Automatic and continuous bag-breaking and unloading device

A technology of unloading device and bag breaking, applied in packaging, transportation and packaging, cutting and unsealing, etc., can solve the problems of unfavorable maintenance management, complex structure design and high maintenance cost, achieve practical and reliable mechanical structure, avoid dust leakage, The effect of convenient maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

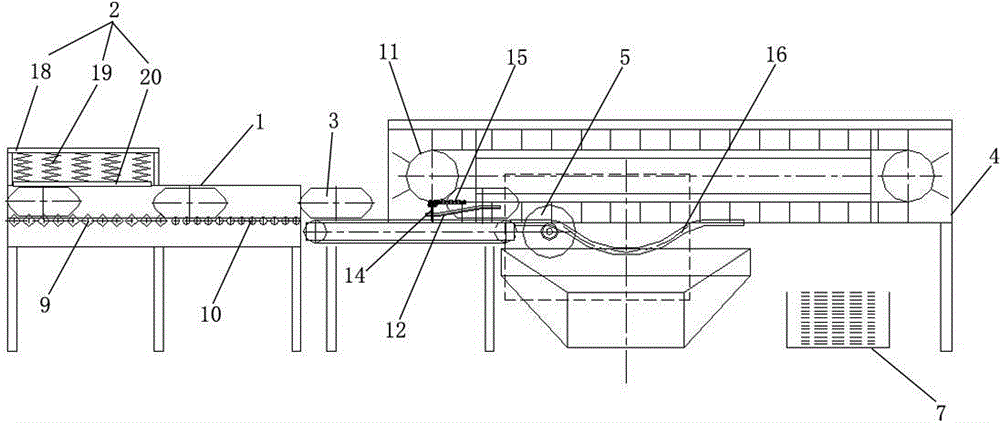

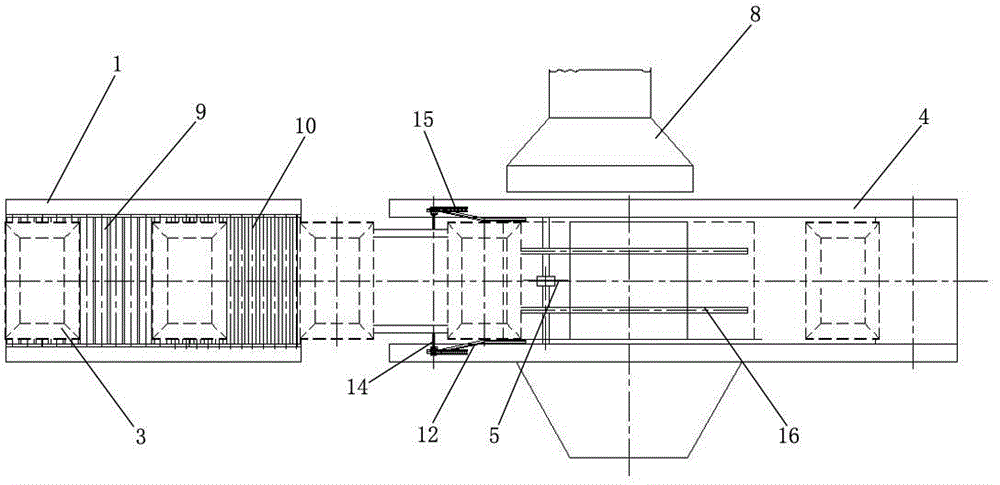

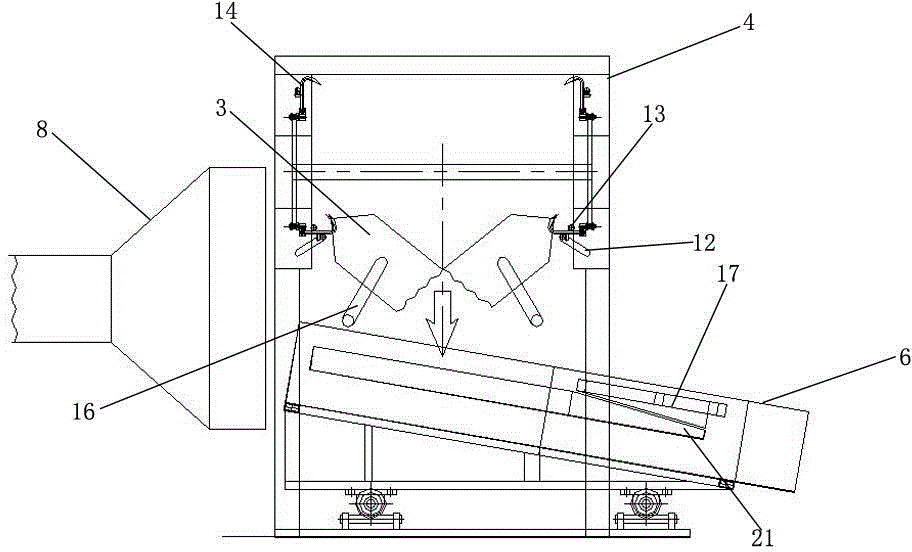

[0021] Such as Figure 1 to Figure 3 The shown automatic continuous bag breaking and unloading device of the present invention includes a bag shaping area, a belt conveyor and a bag breaking unloading area which are arranged separately in the front, middle and rear sections, and the bag is shaped by the belt conveyor The area and the broken bag unloading area are integrated into an integrated structure, so as to realize continuous automatic production. The bag shaping area includes a vibration frame 1 and a spring support 2, and the spring support 2 is erected above the vibration frame 1. As an embodiment of the spring support 2, the spring support 2 includes a frame body 18, a spring 19 and a floating platen 20 On the frame body 18, some springs 19 are fixed at vertical intervals, and the floating ends of the springs 19 are affixed to the floating platen 6, so that the floating platen 6 is floating and crimped on the bag 3 to achieve the effect of smoothing and shaping. A tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com