Overhaul bench for automatic transmission

A technology of automatic transmission and workbench, which is applied in the field of vehicle maintenance, can solve the problems of orderly placement of parts, high labor intensity, and increased usage, so as to avoid waste of oil resources, reduce labor intensity, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

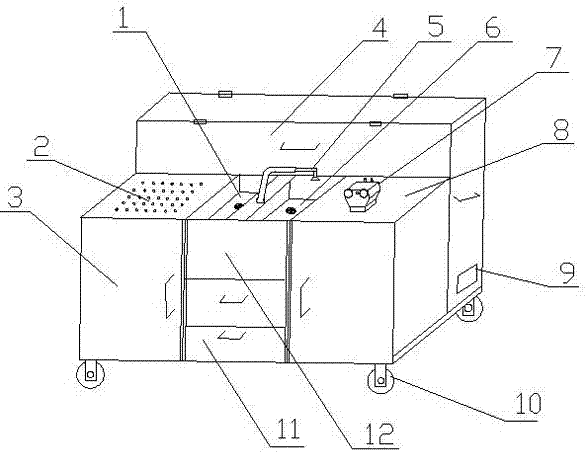

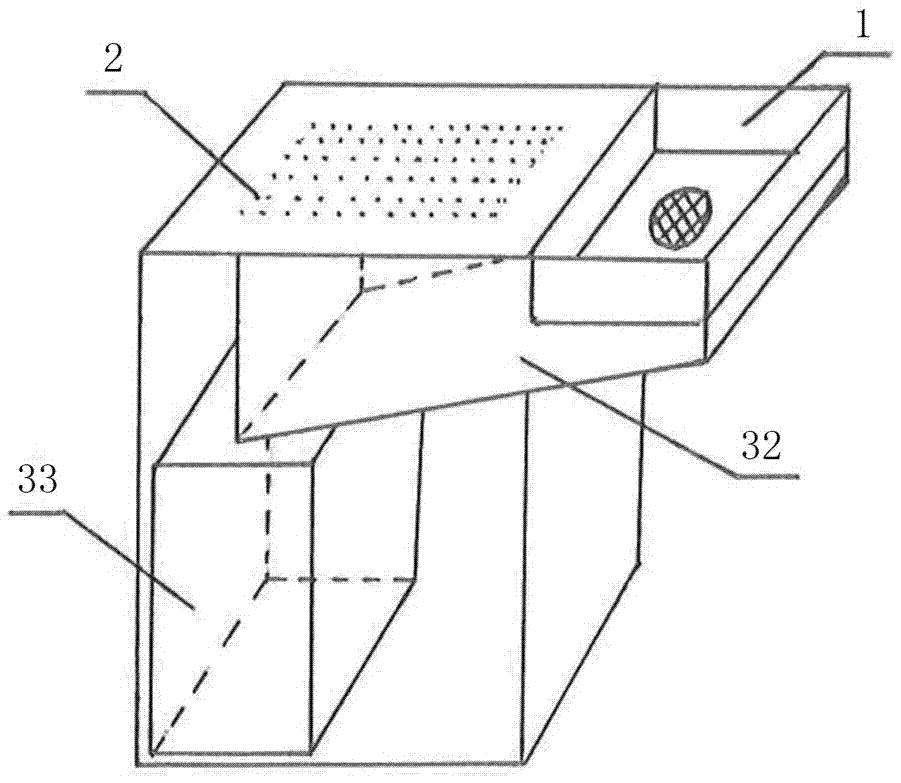

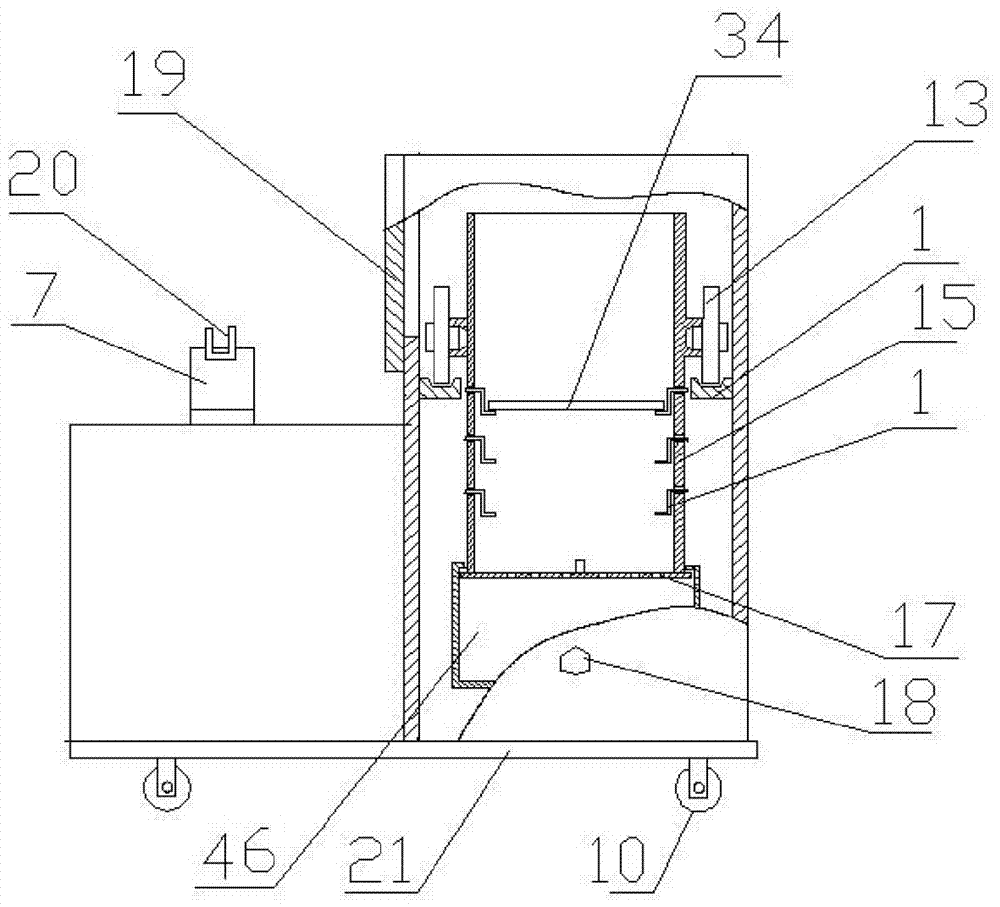

[0024] refer to Figure 1-10 , an automatic transmission maintenance workbench, comprising a base 21, the lower end of the base is provided with a walking wheel 10, the base 21 is provided with a workbench, one side of the workbench is provided with a parts storage cabinet 4, and the workbench is divided into two parts: area, a cleaning area and an inspection area, the disassembly area and the inspection area are located on both sides of the cleaning area, the disassembly area includes a disassembly table 2, the lower end of the disassembly table 2 is provided with a waste oil collection cabinet 3, the present invention The disassembly and assembly area, cleaning area and inspection area are arranged in order from left to right on the workbench. The tools 11 are arranged under the cleaning area, and the parts storage cabinet 4 is located on the back side of the workbench, which is in line with the maintenance procedures of automatic transmissions. , and in line with the operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com