Preparation method and equipment of anti-oxidation and anti-discoloration water-based automobile coating

An anti-discoloration and anti-oxidation technology, used in epoxy resin coatings, polyamide coatings, lighting and heating equipment, etc., can solve the problem that the quality of finished products cannot be well guaranteed, the drying efficiency of raw materials cannot be guaranteed, and To ensure the good state of raw materials and other issues, to achieve the effect of good quality control, avoid the bad of the finished product, and improve the drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

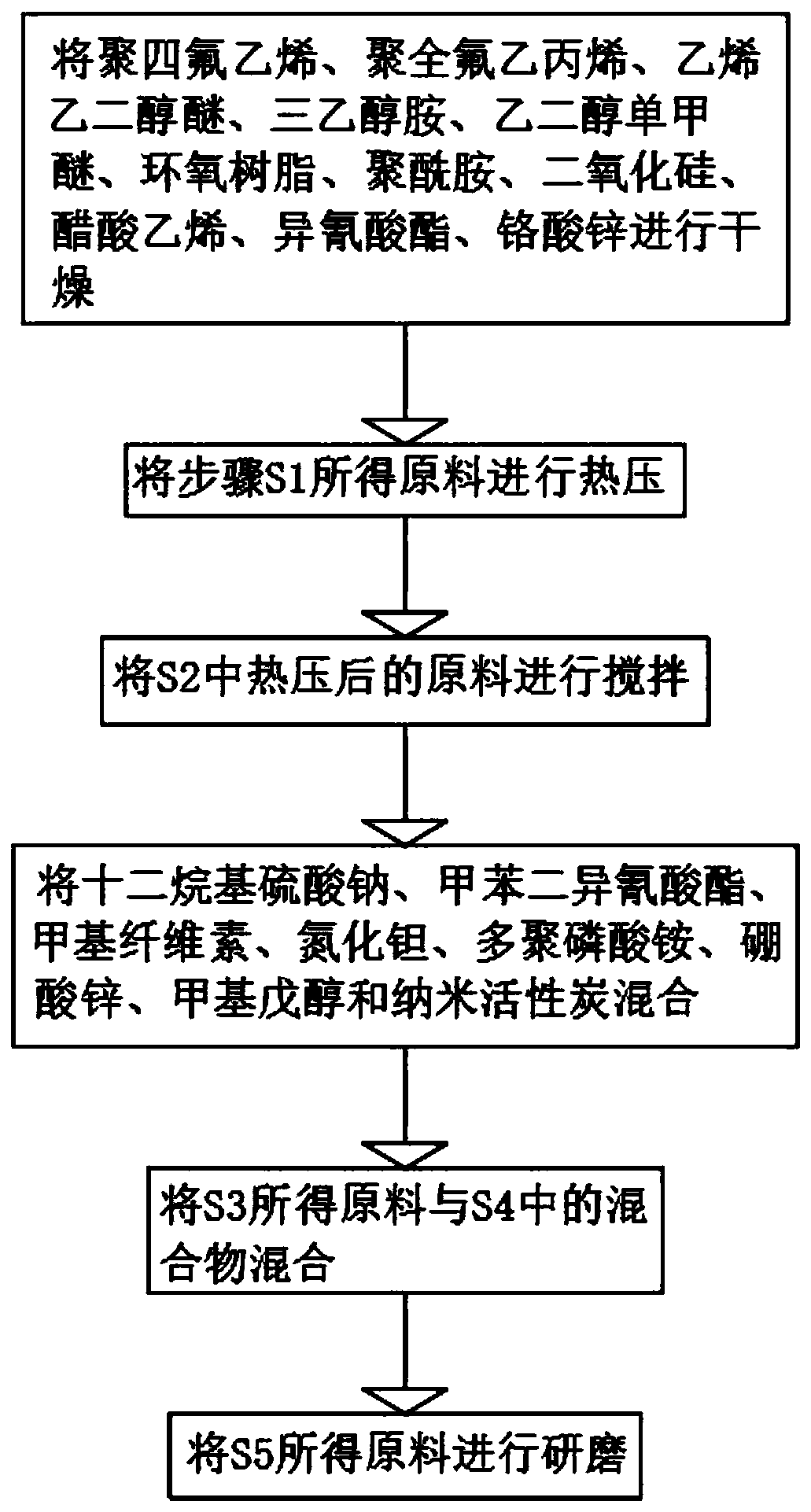

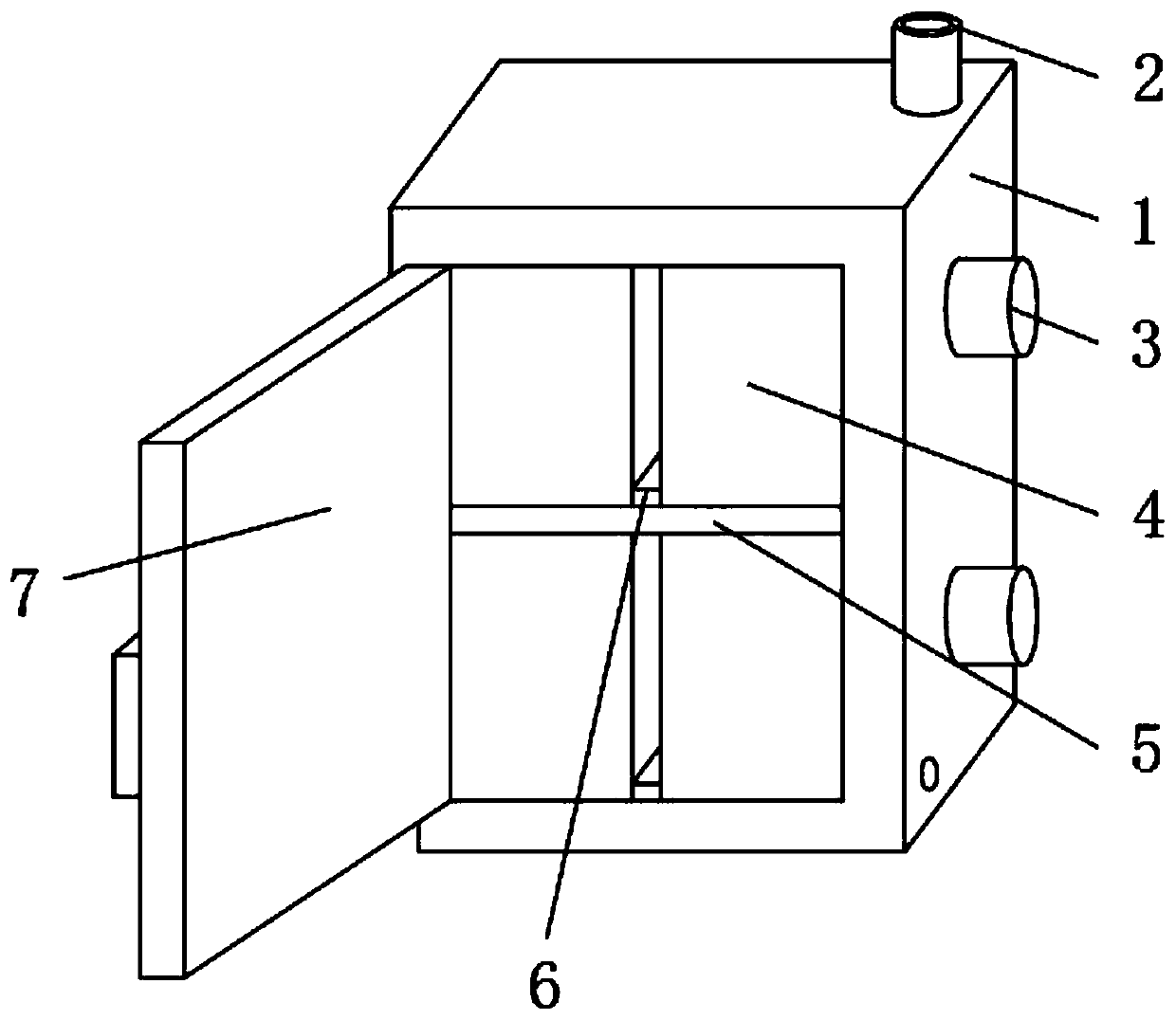

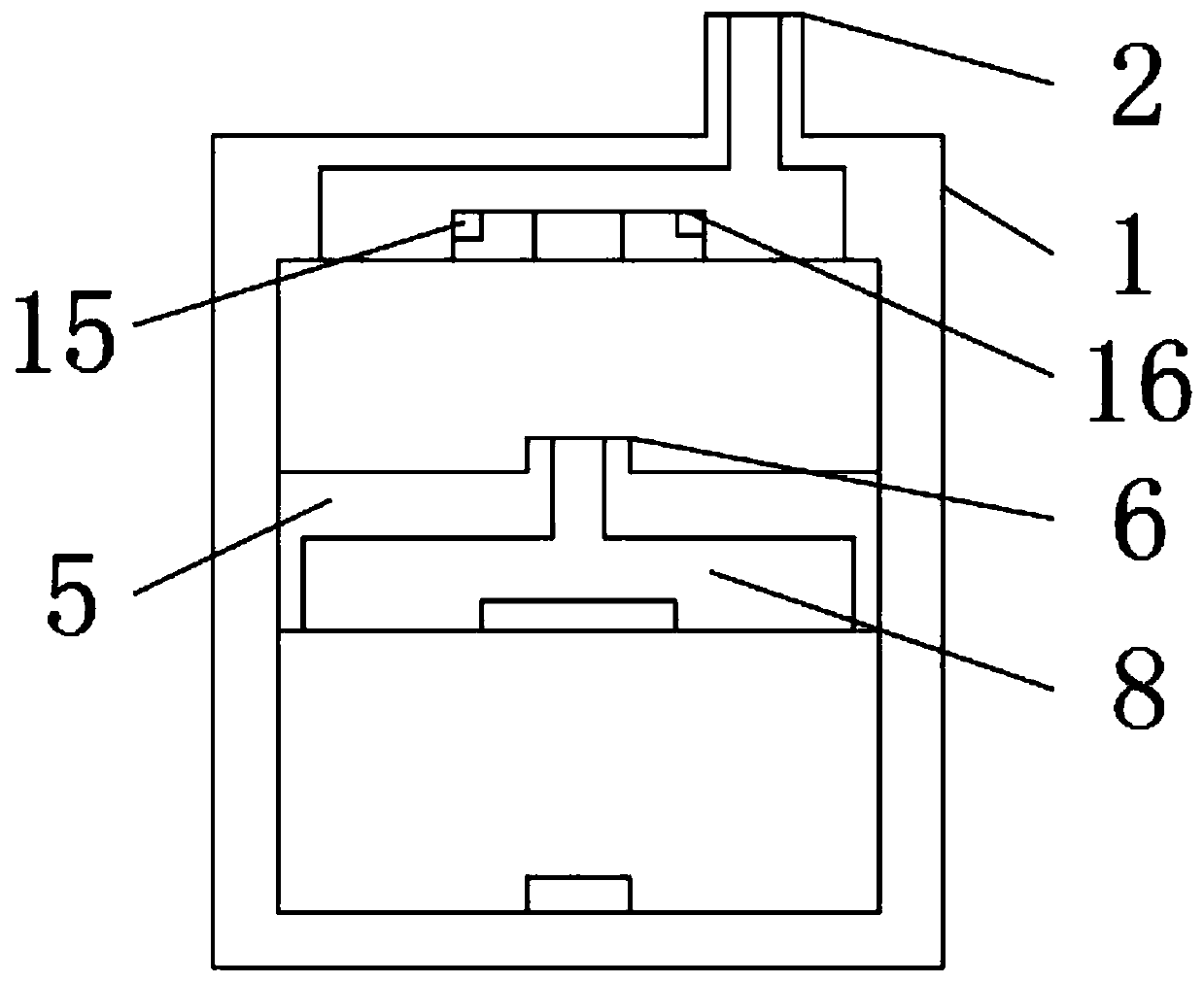

[0038] see Figure 1 to Figure 5 , the preparation method of the anti-oxidation and anti-discoloration water-based automotive coating provided by the present embodiment, such as figure 1 shown, including the following steps:

[0039] S1: 75-80 parts of polytetrafluoroethylene, 32-38 parts of polyperfluoroethylene propylene, 14-16 parts of ethylene glycol ether, 7-11 parts of triethanolamine, 6-8 parts of ethylene glycol monomethyl ether, Put 12-16 parts of epoxy resin, 13-18 parts of polyamide, 5-10 parts of silicon dioxide, 22-24 parts of vinyl acetate, 15-20 parts of isocyanate, and 7-12 parts of zinc chromate into the drying oven, adjust The heating temperature is 54-58°C, dry for 5-10 minutes, and set aside;

[0040]S2: Put the raw materials obtained in S1 into a hot press, keep the heating temperature at 78-80°C, adjust the pressure of the hot press to 5MPa, press for 3-5 minutes, and set aside;

[0041] S3: Stir the hot-pressed raw materials in S2, use a mixer to mix ...

Embodiment 2

[0051] The anti-oxidation and anti-discoloration water-based automotive paint, preparation method and preparation equipment provided by the present embodiment are basically the same as in Example 1, except that:

[0052] It includes the following steps:

[0053] S1: 75 parts of polytetrafluoroethylene, 32 parts of polyperfluoroethylene propylene, 14 parts of ethylene glycol ether, 7 parts of triethanolamine, 6 parts of ethylene glycol monomethyl ether, 12 parts of epoxy resin, and 13 parts of polyamide , 5 parts of silicon dioxide, 22 parts of vinyl acetate, 15 parts of isocyanate, and 7 parts of zinc chromate are put into a drying oven, and the heating temperature is adjusted to 54-58 ° C, dried for 5-10 minutes, and set aside;

[0054] S4: 4 parts of sodium lauryl sulfate, 12 parts of toluene diisocyanate, 6 parts of methyl cellulose, 3 parts of tantalum nitride, 1 part of ammonium polyphosphate, 11 parts of zinc borate, 13 parts of methyl amyl alcohol and 13 parts of nano-...

Embodiment 3

[0056] The anti-oxidation and anti-discoloration water-based automotive paint, preparation method and preparation equipment provided by the present embodiment are basically the same as in Example 1, except that:

[0057] It includes the following steps:

[0058] S1: 78 parts of polytetrafluoroethylene, 35 parts of polyperfluoroethylene propylene, 15 parts of ethylene glycol ether, 10 parts of triethanolamine, 7 parts of ethylene glycol monomethyl ether, 15 parts of epoxy resin, and 15 parts of polyamide , 8 parts of silicon dioxide, 23 parts of vinyl acetate, 18 parts of isocyanate, and 10 parts of zinc chromate are put into a drying oven, and the heating temperature is adjusted to 54-58 ° C, dried for 5-10 minutes, and set aside;

[0059] S4: 6 parts of sodium lauryl sulfate, 13 parts of toluene diisocyanate, 6.5 parts of methyl cellulose, 4 parts of tantalum nitride, 2 parts of ammonium polyphosphate, 14 parts of zinc borate, 15 parts of methyl amyl alcohol and 15 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com