Patents

Literature

31results about How to "Quick blend" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

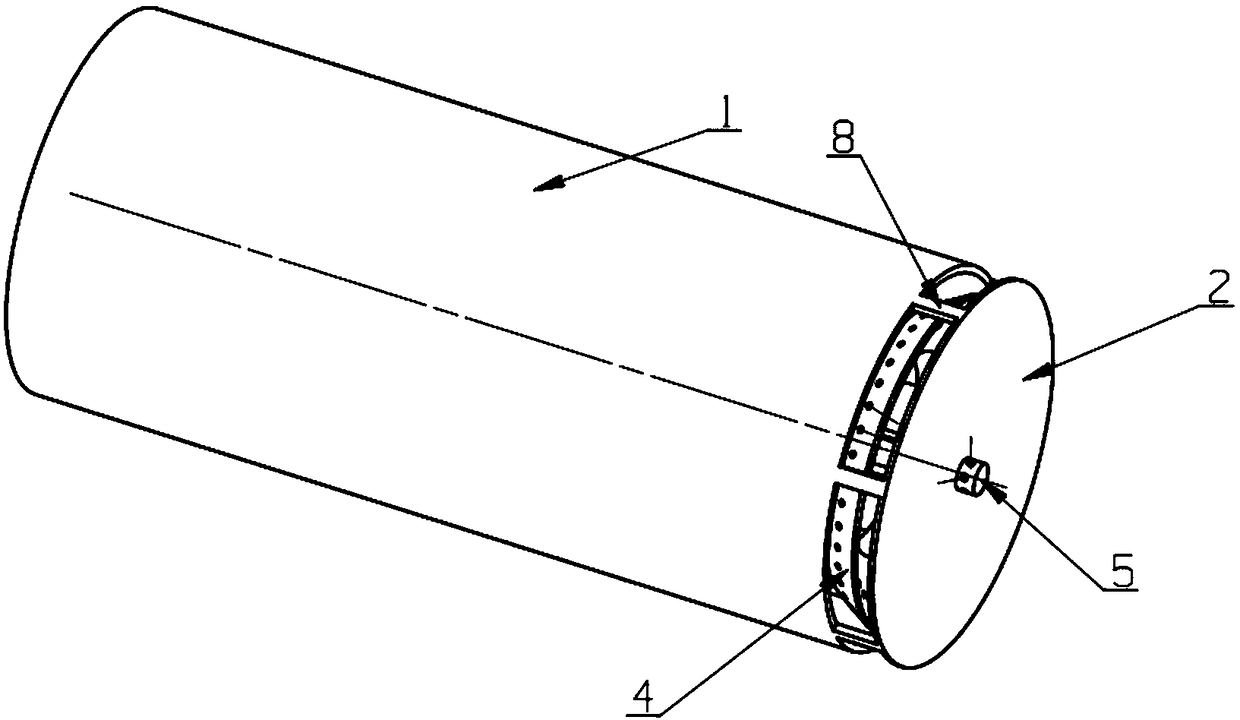

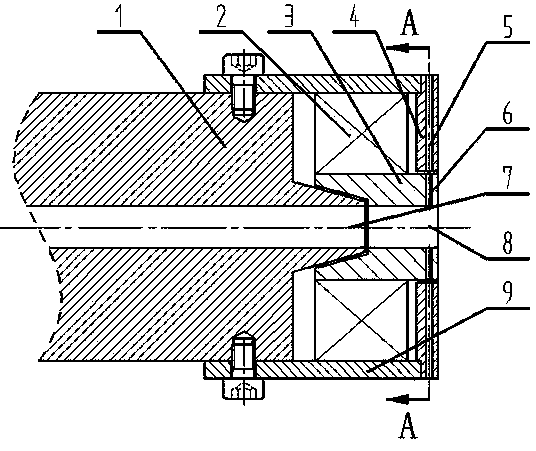

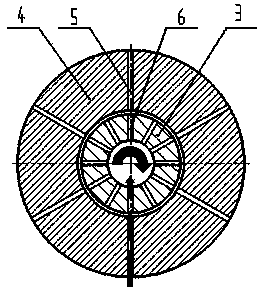

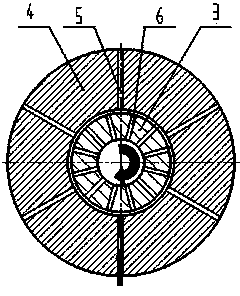

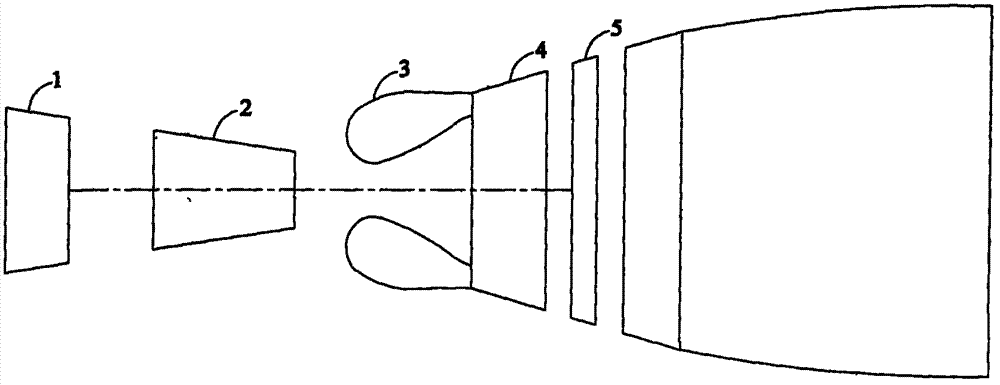

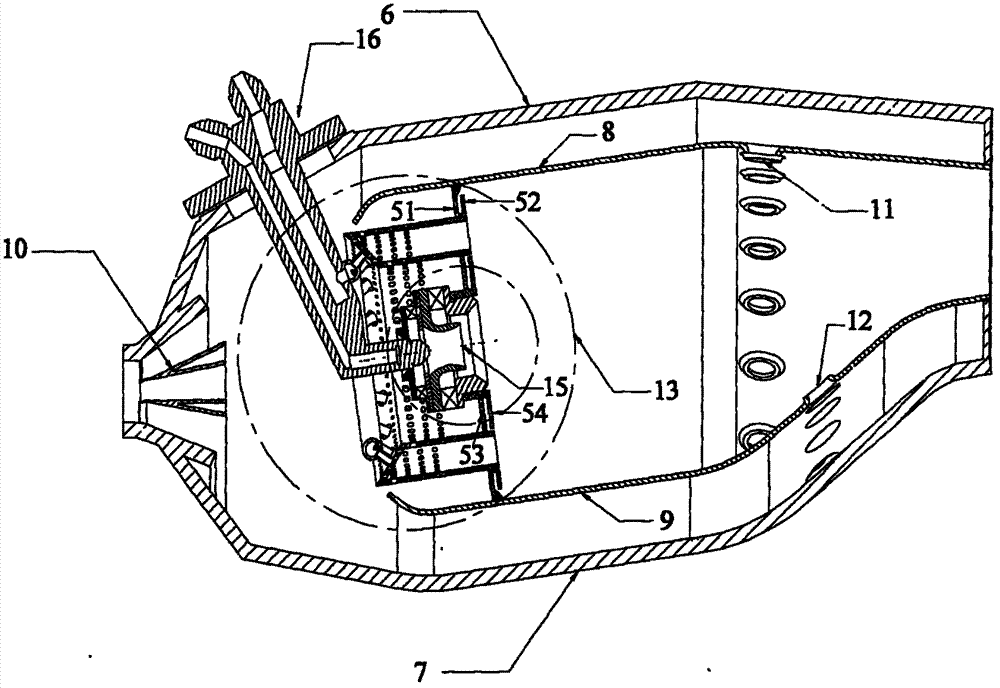

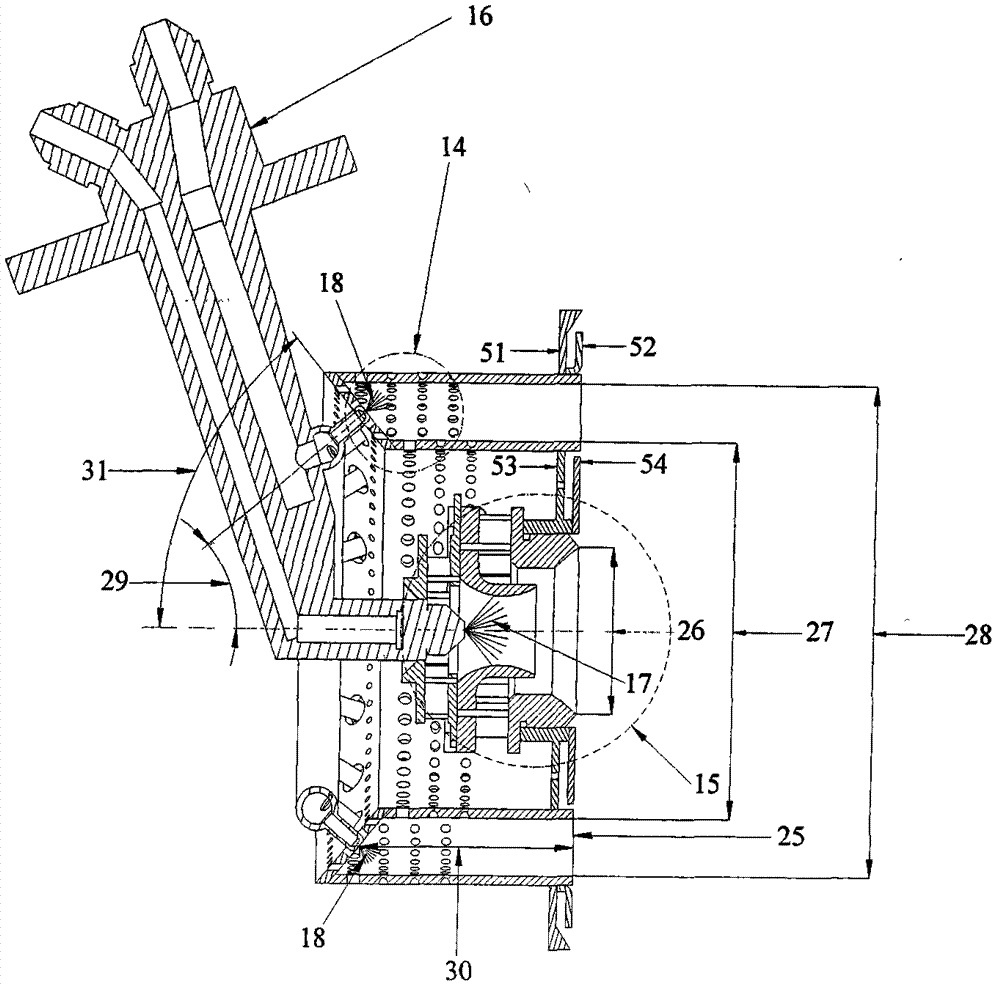

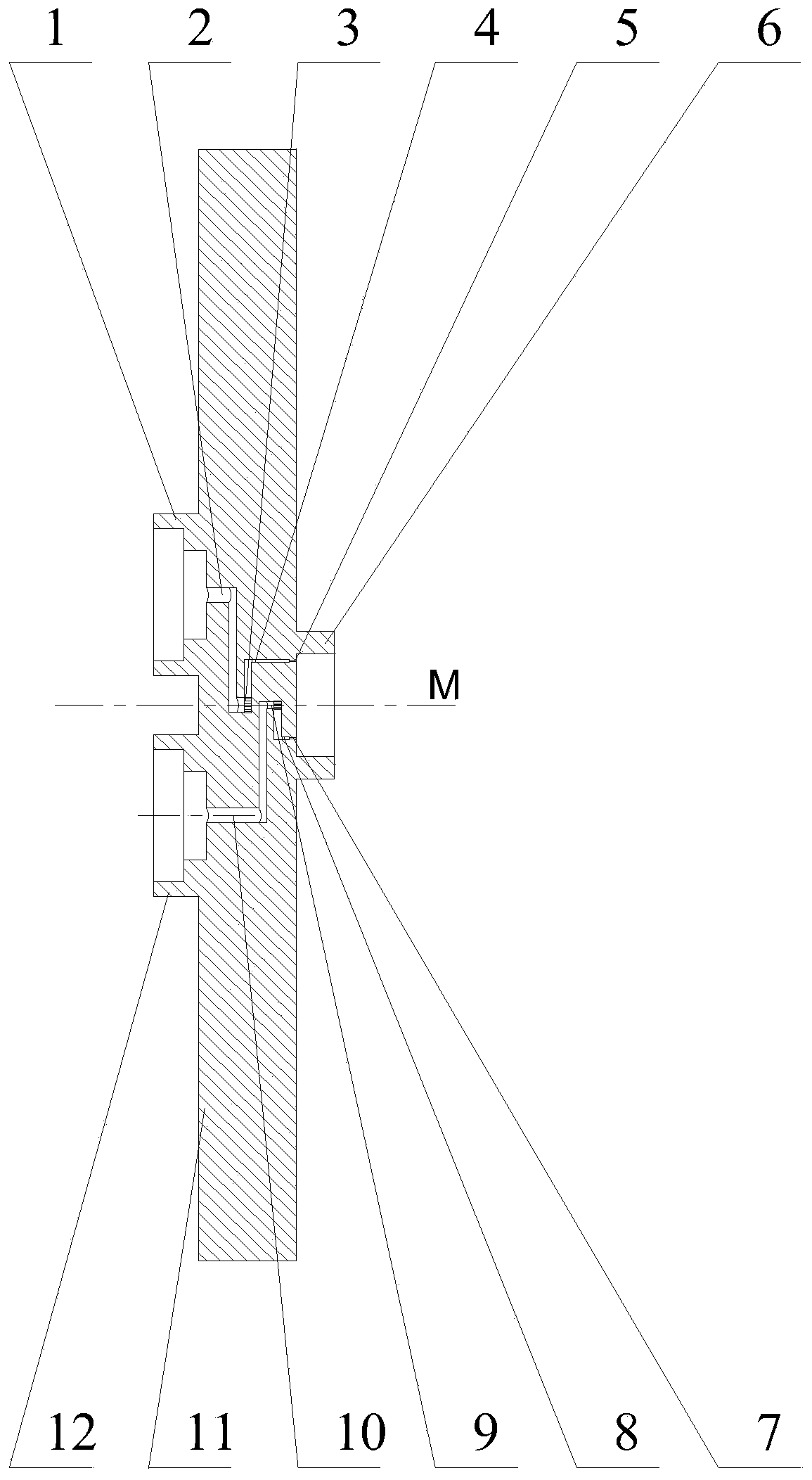

Fuel and air mixing device for low-pollution burning chamber of gas turbine

ActiveCN102506446AFast evaporationQuick blendContinuous combustion chamberIndustrial gasCombustion chamber

