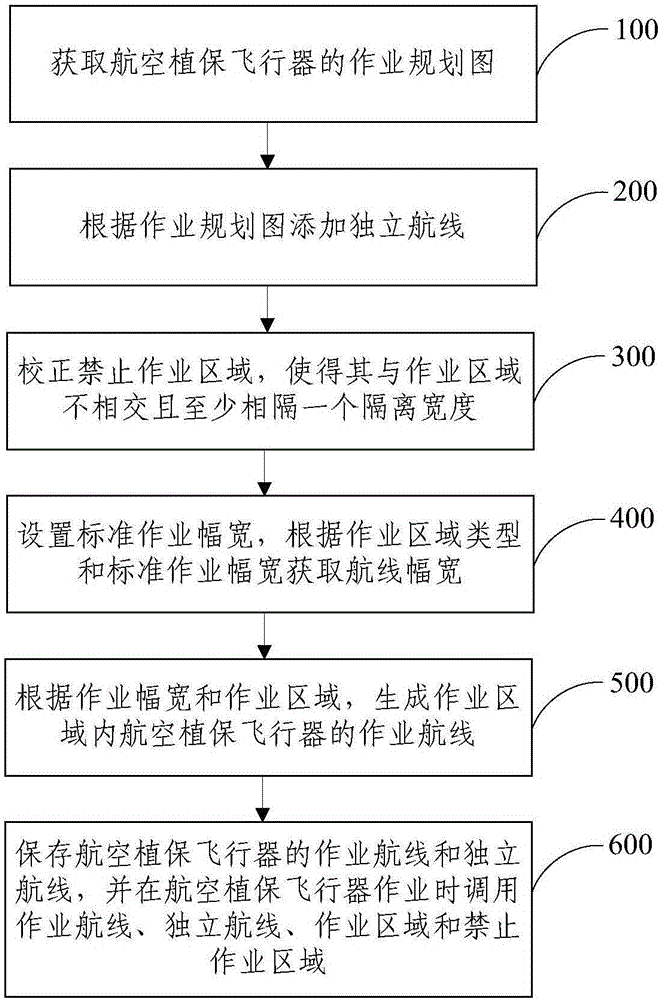

ActiveCN106382933AGuarantee the quality of workImprove accuracyNavigational calculation instrumentsNo-fly zoneAviation

The invention provides an operation air route acquiring method and a system for an aviation plant protection aircraft. The operation air route acquiring method comprises the following steps of: acquiring an operation plan diagram of the aviation plant protection aircraft, adding independent air routes according to the operation plan diagram, correcting an operation forbidding area, acquiring the amplitude widths of the independent air routes, generating operation air routes of the aviation plant protection aircraft according to the independent air routes and the operation amplitude widths, storing the operation air routes of the aviation plant protection aircraft, and calling the operation air routes of the aviation plant protection aircraft in operation. The system comprises a plan diagram acquiring module, an independent air route addition module, a forbidding operation area correction module, an amplitude width acquiring module, an operation air route generation module and an operation air route storage and calling module. By adopting the technical scheme of the invention, a pilot can find routes according to a diagram in operation, and through reasonable route planning, the operation quality can be ensured, meanwhile the aircraft does not fly to a no-fly zone, and the accuracy and reliability of aviation operation of the aviation plant protection aircraft can be improved.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

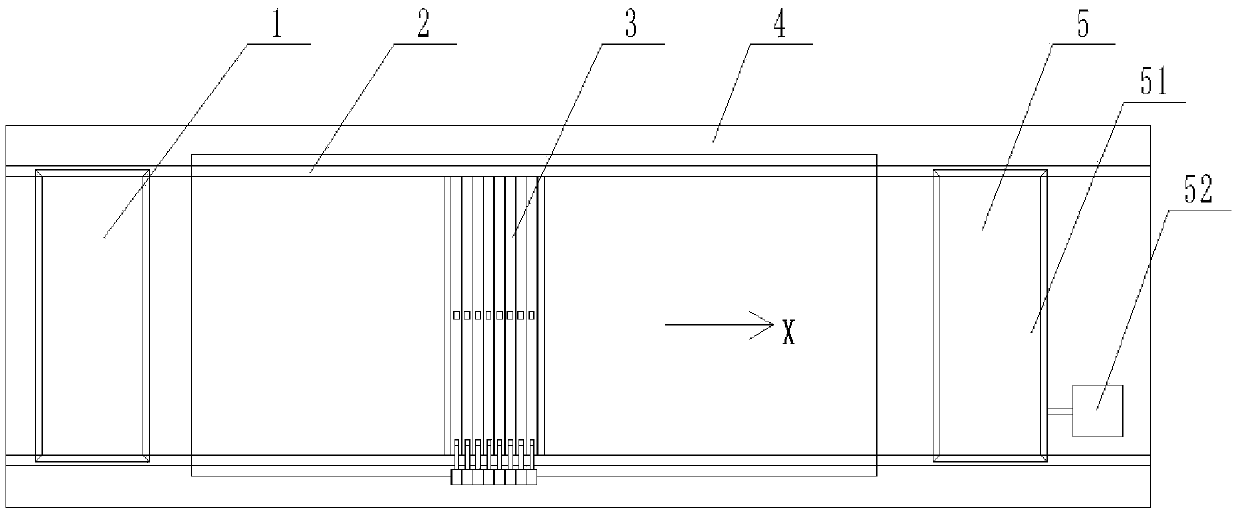

High-speed reciprocating type color 3D printer

ActiveCN105365221AImprove printing efficiencyHigh speed formationManufacturing platforms/substrates3D object support structuresHigh volume manufacturingDark color

The invention discloses a high-speed reciprocating type color 3D (Three-dimensional) printer which comprises a spray head component capable of horizontally moving along one direction, preferably the X-axis direction, and a working table capable of vertically moving along the Z-axis direction, wherein a plurality of spray pipes are mounted on the spray head component, and respectively contain various liquid printing materials including a white base material and various color materials. In one moving process, the spray pipes work separately, an image, particularly an area of darker color in the image, is printed out with the white base material, then colors of the image are printed with the color materials, and partial area in the finally formed image is bulged outward, so that the three-dimension effect of the image is improved, and the image is more vivid; the printing speed of the high-speed reciprocating type color 3D printer is world-leading; and the high-speed reciprocating type color 3D printer is quicker and more flexible, is higher in efficiency, and is especially suitable for mass production.

Owner:范春潮

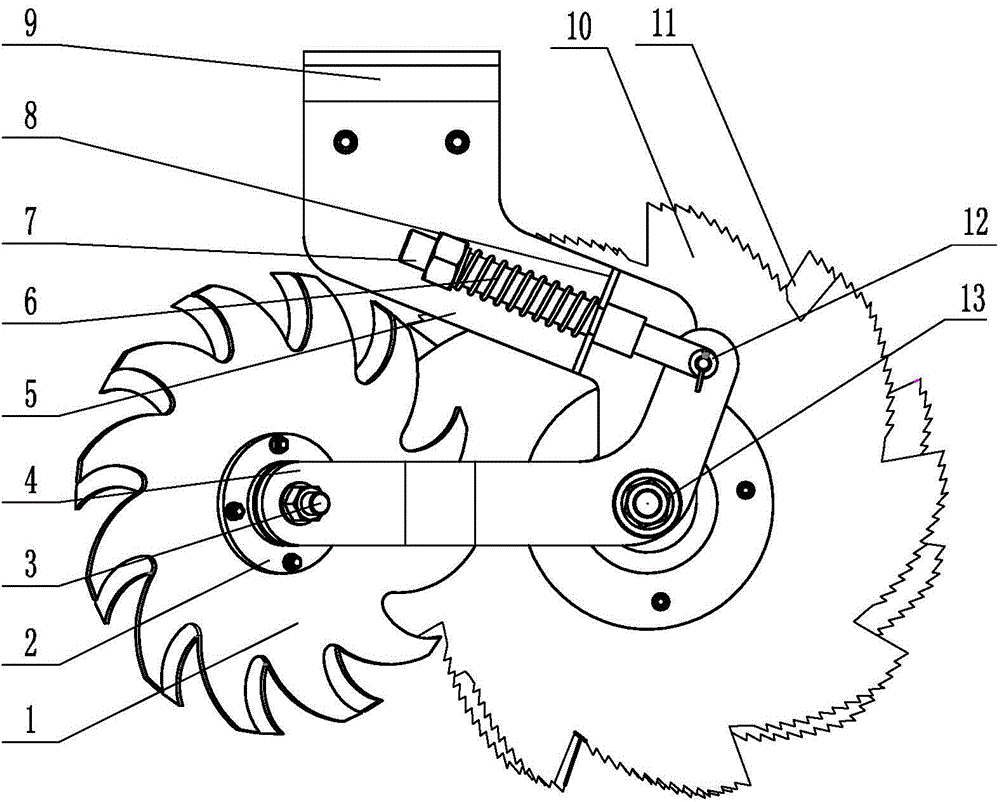

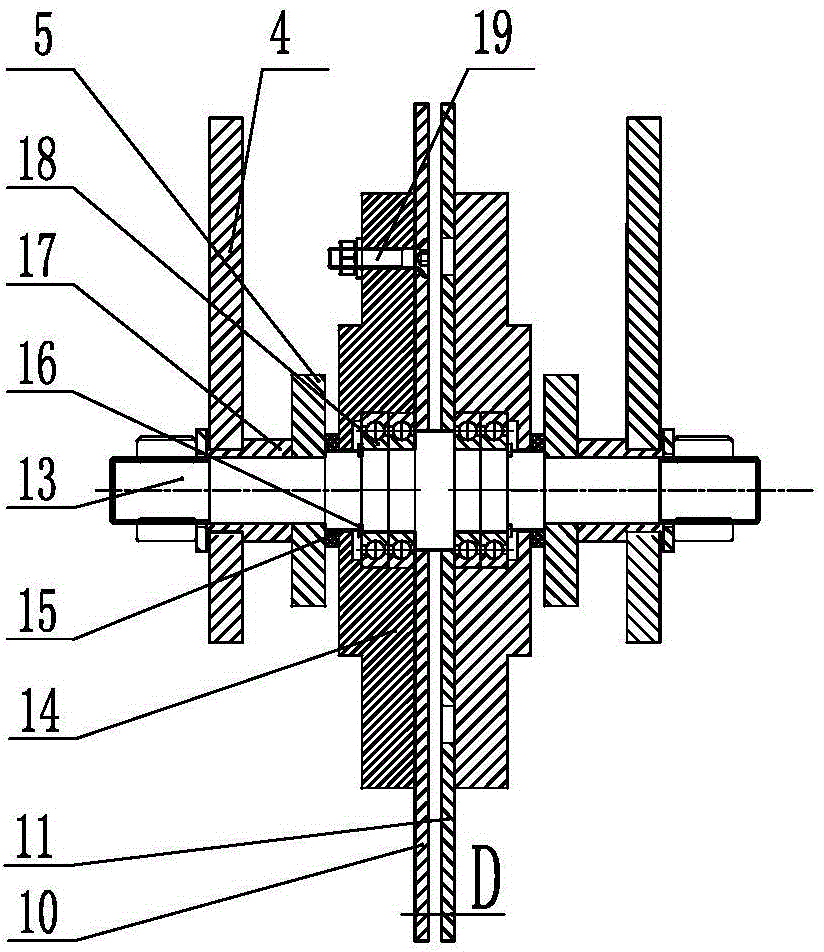

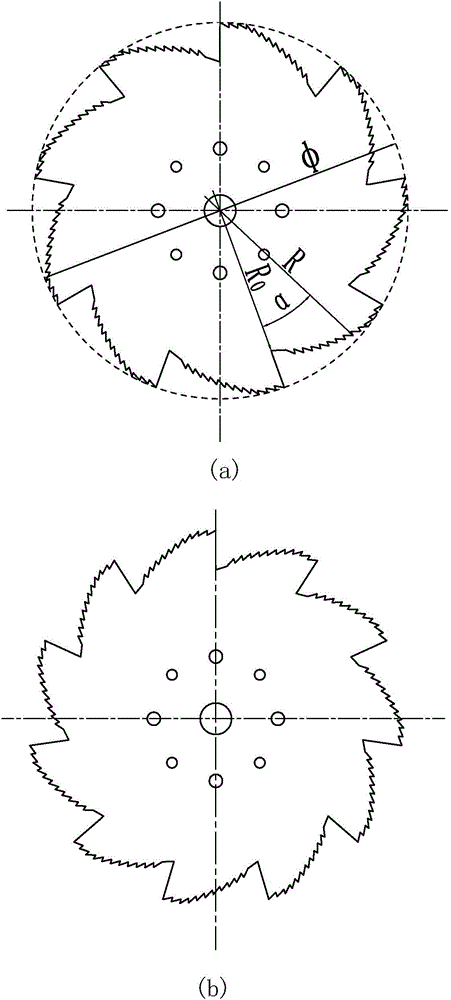

Cutting, shifting and blocking preventing device

InactiveCN104081898AAvoid missed cutsWork resistance is smallSpadesPloughsDevice formAgricultural machinery

The invention discloses a cutting, shifting and blocking preventing device, and belongs to the technical field of agricultural machinery. The cutting, shifting and blocking preventing device comprises a spindle, connecting sleeve plates, inclined plates, a breaking and cutting device and stubble shifting and blocking preventing devices, wherein the breaking and cutting device is mounted in the middle of the spindle, two groups of stubble shifting and blocking preventing devices are symmetrical about the breaking and cutting device and connected to two ends of the spindle, stubble shifting wheels of the stubble shifting and blocking preventing devices and breaking and cutting discs of the breaking and cutting device form deflection angles, and accordingly, the two symmetrical stubble shifting wheels are mounted on two sides of the end part of the breaking and breaking and cutting device in a splayed manner and simultaneously backwards shift stubble and laterally push stubble, straw and weeds; the connecting sleeve plates are symmetrically connected between the breaking and cutting device and the stubble shifting and blocking preventing devices on the spindle and are simultaneously connected with the stubble shifting and blocking preventing devices respectively; and during working, the two connecting sleeve plates are connected with a no-tillage planter for corn ridge culture respectively. The device can cut the stubble, straw and weeds, can shift the stubble, can throw the straw, the stubble and the weeds to the rear side and can push the straw, the stubble and the weeds to furrows on two sides, a clean seed bed is formed on a ridge, blocking is reduced, and the breaking and cutting quality is guaranteed.

Owner:SHENYANG AGRI UNIV

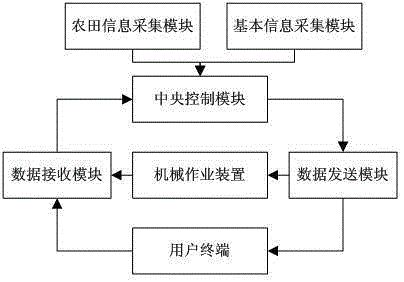

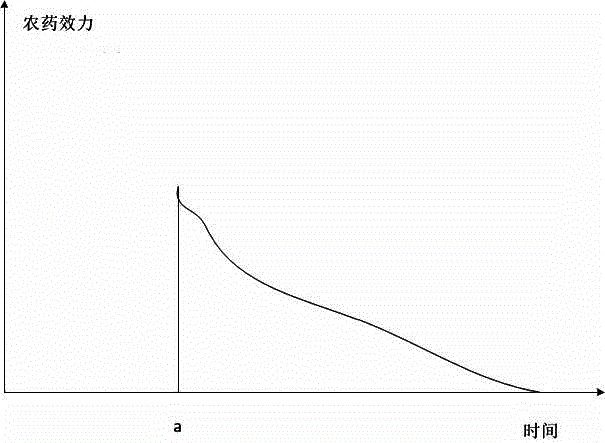

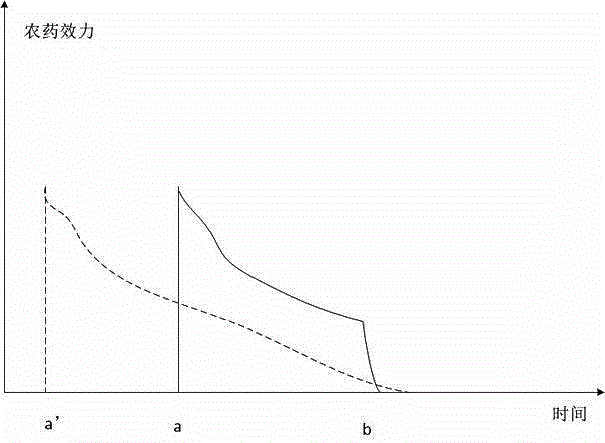

Pesticide spraying machinery management control system based on internet of things

ActiveCN105353689ARefined comprehensive serviceGuaranteed accuracyProgramme controlComputer controlControl systemComputer terminal

The invention discloses a pesticide spraying machinery management control system based on internet of things. The system comprises a basic information acquisition module, a farmland information acquisition module, a central control module, a data transmitting module, a mechanical operation device, a data receiving module and a user terminal. The central control module is used for configuring pesticide application time and pesticide species ratio for each kind of preset agricultural situation information serving as a constraint condition according to agricultural situation station information of a service area to form a preset pesticide application time table and a preset pesticide species ratio table, and acquiring pesticide species ratio and effective pesticide application time period corresponding to each piece of actual agricultural situation information by mapping; the data transmitting module is used for transmitting; and the mechanical operation device comprises a GPS (Global Positioning System) positioning module, a liquid level sensing module and a processing and execution module. By adopting the system, scientific and reasonable pesticide species ratio and effective pesticide application time period can be selected, and accurate operation is implemented by intelligent pesticide spraying machinery, so that the accuracy of pesticide mode and time selection is scientifically ensured.

