High-performance rubber asphalt and preparation method thereof

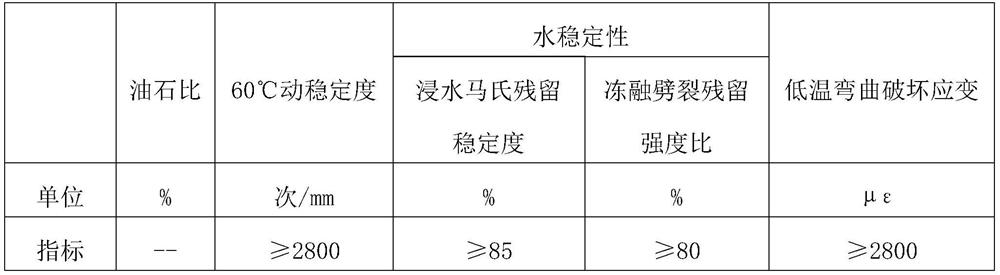

A rubber asphalt, high-performance technology, applied in the field of asphalt material composition and its preparation, can solve the problems of poor comprehensive road performance, asphalt mixture elasticity, poor high-temperature rutting resistance, and low rubber powder doping, etc. To achieve the effect of improving comprehensive road performance, better comprehensive physical performance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of high-performance rubber asphalt of the present invention comprises the following steps:

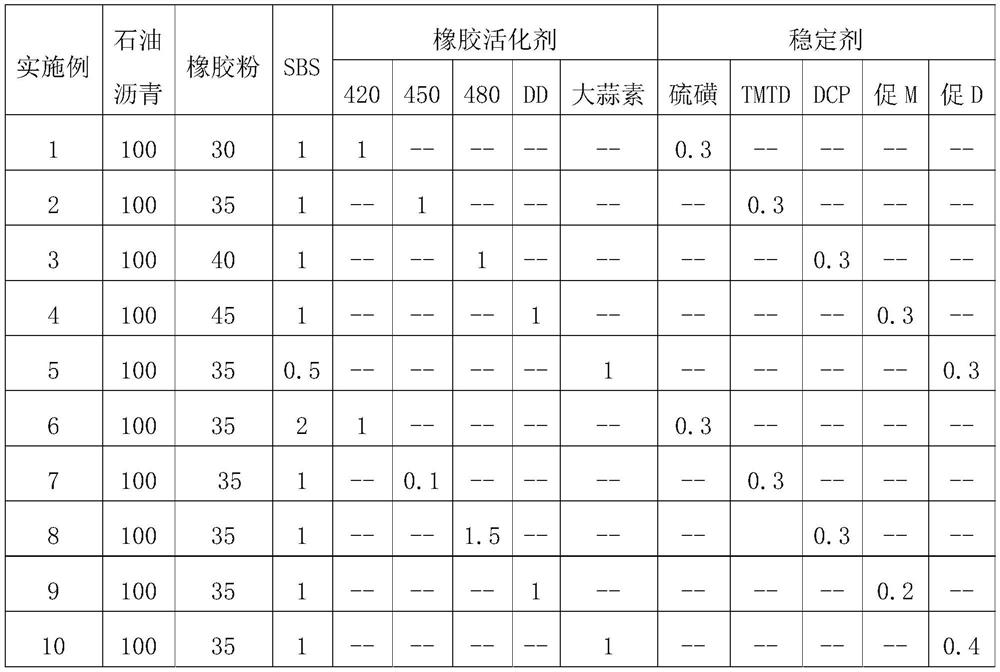

[0043] Step 1, screen out the rubber powder with suitable particle size, weigh the rubber powder, rubber activator and stabilizer according to the measurement, and put them in the high-speed mixing equipment; start the high-speed mixing equipment, and the rubber powder, rubber activator and stabilizer The stabilizer was thoroughly mixed to obtain Mixture A.

[0044] Step 2: Weigh the asphalt and SBS according to the measurement, put the asphalt into the mixing tank, and heat the asphalt to 210-220°C, then add the weighed SBS and 1 / 2 of the mixture A, and heat it at a temperature of 210-220°C 20-45 min at a stirring rate of 500-800 rpm to form mixture B. The heating temperature and holding temperature here are both 215° C., the stirring rate is 650 rpm, and the stirring time is 30 min.

[0045] Step 3, put the mixture B into the high-speed shear emulsifie...

Embodiment 1

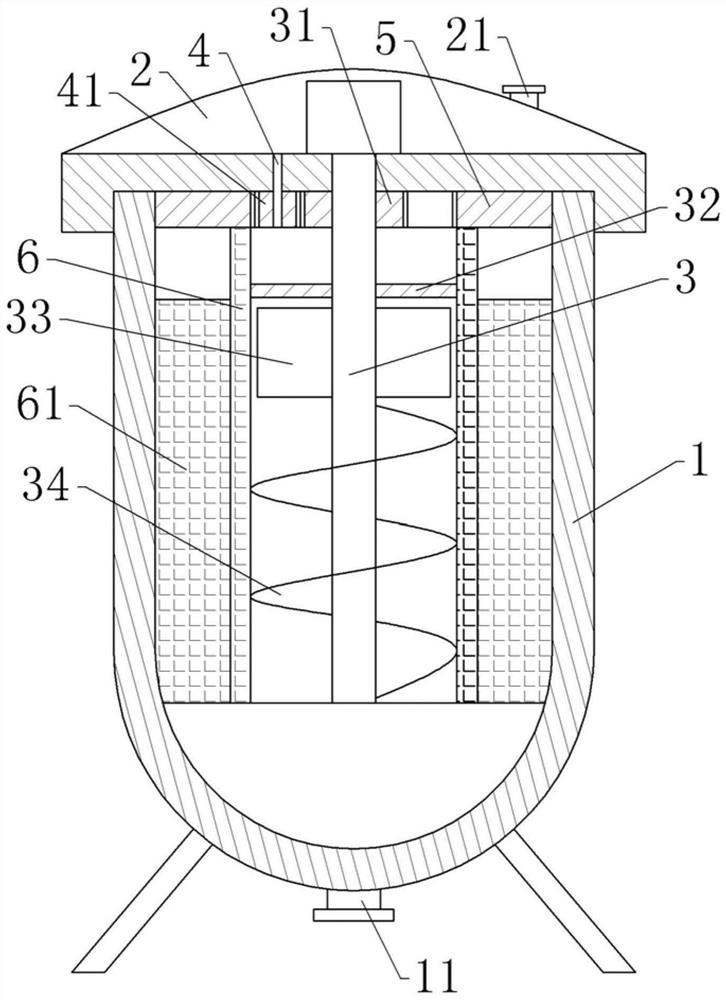

[0050] Embodiment 11 differs from Embodiment 1 only in that, as figure 1 As shown, the high-speed shear emulsifier used includes a tank body 1, a heating channel is arranged on the outer wall of the tank body 1, and a heat source is connected to the heating channel (for example, water, oil, liquid metal, etc. are passed into the heating channel). The top of the tank body 1 is provided with a sealing cover body 2 , the sealing cover body 2 is provided with a material inlet 21 , and the bottom of the tank body 1 is provided with a material outlet port 11 . The material inlet 21 is provided with a sealing plug, and the material outlet 11 is provided with a discharge valve.

[0051] The inner side of the sealing cover 2 is fixed with a motor, the driving shaft 4 of the motor is coaxially fixed with the stirring shaft 3, and the driving gear 31 is coaxially fixed on the stirring shaft 3; the sealing cover 2 is also rotatably connected with the driving shaft 4, and the driving shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com