Patents

Literature

176results about How to "Adjustable vibration frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

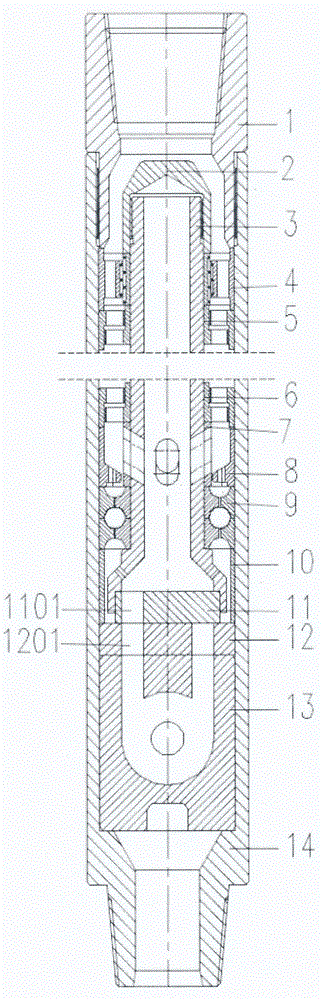

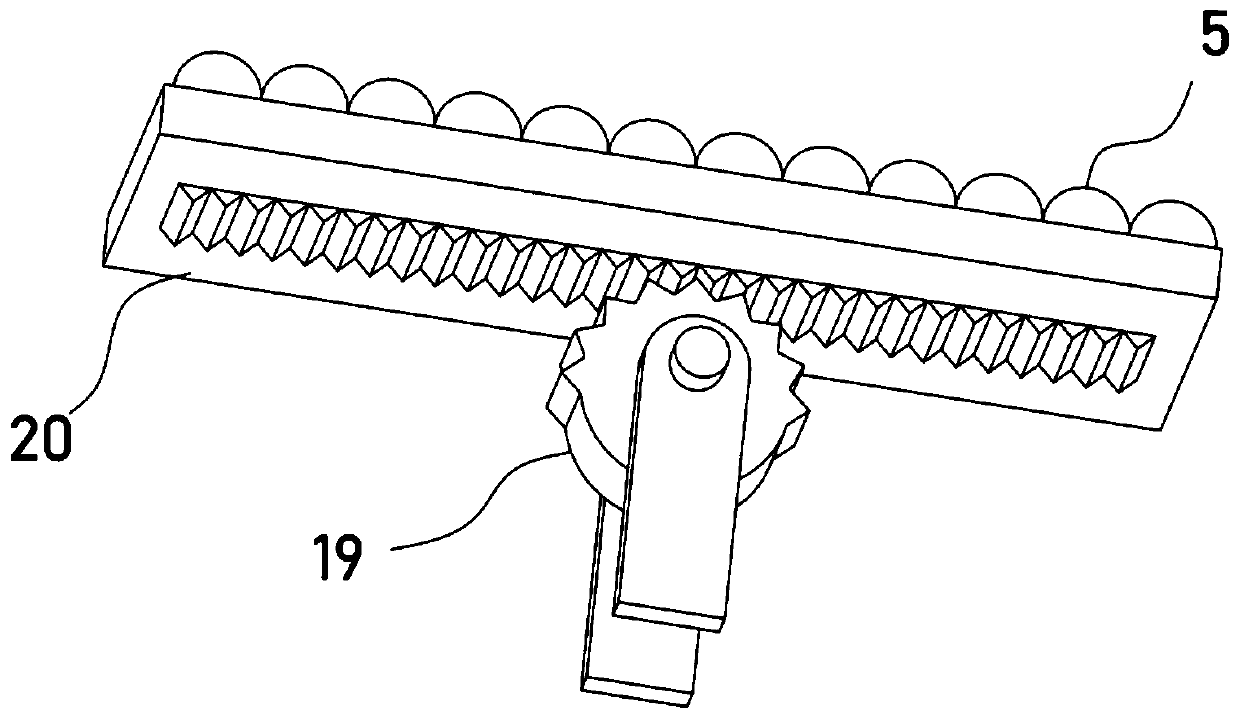

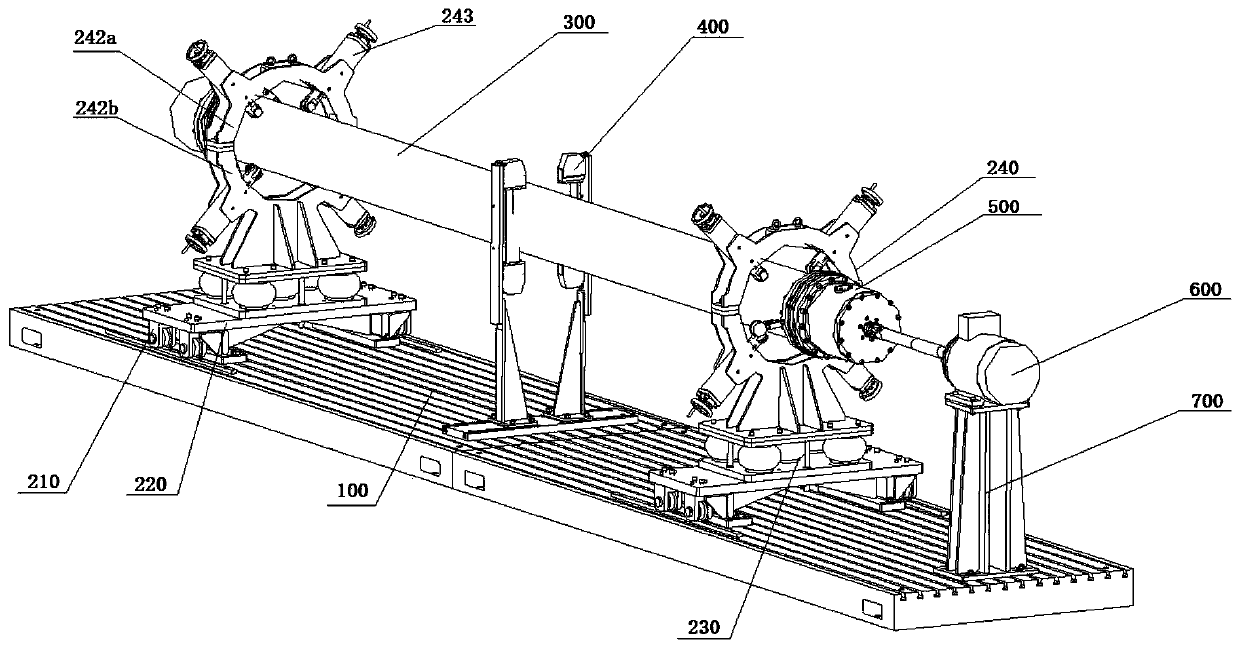

Multi-parameter adjustable cable fretting fatigue device

InactiveCN101017715AAdjustable vibration frequencyAvoid offsetStructural/machines measurementCoupling light guidesButt jointRelative motion