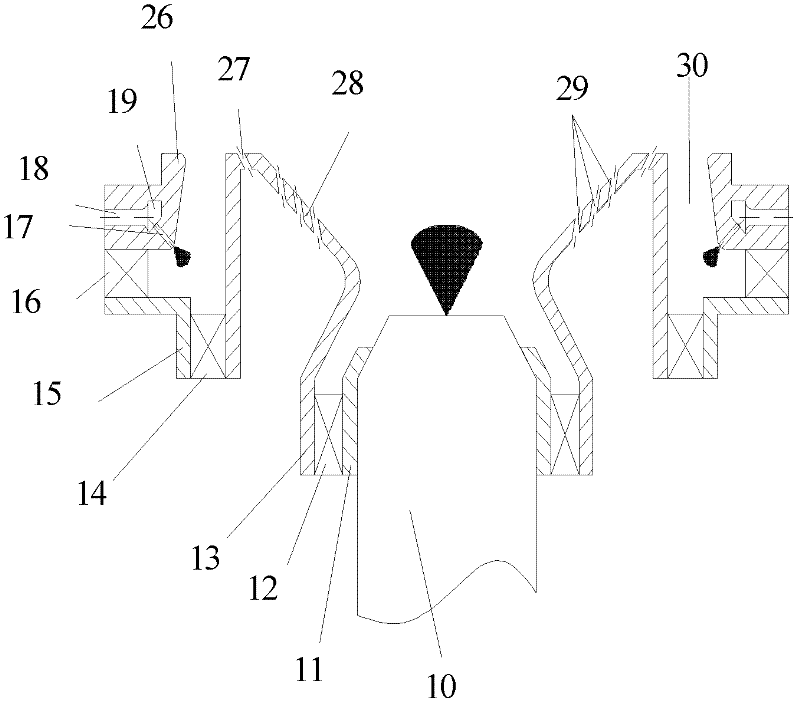

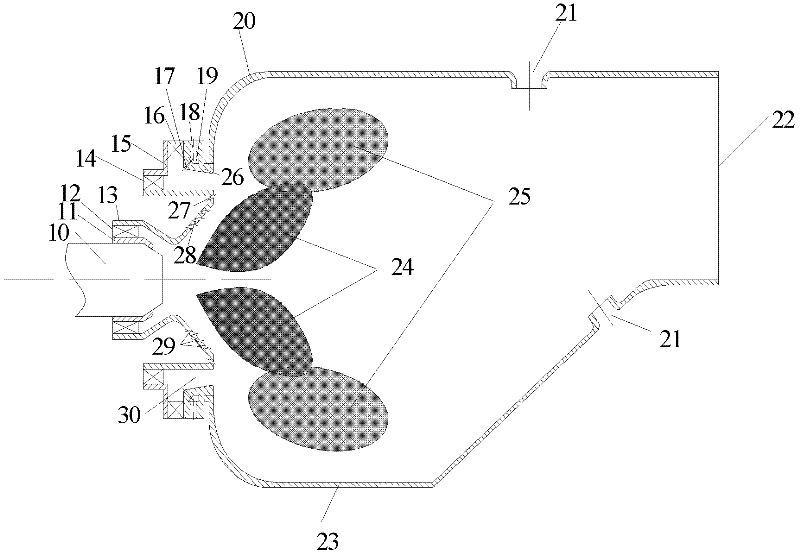

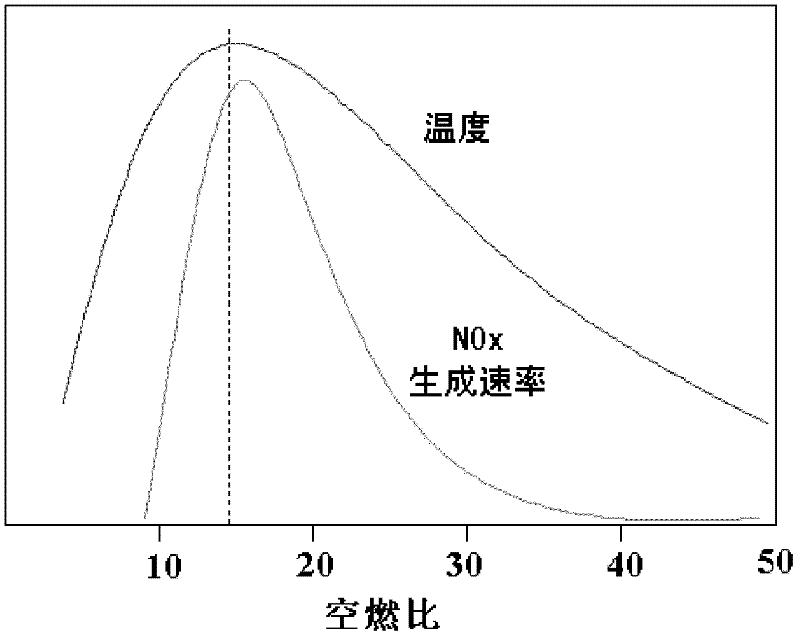

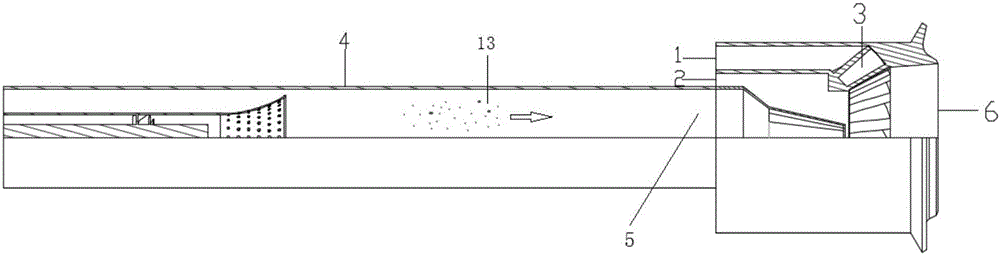

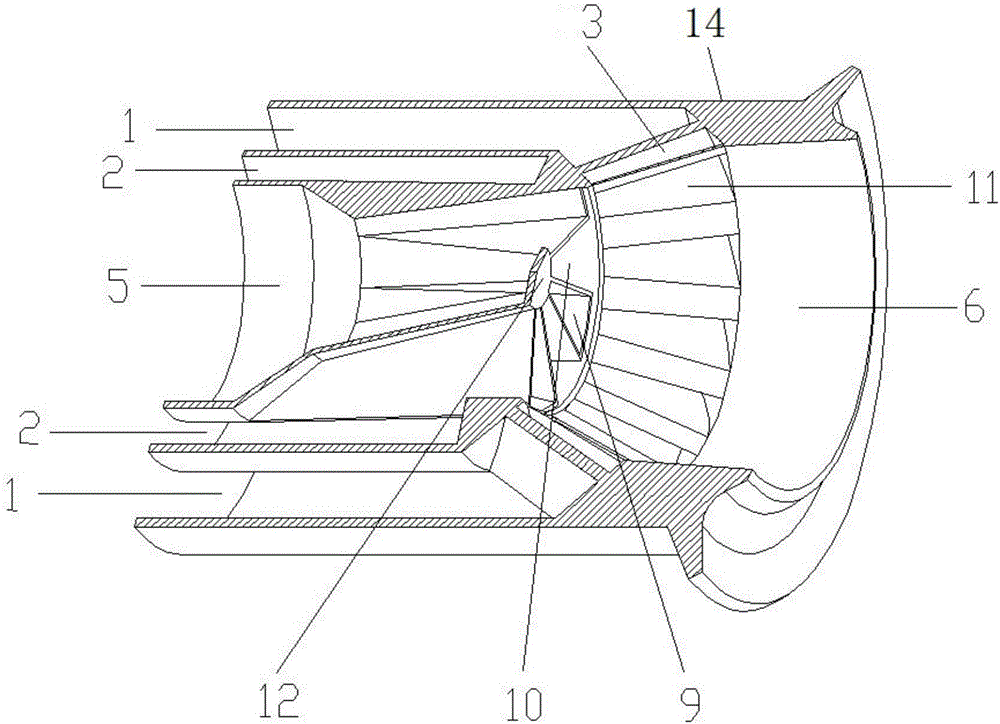

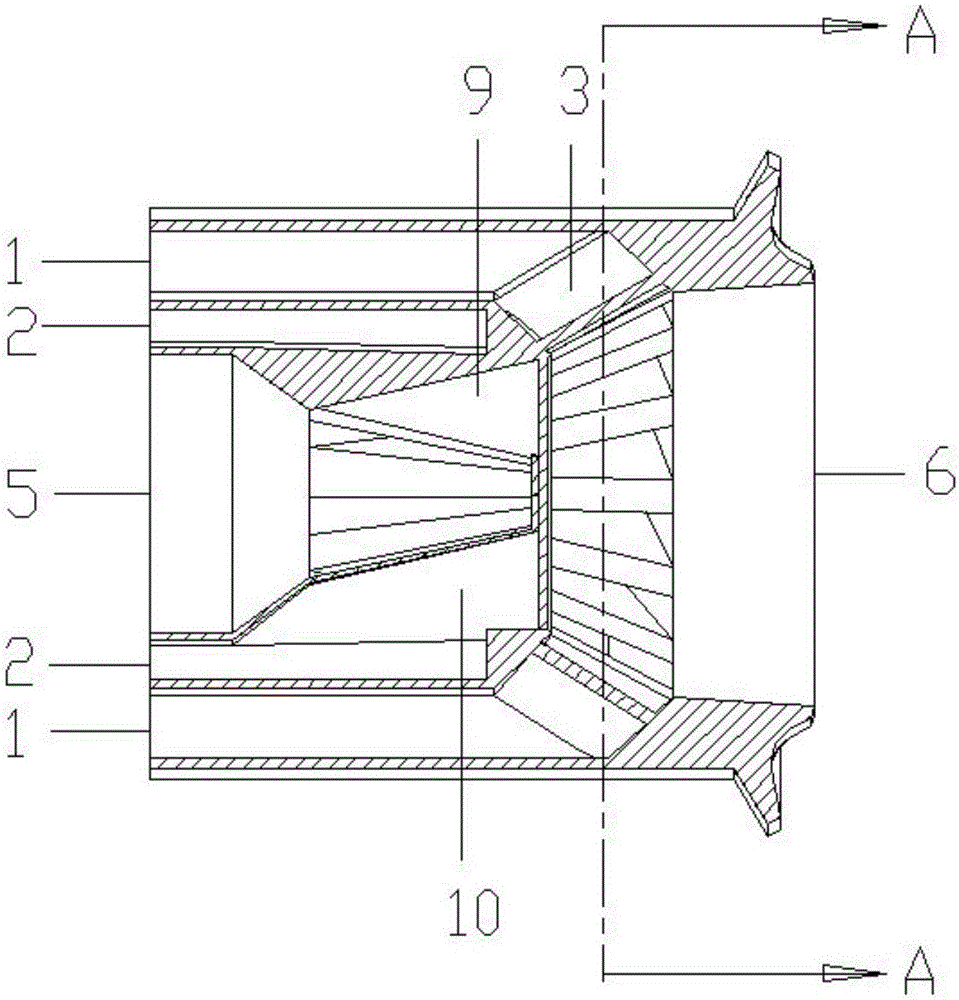

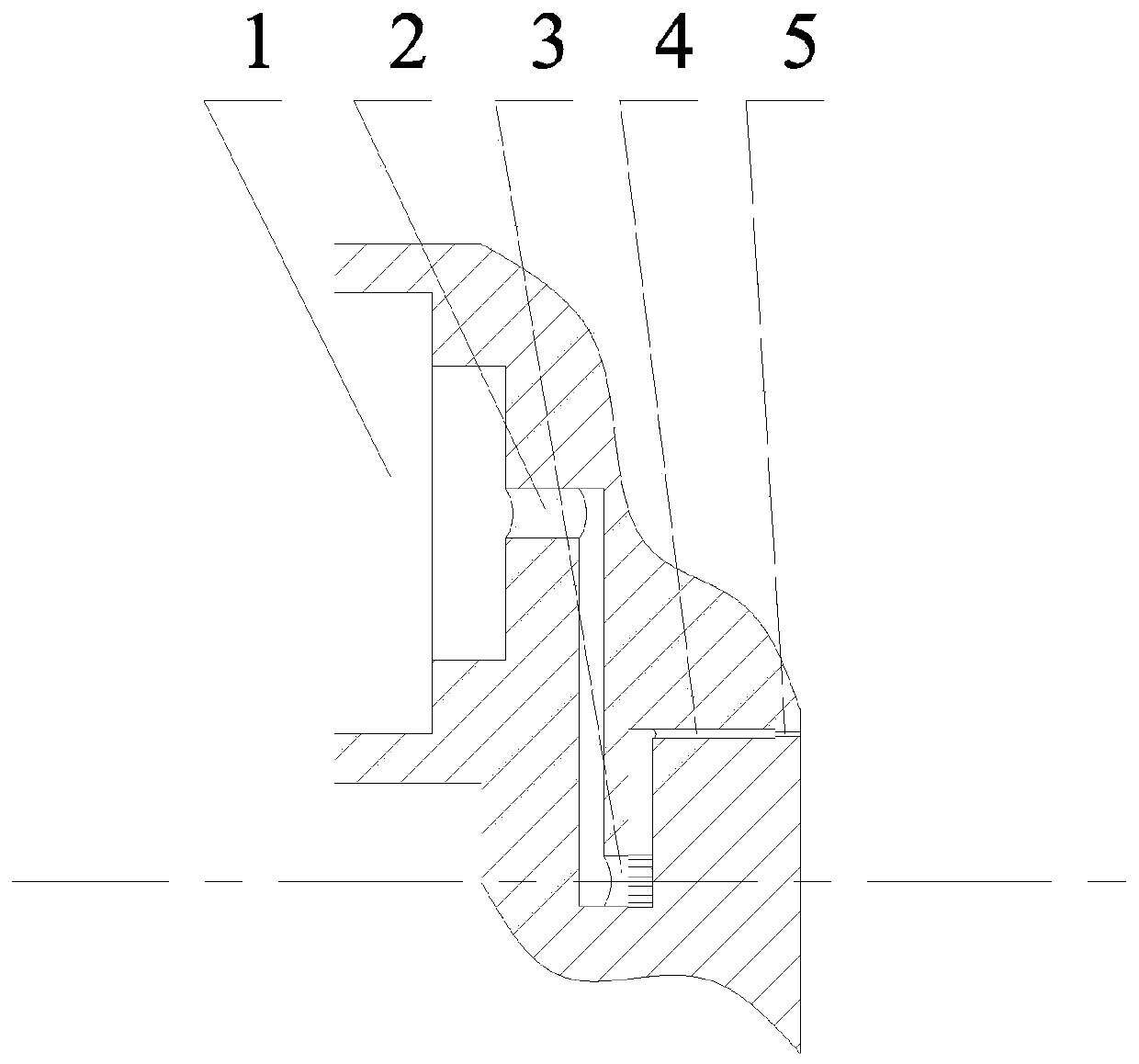

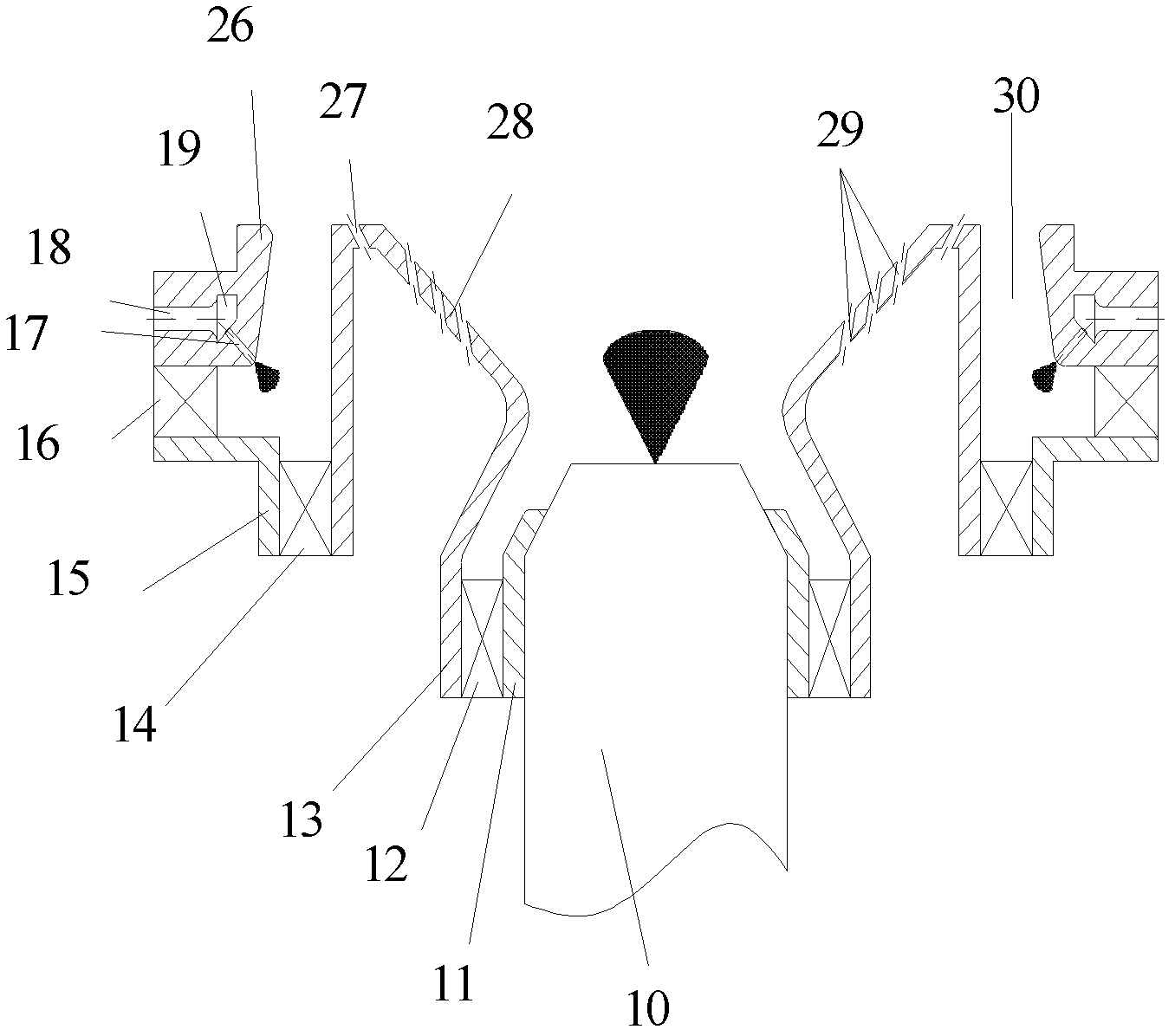

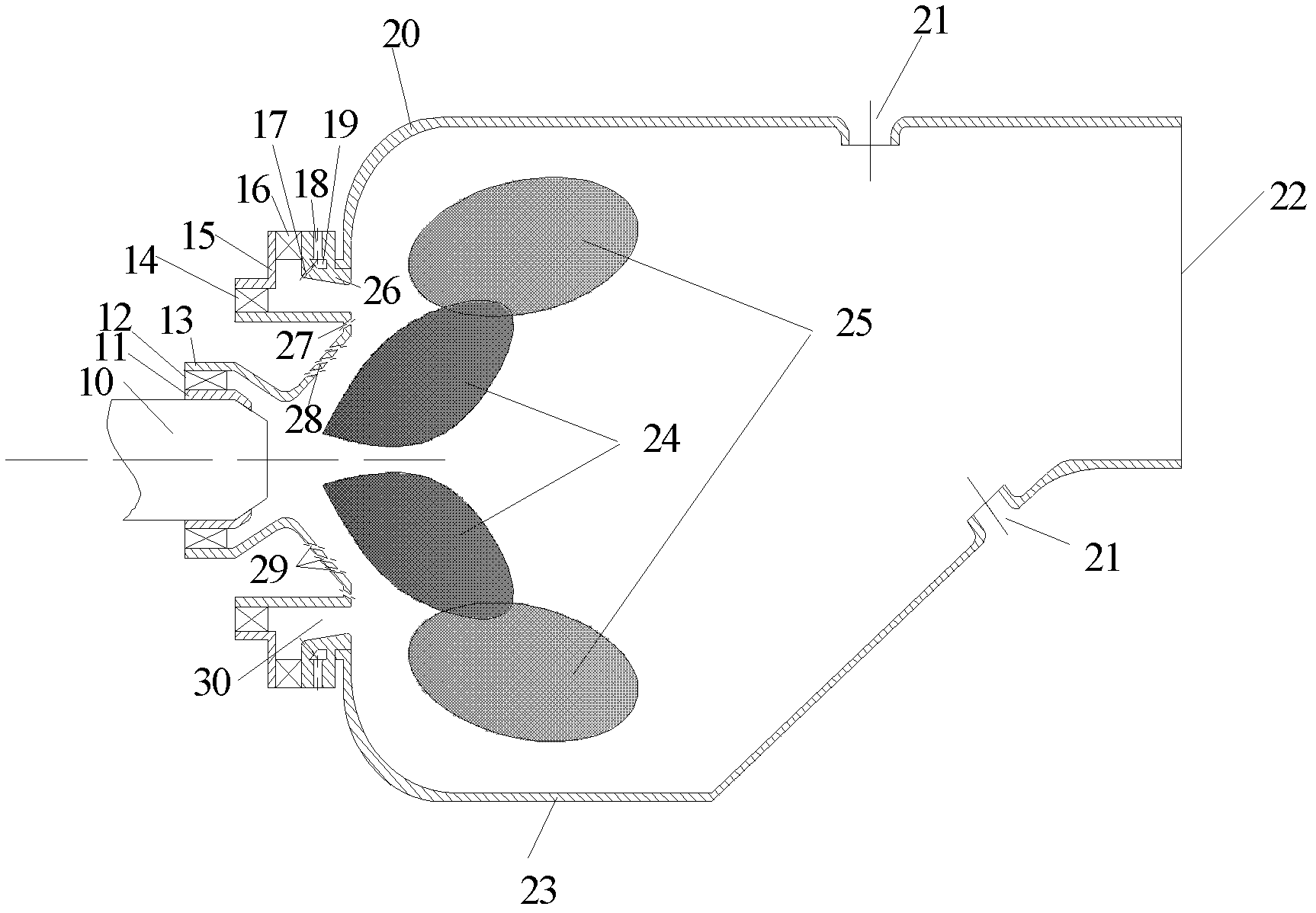

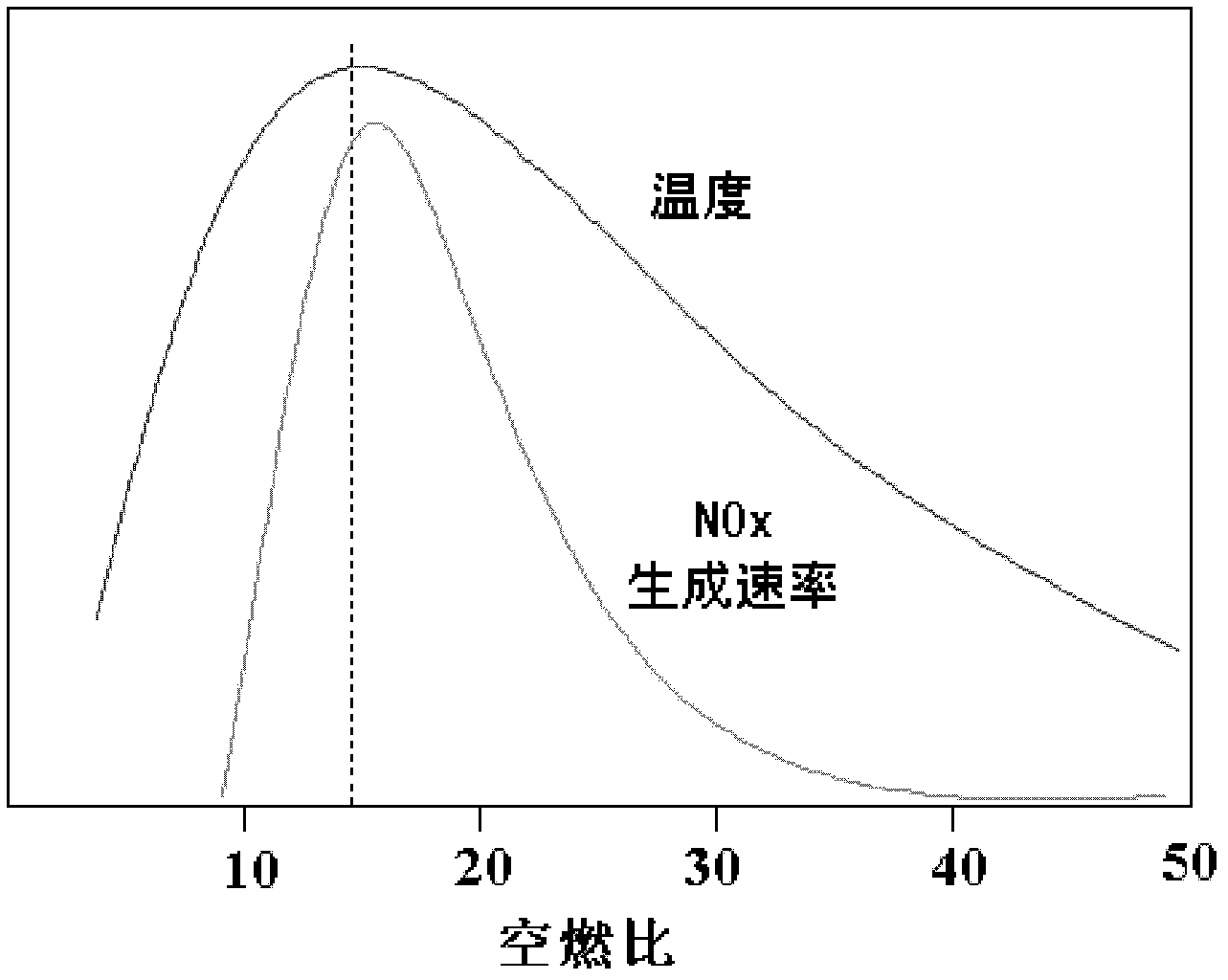

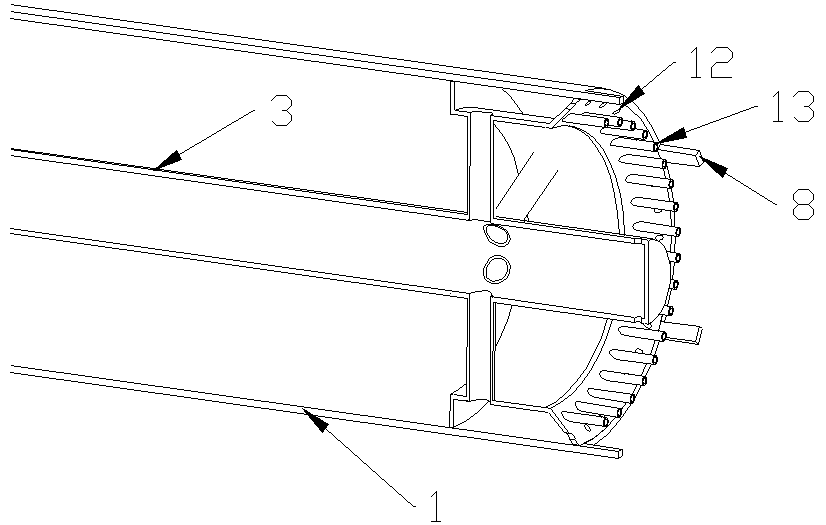

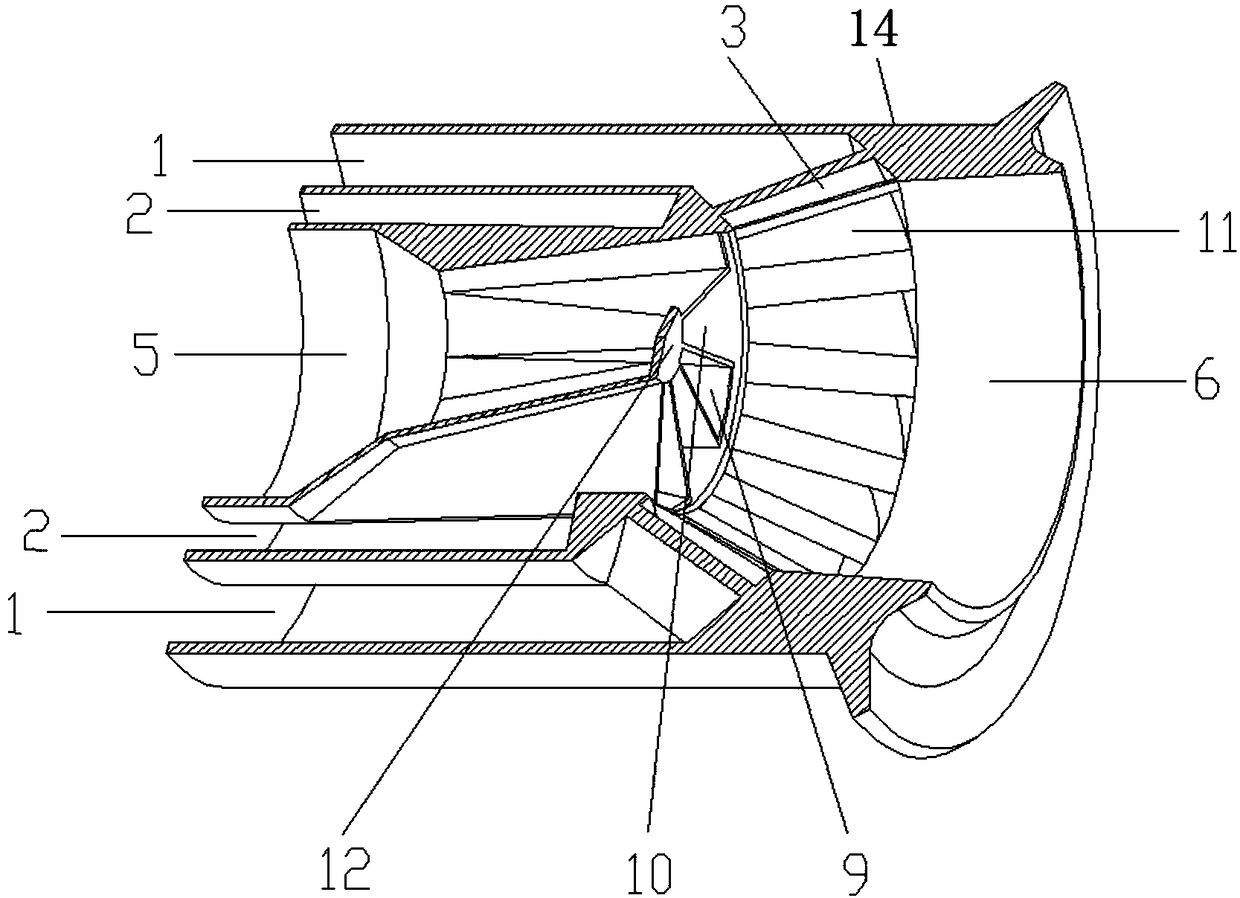

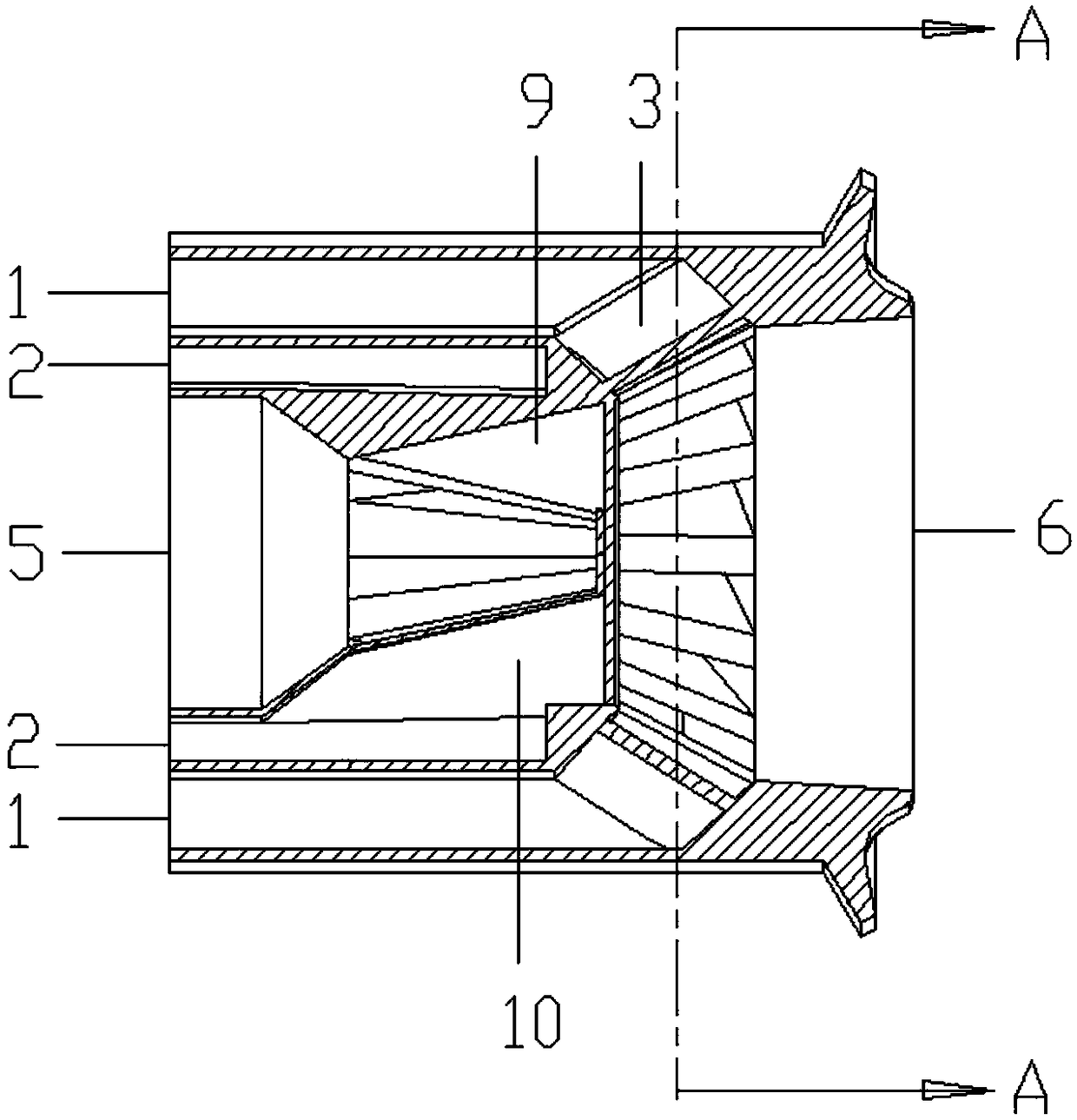

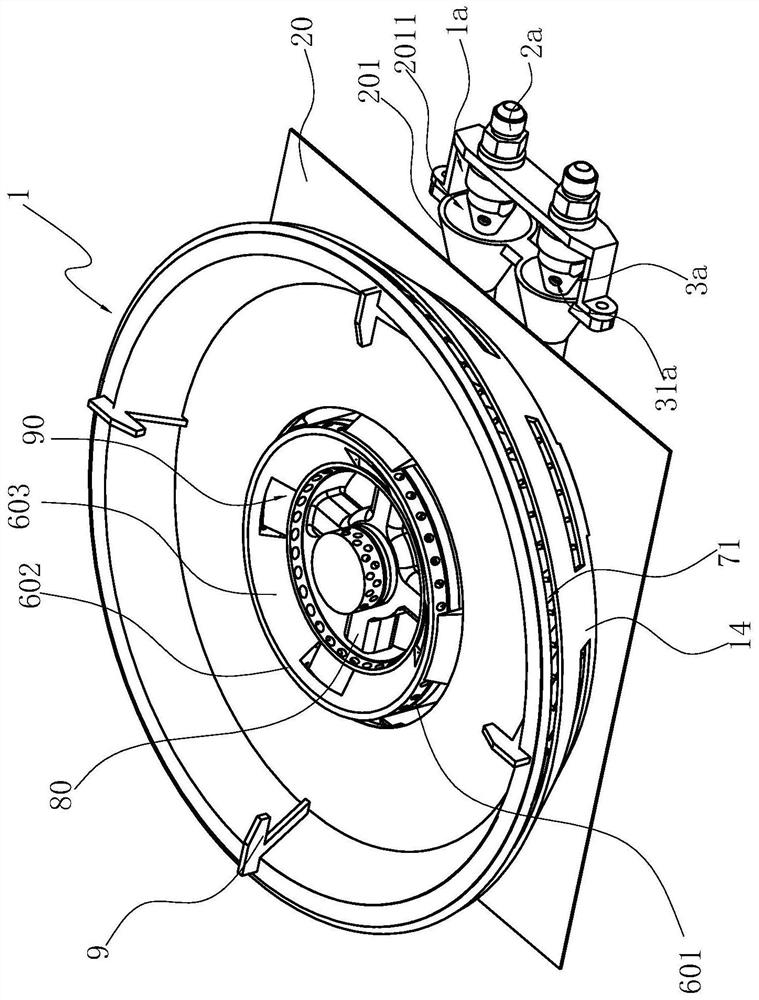

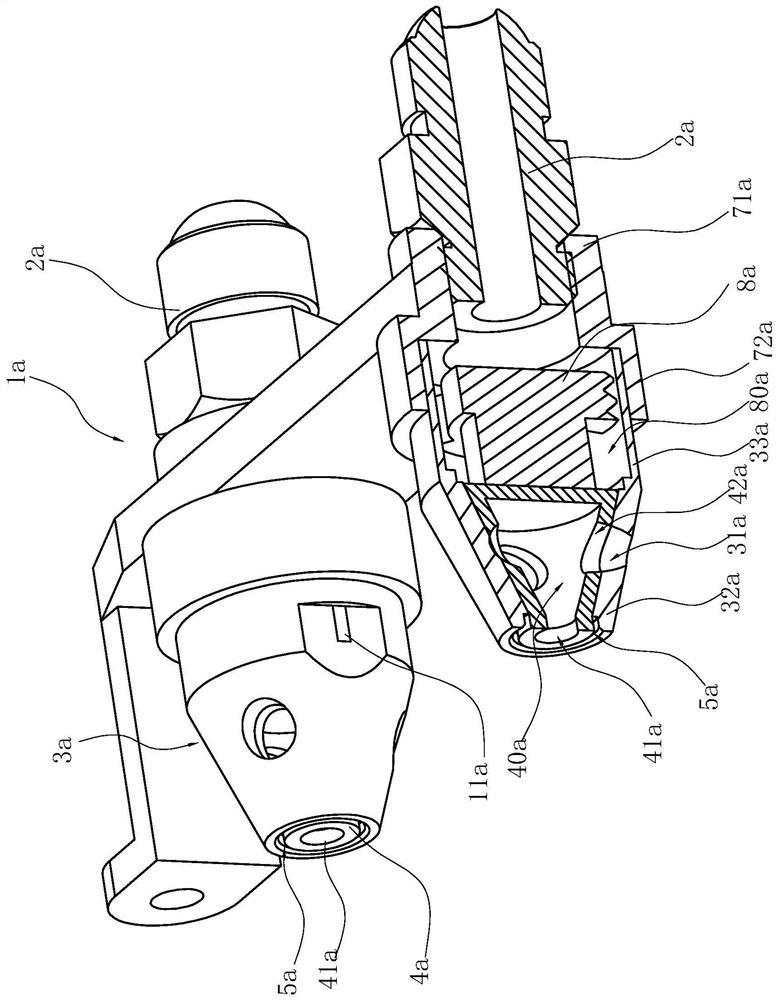

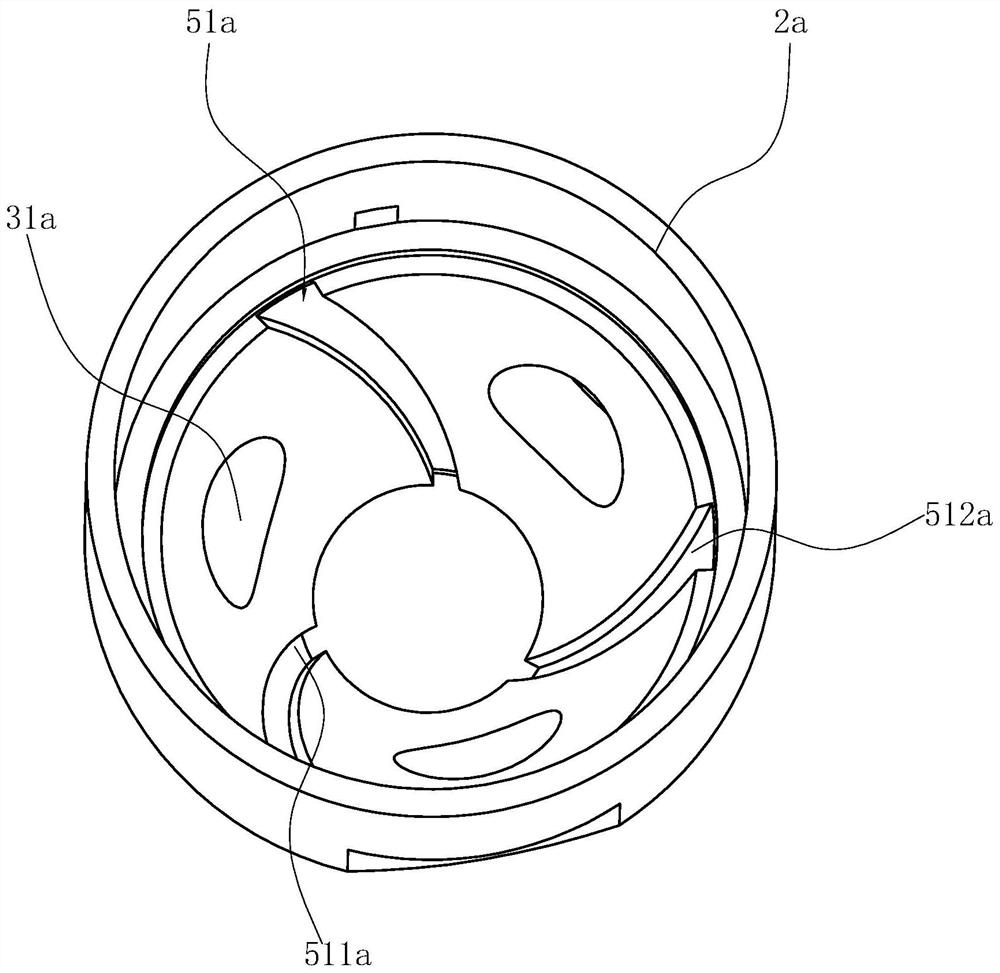

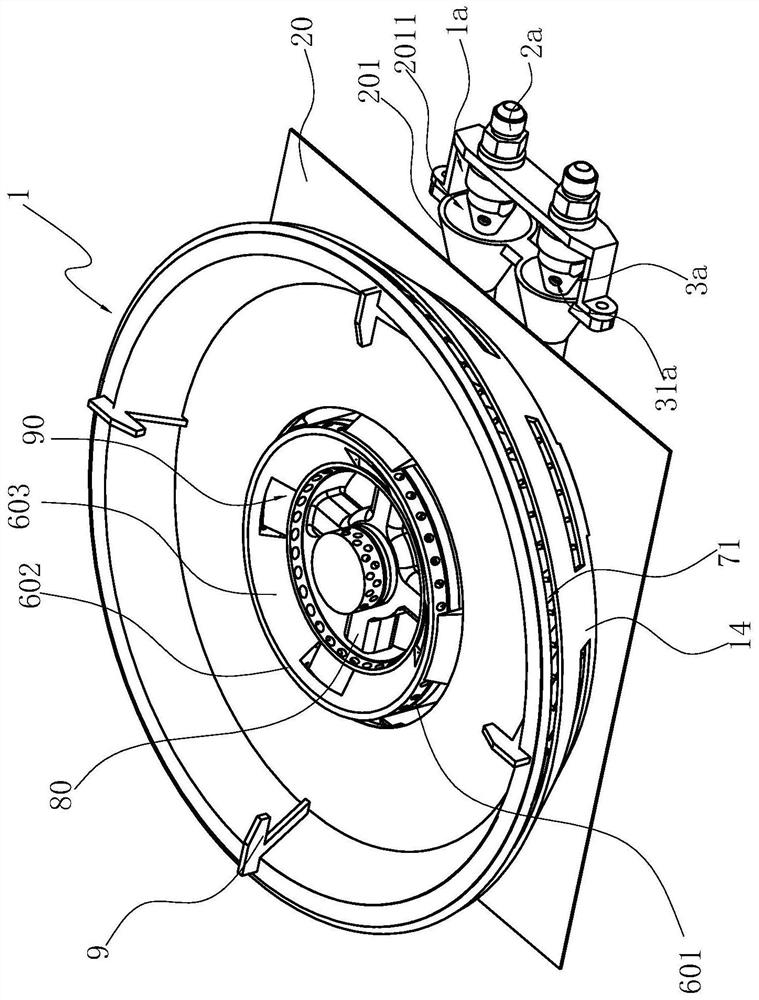

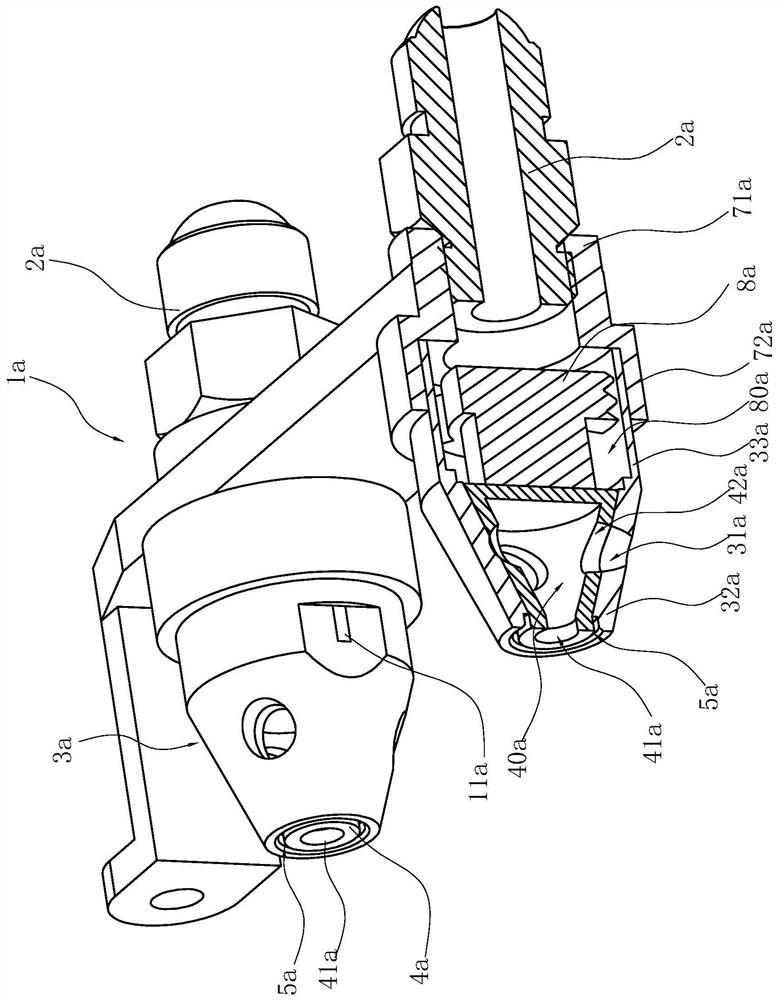

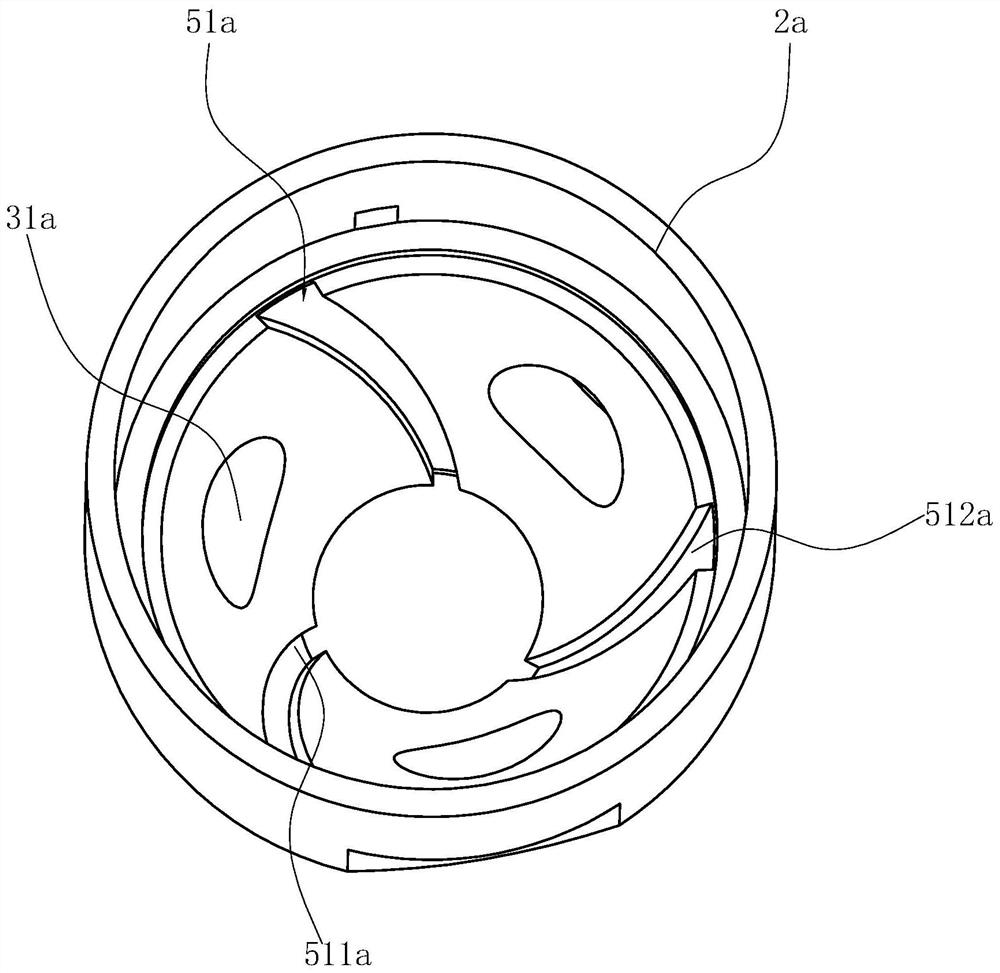

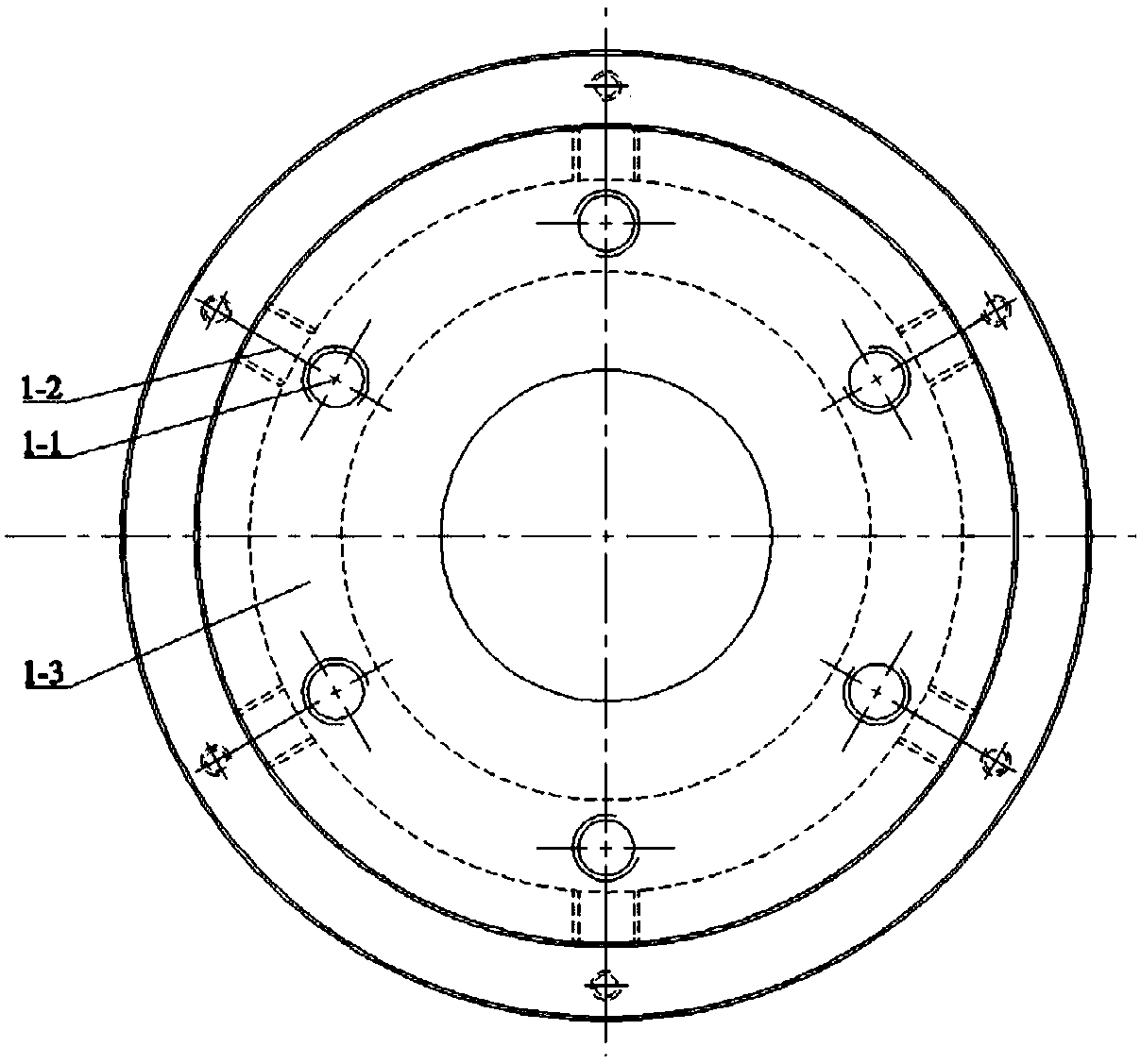

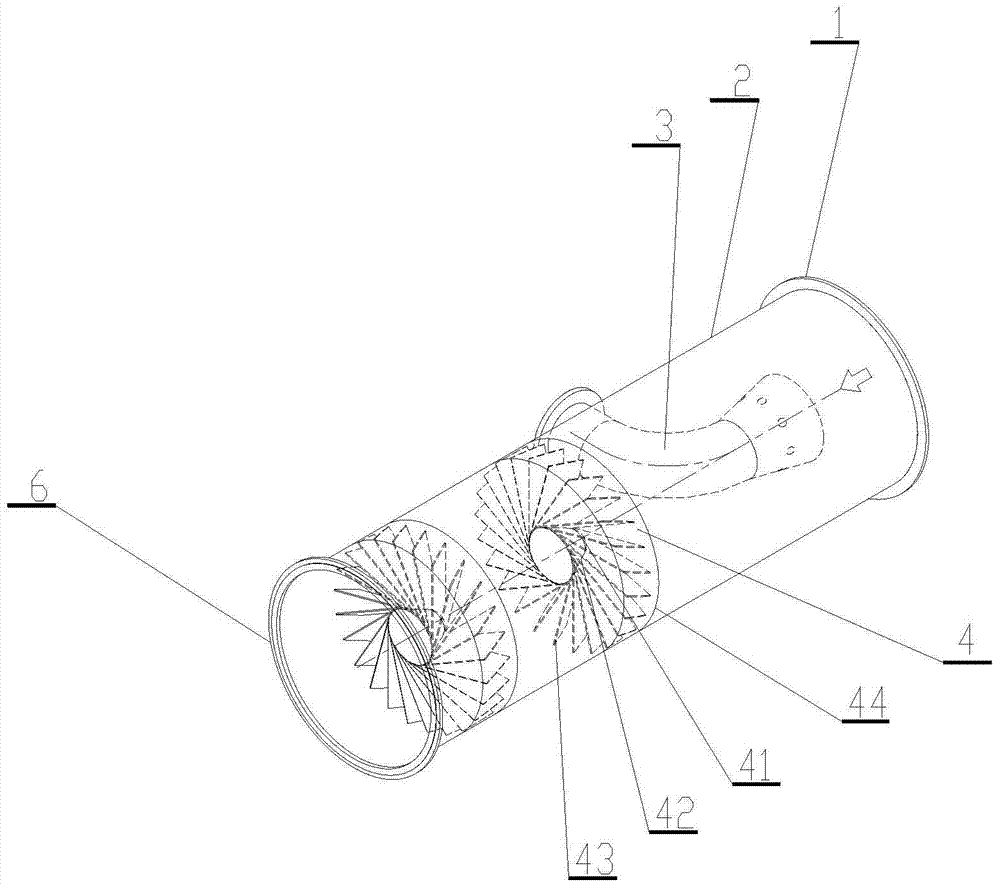

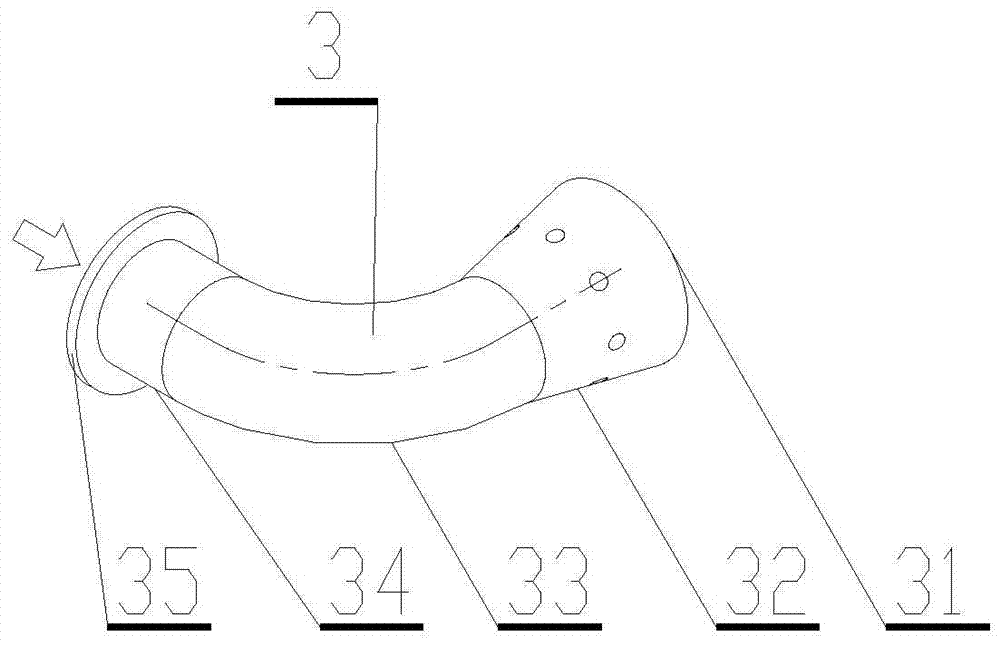

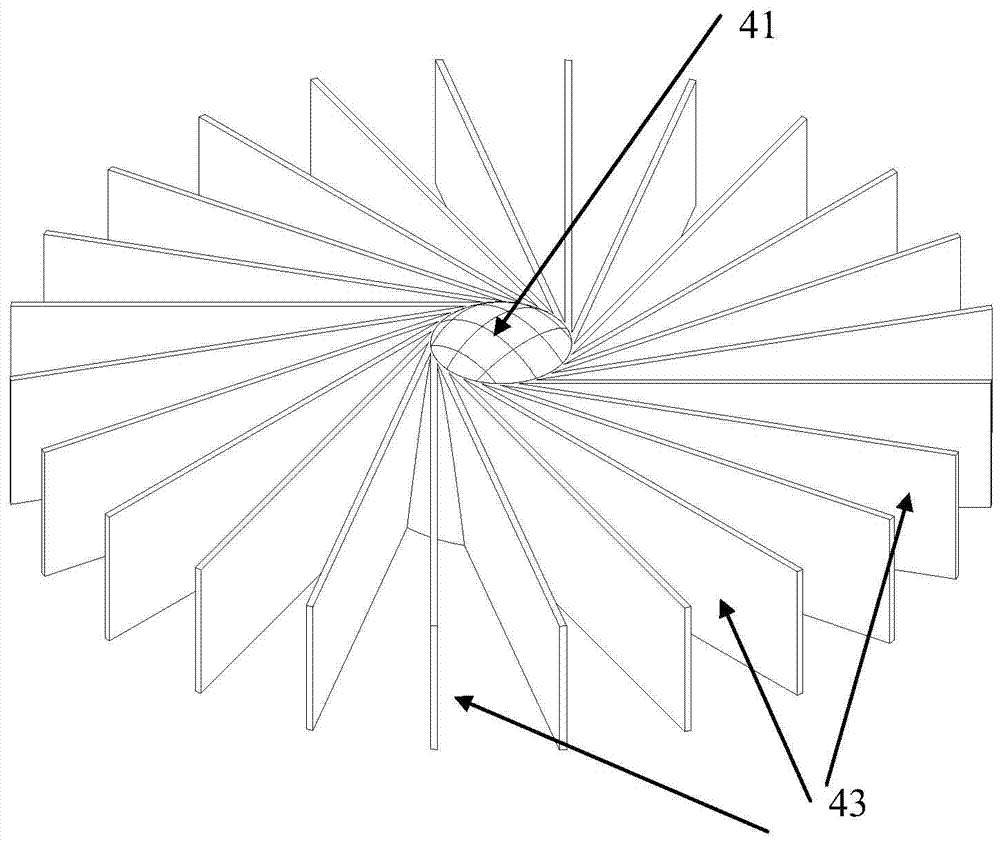

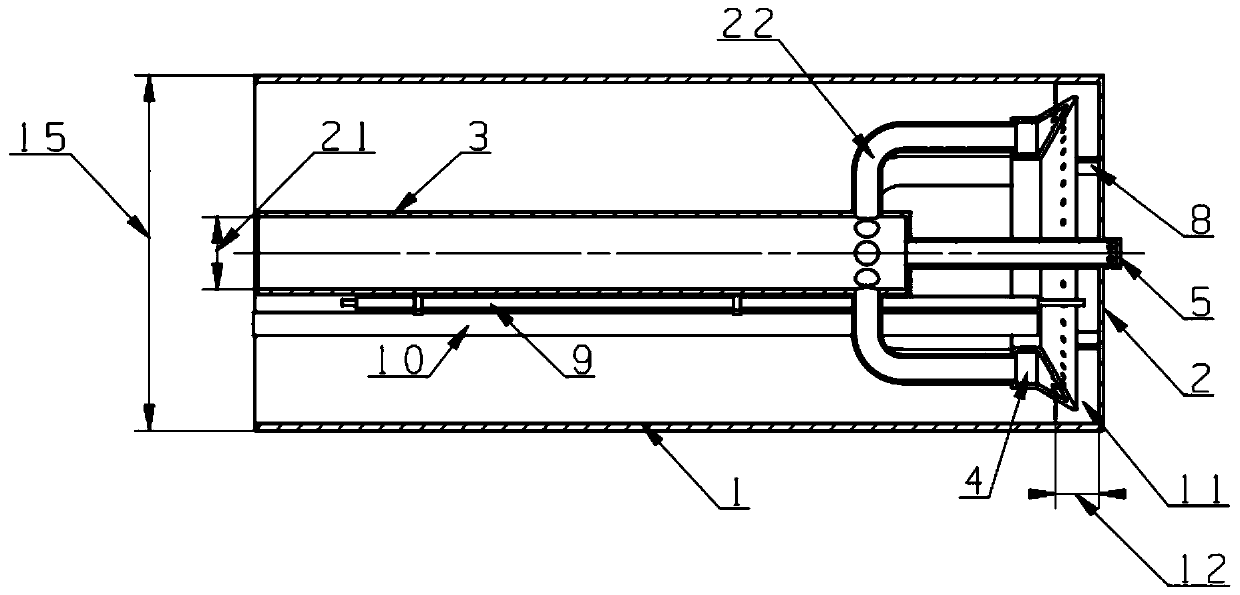

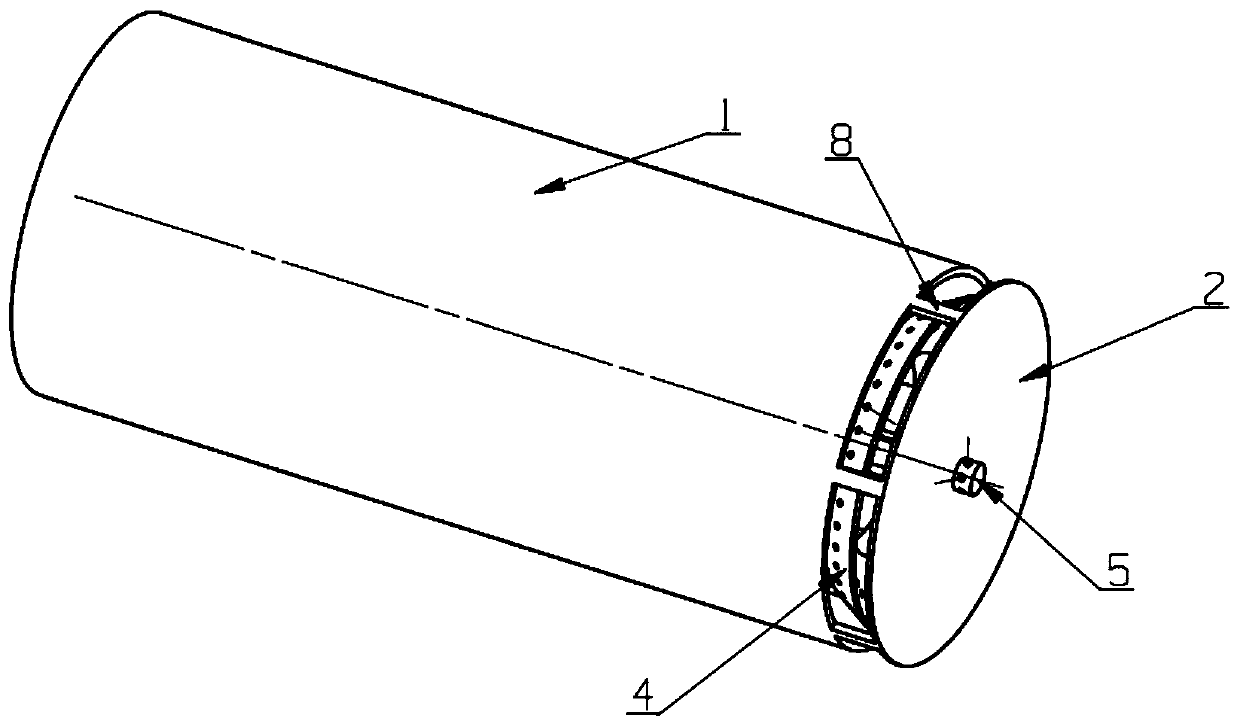

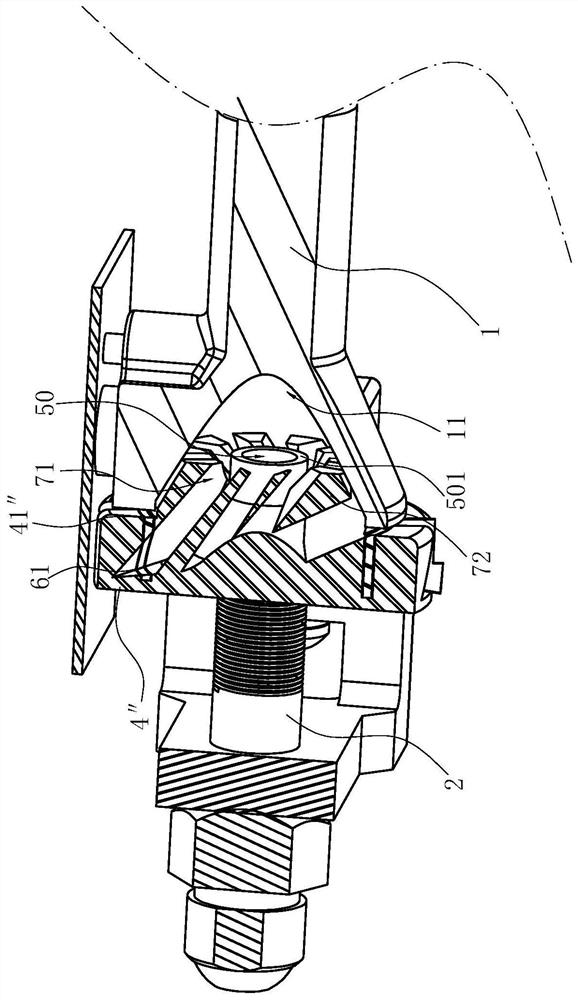

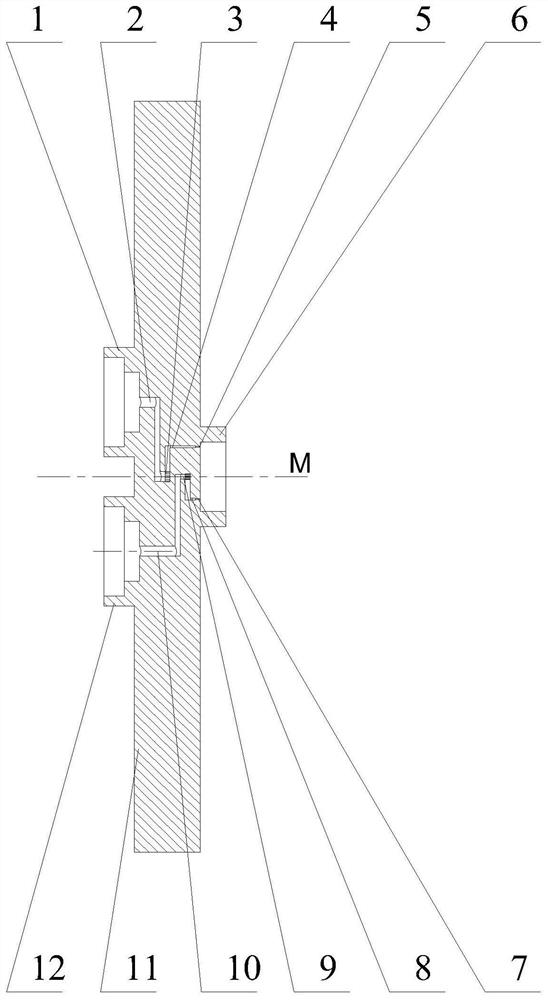

The invention discloses a fuel and air mixing device for a low-pollution burning chamber of a gas turbine. Fuel comprises a main burning level and a duty burning level; and air is supplied by a three-stage cyclone. The fuel and air mixing device is characterized in that the central duty level adopts diffusive burning, and the peripheral main burning level adopts premixing or semi-premixing burning. The central duty level consists of a centrifugal atomizing nozzle and first-stage cyclone air; and the rotating directions of the first-stage cyclone air and second-stage cyclone air are opposite. The fuel of the main burning level is supplied by a multipoint direct-injection type nozzle, the air is respectively supplied by the second-stage cyclone air and third-stage cyclone air, and the rotating directions of the second-stage cyclone air and third-stage cyclone air are opposite. The central duty level is used when in low working conditions such as starting and slowing and the like, so that the stable burning range can be widened, the burning efficiency can be improved and the emission of CO and UHC is reduced; and when in large working conditions, the duty level and the main burning level work simultaneously, the duty level provides a stable ignition source for the main burning level, a main burning area is in a lean-oil state, and the temperature is far lower than the temperatureof insulated flame, so that the emission of NOx under the large working conditions can be obviously reduced. The fuel and air mixing device can be used for an aerial gas turbine engine or an industrial gas turbine.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