Owner:ZHONGNONG ONLINE SHOPPING JIANGSU ELECTRONICS COMMERCE CO LTD

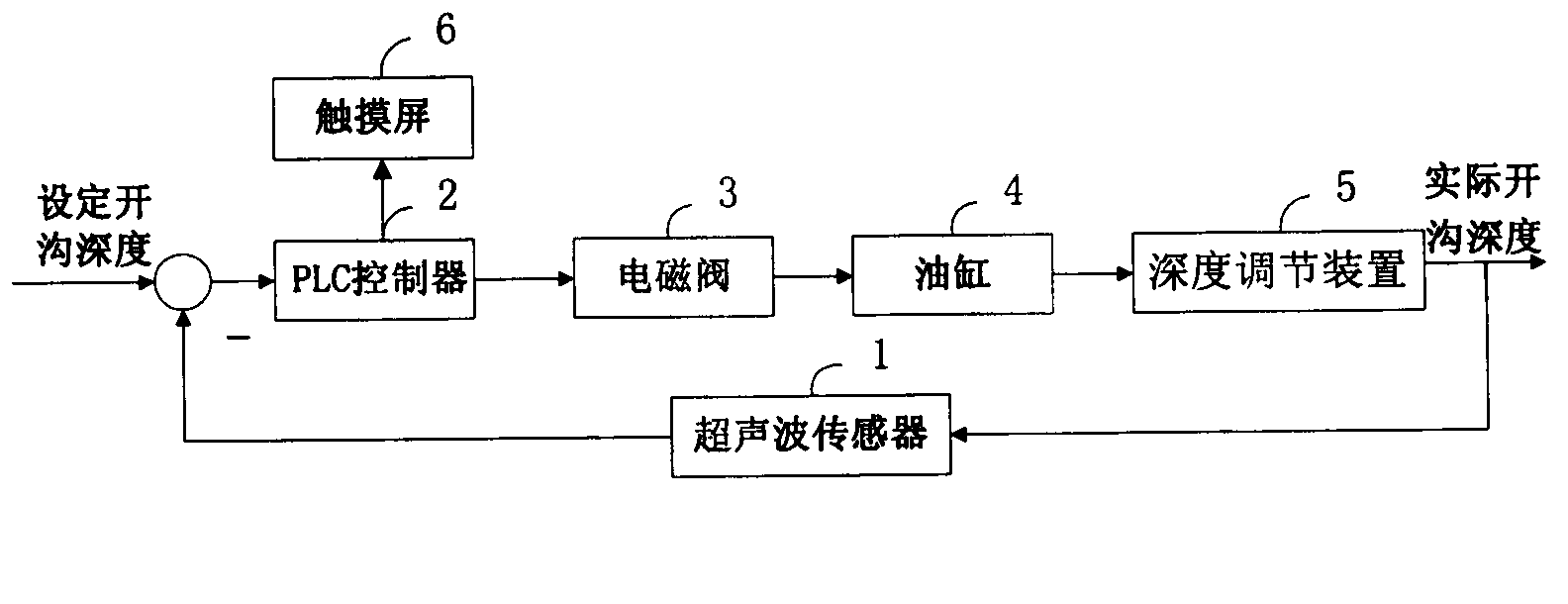

Seeder depth control system

InactiveCN103543755AControl depthDepth adjustmentControl using feedbackProgramme control in sequence/logic controllersSeederElectricity

The invention discloses a seeder depth control system. Land unevenness is collected by an ultrasonic sensor and converted into an electrical signal; the electrical signal is transmitted to a PLC to process; processing results are output an analog output module; action of an electromagnetic valve is controlled; an oil cylinder is driven to descend or ascend; a ditcher depth regulator is controlled in real time. Seeding depth can be regulated quickly and accurately. Seeding depth of a seeder can be precisely controlled effectively. Related parameters can be set in real time through an embedded integrated touch screen. The touch screen is communicated with the PLC through a communication port. Related information acquired is centrally displayed in real time. The seeder depth control system has the advantages that the quality of crop planting is guaranteed, the copying form of each component of a seeding unit of the precision seeder can be designed into independent copying, and seeding depth can be independently controlled according to surface fluctuation.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

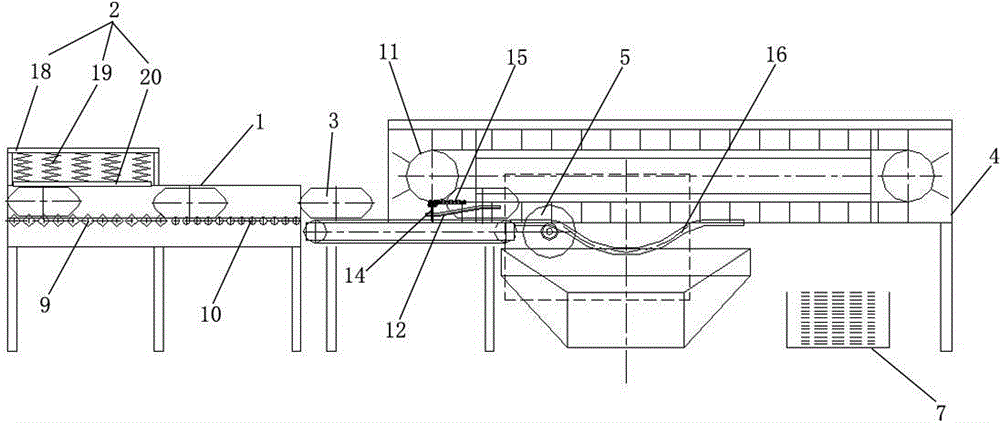

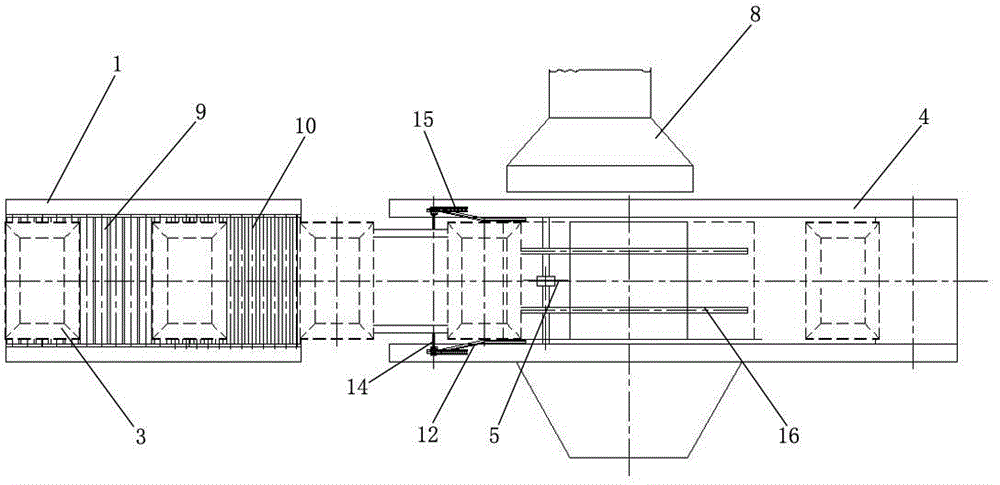

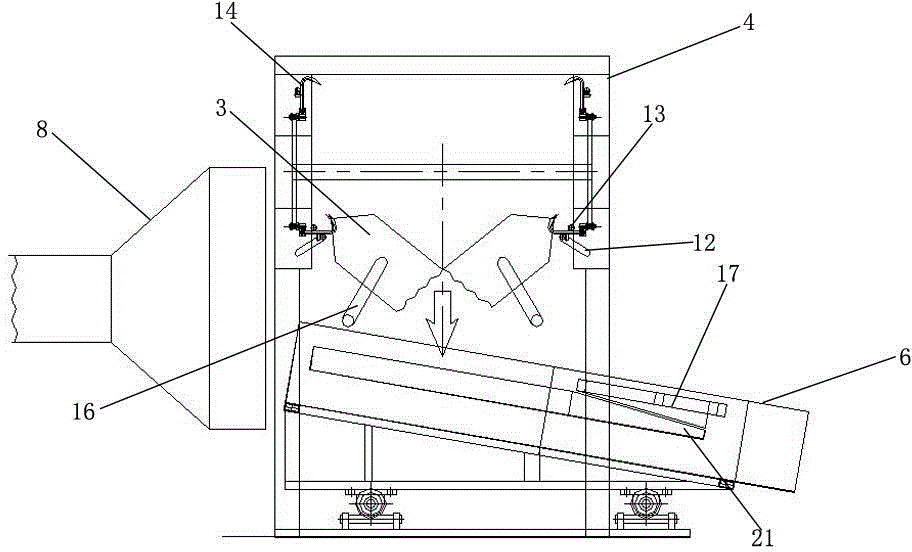

Automatic and continuous bag-breaking and unloading device

ActiveCN104960717ACompact front and backPractical and reliable mechanical structureUnpacking by cuttingButt jointEngineering

The invention discloses an automatic and continuous bag-breaking and unloading device. The automatic and continuous bag-breaking and unloading device comprises a bag reshaping area, a belt conveyer and a bag-breaking unloading area which are arranged on the front, middle and rear sections respectively. The bag-breaking reshaping area comprises a vibration machine frame and a spring supporting frame, wherein the spring supporting frame is arranged above the vibration machine frame in an erected mode; the vibration machine frame is provided with a transmission roller mechanism; a floating interval where bags pass in a reshaping mode is kept between the spring supporting frame and the transmission roller mechanism; the front portion of the belt conveyer is in butt joint with the transmission roller mechanism, and the rear portion of the belt conveyer is in butt joint with the bag-breaking unloading area; the bag-breaking unloading area comprises a rack, a hook mechanism, a cutter, a vibration sieving mechanism, an empty bag collecting frame and a dustproof mechanism. The automatic and continuous bag-breaking and unloading device is simple and compact in structure, integrates the integration and reshaping procedure and the bag-breaking unloading procedure, realizes an automatic and continuous production mode of bag reshaping and bag-breaking unloading, is economical and durable, and is not prone to having faults after being operated for a long time.

Owner:HANGZHOU WAHAHA GROUP

Pasting machine

InactiveCN101144325AAdjustable inclinationMeet the use requirementsBuilding constructionsEngineeringFly ash

The invention relates to a plastering device, and the plastering device belongs to a building construction machinery, the invention comprises a machine seat, a machine frame guide way, an ash supply device and a plastering head, wherein, the plastering head comprises a plastering head frame, a spatula and an ash storage room, the spatula is a rectangular plate, and arranged at the upper part of the plastering head frame, the front face of the ash storage room is composed of an upper soft face cover and a lower hard face cover, the rear face of the ash storage room is composed of a bottom bag, the lower fringe of the spatula is connected with the lower fringe of the bottom bag, an ash outlet is composed of a gap between the upper fringe of the soft face cover and the lower fringe of the spatula, the lower fringe of the hard face cover and the lower fringe of the bottom bag are respectively connected with the two upper fringes of a tubular agitating ash groove, a packing auger is arranged in the agitating ash groove, an ash inlet connected with the ash supply device is arranged on the agitating ash groove, an ash sealing plate is arranged on the both sides of the plastering head frame, the ash sealing plate is arranged on a supporting bearing, a back moving spring is arranged between the ash sealing plate and the plastering head frame. The operation is convenient, the operating is reliable, the invention can easily execute the plastering on the top end of the wall body, the fly ash is reduced, and the working quality and the efficiency are effectively guaranteed.