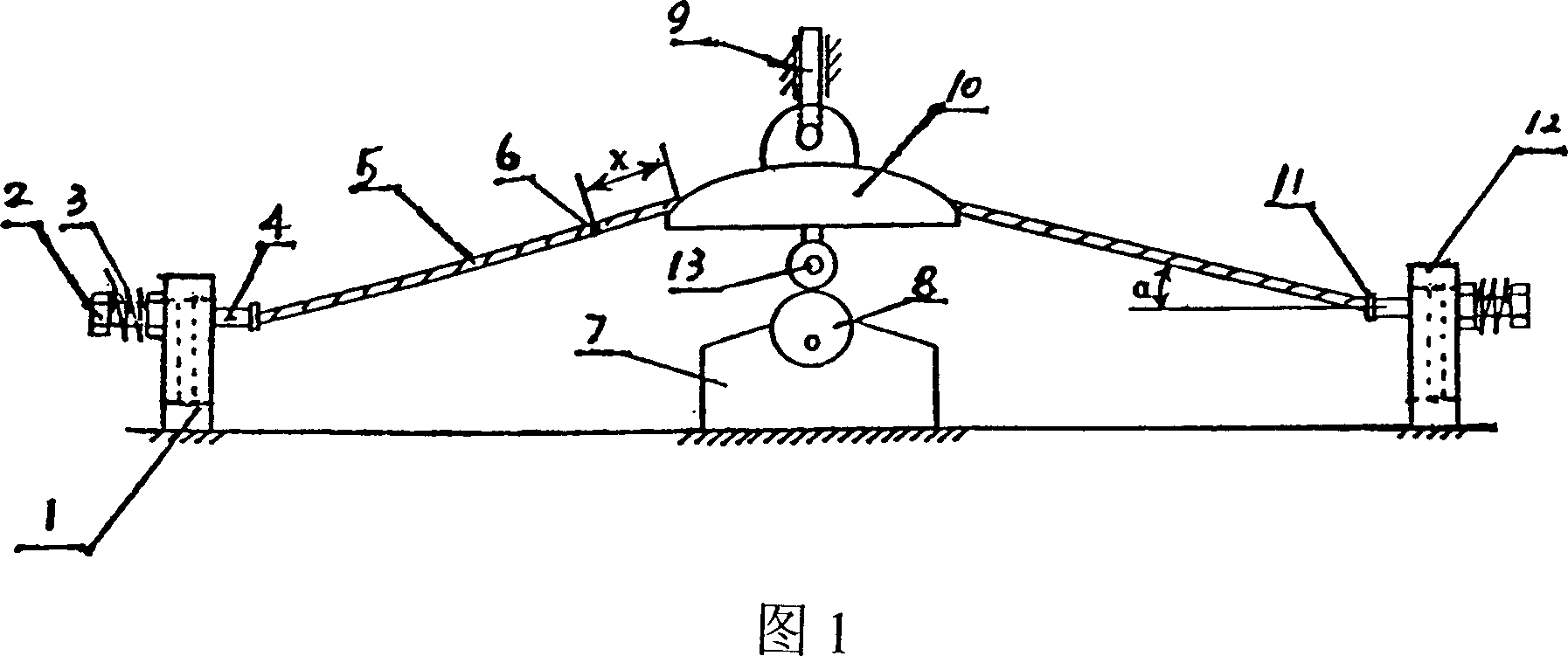

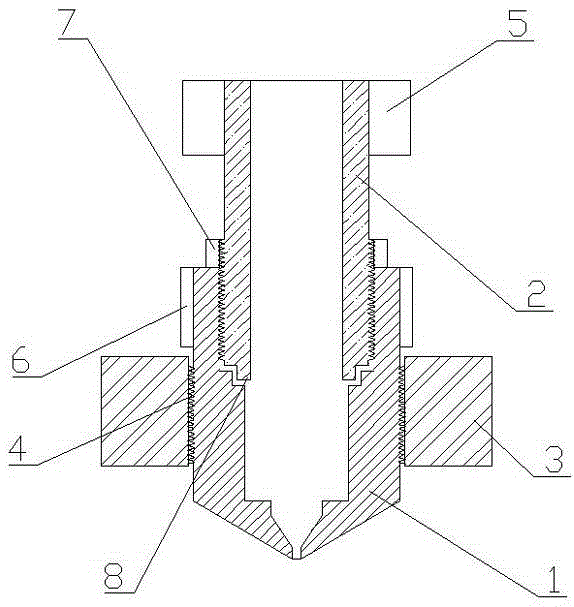

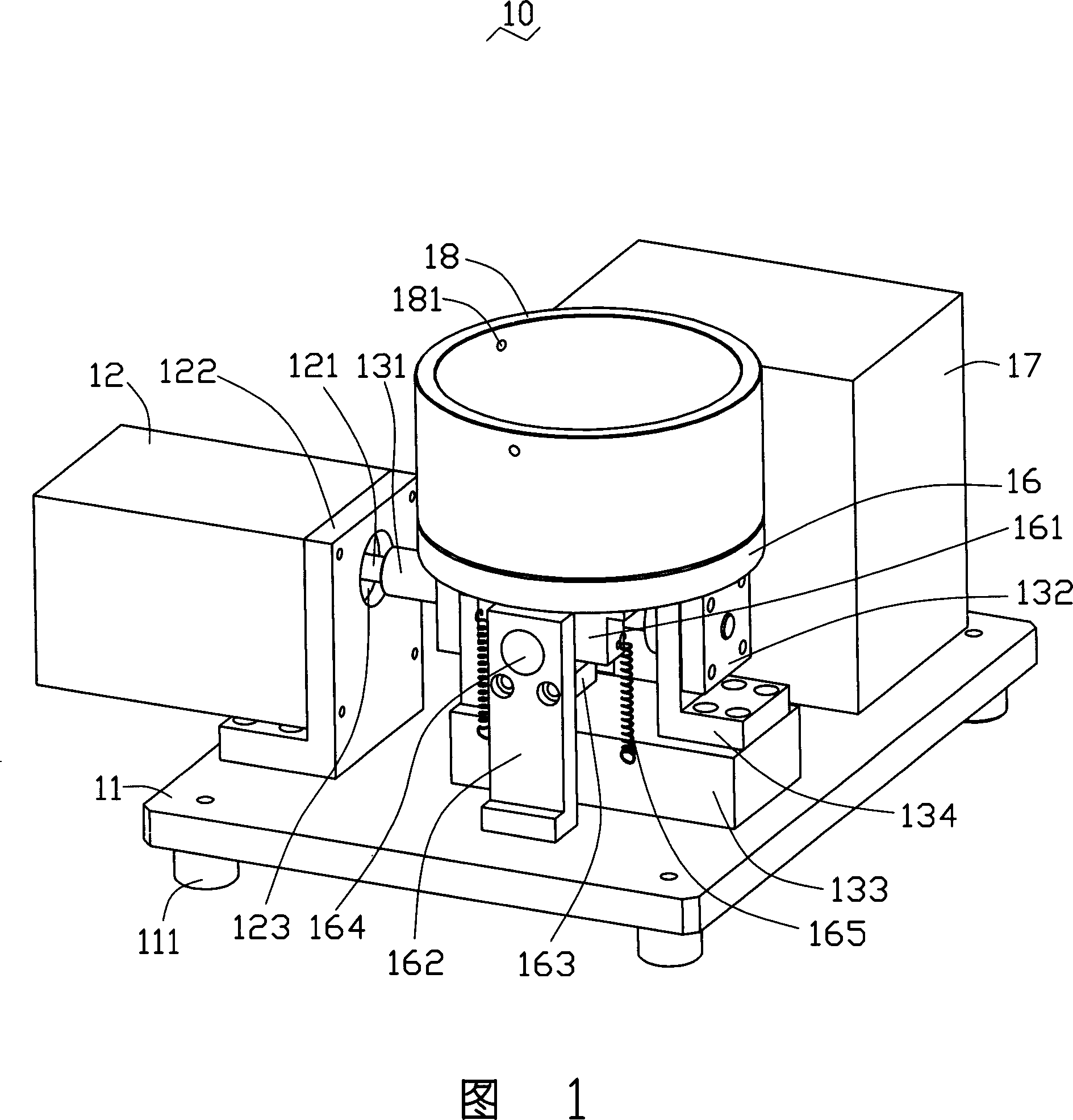

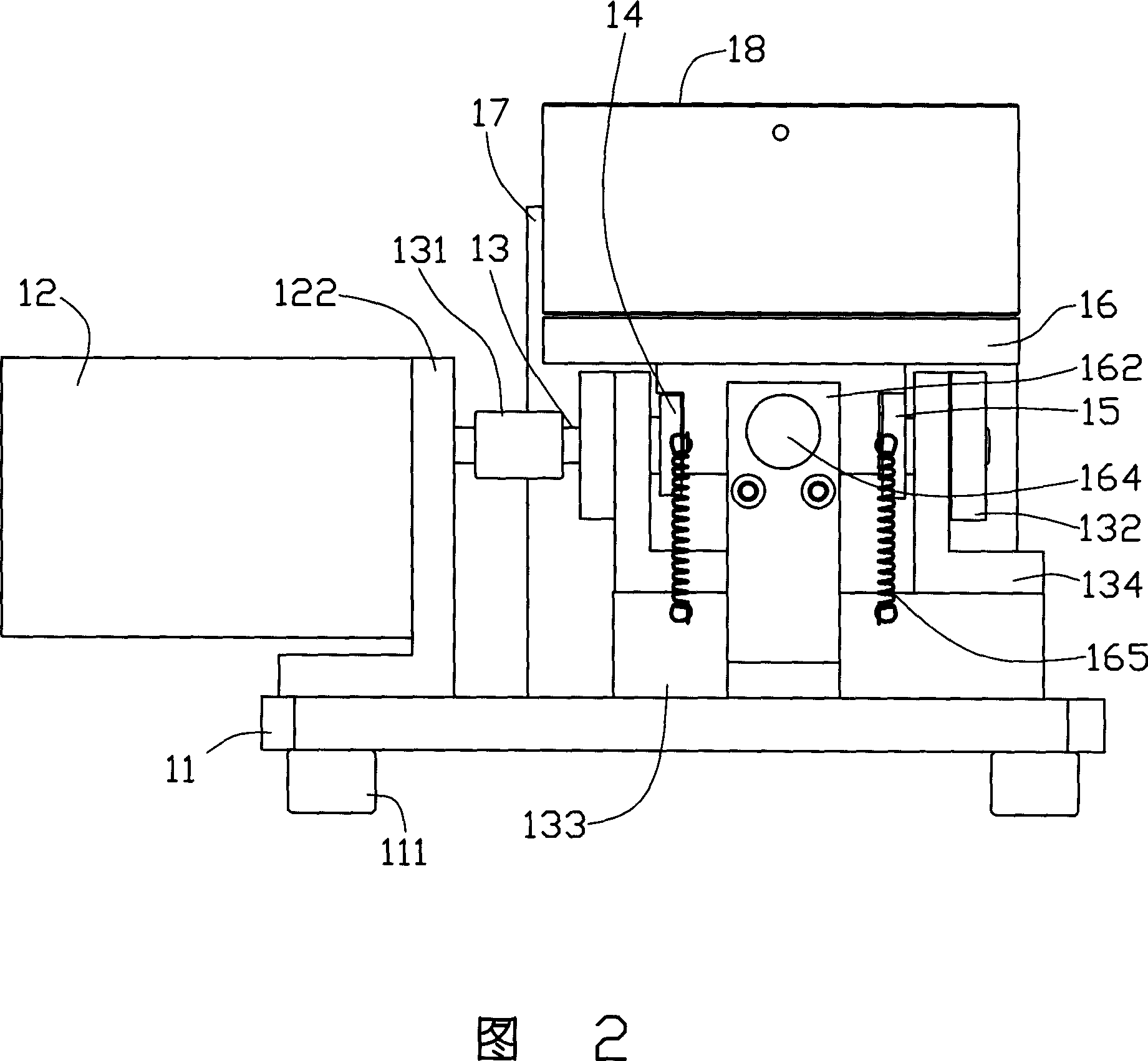

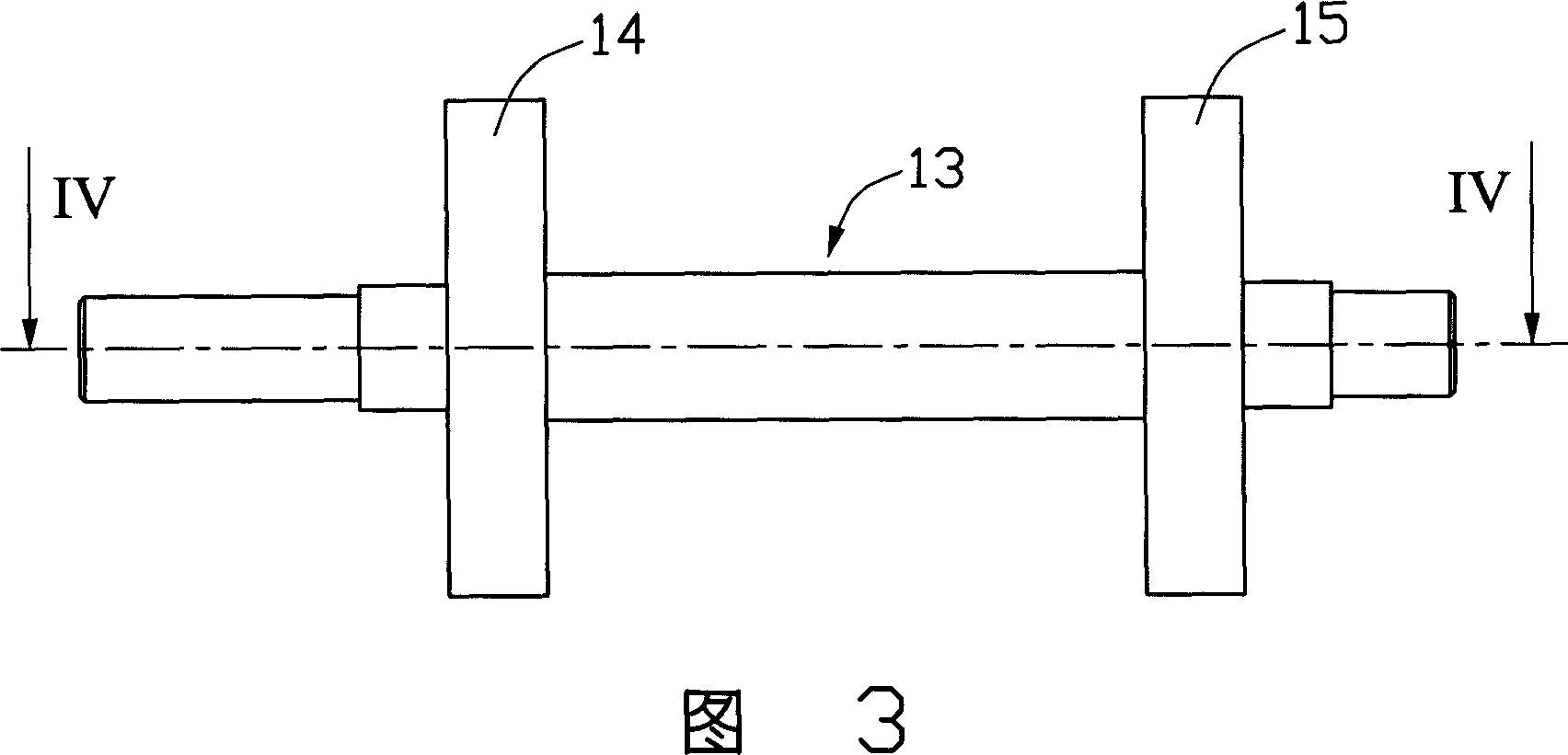

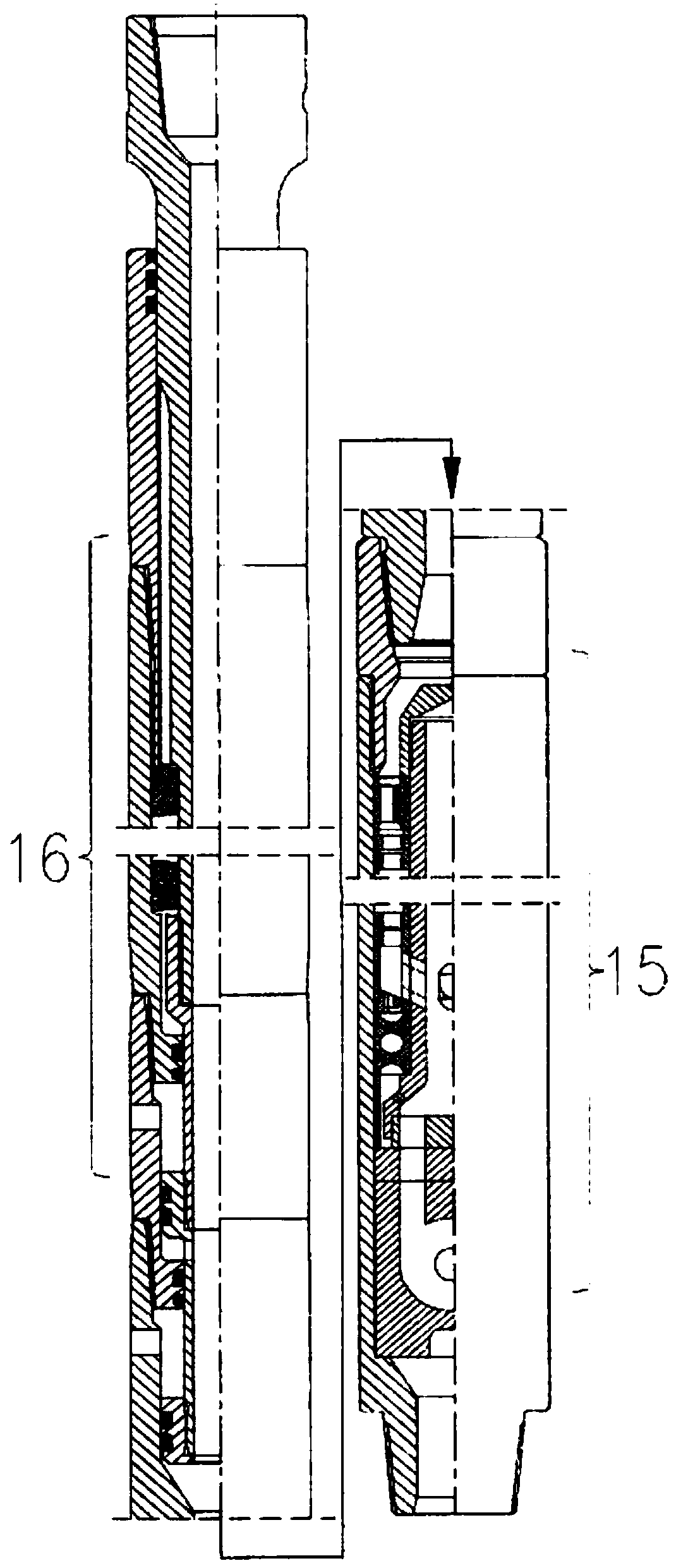

The invention relates to a multi-parameter adjustable cable fretting fatigue device. Wherein, the current wire vibration test bench mainly aims at the macroscopical wire vibrating or weaving; while for research on wire breaking, it is hard to adjust multiple parameters for vibrating frequency and amplitude, loading, and angle. This invention comprises a vibration source device, a tension device, a fixing slot base, a vertical location device, an overhanging-line clamp, some wires, a vibration detector, and a stress-strain detector. This invention completes the test by means of relative motion between the cam on motor shaft and flow butt-joint wheel fixed under the overhanging-line.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