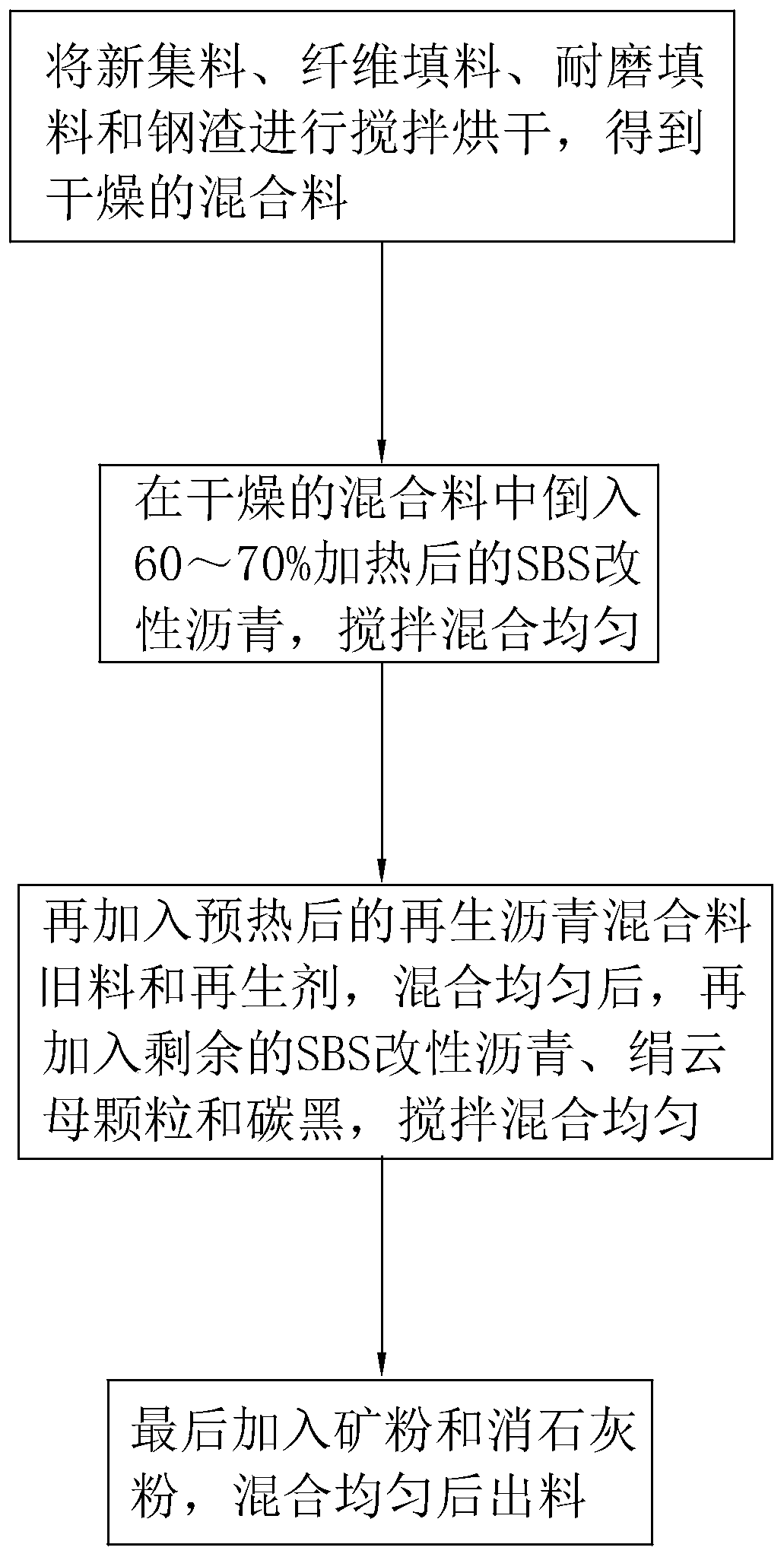

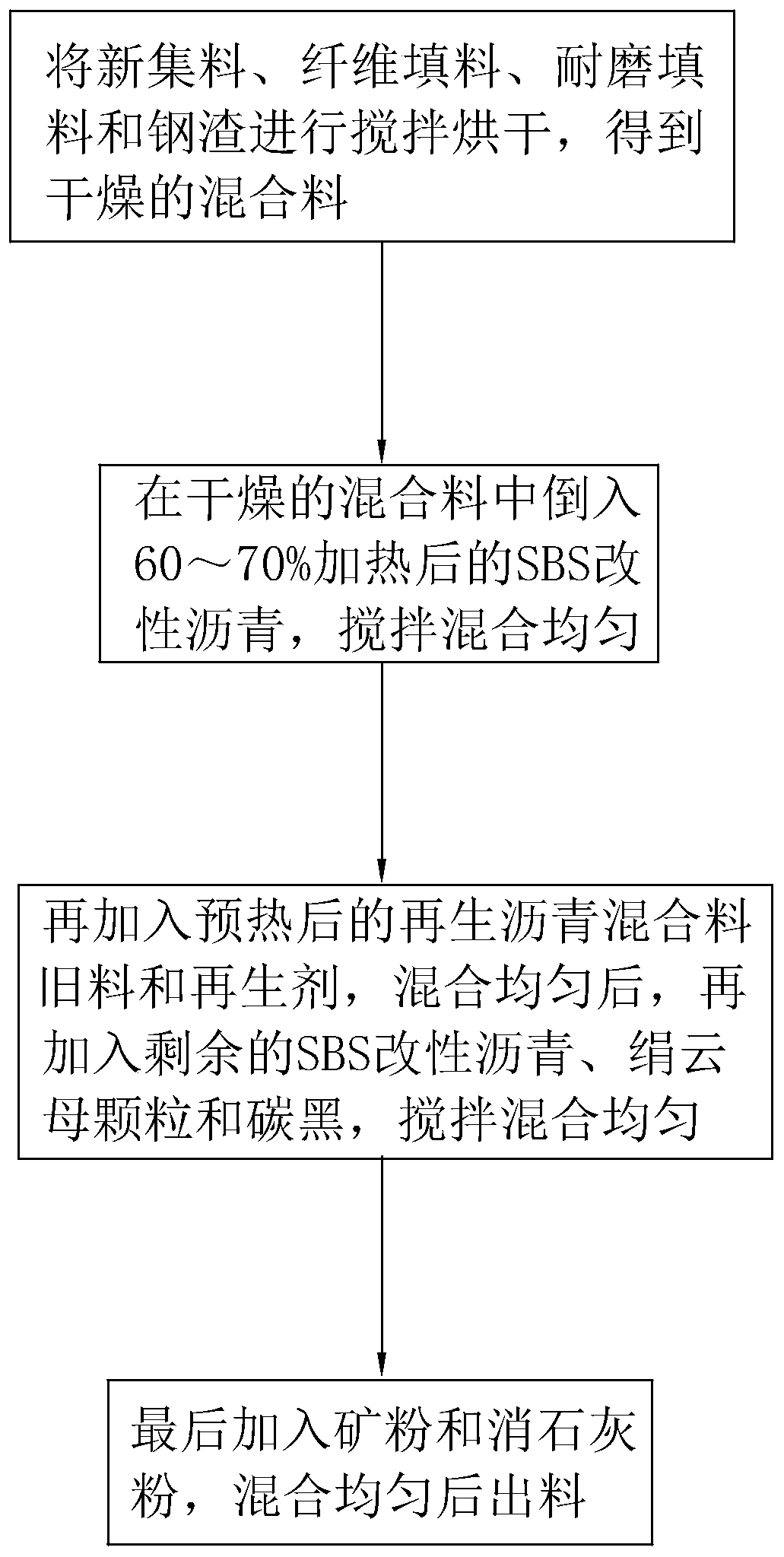

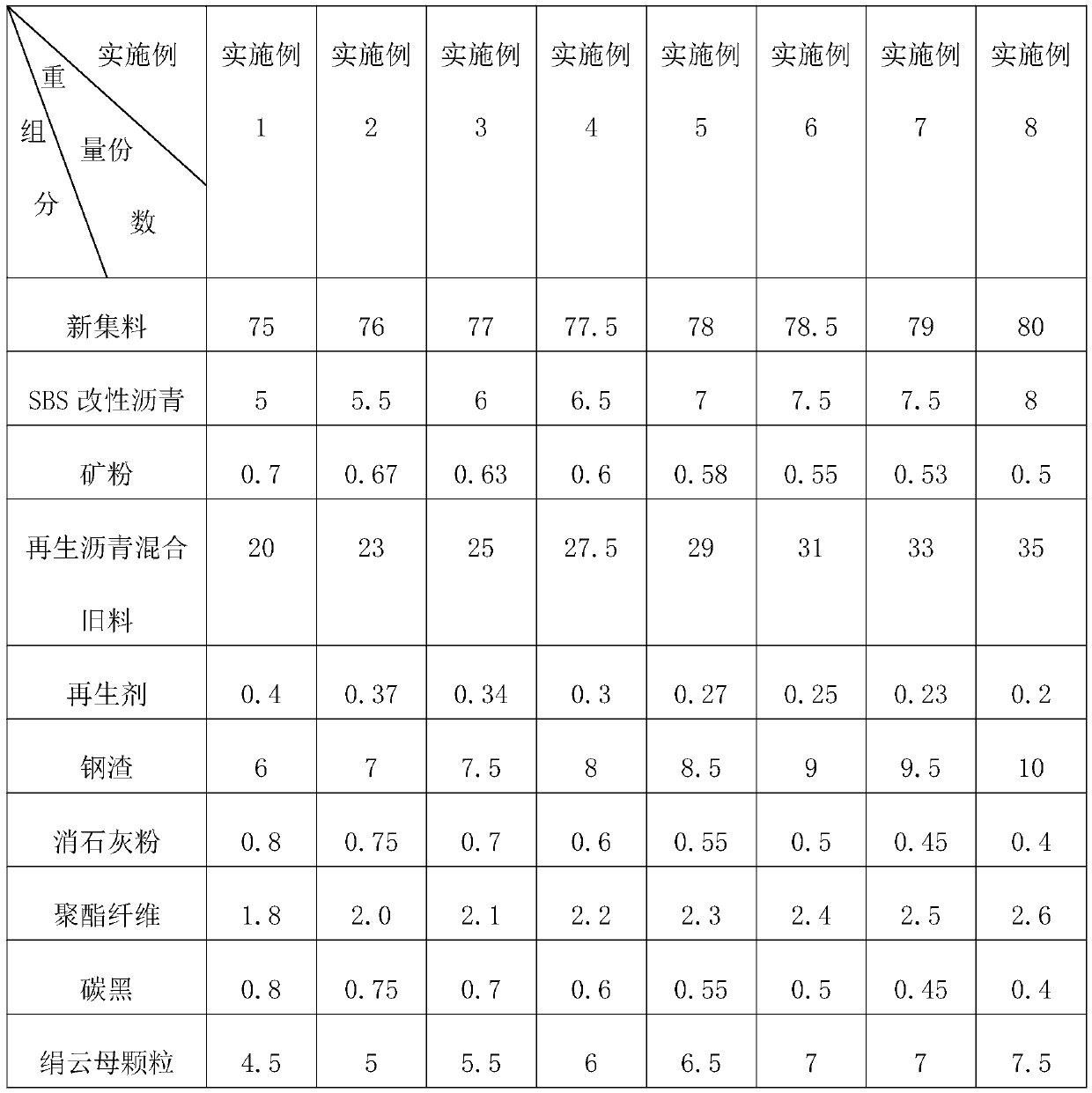

Abrasion-resistant recycled asphalt concrete and preparation process thereof

The invention discloses an abrasion-resistant recycled asphalt concrete and a preparation process thereof, relates to the technical field of asphalt concrete processing, and solves the problem that asphalt concrete pavement is prone to ageing due to frequent temperature changes and is prone to large abrasion during use. The abrasion-resistant recycled asphalt concrete comprises the following components in parts by weight: 75 to 80 parts of new aggregate, 5 to 8 parts of SBS modified asphalt, 0.5 to 0.7 part of mineral powder, 20 to 35 parts of a recycled asphalt mix old material, 0.2 to 0.4 part of a regenerating agent, 6 to 10 parts of steel slag, 0.4 to 0.8 part of hydrated lime powder, 1.8 to 2.6 parts of fiber filler, 0.5 to 1.5 part of abrasion-resistant filler, 0.4 to 0.8 part of carbon black, 4.5 to 7.5 parts of sericite particles. The abrasion-resistant recycled asphalt concrete in the invention has good stability in the use process, is not easy to age due to intermittent friction heat generated between the abrasion-resistant recycled asphalt concrete and a wheel, and is not easy to greatly wear.

Owner:上海宝新特种沥青混凝土有限公司

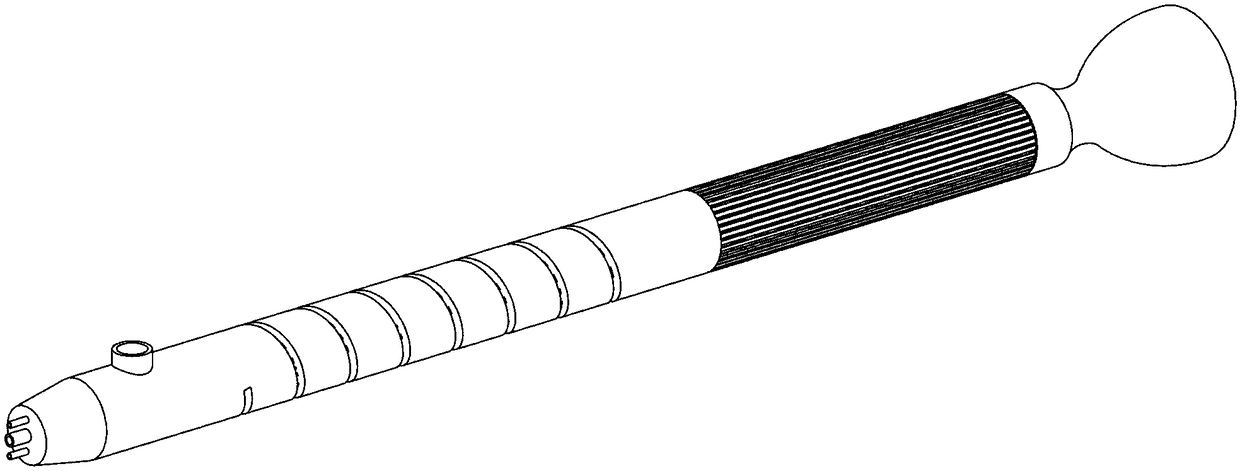

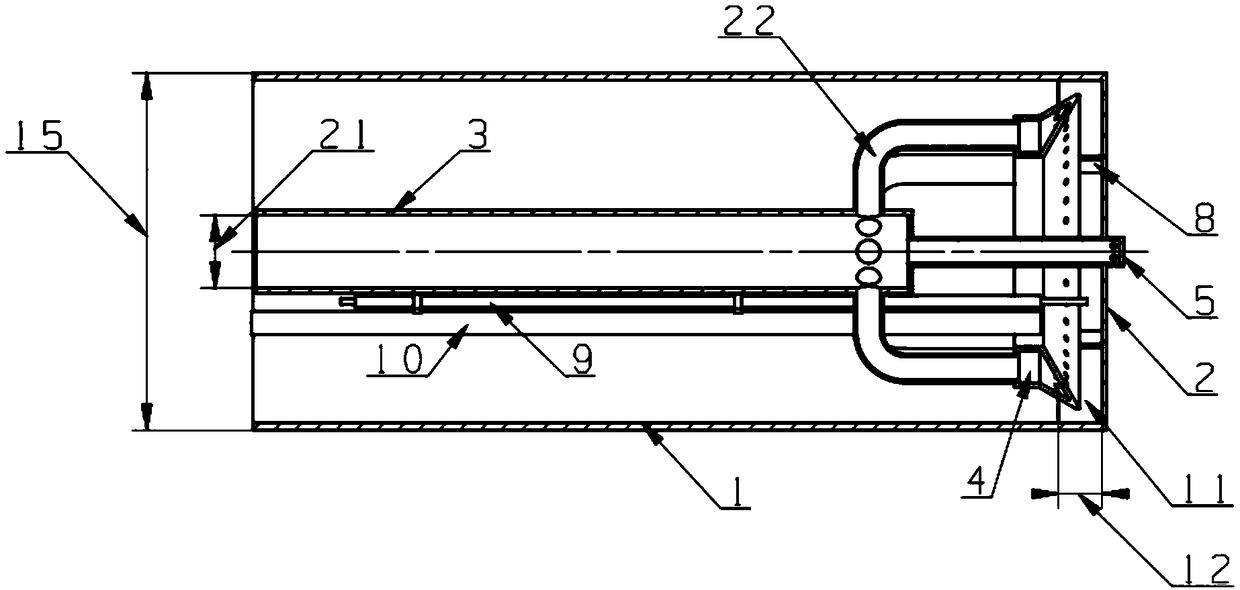

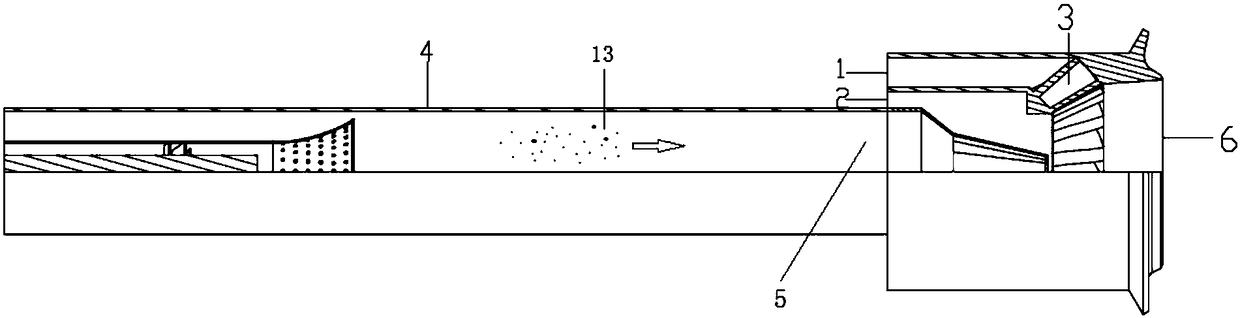

Pulse detonation pushing device based on regenerative cooling structure

InactiveCN109209678ABlending fastLow critical ignition energyIntermittent jet plantsRocket engine plantsRegenerative coolingFuel oil

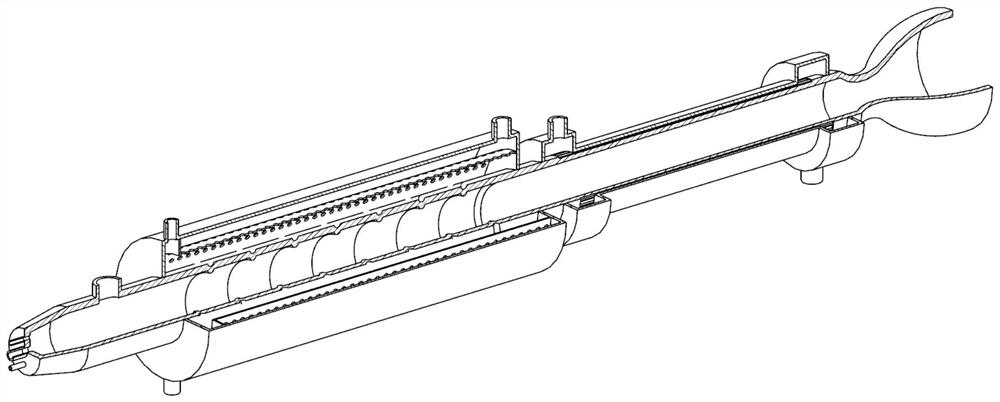

The invention provides a pulse detonation pushing device based on a regenerative cooling structure. Based on the regenerative cooling structure, a convection / impact composite type heat exchange methodis adopted, liquid fuel oil is heated, catalyzed and cracked through heat radiation of detonation combustion, micromolecule gas fuel excellent in detonation performance is generated, the time and distance of deflagration to detonation transition (DDT) of a pulse detonation engine can be effectively shortened, and meanwhile efficient cooling of the wall face of a detonation pipe can be achieved. The catalytic and cracking fuel oil pretreatment method is adopted, the detonation performance of fuel is effectively improved, and meanwhile the pushing performance and safety of the engine are improved. The regenerative cooling structure provides a heat source for a catalytic and cracking reaction, and meanwhile airborne fuel oil is adopted as cooling media to cool the wall face of the detonationpipe. Temperature distribution of the wall face of the detonation pipe is considered, the convection / impact composite type cooling manner is adopted on the DDT segment of the detonation pipe, and a microchannel inner convection heat exchange manner is adopted in the detonation spread segment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

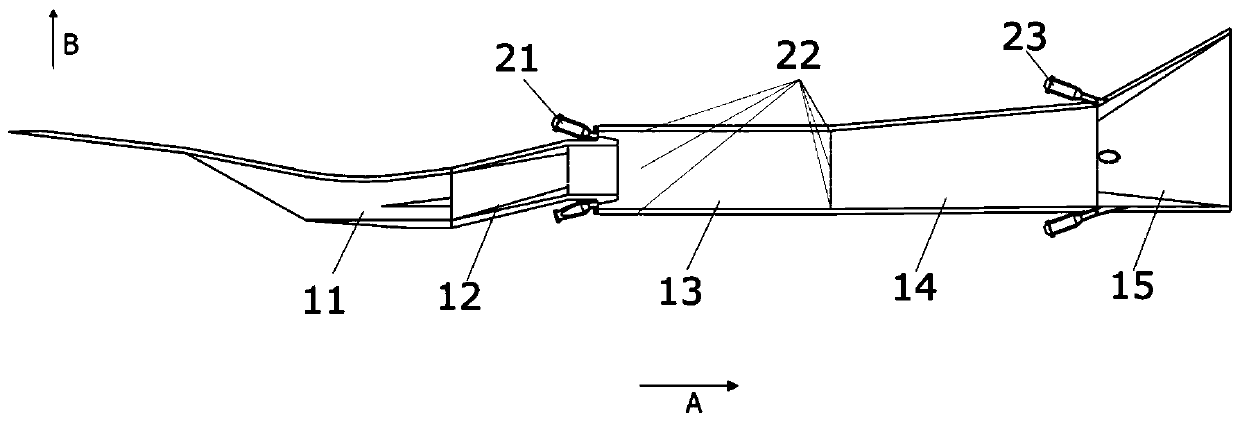

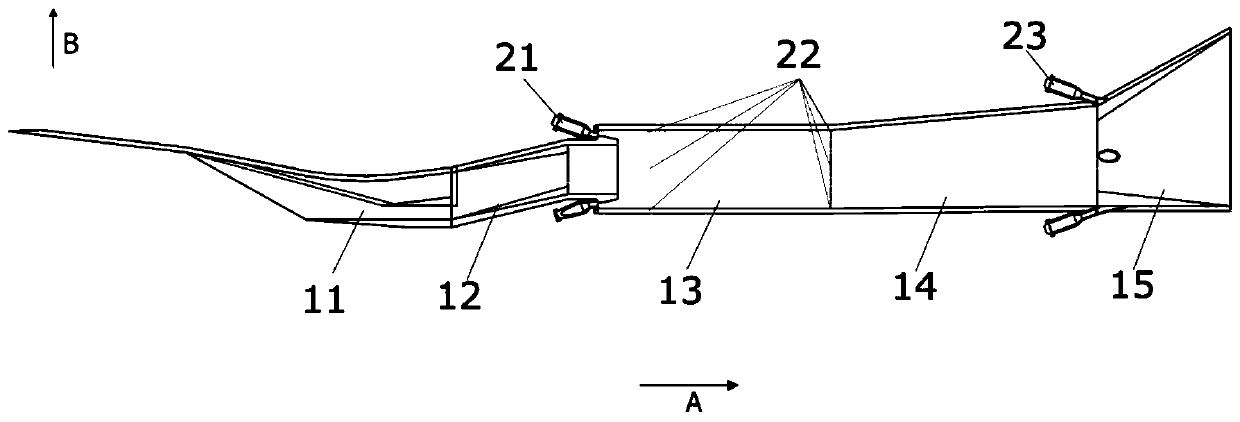

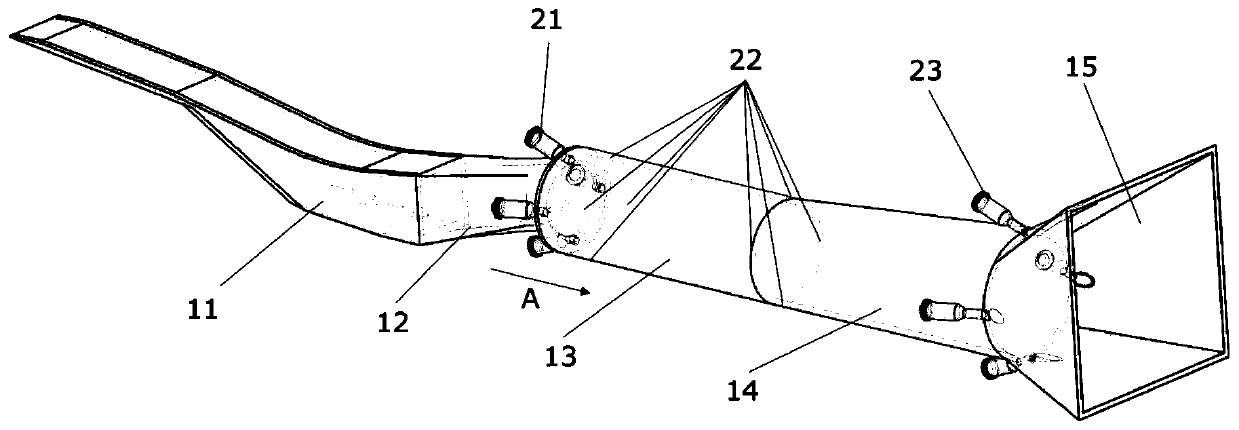

Small-scale two-stage rocket combination ramjet

PendingCN111594344AImprove match stabilityQuick blendContinuous combustion chamberGas turbine plantsRamjetCombustion chamber

The invention provides a small-scale two-stage rocket combination ramjet. The small-scale two-stage rocket combination ramjet comprises an air inlet channel, an isolation section, a first-stage combustion chamber, a second-stage combustion chamber, a tail spraying pipe, a first rocket unit, a fuel injection hole and a second rocket unit. The air inlet channel, the isolation section, the first-stage combustion chamber, the second-stage combustion chamber and the tail spraying pipe are sequentially connected. Airflow flows in through the air inlet channel, passes through the isolation section, the first-stage combustion chamber and the second-stage combustion chamber and then is exhausted outwards through the tail spraying pipe. The air inlet channel provides needed capture air for an RBCC engine through profile changes under different flight Mach numbers and work modes. The isolation section is used for stably isolating the air inlet channel from the first-stage combustion chamber and used for containing pre-combustion shock train formed under the pressure action of the combustion chambers, the situation that the airflow fluctuates greatly at the air inlet section, and consequentlythe combustion efficiency is influenced is avoided, and the matching stability of the air inlet channel and the rocket unit is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