Owner:张兴波

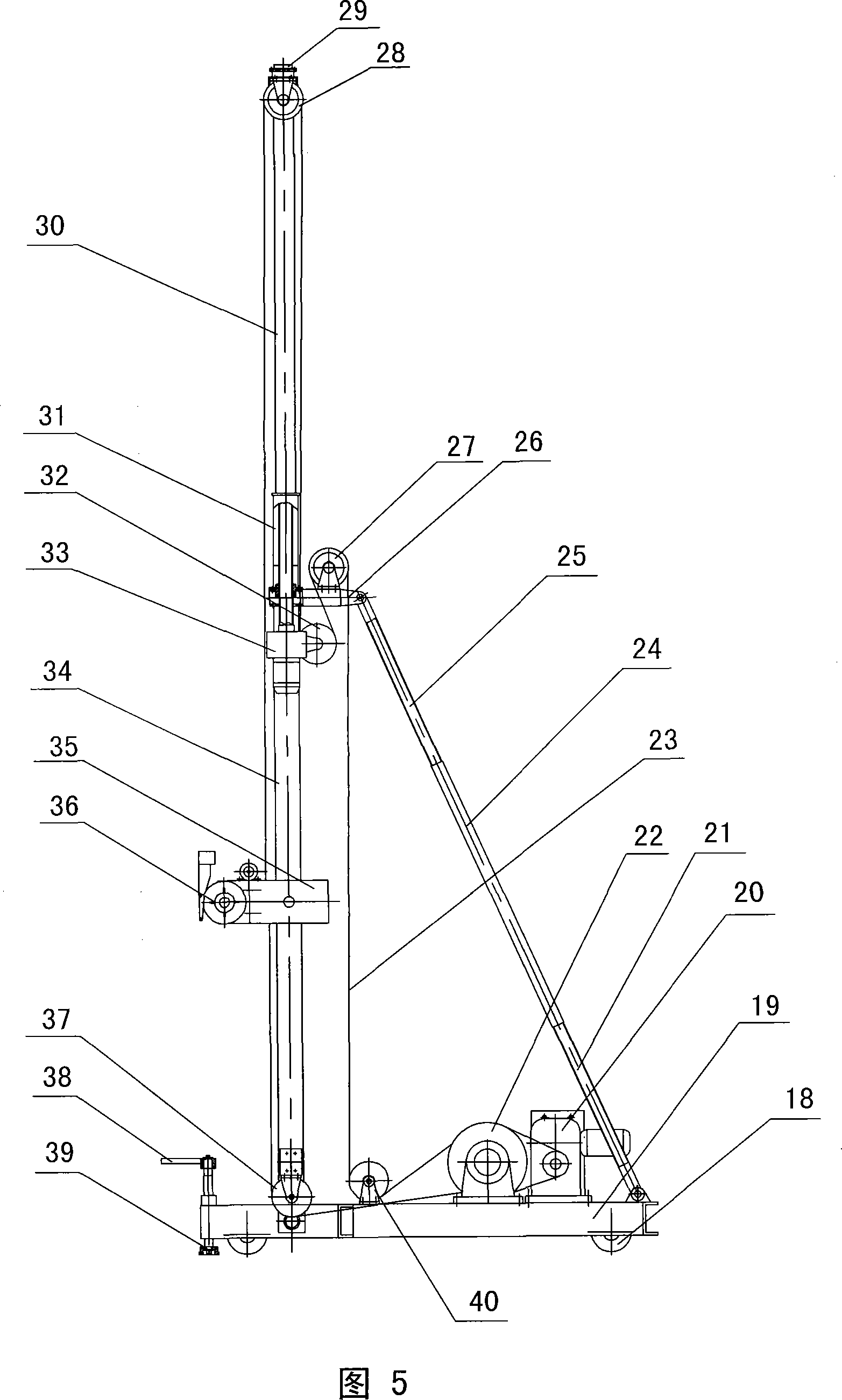

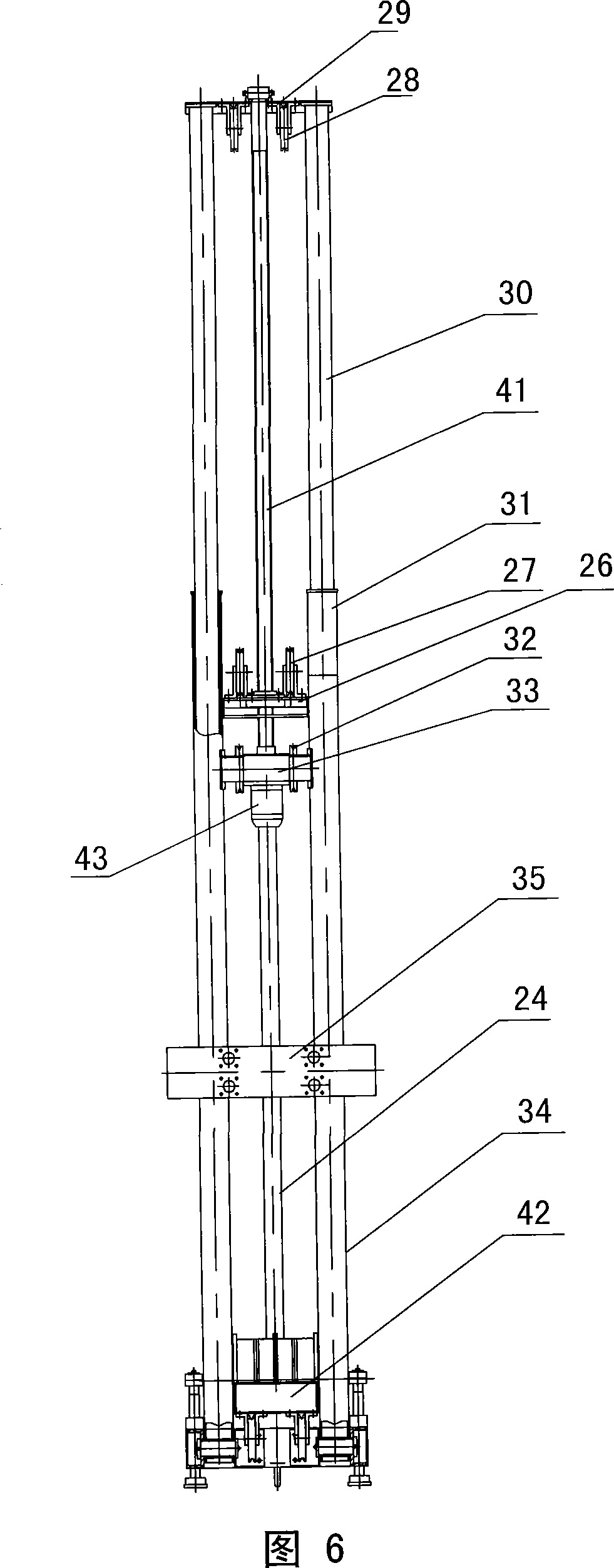

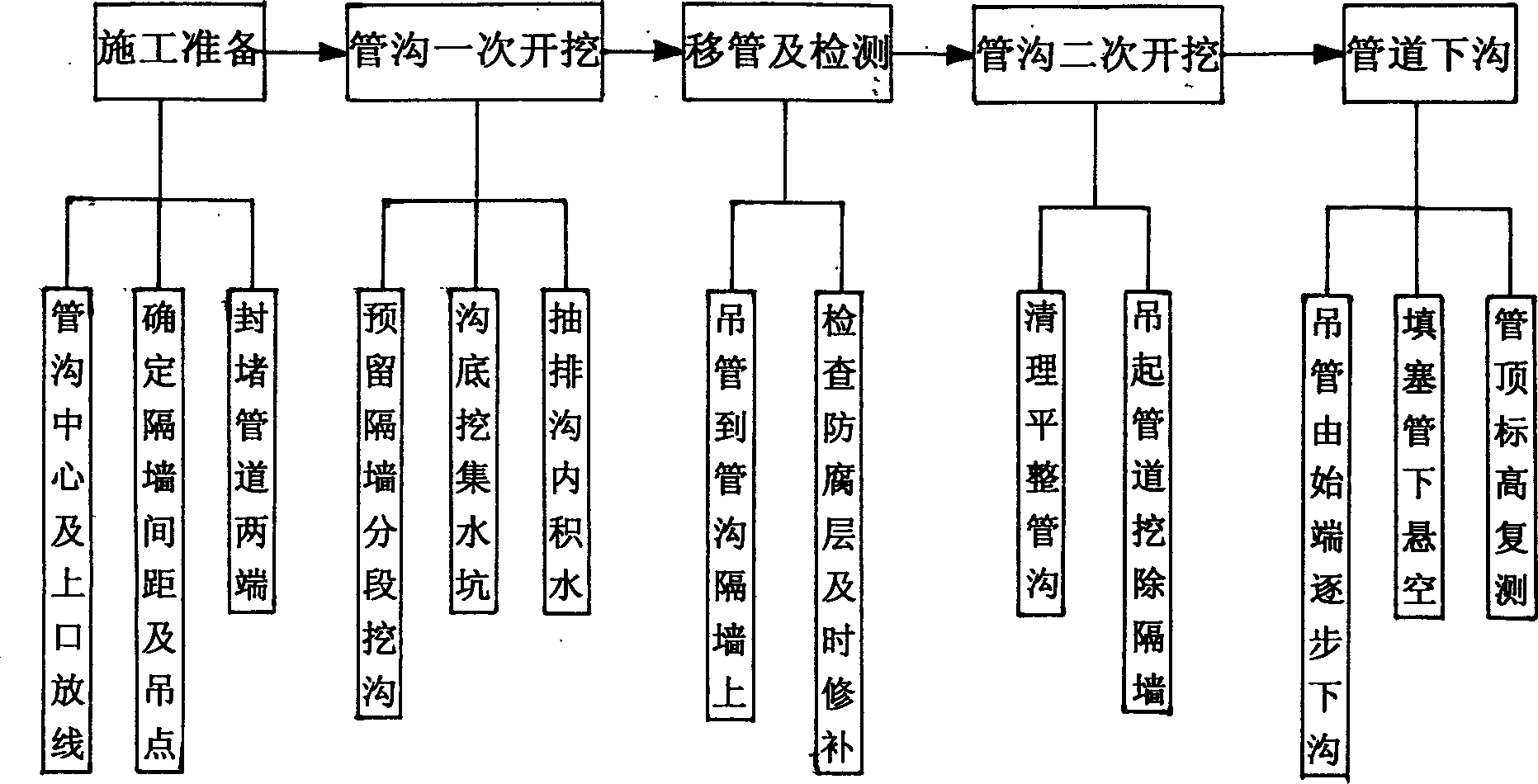

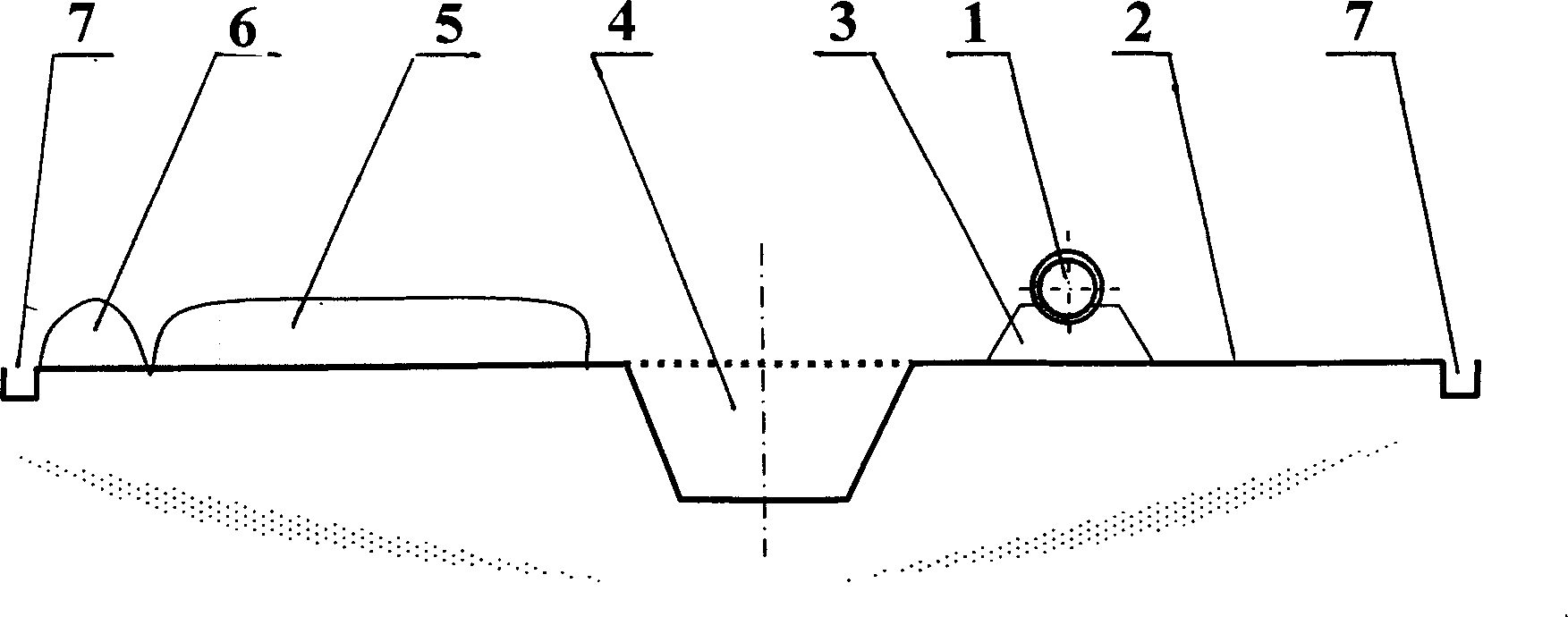

Down-ditch construction method for laying heavy caliber pipeline

InactiveCN1558130AAvoid tipping accidentsGuarantee the quality of workPipe laying and repairDitchPipe layer

The present invention is the construction process of laying wide bore pipe into pipe canal and relates to one important pipeline construction step. The present invention features that during excavating pipe canal, one soil partition wall is preserved in each certain distance; the pipe is first hoisted with two pipe layers and settled on the partition walls, and the initial end of the pipe is lifted before the soil partition wall is dug out with excavator and then settled slowly into the pipe canal; and all the partition walls are dug out successively and the pipes are settled in the pipe canal. The construction process includes the main steps of: preparation, the first pipe canal excavation, shifting pipes and detection, the second pipe canal excavation, and laying the pipes. The main advantages includes using two pipe layers only, low cost, low power consumption, simplified construction process, short construction period, etc.

