Air-pressure auto-excitation type vibrating subsoiler

A self-excited, subsoiler technology, used in agricultural machinery and implements, shovels, plows, etc., can solve the problems of poor adaptability, limited variation range of soil resistance, failure of self-excited vibration, etc. The effect of reducing traction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

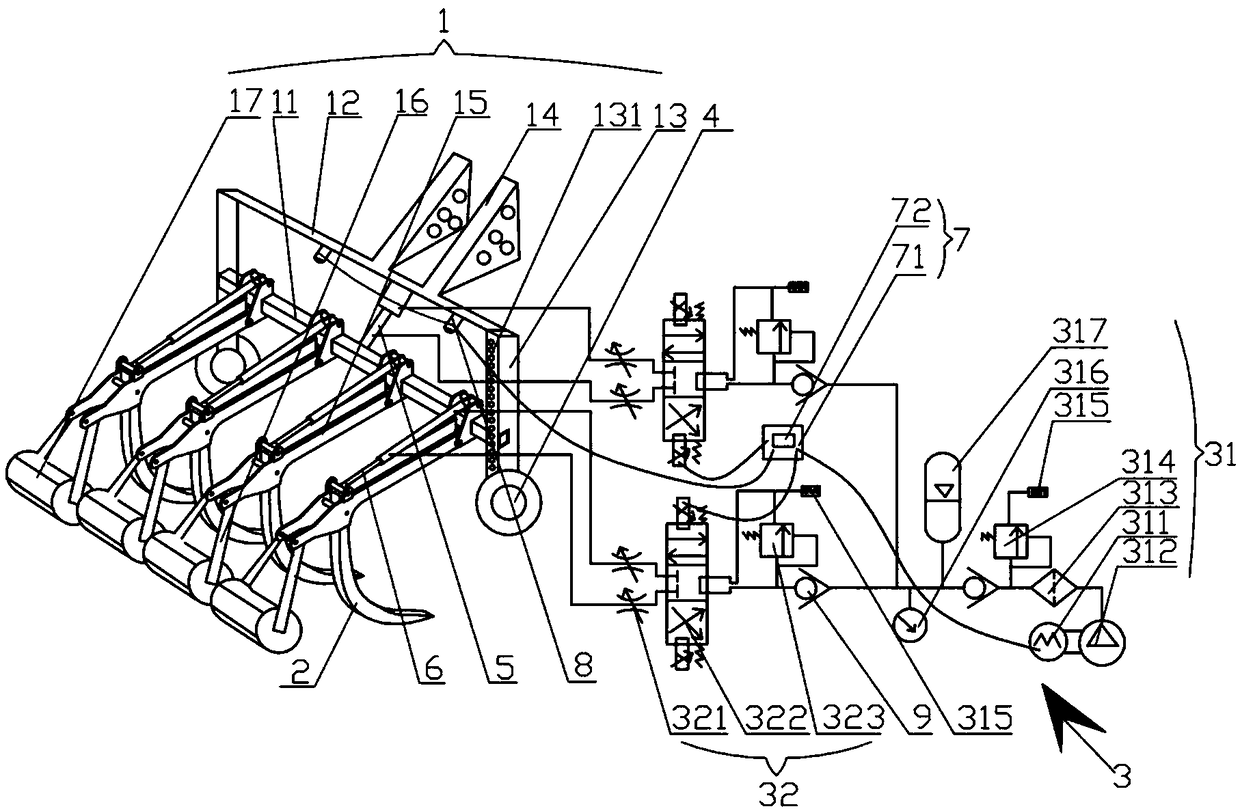

[0025] Such as figure 1As shown, a pneumatic self-excited vibratory subsoiler includes a frame body 1, several subsoiler shovels 2 and an air pressure adjustment system 3, and the frame body 1 includes a beam A11, a beam B12, and two depth-limiting wheel support arms 13 and the suspension arm 14 that is used to connect the frame body 1 with the tractor, the depth-limiting wheel support arm 13 is provided with the depth-limiting wheel 4, the crossbeam A11 and the crossbeam B12 are arranged in parallel, and the two ends of the crossbeam A11 can be respectively along the two depth-limiting wheel support arms. 13 slides up and down, and a cylinder A5 for adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com