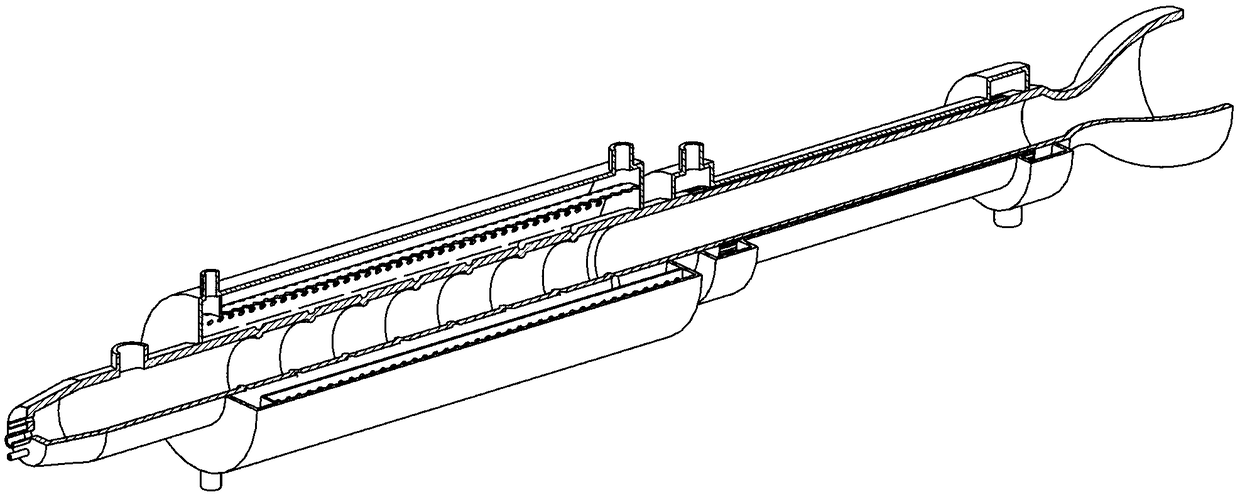

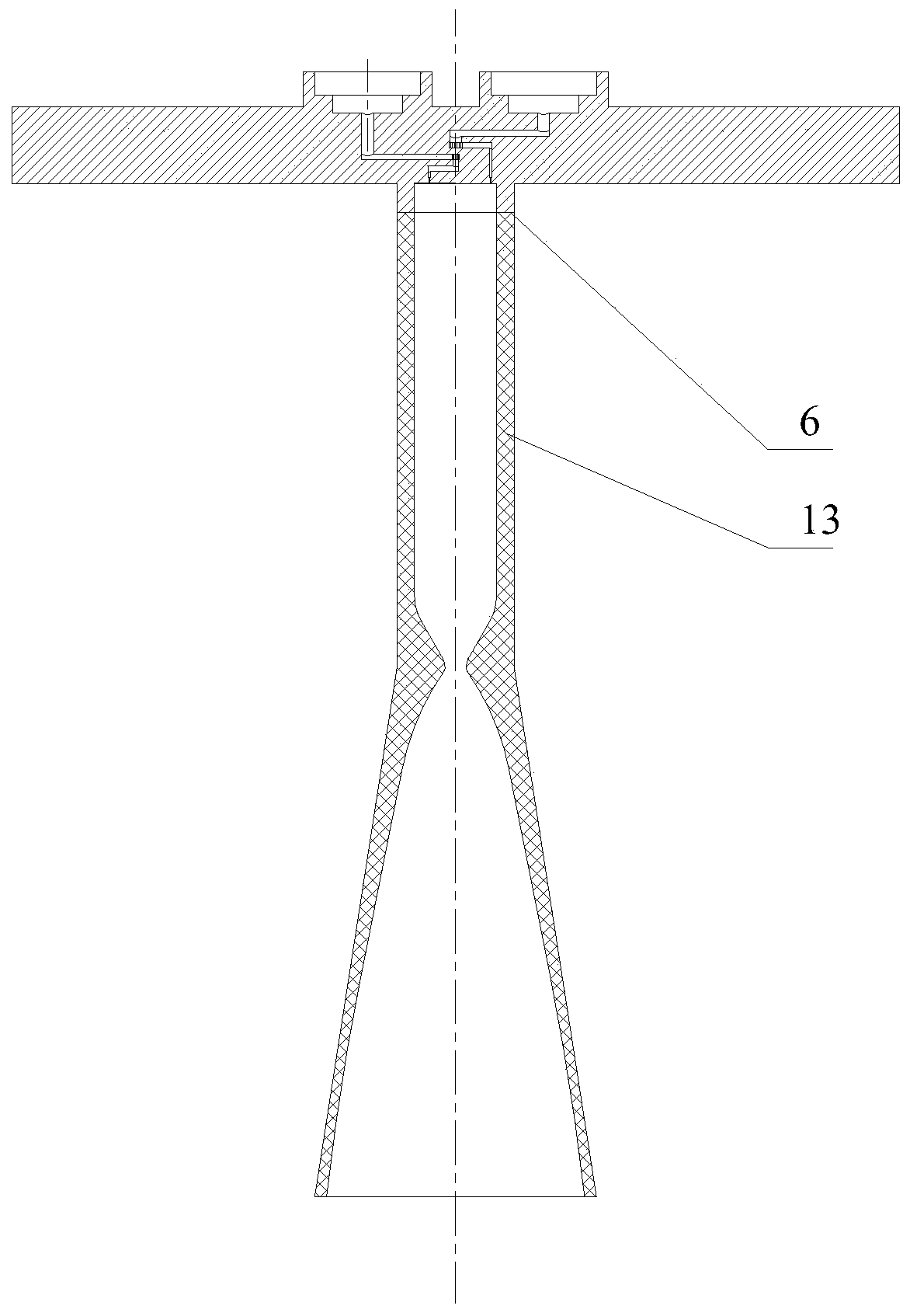

Pyrolysis fuel gas and air rapid mixing device

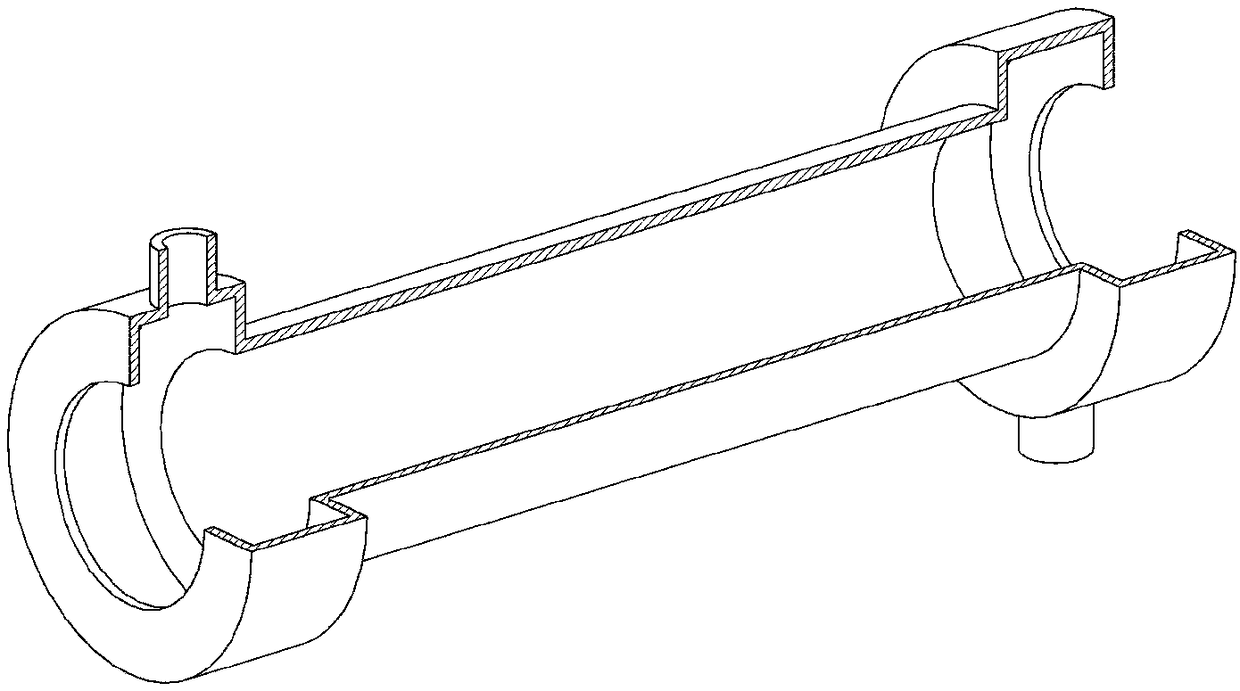

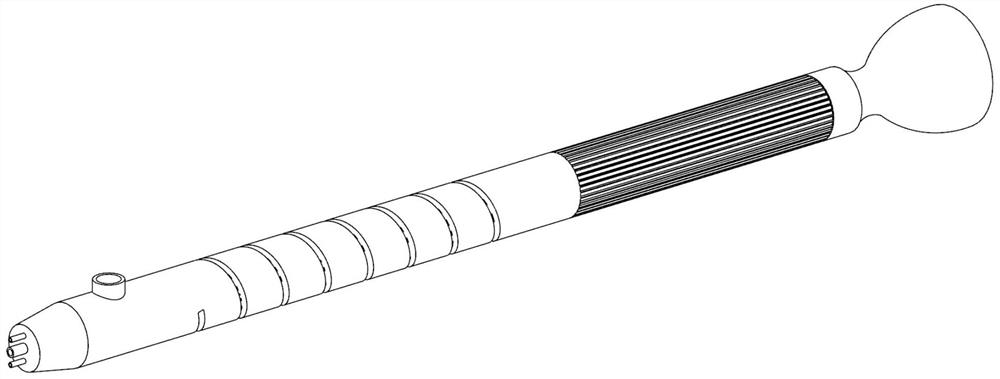

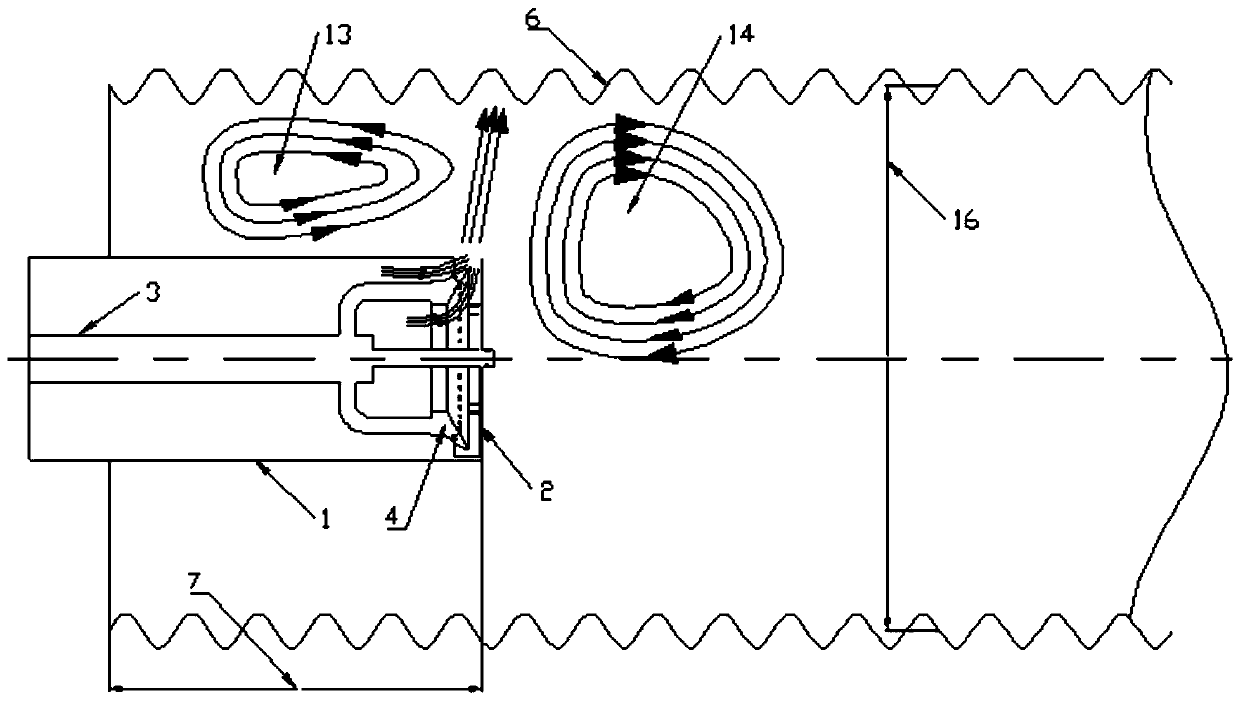

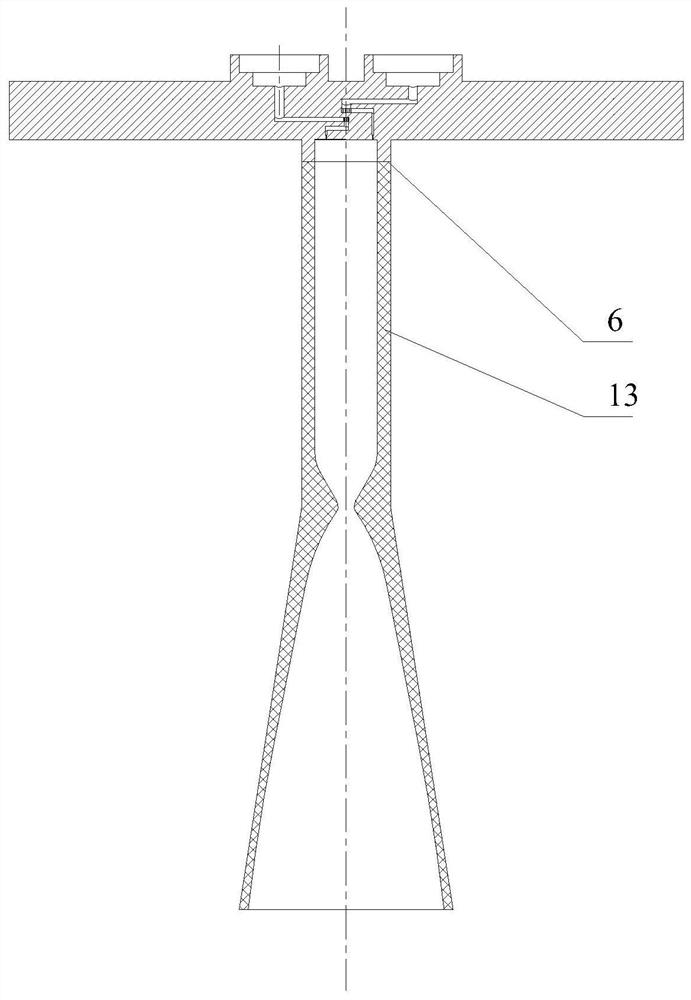

The invention aims at providing a pyrolysis fuel gas and air rapid mixing device. The pyrolysis fuel gas and air rapid mixing device comprises an outer shell, an inner shell and a lobe mixer, wherein the inner shell is arranged in the outer shell; a hydrocyclone air inlet passage is formed between the inner shell and the outer shell; the lobe mixer comprises a lobe mixing structure inner passage wall, lobe convex structures and lobe concave structures; the lobe convex structures and the lobe concave structures are arranged alternately to form an annular structure; the lobe mixing structure inner passage wall is connected with the annular structure; a lobe mixing structure inner passage pyrolysis fuel gas inlet communicating with a rich oil pyrolysis combustion chamber is formed in the lobe mixing structure inner passage wall; the lobe mixer is arranged in the inner shell, and a lobe mixing air passage is formed between the lobe mixing structure inner passage wall and the inner shell; an inclined radial runner provided with cyclone blades is installed at an outlet of the lobe mixer; and a pyrolysis fuel gas and air mixing gas outlet is arranged at an outlet of the inclined radial runner. The pyrolysis fuel gas and air rapid mixing device can complete rapid mixing of pyrolysis fuel gas and air, and lowers generation of lean burning area NOx.

Owner:HARBIN ENG UNIV

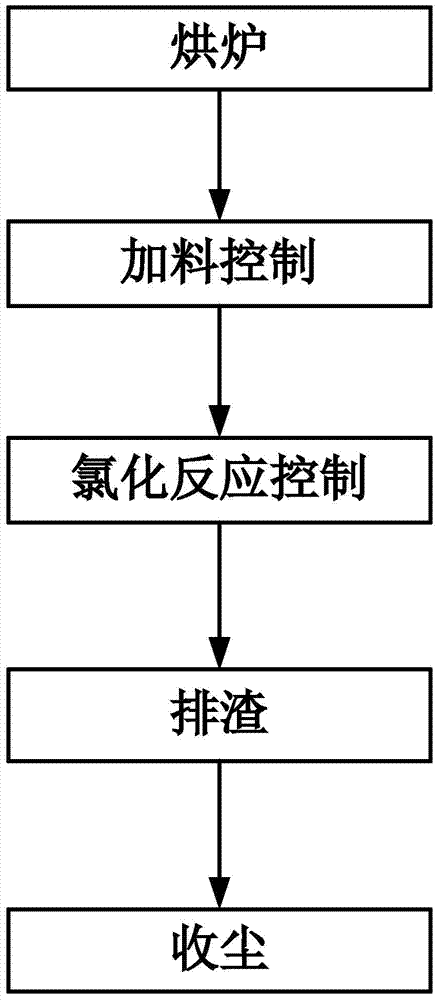

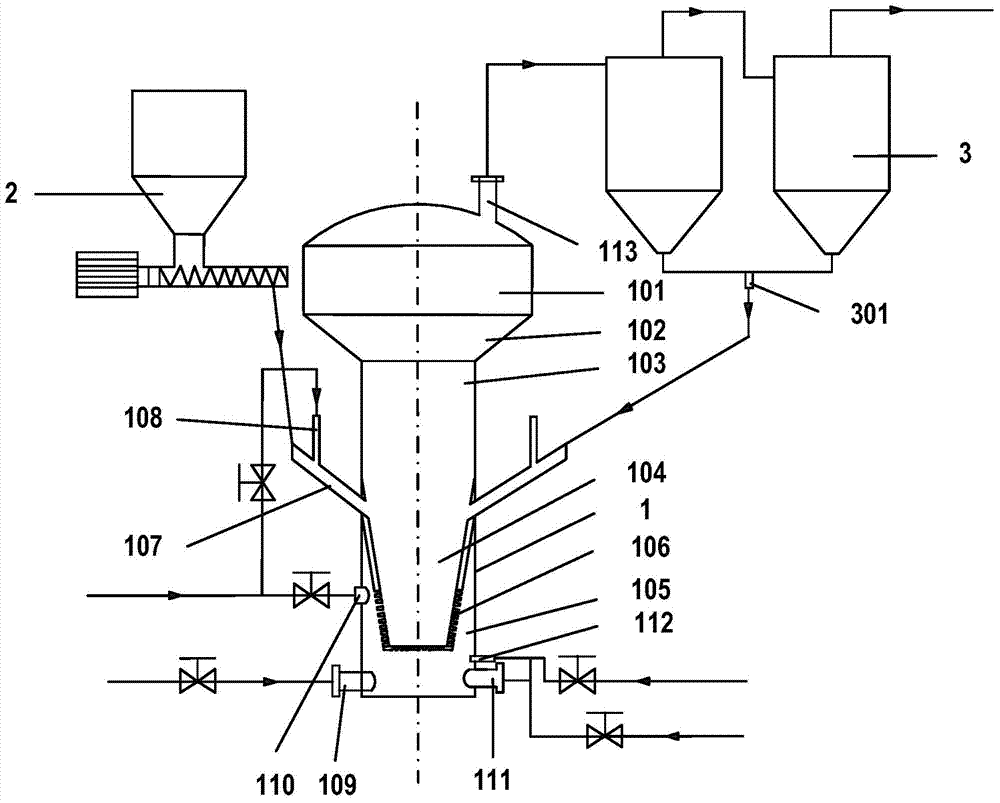

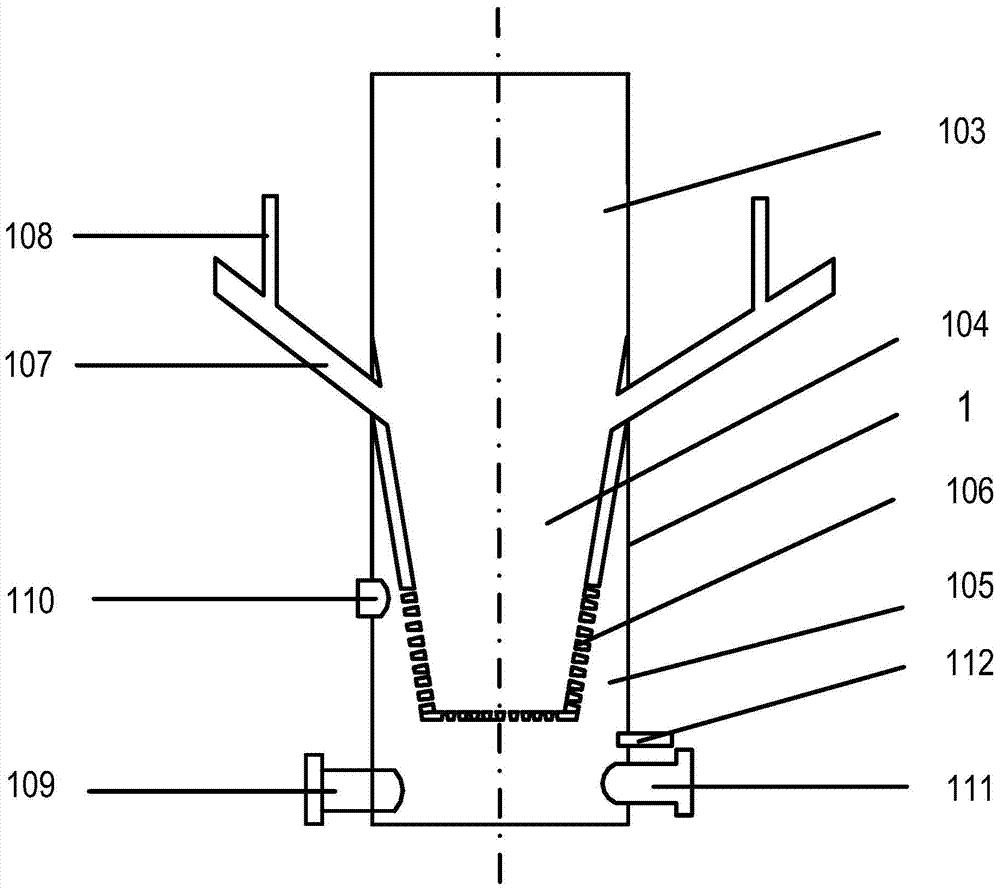

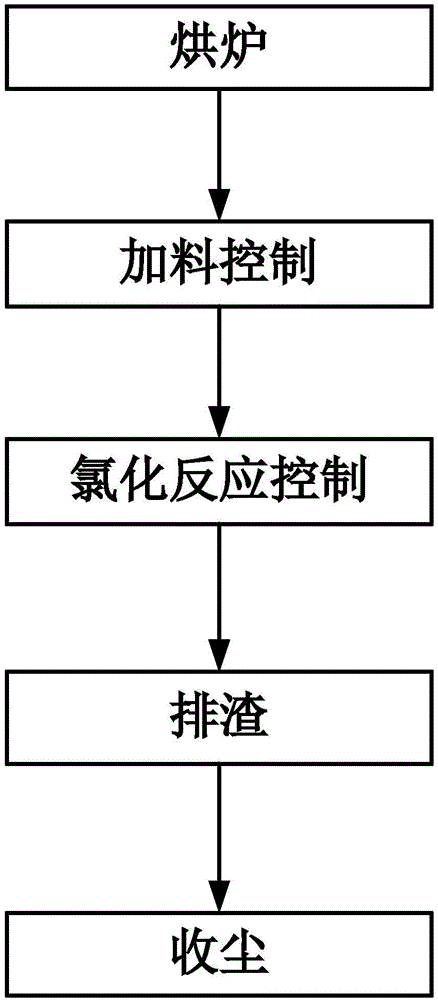

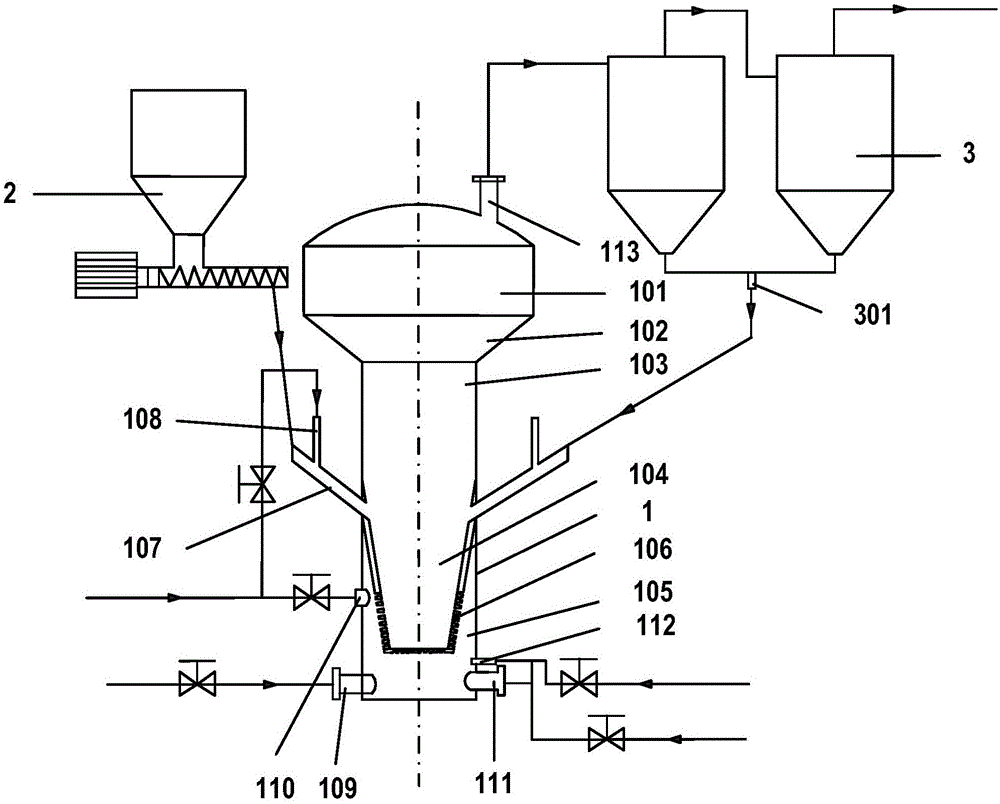

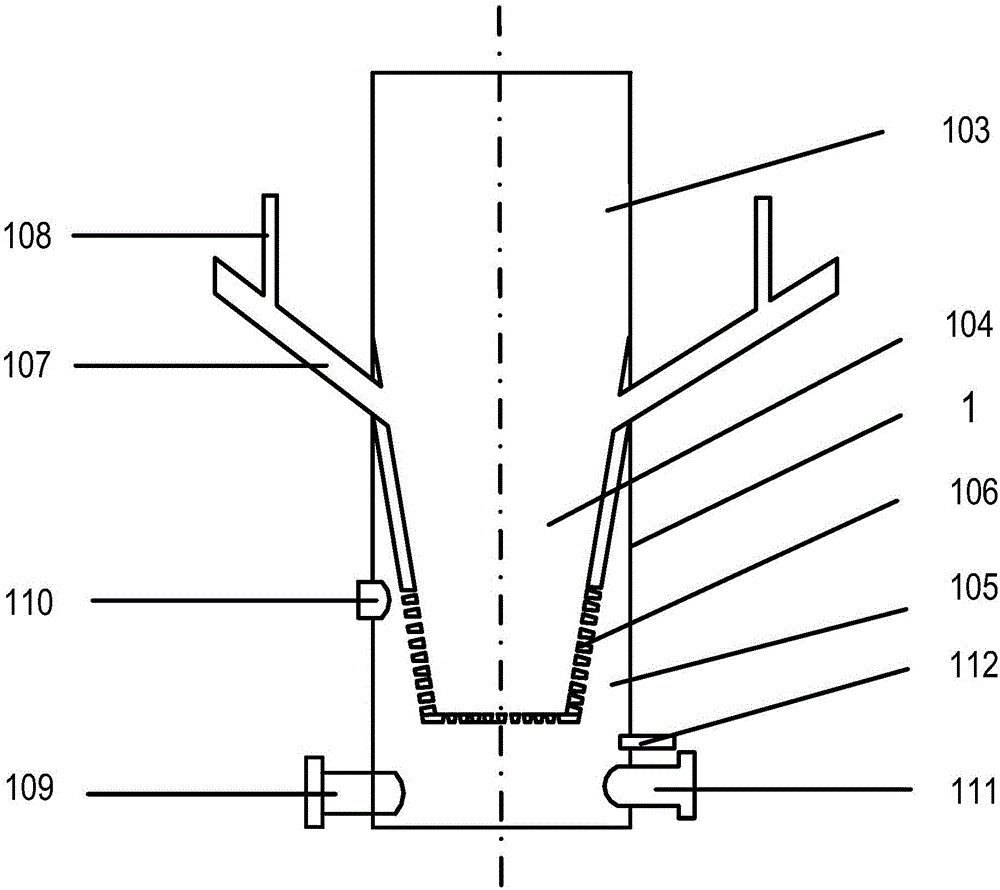

Process for producing titanium tetrachloride in fluidizing chlorination furnace by using artificial rutile

The invention discloses a process for producing titanium tetrachloride in fluidizing chlorination furnace by using artificial rutile. The process includes five steps of: furnace baking, control of feeding, control of chlorination, tail gas slagging and cyclone dust collection. According to the process, the preparation of titanium tetrachloride by using the fine-sized artificial rutile is achieved, and meanwhile the collection and recycle of the artificial rutile in dust slag which is not completely reacted are also achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

