Patents

Literature

65results about How to "Mix quickly and evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

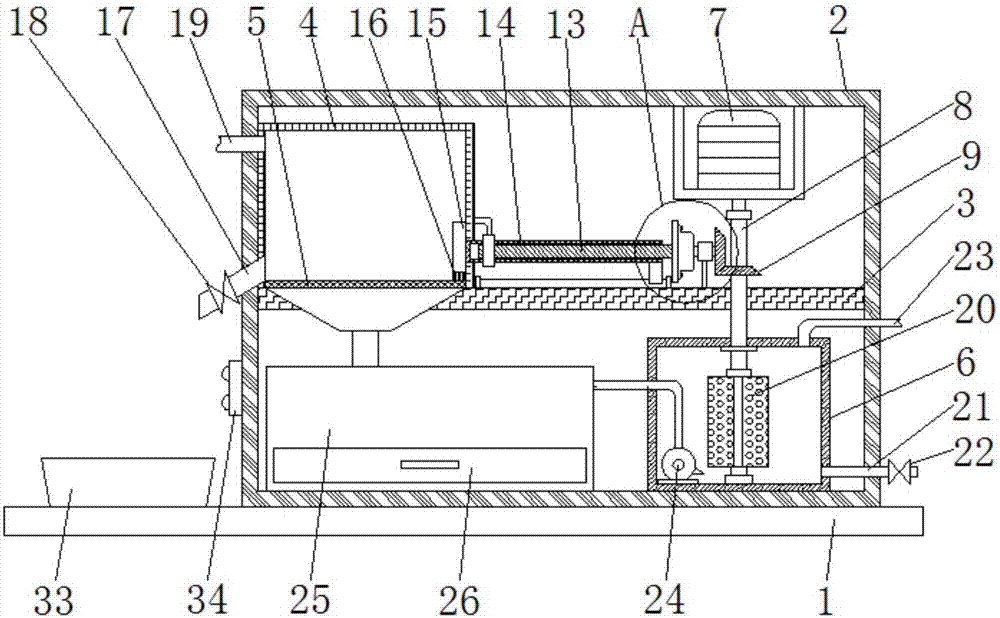

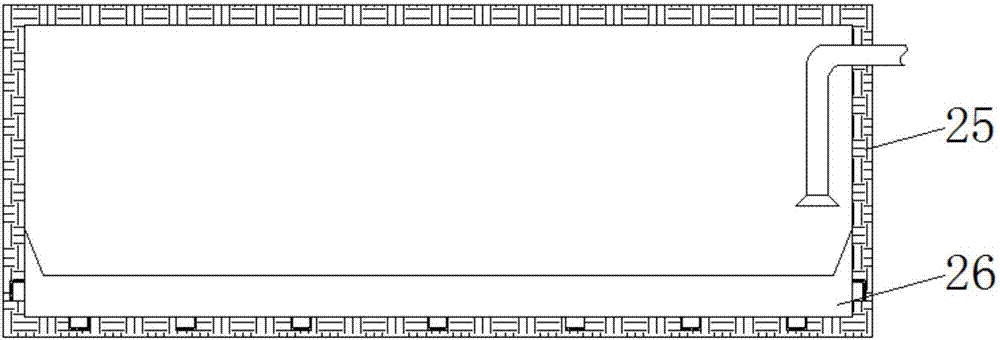

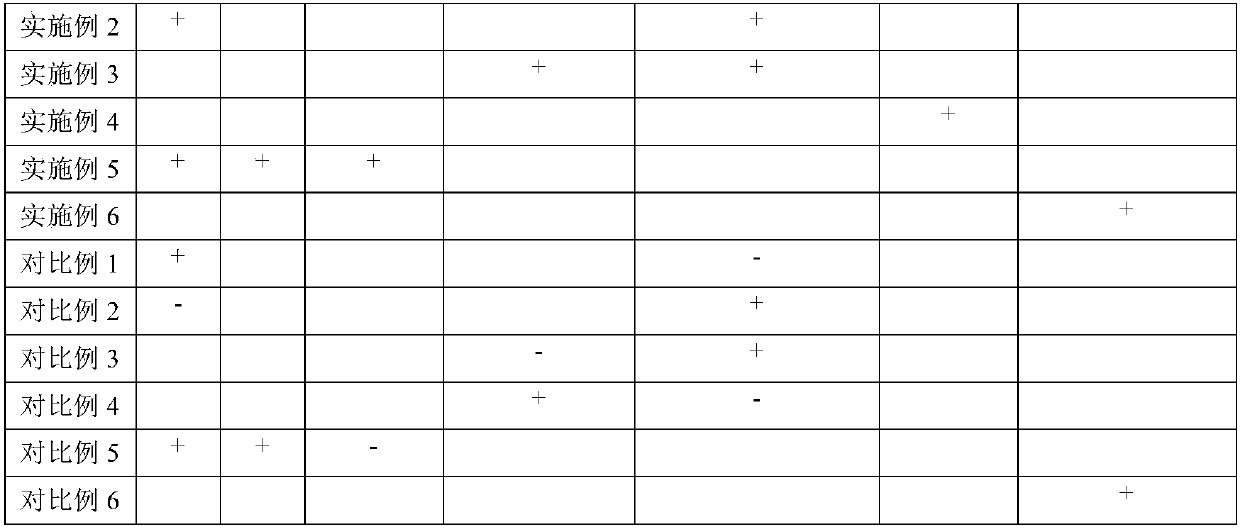

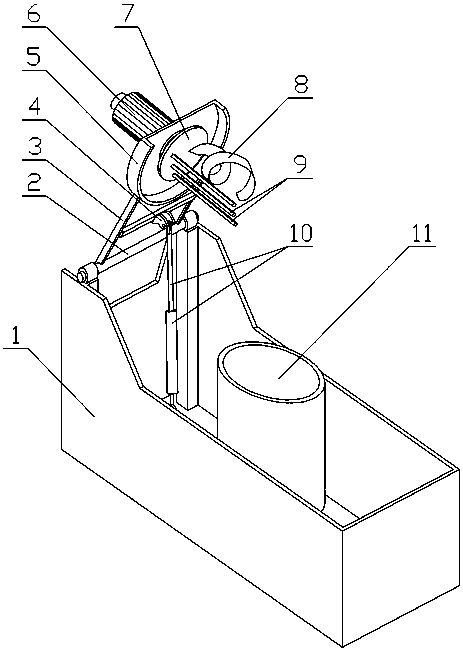

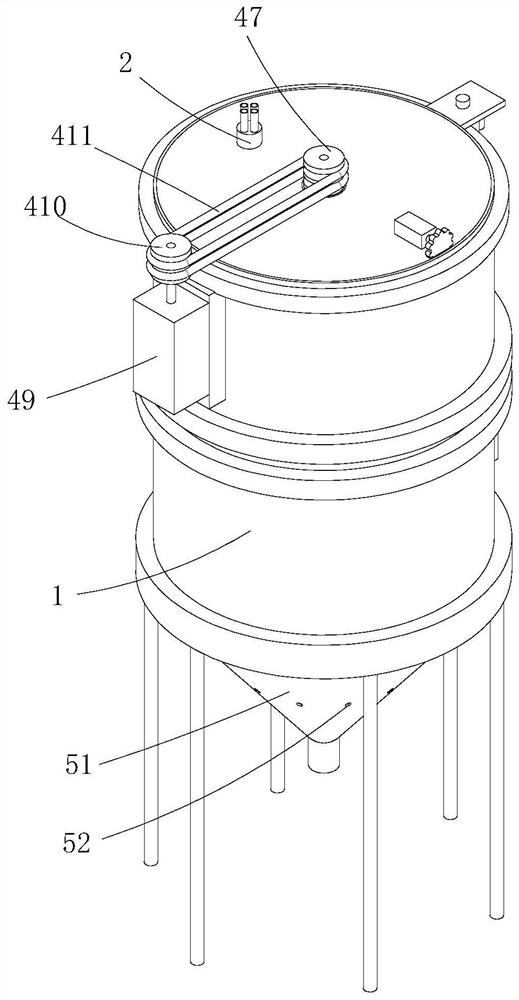

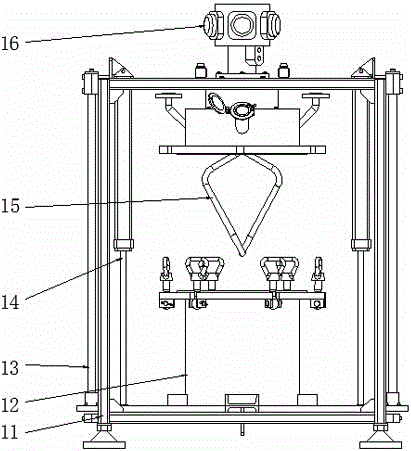

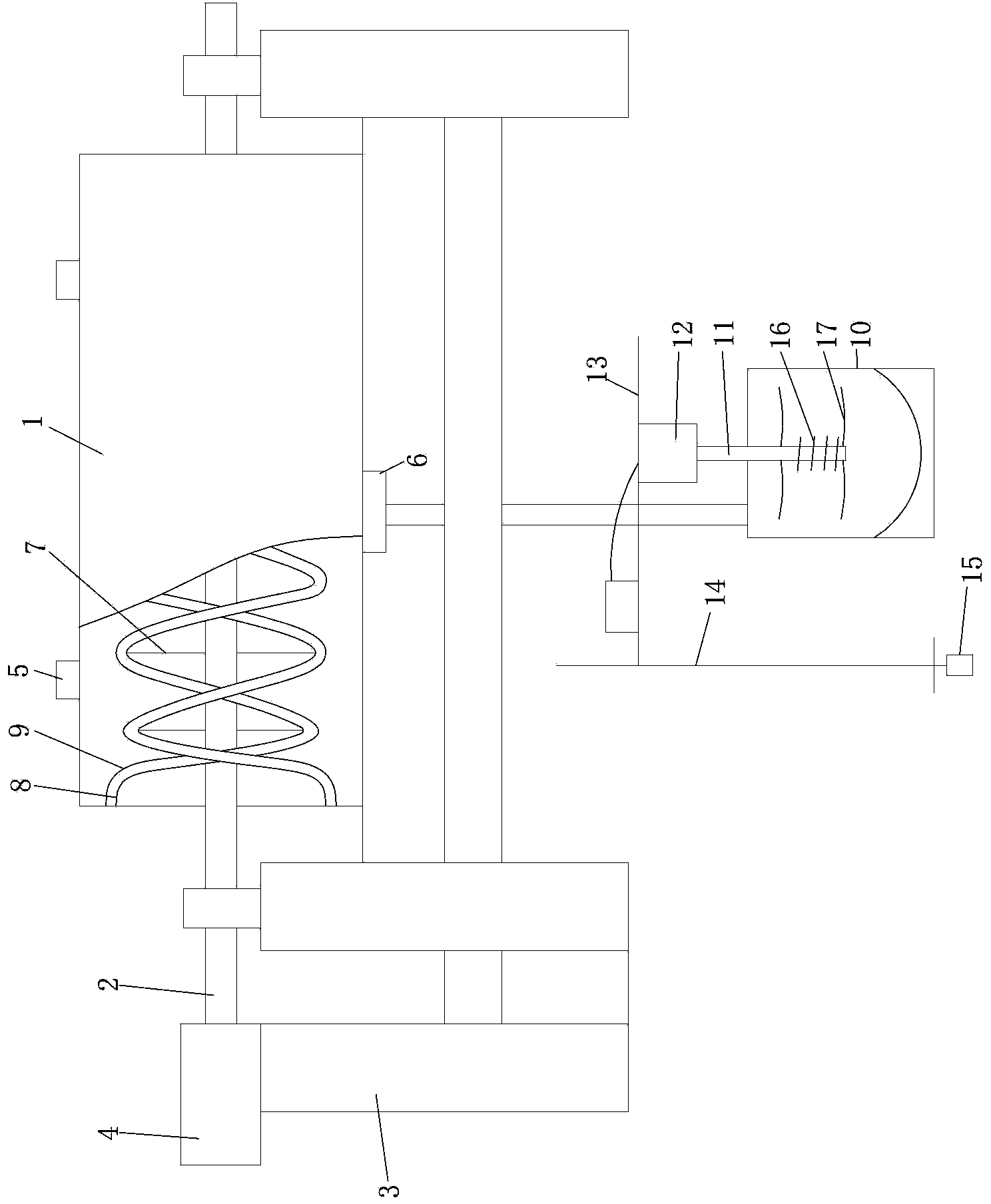

Culturing farm sewage treatment device with environmental protection function

ActiveCN107381938ASave time at workReduce workloadSpecific water treatment objectivesWaste water treatment from animal husbandryWork periodEngineering

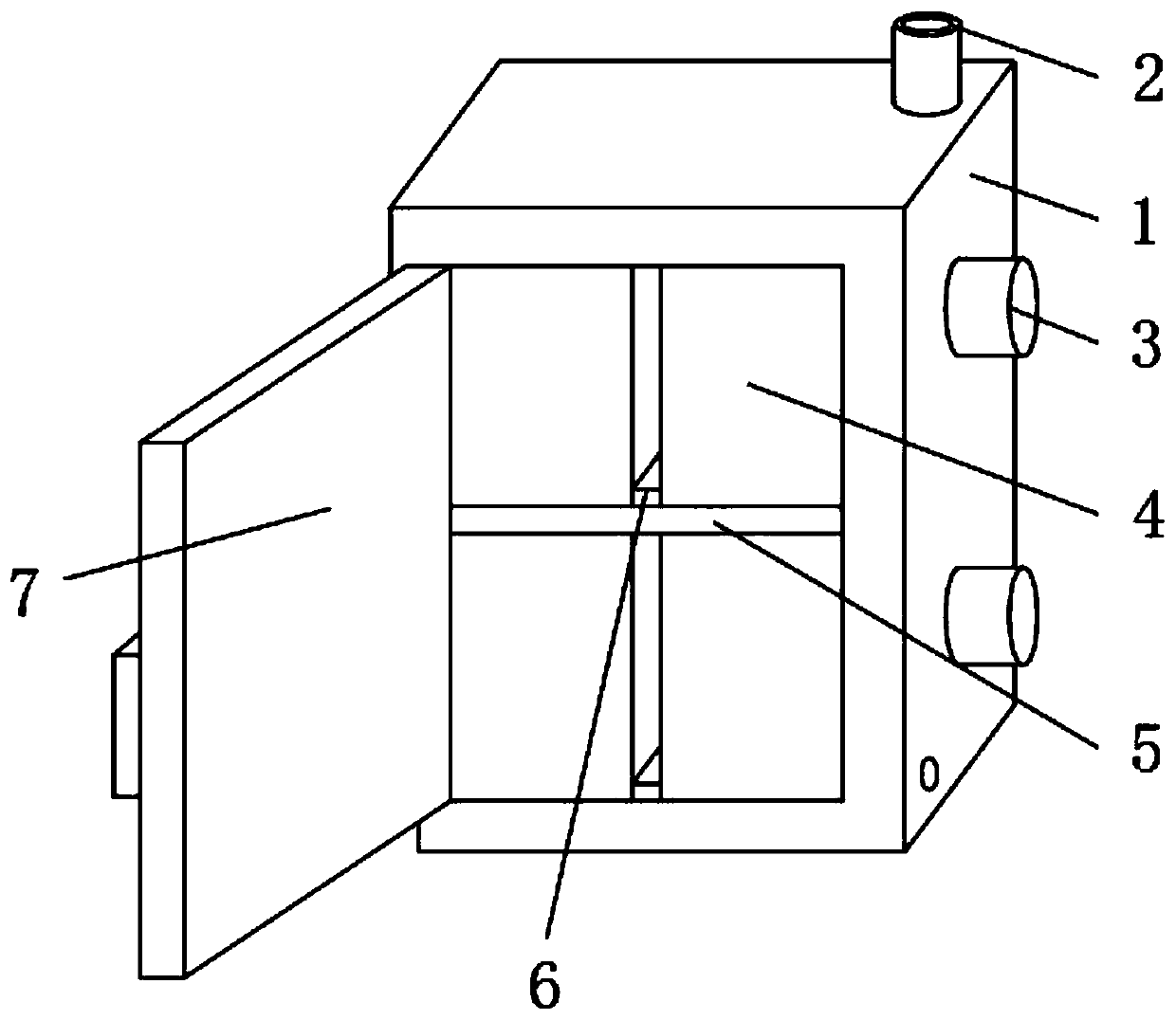

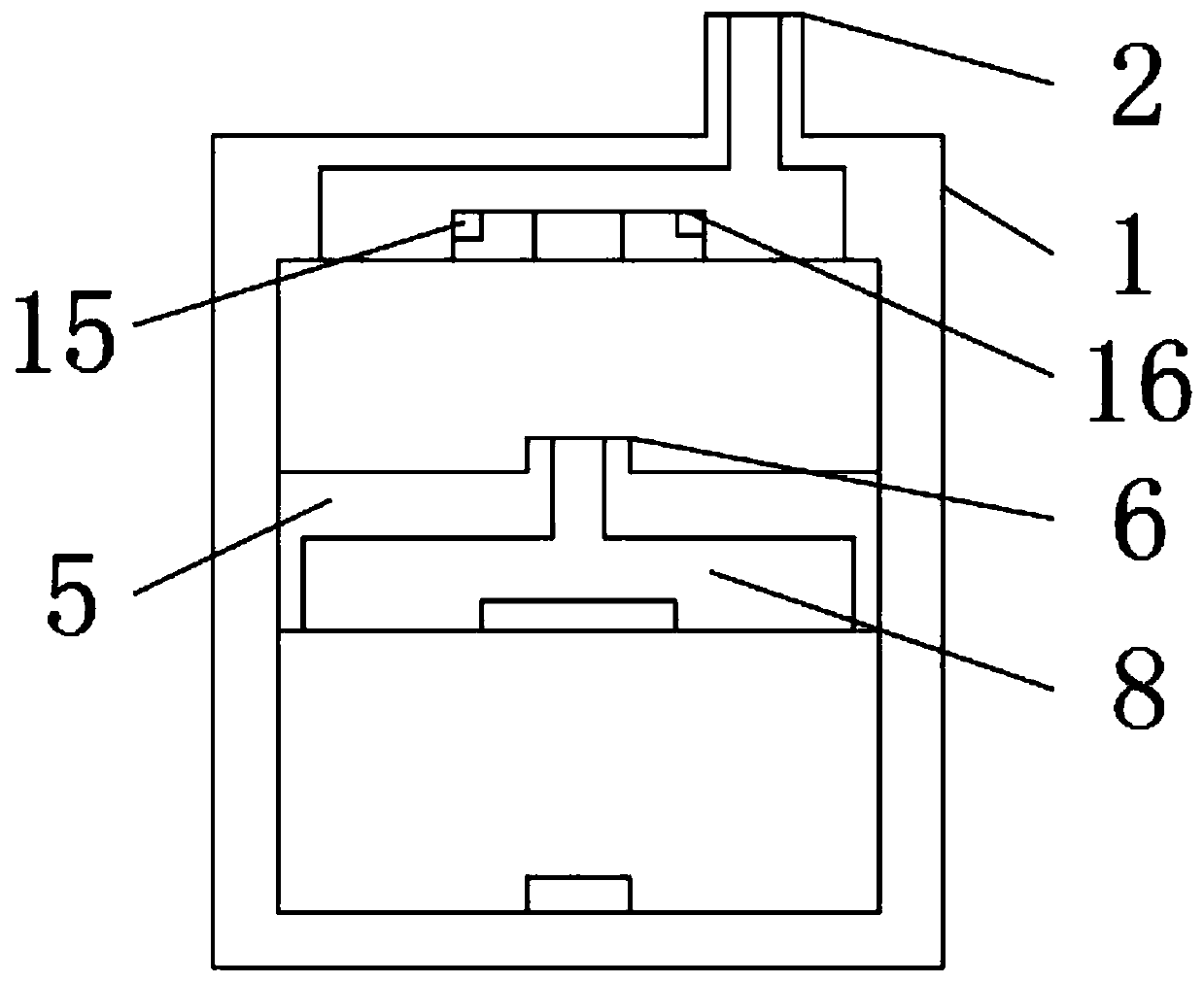

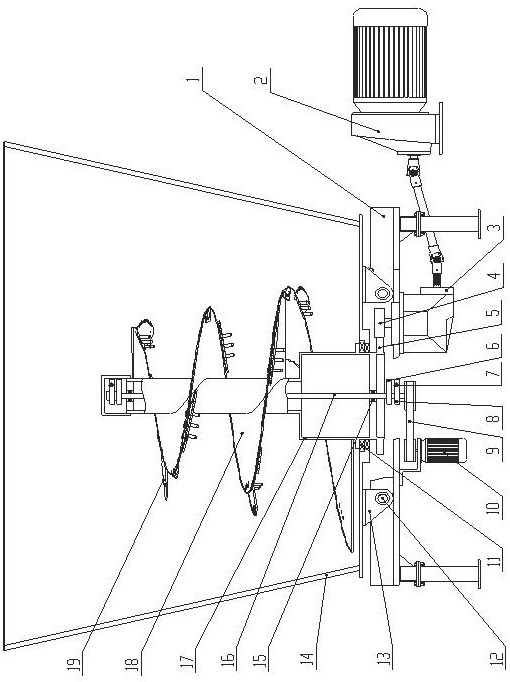

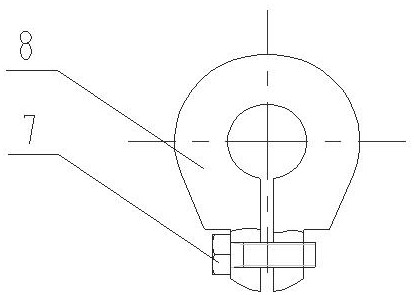

The invention discloses a culturing farm sewage treatment device with environmental protection function. The device includes a pedestal, the top of the pedestal is fixedly connected to a case, a partition plate is fixedly connected between two sides of the case inner wall, one side at the top of the partition plate is fixedly connected to a filter tank, the bottom of the filter tank inner wall is fixedly connected to a filter net, one side at the bottom of the case inner wall is fixedly connected to a disinfection tank, and one side at the top of the case inner wall is fixedly connected to a motor through a mounting rack. The invention relates to the technical field of culturing farm sewage treatment equipment. The culturing farm sewage treatment device with environmental protection function provided by the invention has no need for manual cleaning of the filtered filter residue and precipitated sludge by culture staff, saves a lot of working time for the culture staff, alleviates the workload of culture staff, and realizes fast and thorough automatic cleaning of filter residue and precipitated sludge, thus greatly facilitating the sewage treatment work of the culture staff.