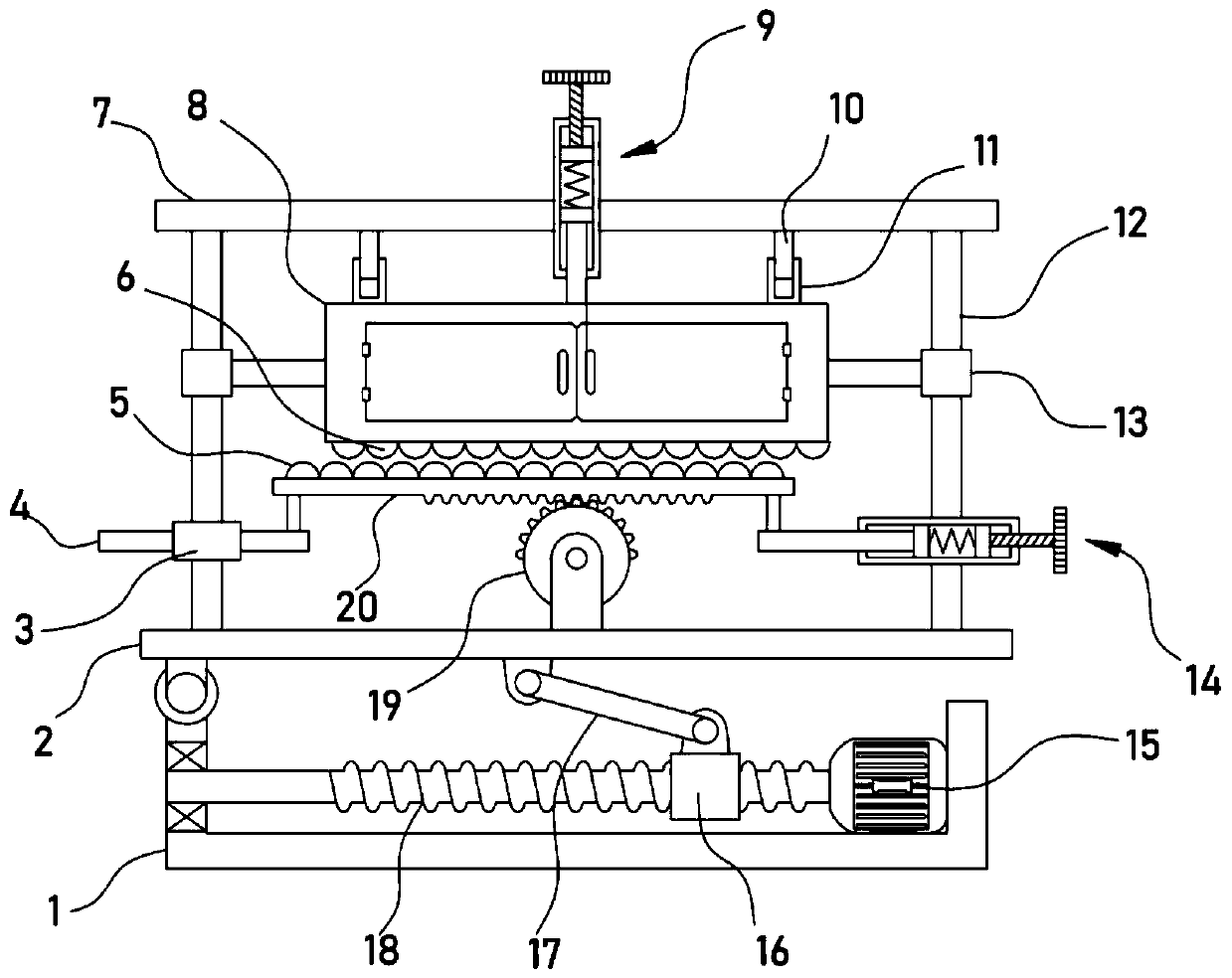

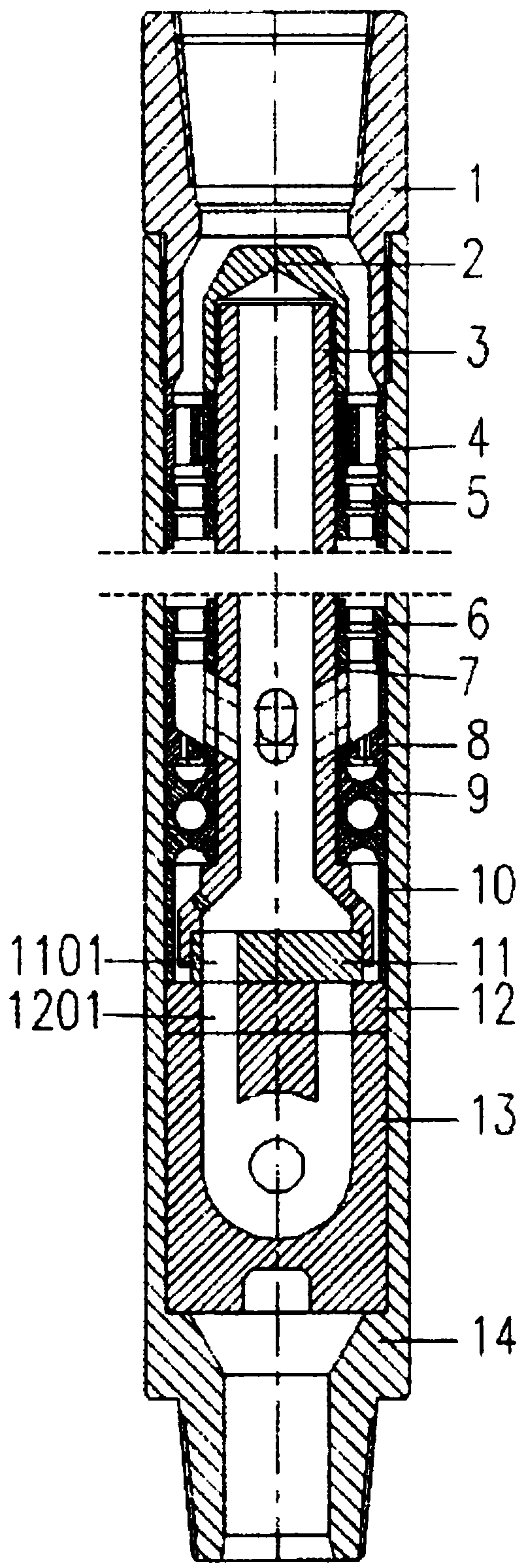

Handheld type branch vibration and fruit harvesting device

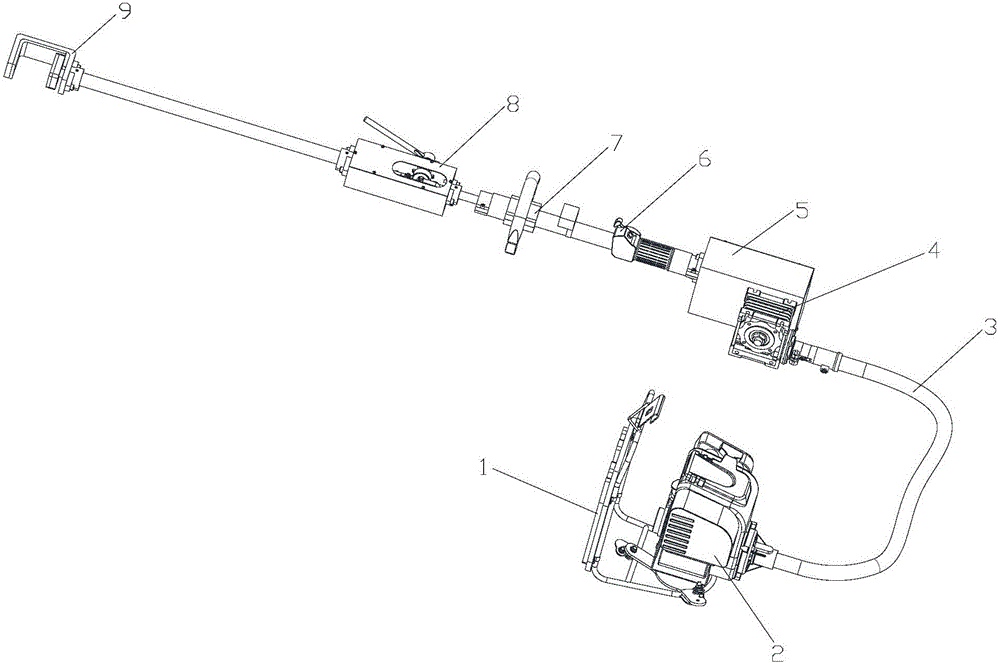

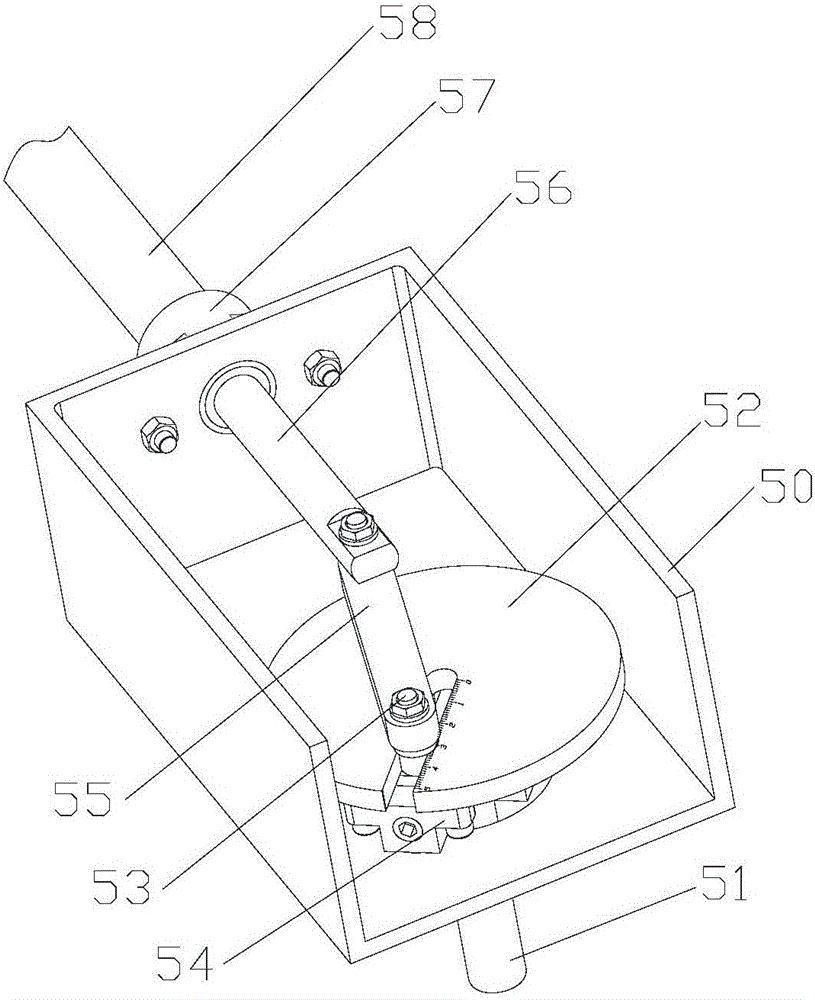

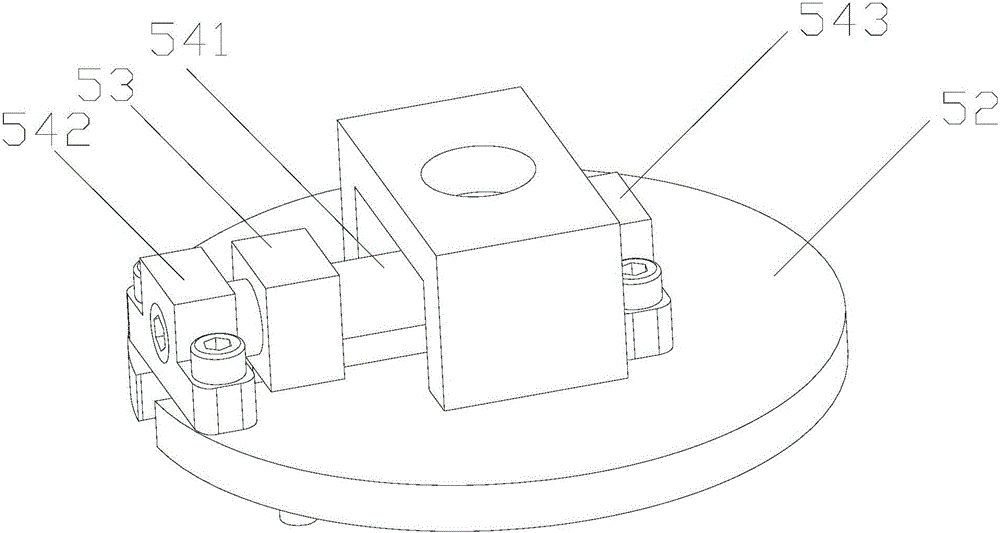

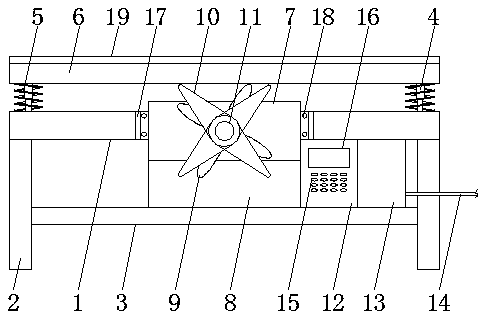

The invention relates to a handheld type branch vibration and fruit harvesting device and belongs to the technical field of fruit harvesting. The handheld type branch vibration and fruit harvesting device comprises a driving mechanism, a transmission mechanism, a vibration mechanism, a vibration-reducing handheld mechanism, a manual clamping mechanism, a branch clamping head and a ratchet wheel locking mechanism. The driving mechanism, a transmission mechanism, a vibration mechanism, a vibration-reducing handheld mechanism and a manual clamping mechanism are connected in sequence. The manual clamping mechanism comprises a crank push rod mechanism which controls clamping or loosening motions of the branch clamping head through forward direction or reverse rotation and is driven by a clamping handle. The ratchet wheel locking mechanism has a locking gear for controlling single forward direction rotation of the clamping handle and an unlocking gear for controlling forward direction or reverse direction rotation of the clamping handle. The handheld type branch vibration and fruit harvesting device can quickly clamp fruit tree branches and adjust vibration amplitude and frequency to perform vibration harvesting of fruits, improve fruit harvesting efficiency, reduce cost and alleviate damage to the fruit tree branches. The vibration-reducing handheld mechanism is adopted to prevent vibration fatigue damage to operators.

