Combined deep scarification and land preparation machine

A soil preparation machine and subsoiling technology, which is applied in the direction of agricultural machinery and equipment, agricultural machinery and implements, shovels, etc., can solve the problems of large traction resistance of deep plowing machinery, damage to the structure of the soil plow layer, and increase the economic burden of farmers. Consistency of plowing depth, smooth field surface, and the effect of ensuring the quality of land preparation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

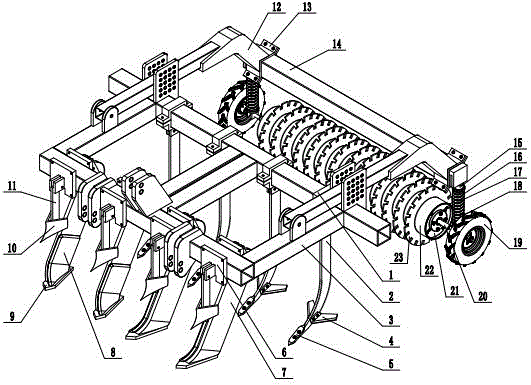

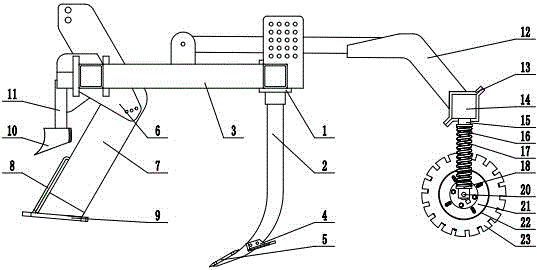

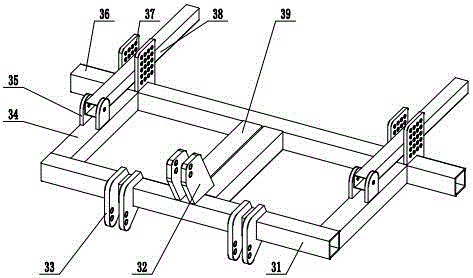

[0019] Below in conjunction with embodiment and accompanying drawing, the present invention will be described in further detail:

[0020] Refer to attached Figure 1~4 , the present invention is characterized in that it includes a frame 3, an omnidirectional subsoiling device and a plowing device. Before, described frame 3 is made of front beam 31, upper suspension plate 32, lower suspension plate 33, beam 34, fixed beam 39, fixed plate 35, limit plate 37, rear beam 36, support beam 38, and described The lower end surface of the upper suspension plate 32 is connected with the upper end surface of the front beam 31 and the upper end surface of the fixed cross beam 39, the lower suspension plate 33 embraces the front beam 31 and is connected, the front end surface of the cross beam 34 is connected to the inside of the front beam 31, and the lower end surface of the fixed plate 35 is connected to the Crossbeam 34 upper end face, support beam 38 front ends are connected with fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com