Owner:阳信亿利源清真肉类有限公司

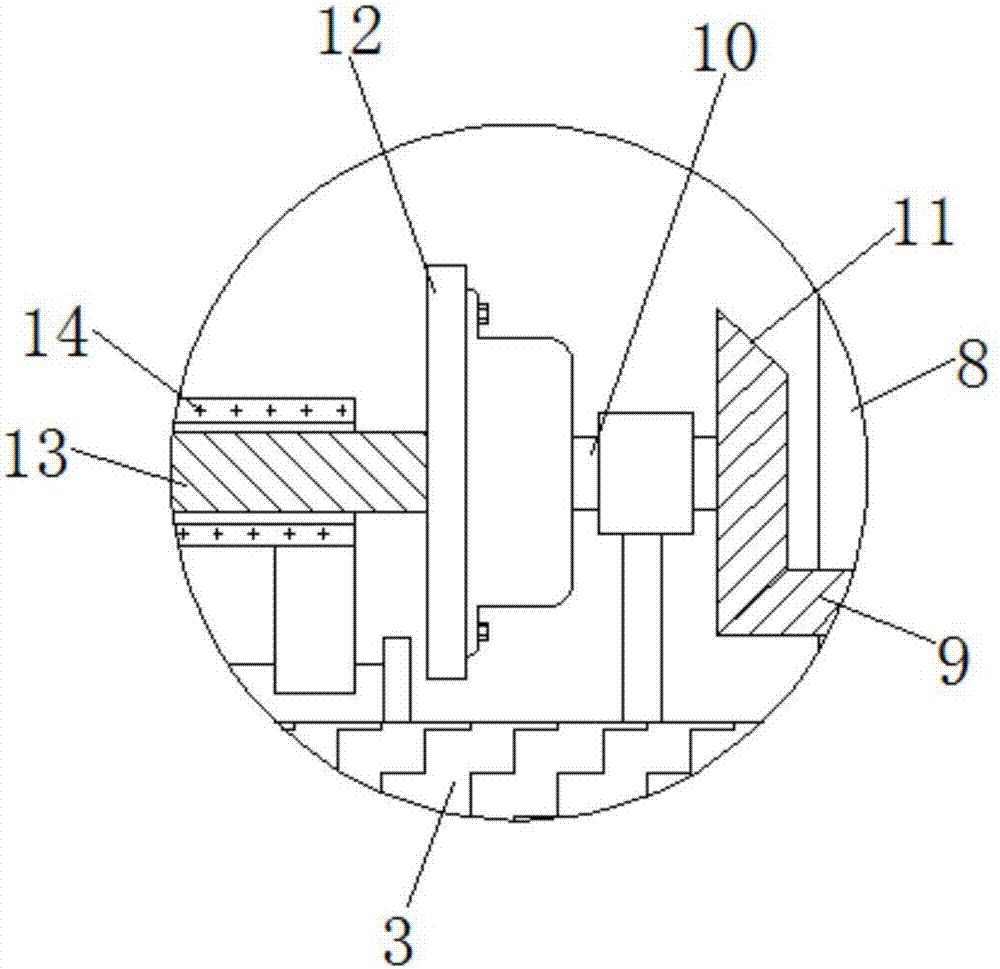

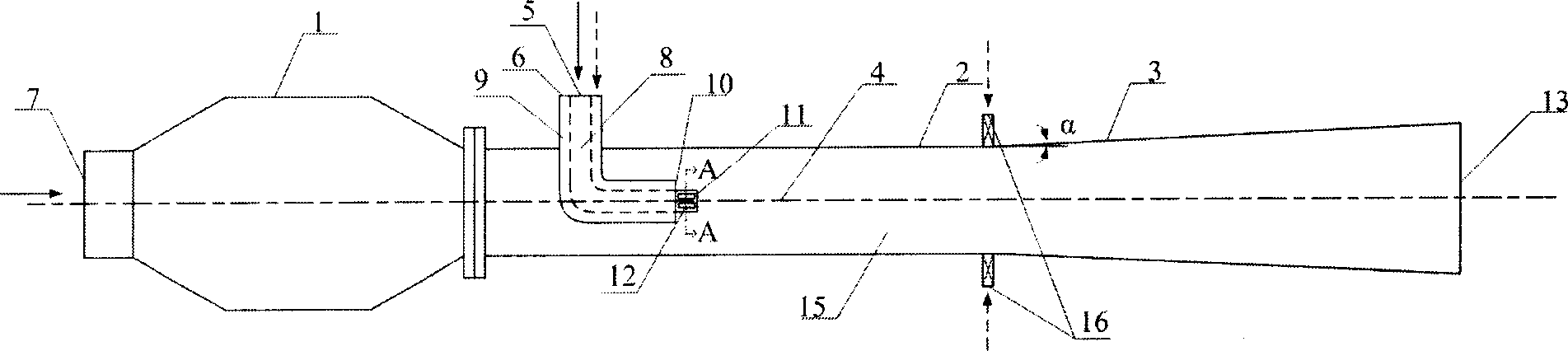

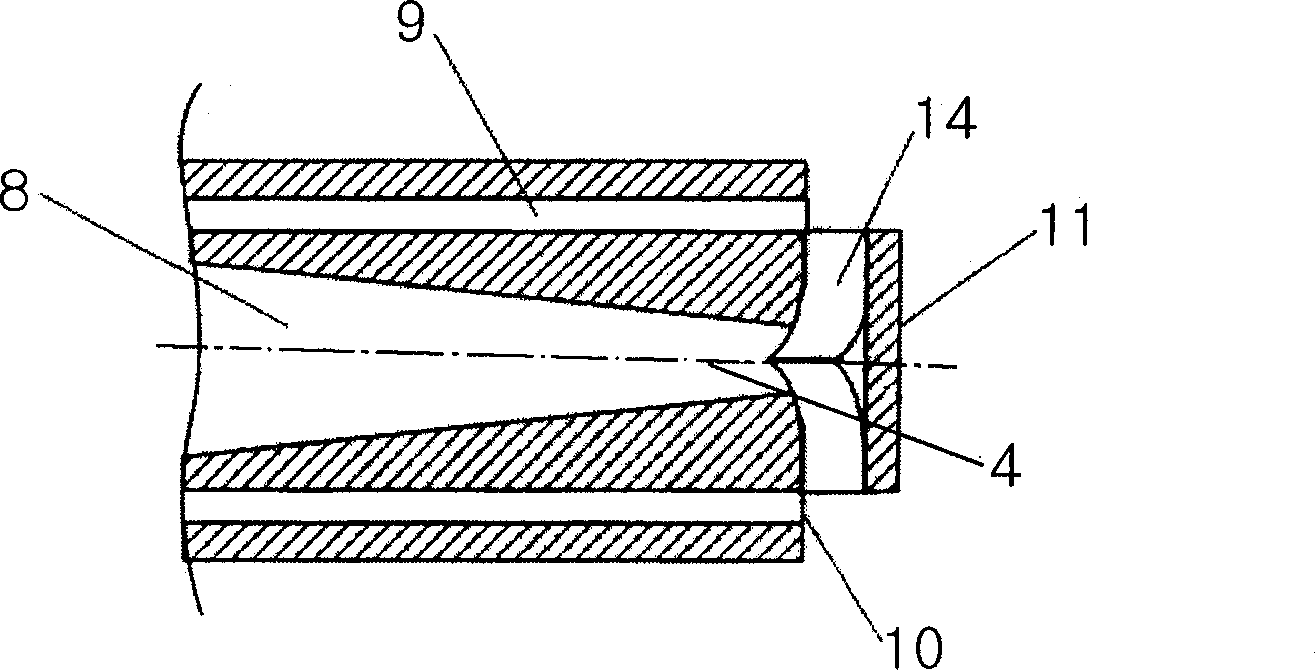

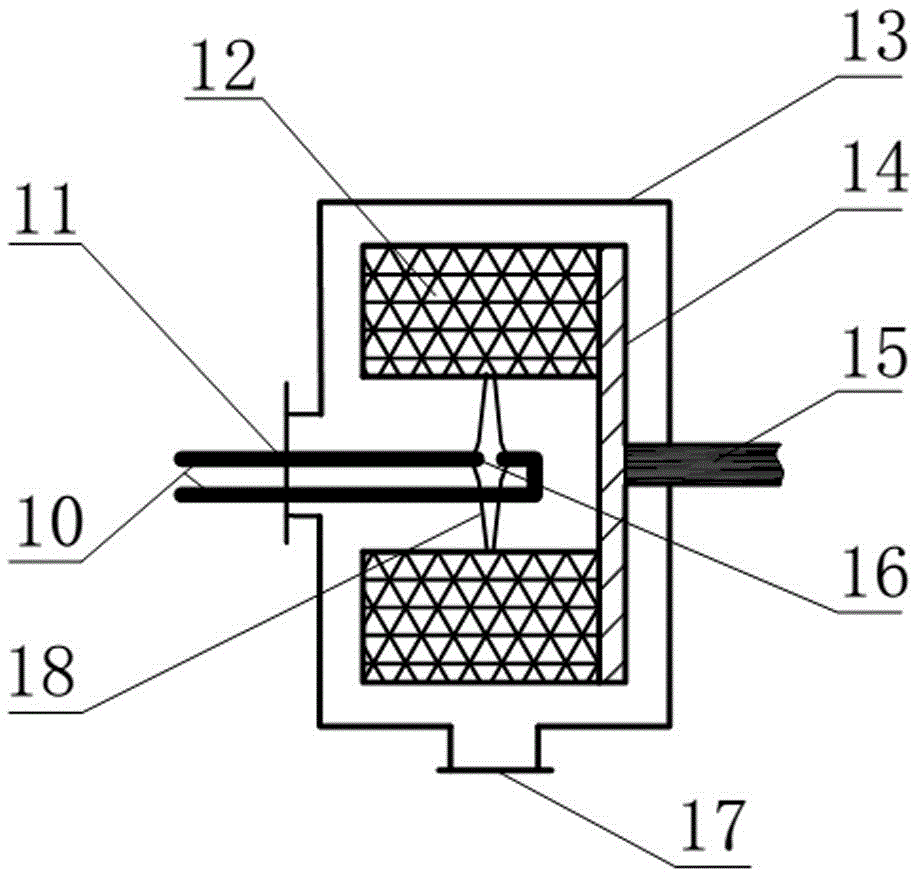

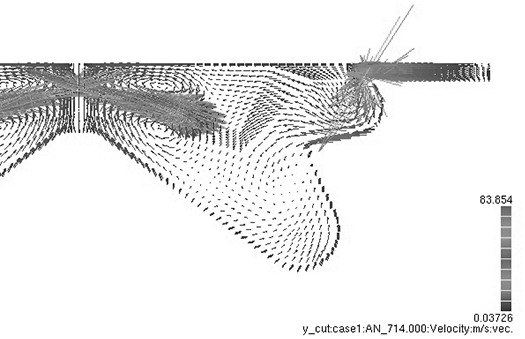

Oxidation reactor for preparing titanium white through chlorination process, and method

This invention discloses oxidation reactor and method for preparing TiO2 by chlorination. The reactor comprises a combustion chamber, a shell of reacting zone, and a shell of developing zone. A TiCl4 inflow pipe is inserted vertically into the shell of the reacting zone, and is bent 90 degrees to form an L-shaped pipe towards the shell of the developing zone. A nozzle is fixed on the end of the L-shaped pipe, and on the same axis of the shells. A cool air entrance is at the connecting part of the shells. The right side of the shell of the developing zone is connected with the flow exit. The tangential and radial TiCl4 cyclone jets can be formed at the axes to mix TiCl4 gas and hot oxygen and react fast and uniformly. The mixing effect can be ameliorated by controlling the relative momentum of the TiCl4 jet. Cool air is applied to blow the nozzle to prevent blockage. The cool air introduced from the connecting part of the shells is applied to control the rection, reduce and scar formation on the reactor wall, and adjust the particle size distribution.

Owner:TSINGHUA UNIV

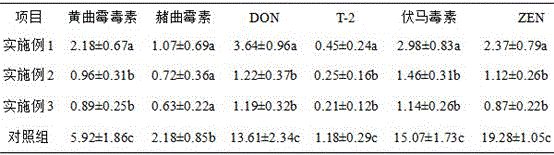

Mycotoxin toxin adsorbent of livestock and poultry feed and preparation process

InactiveCN105309777APromote digestion and absorptionImprove immunityAnimal feeding stuffAccessory food factorsMycotoxinVitamin C

The invention discloses a mycotoxin toxin adsorbent of a livestock and poultry feed and a preparation process. The mycotoxin toxin adsorbent is prepared from modified montmorillonite, yeast extract, lactobacillus acidophilus, lactobacillus amylovorus, sialic acid lactobacillus, streptococcus thermophilus, bacillus subtilis, honeysuckle extract, camellia oil extract, glycyrrhizic acid, echinacea extract, eugenol, cinnamic aldehyde, baicalin, vitamin C, vitamin E and zinc methionine. The mycotoxin toxin adsorbent provided by the invention can realize efficient adsorption on a plurality of types of common mycotoxin and the conversion rate of the feed is improved; meanwhile, the balance of intestinal flora of livestock and poultry can be promoted, and the added zinc methionine in the formula also has the effect of protecting livers; and the selected raw materials are natural and pollution-free and have a very good application value in feed and cultivation industries.

Owner:SHANDONG RUNMU BIOLOGICAL TECH CO LTD

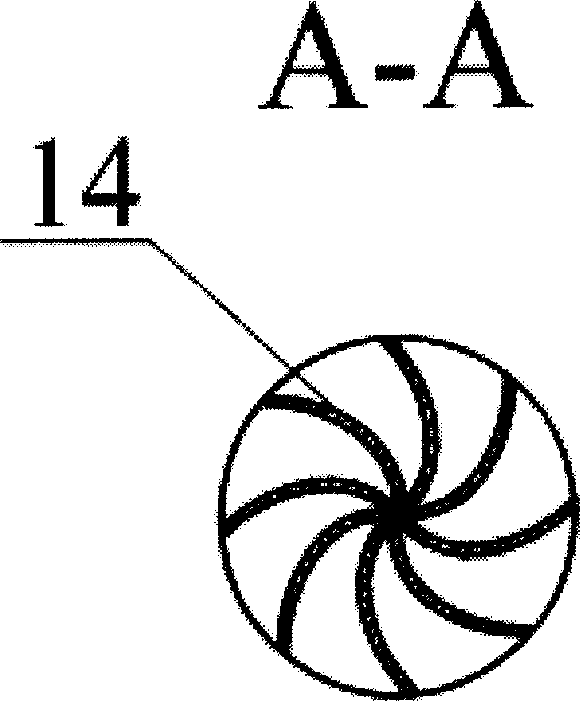

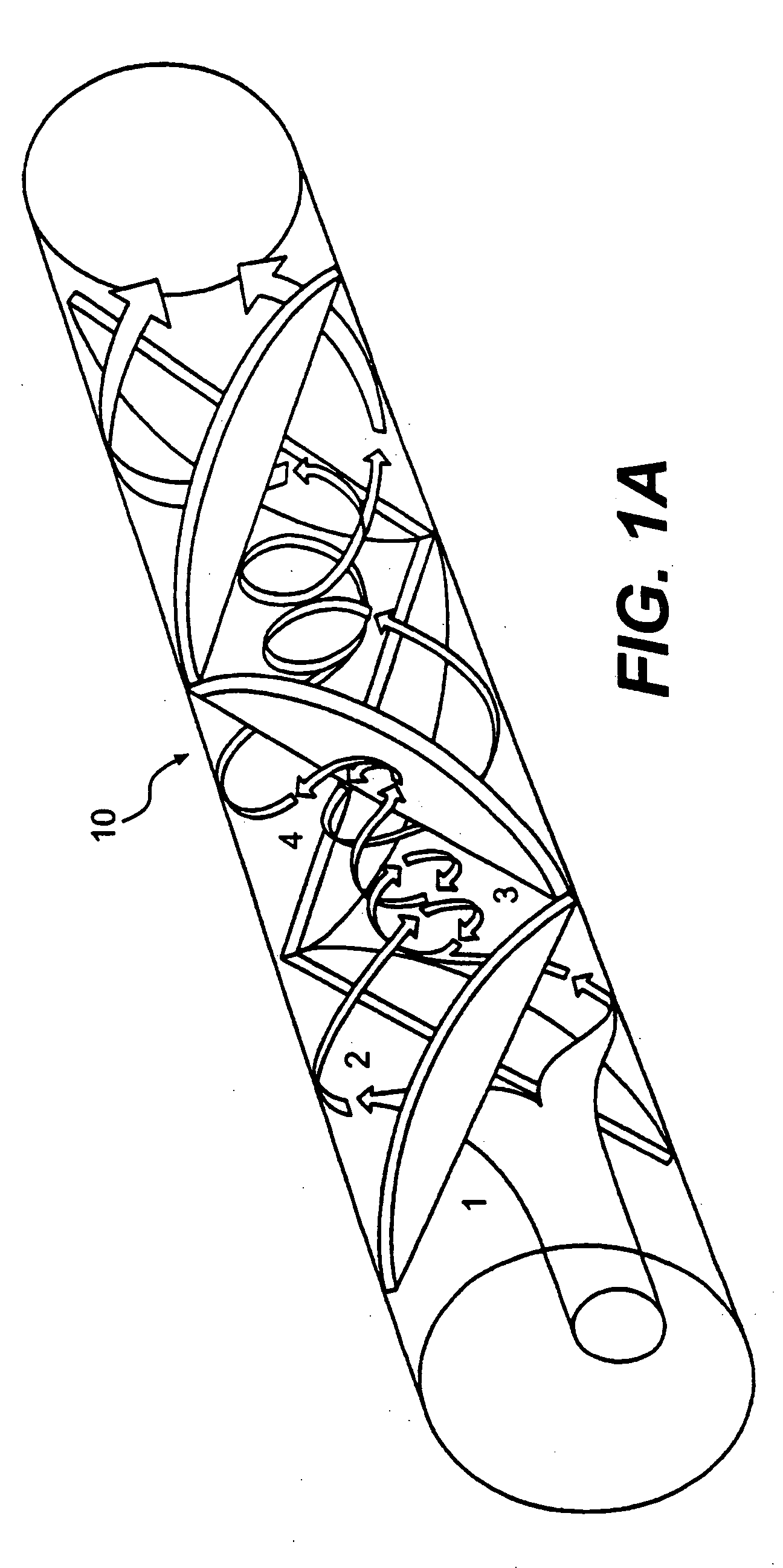

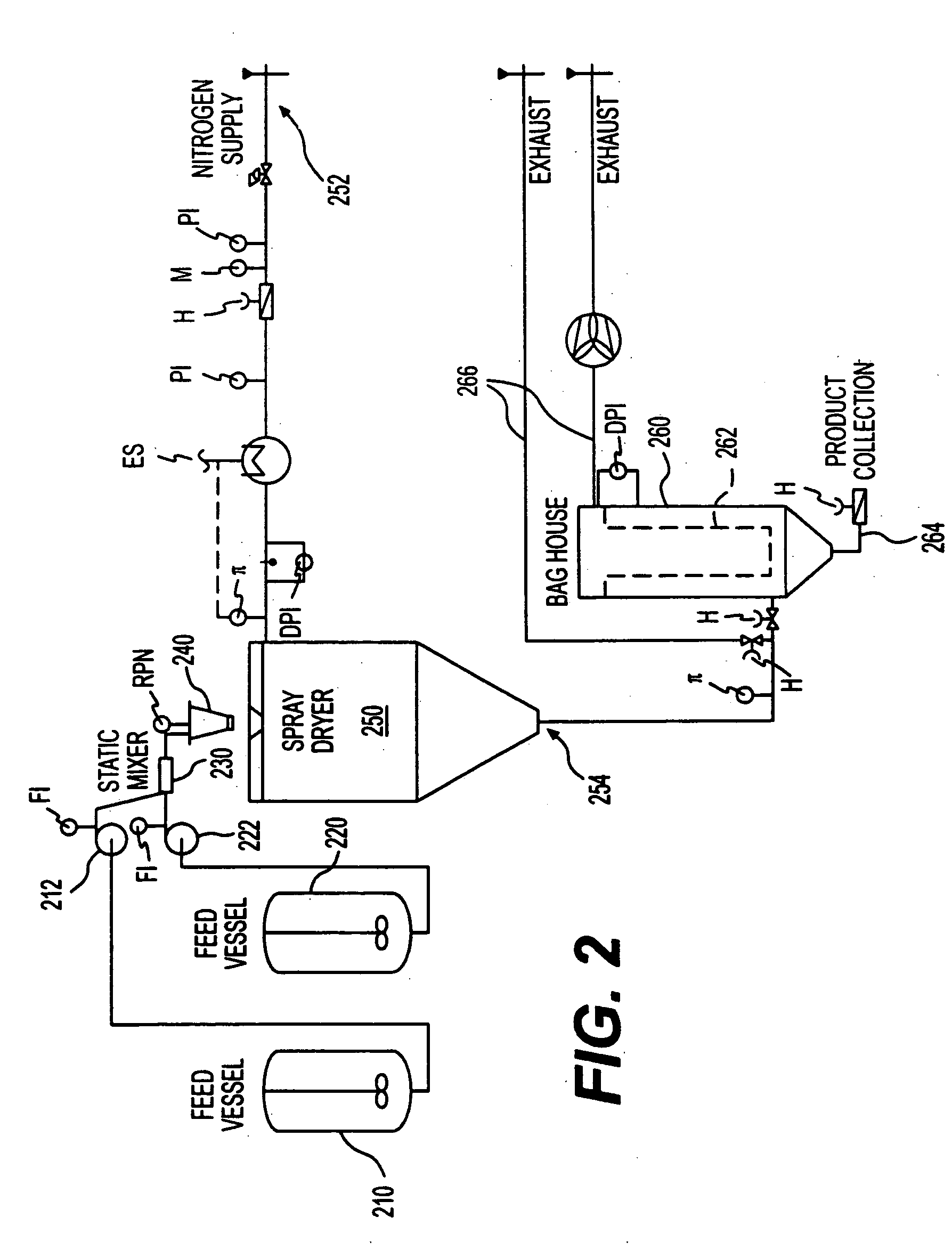

Method and apparatus for producing dry particles

InactiveUS20060039987A1Mix quickly and evenlyMinimize timeBiocideOrganic active ingredientsEngineeringParticle method

Method and apparatus for producing dry particles. Two liquid components are combined in a static mixer, atomized into droplets, and the droplets dried to form dry particles. Use of the static mixer enables incompatible liquid components to be rapidly and homogeneously combined. The present invention optimizes process conditions for increasing and controlling particle porosity. The present invention also allows for optimization of particle size in real-time during particle production.

