Down-ditch construction method for laying heavy caliber pipeline

A technology of large-diameter pipelines and construction methods, which is applied in the construction field of laying large-diameter pipelines under the ditch, can solve the problems of unguaranteed construction safety, difficulty in unified coordination and command, and increased construction costs, so as to ensure the safety of people and equipment, The effect of saving equipment investment and preventing dumping accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

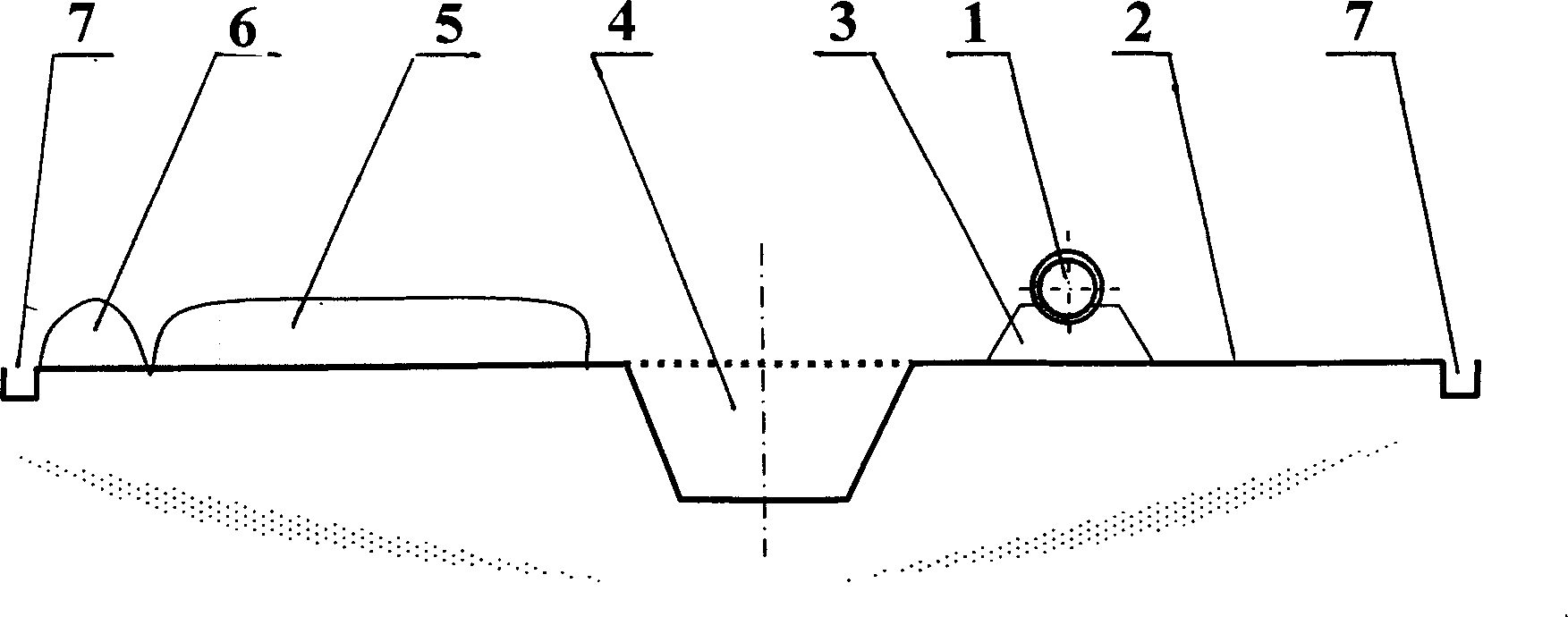

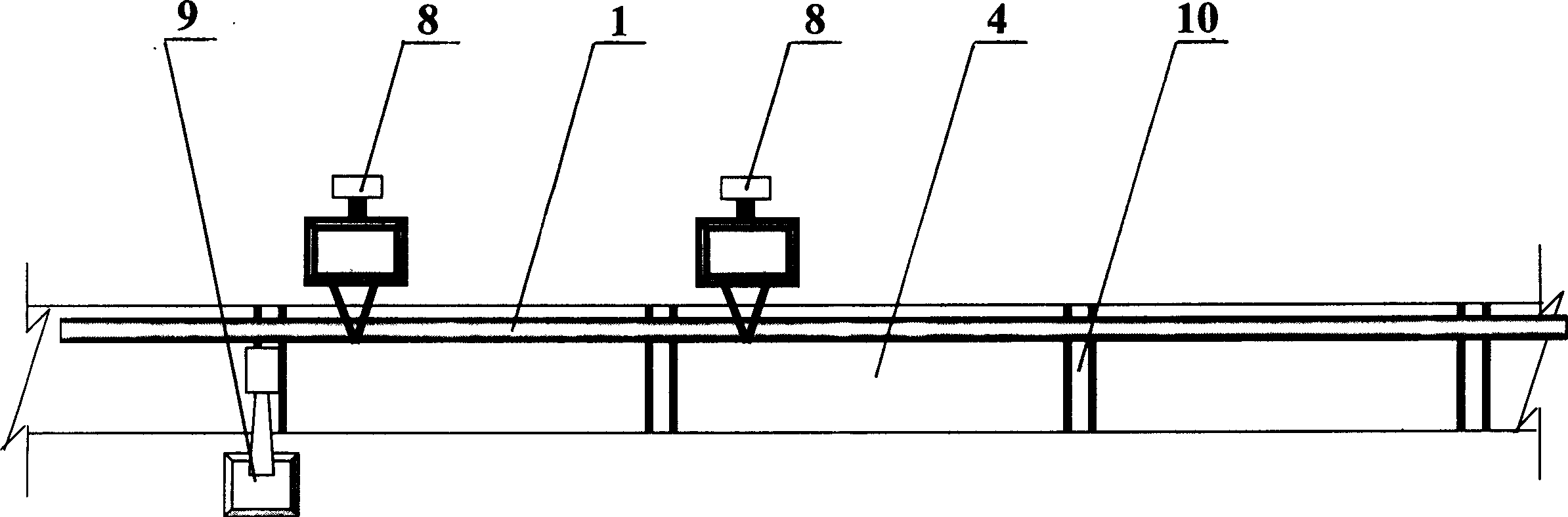

[0015] An embodiment is illustrated in conjunction with the accompanying drawings:

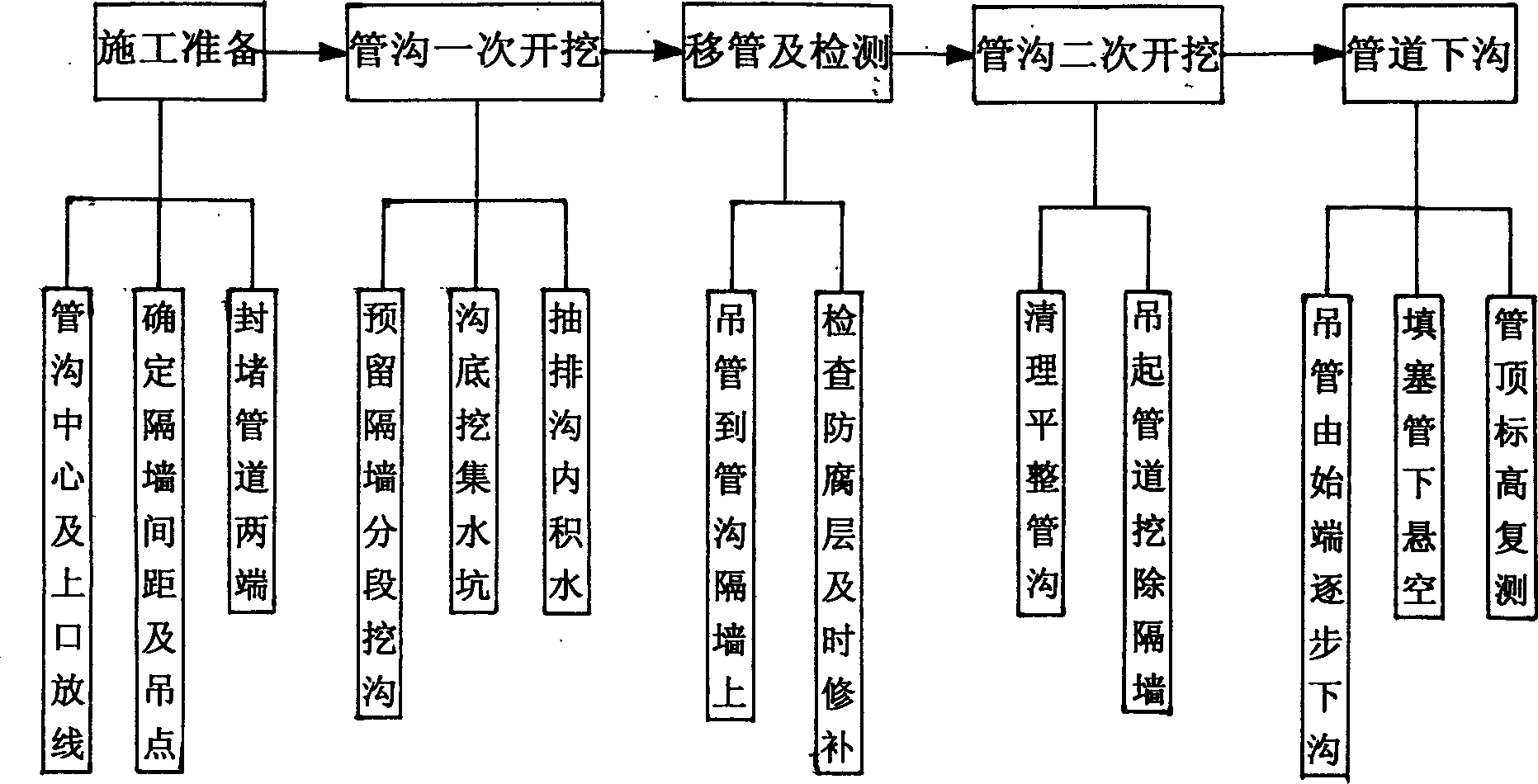

[0016] Depend on figure 1 As shown, the basic construction procedures of the present invention are: construction preparation, primary excavation of the pipe trench, pipe transfer and detection, secondary excavation of the pipe trench, and trenching of the pipeline. The brief technical contents (or sub-processes) of each process are:

[0017] Construction preparation: including laying out the center of the pipeline and the upper opening, determining the distance between partition walls and lifting points, and sealing off both ends of the pipeline.

[0018] One-time excavation of pipe trenches: including segmental excavation of reserved partition walls, excavation of sump pits at the bottom of trenches, and pumping and drainage of accumulated water in trenches.

[0019] Pipe transfer and inspection: including hanging the pipe partition wall, inspecting the anti-corrosion layer and repairing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com