Owner:NO 3 BRANCH OF SHENGLI PETROCHEM BUILDING CO LTD SHENGLI OIL FIELD

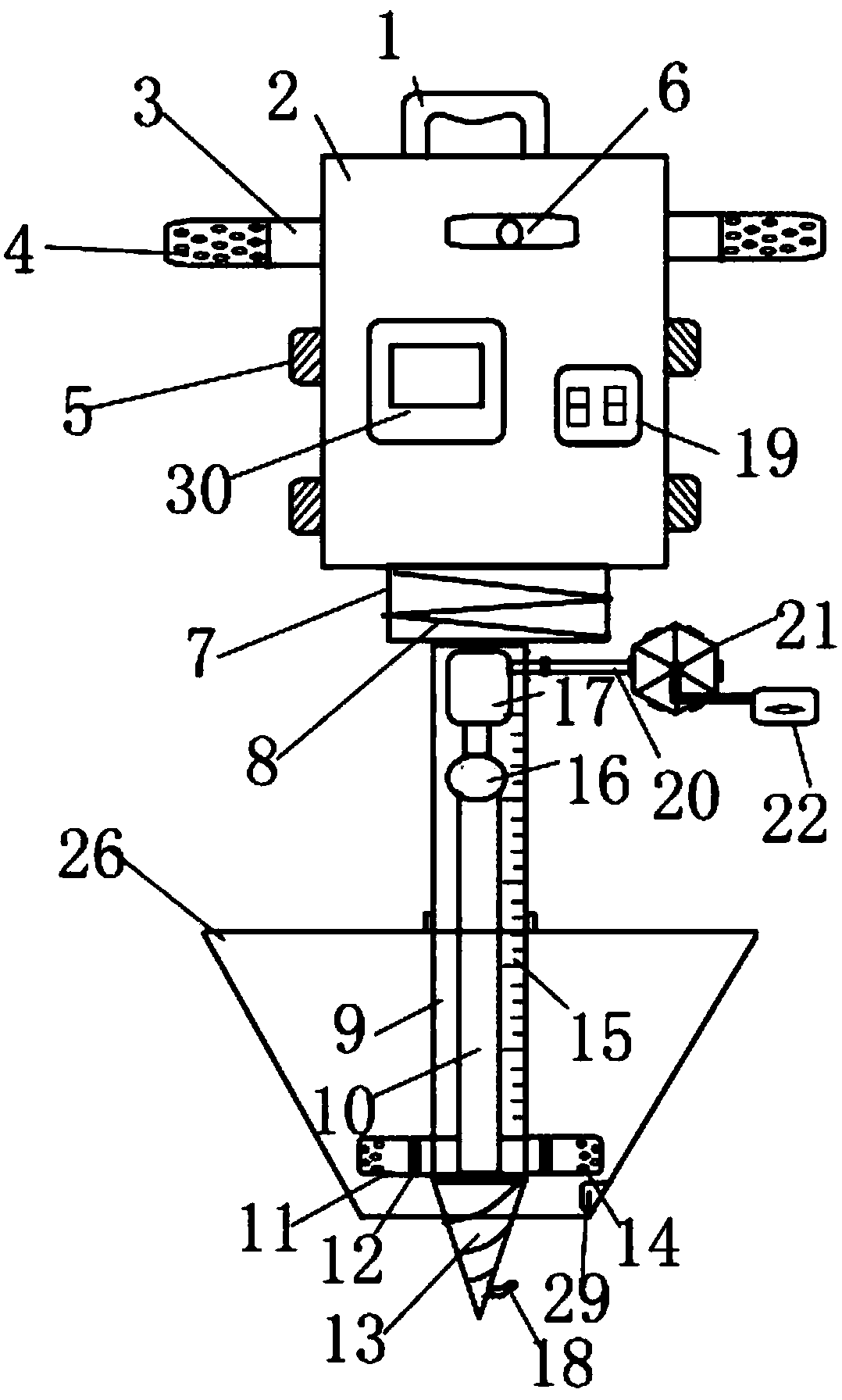

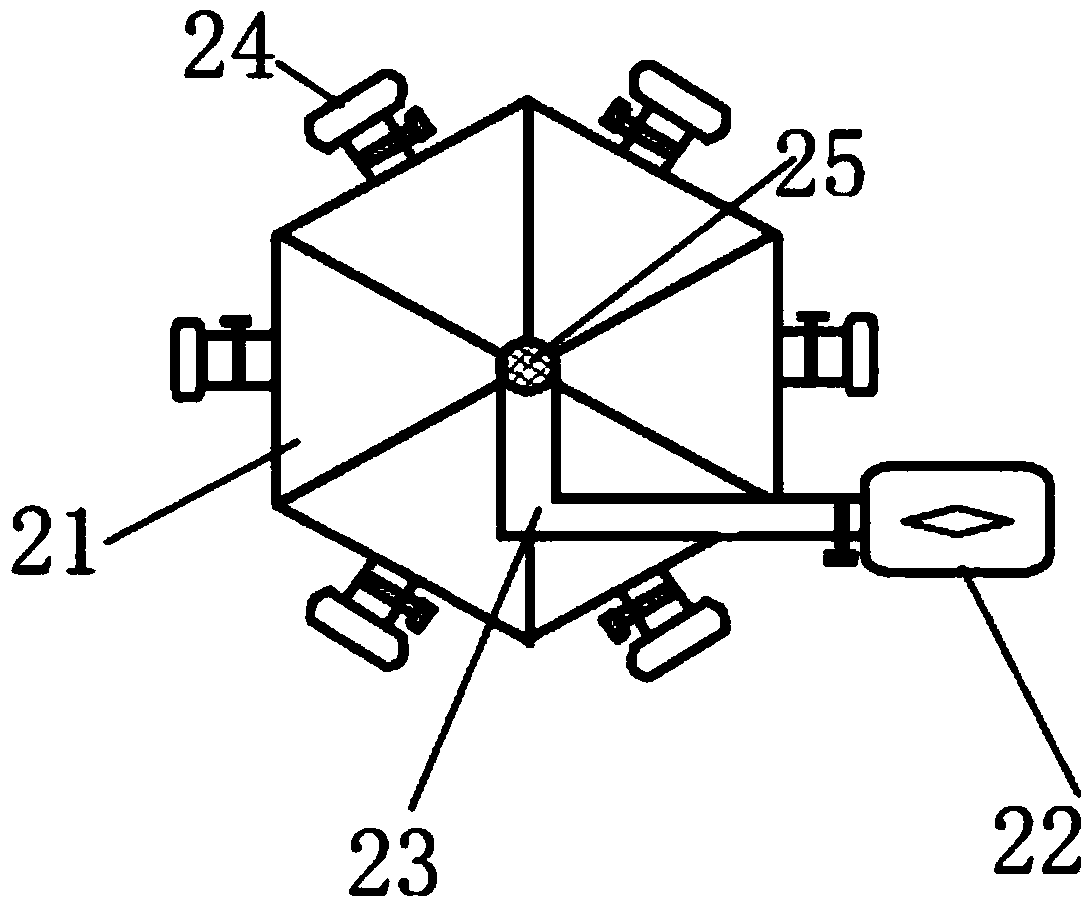

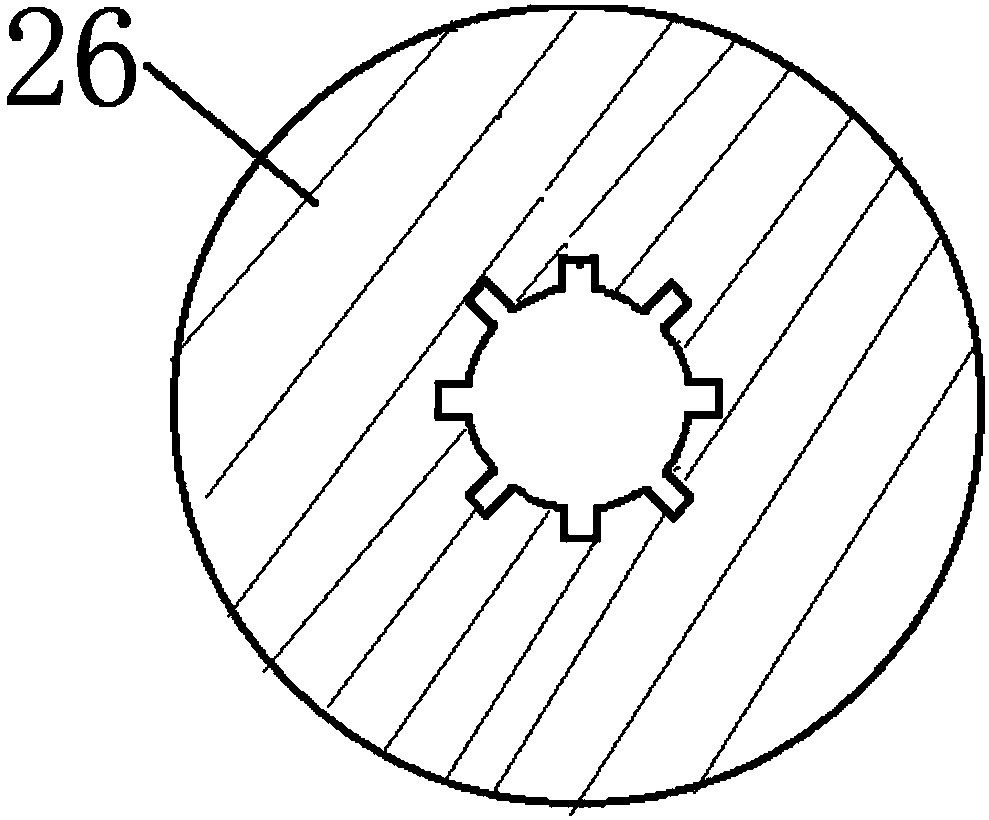

Safety water quality detecting and sampling device

InactiveCN107796667AEasy extractionEasy accessWithdrawing sample devicesMaterial analysis by optical meansWater qualityEngineering

The invention discloses a safety water quality detecting and sampling device which comprises a motor, LED (light-emitting diode) lamps, a level gauge, a damping spring, a rotating shaft, a water conveying pipe, water taking heads, filtering screens, a drilling bit, an air bag, a water collection bottle, a sampling spoon and a timer. A handle is arranged at the top end of the motor, hand shanks arearranged on two sides of the motor, antiskid sleeves sleeve the hand shanks, the LED lamps are arranged on the side wall of the motor, the timer is arranged on the motor, the level gauge is arrangedon the motor, the motor is connected with the rotating shaft through a connecting part, the damping spring is arranged in the connecting part, the drilling bit is arranged at the bottom end of the rotating shaft, the water taking heads are arranged on two sides of the bottom end of the rotating shaft, through holes are formed in the water taking heads, the filtering screens are arranged in the water taking heads, the water conveying pipe is arranged in the rotating shaft, one end of the water conveying pipe is connected with the water taking heads, the other end of the water conveying pipe isconnected with the water collection bottle, the air bag is arranged on the water conveying pipe, scales are arranged on the rotating shaft, and the sampling spoon is arranged on the side wall of the bottom end of the drilling bit. The device is convenient in detection, simple in structure and convenient to use, and popularization is facilitated.

Owner:BEOSON JIANGSU FOOD SAFETY TECH CO LTD

Marketing activity information creating method and device and computer equipment

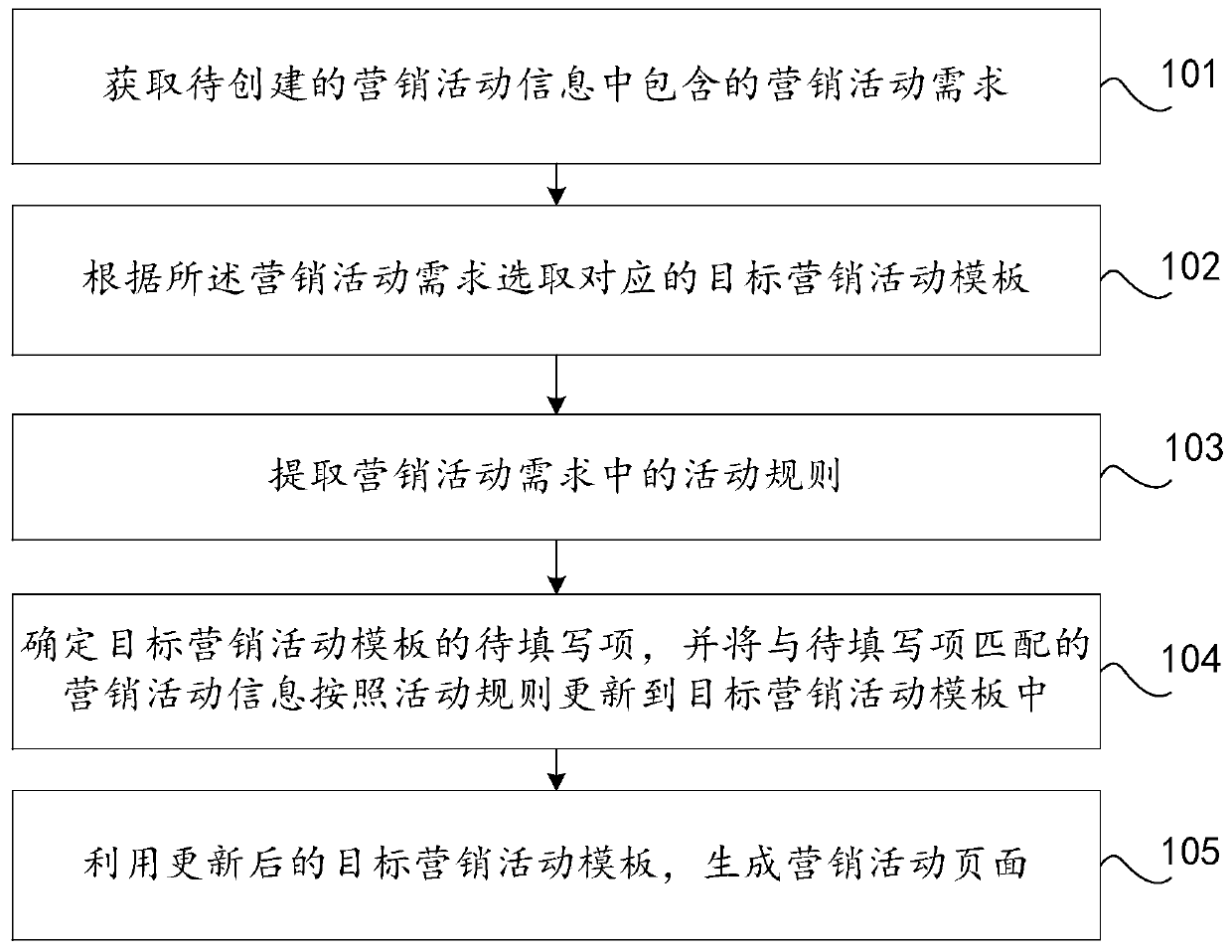

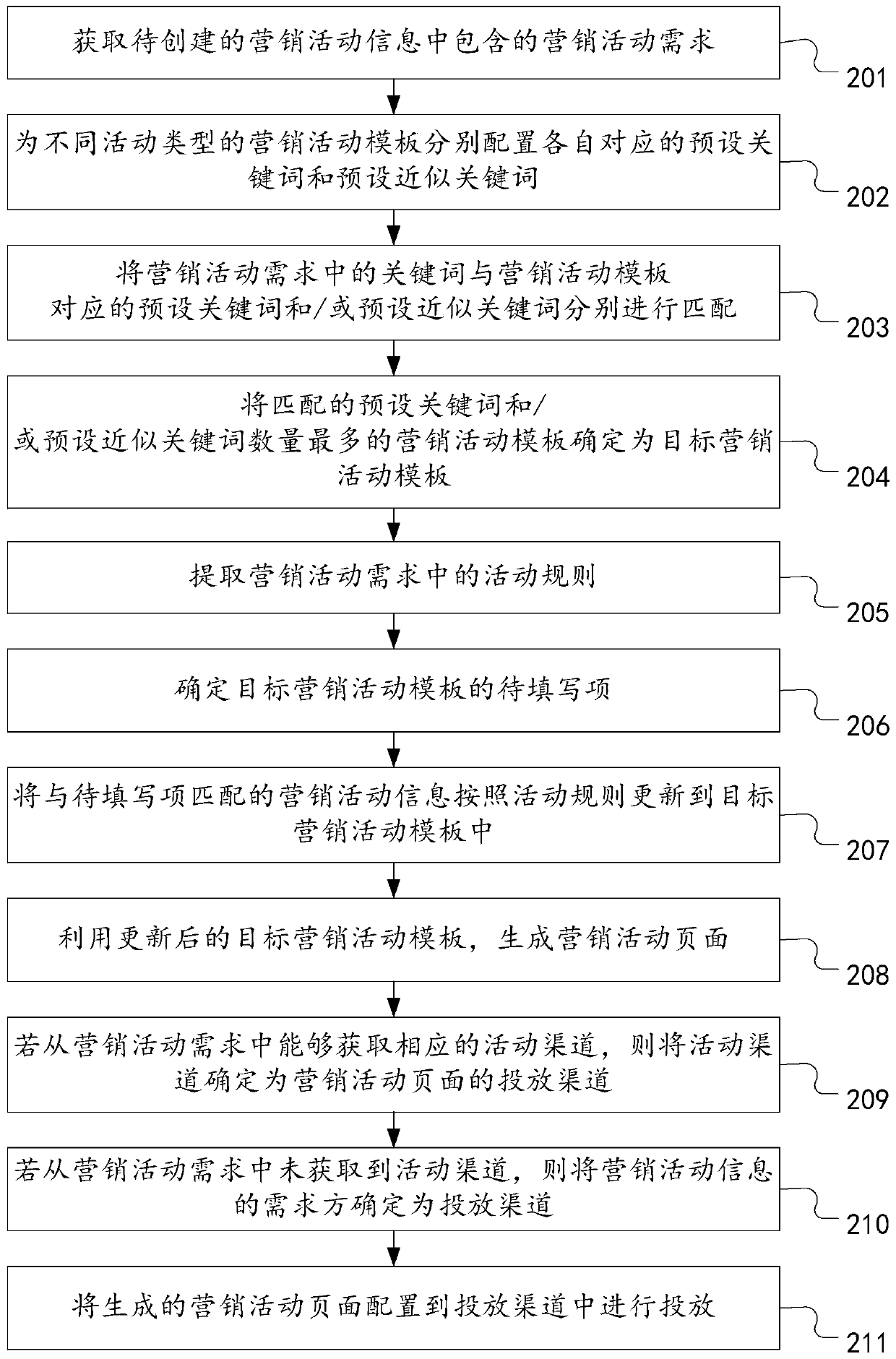

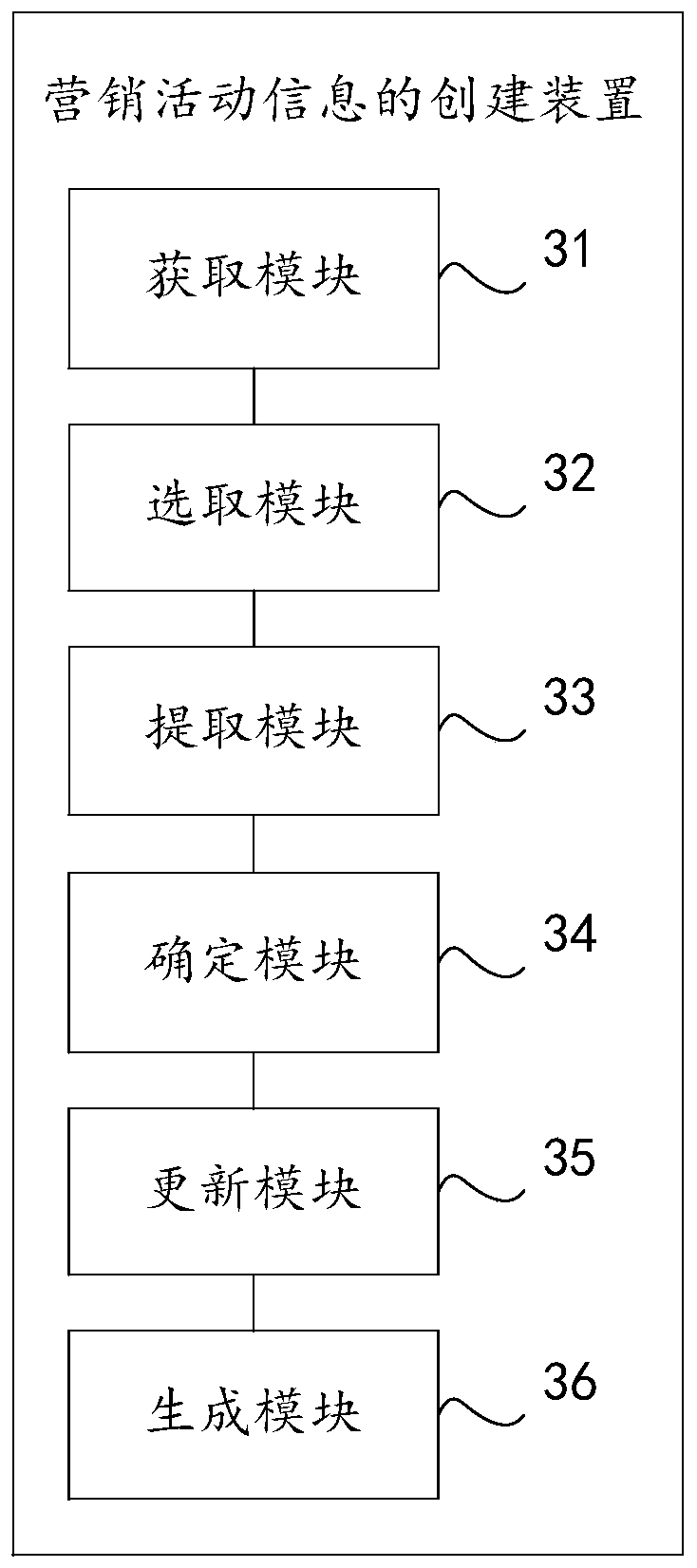

The invention discloses a marketing activity information creating method and device and computer equipment, relates to the technical field of computers, and can effectively solve the problems that time and labor costs are easily increased and the working quality cannot be ensured when a marketing activity is manually configured, and the method comprises the following steps: obtaining a marketing activity demand contained in marketing activity information to be created; selecting a corresponding target marketing activity template according to the marketing activity demand; extracting the activity rule in the marketing activity demand; determining a to-be-filled item of the target marketing activity template; updating the marketing activity information matched with the to-be-filled item to the target marketing activity template according to the activity rule; and generating the marketing activity page by using the updated target marketing activity template. The method and the device aresuitable for creating marketing activities.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