Owner:CIVITAS THERAPEUTICS

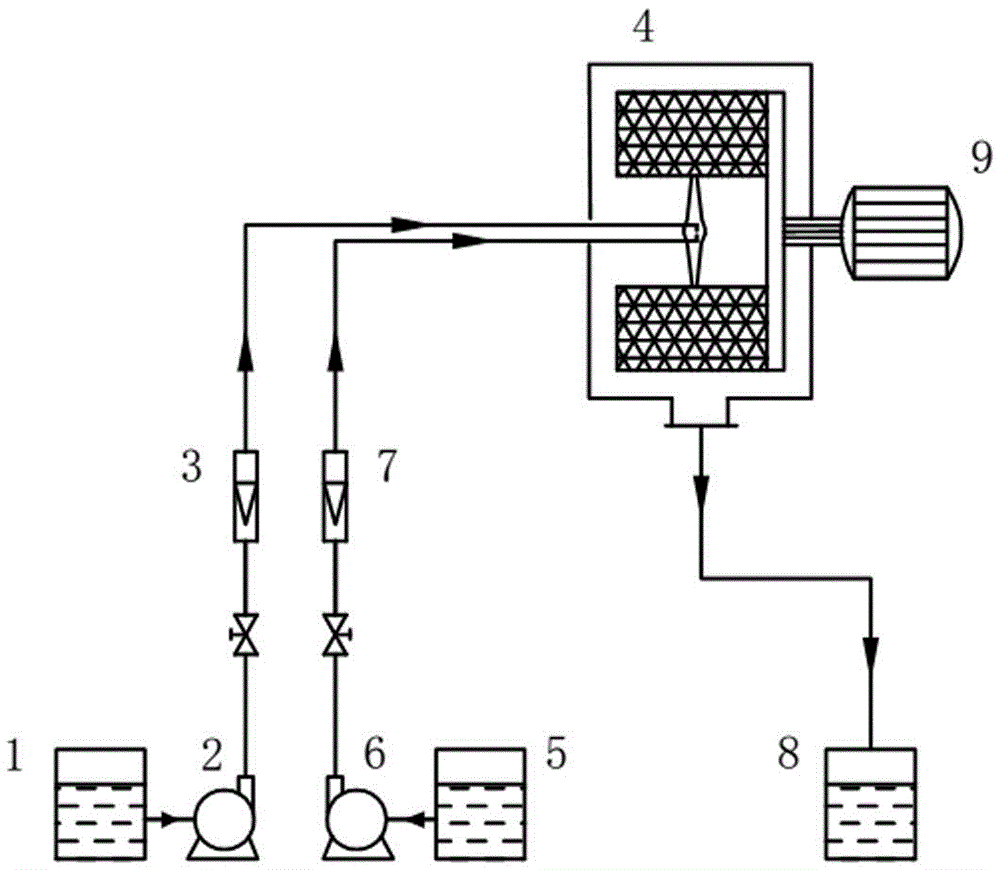

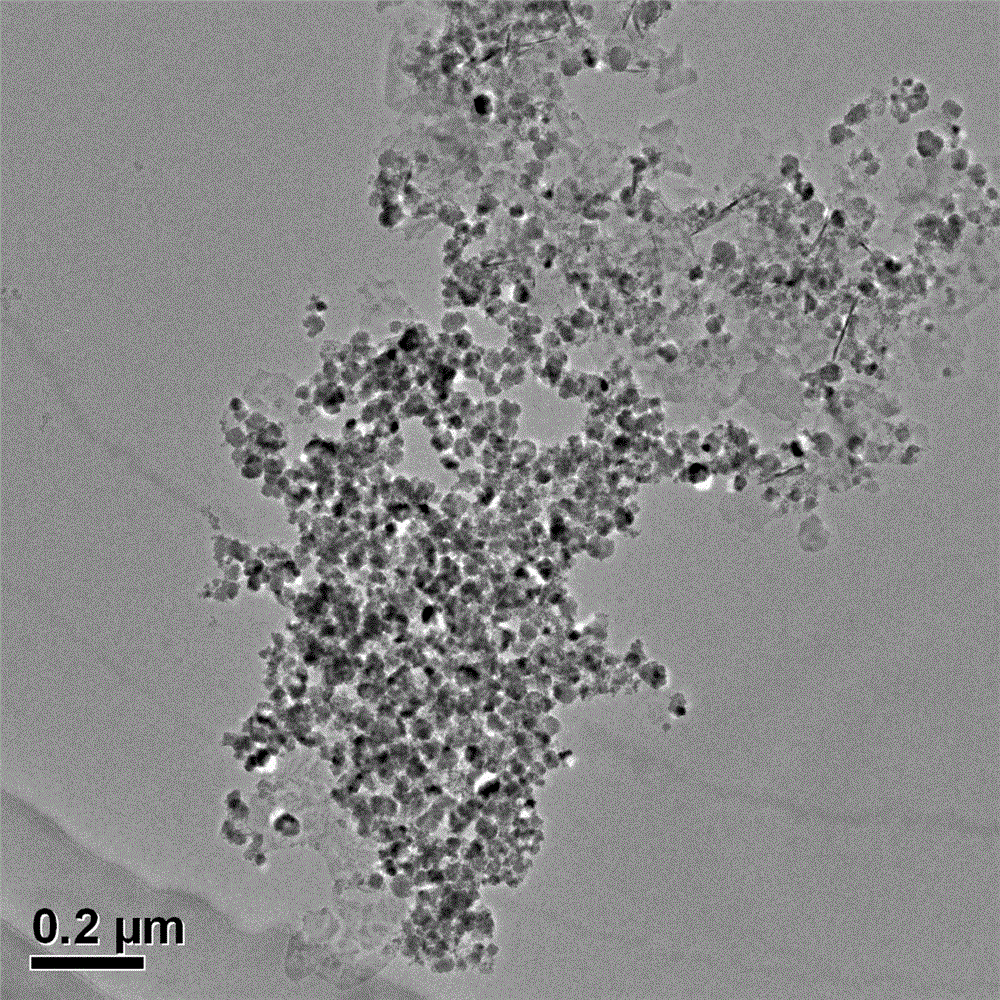

Method and device for supergravity on-line preparation of nano zero-valent iron and synchronous treatment on nitrobenzene wastewater

ActiveCN105858856AAvoid feedingEasy to prepareNanostructure manufactureWater contaminantsRetention timeFerrous salts

The invention belongs to the technical field of preparation of nano materials and nitrobenzene wastewater treatment, particularly relates to a method and a device for supergravity on-line preparation of nano zero-valent iron and synchronous treatment on nitrobenzene wastewater, and aims to solve the problems that conventional nano zero-valent iron is complex in preparation process, conditions are rigorous, the preparation process is not easy to amplify, nanoparticles are easy to agglomerate, oxidize and deactivate in the processes of drying, storage and use, and the like. The method comprises the following steps: enabling a ferrous salt containing nitrobenzene wastewater solution and a KBH4 or NaBH4 aqueous solution to react in an impinging stream device for collision, feeding into a rotating packed bed for mixing and reacting, and implementing preparation of nano zero-valent iron and treatment on the nitrobenzene wastewater by using the nano zero-valent iron simultaneously. The method and the device have the advantages that the situation that the nano zero-valent iron can be reacted with nitrobenzene only after being completely developed into large particles in a conventional method is avoided, the nano zero-valent iron can be relatively sufficiently utilized, the amount can be remarkably reduced, multiple steps of reaction is reduced to one step, the reaction can be implemented rapidly, the retention time is shortened, continuous operation can be achieved, and the method and the device are applicable to nitrobenzene wastewater treatment which is large in treatment volume and heavy in treatment task.

Owner:ZHONGBEI UNIV

Combustion device for rotational flow mixed combustion by spraying air above uniformly distributed gas jets in loop

The invention relates to a combustion device for rotational flow mixed combustion by spraying air above uniformly distributed gas jets in a loop. The problems that a combustion device has a complex structure and requires a larger combustion space, gas mixing is non-uniform, the combustion is incomplete, the environment is polluted and the energy is wasted are effectively solved. The upper part inside a wall body of a combustion chamber is provided with a rotational flow and backflow combustion chamber; a gas inlet pipe and an air inlet pipe are arranged on a cylinder; the gas inlet pipe is connected with a gas distributing loop; the gas jets on the upper part of the gas distributing loop are connected with an airflow mixing loop; the airflow mixing loop is positioned at the bottom of the rotational flow and backflow combustion chamber; the air inlet pipe is connected with the airflow mixing loop through an air inlet jet; a guide baffle is arranged in the air inlet jet; an airflow outlet is formed in the wall body of the combustion chamber or in the top of a spherical arch; and the lower part of the rotational flow and backflow combustion chamber is provided with an outlet section of the combustion device. Key problems of unstable combustion, low combustion intensity, low combustion temperature and the like of low-heat value gas are effectively solved, and the combustion device is low in manufacturing cost and has a simple structure.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

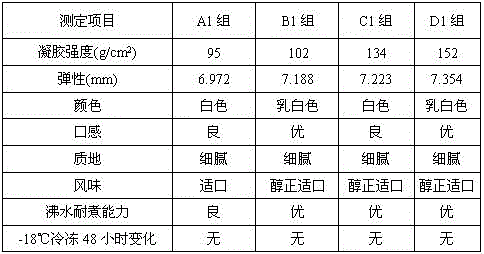

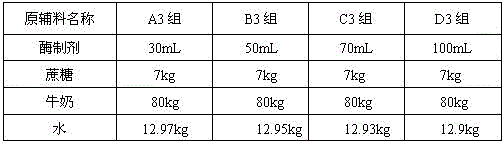

Application of liquid enzyme preparation in improvement of food texture

InactiveCN105852053AReduce pollutionImproved Gel TestFood scienceSoybean productGlutamine transaminase

The invention relates to an application of a liquid enzyme preparation in improvement of food texture. The liquid enzyme preparation is glutamine transaminase. The liquid enzyme preparation has the advantages that the food texture can be effectively improved; after proofing by the testing results of protein gel property, compared with the powder enzyme preparation, the water-retaining property and gel property on the protein are better, the dissolving speed is quicker, and the distribution is more uniform; the dust pollution likewise caused by the powder enzyme preparation can be avoided, the storage is convenient, and more safety and health in use are realized; when the liquid enzyme preparation is applied to soybean products, meat products, milk products, aquaculture products and flour products, the product quality is obviously improved, the product texture is improved, the production processing time is effectively shortened, and the production cost is reduced.

Owner:SHANGHAI KINRY FOOD INGREDIENTS +1

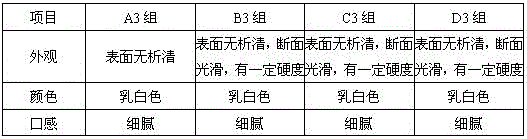

Method for detecting glucose based on prussian blue membrane biological electrode

InactiveCN107271514AMix quickly and evenlyDetection concentration is accurateMaterial analysis by electric/magnetic meansD-GlucosePrussian blue

The invention discloses a method for detecting glucose based on a prussian blue membrane biological electrode. The method comprises the following concrete steps: SS1) cleaning a sample tank; SS2) activating the enzyme reacting with the glucose on the prussian blue membrane biological electrode and cleaning the sample tank; SS3) performing high spot calibration and cleaning the sample tank; SS4) adding quantitative glucose solution in known concentration into the sample tank, using a detection circuit for detecting, judging as successful high spot calibration if the detected concentration scope of the glucose solution is within 95%-105% of the known concentration after the current value of the detection circuit is stable, cleaning the sample tank according to the process in the step SS1) and skipping to the step SS6, and if not, judging if the detection times exceeds three, if not, skipping to the step SS3 and replacing the prussian blue membrane biological electrode and cleaning the sample tank; SS5) performing low spot calibration; and SS6) adding quantitative unknown glucose solution into the sample tank and regarding a display concentration of the detection circuit as the concentration of the to-be-detected glucose solution after the current value of the detection circuit is stable.