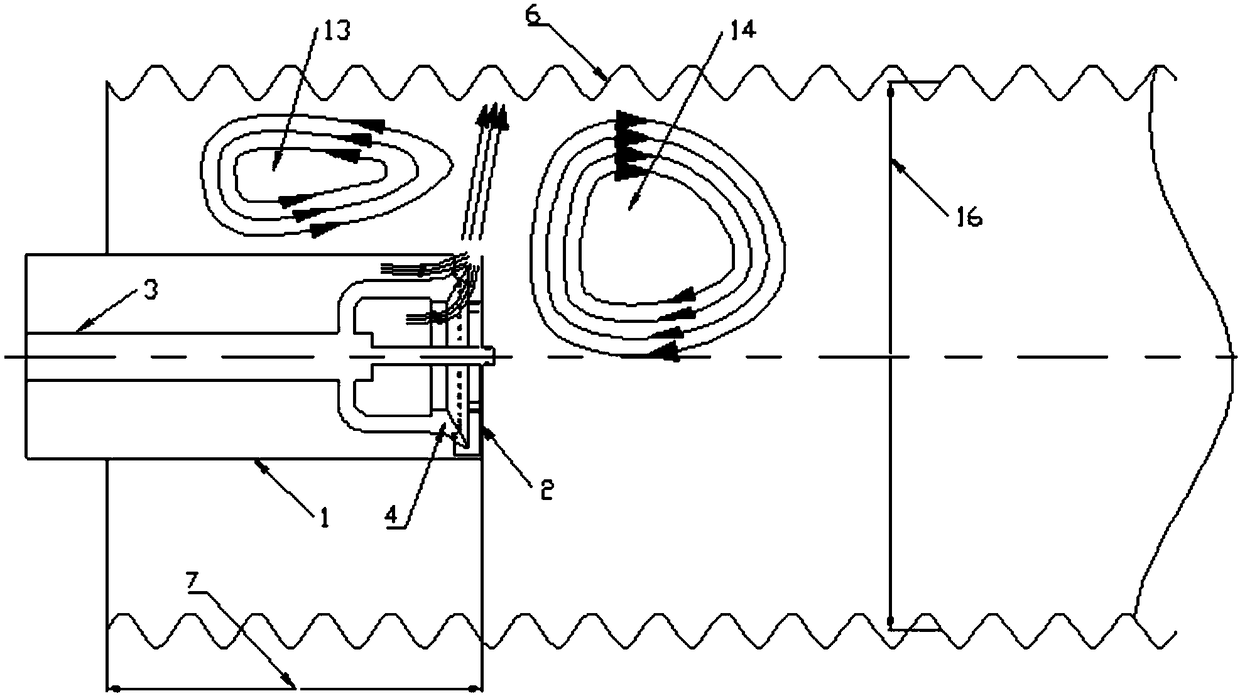

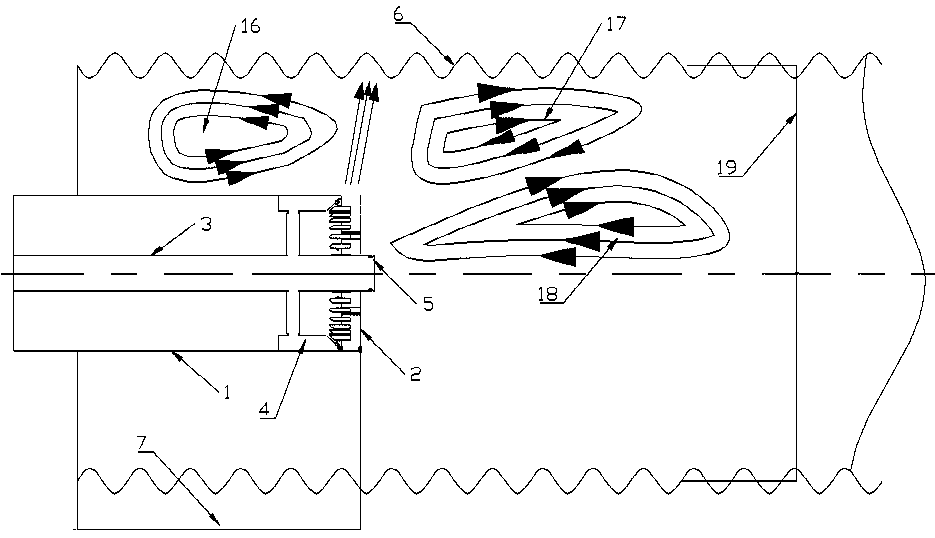

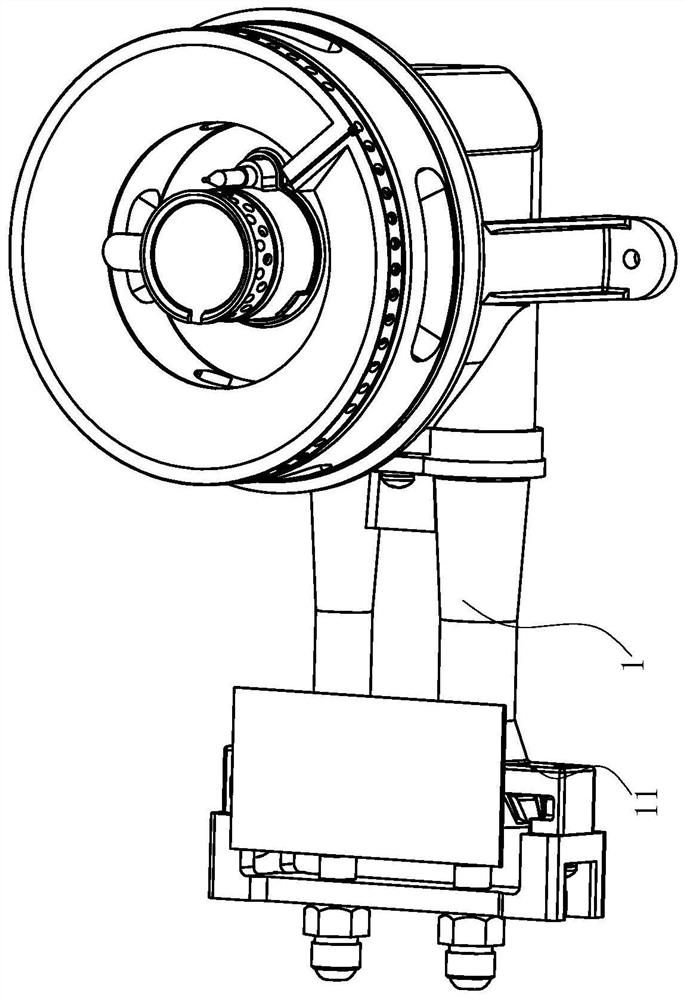

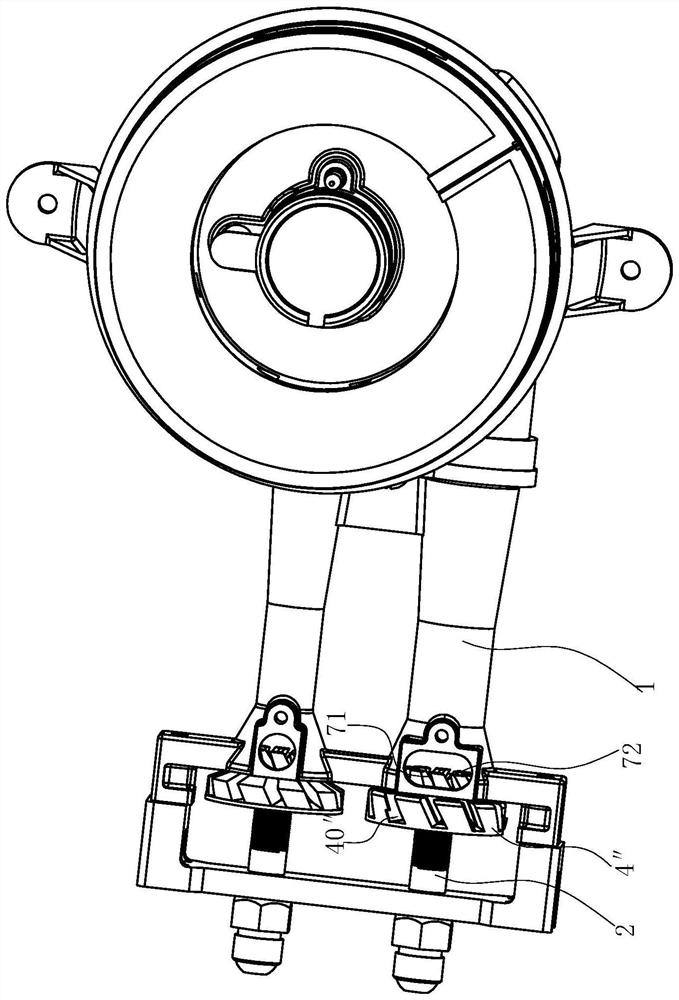

Multi-point direct injecting and opposite shearing and fast-mixing radial injection low-nitrogen combustor

ActiveCN109442398AQuick blendEven distribution of equivalence ratioGaseous fuel burnerLow nitrogenEngineering

The invention discloses a multi-point direct injecting and opposite shearing and fast-mixing radial injection low-nitrogen combustor. The combustor is composed of a combustor gas circuit main pipe, acombustor head baffle, a central fuel supply pipe, a main path fuel injection device and an ignition path system; a seam groove with a radial opening is formed between the tail end of the combustor gas path main pipe and the combustor head baffle, gas is accelerated out through the radial seam groove after passing by the two sides of the main path fuel injection device, gaseous fuel is transversely sprayed into the accelerated gas flow through small holes in the two sides of the fuel injection device, the gas flow at the two sides of the fuel injection device is subjected to intersection shearing, the mixing of the gas and the fuel is accelerated, and the mixed gas is injected into a hearth through the radial groove; one stream of the mixed gas flow is deflected to the downstream after being collided with the hearth, so that a mainstream vortex is formed, the other stream of the mixed gas flow is deflected to the upstream, and an upstream vortex is formed; and the fuel is direct injected in a multi-point mode, the equivalent ratio is uniformly distributed, the flame impacts the wall surface of the hearth, heat exchange is accelerated, the internal circulation of the flue gas is formed due to the presence of the upstream vortex, and the comprehensive characteristics achieve the effect of reducing the emission of nitrogen oxide of the combustor.

Owner:BEIHANG UNIV

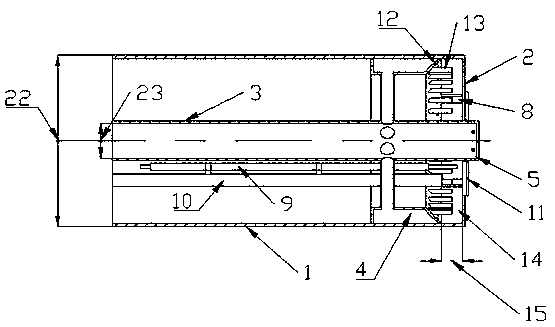

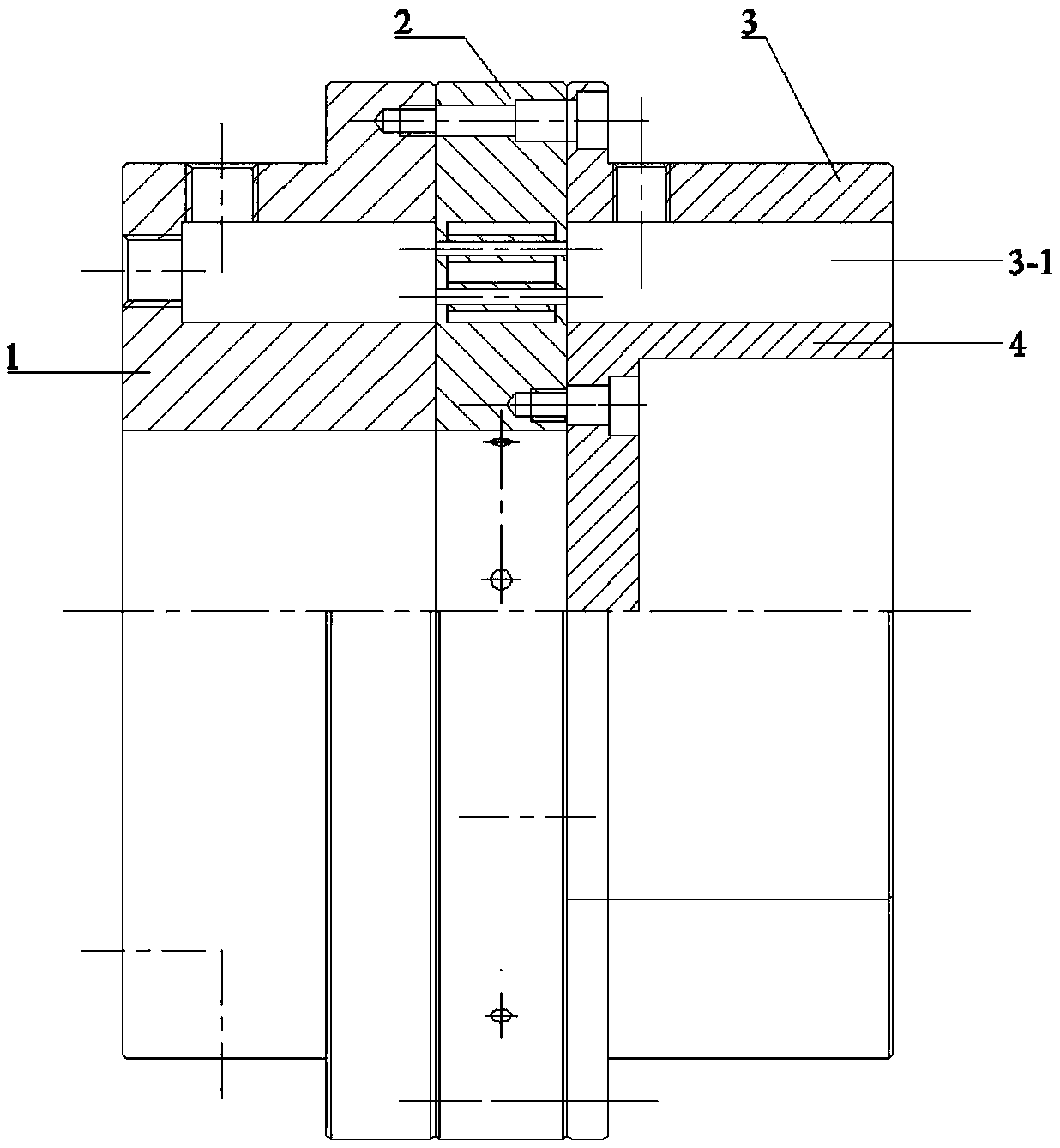

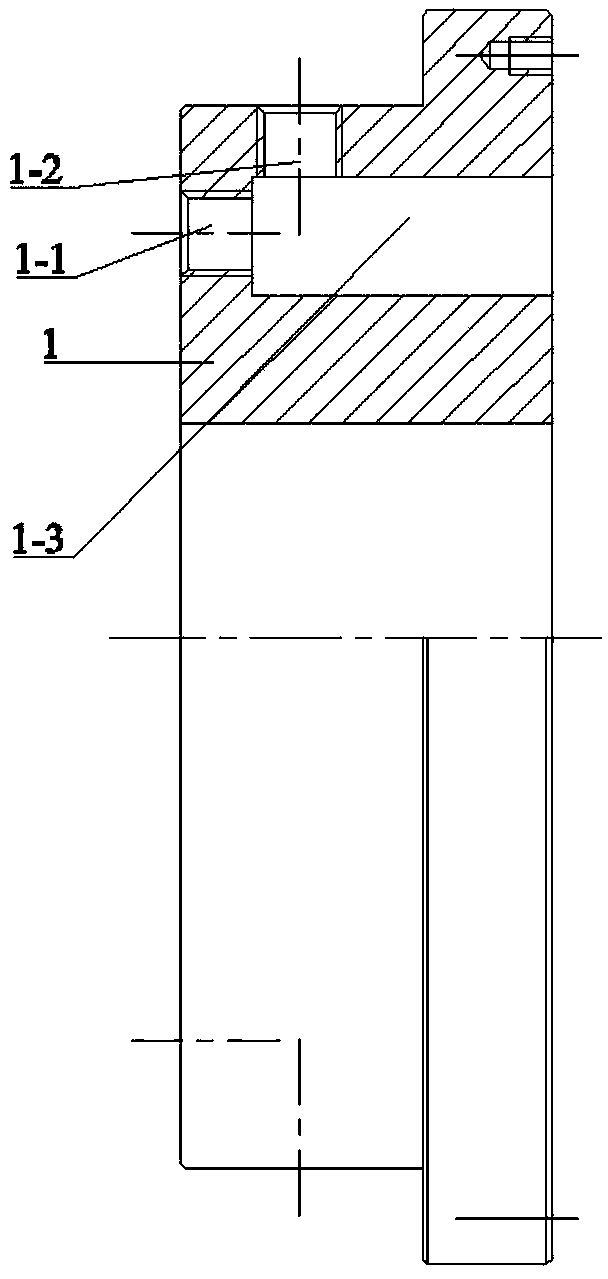

Pulse type micro-jet gas nozzle control device

InactiveCN104613470AImprove combustion efficiencyQuick blendGaseous fuel burnerSpray nozzleEngineering

The invention provides a pulse type micro-jet gas nozzle control device. The pulse type micro-jet gas nozzle control device comprises a gas nozzle and a combustion-supporting gas pulse jetting mechanism. A gas jetting through hole is formed in the gas nozzle, and the combustion-supporting gas pulse jetting mechanism is provided with a combustion-supporting gas jetting hole and a central mixing chamber. The gas jetting through hole and the combustion-supporting gas jetting hole are communicated with the central mixing chamber, the axis of the gas jetting through hole does not coincide with the axis of the combustion-supporting gas jetting hole, and the combustion-supporting gas pulse jetting mechanism comprises an opening and closing control device for controlling opening and closing of the combustion-supporting gas jetting hole. The pulse type micro-jet gas nozzle control device has the advantages that the jetting directions of gas and combustion-supporting gas do not coincide, in this way, the gas and the combustion-supporting gas are easily and rapidly mixed in the central mixing chamber, the flow of the gas can be controlled through the gas jetting through hole, the flow of the combustion-supporting gas is controlled through the combustion-supporting gas jetting hole, pulse jetting of the combustion-supporting gas is achieved through the opening and closing control device so that the intensity and stability of flames can be controlled, and the maximum combustion efficiency of the gas is achieved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Multi-element biological organic synergistic fertilizer and manufacturing method thereof

InactiveCN107973652AReasonable compositionNutrient balanceBio-organic fraction processingBacteriaMicrobial agentPhosphate

The invention discloses a multi-element biological organic synergistic fertilizer and a manufacturing method thereof. The multi-element biological organic synergistic fertilizer is prepared from the following raw materials in parts by weight: 150 parts of mushroom residues, 200 to 300 parts of tobacco residues, 40 to 60 parts of plant ash, 40 to 60 parts of wormcast, 2 to 4 parts of a compound microbial agent, 0.8 to 1.6 parts of a synergist, 80 to 120 parts of urea, 100 to 150 parts of monoammonium phosphate, 100 to 150 parts of potassium sulfate, 5 to 10 parts of a dispersing synergist and 4to 8 parts of a coating agent. The multi-element biological organic synergistic fertilizer disclosed by the invention is reasonable in components and balanced in nutrients, the utilization rate of the fertilizer is greatly improved through the synergistic effect of the components, the requirements of crops on the nutrients are sufficiently met, the fertilizer is economical, environmentally-friendly and good in fertilizer efficiency, the effect of the fertilizer is developed to the maximum extent, the yield can be improved, the quality can also be improved, and the fertilizer is an ideal biological green and environmentally fertilizer.

Owner:山东中新农业发展有限公司

Low-emission combustion chamber with main combustible stage head part multi-point slant oil taking

ActiveCN102175045BSmall sizeSimple structureContinuous combustion chamberCombustion chamberEvaporation

The invention relates to a low-emission combustion chamber with main combustible stage head part multi-point slant oil taking. A single-ring cavity structure is adopted; the combustion chamber is composed of a combustion chamber outer casing, a combustion chamber inner casing, a flame tube outer wall, a flame tube inner wall and a combustion chamber head part; all the air for combustion enters a flame tube from the combustion chamber head part, a classification combustion scheme is adopted, and is divided into a pre-combustion stage and a primary combustion stage; a diffusion combustion organization mode with stable rotational flow is adopted for the pre-combustion stage, and a premixing combustion organization mode with slant oil supplying is adopted for the main combustible stage; the stable working range of the combustion chamber is mainly controlled by the pre-combustion stage, the stable combustion in the combustion chamber within a wider working range can be ensured, and simultaneously a stable ignition source can be provided for the main combustion stage; and the pollution emission of the combustion chamber is mainly controlled by the main combustion stage, and the equivalent weight ratio of the premixing gas of the main combustion stage is controlled in a low-pollution combustion range, thus the great pollution emission reduction of the whole combustion chamber can be ensured. The premixing and pre-evaporation structure provided by the invention is simple, the favorable combustion stability of the combustion chamber is ensured, and simultaneously the pollution emission is reduced greatly.

Owner:BEIHANG UNIV

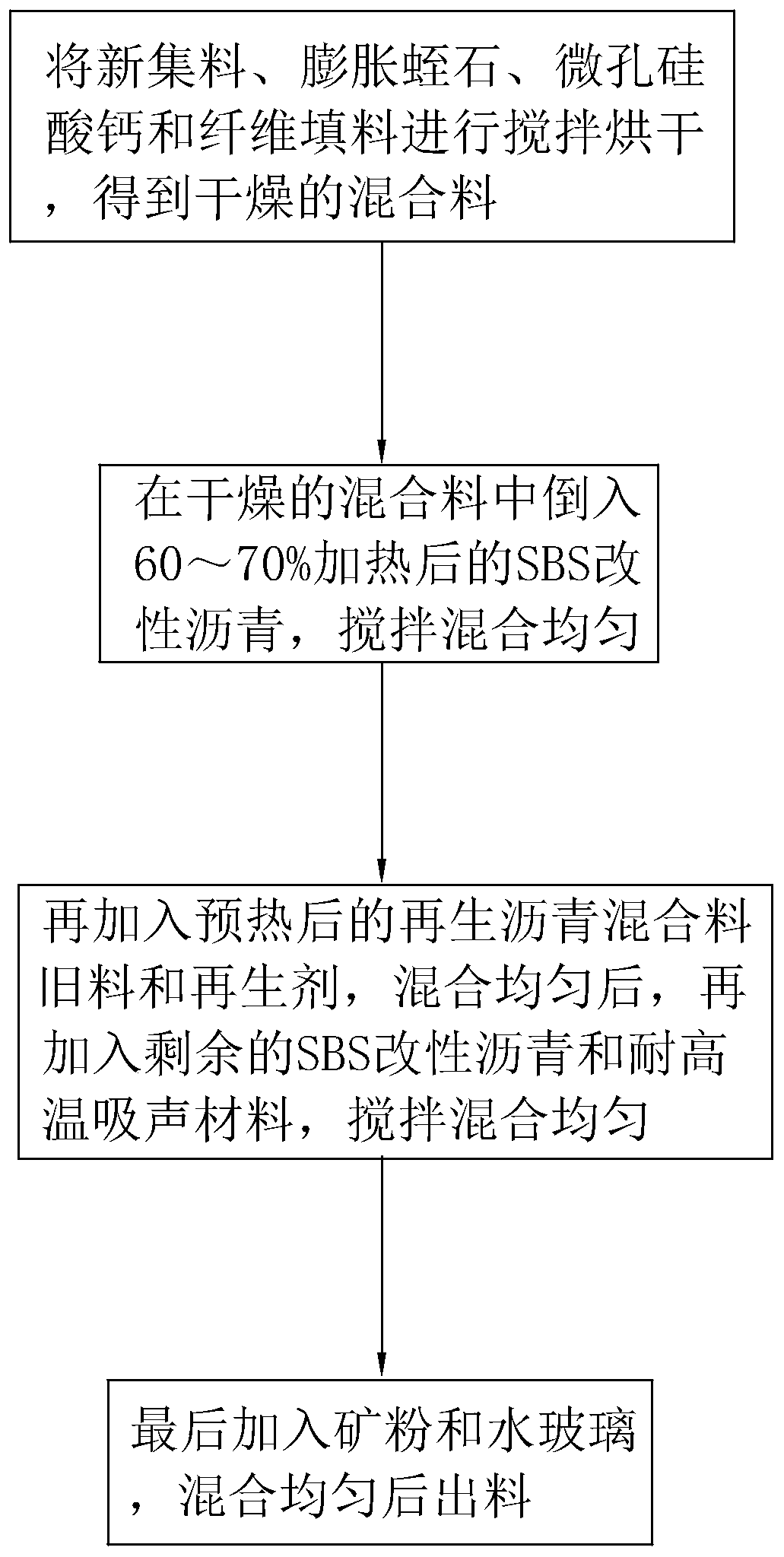

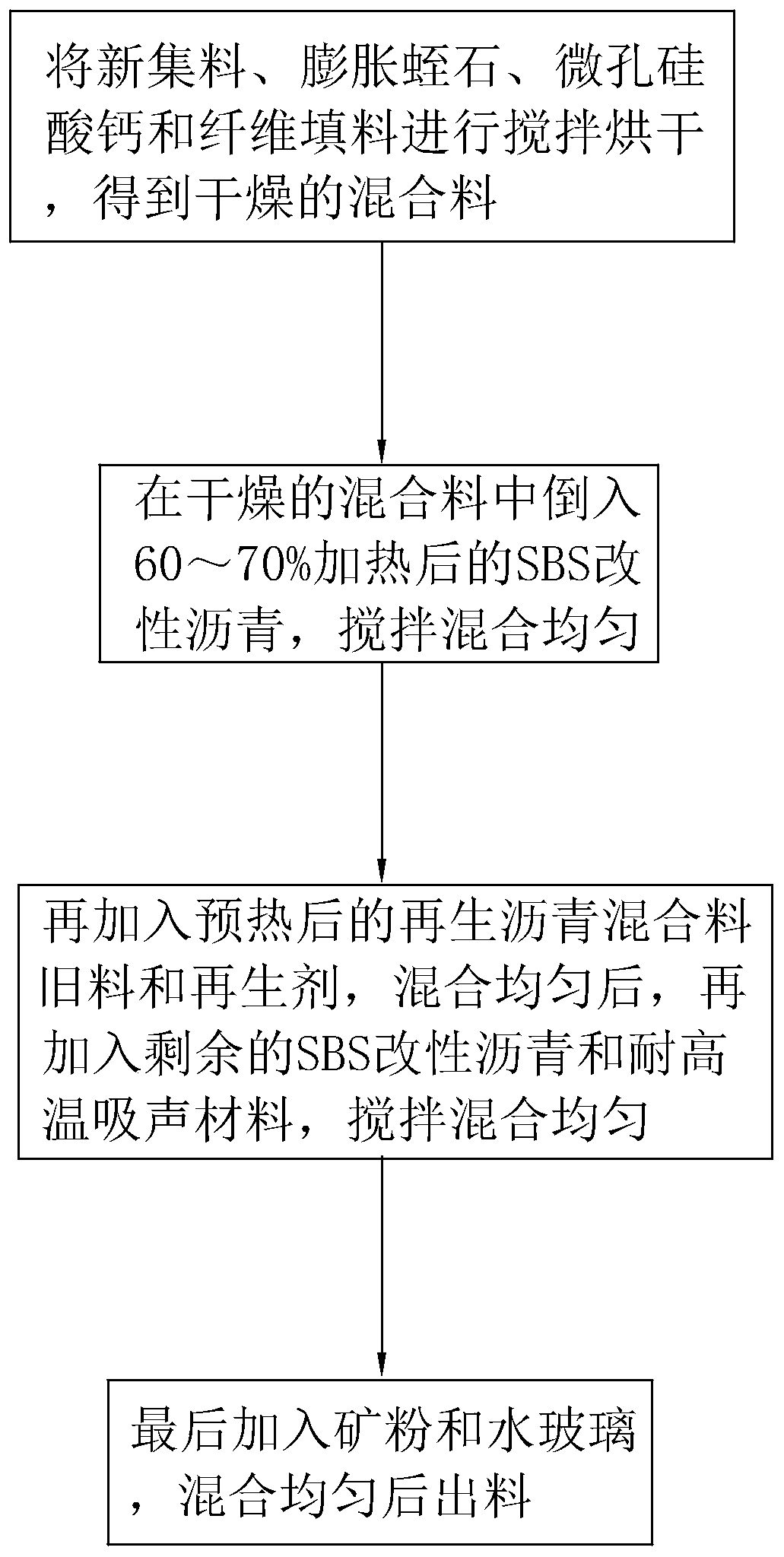

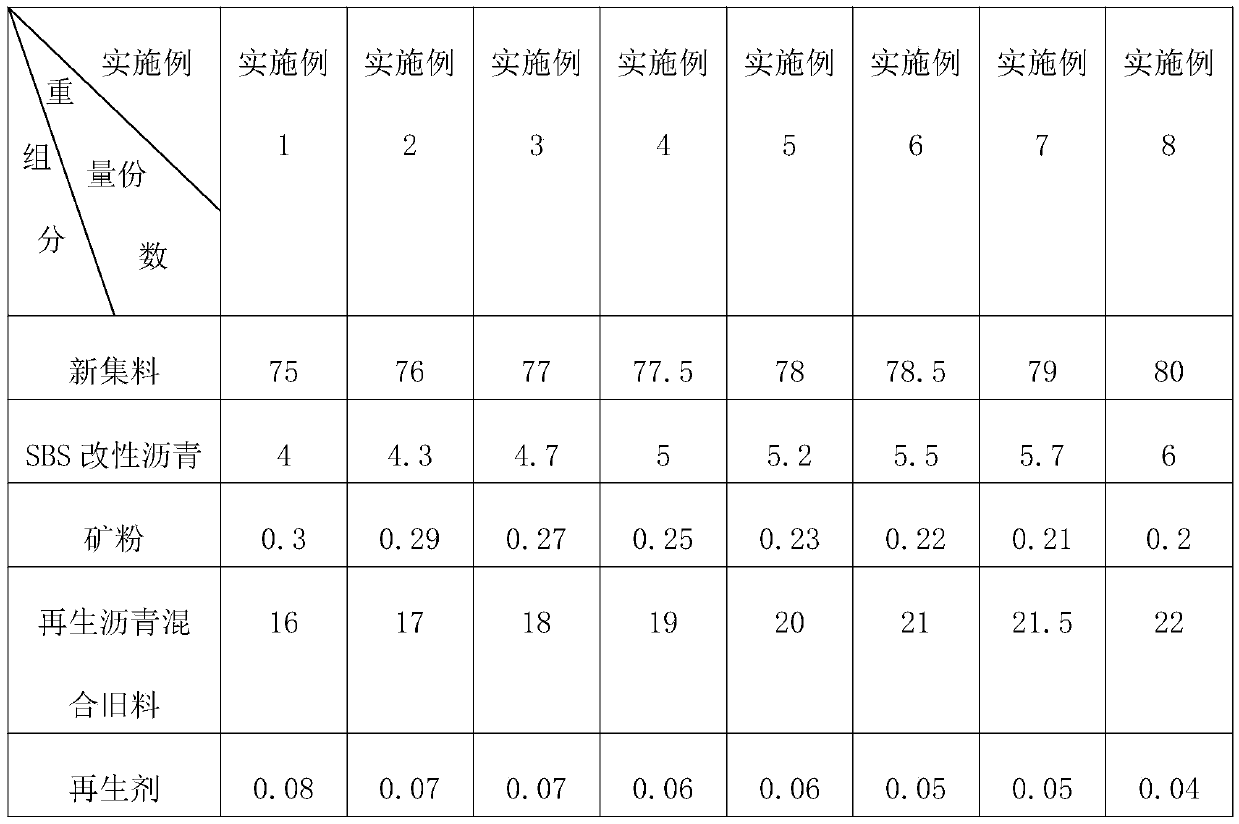

Sound-absorbing environmentally-friendly recycled asphalt concrete and preparation process thereof

ActiveCN109704652ASave raw materialsImprove qualitySolid waste managementCeramicwareCalcium silicateUrban noise

The invention discloses sound-absorbing environmentally-friendly recycled asphalt concrete and a preparation process thereof, relates to the technical field of asphalt concrete processing, and solvesthe problem that asphalt concrete cannot effectively reduce urban noise during use due to poorer stability of noise reduction of the asphalt concrete. The asphalt concrete comprises the following components, in parts by weight: 75-80 parts of novel aggregate, 4-6 parts of SBS modified asphalt, 0.2-0.3 part of mineral powder, 16-22 parts of a recycled asphalt mixed old material, 0.04-0.08 part of aregenerant, 2.5-4.5 parts of a fibrous filler, 4-6 parts of a high-temperature-resistant sound-absorbing material, 3-3.5 parts of expanded vermiculite, 0.6-1.2 parts of water glass, and 0.4-0.8 partof microporous calcium silicate. The sound-absorbing environmentally-friendly recycled asphalt concrete provided by the invention has good sound-absorbing noise-reducing effects, can maintain good stability during use, and has a longer overall service life.