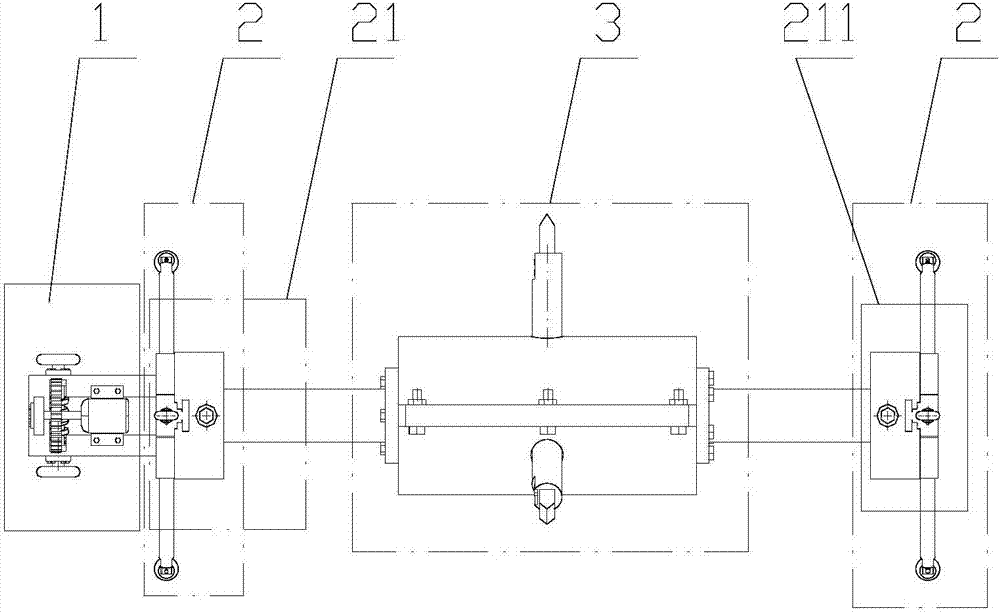

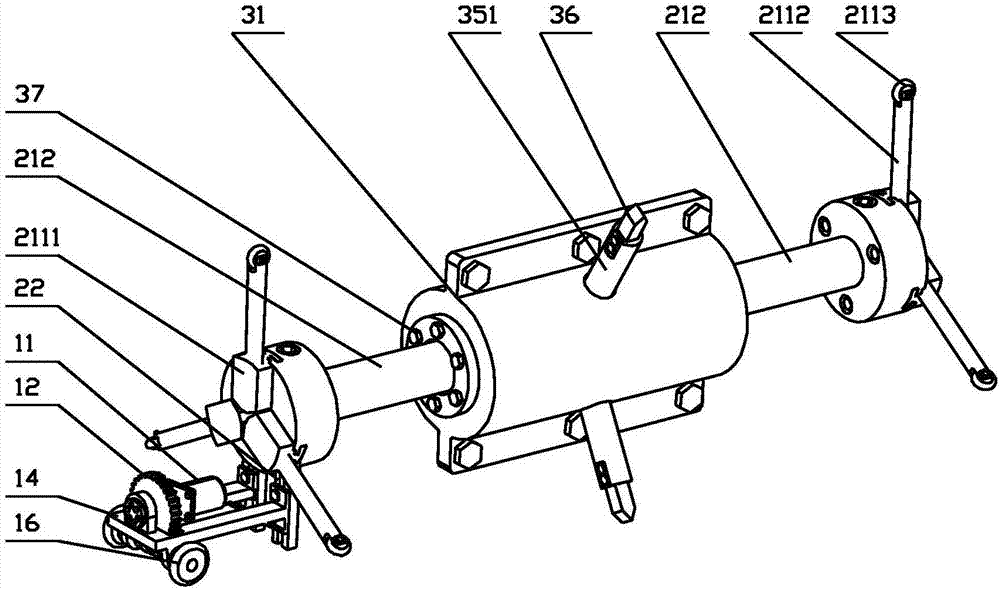

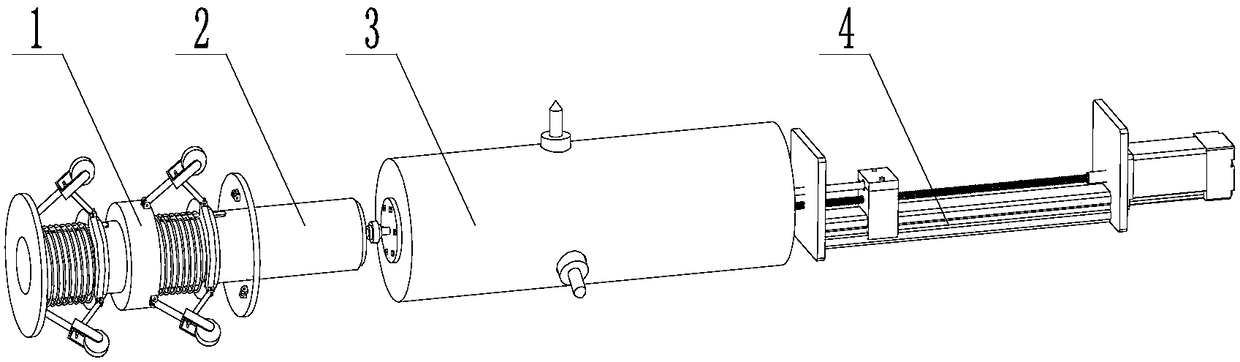

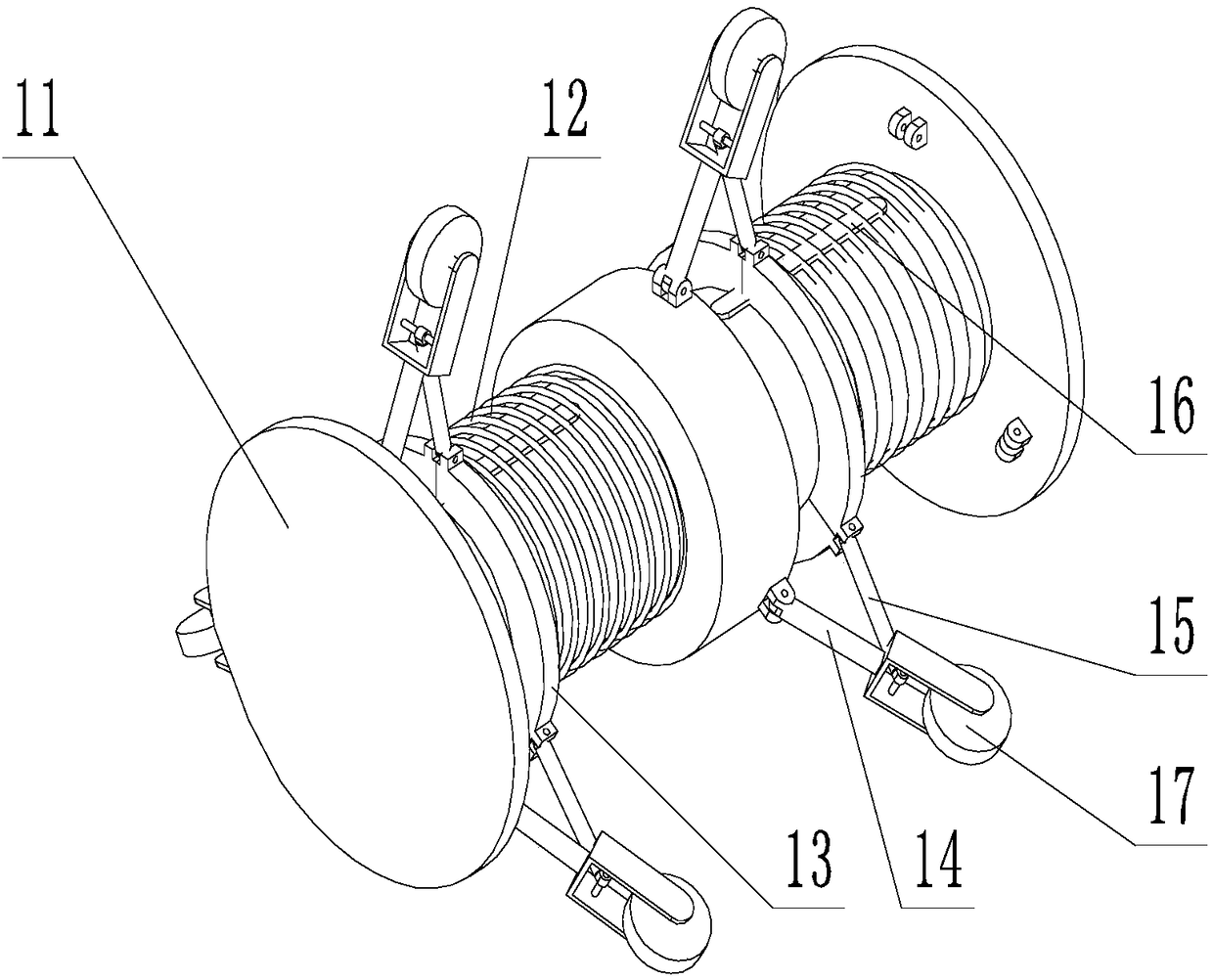

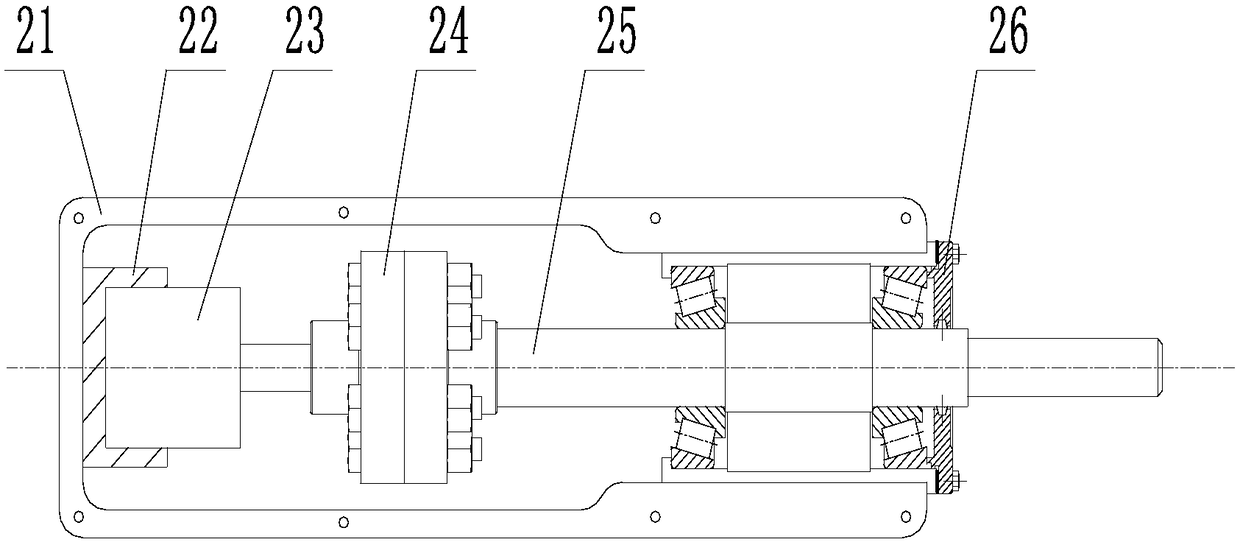

Pipeline inner wall bionic groove surface machining device and machining method thereof

ActiveCN107139251AGuarantee the quality of workCompact designMetal working apparatusTorsional deformationMachining process

The invention provides a pipeline inner wall bionic groove surface machining device and a machining method thereof. The device comprises a drive mechanism used for providing drive force, a traveling mechanism used for supporting the inner wall face of a pipeline, a machining mechanism used for machining a bionic groove in the inner wall of the machined pipeline, and a controller. The drive mechanism is installed on the traveling mechanism through bolts. The machining mechanism is fixedly connected with the traveling mechanism through bolts. The drive mechanism and the machining mechanism are electrically connected with corresponding control ends of the controller. The method comprises the steps that according to the diameter of the pipeline needing to be machined, a front and back traveling unit is adjusted in a rotating manner, after the machining mechanism is moved to the position, to be machined, on the inner wall of the pipeline, the traveling unit stops moving and presses the inner wall of the pipeline, the cutter position of the machining mechanism is adjusted, and the groove in the inner wall of the pipeline begins to be machined. The device has the beneficial effects that tangential counter force borne by three tools in the cutting machining process can be offset, thus, bending deformation and torsional deformation are avoided, and meanwhile the device is high in precision, simple in structure and easy to operate.

Owner:ZHEJIANG UNIV OF TECH

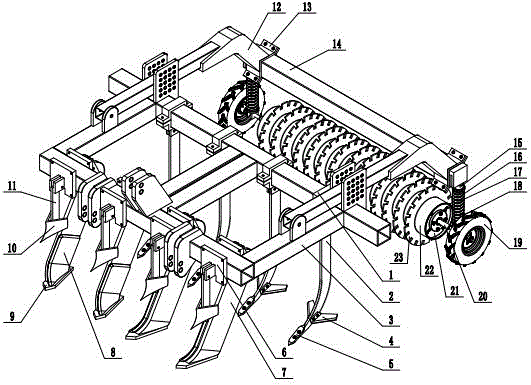

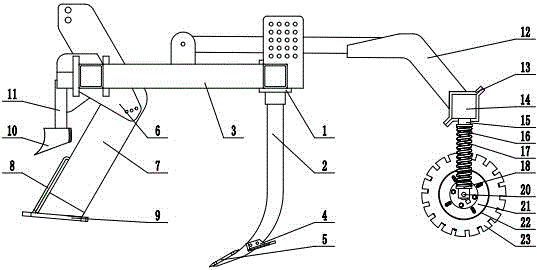

Combined deep scarification and land preparation machine

InactiveCN105981496ALow traction resistanceGuaranteed profilingSpadesSaving energy measuresConventional tillageScarification

The invention relates to a combined deep scarification and land preparation machine which is characterized by comprising a rack, a full-direction deep scarification device and a turnover device, wherein the turnover device is arranged in front of the full-direction deep scarification device; the rack consists of a front beam, an upper suspended plate, lower suspended plates, transverse beams, fixed transverse beams, fixing plates, limiting plates, a rear beam and support beams; a partial deep scarification device is arranged on the rear beam; a soil crushing depth limiting device is arranged behind the support beams. According to the combined deep scarification and land preparation machine, a shallow layer and a conventional tillage mellow soil layer are loosened by using the turnover device, subsequently deep soil is cut by using the full-direction deep scarification device and is crushed by using the partial deep scarification device, furthermore the ploughed soil is crushed and flattened by using disc cutters in the soil crushing depth limiting device. In a word, by adopting the combined deep scarification and land preparation machine, combined soil preparation, shallow layer turnover operation, single full-direction deep scarification operation and partial deep scarification operation can be achieved according to agricultural requirements of different crops, the effect of one-machine multi-functions is achieved, the resistance can be reduced, the energy can be saved, and a good operation effect can be achieved.