Owner:NANJING UNIV OF TECH

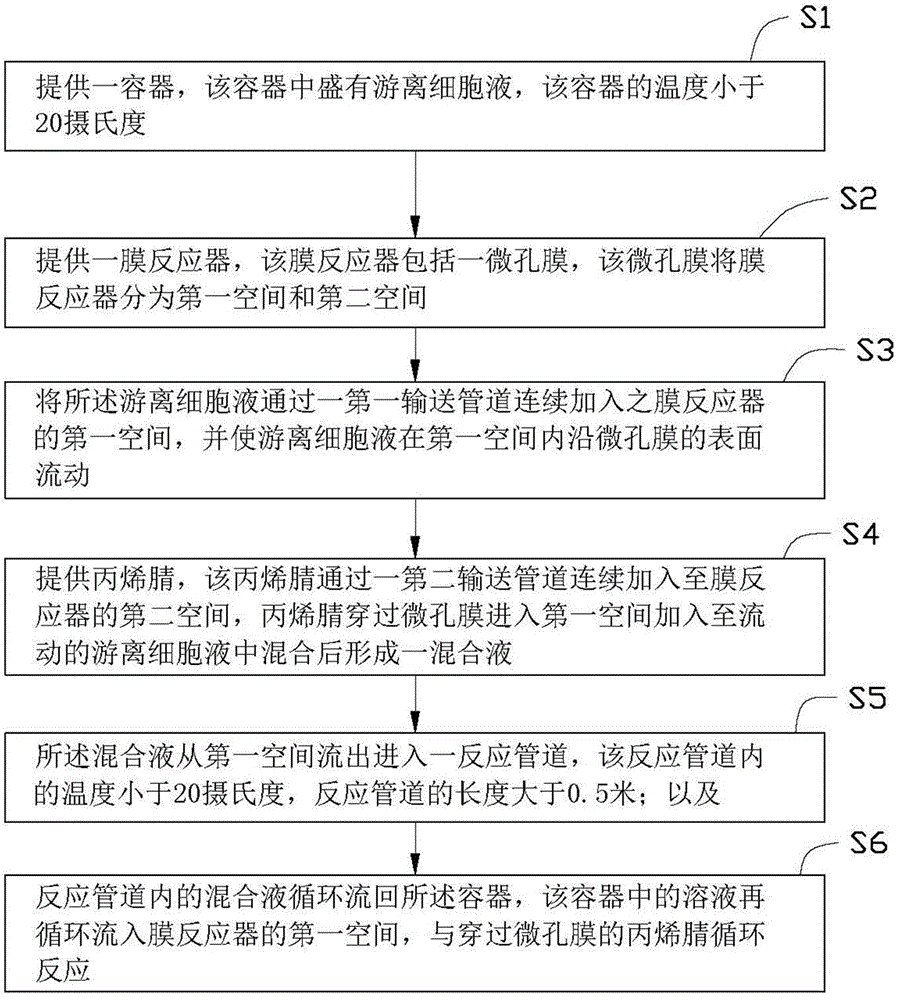

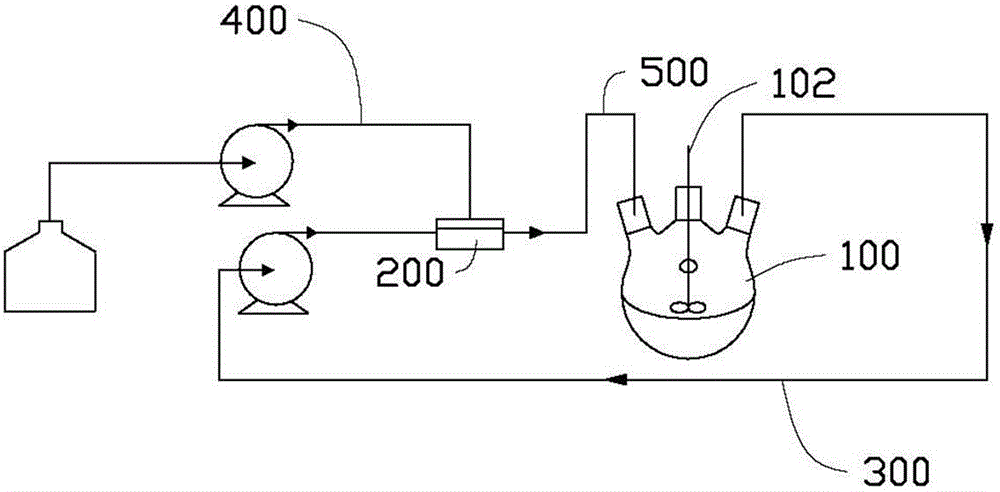

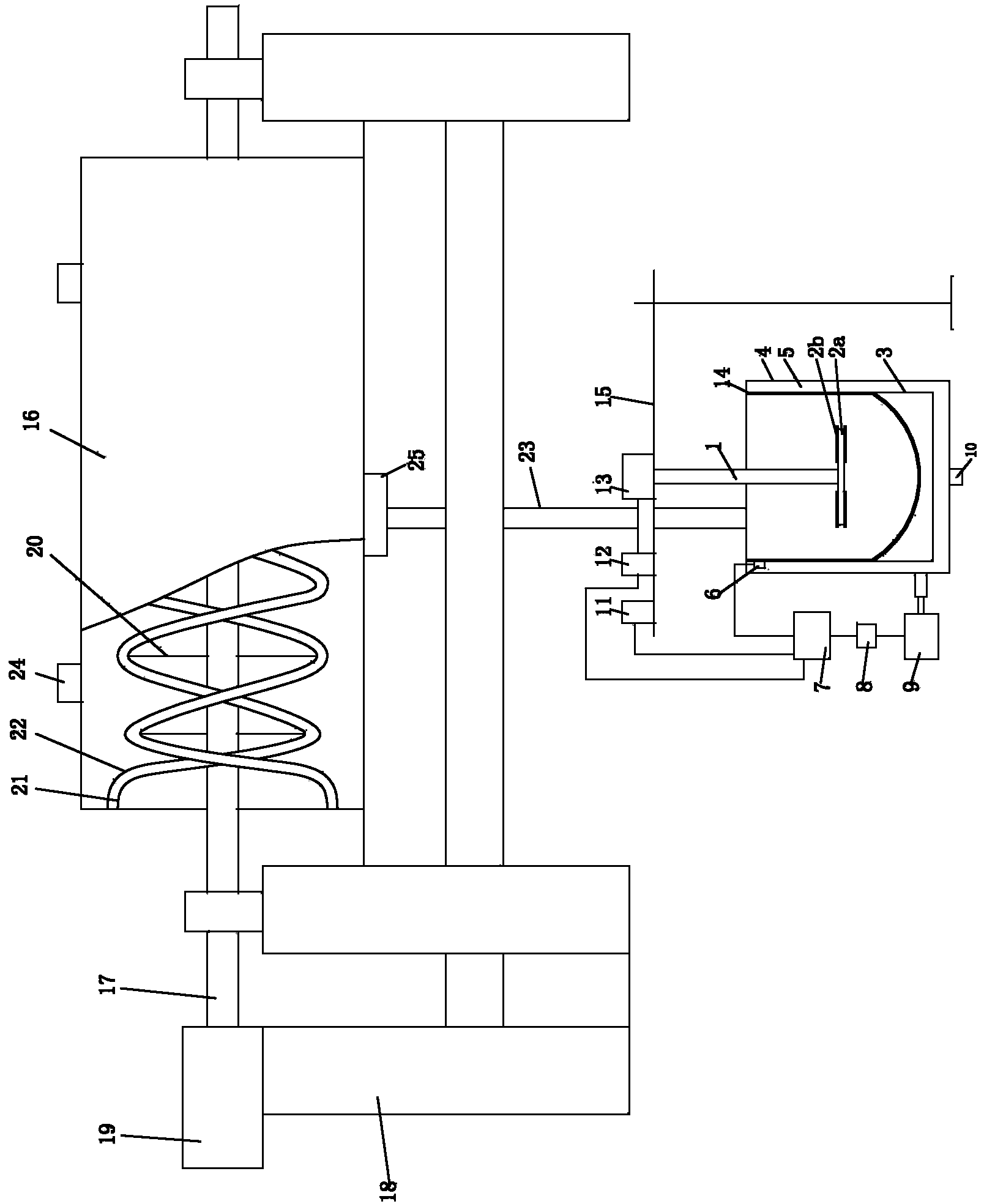

Method of synthesizing acrylamide by using acrylonitrile hydratase

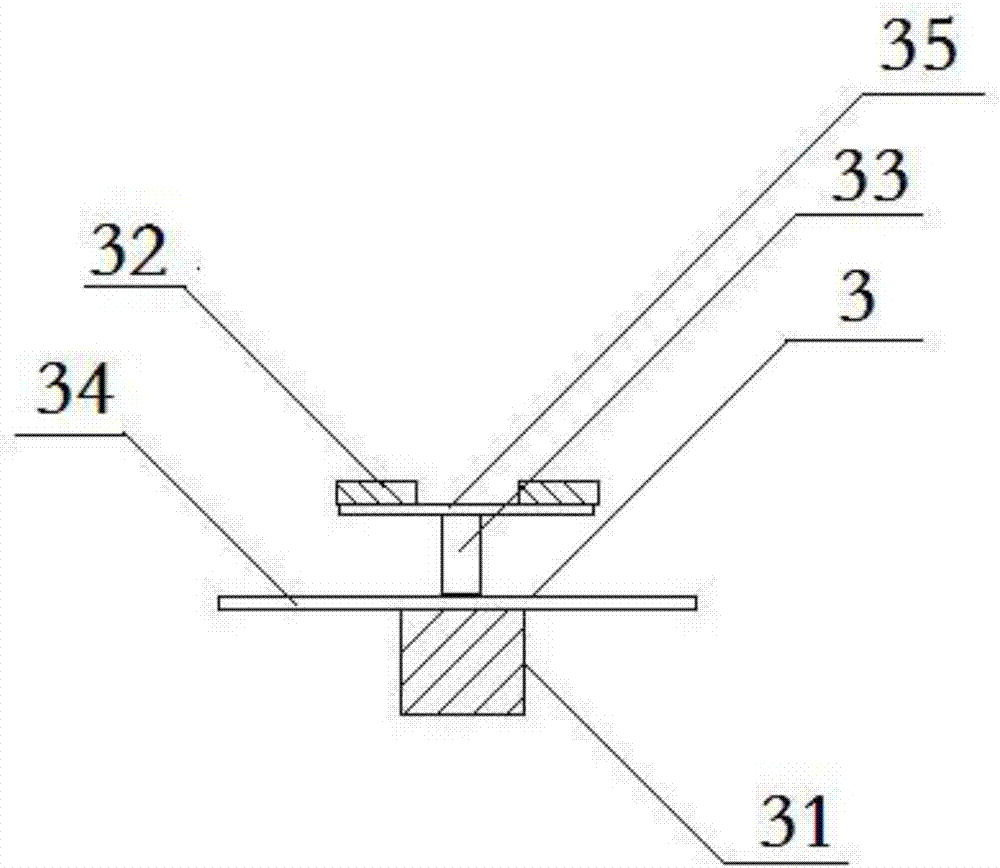

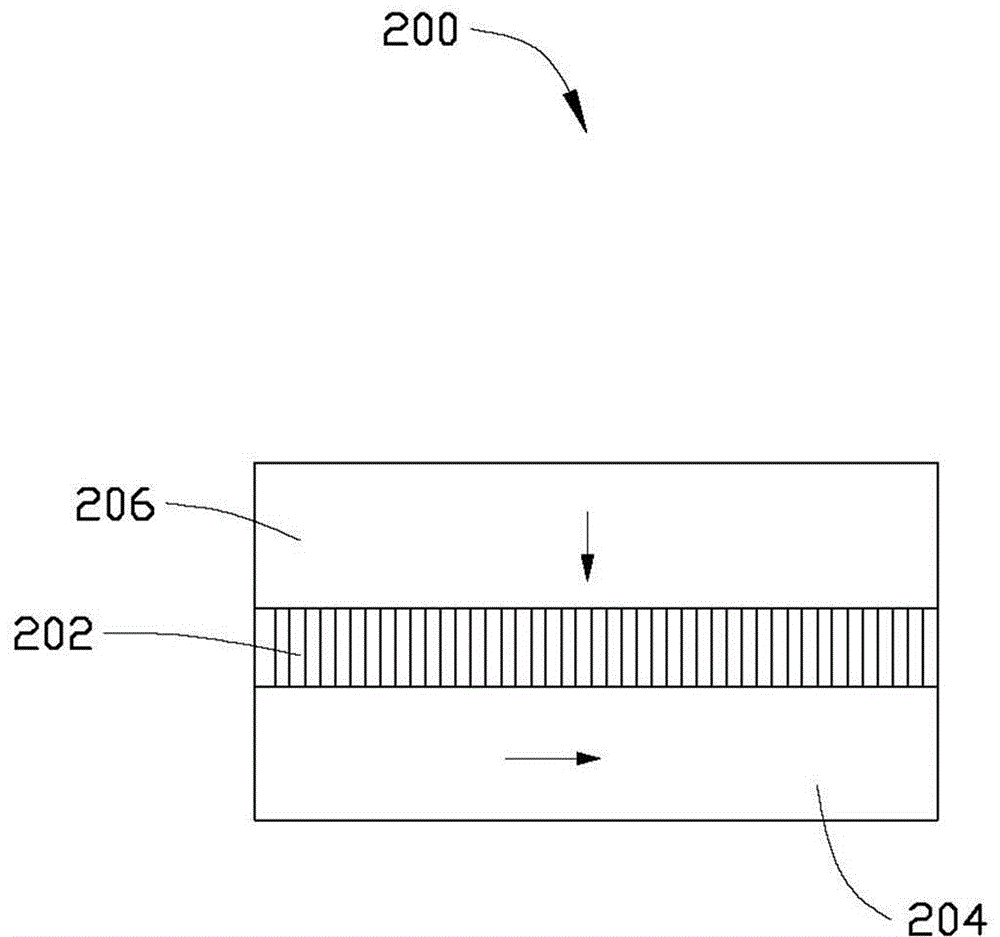

ActiveCN104059948AImprove heat transfer performanceIncrease the apparent reaction rateBioreactor/fermenter combinationsBiological substance pretreatmentsAcrylonitrileMembrane reactor

The invention relates to a method of synthesizing acrylamide by using acrylonitrile hydratase. The method comprises the following steps: providing a container which contains a free cell solution; providing a film reactor which comprises a microporous film dividing the film reactor into a first chamber and a second chamber; continuously adding the free cell solution to the first chamber of the film reactor through a first conveying pipeline, wherein the free cell solution flows along the surface of the microporous film in the first chamber; providing acrylonitrile which is continuously added into the second chamber of the film reactor through a second conveying pipeline, wherein acrylonitrile penetrates through the microporous film and enters the first chamber to be added into the flowing free cell solution to be mixed to form a mixed solution, and the mixed solution flows out of the second chamber and enters a reaction pipeline; circularly regurgitating the mixed solution in the reaction pipeline to the container, wherein the solution in the container then circularly flows into the first chamber of the film reactor to circularly react with acrylonitrile penetrating through the microporous film.

Owner:TSINGHUA UNIV

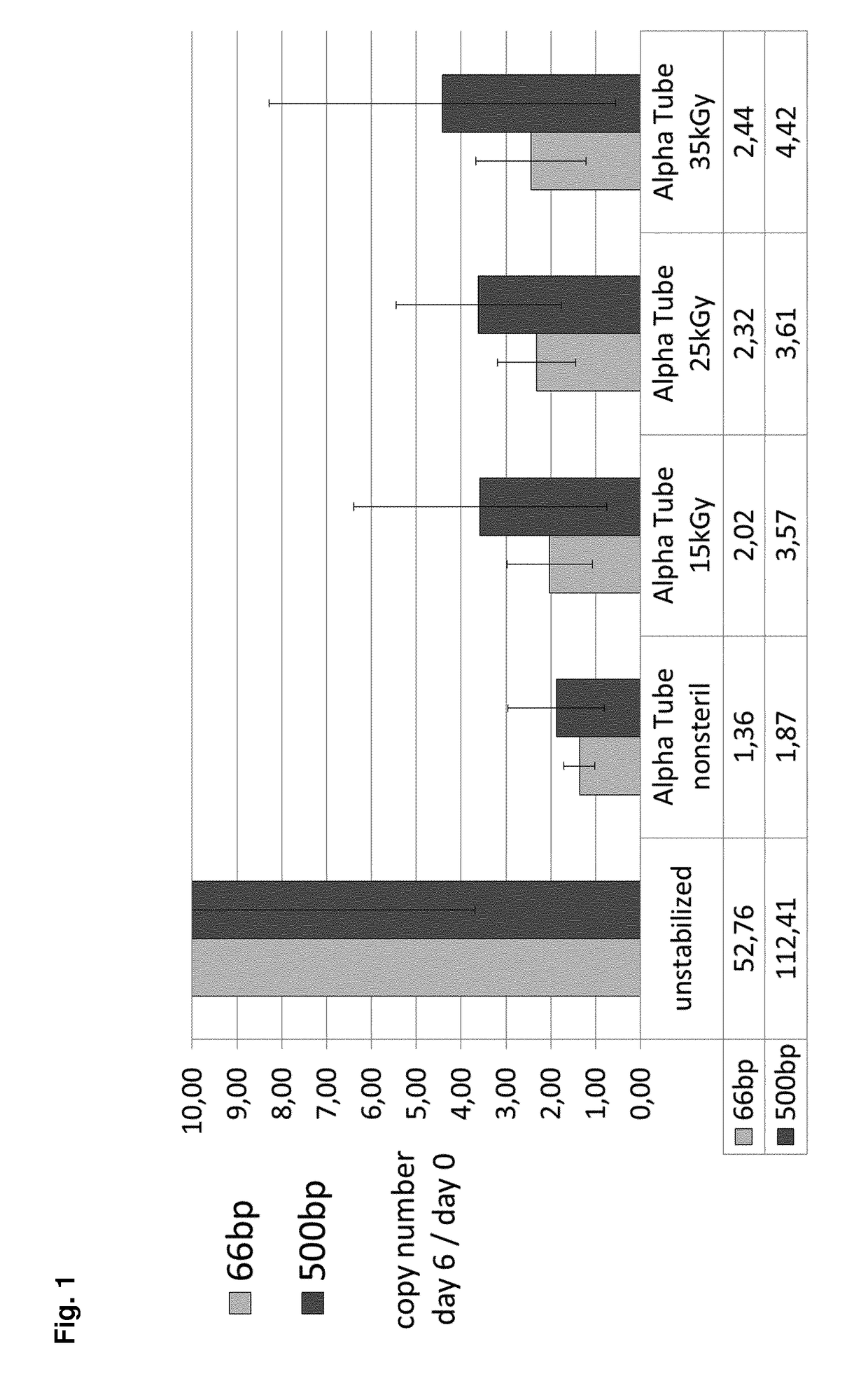

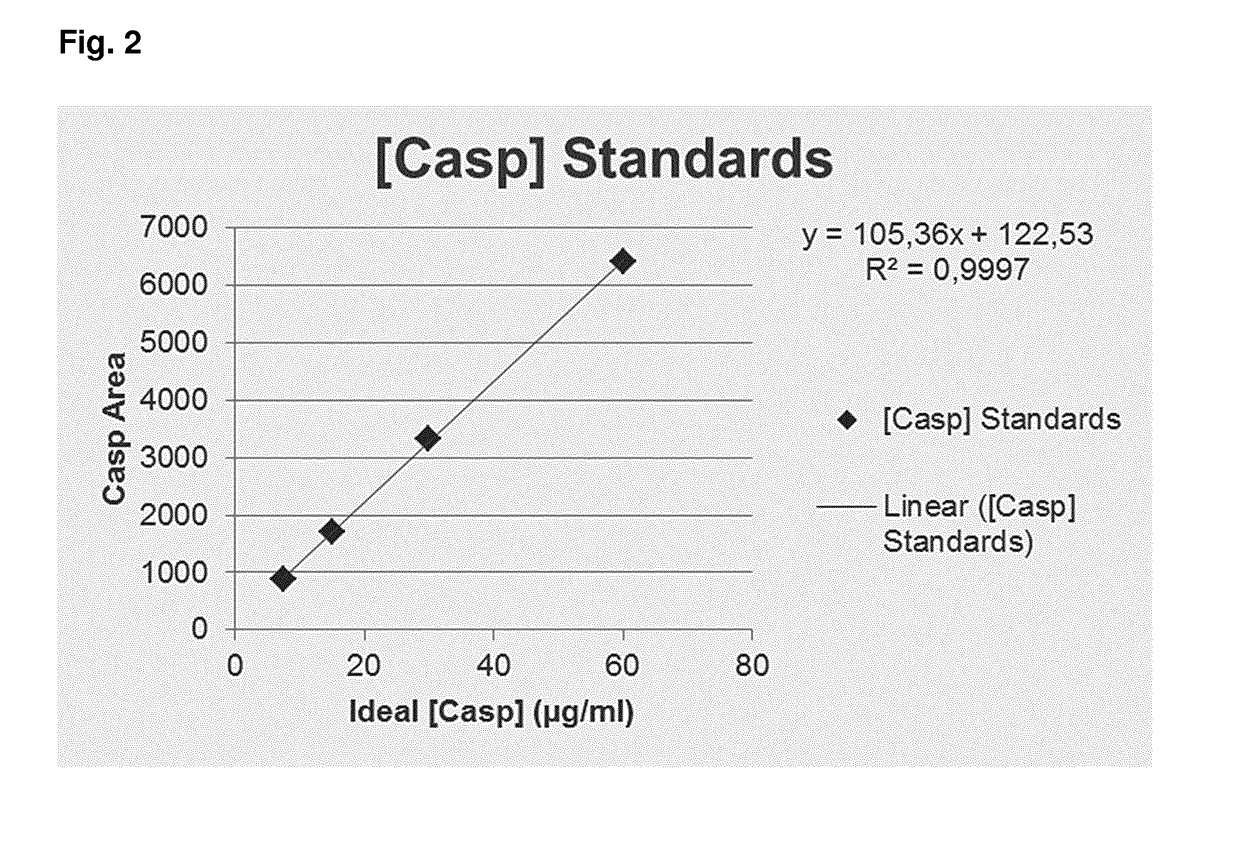

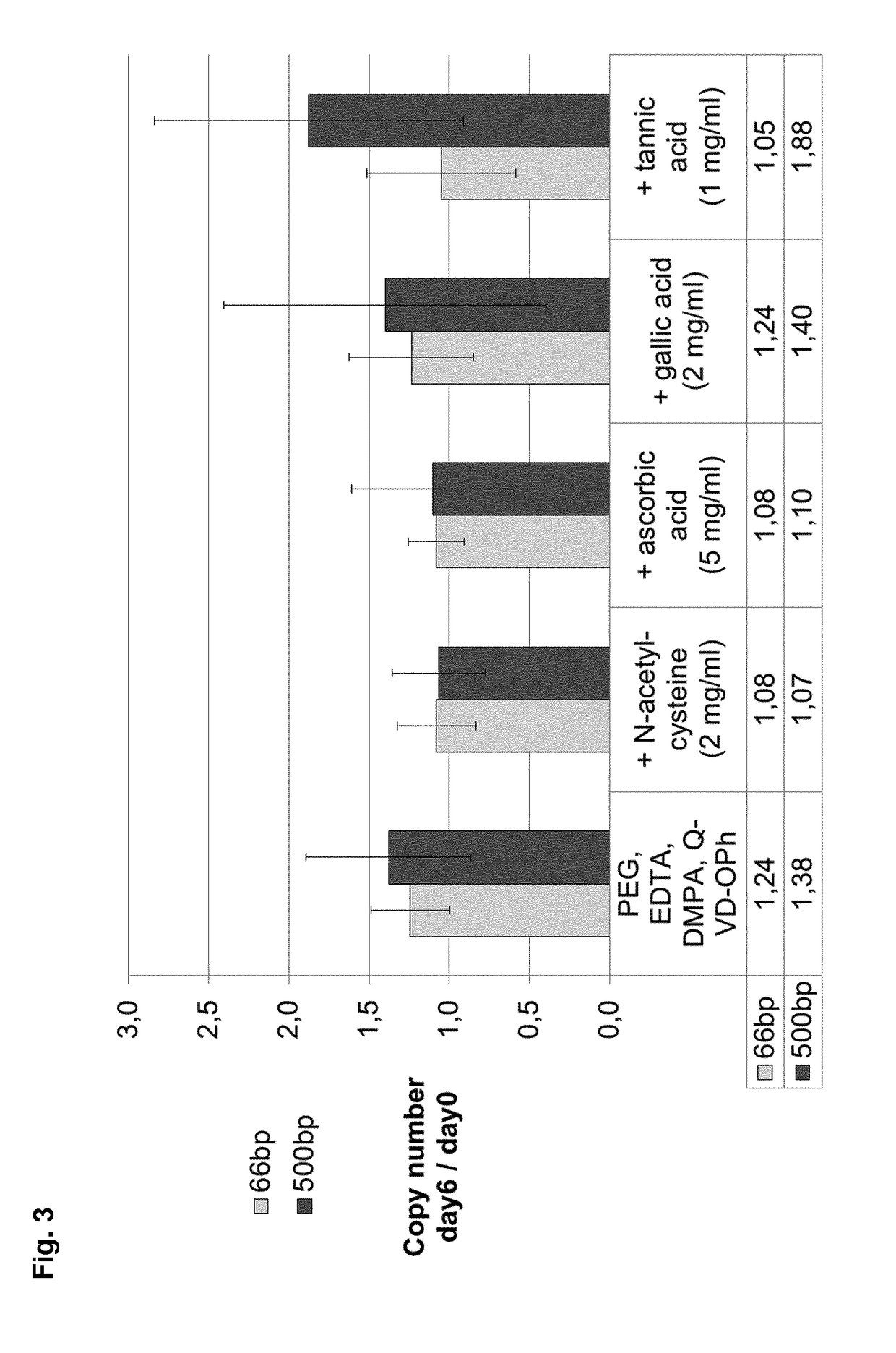

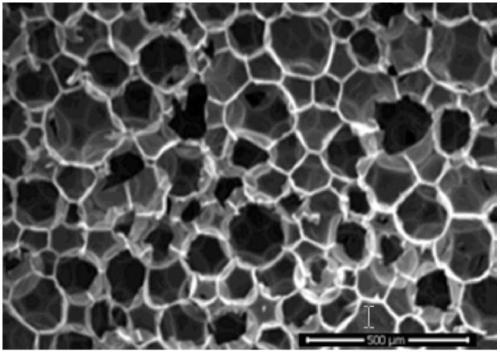

Method of preparing sterilized compositions for stabilization of extracellular nucleic acids

ActiveUS20180312903A1Stable maintenanceInterfere with activityMicrobiological testing/measurementDNA preparationIntracellularCell Surface Proteins

The present invention provides a method for preparing a sterilized composition suitable for stabilizing an extracellular nucleic acid population of a biological sample. Also provided are sterilizable compositions, wherein the compositions in sterilized form are suitable for stabilizing an extracellular nucleic acid population of a biological sample. Further useful methods, devices, kits and uses are also provided. Further sterilisable and sterilized compositions described herein are also suitable to stabilize intracellular nucleic acids (e.g. intracellular DNA such as genomic DNA and / or intracellular RNA) and cell characteristics, such as e.g. cell surface proteins and / or the cell morphology.

Owner:QIAGEN GMBH

Air disinfection gasification method and air disinfection gasification apparatus

ActiveCN104826154AAchieving Green SecurityImprove content accuracyGaseous substancesHigh concentrationChlorine dioxide

A purpose of the present invention is to provide an air disinfection gasification method and an air disinfection gasification apparatus. The method comprises: placing chlorine dioxide matrix tablets and a proper amount of water into a plurality of sequentially-communicated closed reaction pools; carrying out aeration on the first reaction pool by using an aeration pump; adopting the mixed gas comprising the chlorine dioxide gas generated in the previous reaction pool and a small amount of chlorine gas as the aeration gas, and introducing the aeration gas into the communicated subsequent reaction pool; and in the last reaction pool, obtaining the high-purity chlorine dioxide disinfection gas. With the method and the apparatus of the present invention, the high-concentration air disinfection gas can be generates, the disinfection efficiency is high, and the concentration of the chlorine dioxide gas released into the air is uniform.

