Hoisting device for construction

A technology for construction and equipment, applied to cranes, etc., can solve problems such as small operating radius, inconvenient handling, and heavy weight of full-angle hoists, and achieve the effects of preventing dumping accidents, increasing operating range, and good marketing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

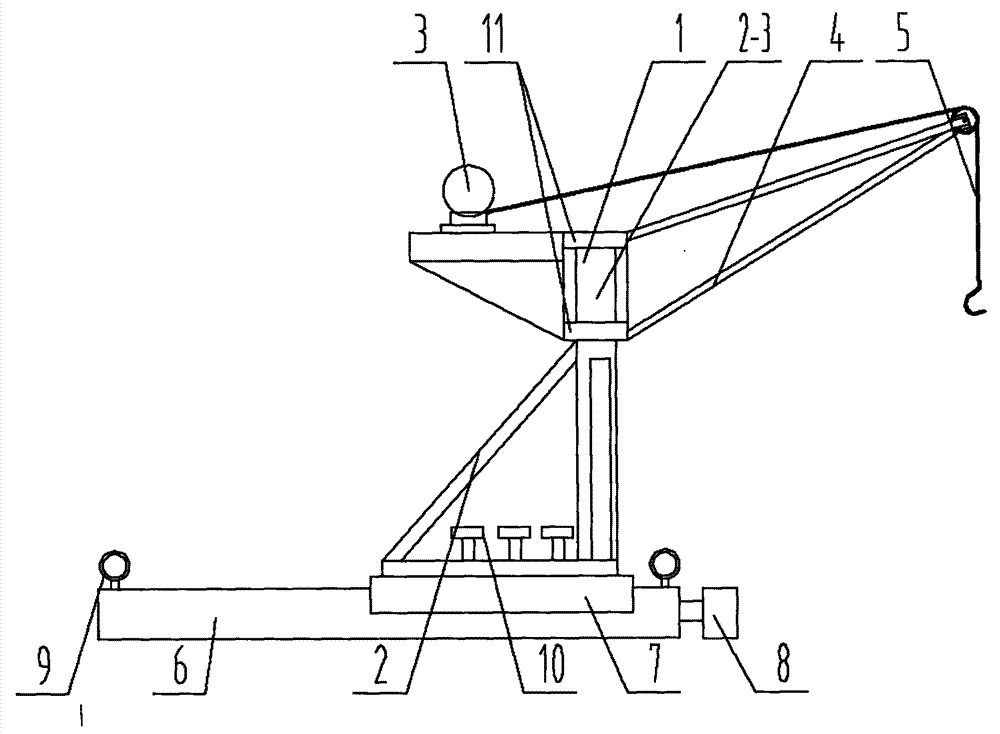

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

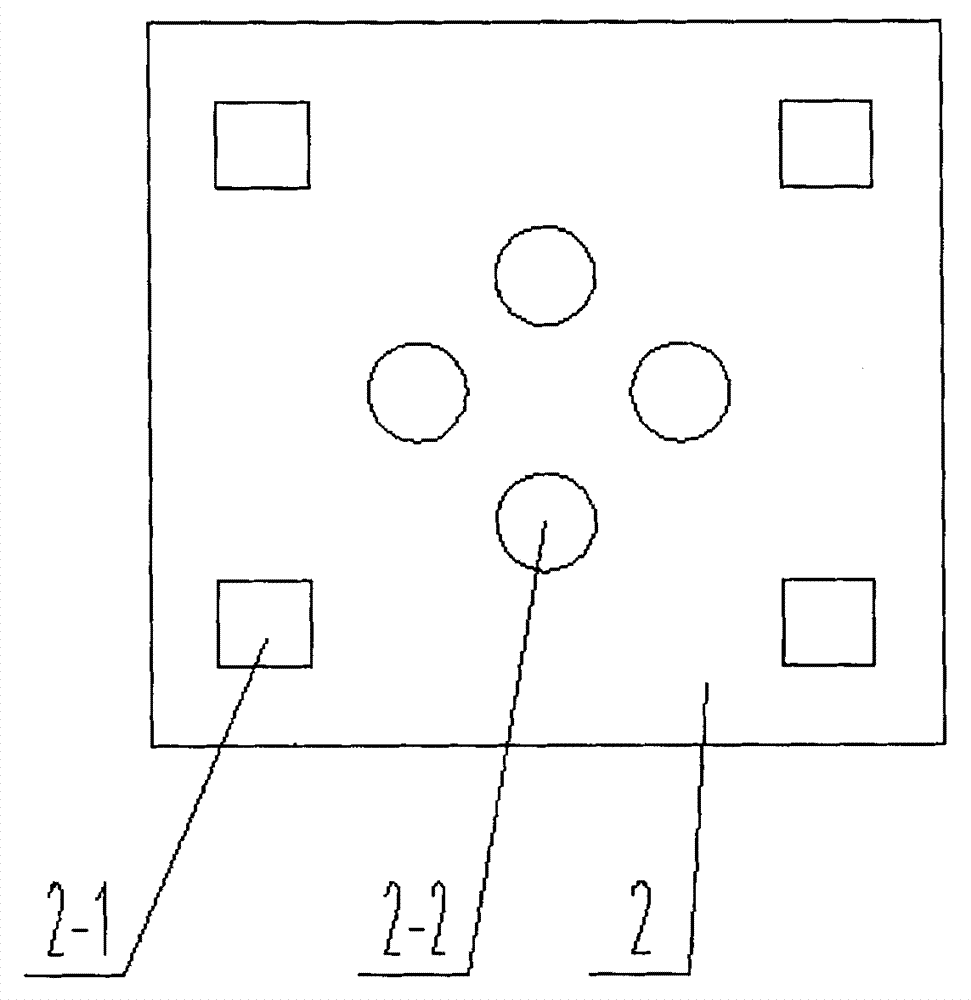

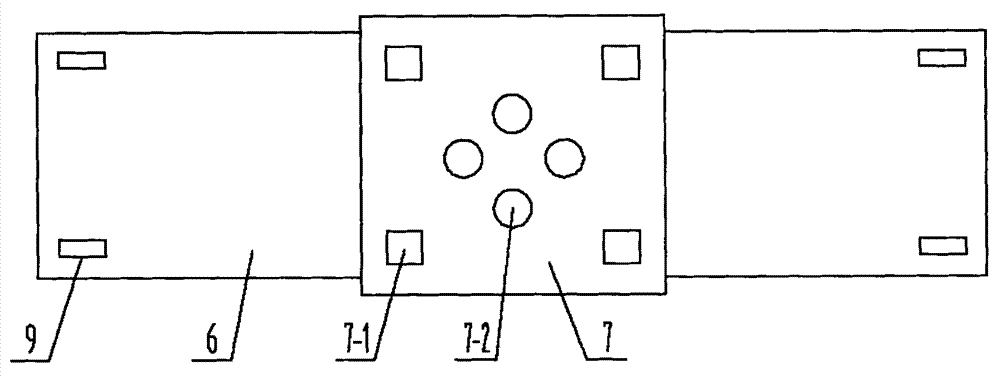

[0014] like figure 1 , 2 , 3, the present invention comprises a full-angle hoist main frame, a turret 1 and an underframe 2, a full-angle hoist main frame includes a reduction motor 3, a boom 4 and a wire rope device 5, and the top of the turret 1 and the boom Connected, the turret 1 is movably assembled on the rotating shaft 2-3 located at the bottom frame 2 through a pair of tapered bearings 11. It also has a moving device and a set of locking screws 10. The moving device includes a dovetail groove slide rail 6, a dovetail slide Block 7 and transmission lead screw pair 8, dovetail groove slide rail 6 are fixedly installed on the ground, dovetail slide block 7 is respectively provided with a group of assembly groove 7-1 and a group of avoidance locking hole 7-2, and dovetail slide block 7 is movable Assembled on the dovetail slide rail 6, the transmission lead screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com