Owner:SHIHEZI UNIVERSITY

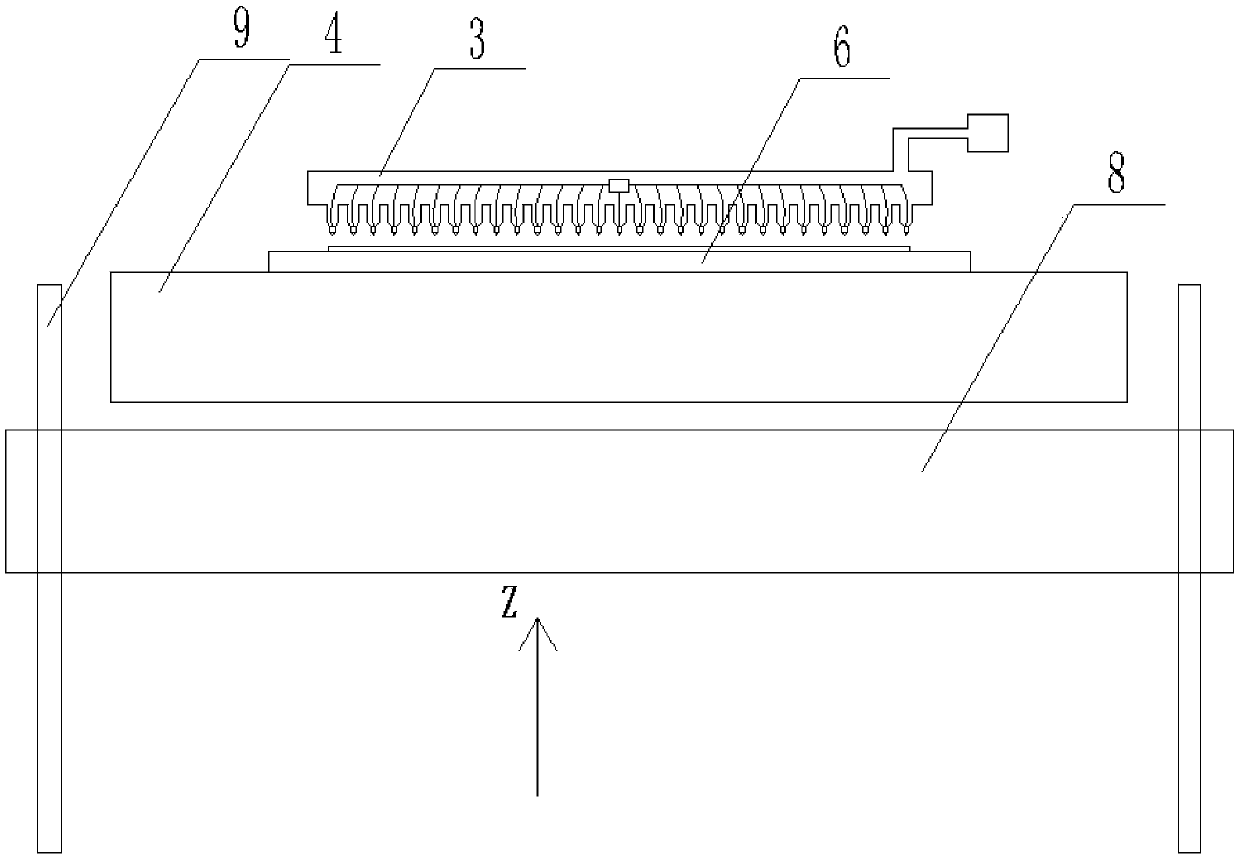

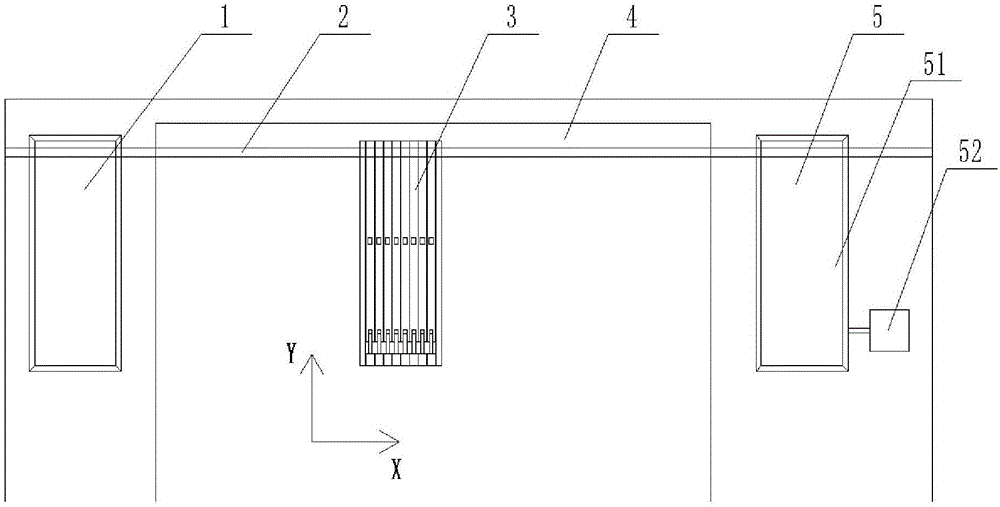

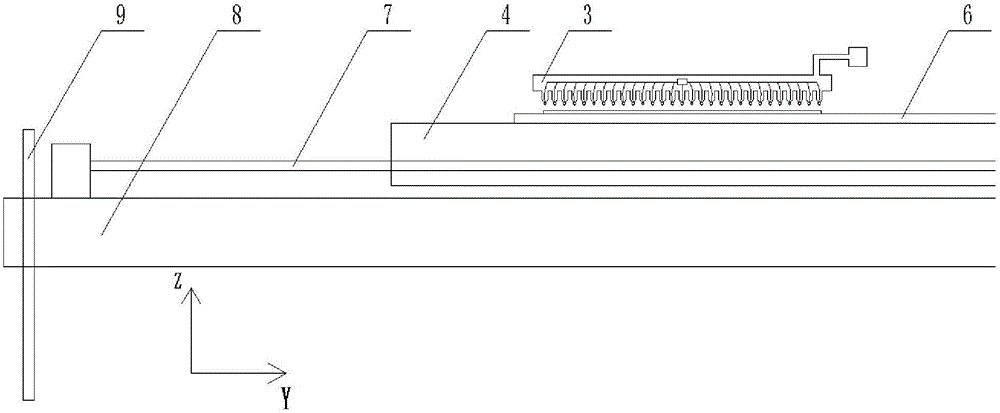

Rapid color 3D printing device

ActiveCN105082539AImprove printing efficiencyPromote rapid formationAdditive manufacturing apparatusHigh volume manufacturingDark color

The invention discloses a rapid color 3D printing device. The device comprises a nozzle assembly capable of moving in the X-axis direction and a workbench capable of moving in the Y-axis direction and the Z-axis vertical direction. A plurality of spraying pipes are installed on the nozzle assembly and contain various liquid printing materials including the white matrix material and the various color materials. When the rapid color 3D printing device moves one time, all the spraying pipes work respectively. Firstly, an image is printed through the white matrix material, in particular, the region, with the dark color, of the image is printed through the color materials, and the partial region of the finally-formed image protrude outwards, so that the third dimension of the image is improved, the image is more vivid, and the rapid color 3D printing device is rapid, efficient and flexible in printing and suitable for mass production.

Owner:范春潮

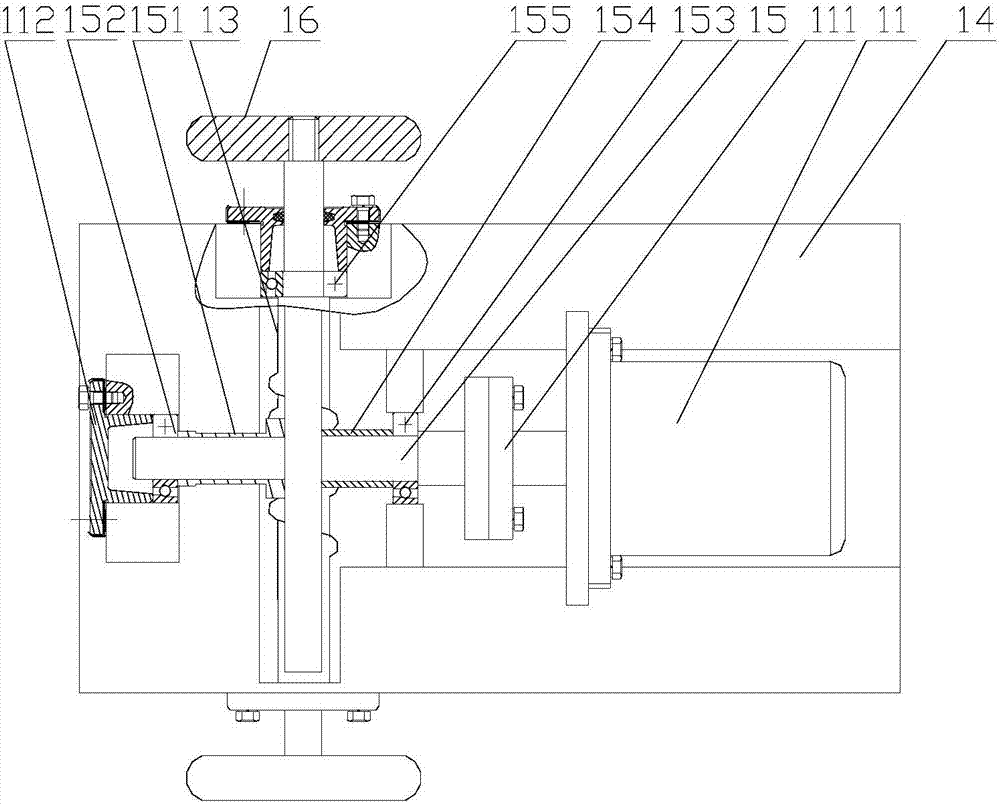

Processing device and processing method of simulated groove in inner wall of conical water inlet pipe of water pump

PendingCN108213534ARealize continuous processingSelf-lockingMilling equipment detailsSelf lockingEngineering

The invention discloses a processing device and a processing method of a simulated groove in the inner wall of a conical water inlet pipe of a water pump. The processing device comprises a supportingmechanism, a processing mechanism, a rotating mechanism and a feeding machine, wherein the supporting mechanism is arranged at the outer part of the rotating mechanism; an output end of the rotating mechanism is connected with one end of the processing mechanism; the other end of the processing mechanism is connected with an action end of the feeding mechanism; one end of the supporting mechanismis defined as a front part, and one end of the feeding mechanism is defined as a rear part. The processing method comprises the following steps: fixing well a pipeline requiring to be processed, and regulating the feeding mechanism until a cutting tool assembly arrives a to-be-processed position; regulating the shape of a supporting frame, and enabling the supporting frame to press the inner wallof the pipeline; regulating a cutting blade of a cutting tool to be in contact with the inner wall of a to-be-processed pipeline; starting a rotating part, and starting to process a groove in the inner wall of the pipeline; repeating the operation, thus realizing continuous processing of the simulated groove in the to-be-processed pipeline. The processing device and the processing method, disclosed by the invention, have the beneficial effects that an application range is extremely wide, and the processing device and the processing method are not influenced by the size of a pipe wall; a self-locking function is obtained, and the accuracy is higher; the processing quality is high.

Owner:ZHEJIANG UNIV OF TECH

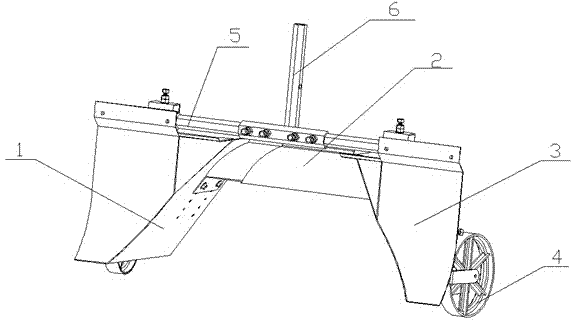

Trapezoidal ridge shaping device

InactiveCN104718809AAvoid damageImprove performancePloughsAgricultural engineeringAgricultural science

The invention relates to the technical field of agricultural machines, in particular to a trapezoidal ridge shaping device. The trapezoidal ridge shaping device is characterized by comprising shaping side boards, an adjusting top board, soil heaping boards, adjusting wheels, an adjusting guide pipe and a hanging device, various aspects can be adjusted through the whole device, the width of a ridge can be adjusted through the shaping side boards, the height of the ridge can be adjusted through the adjusting top board, the walking height of the whole device can be adjusted through the adjusting wheels, multiple functions are achieved, the performance of an agricultural implement is improved, trapezoidal ridges of different sizes can be shaped, the structure is unique, connection is reliable, and disassembly and assembly are convenient. By the adoption of the trapezoidal ridge shaping device, the convention that other ridge shaping devices can not be adjusted for a long time or only can be locally adjusted at a small amount is broken through, the problems existing in the aspects of adjustability and adaptability of the trapezoidal ridge shaping device are solved, the trapezoidal ridge shaping device has the advantages of being flexible, adjustable, convenient to use and wide in application range in the agricultural machine work process, and the performance of the agricultural instrument is completed.

