Power slip capable of realizing on-line quick change of clamp tooth boxes and automatic lubrication

A technology of automatic lubrication and power slips, which is applied to drilling equipment, earthwork drilling, drilling pipes, etc., can solve the problems of high labor intensity, reduced work efficiency, and low safety performance of workers, so as to reduce labor intensity and improve automation degree, the effect of realizing the quick change function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

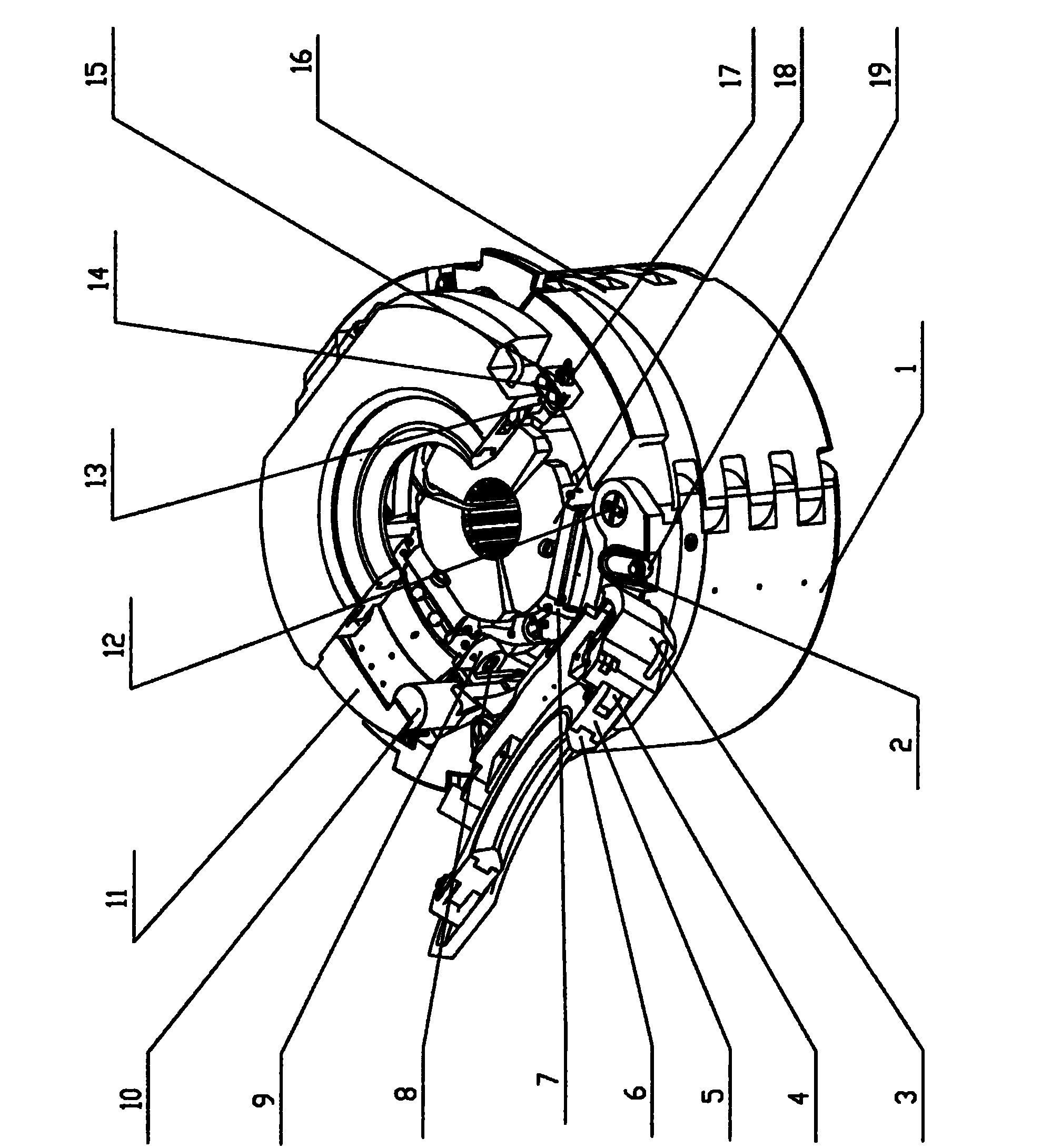

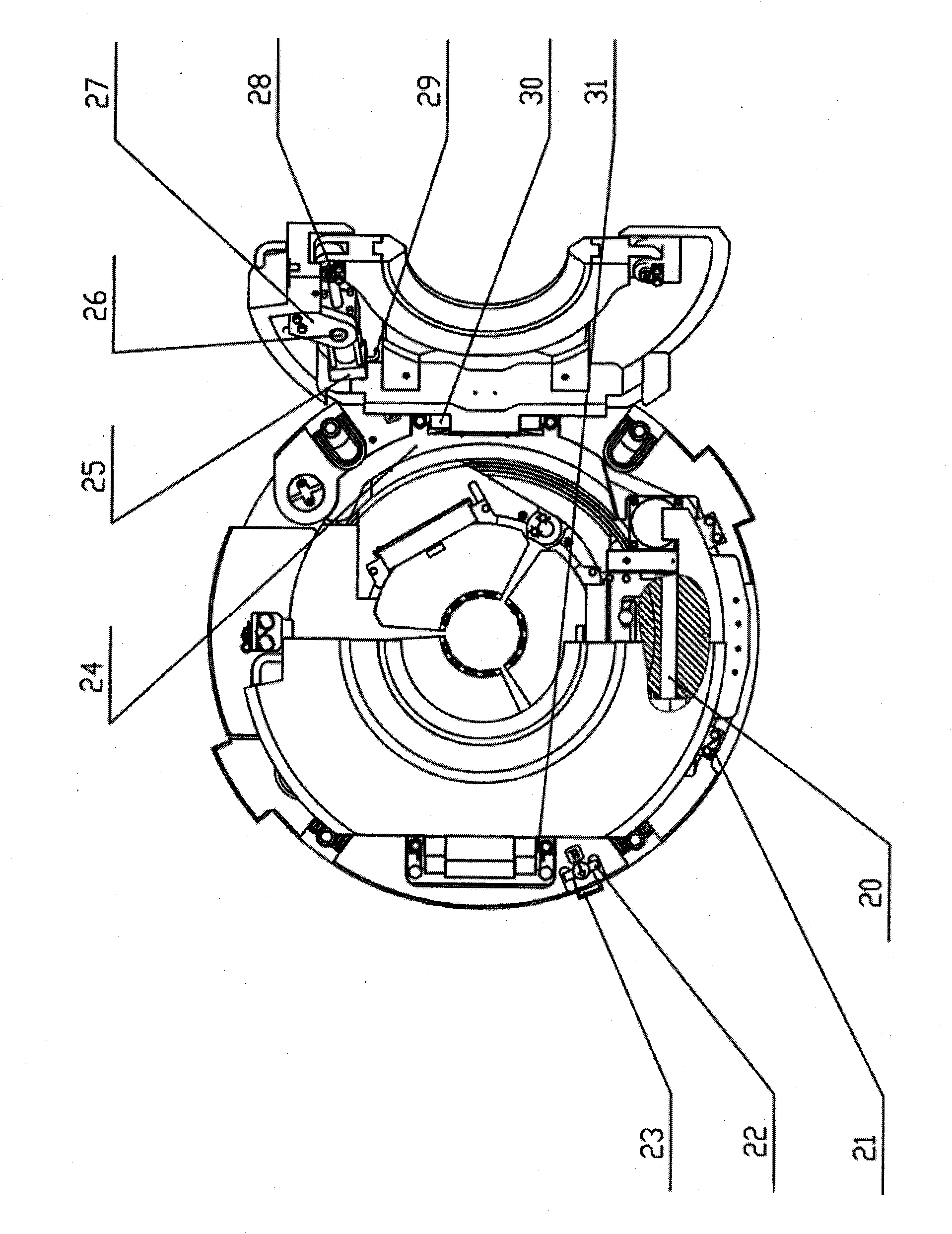

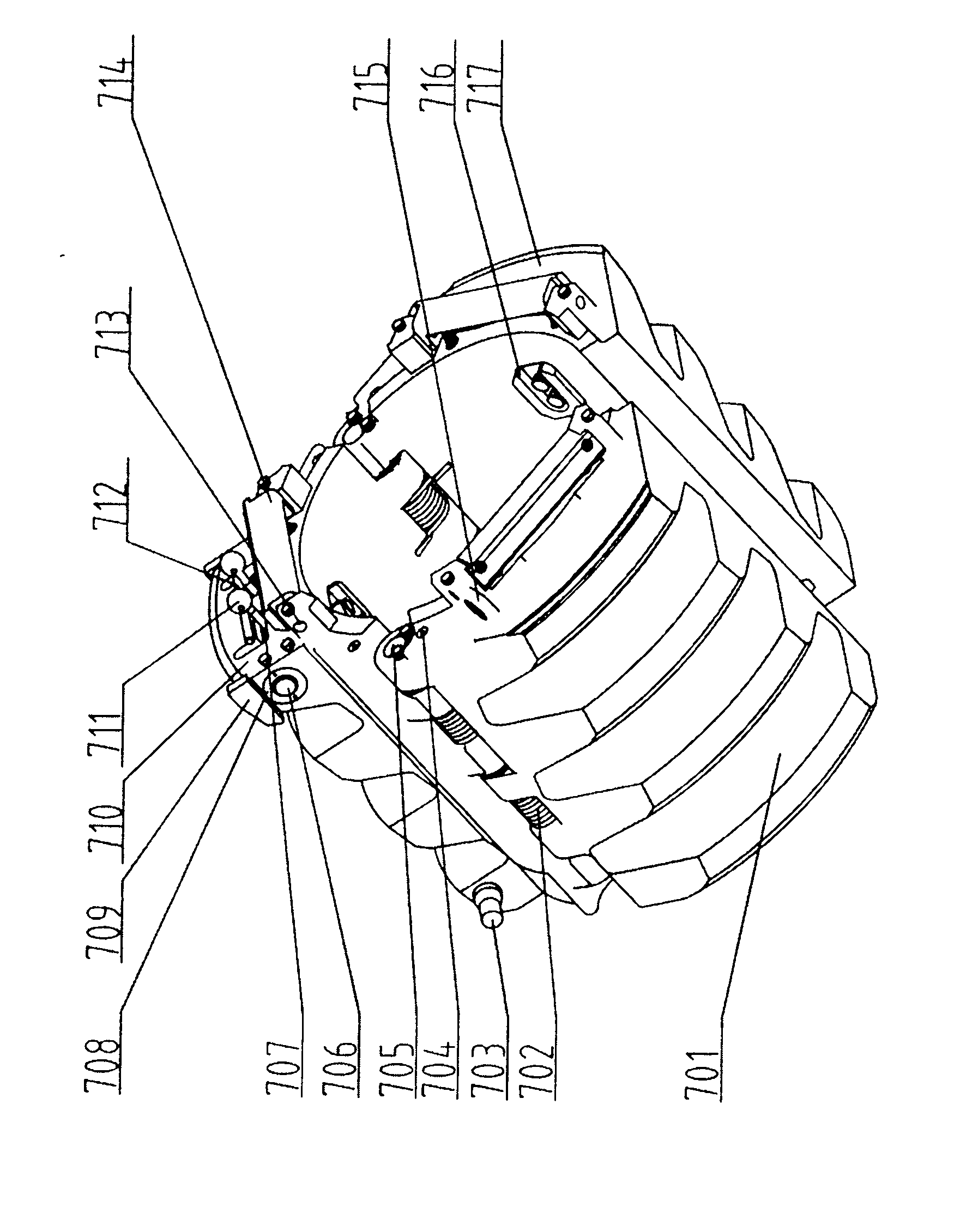

[0017] Example 1: Combining Figure 1-Figure 5 , the present invention is a power slip that can be quickly changed online and automatically lubricated. It is composed of a slip shell, a slip cover, a slip body (7) and a clamp box (18). The upper cover (5) is connected to the upper cover pin base (29) through the pin shaft, the upper cover pin base (29) is bolted to the slip shell (1), and the slip body (7) is passed through the lifting shaft (8) It is connected with the swing arm (9) of the lift cylinder, the swing arm of the lift cylinder (9) is fixed on the rotation shaft of the left and right lift cylinders, the left lift cylinder (10) is bolted to the slip shell (1), and the three jaw boxes (18 ) is connected with the slip body (7) through the block (716), and is axially fixed with the clip plate (714) on the slip body (7) through the convex edge.

[0018] The present invention also has the following technical characteristics:

[0019] The slip shell includes a slip shel...

Embodiment 2

[0023] Example 2: Combining Figure 1-Figure 5 , the present invention is a power slip that can be quickly changed on-line and automatically lubricated, such as figure 1 Summary of the invention: the present invention mainly is made up of slip shell, slip loam cake, slip is provided (7) and jaw tooth box (18).

[0024] In the present invention, the slip upper cover plate (5) is hinged to the upper cover pin shaft base (30) through the upper cover rotating shaft (31), and is axially fixed by bolts and the flange of the upper cover rotating shaft (31). The upper cover pin base (30) is connected to the slip housing (1) by bolts. The slip body (7) is hinged to the swing arm (9) of the lifting cylinder through the sliding shaft (8). The lifting cylinder swing arm (9) is connected on the left lifting cylinder (10) fixed on the slip housing (1) by screws through the left and right lifting cylinder synchronous shafts (20).

[0025] Such as figure 1 , figure 2 and Figure 4The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com