Owner:SHANXI YASEN INDAL

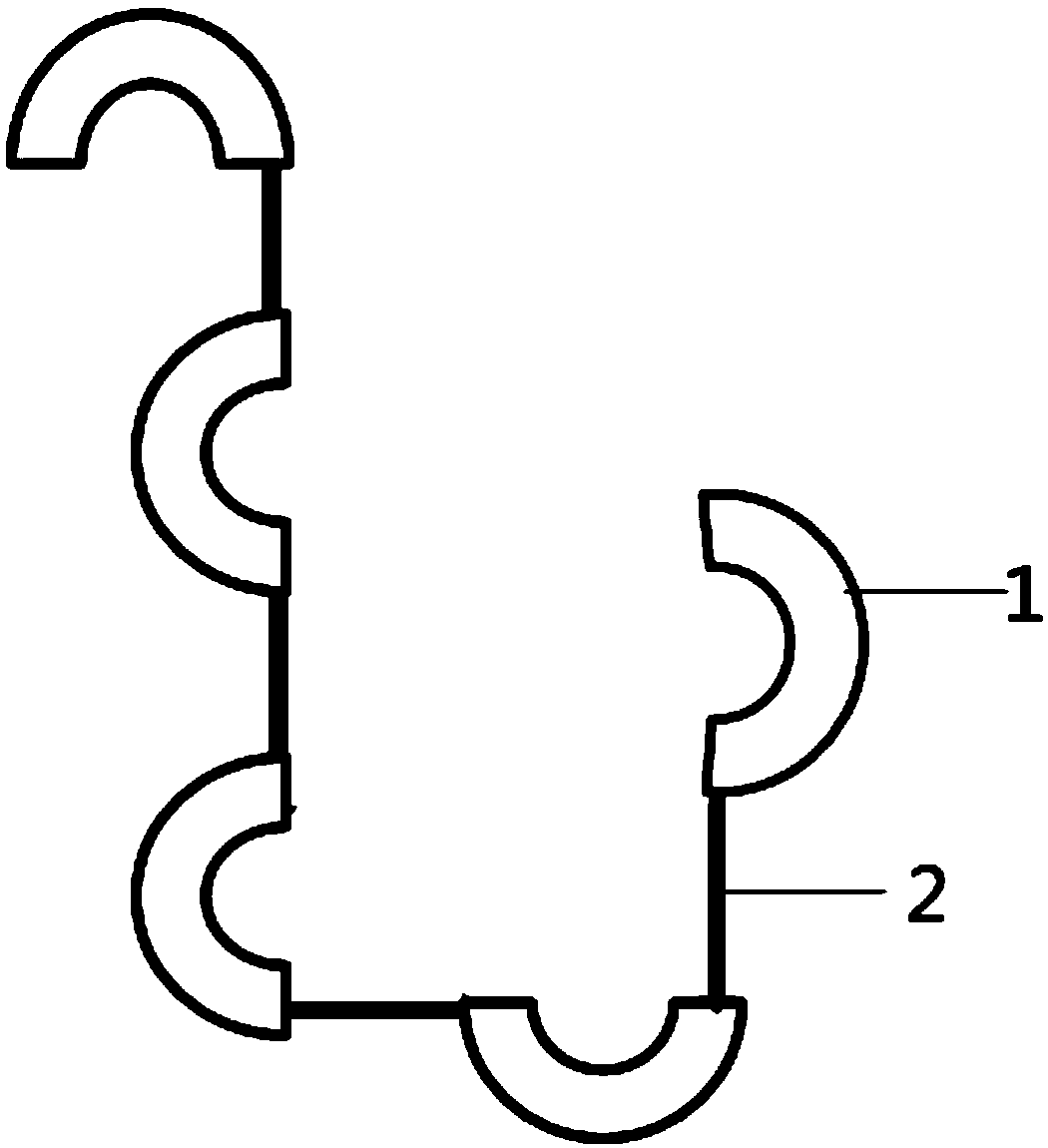

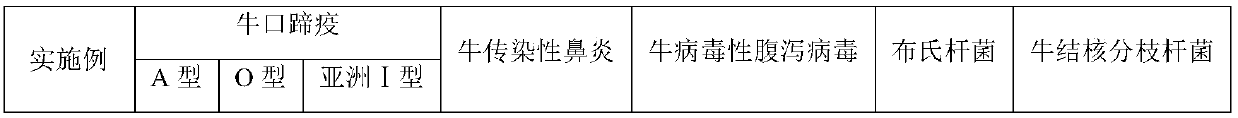

Micro-fluidic chip immunodiagnosis kit and preparation method thereof

The invention provides a micro-fluidic chip immunodiagnosis kit and a preparation method thereof, and relates to the technical field of micro-fluidic chips. The micro-fluidic chip immunodiagnosis kitcomprises a micro-fluidic chip substrate and an antigen, the micro-fluidic chip substrate is provided with a sector-shaped concave portions formed by connecting tubular cavities in series, and the sector-shaped concave portions are treated with dopamine and glutaraldehyde; the number of the sector-shaped concave portions is larger than or equal to 4. The antigen covers the surfaces of part of thesector-shaped concave portions of the micro-fluidic chip substrate. According to the micro-fluidic chip immunodiagnosis kit, the technical problem that in the prior art, a micro-fluidic chip immunodiagnosis kit high in sensitivity and accuracy is in lack in the prior art is relieved; the preparation method of the micro-fluidic chip immunodiagnosis kit is provided. According to the method, antigencovering is fast, the process is simple, and the consumed time is short.

Owner:TIANJIN RINGPU BIO TECH

Multi-stage electrocatalytic oxidation wastewater treatment device

PendingCN114873691AEasy to handleImprove processing efficiencySustainable biological treatmentWater/sewage treatment by oxidationCatalytic oxidationOxidizing agent

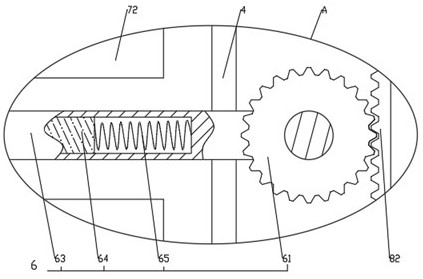

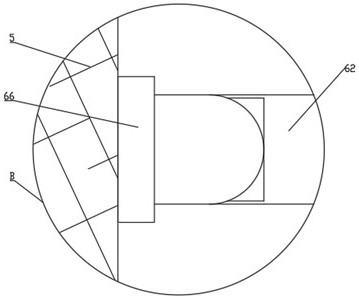

The invention is applicable to the field of wastewater treatment, and provides a multistage electrocatalytic oxidation wastewater treatment device which comprises a treatment box, a partition plate is fixedly connected to the interior of the treatment box and divides the interior of the treatment box into a mounting chamber and a treatment chamber, and a water inlet pipe and a water outlet pipe are arranged on the side face of the treatment box. The water inlet pipe and the water outlet pipe are located on the two sides of the treatment box, and two first mounting boxes are fixedly connected to the inner top wall of the treatment box. Multi-stage electro-catalysis is used, and different oxidants are introduced, so that the wastewater treatment effect is greatly enhanced; the gear drives the telescopic rod to swing, and the telescopic rod drives the scraping plate to scrape dirt on the surface of the electrode plate, so that the condition that dirt is generated on the surface due to long-time operation of the electrode plate is avoided, and the wastewater treatment efficiency is improved; the stirring mechanism repeatedly stirs the wastewater, so that ozone and hydrogen peroxide are quickly and uniformly mixed with the wastewater, the electro-catalysis effect is improved, and the wastewater treatment effect is greatly enhanced.

Owner:HENAN QINGBO ENVIRONMENT ENG

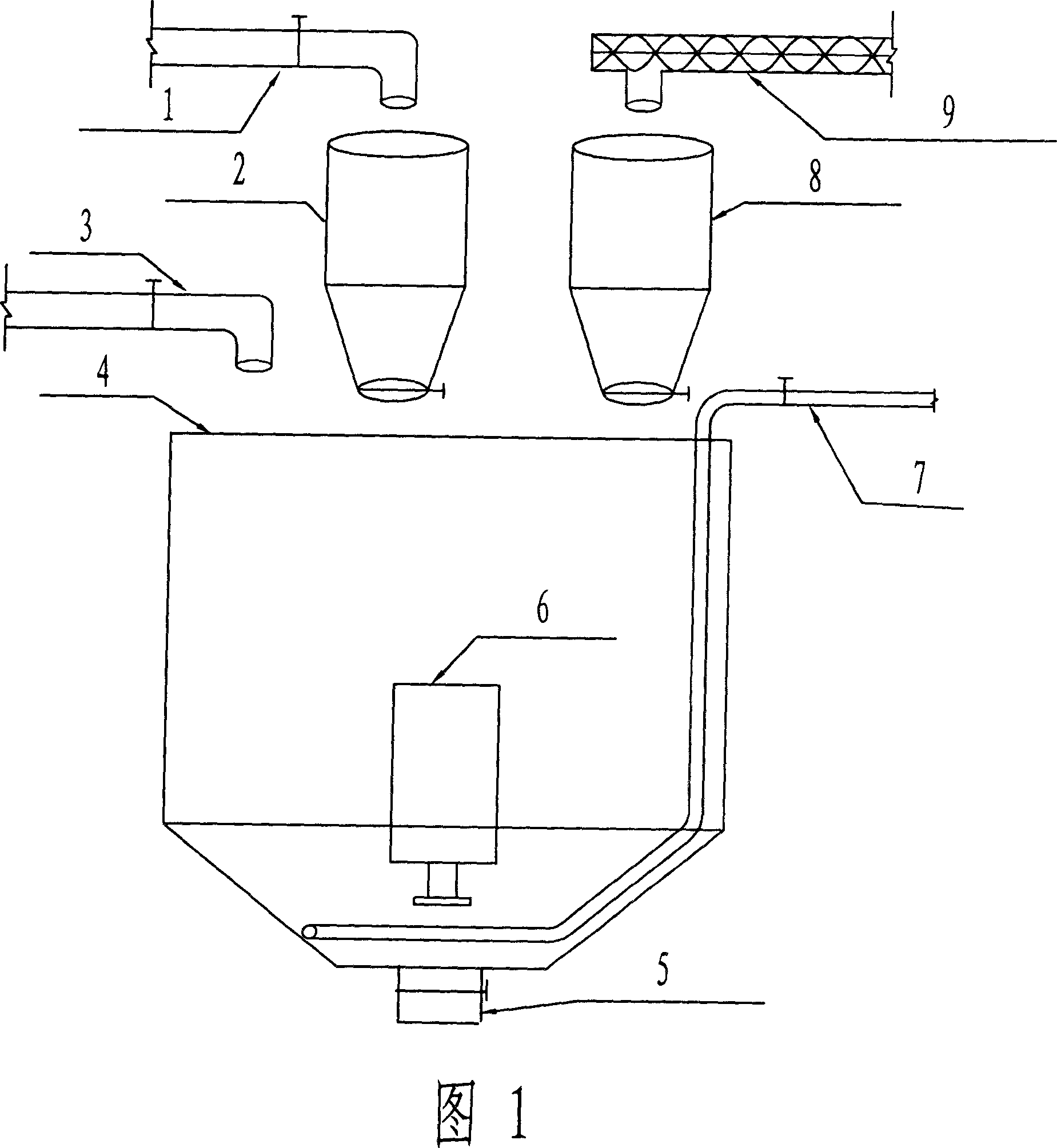

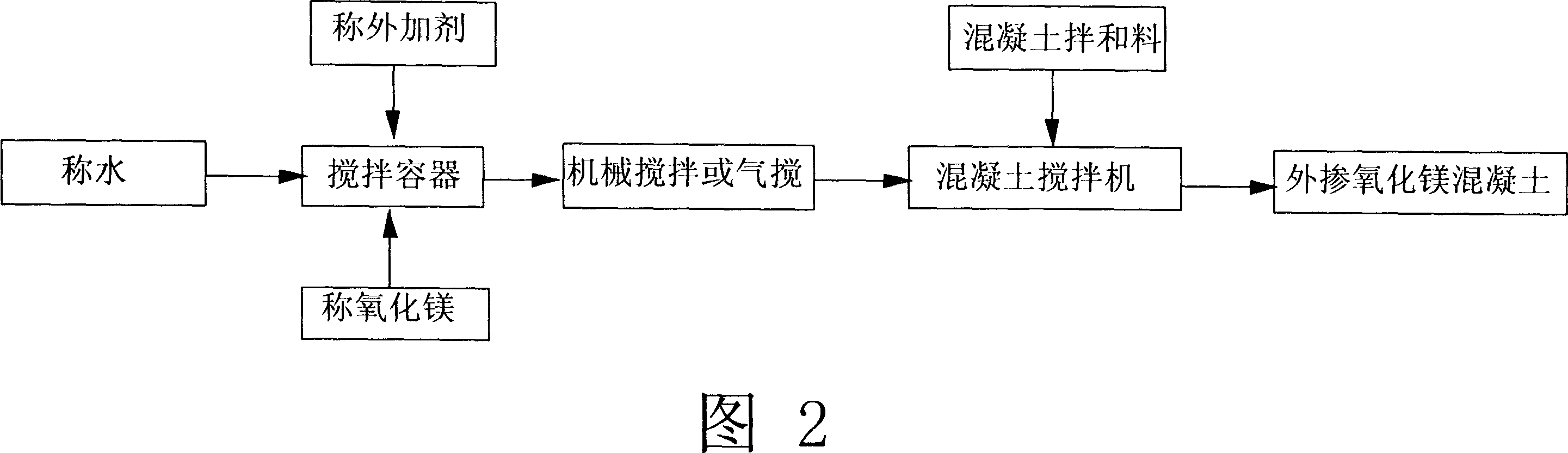

Method of fast and equably mixing concrete with added magnesium oxide

InactiveCN1919562AIncrease productivityShorten construction timeCement mixing apparatusMaterials scienceMagnesium

The invention discloses a rapid-even stirring magnesium oxide concrete external doping method, which comprises the following steps: putting water, dried material of magnesium oxide and additive in the water-weighing hopper, stirring mechanically or pneumatically to prepare composite liquid of magnesium oxide, adding in the stirrer to mix with concrete and sand, stone and cement, stirring to obtain the external doped magnesium oxide concrete.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

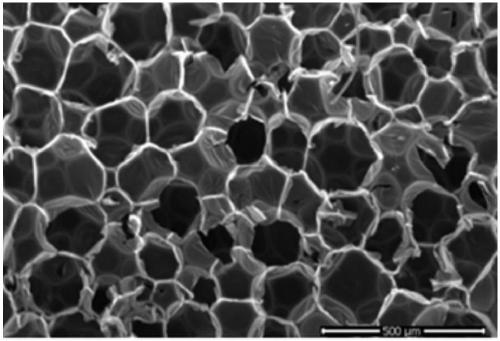

Polyurethane foaming method by combining and using carbon dioxide and organic amine

The invention discloses a polyurethane foaming method by combining and using carbon dioxide and organic amine. The method comprises the following step of mixing a polyurethane foaming composition witha polyisocyanate monomer and / or isocyanate-terminated prepolymer for foraming, wherein before mixing, carbon dioxide is added to the polyurethane foaming composition, or added into the polyisocyanatemonomer and / or isocyanate-terminated prepolymer, or simultaneously added into the polyurethane foaming composition and the polyisocyanate monomer and / or isocyanate-terminated prepolymer, and the carbon dioxide is gas carbon dioxide, liquid carbon dioxide, subcritical carbon dioxide and / or supercritical carbon dioxide.

Owner:BUTIAN NEW MATERIAL TECH CO LTD +1

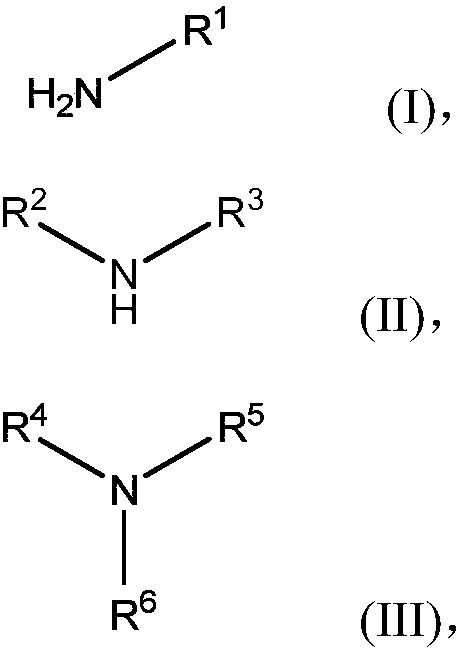

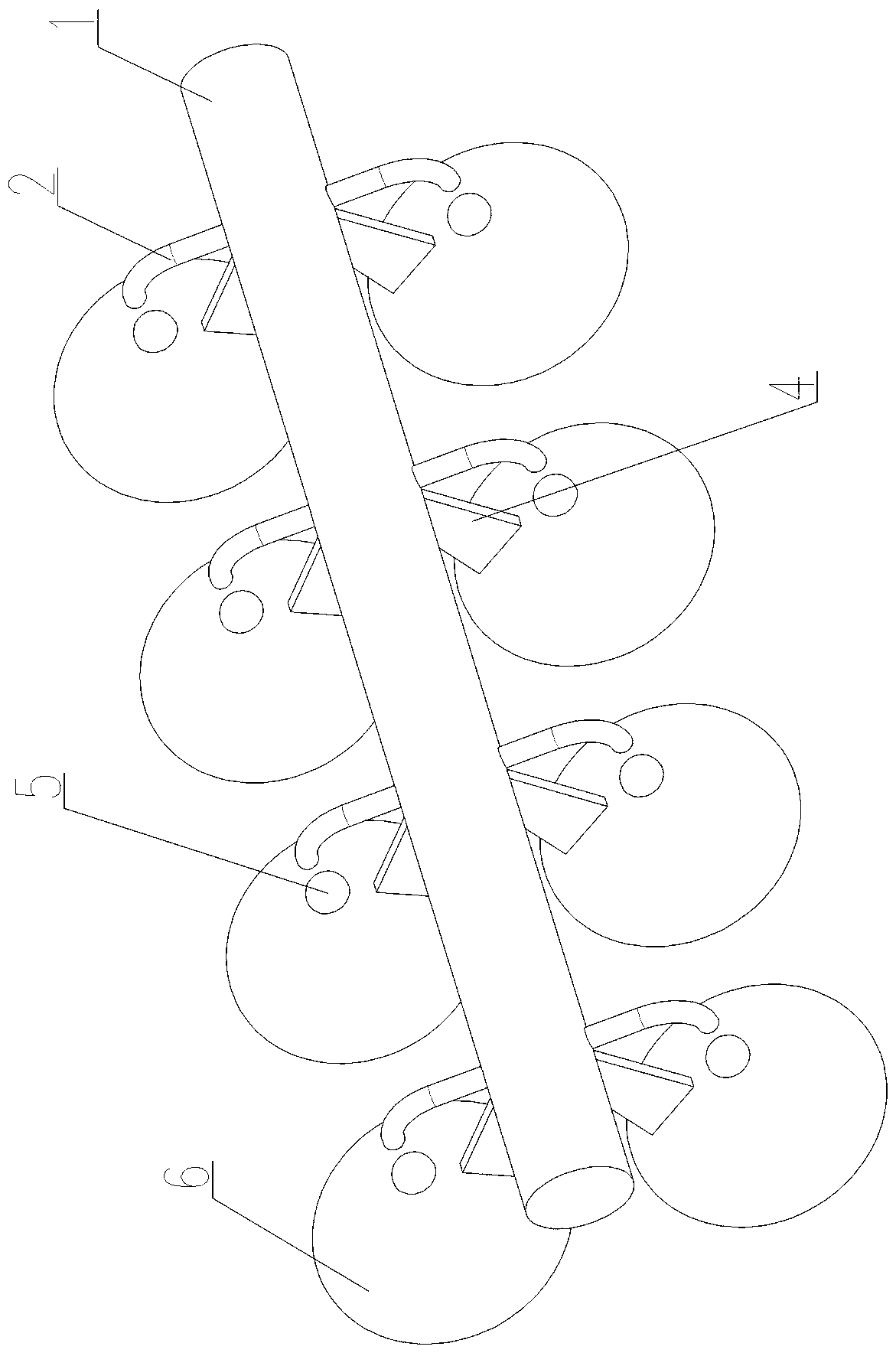

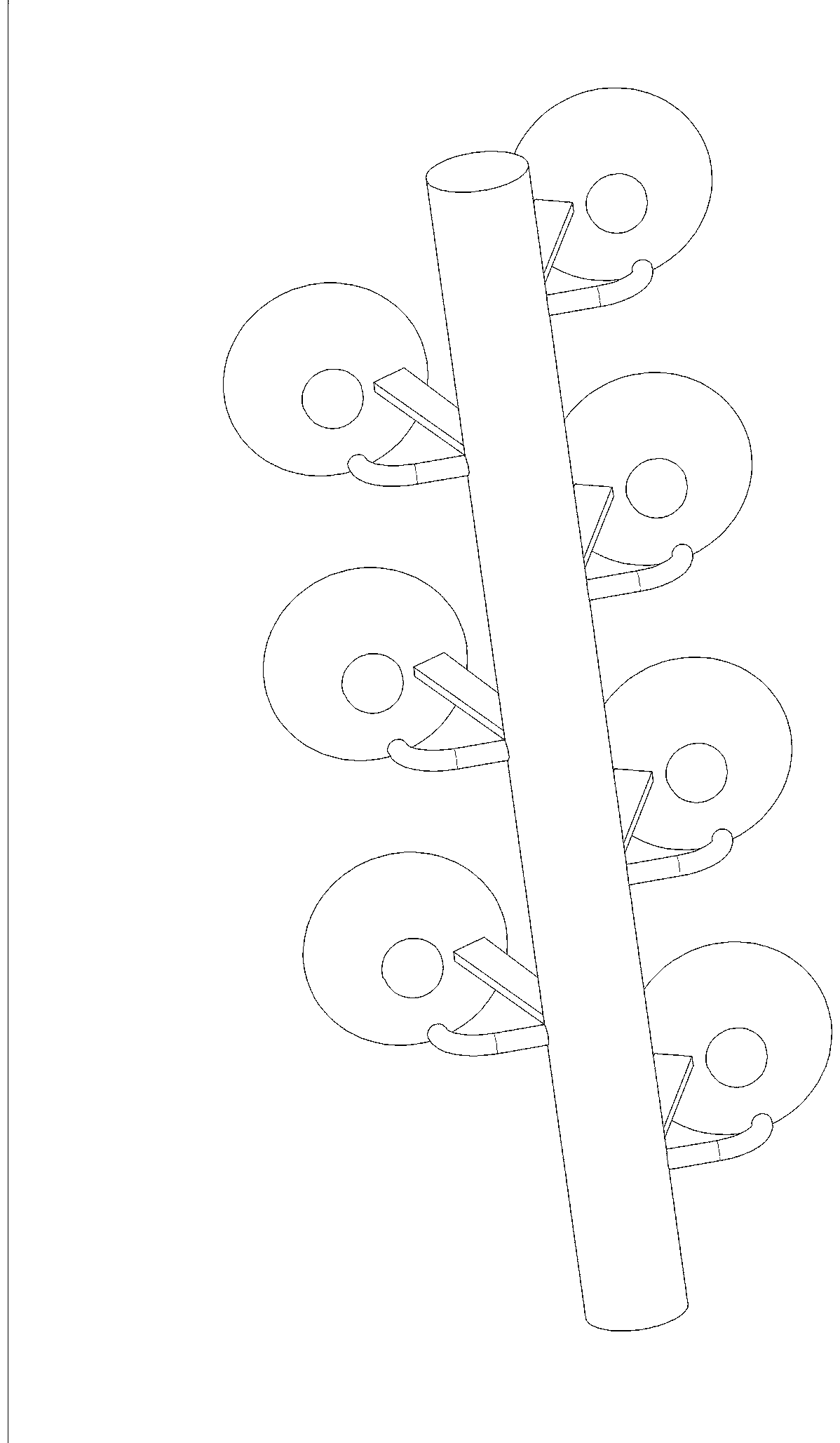

Efficient ammonia mixing and spraying device for flue gas denitration system

PendingCN108043224ANo serious problem of dust accumulationEliminate ash cloggingDispersed particle separationAmmoniacal nitrogenFlue gas