Owner:GANSU AGRI UNIV

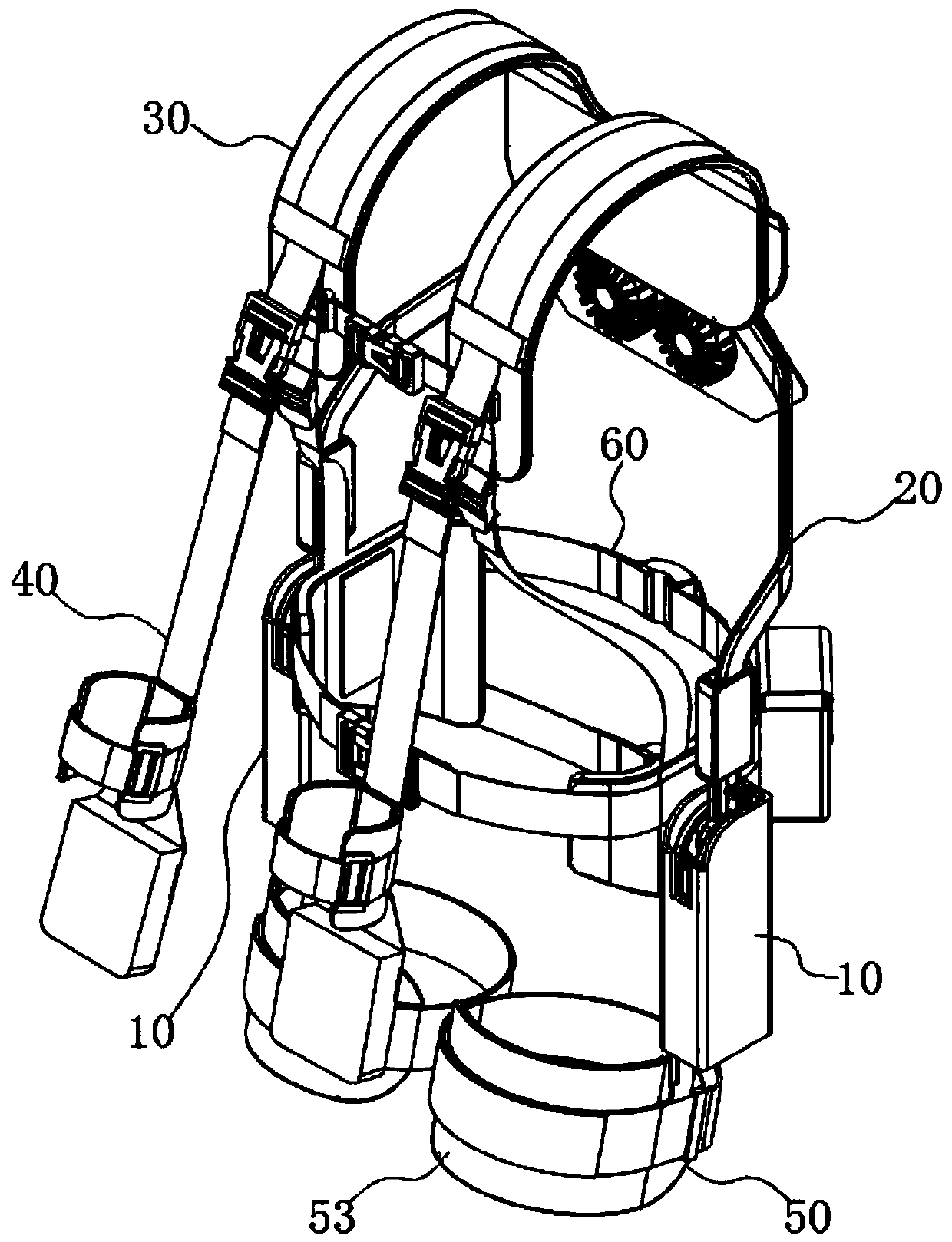

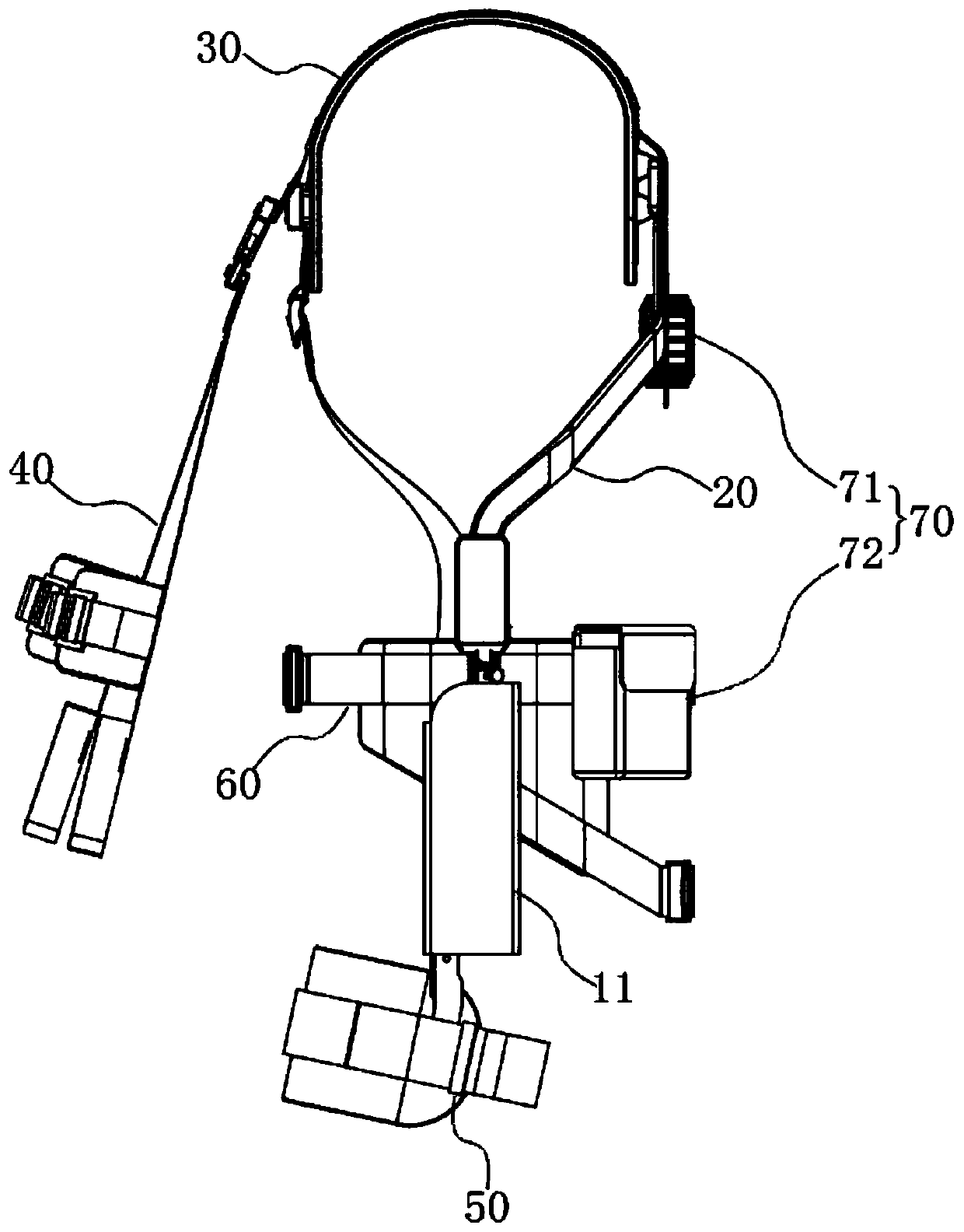

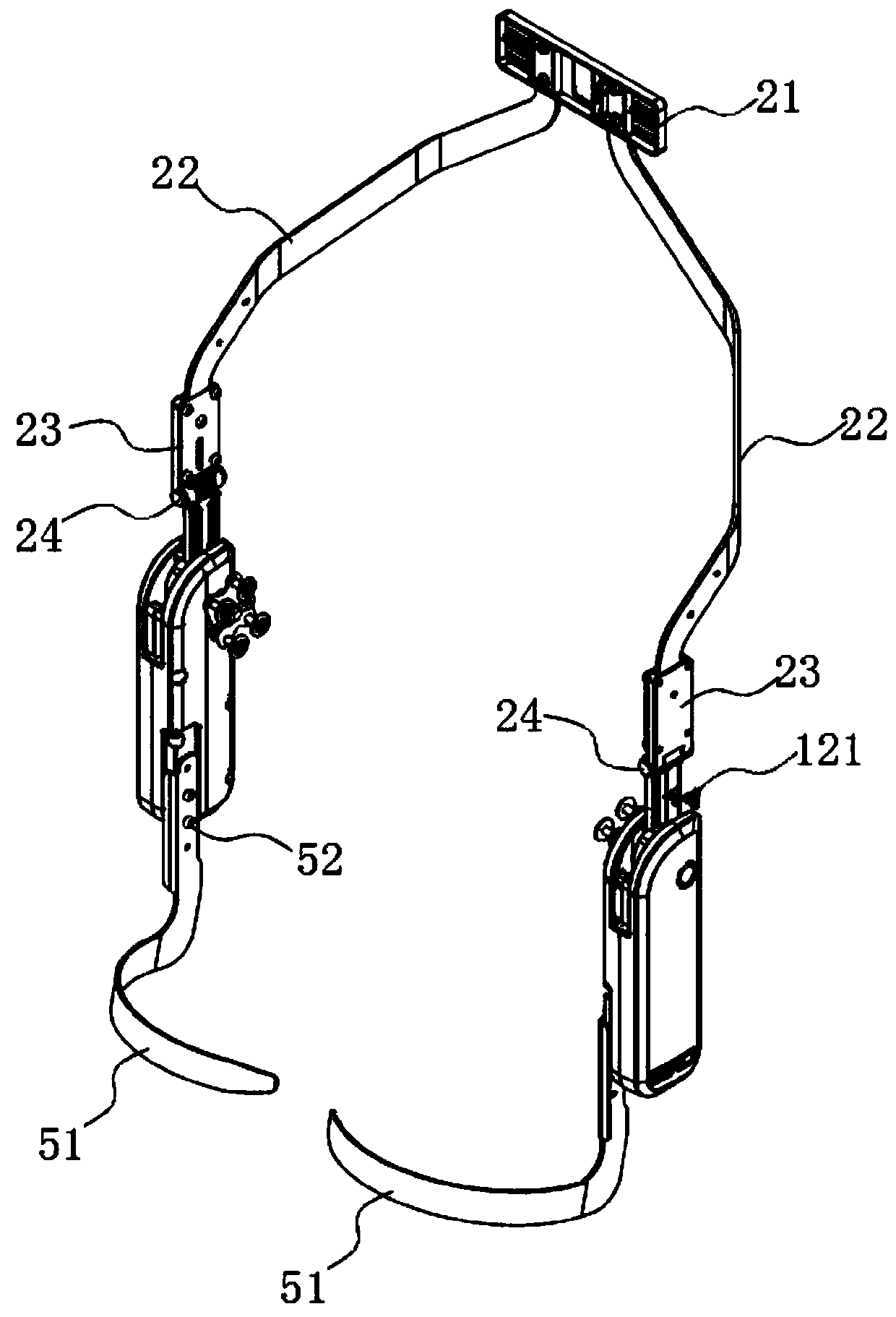

Exoskeleton device

The invention relates to an exoskeleton device. The exoskeleton device comprises an energy storage mechanism, a back supporting mechanism, a shoulder supporting mechanism and a hand power assisting mechanism, wherein the back supporting mechanism is movably arranged on the energy storage mechanism, the shoulder supporting mechanism is connected with the back supporting mechanism, and the hand power assisting mechanism is connected with the shoulder supporting mechanism. When a heavy object is carried, a body of a wearer bends forwards, at the moment, the back supporting mechanism extrudes theenergy storage mechanism, and the energy storage mechanism is pressed to store elastic energy; in the process that the wearer moves and lifts the heavy object and recovers an upright posture, the energy storage mechanism releases the elastic energy and can effectively support shoulders of the wearer, and therefore loads and stress of waist joints and hip joints of the wearer are relieved; and meanwhile, the hand power assisting mechanism can synchronously transmit a load borne by an upper limb to the shoulder supporting mechanism and the back supporting mechanism, so that the stress of shoulder joints, elbow joints, wrist joints and finger joints is greatly reduced or disappears, and then the problem of strain of the upper limb is effectively relieved and even solved.

Owner:GUANG ZHOU HYETONE IND TECH CO LTD

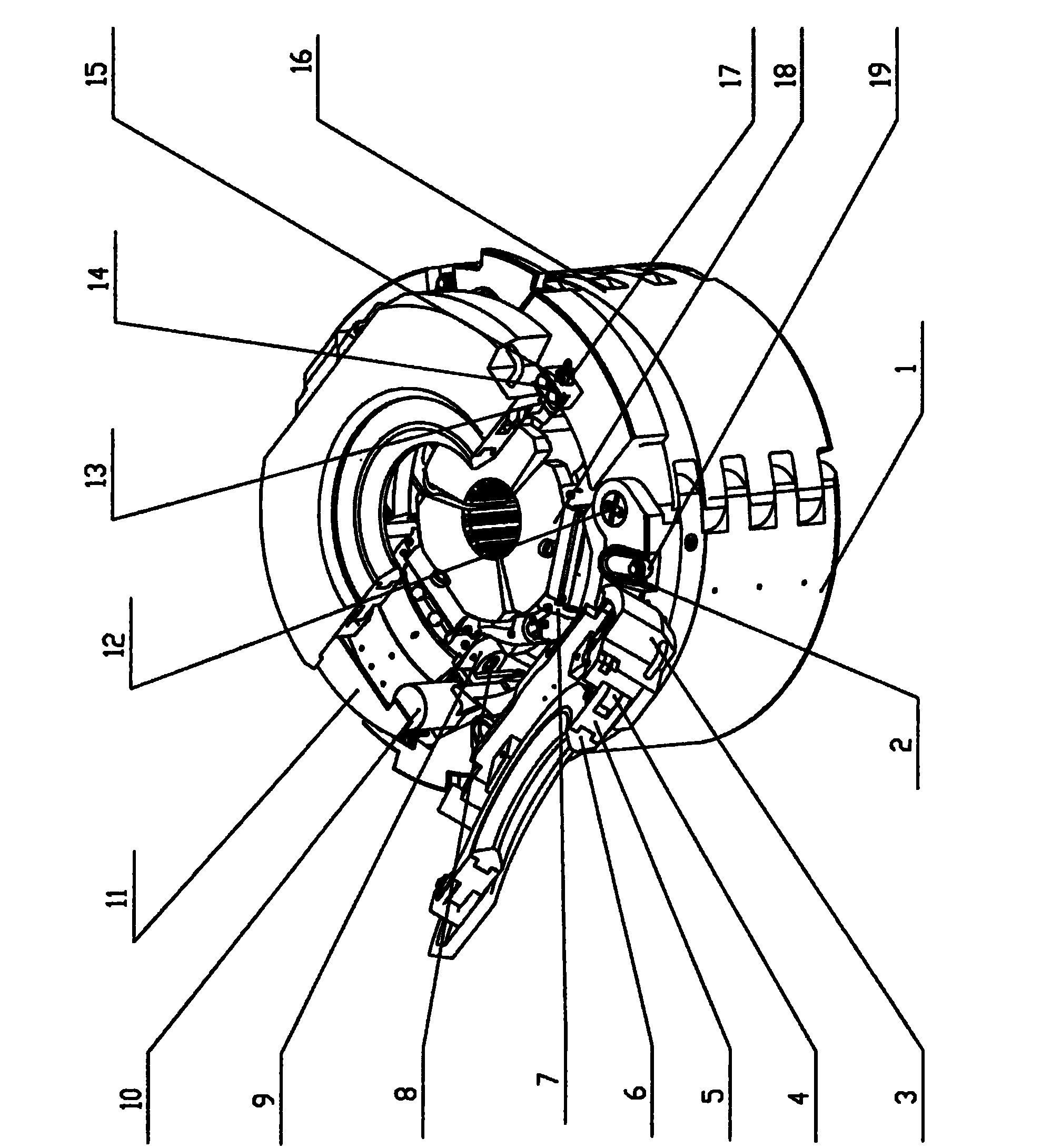

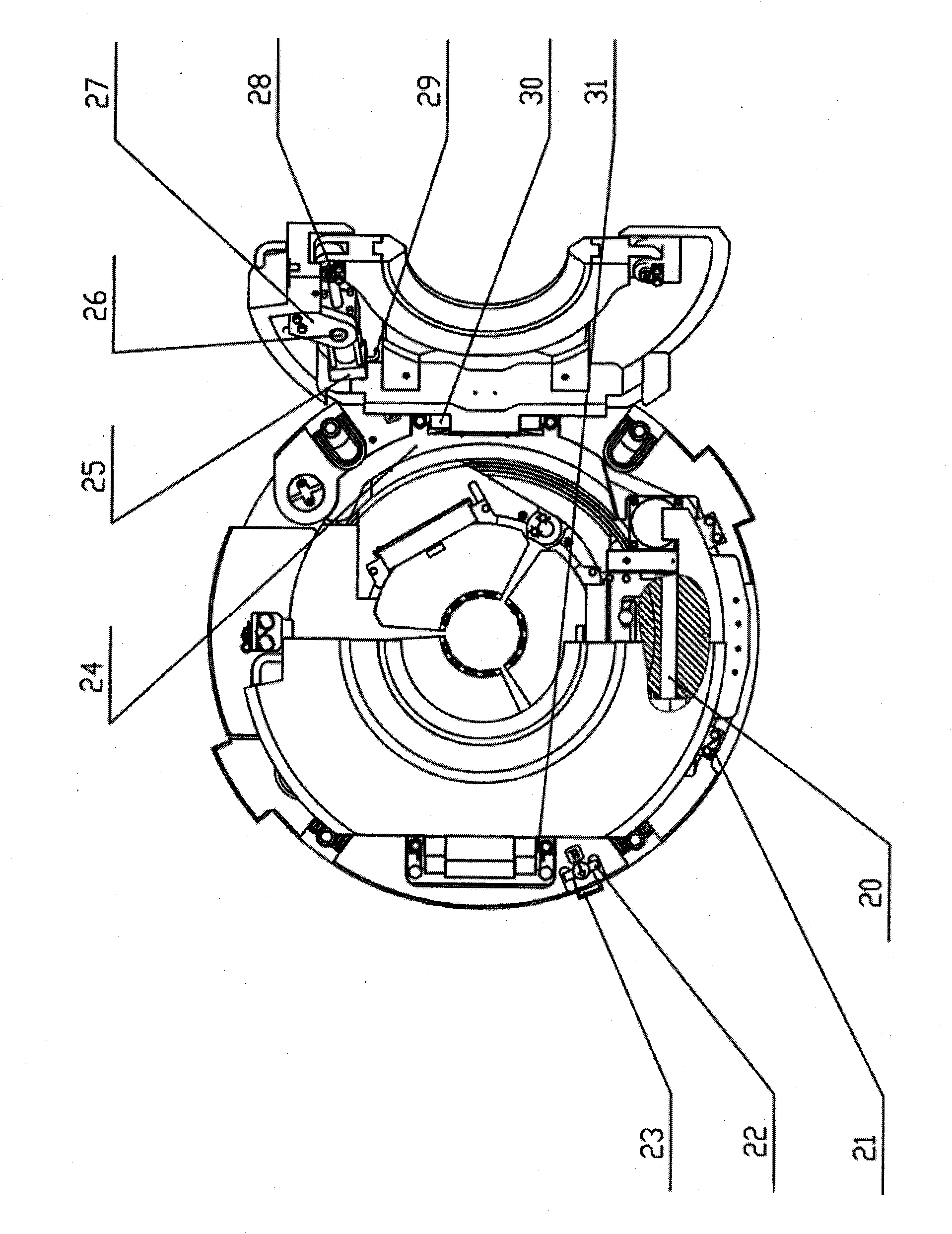

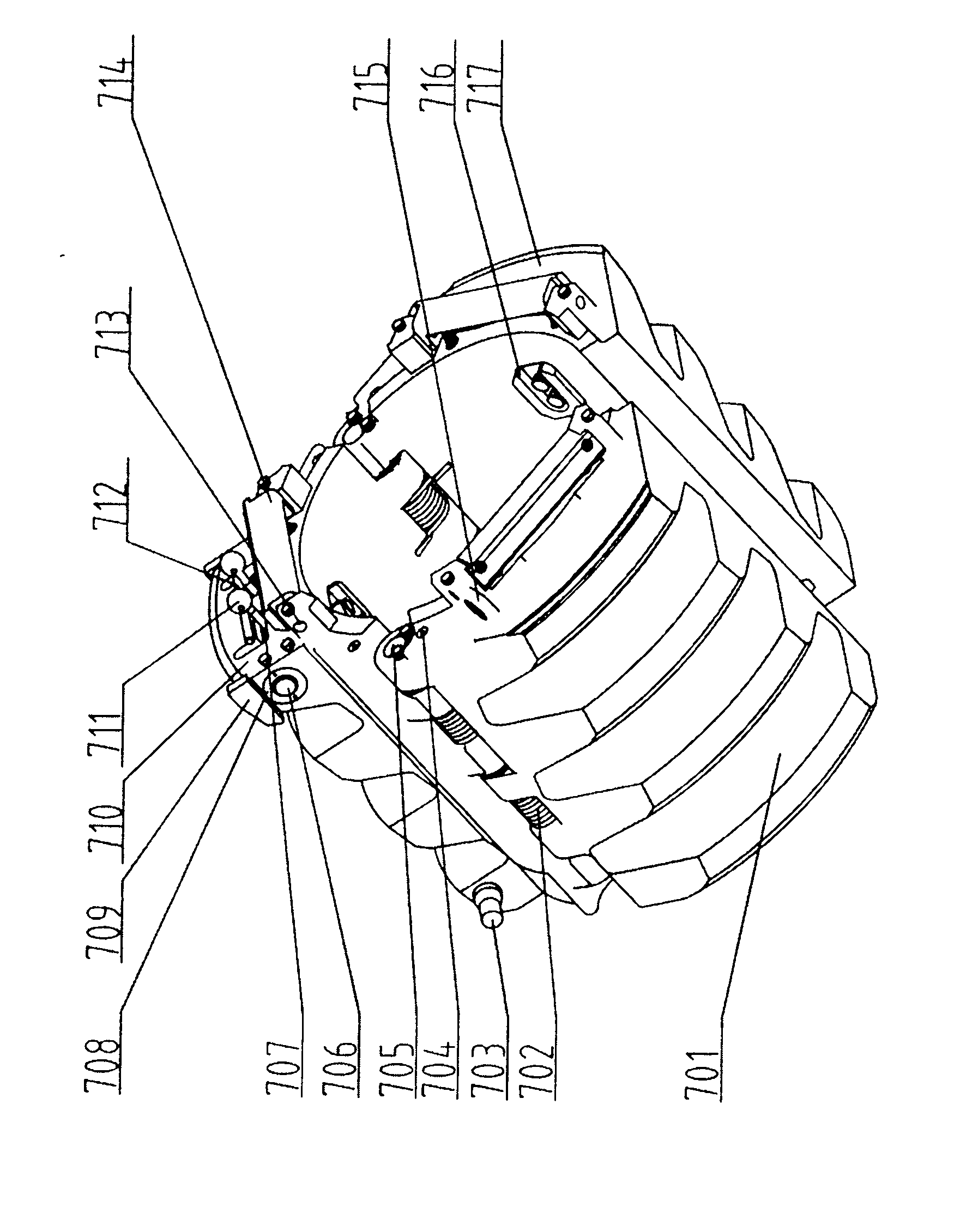

Power slip capable of realizing on-line quick change of clamp tooth boxes and automatic lubrication

InactiveCN102182408AHigh degree of automationRealize the quick change functionDrilling rodsDrilling casingsEngineeringLubrication

The invention aims at providing a power slip capable of realizing on-line quick change of clamp tooth boxes and automatic lubrication, which can realize the quick change function of the slip, increase the pipe diameter clamping range and improve the working efficiency. The power slip comprises a slip housing, a slip upper cover, a slip body and the clamp tooth boxes, wherein a slip upper cover plate is connected with an upper cover pin shaft base through a pin shaft, the upper cover pin shaft base is in bolted connection with the slip housing, the slip body is connected with a swing arm of a lifting oil cylinder through a lifting shaft, the swing arm of the lifting oil cylinder is fixed on a rotating shaft of a left lifting oil cylinder and a right lifting oil cylinder, the left lifting oil cylinder is in bolted connection with the slip housing, the three clamp tooth boxes are connected with the slip body through clamping blocks, and the axial fixing is realized with a clamping plate on the slip body through a convex edge. By adopting the power slip, the degree of automation of the clamping process of the slip is improved, the automation of the clamping process is completely realized, the labor intensity of a worker is reduced, and the safety guarantee is improved. The clamping of the slip and the centering are performed step by step, the working quality is ensured, the quick change function of the slip is realized, the pipe diameter clamping range is increased, and the working efficiency is improved.