Owner:SHANGHAI SHISHEN IND & TRADE CO LTD

Dual-component attitude-controlled thruster injector with micro-flow-channel liquid collecting cavity

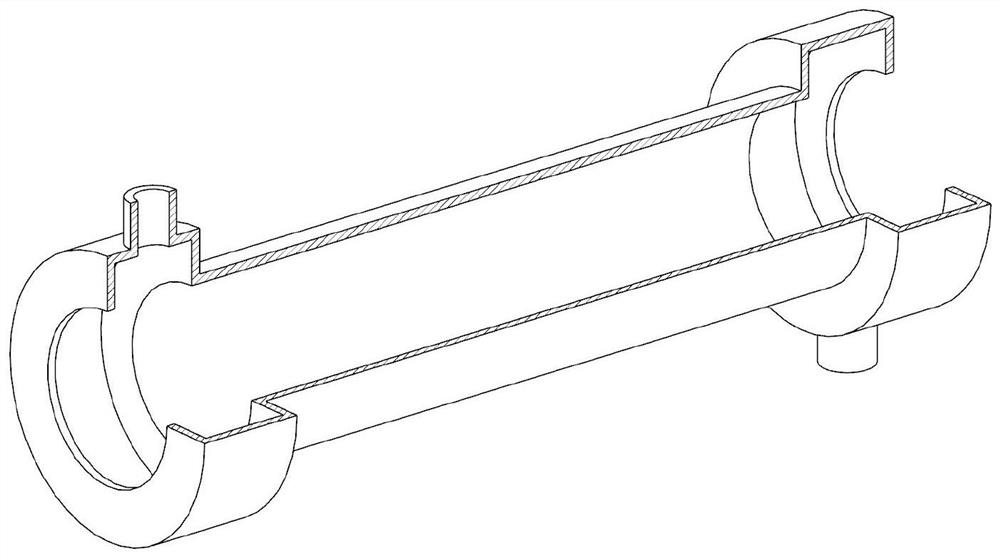

ActiveCN111472897AAbsolutely safe isolationLightweight and small volume designRocket engine plantsThrust chamberEngineering

The invention discloses a dual-component attitude-controlled thruster injector with a micro-flow-channel liquid collecting cavity. The dual-component attitude-control thruster injector comprises an oxygen path connecting nozzle, a combustion path connecting nozzle, an injector structure body and a thrust chamber butt joint interface; the oxygen path connecting nozzle, the combustion path connecting nozzle and the thrust chamber butt joint interface are integrally connected with the injector structure body; the oxygen path connecting nozzle is located on one side of the upstream end face of theinjector structure; the combustion path connecting nozzle is located on the other side of the upstream end face of the injector structure; the thrust chamber butt joint interface is located on the downstream end face of the injector structure; one end of an injector oxygen path flow channel communicates with the oxygen path connecting nozzle, and the other end of the injector oxygen path flow channel communicates with the thrust chamber butt joint interface. The dual-component attitude-controlled thruster injector produces high quality atomization, and enables an oxidant and a combustion agent to be efficiently blended and combusted in a thrust chamber.

Owner:BEIJING INST OF CONTROL ENG

Novel oil absorption cotton

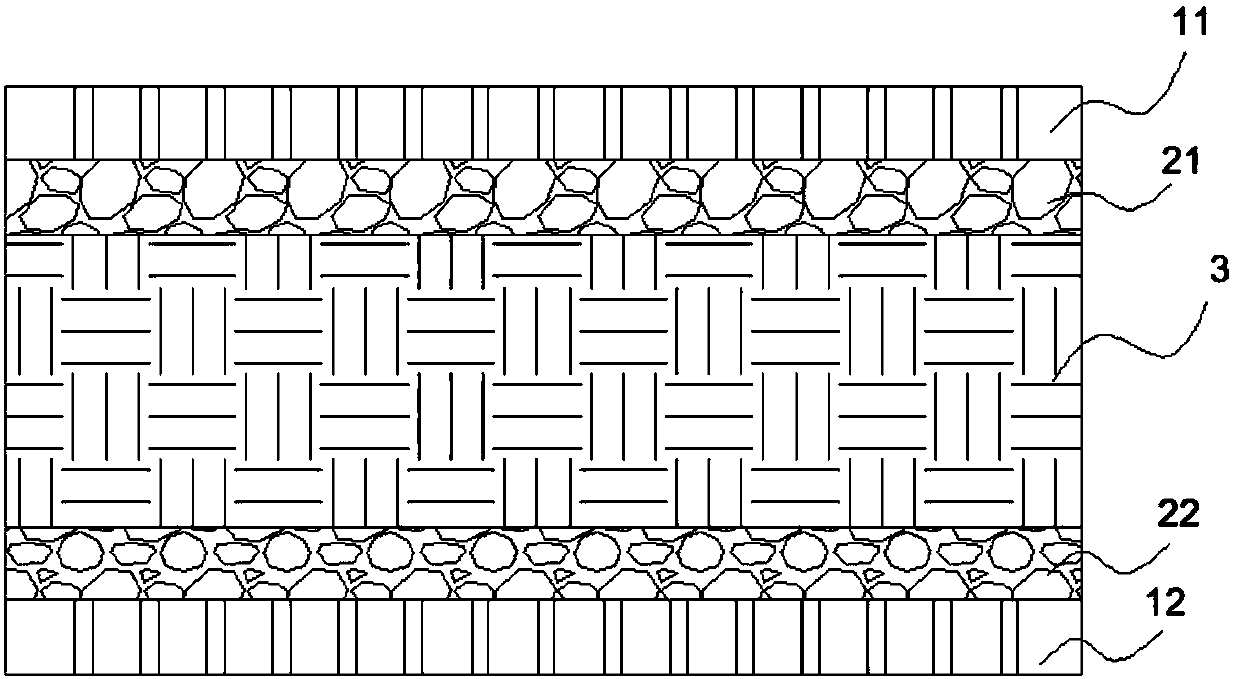

InactiveCN107792901AFast oil absorptionAvoid oil spill areaFatty/oily/floating substances removal devicesSynthetic resin layered productsPolypropyleneCotton cloth

The invention relates to novel oil absorption cotton. The novel oil absorption cotton comprises a porous cotton cloth layer, a filtering layer and a graphene aerogel layer with a 3D (Three Dimensional) porous framework, which are arranged in a laminated manner, wherein the graphene aerogel layer is nitrogen-doped graphene aerogel, and the doping mass percent of nitrogen is 50 percent to 80 percent; the porous cotton cloth layer is made of super-hydrophobic / super-oleophilic polypropylene. The porous cotton cloth layer comprises a first cotton cloth layer and a second cotton cloth layer; the filtering layer comprises a first filtering layer and a second filtering layer; the first filtering layer and the second filtering layer are arranged on two opposite side faces of the graphene aerogel layer respectively; the first cotton cloth layer is arranged at one side, far away from the graphene aerogel layer, of the first filtering layer; the second cotton cloth layer is arranged at one side, far away from the graphene aerogel layer, of the second filtering layer. The novel oil absorption cotton provided by the invention can be repeatedly utilized and the oil absorption efficiency is not remarkably reduced; the novel oil absorption cotton has an ultrahigh oil absorption rate and ultrahigh oil absorption efficiency.

Owner:SUZHOU BD ENVIRONMENTAL PROTECTION

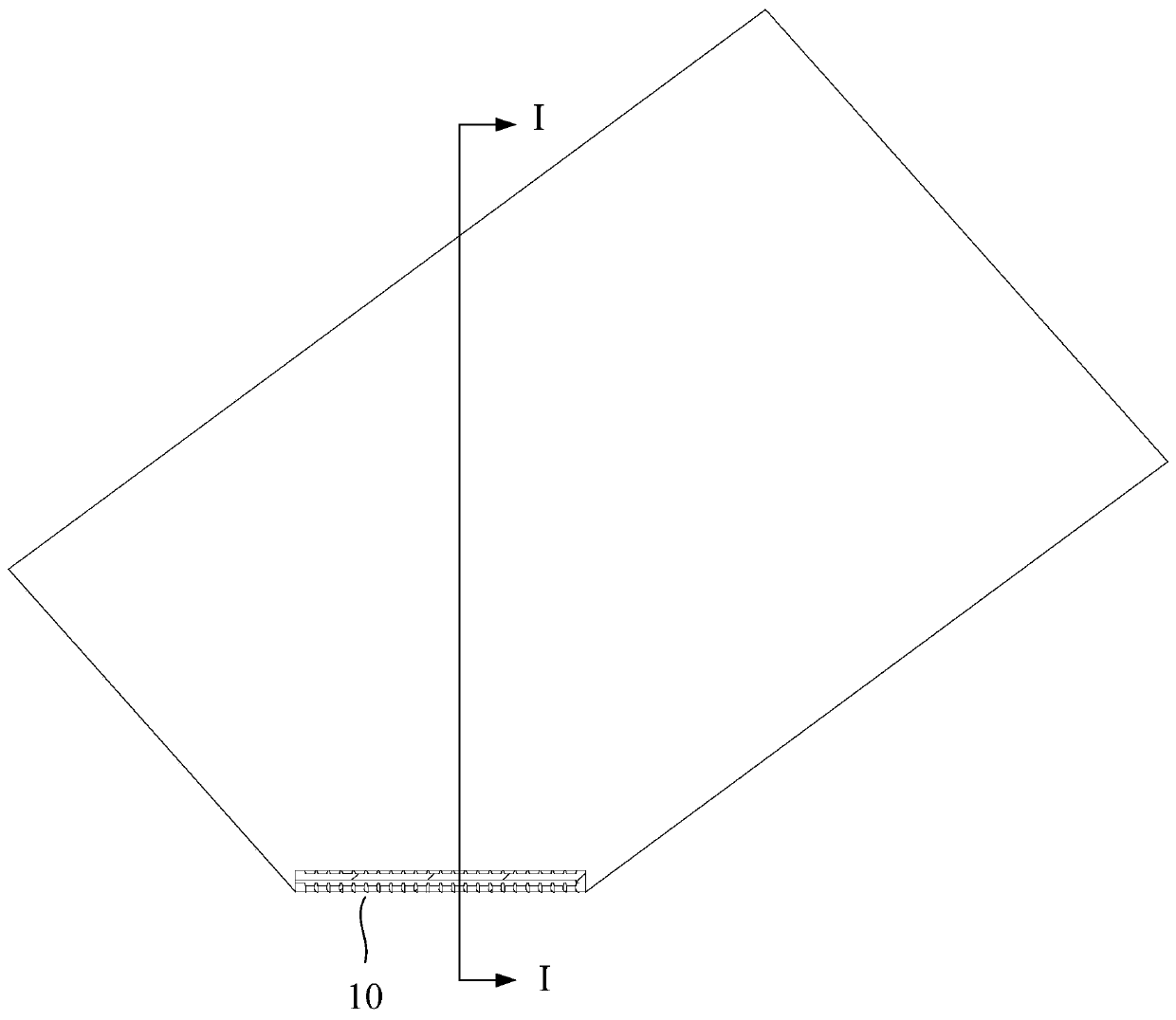

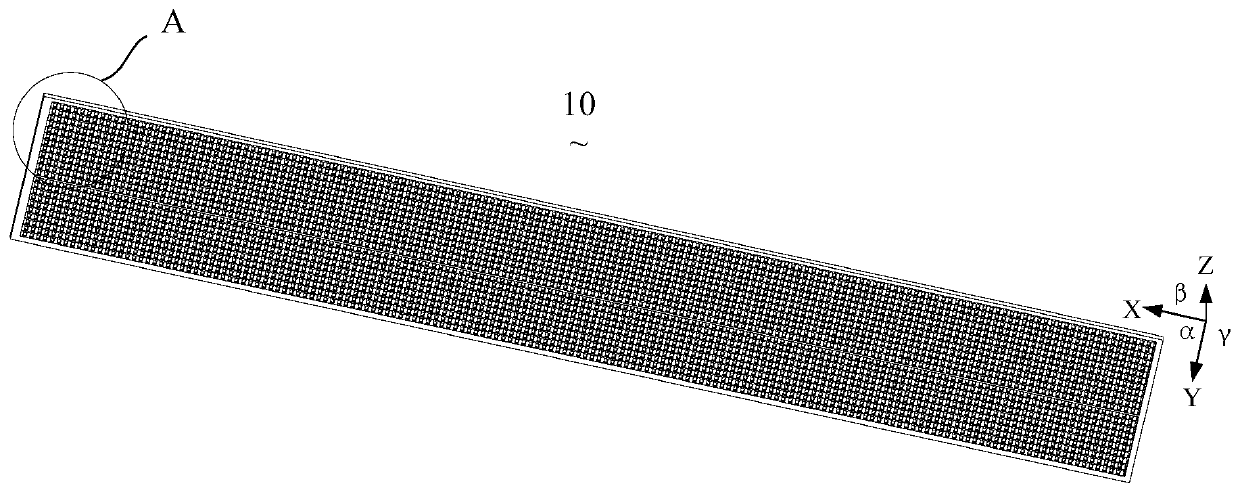

Air deflector and air conditioner

PendingCN109855176ASmall sizeHigh strengthLighting and heating apparatusAir conditioning systemsEngineeringIndoor air

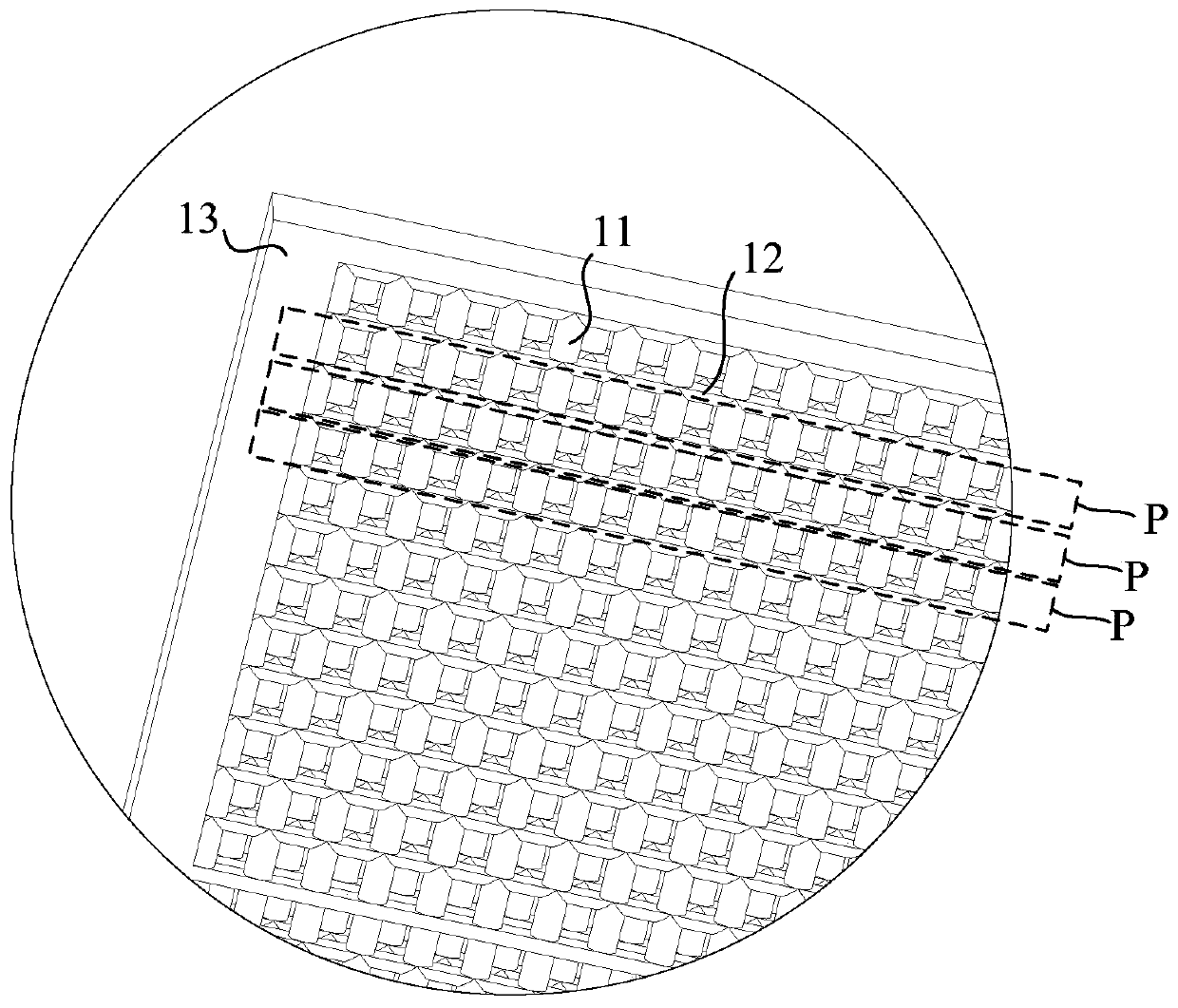

The invention discloses an air deflector and an air conditioner. The air deflector comprises a turbulent flow piece, a first connecting member and a second connecting member, the turbulent flow piececomprises at least two turbulent flow layers in interlayer arrangement, each turbulent flow layer includes at least one turbulent flow row, and each turbulent flow row includes a plurality of turbulent flow columns arranged at intervals; in two interlayer adjacent turbulent flow rows, the multiple turbulent flow columns in one turbulent flow row and the multiple turbulent flow columns in another turbulent flow row are staggered in the interlayer arrangement direction; the first connecting member is connected with the multiple turbulent flow columns in the turbulent flow rows; the second connecting member is connected with the at least two turbulent flow layers; and the air deflector is installed at an air outlet. By means of the technical scheme, airflow which is blown out can be quickly blended with indoor air, and an ideal windless effect is achieved.

Owner:GUANGZHOU HUALING REFRIGERATION EQUIP +1

Fuel and air mixing device for low-pollution burning chamber of gas turbine

ActiveCN102506446BFast evaporationQuick blendContinuous combustion chamberIndustrial gasCombustion chamber

The invention discloses a fuel and air mixing device for a low-pollution burning chamber of a gas turbine. Fuel comprises a main burning level and a duty burning level; and air is supplied by a three-stage cyclone. The fuel and air mixing device is characterized in that the central duty level adopts diffusive burning, and the peripheral main burning level adopts premixing or semi-premixing burning. The central duty level consists of a centrifugal atomizing nozzle and first-stage cyclone air; and the rotating directions of the first-stage cyclone air and second-stage cyclone air are opposite. The fuel of the main burning level is supplied by a multipoint direct-injection type nozzle, the air is respectively supplied by the second-stage cyclone air and third-stage cyclone air, and the rotating directions of the second-stage cyclone air and third-stage cyclone air are opposite. The central duty level is used when in low working conditions such as starting and slowing and the like, so that the stable burning range can be widened, the burning efficiency can be improved and the emission of CO and UHC is reduced; and when in large working conditions, the duty level and the main burning level work simultaneously, the duty level provides a stable ignition source for the main burning level, a main burning area is in a lean-oil state, and the temperature is far lower than the temperature of insulated flame, so that the emission of NOx under the large working conditions can be obviously reduced. The fuel and air mixing device can be used for an aerial gas turbine engine or an industrial gas turbine.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

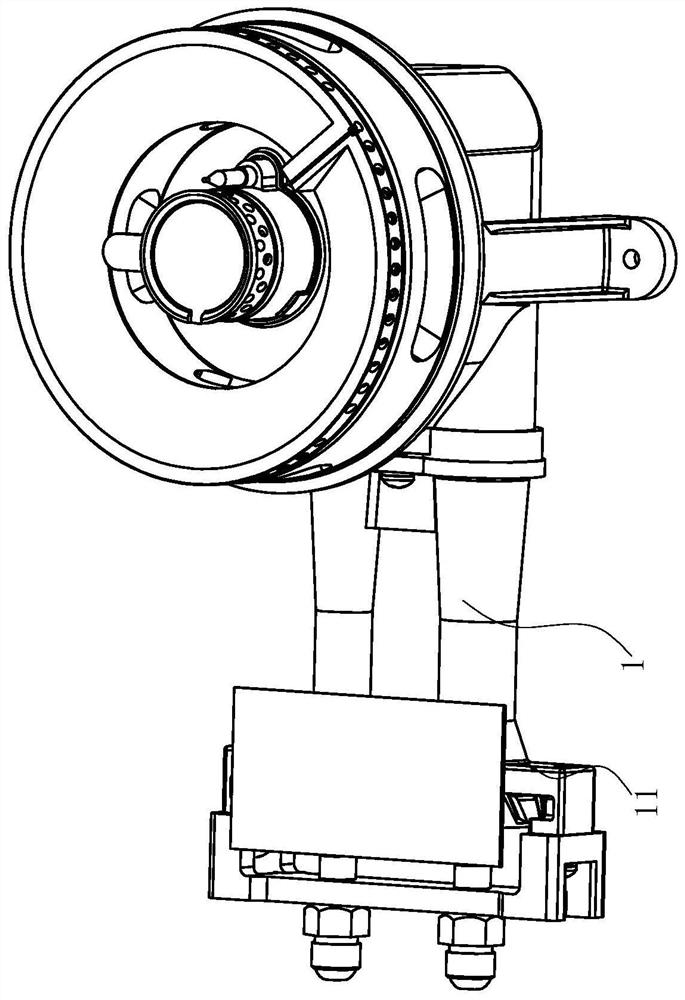

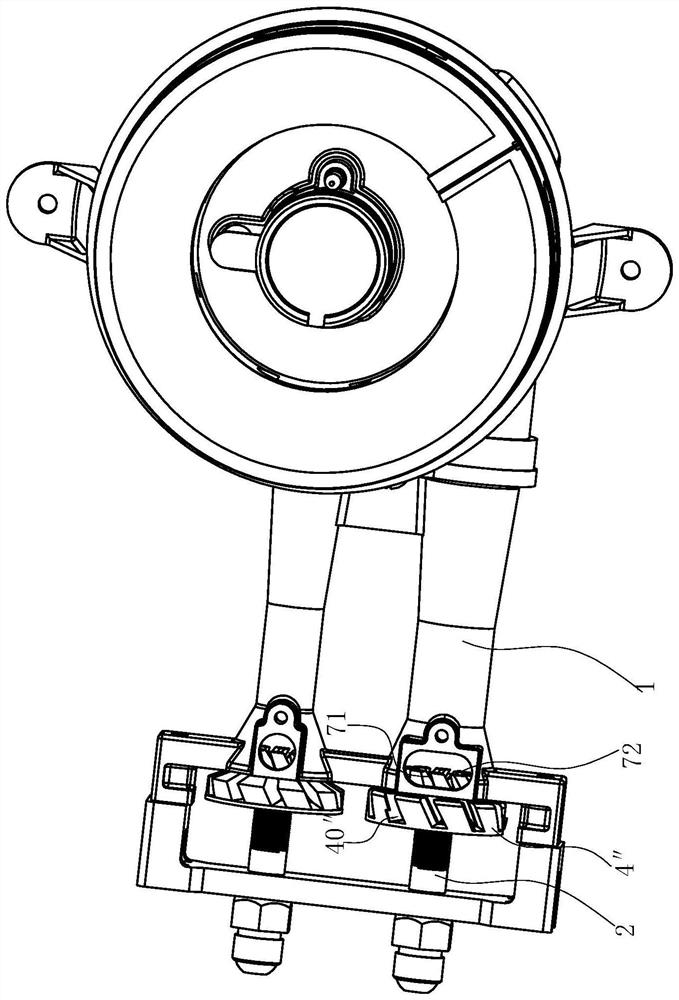

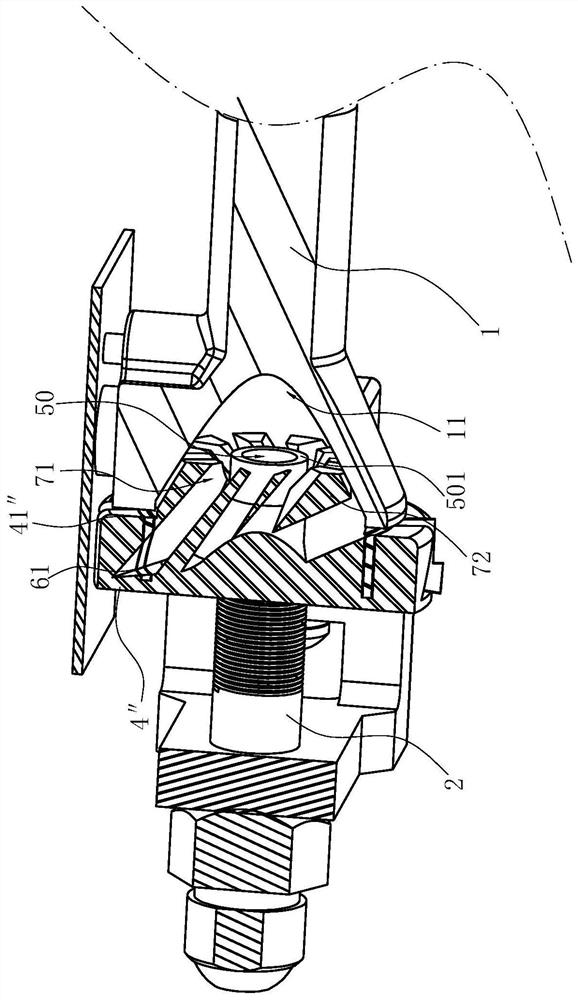

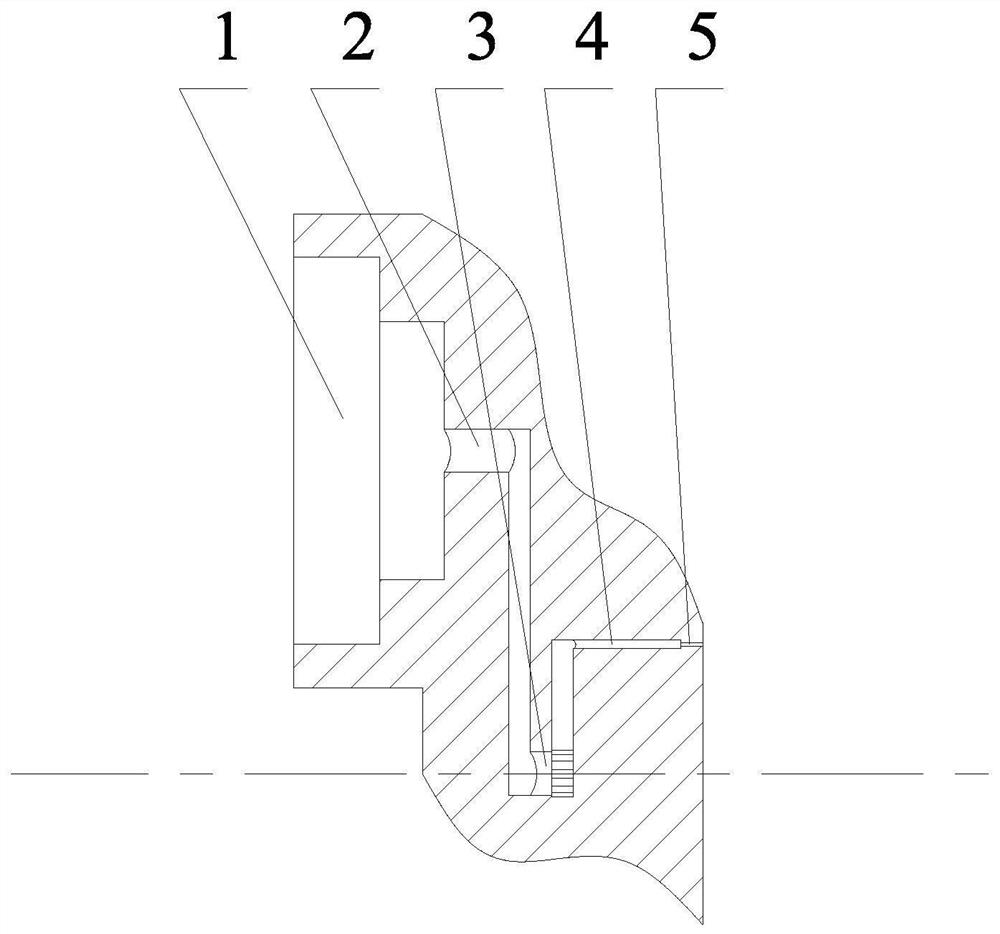

Air door adjusting mechanism used for gas cooking appliance

ActiveCN111964053AImprove combustion efficiencyImprove thermal efficiencyDomestic stoves or rangesGaseous fuel burnerEngineeringAir door

The invention relates to an air door adjusting mechanism used for a gas cooking appliance. The air door adjusting mechanism comprises an injection pipe, a nozzle seat and a nozzle which is mounted onthe nozzle seat, the nozzle opening of the nozzle faces the air inlet end of the injection pipe, and the air door adjusting mechanism is characterized in that the air door adjusting mechanism furthercomprises an air guide part which is mounted on the nozzle seat; the air guide component can move relative to the air inlet end of the injection pipe in the axis direction of the injection pipe; and the air guide component comprises a body, a central hole aligned with the nozzle is formed in the center of the body, the body is further provided with at least two guide parts arranged around the central hole at intervals in the circumferential direction, and a primary air channel used for guiding primary air is formed by an interval between every two adjacent guide parts. Compared with the priorart, the air door adjusting mechanism has the advantages that the novel air guide component is provided, fuel gas is discharged from the center of the air guide component, and the guide parts are arranged in the circumferential direction of the air guide component body at intervals, so that the fact that primary air can rotate on the periphery of the fuel gas is achieved, and then the fuel gas andthe primary air are promoted to be rapidly mixed on the gas inlet end of the injection pipe firstly.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

The Process of Producing Titanium Tetrachloride Using Artificial Rutile in Fluidized Chlorination Furnace

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Low-nitrogen combustor with rotational flow flame stabilizing and radial injection function

The invention provides a low-nitrogen combustor with a rotational flow flame stabilizing and radial injection function. The low-nitrogen combustor is composed of a combustor air channel main pipe, a combustor flame stabilizing disc, a center fuel supply pipe, a main channel dispersed fuel direct injection head, a flame stabilizing fuel injection head and an ignition channel system. A slot with a radial opening is formed between the tail end of the combustor air channel main pipe and the combustor flame stabilizing disc, and air is accelerated to flow out through the main channel dispersed fueldirect injection head along the radial slot; and after mixed gas flow collides with a hearth, one stream of gas flow deviates downstream to form downward vortex, and the other stream of gas flow deviates upstream to form upstream vortex. A rotational flow blade structure is arranged in the center of the flame stabilizing disc, a center flow return structure is formed downstream, the center flameis more stable and reliable in a diffusive combustion manner, and the oscillation risk of the hearth is reduced. Main channel combustion belongs to semi-premixed combustion, and dispersed fuel is directly injected, so that the equivalence ratio is evenly distributed; and due to the existence of the upstream vortex, internal circulation of smoke is formed, and the above overall characteristic achieves the effect of reducing nitric oxide emissions of the combustor.