Owner:SOUTH CHINA AGRI UNIV

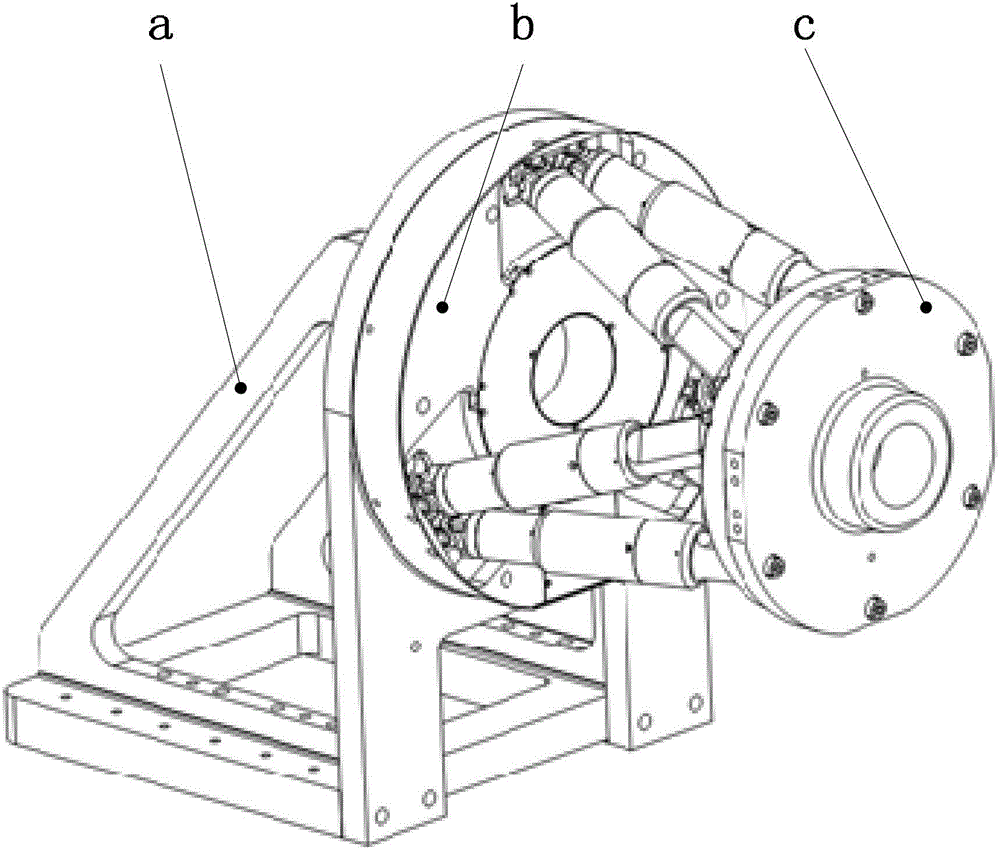

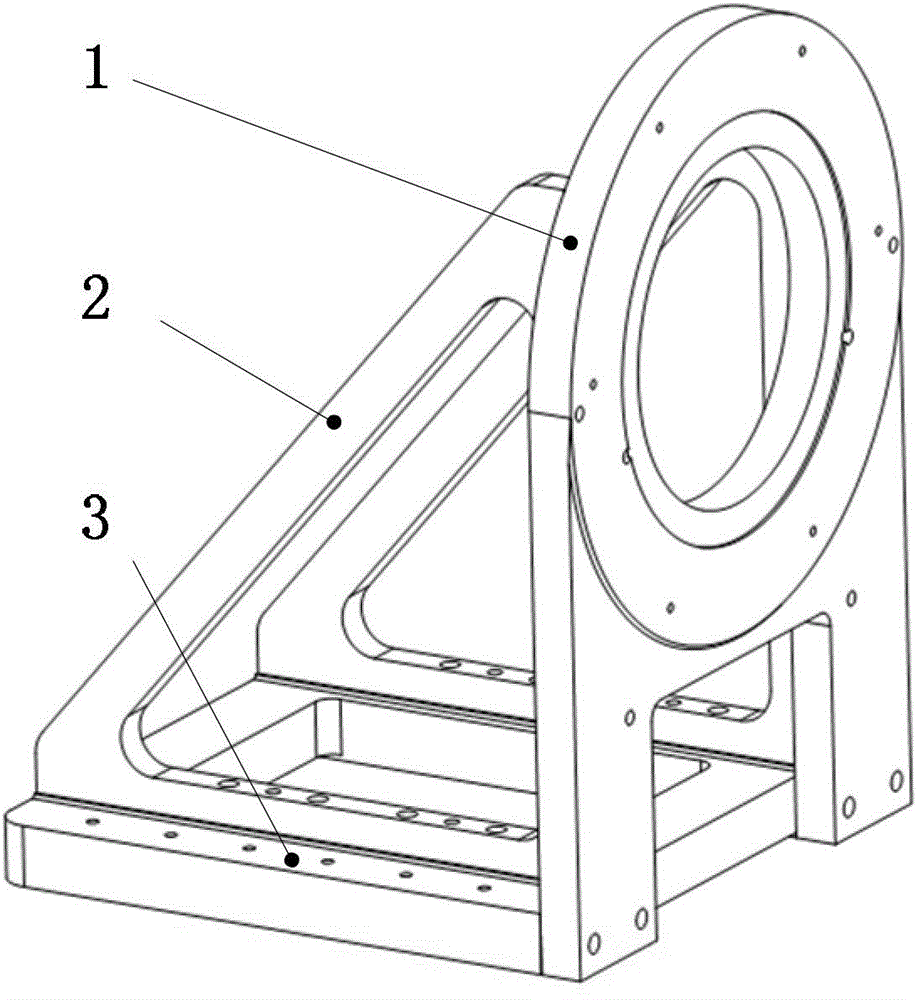

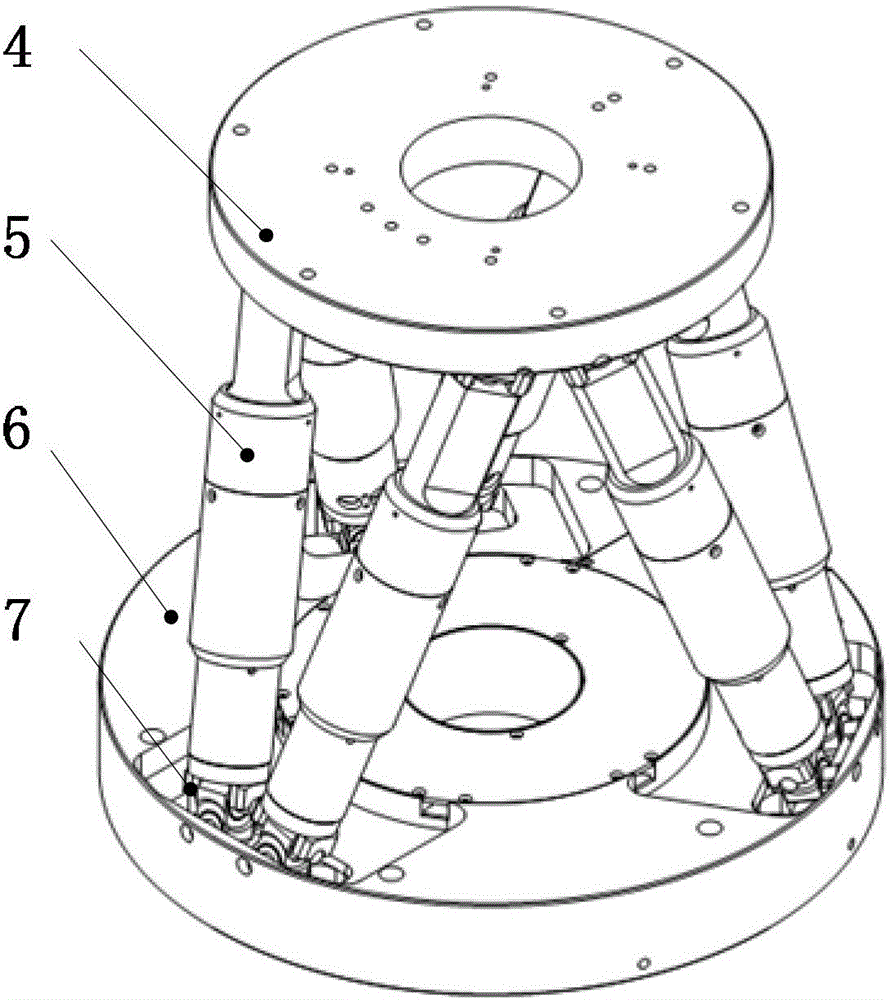

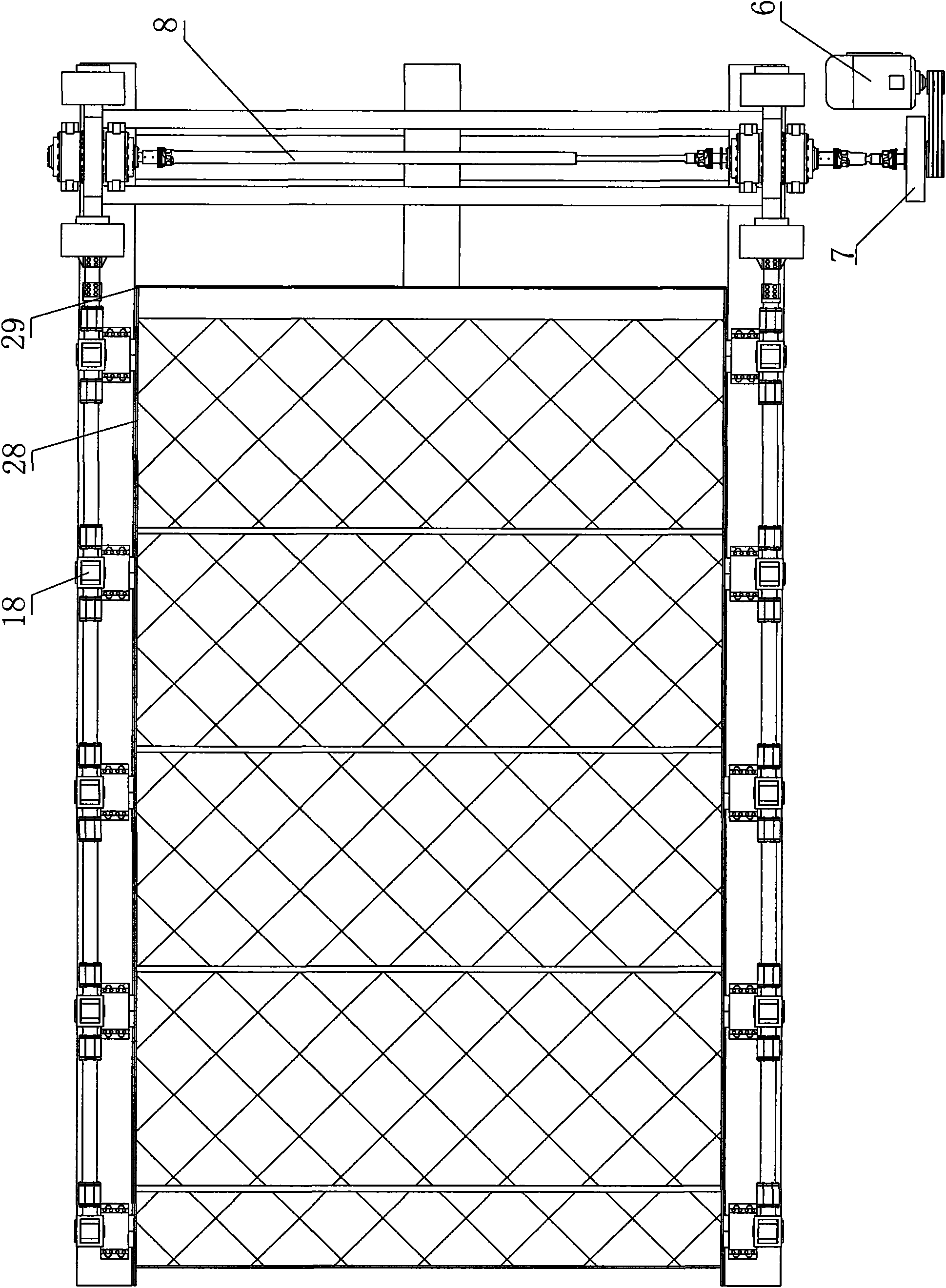

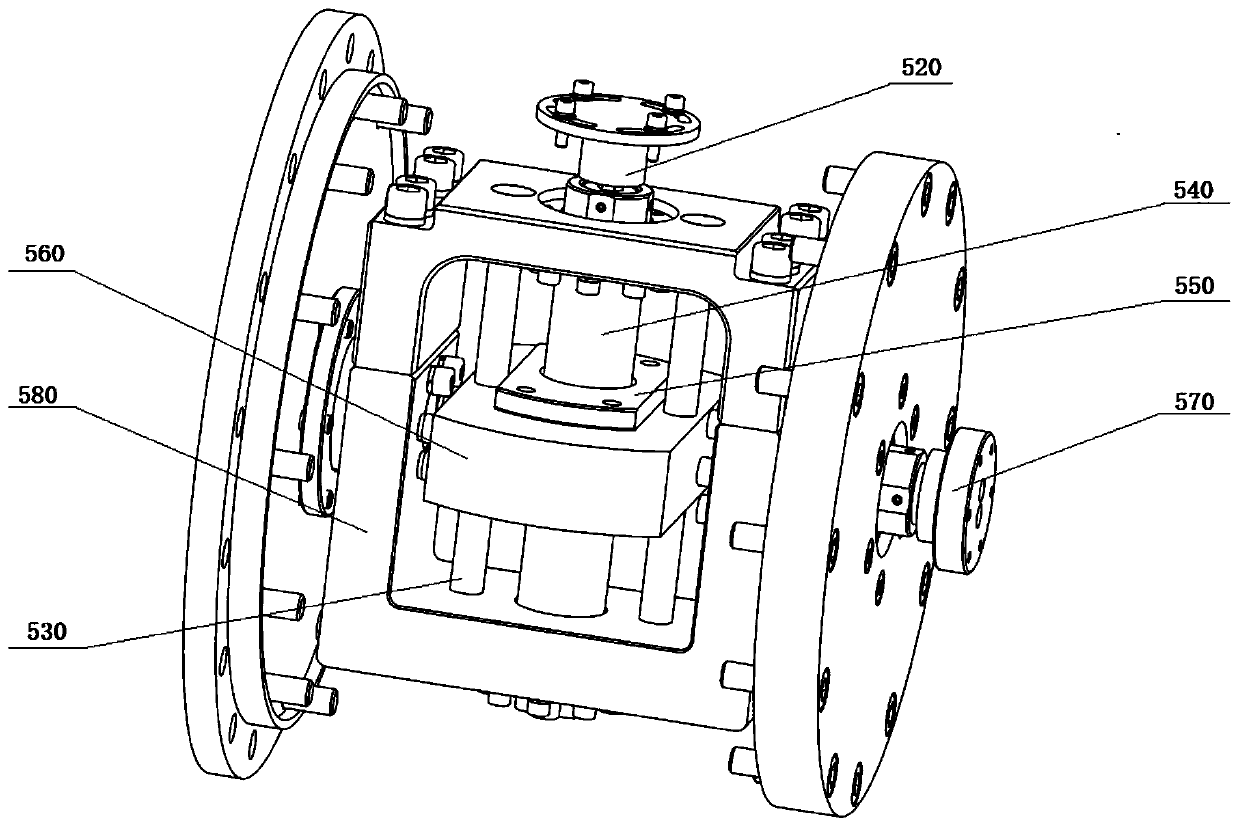

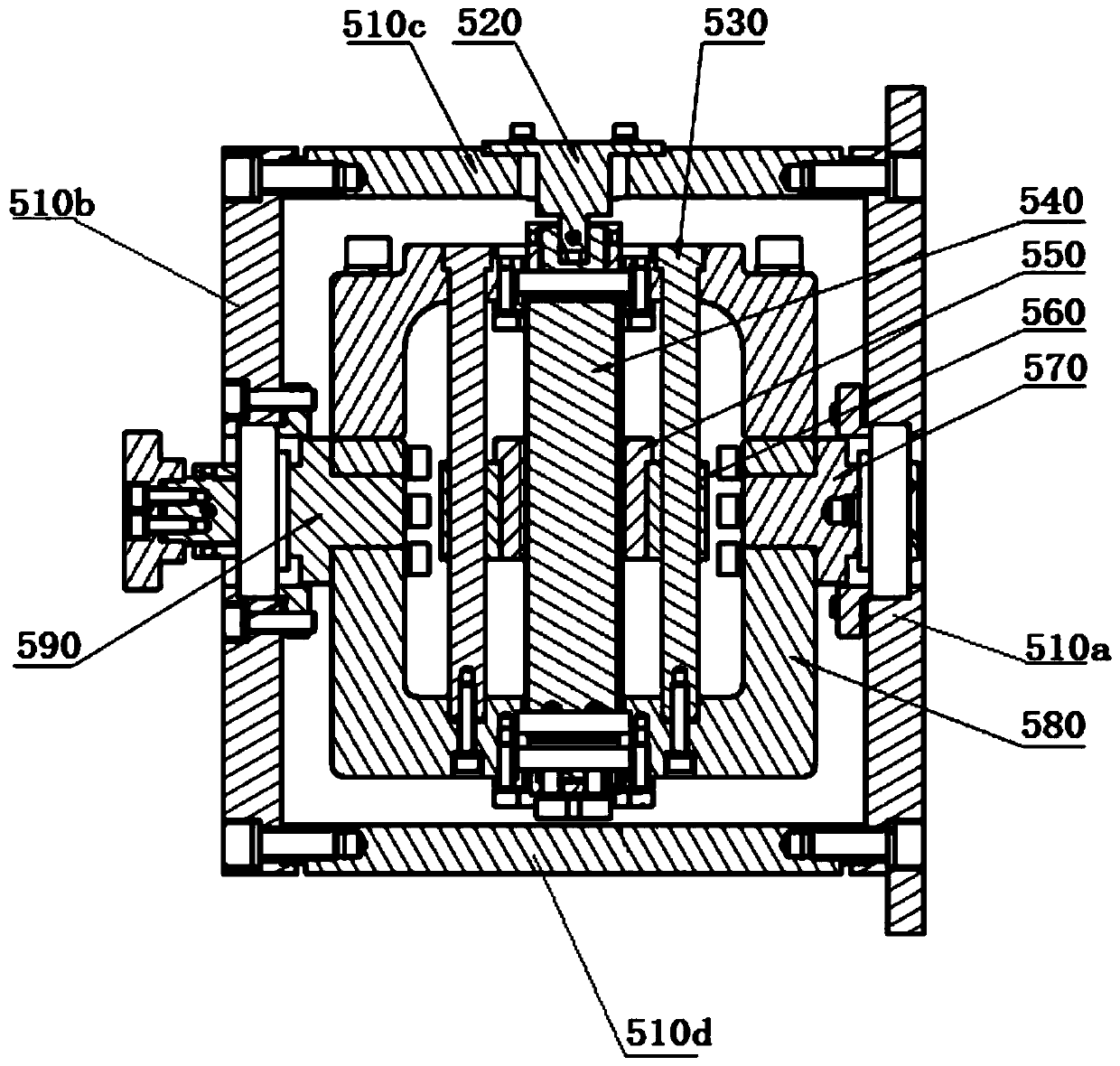

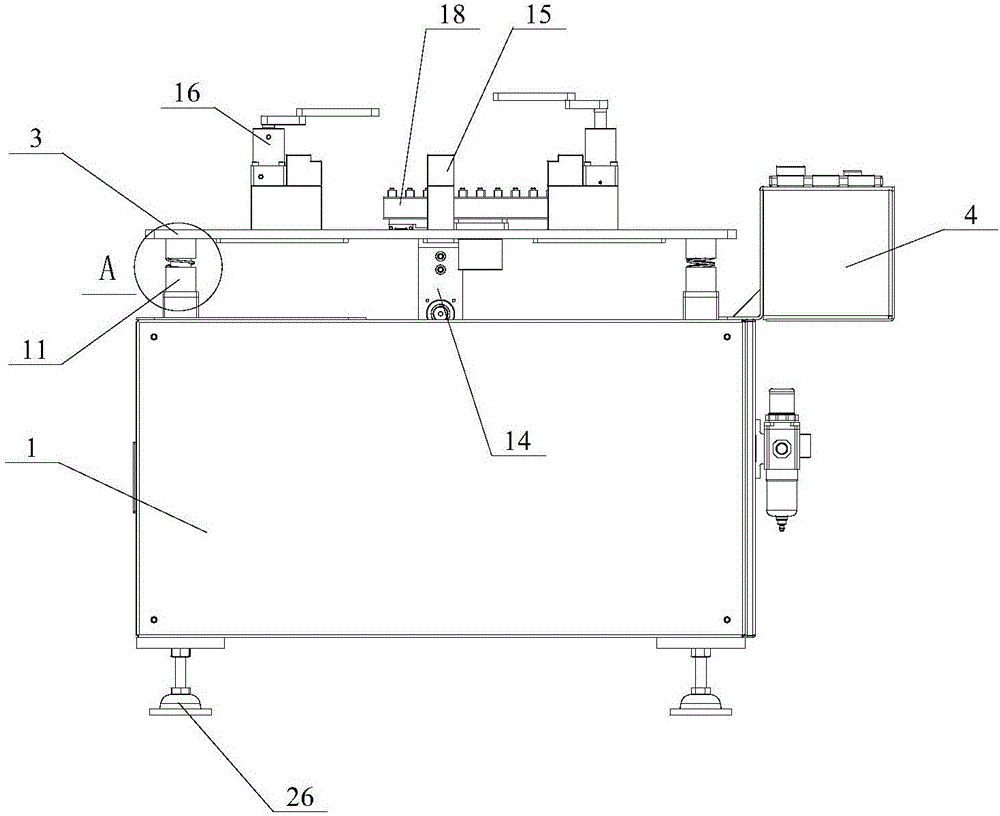

High-precision vibration simulation system based on multi-axis multi-degree of freedom

InactiveCN103335801AAdjustable vibration frequencyWide adaptabilityVibration testingWork cycleMulti degree of freedom

The invention discloses a high-precision vibration simulation system based on multi-axis multi-degree of freedom. The high-precision vibration simulation system comprises a mounting base, a shunt-wound multi-degree-of-freedom motion platform and a mechanical changeover panel, wherein the bottom of the mounting base is connected with a mounting connection platform, and the side surface of the mounting base is connected with the shunt-wound multi-degree-of-freedom platform; the mechanical changeover panel is fixed on a mobile platform of the shunt-wound multi-degree-of-freedom platform. The high-precision vibration simulation system greatly simplifies the design process under the premise of improving the system performance, improves the system positioning accuracy, besides, shortens the work cycle, and lowers various costs, as well as unnecessary expenditures in case of repeated design, manufacture, installation, debugging and the like after the design does not meet the requirements.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