The invention provides an efficient ammonia mixing and spraying device for a flue gas denitration system. The device includes an ammonia spraying pipe bundle with ammonia spraying ports, and static quick mixing units; the ammonia spraying pipe bundle with the ammonia spraying ports includes an ammonia spraying pipe, the ammonia spraying pipe is connected into a denitration flue channel, the denitration flue channel is internally communicated with the multiple ammonia spraying ports, and ammonia is sprayed out through the ammonia spraying ports, wherein the opening direction of the ammonia spraying ports is the same as the flowing direction of flue gas in the denitration flue channel; the device is further provided with the static quick mixing units, and each ammonia spraying port is independently matched with one static quick mixing unit; the static quick mixing units and the ammonia spraying ports are oppositely arranged, each static quick mixing unit includes a drainage component anda basal flow choking part, and the basal flow choking parts and the drainage components are matched with each other to guide the ammonia sprayed out from the ammonia spraying ports to conduct entrainment diffusion. The efficient ammonia spraying device capable of quickly and evenly mixing is reasonable in structure and convenient to process, has less device ash deposition and small needed mixingspace for spraying, and is beneficial to quick mixing of the ammonia and nitrogen and suitable for the flue gas denitration system.

Owner:浙江百能科技有限公司 +1

Grinding wheel raw material mixing machine

InactiveCN108619970AWell mixedMix quickly and evenlyTransportation and packagingRotary stirring mixersPulp and paper industryGrinding wheel

The invention relates to a grinding wheel raw material mixing machine, which is provided with an open type machine case, wherein a material mixing tank is arranged at one side inside the machine case;a rotating shaft is transversely arranged at one side of the upper part of the machine case; a rotating plate is arranged in a way of being fixedly connected with the rotating shaft; a hinging lug isarranged in the middle position of the rotating plate; a jacking air cylinder is arranged in the machine case arranged under the hinging lug; the lower end of the jacking air cylinder is hinged to the bottom of the machine case; a piston rod of the jacking air cylinder is hinged to the hinging lug; the upper part of the rotating plate is fixedly connected with a material tank cover plate; a stirring motor is arranged at the back side of the material tank cover plate; an output shaft of the stirring motor penetrates through the material tank cover plate and extends out from the front side of the material tank cover plate; a stirring seat is fixedly arranged at the front end of the output shaft of the stirring motor; a plurality of straight stirring rods are arranged in positions at one side on the stirring seat; a spiral plough share material stirring plate is arranged in a position at the other side on the stirring seat. The structure improvement is simple and practical; the stirringand material mixing efficiency is high; the uniformity of the mixed raw materials is high; good practical use and popularization values are realized.

Owner:湖北磊鑫研磨科技股份有限公司

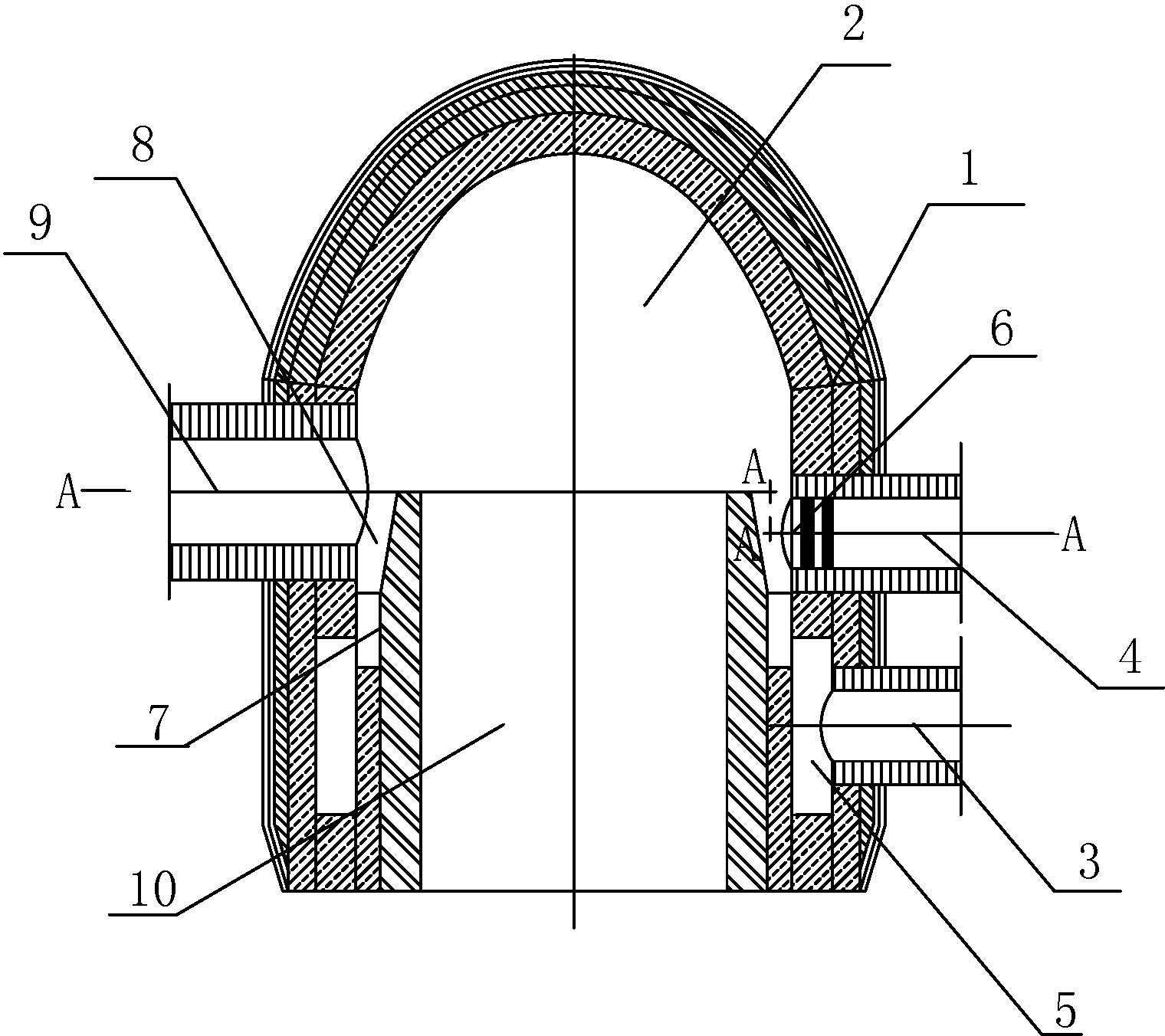

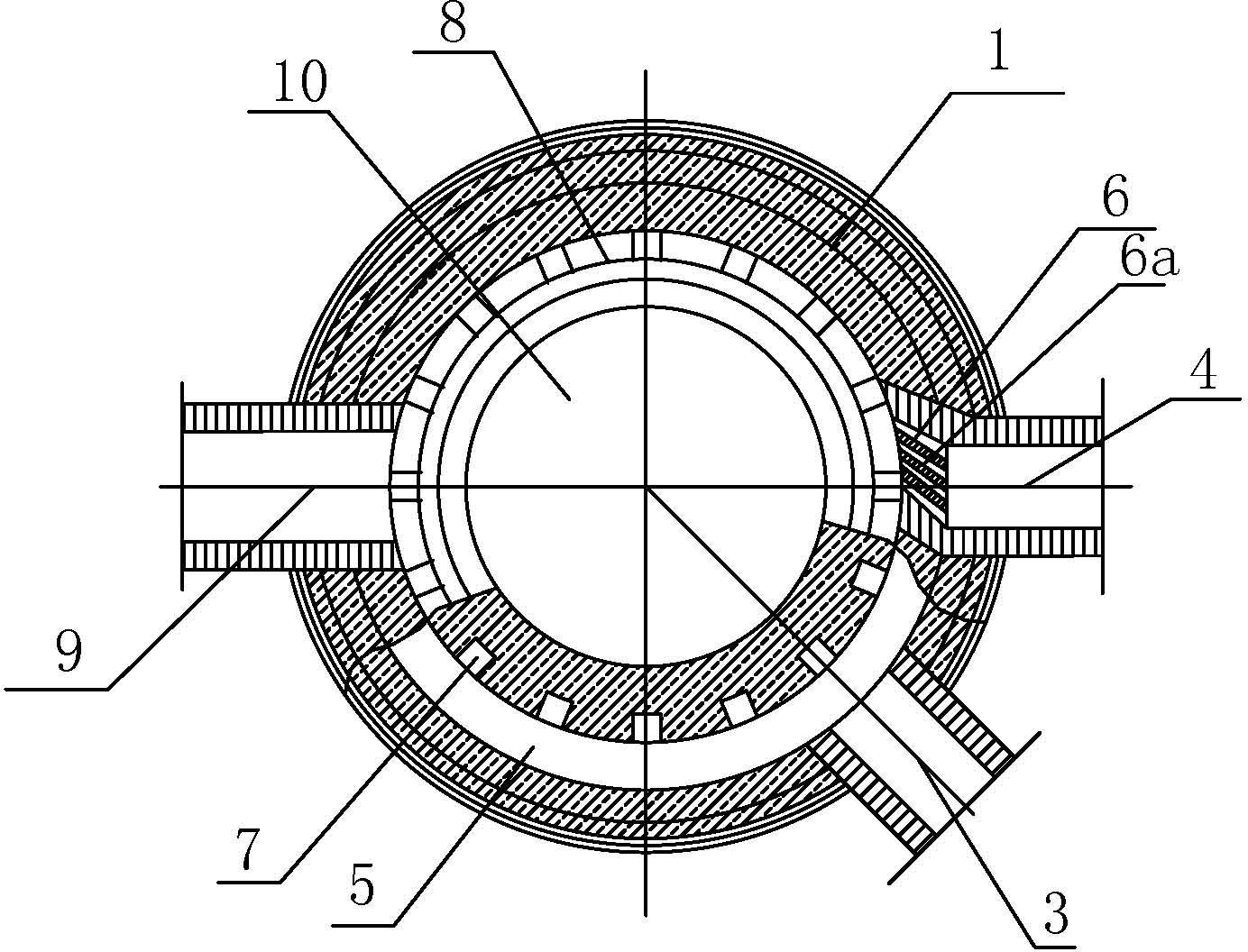

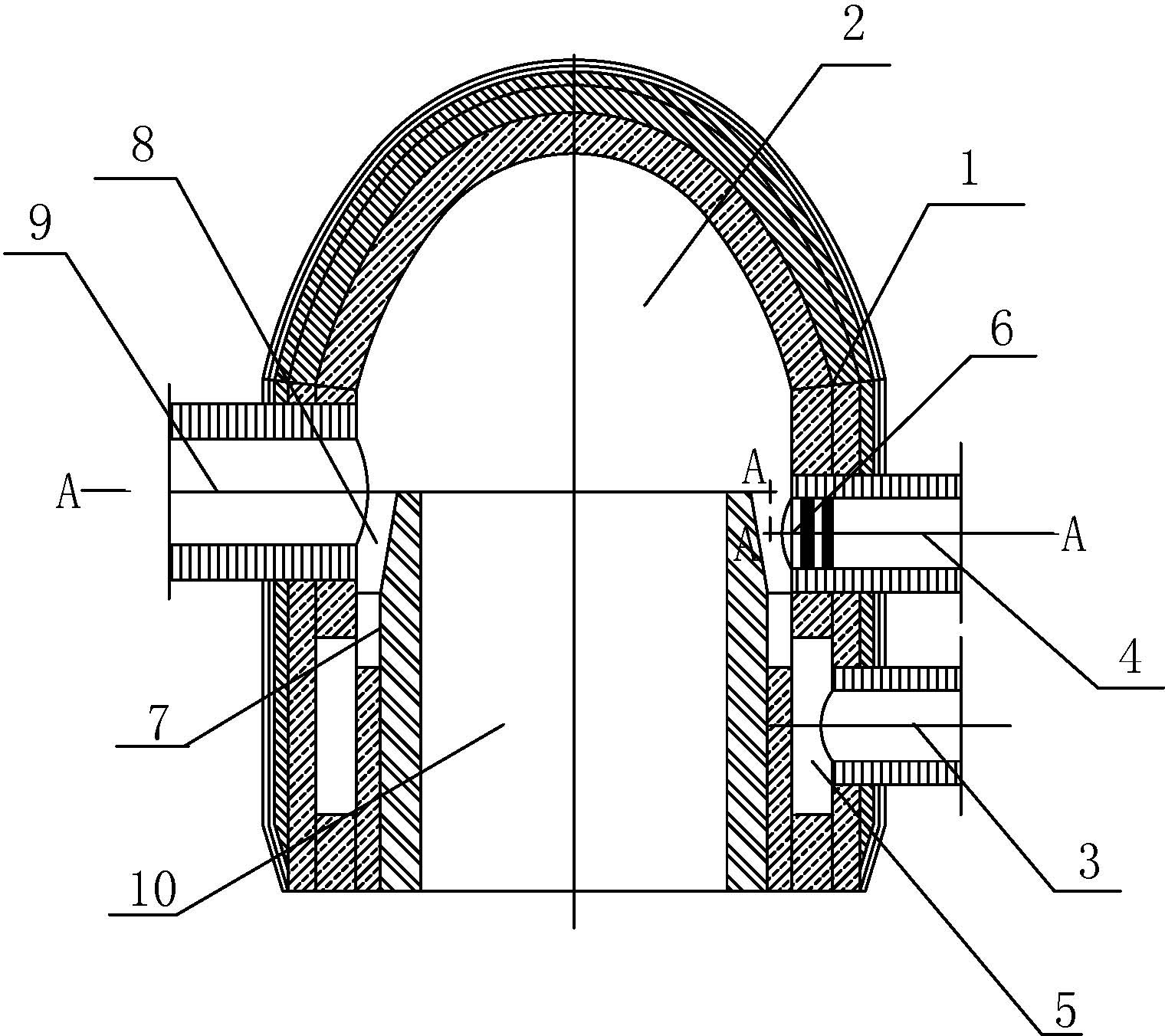

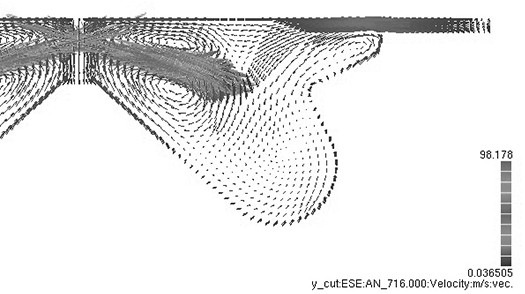

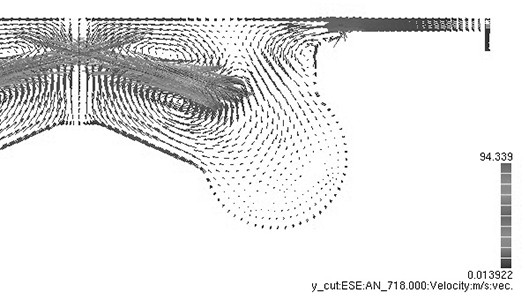

High-low type dual-vortex-chamber dual-necking combustion chamber

InactiveCN111648876AHigh speedMix quickly and evenlyMachines/enginesPistonsCombustion chamberGas cylinder

The invention provides a high-low type dual-vortex-chamber dual-necking combustion chamber, and vortex chambers are distributed high and low. The combustion chamber comprises an upper vortex chamber with circular-arc type necking and a low vortex chamber with circular-arc type necking, wherein a boundary ridge is arranged between the upper vortex chamber and the lower vortex chamber; the center ofthe combustion chamber is provided with a round-top frustum; the boundary ridge of the upper and lower vortex chambers and the upper vortex chamber define a guide inclined surface; and the upper vortex chamber and the top of a piston define a curved surface. The high-low type dual-vortex-chamber dual-necking combustion chamber is suitable for a supercharged and mid-cooling direct-injection type diesel engine. The high-low type dual-vortex-chamber dual-necking combustion chamber can organize and utilize horizontal vortex around the center line of a gas cylinder and longitudinal rolling flow toimprove fuel oil-gas mixing, so that a gas mixture is uniform, combustion is sufficient, local high-temperature areas are fewer, and NOx and SOOT emission amount is reduced. Flywheel effect further can be formed on the upper vortex chamber; the circular-arc type necking structure of the upper vortex chamber can define vortex with biggest linear speed in the whole combustion chamber, and time of duration lasts from the later period of a compression stroke to an early-medium period of working stroke. The upper vortex chamber stores fresh air during the compression stroke, so that gas is provided for oxidizing SOOT in the after combustion period.