Owner:王晓峰

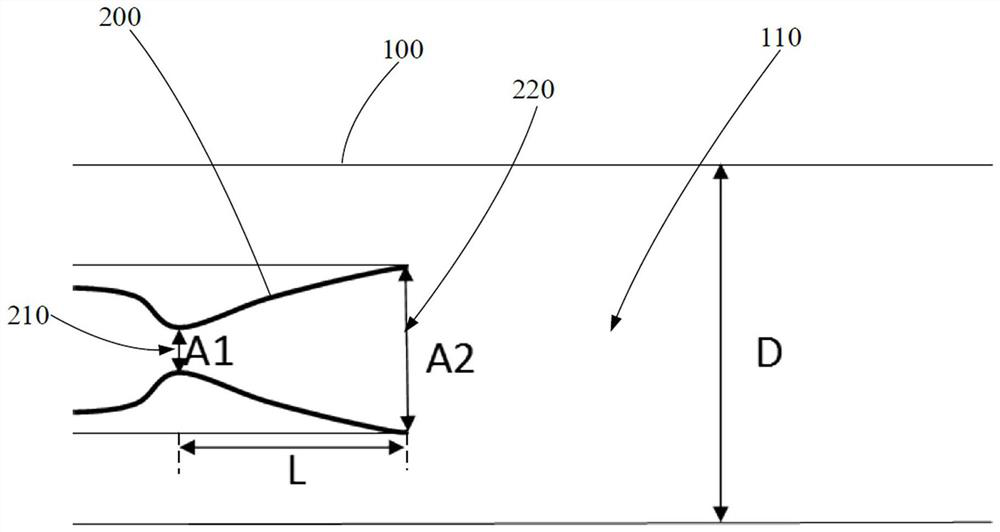

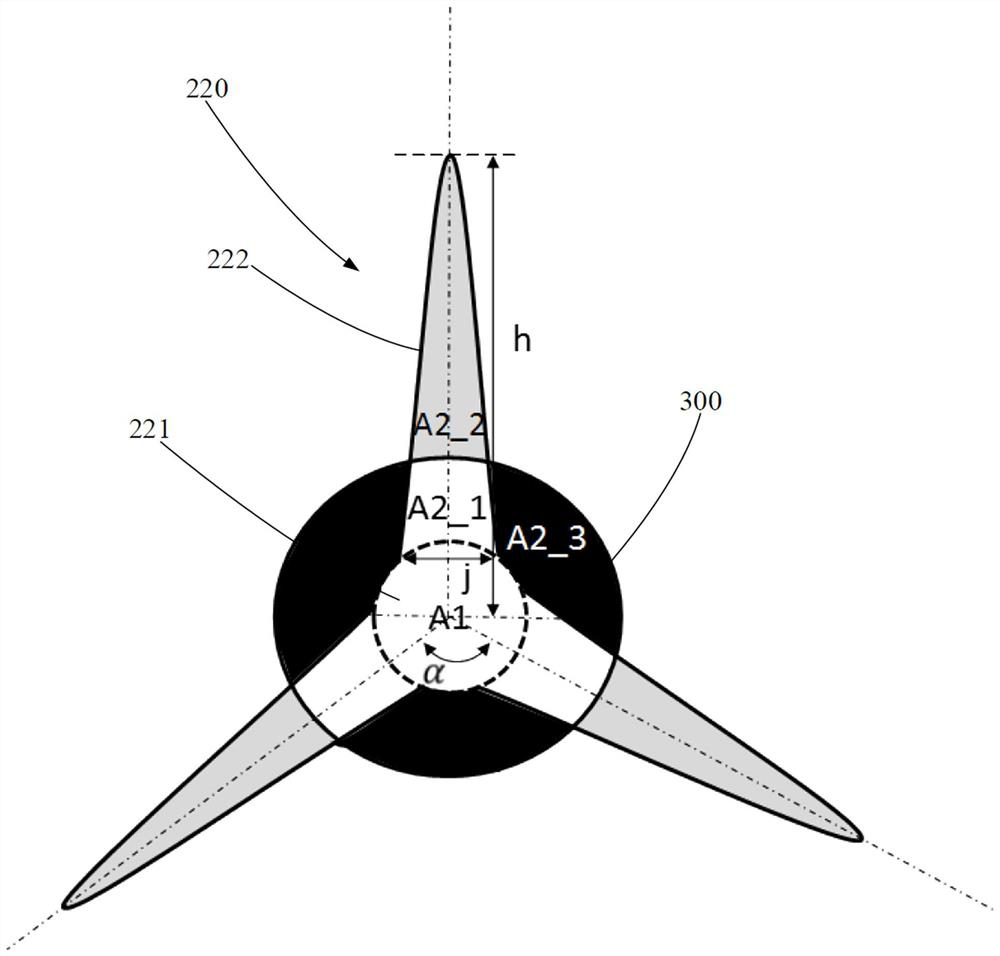

Rocket nozzle applied to RBCC engine and RBCC engine

ActiveCN112628027AIncrease contact areaImprove mixing efficiencyRocket engine plantsRam jet enginesJet flowEngineering

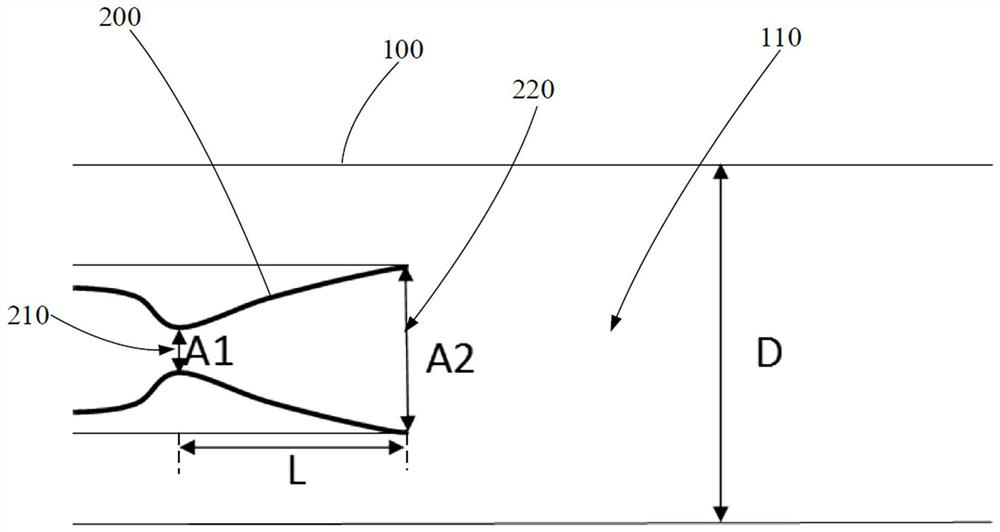

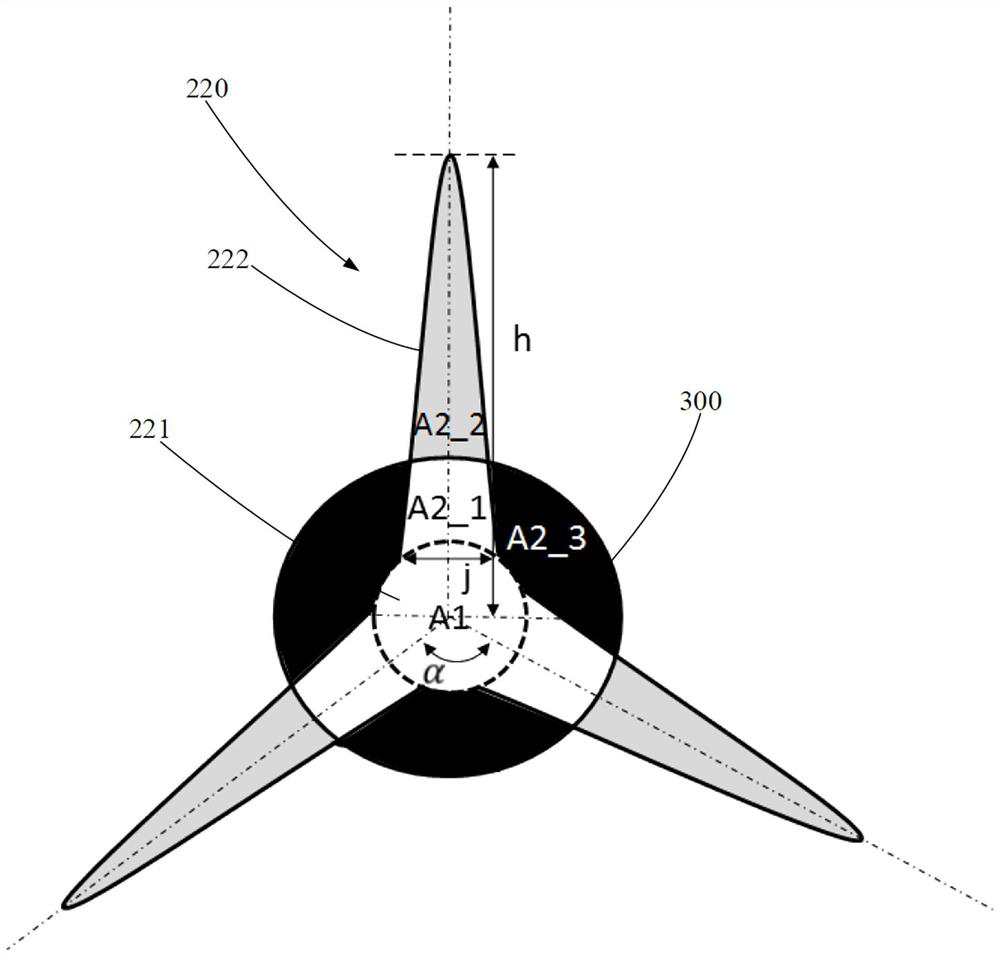

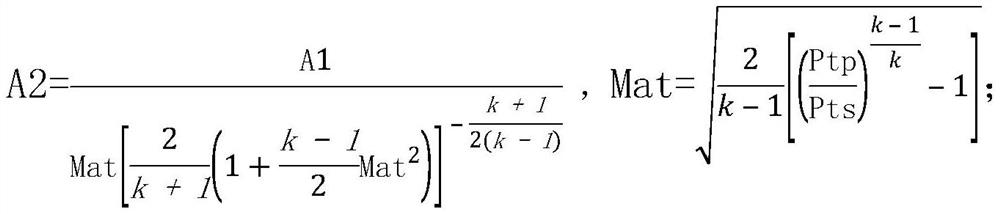

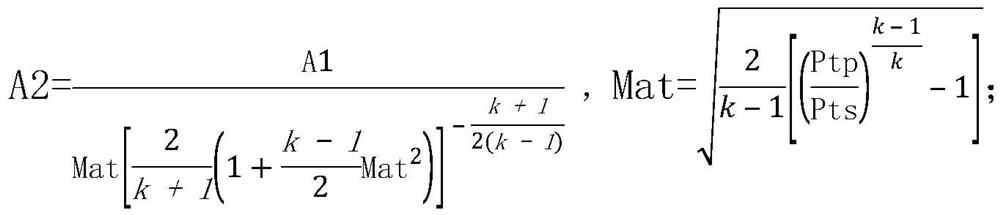

The invention relates to a rocket nozzle applied to an RBCC engine and the RBCC engine. According to the rocket nozzle applied to the RBCC engine, the RBCC engine is provided with an inner flow channel, the rocket nozzle is arranged in the inner flow channel, the rocket nozzle comprises a throat part and an outlet, the throat part is round, and the area of the throat part is A1; the outlet communicates with the throat part and is positioned on the isolation section of the inner flow channel, the outlet is not round, and the area of the outlet is A2; the numerical value of A2 is estimated through the following mathematical model, so that when the RBCC engine is in the design working condition, jet flow of the rocket nozzle and injected air meet the pressure matching condition, K is the specific heat ratio of fuel in the rocket nozzle, Mat is the Mach number of the outlet, Pts is the total pressure of the injected air, and Ptp is the total pressure of the rocket.

Owner:NAT UNIV OF DEFENSE TECH

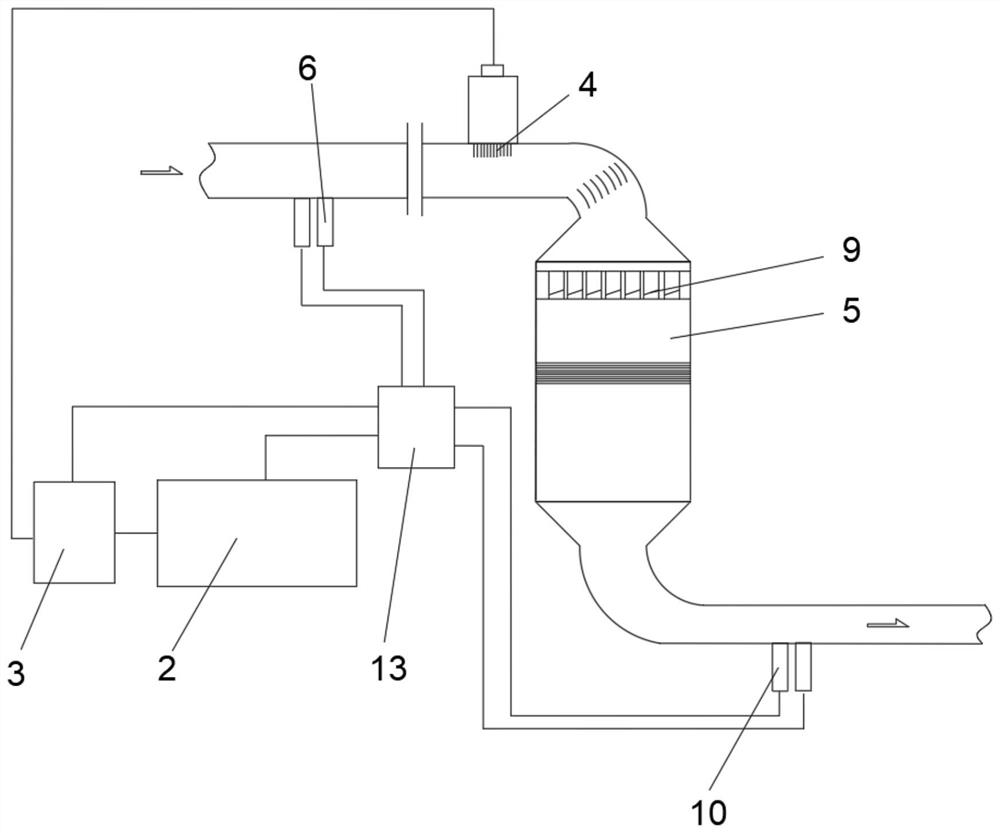

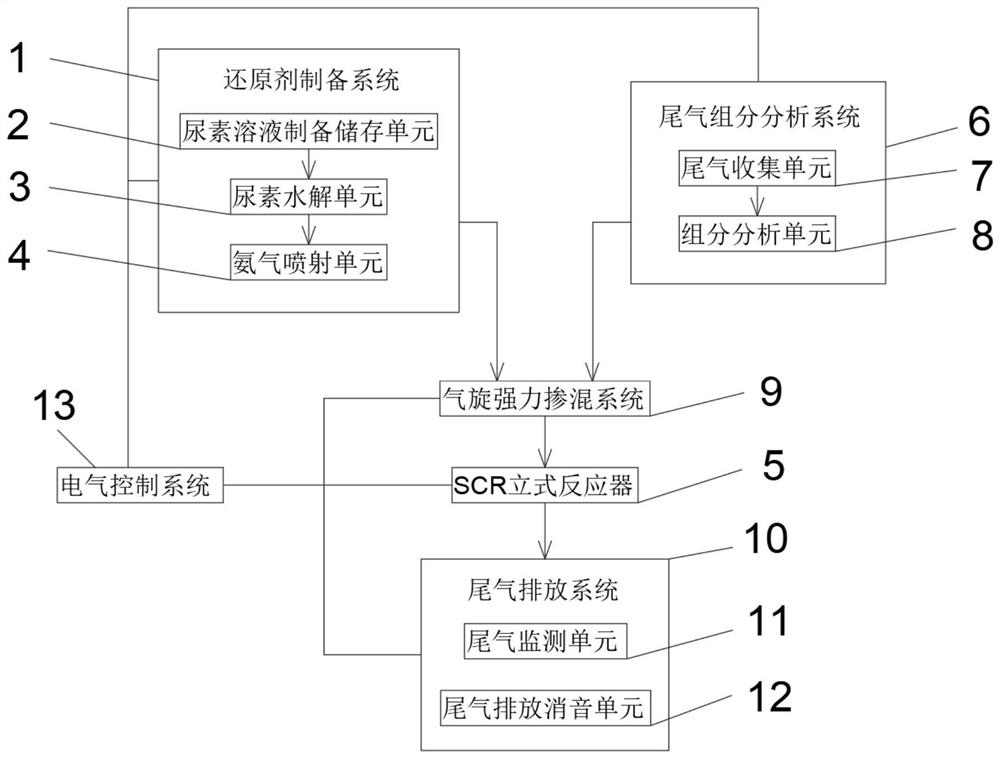

Skid-mounted urea hydrolysis SCR denitration integrated system

PendingCN114259869AMix quickly and evenlyQuick blendDispersed particle separationControl systemPtru catalyst

The invention discloses a skid-mounted urea hydrolysis SCR (Selective Catalytic Reduction) denitration integrated system which comprises a reducing agent preparation system, a tail gas component analysis system, a cyclone powerful mixing system, an SCR vertical reactor, a tail gas emission system and an electrical control system, the tail gas component analysis system is used for collecting and outputting diesel engine tail gas; according to the invention, tail gas and ammonia gas are premixed in the gas inlet flue and then enter a gas inlet of the SCR vertical reactor 5, and at the moment, fan blades which are driven by an explosion-proof motor and rotate at a high speed can strongly disturb a tail gas and ammonia gas mixer body, so that the tail gas and the ammonia gas are rapidly and uniformly mixed and enter a catalyst bed through the guidance of a guide plate; therefore, the tail gas and the ammonia gas are rapidly mixed, the mixing distance is effectively shortened, the mixing effect is good, the utilization rate of a catalyst is improved, the size of equipment is reduced, and the occupied area of the equipment is reduced.

Owner:北京中环科远科技有限公司

Rocket nozzle and rbcc engine applied to rbcc engine

ActiveCN112628027BIncrease contact areaIncrease thrust-to-weight ratioRocket engine plantsRam jet enginesJet flowMathematical model

The invention relates to a rocket nozzle applied to an RBCC engine and the RBCC engine. The rocket nozzle applied to the RBCC engine, the RBCC engine is provided with an inner flow channel, the rocket nozzle is arranged in the inner flow channel, the rocket nozzle includes: a throat, and the shape of the throat is a circle shape, and the area of the throat is A1; and the outlet, the outlet communicates with the throat and is located in the isolation section of the inner flow channel, the shape of the outlet is not circular, and the area of the outlet is A2; the value of A2 is estimated by the following mathematical model, so that when the RBCC engine is in the design condition, the jet flow of the rocket nozzle and the injection air meet the pressure matching condition: where K is the The specific heat ratio of the fuel in the rocket nozzle, Mat is the Mach number of the outlet, Pts is the total pressure of the ejected air, and Ptp is the total pressure of the rocket.

Owner:NAT UNIV OF DEFENSE TECH

A pyrolysis gas-air rapid mixing device

The invention aims at providing a pyrolysis fuel gas and air rapid mixing device. The pyrolysis fuel gas and air rapid mixing device comprises an outer shell, an inner shell and a lobe mixer, wherein the inner shell is arranged in the outer shell; a hydrocyclone air inlet passage is formed between the inner shell and the outer shell; the lobe mixer comprises a lobe mixing structure inner passage wall, lobe convex structures and lobe concave structures; the lobe convex structures and the lobe concave structures are arranged alternately to form an annular structure; the lobe mixing structure inner passage wall is connected with the annular structure; a lobe mixing structure inner passage pyrolysis fuel gas inlet communicating with a rich oil pyrolysis combustion chamber is formed in the lobe mixing structure inner passage wall; the lobe mixer is arranged in the inner shell, and a lobe mixing air passage is formed between the lobe mixing structure inner passage wall and the inner shell; an inclined radial runner provided with cyclone blades is installed at an outlet of the lobe mixer; and a pyrolysis fuel gas and air mixing gas outlet is arranged at an outlet of the inclined radial runner. The pyrolysis fuel gas and air rapid mixing device can complete rapid mixing of pyrolysis fuel gas and air, and lowers generation of lean burning area NOx.

Owner:HARBIN ENG UNIV

Nozzle for gas stove and gas stove using nozzle

ActiveCN112013387AImprove the defect of insufficient ejectionQuick blendDomestic stoves or rangesAir/fuel supply for combustionEngineeringMechanics

The invention relates to a nozzle for a gas stove and a gas stove using the nozzle. The nozzle comprises a body, the nozzle is characterized in that the body comprises a nozzle part located at the downstream position of the body so as to allow gas to be sprayed into the body, an outlet part located at the upstream portion of the body, an air chamber and an gas outflow part, the air chamber is arranged in the outlet part and is relatively isolated from the nozzle part, and the air chamber is provided with an air inflow hole in fluid communication with the outlet part and a primary air hole formed in the outer surface of the pipe wall corresponding to the outlet part and communicating with the air inflow hole. Compared with the prior art, the novel nozzle has the advantages that the gas outflow part of the nozzle is located at the periphery of the outlet part, and the air chamber allowing primary air to enter independently is arranged at the inner periphery of the outlet part, so that gas and the primary air are promoted to be rapidly mixed in front of the outlet part of the nozzle, and then the nozzle is provided with an inner channel air injection structure and an outer channel airinjection structure.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A nozzle for a gas stove and a gas stove using the nozzle

ActiveCN112013387BImprove the defect of insufficient ejectionQuick blendDomestic stoves or rangesAir/fuel supply for combustionThermodynamicsGas cooking stove

The invention relates to a nozzle for a gas cooker and a gas cooker using the nozzle, which includes a body, and is characterized in that: the body includes a nozzle portion located downstream of the body for injecting gas into the body; located upstream of the body The outlet part at the outlet part is arranged in the outlet part and is relatively isolated from the nozzle part. The air chamber has an air inflow hole in fluid communication with the outlet part. Compared with the prior art, the primary air hole and the gas outflow part connected by the holes, the present invention has the advantage of providing a new nozzle, the gas outflow part of the nozzle is located at the periphery of the outlet part, and the inner periphery of the outlet part is set There is an independent air chamber for primary air to promote rapid mixing of gas and primary air prior to the outlet of the nozzle, so that the nozzle has an inner and outer dual-channel air injection structure.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A Rotating Detonation Engine with Premixed Injection

ActiveCN107605600BQuick blendReduce the temperatureTurbine/propulsion engine coolingGas turbine plantsDetonationCombustor

The invention discloses a premixed jet rotating detonation engine device. The premixed jet rotating detonation engine device is characterized in that in the gas flow direction, a premixed gas collecting cavity is located at the most front end, an oxidizer gas inlet hole and an fuel gas inlet hole are formed in the front end face and the outer wall face of the premixed gas collecting cavity correspondingly, and an oxidizer and fuel are mixed in the premixed gas collecting cavity; an gas jetting device is connected to the downstream of the premixed gas collecting cavity, a plurality of circulargas jetting holes are evenly distributed in the gas jetting device in the circumferential direction and radial direction, cooling grooves which communicate mutually in the circumferential direction and radial direction are formed in the position between the gas jetting holes, and cool liquid flows into from a liquid inlet and flows out from an liquid outlet; and an annular combustor is connected to the downstream of the gas jetting device, and premixed gas enters the annular combustor through the gas jetting holes for combustion. According to the premixed jet rotating detonation engine, by arranging the gas jetting device provided with the cooling grooves and in a certain axial direction, fire in the annular combustor can be effectively prevented from returning to the premixed gas collecting cavity, and steady working of the rotating detonation engine adopting the premixed jet mode is achieved; and compared with the non premixed jet mode, working stability and the propulsion performance of the engine are improved.

Owner:NANJING UNIV OF SCI & TECH

A pulse detonation propulsion device based on regenerative cooling structure

InactiveCN109209678BQuick blendLow critical ignition energyIntermittent jet plantsRocket engine plantsPretreatment methodEngineering

The invention provides a pulse detonation pushing device based on a regenerative cooling structure. Based on the regenerative cooling structure, a convection / impact composite type heat exchange methodis adopted, liquid fuel oil is heated, catalyzed and cracked through heat radiation of detonation combustion, micromolecule gas fuel excellent in detonation performance is generated, the time and distance of deflagration to detonation transition (DDT) of a pulse detonation engine can be effectively shortened, and meanwhile efficient cooling of the wall face of a detonation pipe can be achieved. The catalytic and cracking fuel oil pretreatment method is adopted, the detonation performance of fuel is effectively improved, and meanwhile the pushing performance and safety of the engine are improved. The regenerative cooling structure provides a heat source for a catalytic and cracking reaction, and meanwhile airborne fuel oil is adopted as cooling media to cool the wall face of the detonationpipe. Temperature distribution of the wall face of the detonation pipe is considered, the convection / impact composite type cooling manner is adopted on the DDT segment of the detonation pipe, and a microchannel inner convection heat exchange manner is adopted in the detonation spread segment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Swirl mixing device

ActiveCN105032225BImprove qualityImprove stabilityFlow mixersMixing gases with gases/vapoursCycloneExternal energy

Owner:HUATIAN ENG & TECH CORP MCC

A Multipoint Direct Injection Opposite Cut Fast Mixing Radial Injection Low Nitrogen Burner

ActiveCN109442398BQuick blendEven distribution of equivalence ratioGaseous fuel burnerThermodynamicsNitrogen oxides

The invention discloses a multi-point direct injecting and opposite shearing and fast-mixing radial injection low-nitrogen combustor. The combustor is composed of a combustor gas circuit main pipe, acombustor head baffle, a central fuel supply pipe, a main path fuel injection device and an ignition path system; a seam groove with a radial opening is formed between the tail end of the combustor gas path main pipe and the combustor head baffle, gas is accelerated out through the radial seam groove after passing by the two sides of the main path fuel injection device, gaseous fuel is transversely sprayed into the accelerated gas flow through small holes in the two sides of the fuel injection device, the gas flow at the two sides of the fuel injection device is subjected to intersection shearing, the mixing of the gas and the fuel is accelerated, and the mixed gas is injected into a hearth through the radial groove; one stream of the mixed gas flow is deflected to the downstream after being collided with the hearth, so that a mainstream vortex is formed, the other stream of the mixed gas flow is deflected to the upstream, and an upstream vortex is formed; and the fuel is direct injected in a multi-point mode, the equivalent ratio is uniformly distributed, the flame impacts the wall surface of the hearth, heat exchange is accelerated, the internal circulation of the flue gas is formed due to the presence of the upstream vortex, and the comprehensive characteristics achieve the effect of reducing the emission of nitrogen oxide of the combustor.

Owner:BEIHANG UNIV

A damper adjustment mechanism for a gas cooker

ActiveCN111964053BImprove combustion efficiencyImprove thermal efficiencyDomestic stoves or rangesGaseous fuel burnerEngineeringDamper

The invention relates to a damper adjustment mechanism for a gas cooker, which includes an injection pipe, a nozzle seat and a nozzle installed on the nozzle seat, the nozzle of the nozzle faces the air inlet end of the injection pipe, and is characterized in that: It includes an air guide installed on the nozzle seat, and the air guide can move relative to the air inlet end of the ejector tube along the axis of the ejector tube; the air guide includes a body, and the center of the body has a The central hole in which the nozzles are aligned, the body also has at least two guide parts arranged at intervals around the central hole along the circumferential direction, the interval between adjacent guide parts forms a primary air channel for guiding primary air, which is similar to the existing Compared with the prior art, the advantage of the present invention is to provide a new air guide, the center of the air guide is gas, and the guide parts are arranged at intervals along the circumference of the air guide body, which can realize the primary air to rotate around the gas , and then promote the rapid mixing of gas and primary air before the gas inlet end of the injection tube.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A dual-component attitude control thruster injector with a micro-channel liquid collection chamber

ActiveCN111472897BAbsolutely safe isolationLightweight and small volume designRocket engine plantsThrust chamberEngineering

The invention discloses a dual-component attitude control thruster injector with a micro flow channel liquid collection chamber, comprising: an oxygen circuit joint, a combustion line joint, an injector structure and a thrust chamber docking interface; wherein, The oxygen circuit nozzle, the fuel circuit nozzle and the thrust chamber docking interface are integrally connected with the injector structure; the oxygen circuit nozzle is located on the side of the upstream end face of the injector structure; The other side of the upstream end face of the injector body; the butt joint of the thrust chamber is located on the downstream end face of the injector structure; One end of the flow path of the injector is connected with the nozzle of the oxygen path, and the other end of the flow path of the oxygen path of the injector is connected with the interface of the thrust chamber; The other end of the flow path of the burner is connected with the butt joint of the thrust chamber. The present invention produces high-quality atomization that enables efficient mixing and combustion of oxidant and combustion agent within the thrust chamber.

Owner:BEIJING INST OF CONTROL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com