Oxidation reactor for preparing titanium white through chlorination process, and method

A technology of oxidation reactor and chlorination method, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of prolonging the time of full mixing and affecting the particle size distribution of titanium dioxide, so as to prevent formation and blockage and reduce corrosion With the possibility of scarring, the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

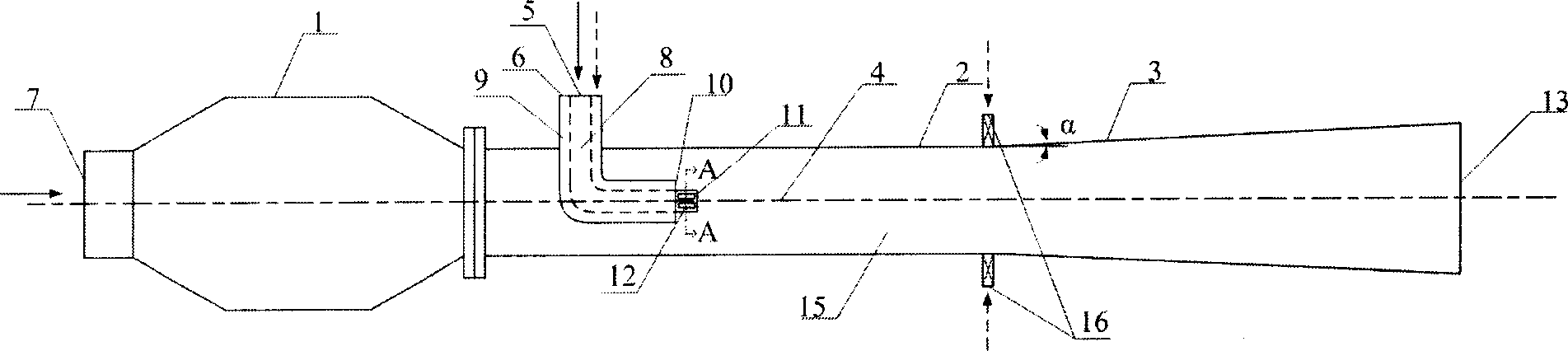

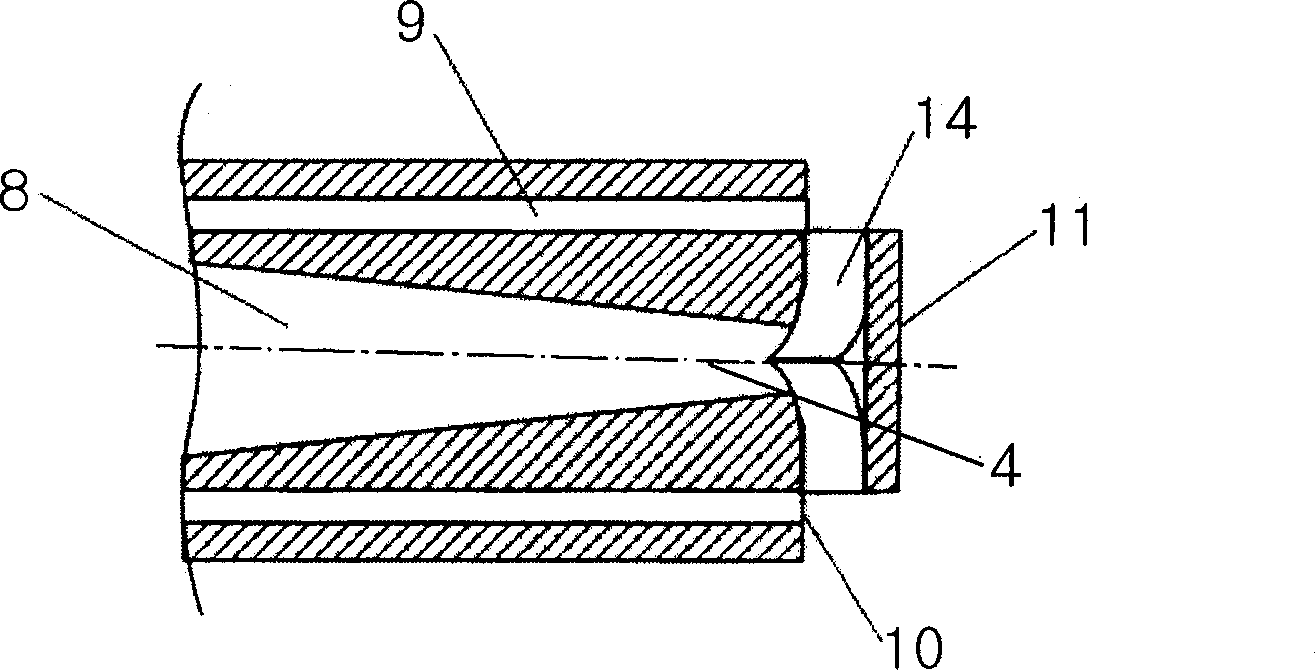

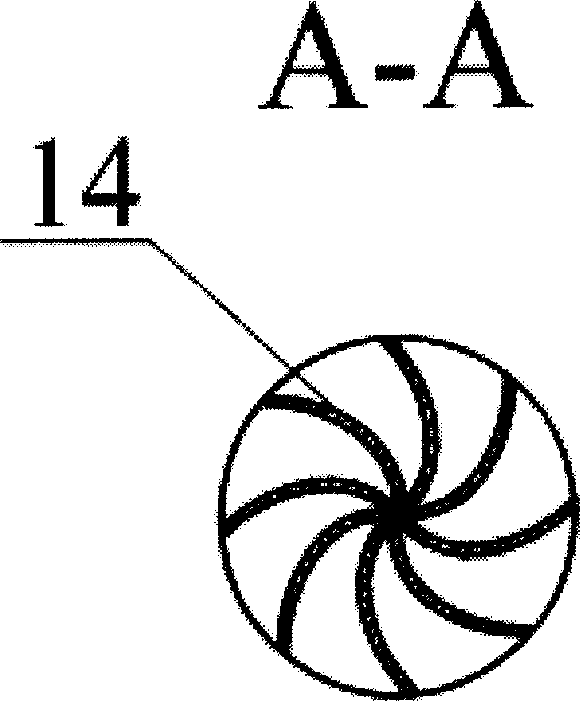

[0033] The shell of the development zone of the oxidation reactor of the present invention is a gradually expanding cone with a taper α of 8 degrees. The gap between the cooling jacket and the titanium tetrachloride delivery pipe is 3mm, and there are 10 nozzles on the side wall of the nozzle, in:

[0035] Oxygen temperature entering the reaction chamber after combustion: 1500°C

[0036] Titanium tetrachloride and aluminum trichloride: Temperature: 450°C

[0037] Mass ratio of titanium tetrachloride to aluminum trichloride: 100:1

[0038] Cooling gas A: Oxygen, temperature: 25°C

[0039] Cooling gas B: Chlorine, temperature: 25°C

[0040] Operating under the same conditions, there is no scarring in the reactor, the working surface in the furnace is smooth, and the particle size and particle size distribution of the product can be adjusted according to the length of the reactor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com