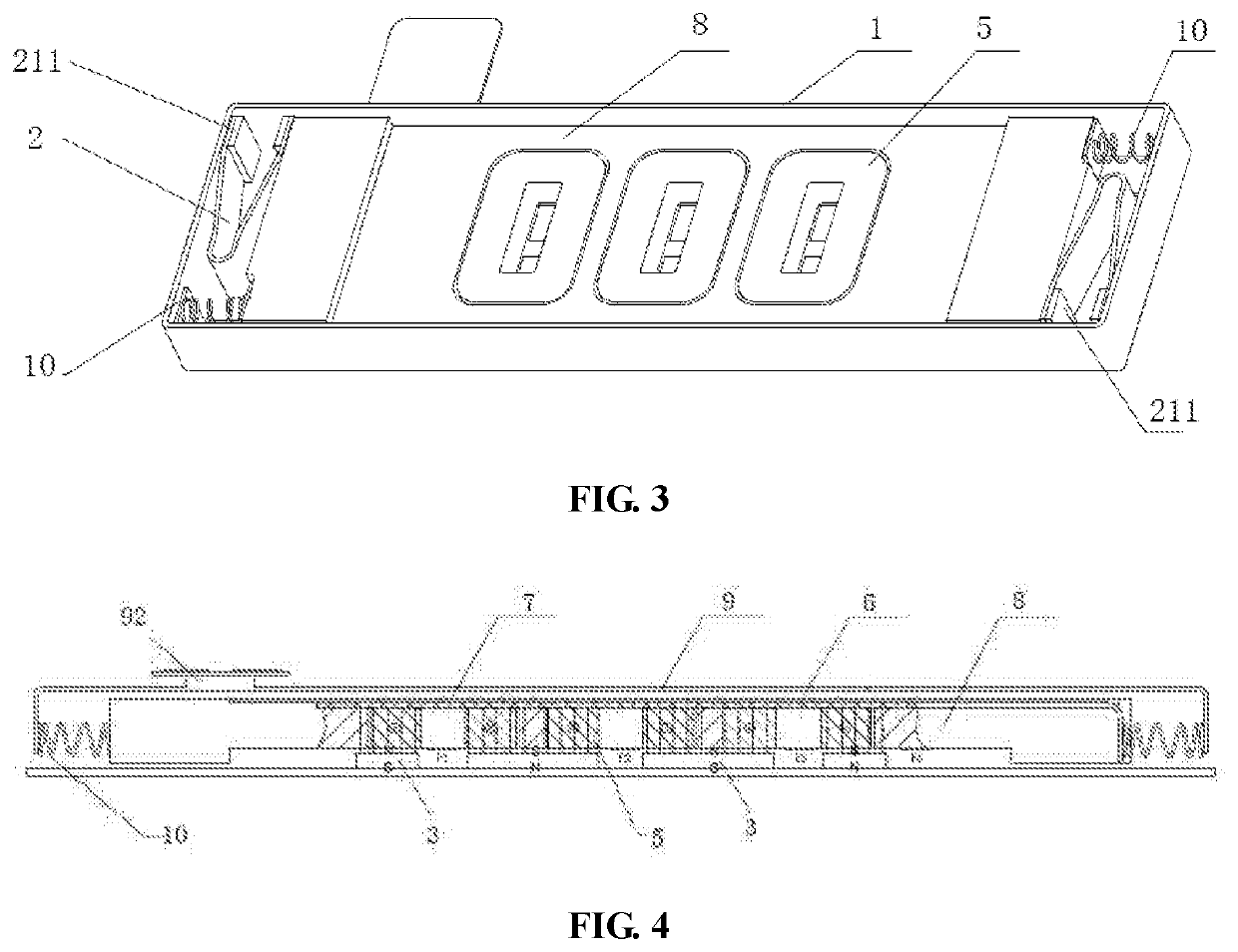

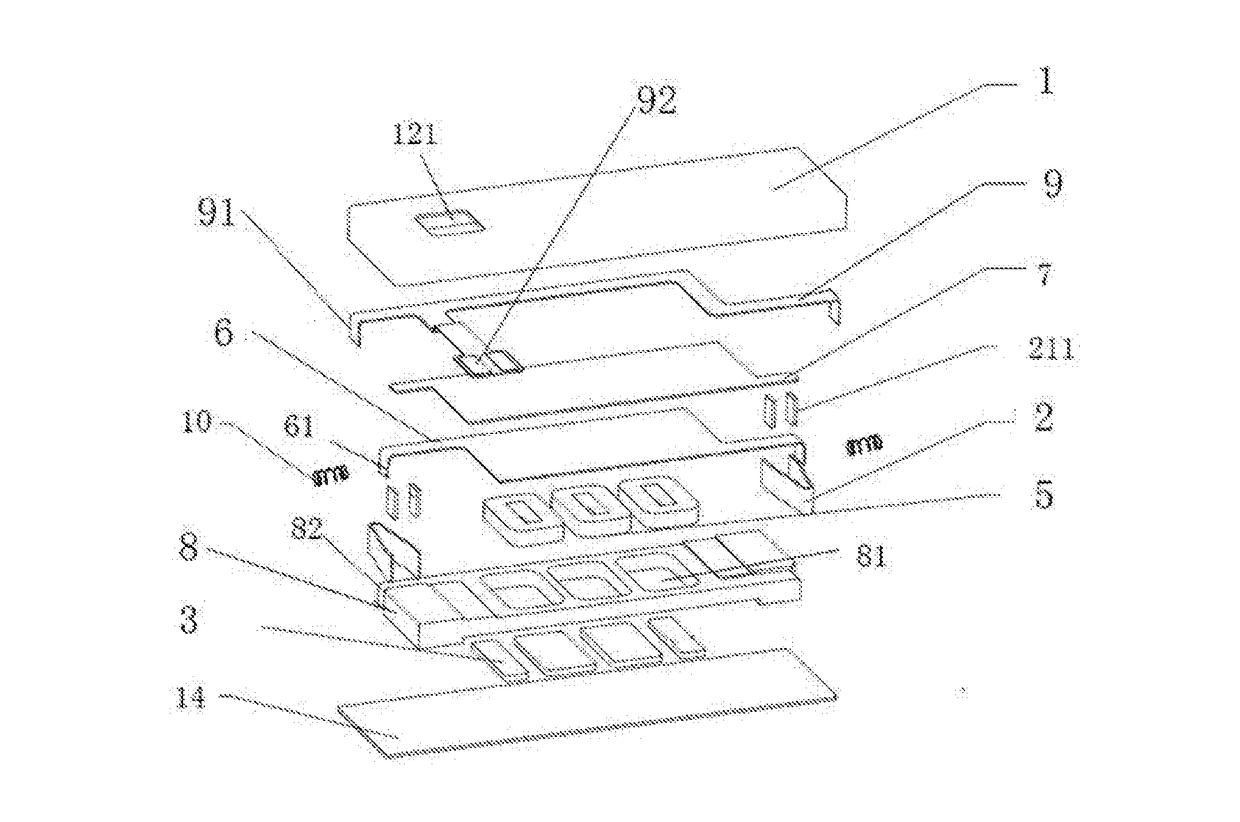

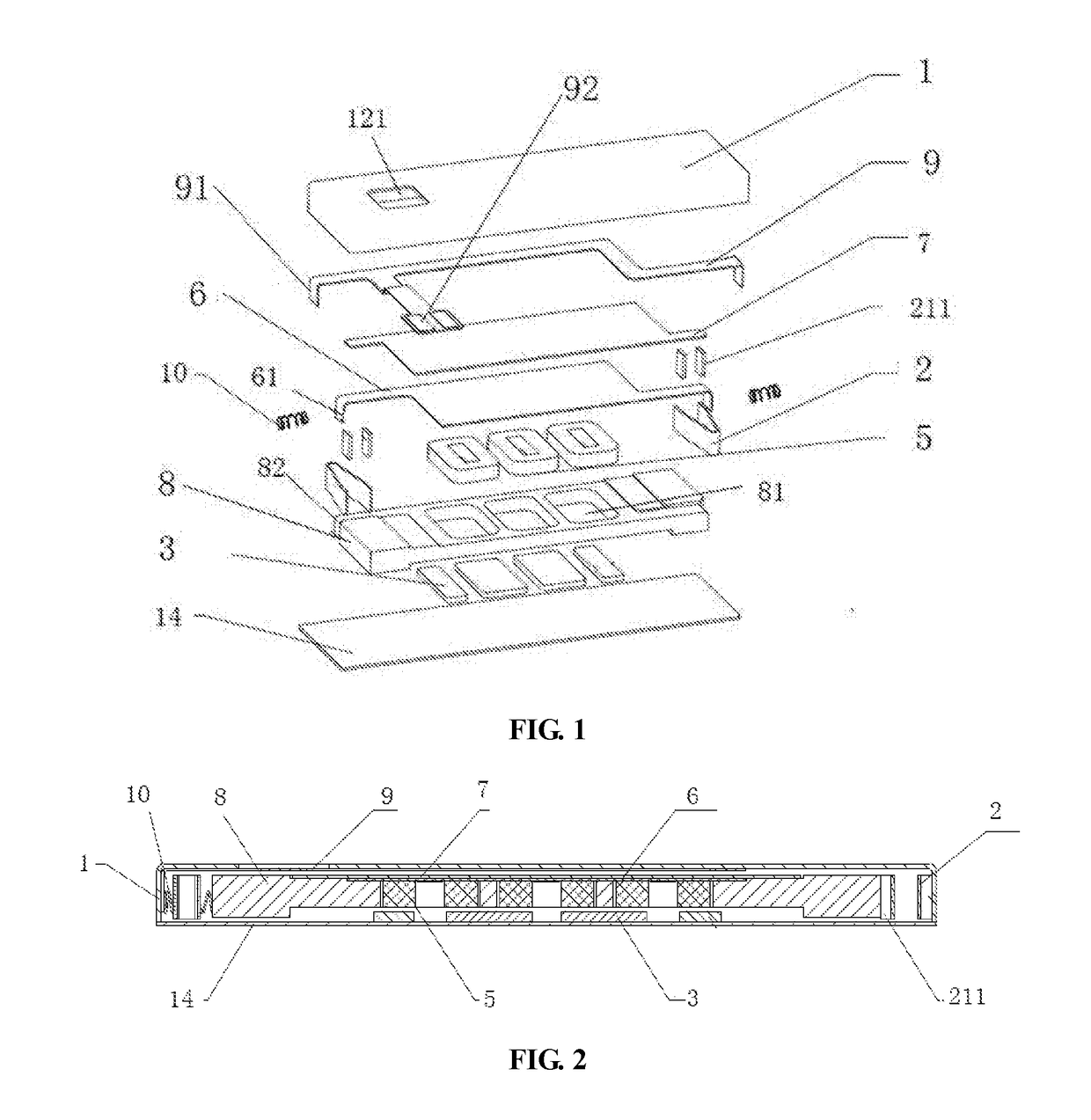

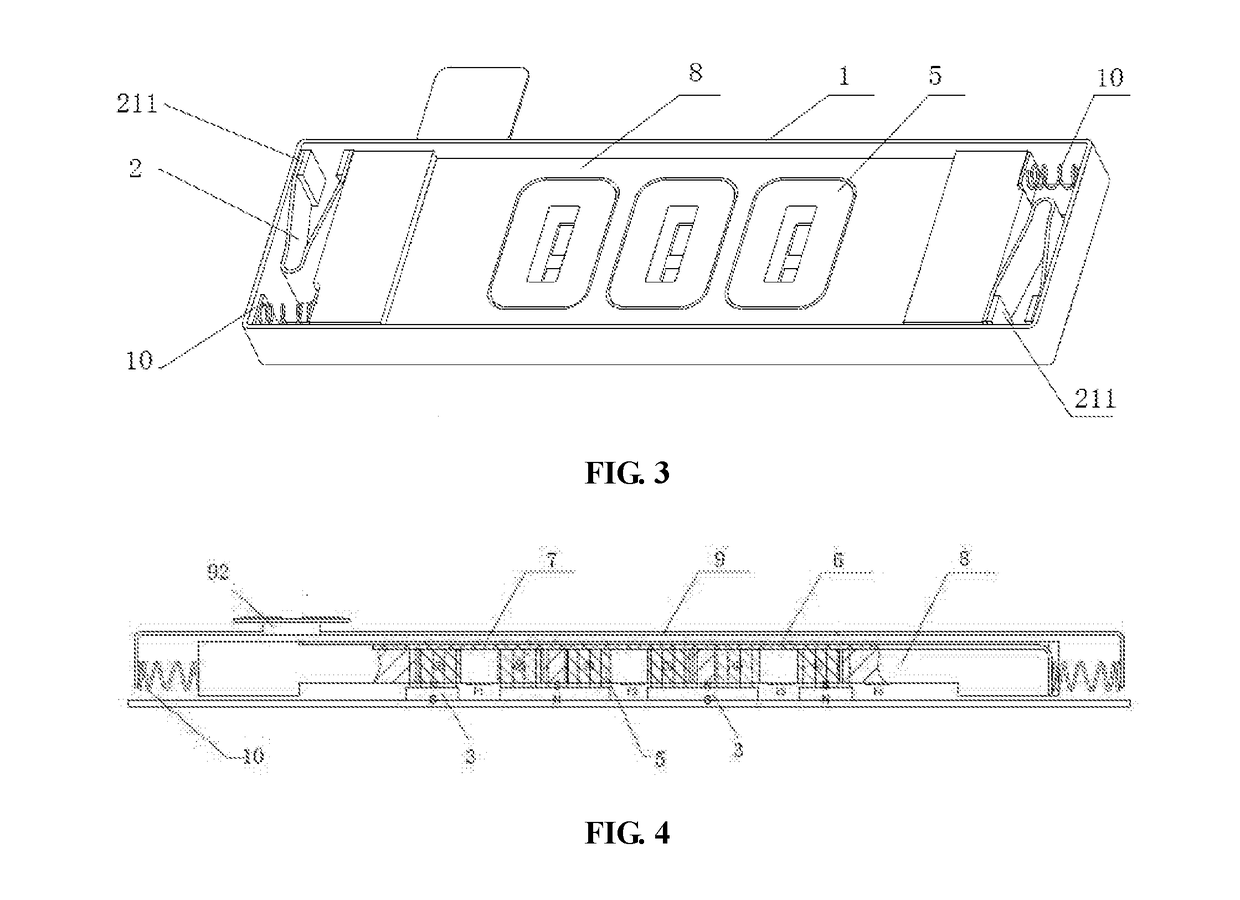

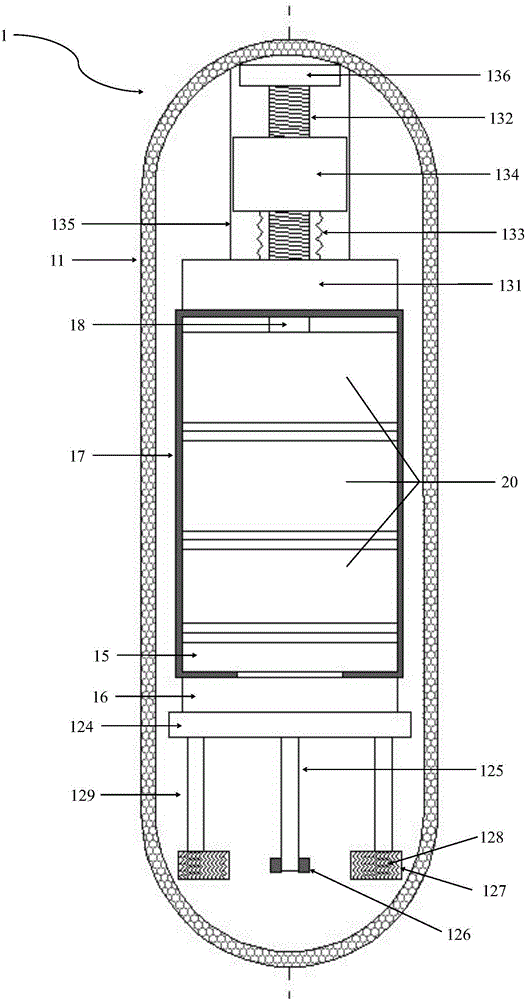

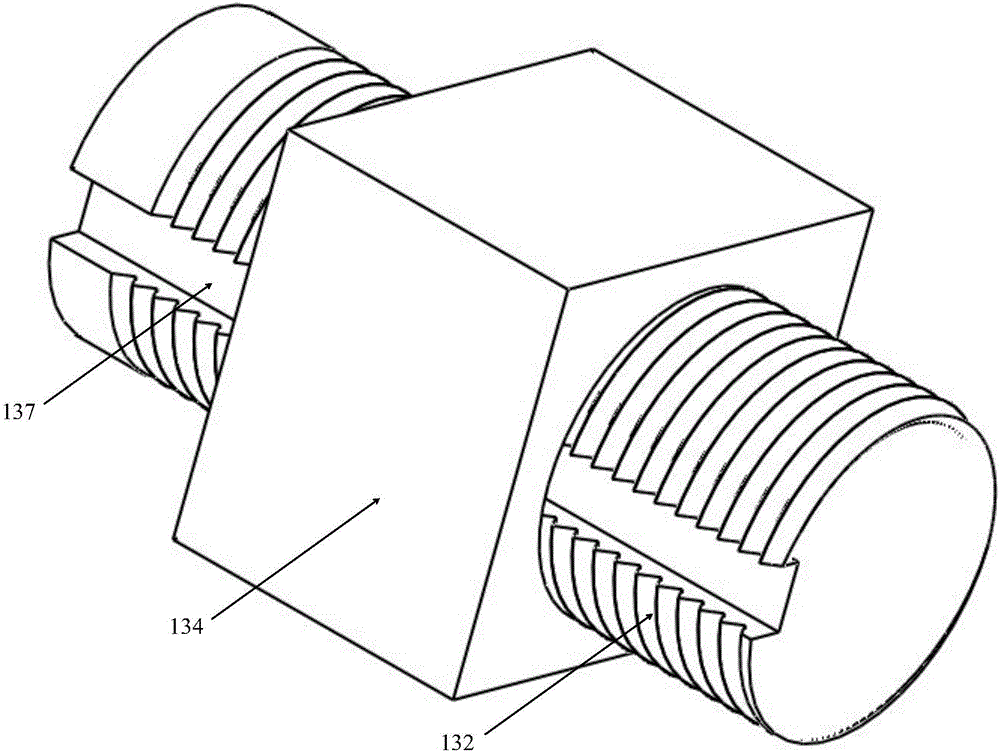

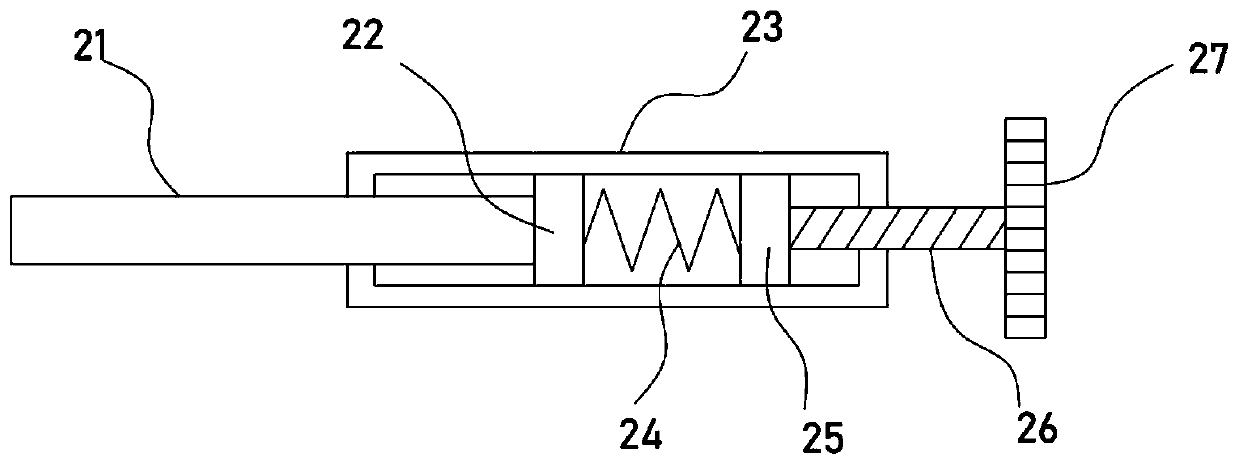

Linear motor with electric current injection assembly with springs connected to movable coil inside a mass block

ActiveUS10547233B2Adjustable vibration frequencyMiniaturizationWindingsSupports/enclosures/casingsElectric machineLinear motor

The present invention provides a linear motor, wherein, a coil is fastened on a mass block that is suspended inside a housing, and a magnet is fastened on the housing and thus does not move during use. In the linear motor of the present invention, the design route that utilizes coil motion to drive mass block motion is different from the traditional route that utilizes magnet motion to drive mass block