Owner:JIANGSU UNIV OF SCI & TECH

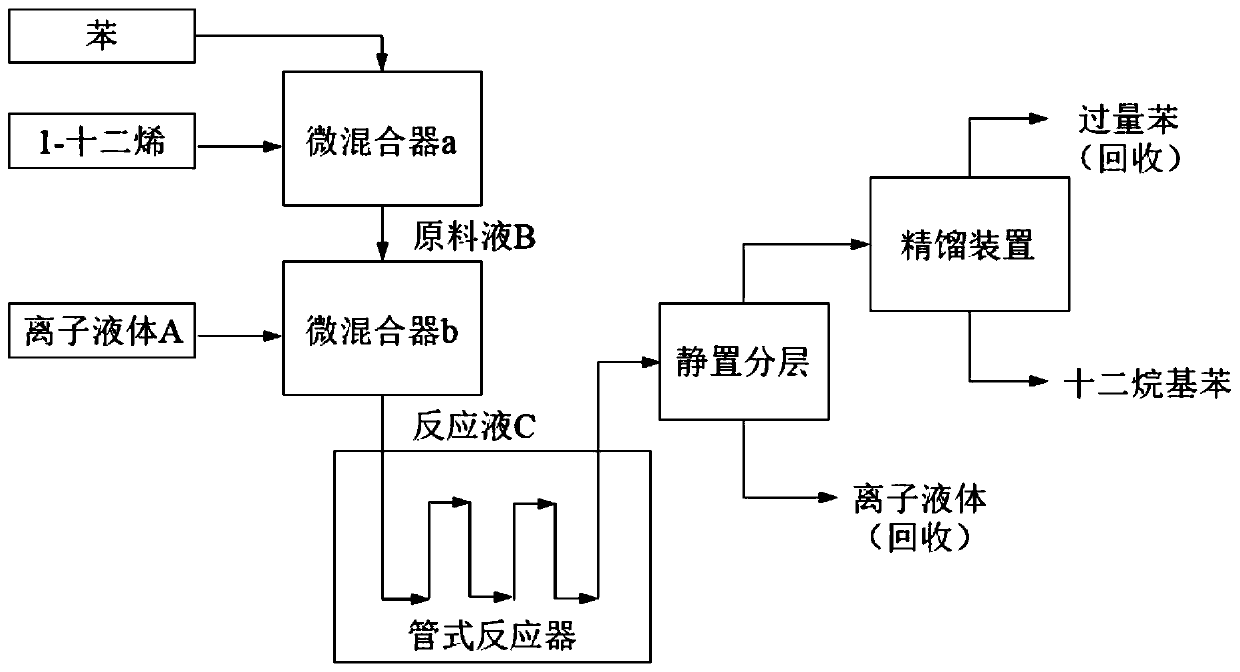

Method for continuously preparing dodecyl benzene

InactiveCN110283031AHigh synthesis efficiencyMix quickly and evenlyOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsAluminium chlorideIonic liquid

The invention belongs to the technical field of chemical engineering, and relates to a method for continuously preparing dodecyl benzene. The method comprises the following steps that 1, trimethylamine hydrochloride and aluminum chloride are stirred and mixed according to a ratio to prepare an ionic liquid catalyst A; 2, benzene and 1-dodecene are introduced into a micro-mixer a to be quickly and evenly mixed in proportion to obtain a raw material liquid B; 3, a catalyst A and the raw material liquid B are continuously introduced into a micro-mixer b to be rapidly and uniformly mixed to obtain a reaction liquid C, and the reaction liquid C enters a tubular micro-reactor for reaction; 4, the product mixture stands still and is layered, and an ionic liquid A is recycled; 5, an upper layer organic phase obtained in step 4 is rectified to obtain the product dodecyl benzene. The method is environmentally friendly, and can effectively solve the problems of high corrosion, high pollution and the like in a traditional technology. Material flows are rapidly and uniformly mixed, the reaction efficiency is high, the yield of monoalkyl benzene is nearly 100% in a very short time, and the yield of two-position isomer can reach 44% or above; the reaction is conducted in the tubular micro-reactor, the reaction time can be accurately controlled, and the product quality is stable.

Owner:TSINGHUA UNIV

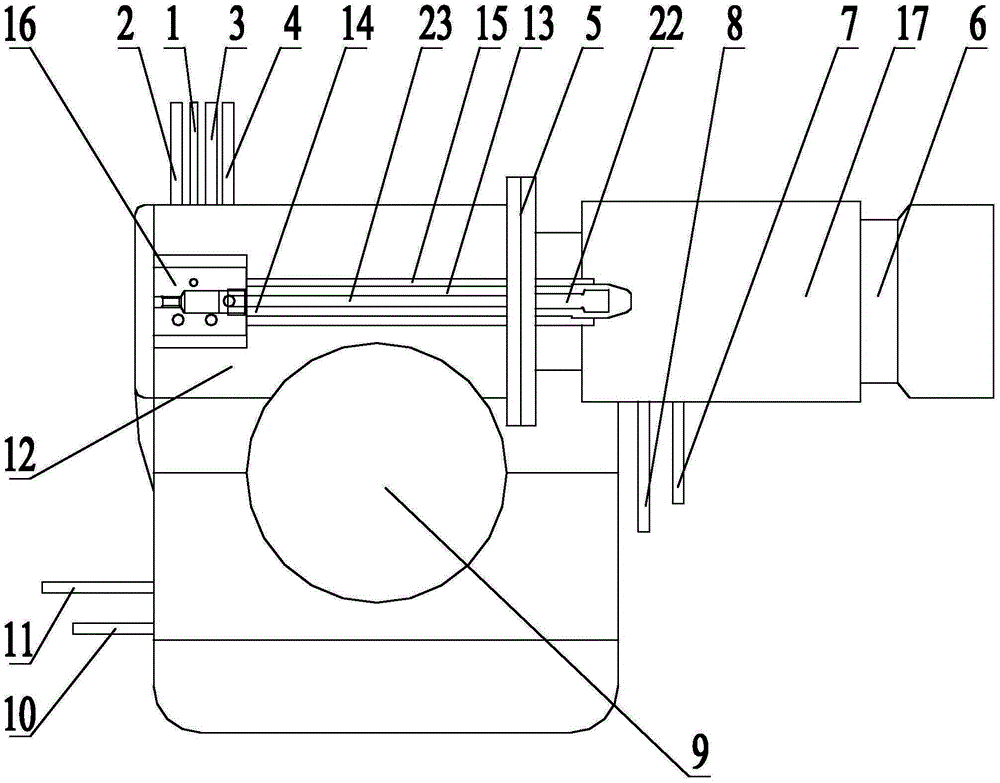

Stirring device for injection molding machine

The invention discloses a stirring device for an injection molding machine. The stirring device comprises a barrel, a feeding assembly arranged at the upper end of the barrel, a first stirring assembly arranged in the barrel, a discharging assembly arranged in the middle of the barrel and a second stirring assembly arranged at the lower end of the barrel. The stirring device has the good stirringeffects on various injection molding raw materials and is low in electric energy consumption.

Owner:浙江百力塑业有限公司

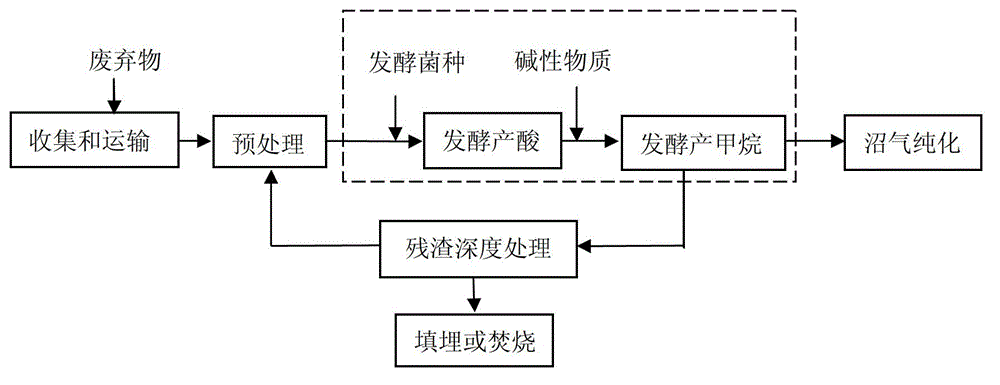

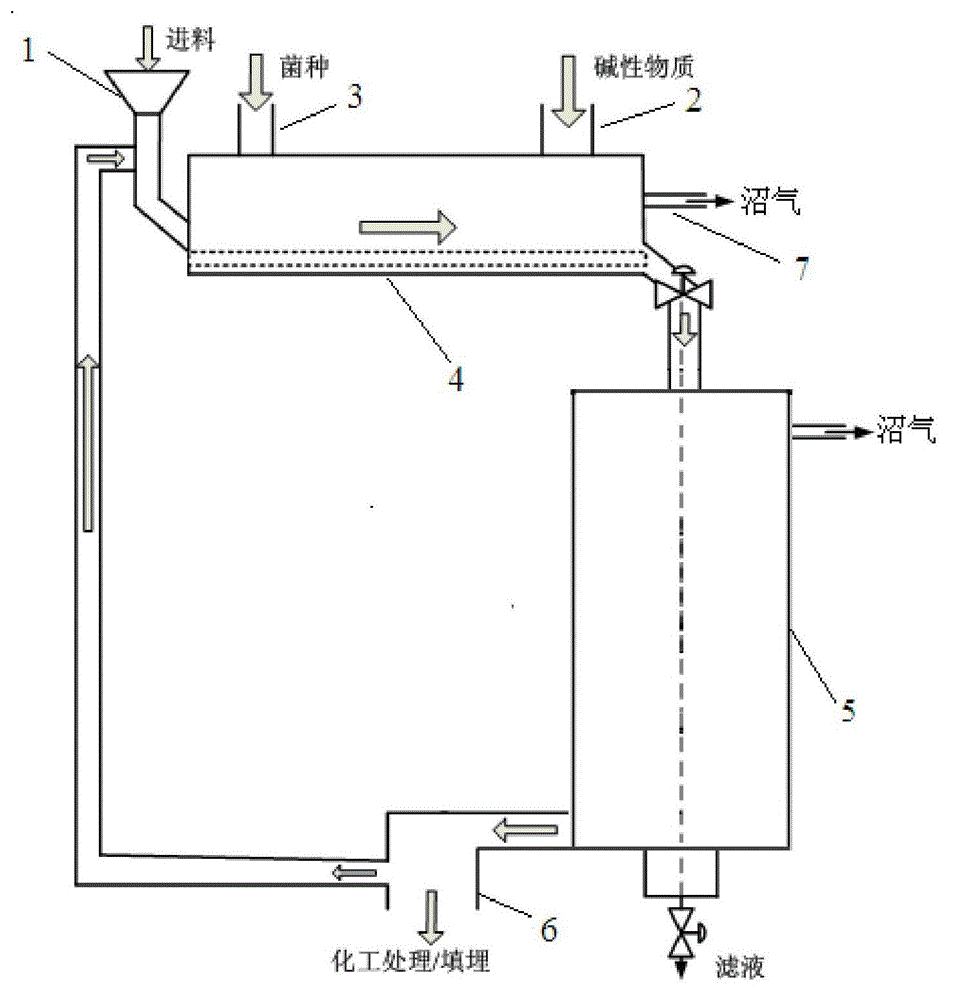

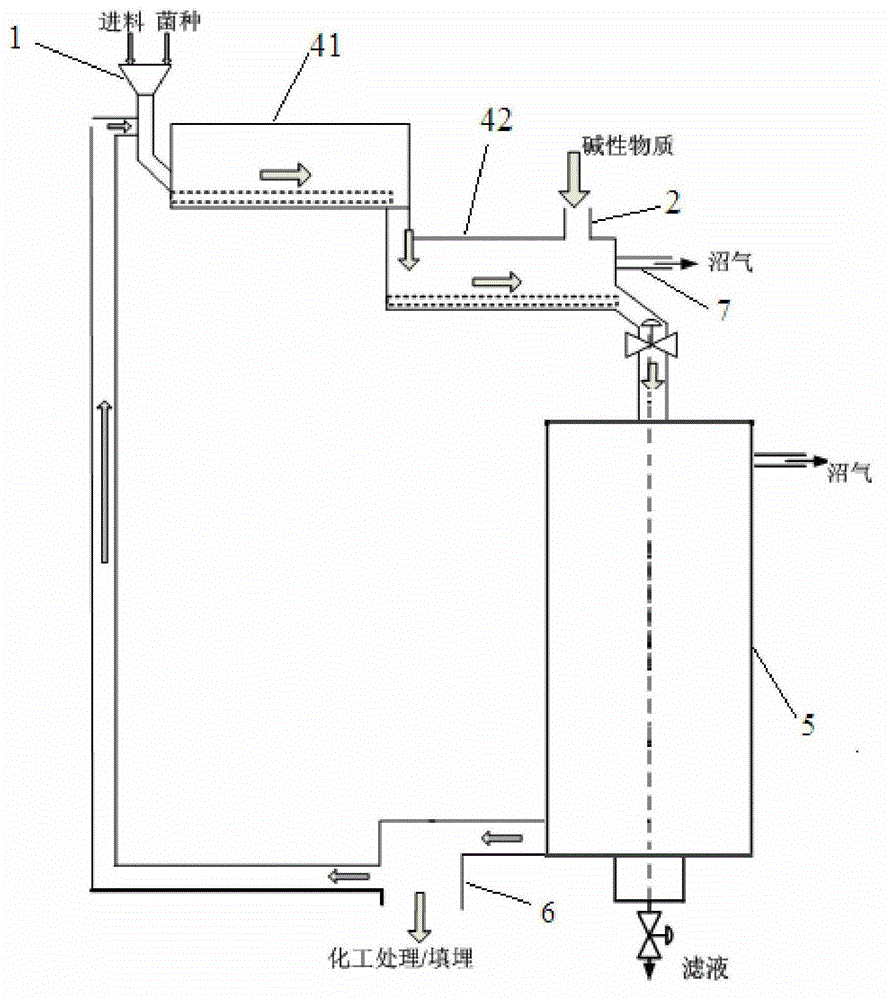

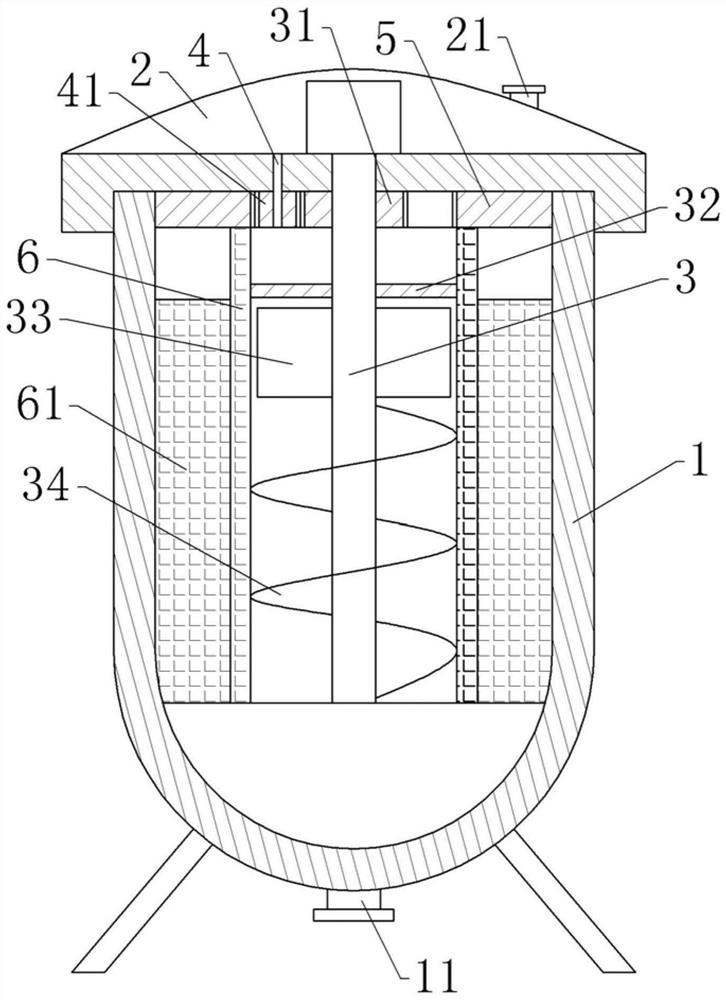

Waste two-stage dry digestion method and device

InactiveCN104004795AEasy to zoom inIncrease production capacityBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobial inoculationOrganic acid

The present invention provides a method and a device for two-stage dry digestion of wastes. The method comprises: inoculating microorganisms in a first-stage reactor, to make waste materials fully fermented to produce acid; after acid production is finished, using alkaline substances to neutralize organic acid so as to regulate the pH value; and performing a second stage of dry fermentation to produce methane. The method can effectively overcome suppression of organic acid to a digestion process during anaerobic digestion, and does not produce a large amount of waste water because rinsing is not required.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

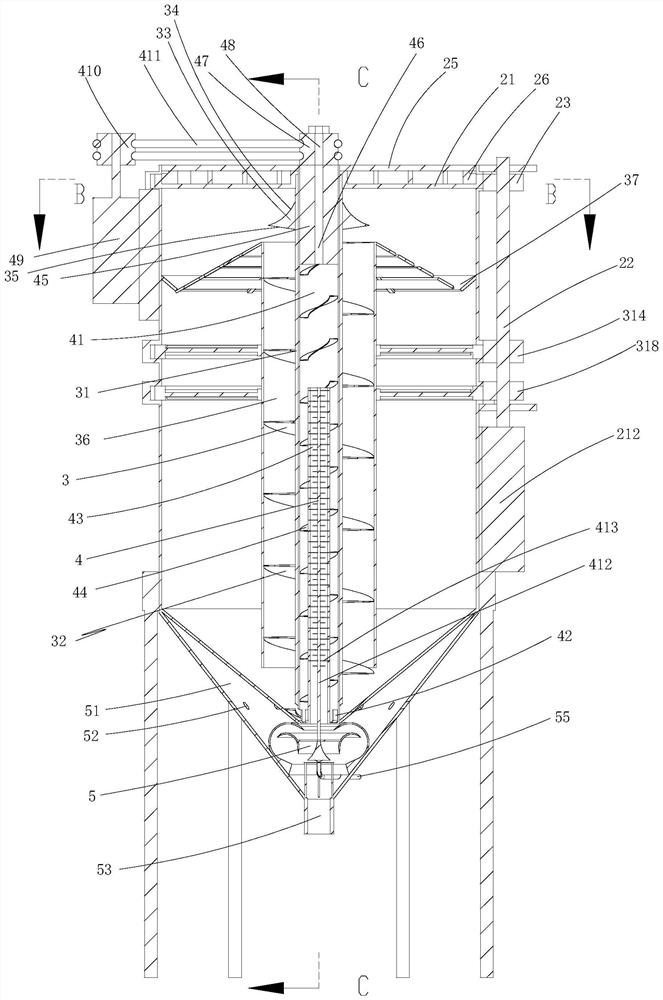

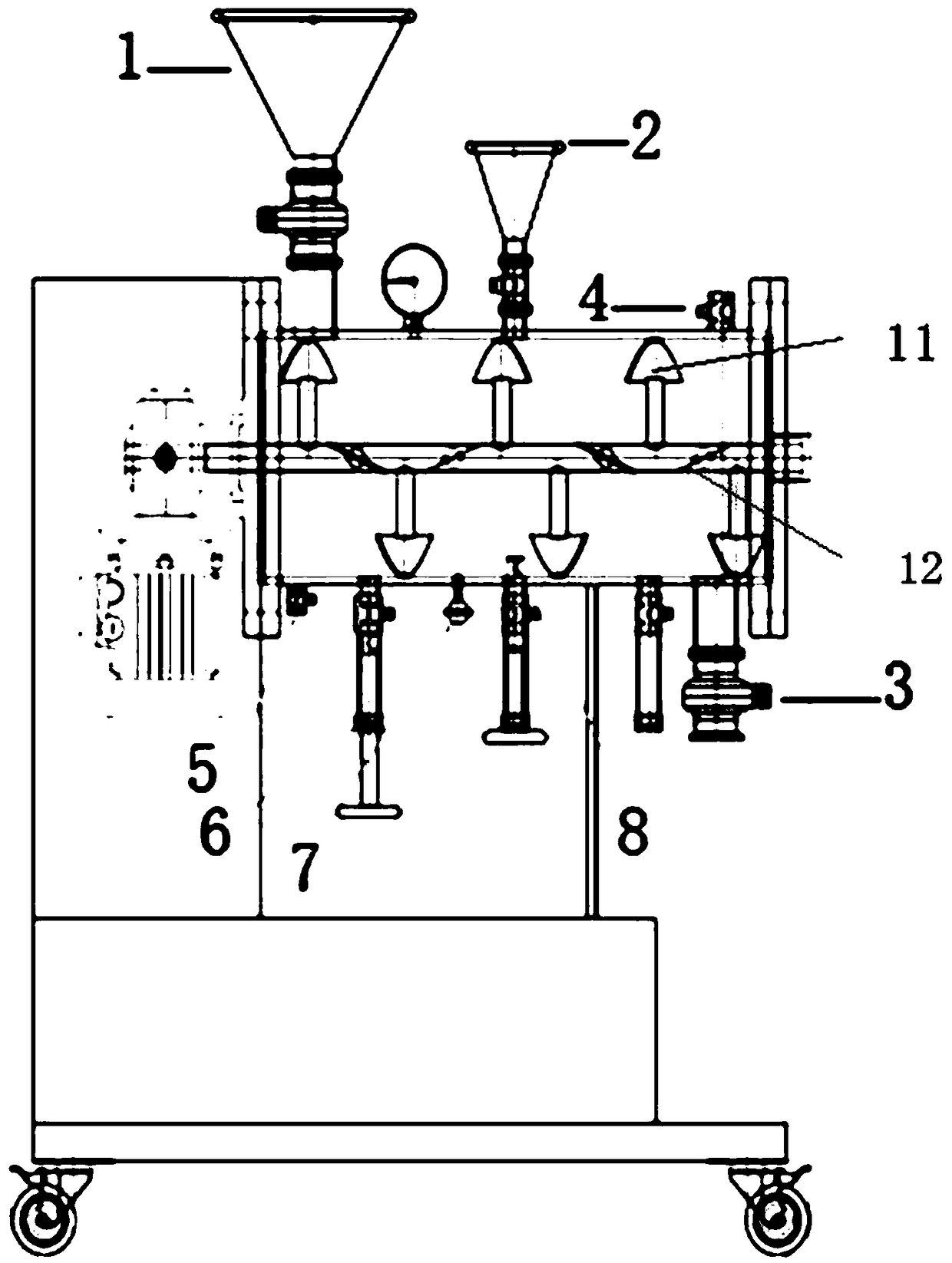

Continuous dry digestion device and processing method for wastes

InactiveCN109321436ALow operating costHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryDigestion

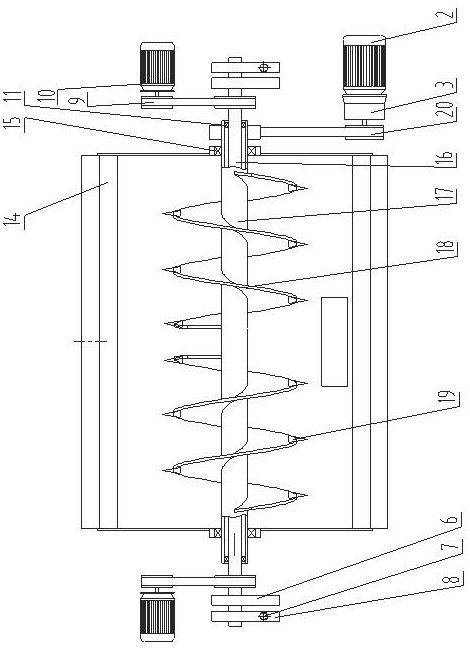

The invention discloses a continuous dry digestion device for wastes. The continuous digestion device comprises a reactor, wherein a compound stirring system is arranged in the reaction cavity of thereactor; the compound stirring system comprises a stirring shaft; a plurality of flat-paddle type stirring paddles are distributed on the stirring shaft along an axial direction, and two adjacent flat-paddle type stirring paddles are distributed along opposite directions; a paddle is fixedly arranged between two adjacent flat-paddle type stirring paddles; the vane of the paddle extends along the axial direction of the stirring shaft and forms an included angle with the stirring shaft. Through the dry digestion of microbial fermentation, the operation cost of a dry digestion process can be greatly lowered, and in addition, digestion reaction can be accelerated so as to be favorable for improving the yield of methane. The invention also discloses a continuous dry digestion method for wastes.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

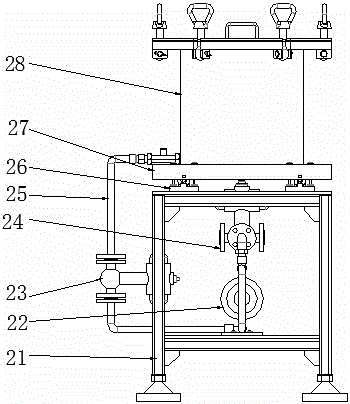

Resin mixture stirring system

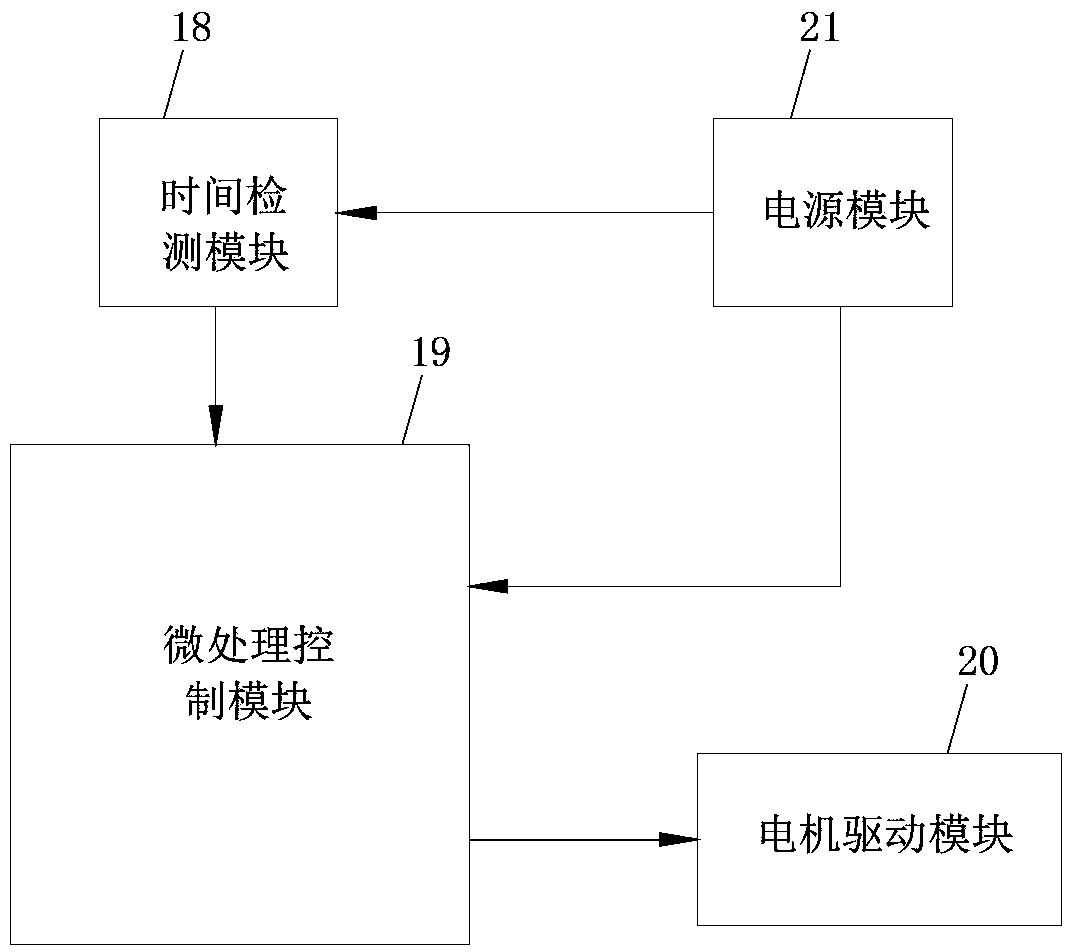

PendingCN106807278AGuaranteed normal operationMix quickly and evenlyTransportation and packagingRotary stirring mixersControl systemElectronic control system

The invention relates to the technical field of glass steel production and discloses a resin mixture stirring system. The resin mixture stirring system comprises a stirring device, an ingredient supplying device, a resin supplying device, a pneumatic system and an electronic control system; the output end of each of the ingredient supplying device and the resin supplying device is connected with the input end of the stirring device, the electronic control system is electrically connected with the pneumatic system and the resin supplying device, and the pneumatic control system is in gas connection with the stirring device and the ingredient supplying device. Compared with the prior art, the resin mixture stirring system is arranged in a manner of one supplying two, namely one bucket of each of materials can supply for two blenders simultaneously, equipment including the blenders, various feeding systems, the electronic control system and the pneumatic system can be operated efficiently and precisely, the stirring device have the materials stirred unevenly, and the mixture is formulated precisely through the electronic control system; production efficiency and product quality are improved, and safe production is performed through the pneumatic system.

Owner:广州潮流水上乐园设备有限公司

Coating material mixing stirring system with cooling structure

InactiveCN104338472AMix quickly and evenlyFine dispersionMixer accessoriesAudio power amplifierEngineering

The present invention relates to a coating material mixing stirring system with a cooling structure. According to the system, a cooling space is formed between an inner tank and an outer tank, the outer wall surface of the inner tank is provided with a temperature sensor, the output end of the temperature sensor is connected with a controller, the output end of the controller is connected with the input end of an amplifier, the output end of the amplifier is connected with a water pump, the water pump is communicated with the cooling space through a pipeline, a spiral stirring body and a support rod fixed on the rotation shaft are fixedly connected, the spiral stirring body at least comprises the inner layer spiral stirring blade and the outer layer spiral stirring blade, the distance between the top point of the inner layer spiral stirring blade and the rotation shaft is less than the distance between the top point of the outer layer spiral stirring blade and the rotation shaft, the output end of a driving motor is connected with the rotation shaft, and the mixed material output port of a mixing device is communicated with the inner tank through a pipeline. According to the present invention, the suitable temperature can be provided by adjusting the temperature of the stirring tank when the coating material is stirred, and the stirring is uniform.

Owner:CHANGZHOU HAOBANG NANO TECH PAINT

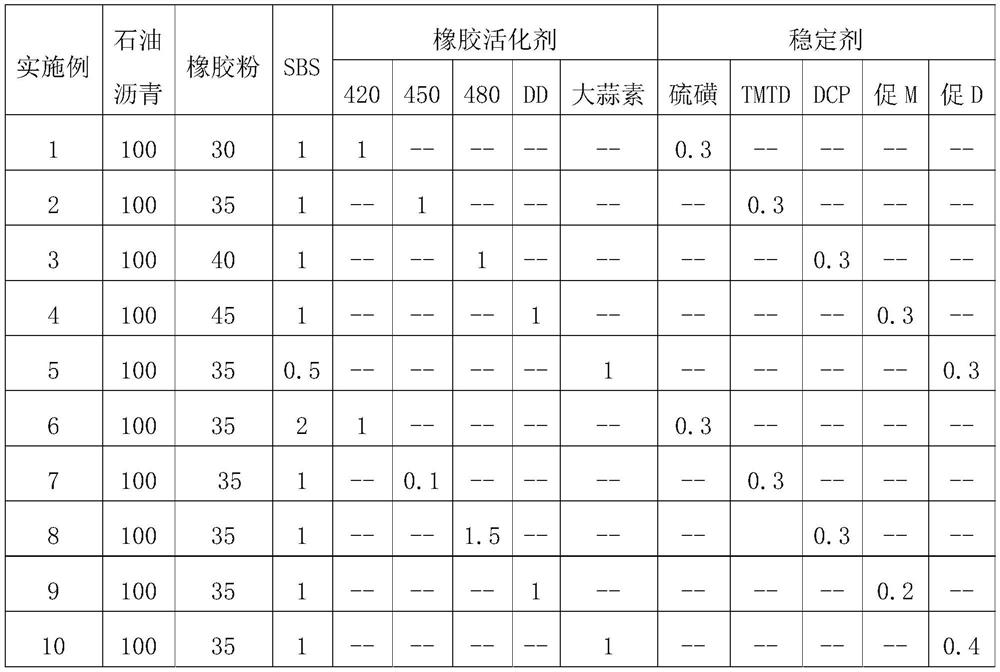

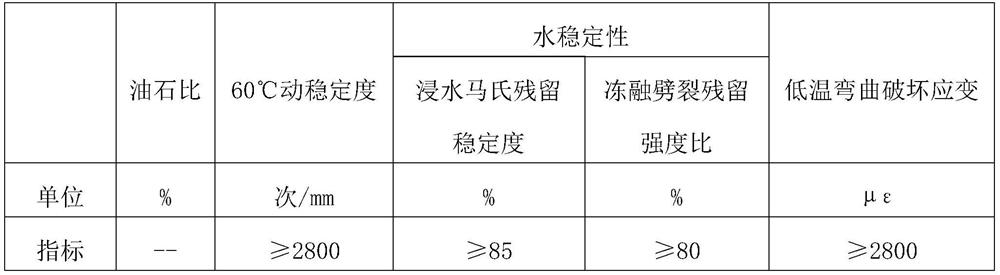

High-performance rubber asphalt and preparation method thereof

ActiveCN112457679AImprove mixing uniformityImprove performanceBuilding insulationsRubberized asphaltPolymer chemistry

The invention belongs to the technical field of asphalt material compositions and preparation methods thereof, and discloses high-performance rubber asphalt and a preparation method thereof, and the high-performance rubber asphalt comprises asphalt, rubber powder, SBS, a rubber activator and a stabilizer. The preparation method comprises the following steps: uniformly mixing the rubber powder, therubber activator and the stabilizer to obtain a mixture A, and stirring 1 / 2 of the mixture A with the asphalt and the SBS while keeping the temperature to obtain a mixture B; grinding the mixture B by using a grinder to obtain a mixture C, adding the rest of the mixture A into the mixture C, and stirring while keeping the temperature to obtain a mixture D; and grinding the mixture D, and stirringwhile keeping the temperature to obtain the finished rubber asphalt. Compared with the existing rubber asphalt, the high-performance rubber asphalt provided by the invention has the advantages that the addition proportion of the rubber powder is high, the comprehensive physical properties of the rubber asphalt are excellent, the elasticity of the asphalt mixture is more sufficient, the high-temperature anti-rutting capability (dynamic stability at 60 DEG C) is strong, and the rutting probability of a pavement is low.

Owner:北京路德永泰环保科技有限公司

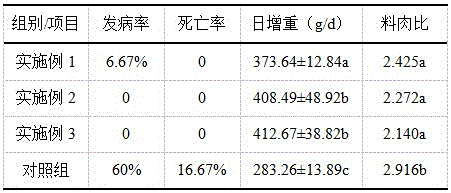

A kind of pig feed mycotoxin degradation adsorbent and its application

ActiveCN104304687BInhibitionReduce the risk of diseaseAnimal feeding stuffAccessory food factorsPhytaseLactobacillus salivarius

Owner:佛山播恩生物科技有限公司

Coating material mixing dispersion system capable of making coating material forward rotate and reverse rotate

The present invention relates to a coating material mixing dispersion system capable of making a coating material forward rotate and reverse rotate. According to the system, one end of a rotation shaft penetrates through a material cylinder, both ends of the rotation shaft are supported on a bracket through bearings, the rotation shaft body positioned in the material cylinder is symmetrically provided with a pair of spiral stirring bodies, the spiral stirring body and a support rod fixed on the rotation shaft are fixedly connected, the spiral stirring body at least comprises the inner layer spiral stirring blade and the outer layer spiral stirring blade, the distance between the top point of the inner layer spiral stirring blade and the rotation shaft is less than the distance between the top point of the outer layer spiral stirring blade and the rotation shaft, the output end of a driving motor is connected with the rotation shaft, a rotation motor is fixed on the support frame, the output end of the rotation motor is connected with the rotation shaft, the lower portion of the rotation shaft is positioned inside a stirring container, the lower portion of the rotation shaft is provided with a spiral cutting blade, the stirring blade is fixed on the lower portion of the rotation shaft, and the diameter of the stirring blade is larger than the diameter of the spiral cutting blade. According to the present invention, the material can be uniformly dispersed, and the material thinning degree can be improved.

Owner:CHANGZHOU HAOBANG NANO TECH PAINT

Preparation method and equipment of anti-oxidation and anti-discoloration water-based automobile coating

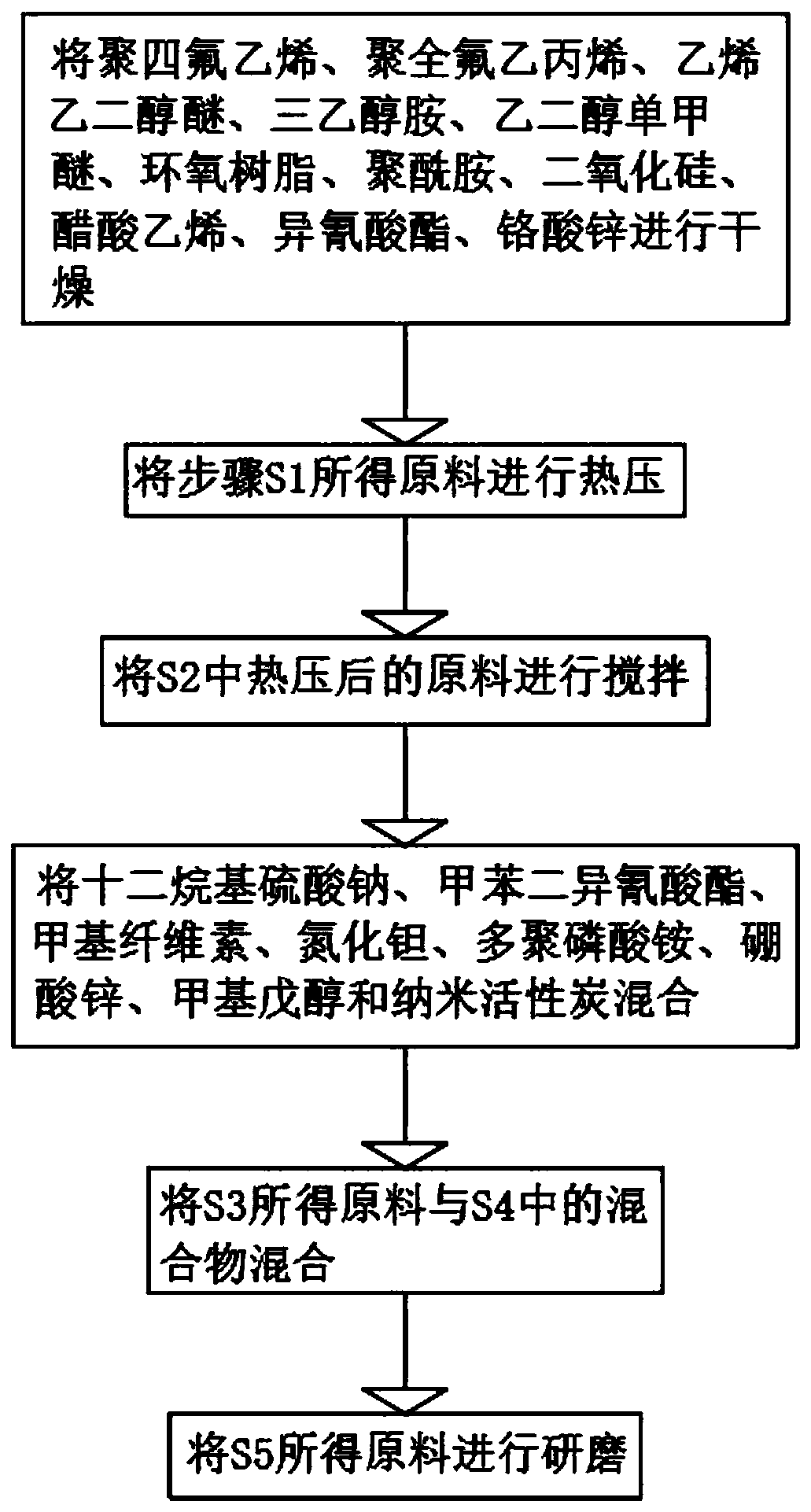

PendingCN110951334AMix quickly and evenlyImprove drying efficiencyDrying machines with non-progressive movementsDrying solid materialsCelluloseOxidation resistant

The invention discloses a preparation method of an anti-oxidation and anti-discoloration water-based automobile coating. The preparation method comprises the following steps of S1, drying raw materials; S2, putting the raw materials obtained in step S1 into a hot press; S3, stirring the raw materials subjected to hot pressing in S2; S4, adding lauryl sodium sulfate, toluene diisocynate, methyl cellulose, tantalum nitride, ammonium polyphosphate, zinc borate, methyl amyl alcohol and nano activated carbon into a reaction kettle; S5, adding raw materials obtained in S3 into the reaction kettle; and S6, grinding the raw materials obtained in S5. The invention further discloses preparation equipment of the oxidation-resistant and color-change-resistant water-based automobile coating. The preparation equipment comprises a shell, and a door body is movably connected to an outer surface of a front end of the shell. The preparation method and equipment of the oxidation-resistant and color-change-resistant water-based automobile coating are improved at the same time, so that the defect of a finished product caused by poor compatibility of multiple components is avoided, the quality control effect is good, the drying efficiency of the raw materials can be effectively improved, and the use is convenient.

Owner:广东华斓汽车材料研究院

Variable-frequency and variable-intensity feed vibration cutting and stirring device and method

PendingCN114768636AAdjust vibration intensityAdjustable vibration frequencyShaking/oscillating/vibrating mixersTransportation and packagingSpiral bladeEngineering

The invention relates to a feed vibration cutting and stirring device and method with variable frequency and strength, the feed vibration cutting and stirring device comprises a tank body, a cutting and stirring main shaft and a first driving device for driving the cutting and stirring main shaft to rotate, and the cutting and stirring main shaft is fixedly provided with a spiral blade located in the tank body; cutting blades are installed on the spiral blades, and a vibration mechanism is further installed on the cutting and stirring main shaft. The vibration intensity and the vibration frequency can be adjusted, so that the proper vibration intensity and frequency can be selected according to specific operation conditions, and feed in the tank body is subjected to vibration cutting and stirring; by means of vibration, cutting resistance between the cutting blades and materials is reduced, friction resistance between the spiral blades and the materials is reduced, viscous force between the materials is reduced, the materials can be mixed and cut rapidly and evenly, and the device has the advantages of being rapid in machining, even in mixing and capable of saving energy. And the abrasion of the spiral blade, the cutting blade and the tank body is reduced.

Owner:SHANDONG AGRICULTURAL UNIVERSITY +1

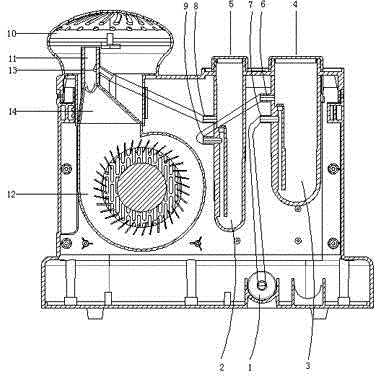

Heating atomization burner

InactiveCN104791785AImprove combustion efficiencyFine and uniform oil dropletsBurnersOptimal designFuel oil

The invention discloses a heating atomization burner, relates to a fuel atomizer, and belongs to the technical field of optimal design of burners. The burner comprises a burner chassis (12), a mixing chamber (17) and a burning head (6), wherein the burner chassis (12) is connected with a heating steam inlet (10), a heating oil joint (18), a heavy oil heater (20) and a temperature measurer (11); the burner chassis (12) is connected with a nozzle (22); a steam channel (23) is formed in the burner chassis (12); the outer side of the steam channel (23) is provided with a light oil channel (13) and a heavy oil channel (14), and is coated with a seamless steel pipe (15); the mixing chamber (17) is arranged between the burner chassis (12) and the burning head (6); and a burner igniter (16) is additionally arranged on the burner chassis (12). The burner is high in burning efficiency and reasonable in air distribution, improves the space distribution uniformity in fuel atomization, improves the burning performance, and reduces the pollutant discharge.

Owner:都傧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com