Owner:浙江欧佩亚海洋工程有限公司

Concrete vibrating leveling device

InactiveCN104453241AImprove compaction efficiencyIncrease height differenceBuilding material handlingSlide plateEngineering

The invention relates to a concrete vibrating leveling device which comprises a spliced rail. A sliding plate is arranged on the spliced rail, the lower end face of the sliding plate is provided with at least two rollers correspondingly clamped to the spliced rail, the upper end face of the sliding plate is fixedly provided with a positioning lifting frame, the positioning lifting frame comprises a guide rod and a lead screw, the upper end of the guide rod and the upper end of the lead screw are each fixedly provided with an upper end cap, the upper end caps are fixedly provided with a first motor, a shaft of the first motor is connected with the lead screw, the guide rod is provided with a left sliding sleeve, the lead screw is provided with a right sliding sleeve, a cam box is arranged in front of the left sliding sleeve and the right sliding sleeve, a second motor is fixed to the cam box, a shaft of the second motor is connected with transverse rods transversely arranged in the cam box, the transverse rods correspond to through holes and are each sleeved with an ejector rod cam, and vibration bars are arranged in the through holes in a penetrating mode. According to the device, concrete is tamped through the vibration bars by means of the ejector rod cams fixed to the transverse rods, tamping efficiency of the vibration bars is improved, and the aim that vibration and tamping of the vibration bars are carried out at the same is achieved.

Owner:NANJING DENGYU MACHINERY EQUIP MFG CO LTD

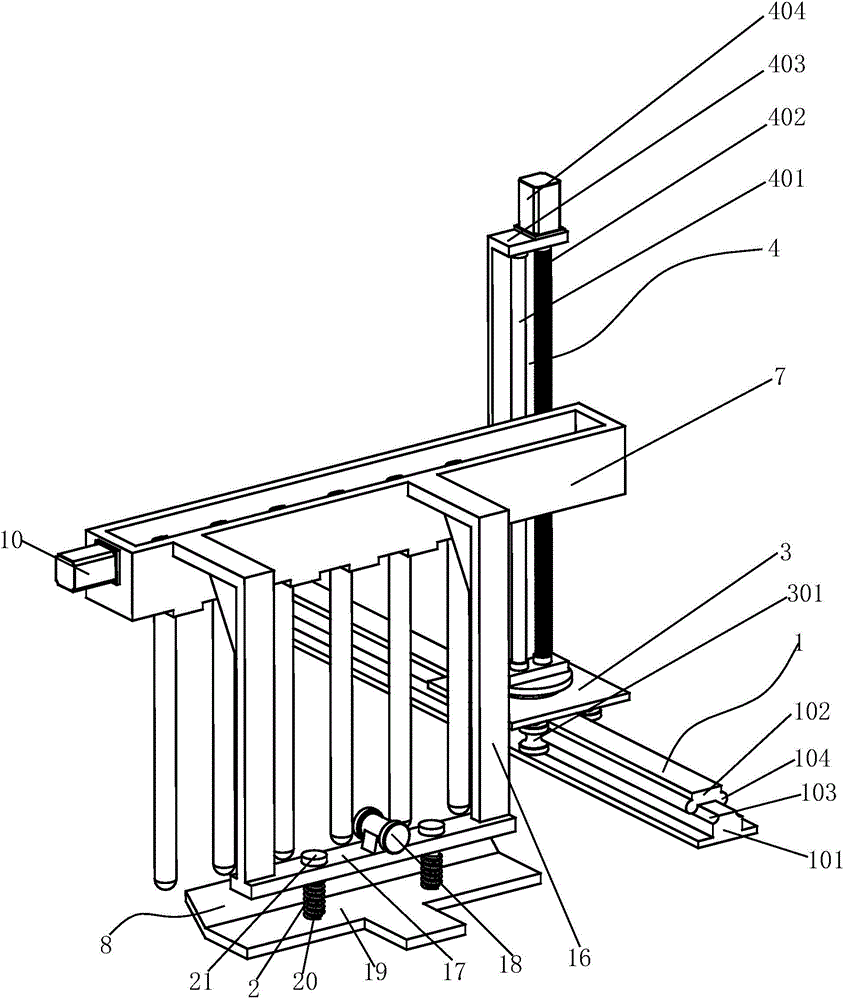

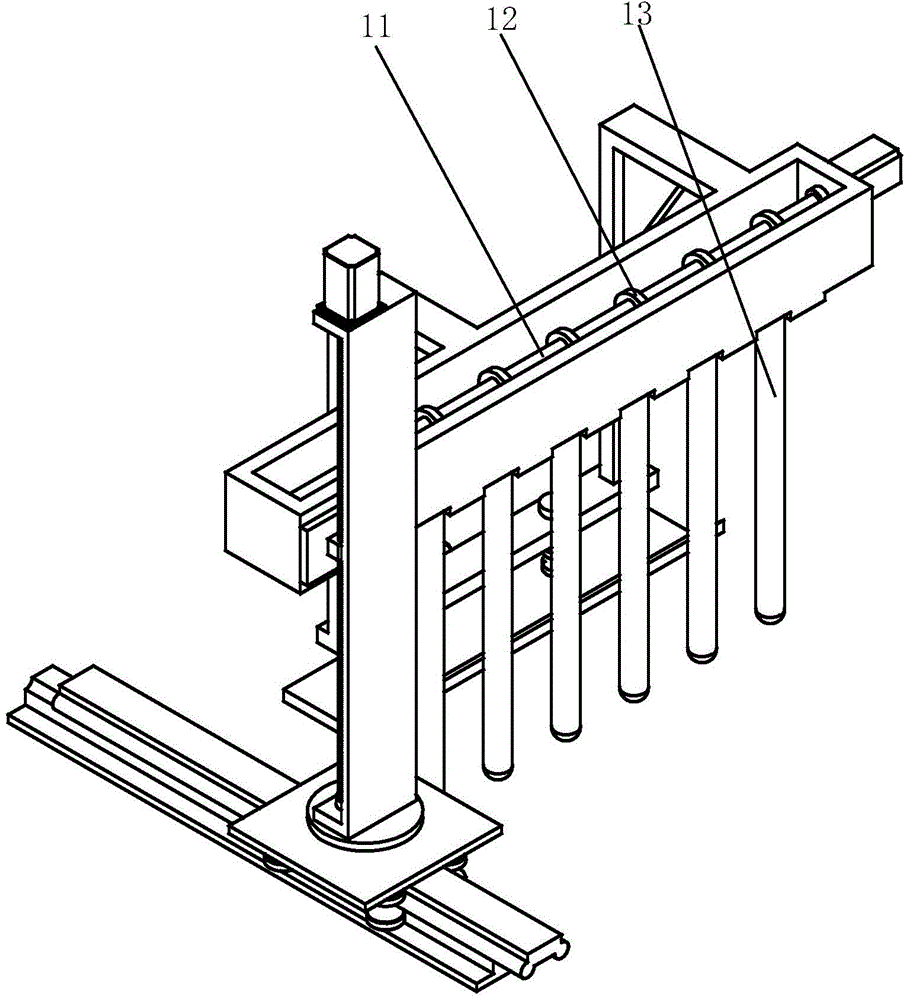

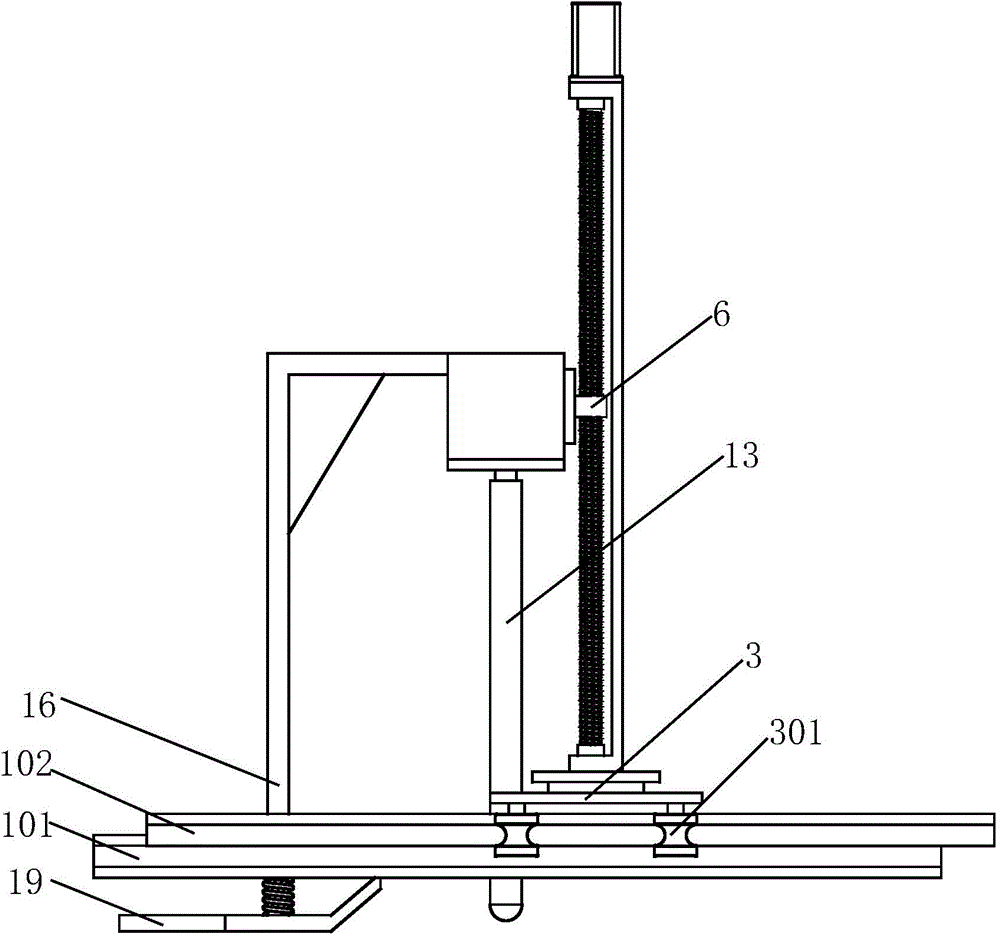

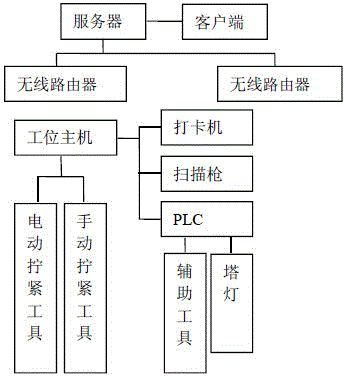

Quantized assembly and overhaul control system for locomotive

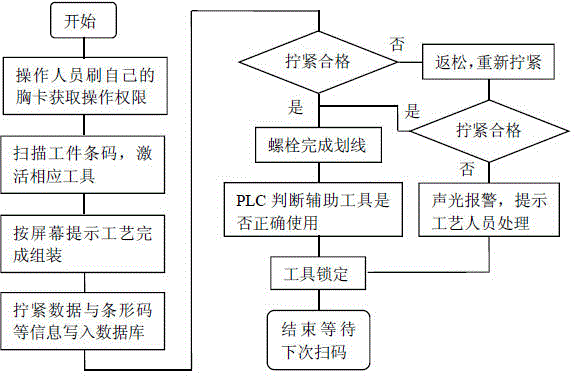

ActiveCN104950793AGuaranteed assembly qualityGuaranteed workmanshipProgramme control in sequence/logic controllersControl systemProgrammable logic controller

The invention provides a quantized assembly and overhaul control system for a locomotive. The system comprises a client, a server and an operating terminal, wherein the server is a database server; the operating terminal comprises multiple workstations; the client is connected with the server through a network; the workstations are in data interaction with the server through wireless nodes; each workstation comprises a workstation host, a card punch, a scanning gun, a PLC (programmable logic controller), an electric tightening tool, a manual tightening tool, a tower lamp and auxiliary tools, the card punch, the scanning gun and the PLC are connected with the workstation host through data lines respectively, data transmission interfaces of the electric tightening tool and the manual tightening tool are connected with the workstation host respectively, the tower lamp is connected with a PLC control port through a data line, and sensors are arranged at storage places of the auxiliary tools and connected with the PLC control port. The quantized assembly and overhaul control system for the locomotive can guarantee the tightening process and the tightening precision, effectively prevents wrong assembly, realizes whole tracing of the production process, and guarantees the assembly quality of the locomotive and a high-speed bullet train.

Owner:SHANGDONG TONGLIDA INTELLIGENT MACHINERY

Environment-friendly printing wastewater treatment equipment

ActiveCN112023469AImprove processing efficiencyEasy to collectStationary filtering element filtersTreatment pondProcess engineering

The invention discloses environment-friendly printing wastewater treatment equipment. The equipment comprises a treatment tank, a collecting box, a first cleaning scraper blade, a second cleaning scraper blade and a cleaning scraper blade auxiliary mechanism, by arranging the first cleaning scraper blade and a collecting box, flocculent impurities on the surface of the wastewater in the treatmenttank can be well removed, and can be well collected for centralized treatment, so that waste of wastewater material resources is avoided, and the working efficiency of wastewater treatment is improved; in the process, an intercepting filter screen is driven by a telescopic rod to move upwards, the flocculent impurities in the wastewater can be separated out to the maximum extent, then the workingquality of a wastewater pool is guaranteed, the working economic benefits are guaranteed, a good auxiliary effect is achieved on the first cleaning scraper blade for scraping the flocculent impuritieson the intercepting filter screen, one-time cleaning is more sufficient, therefore, workload is reduced, and working efficiency is improved.

Owner:台州精微顺自动化有限公司

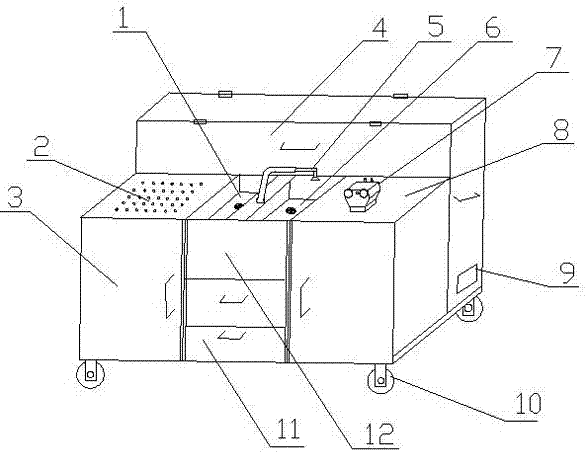

Overhaul bench for automatic transmission

ActiveCN107323435AReduce labor intensityEasy to disassembleVehicle servicing/repairingOther workshop equipmentAutomatic transmissionWaste oil

An overhaul bench for an automatic transmission comprises a base. A workbench is arranged on the base. A part storage cabinet is arranged on one side of the workbench which is divided into a disassembly area, a cleaning area and an overhaul area. The disassembly area and the overhaul area are located on the two sides of the cleaning area. The disassembly area comprises a disassembly table; a waste oil collecting cabinet is arranged at the lower end of the disassembly table; a cabinet door is hinged to one side of the waste oil collecting cabinet; a plurality of oil leakage holes communicating with the waste oil collecting cabinet are formed in the upper portion of the disassembly table; and a waste oil collecting bucket and a flow guide plate are arranged in the waste oil collecting cabinet. The cleaning area comprises a coarse washing groove and a fine washing groove which are arranged side by side. The overhaul area is located on one side of the cleaning area, and an overhaul table of the overhaul area is provided with an overhaul clamp. The overhaul bench is clear in area dividing and can be used as a whole, maintenance workers can achieve all procedure operation wholly of the automatic transmission according to overhaul procedures, all parts can be used separately, the functions are independent, and spaces are sealed independently and are not limited by time and space.

Owner:JINING POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com