motion, thereby the traditional “moving-magnet type” is changed into “moving-coil type” of the present invention. When the linear motor provided by the present invention is used in a highly magnetic environment, even if magnetic shield plates for shielding external magnetic induction lines are glued on both outer sides of the housing, because the magnet is fixed stationary itself, no vertical deviation of the magnet due to influence of the shield plates like in the prior art occurs. Meanwhile, even if the magnetic shield plates exert vertical forces on the coil, because such forces exerted by the shield plates on the coil are very small, they are hardly able to drive the coil to move in the vertical direction, and thus no vertical deviation of the coil is caused, so that vibration noise is avoided.

Owner:JINLONG MACHINERY & ELECTRONICS CO LTD

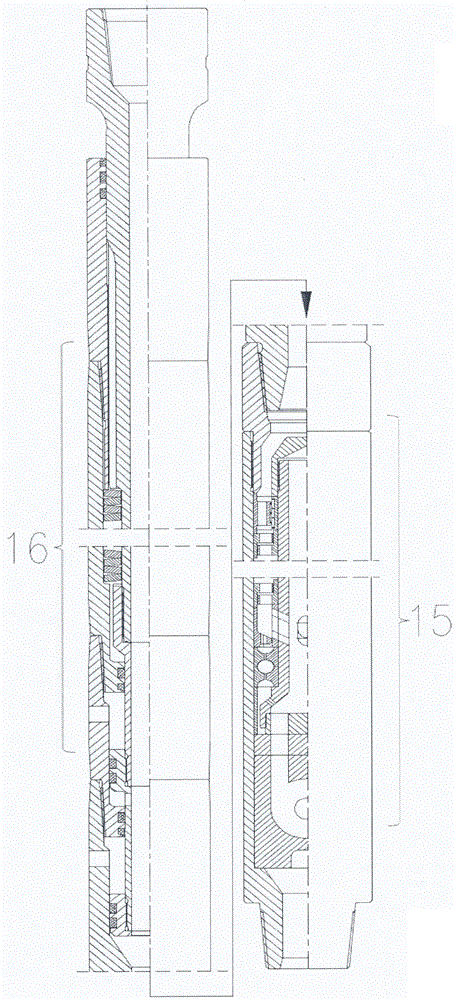

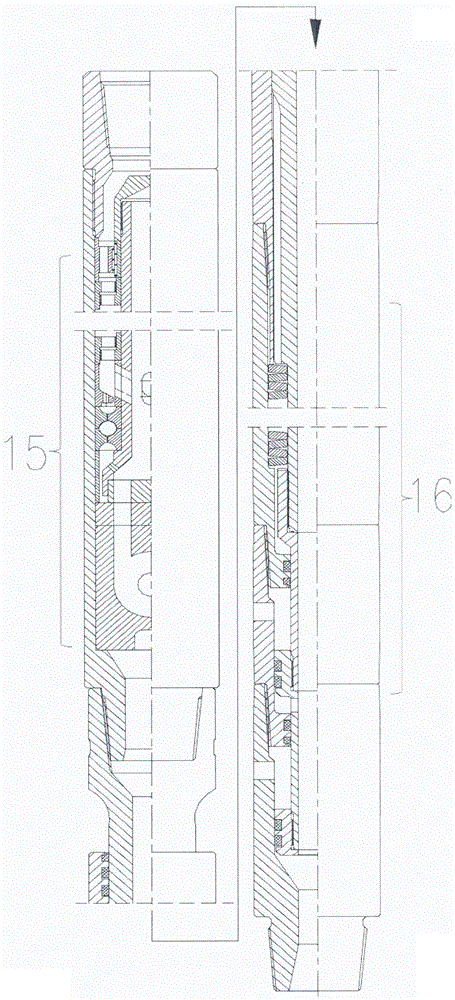

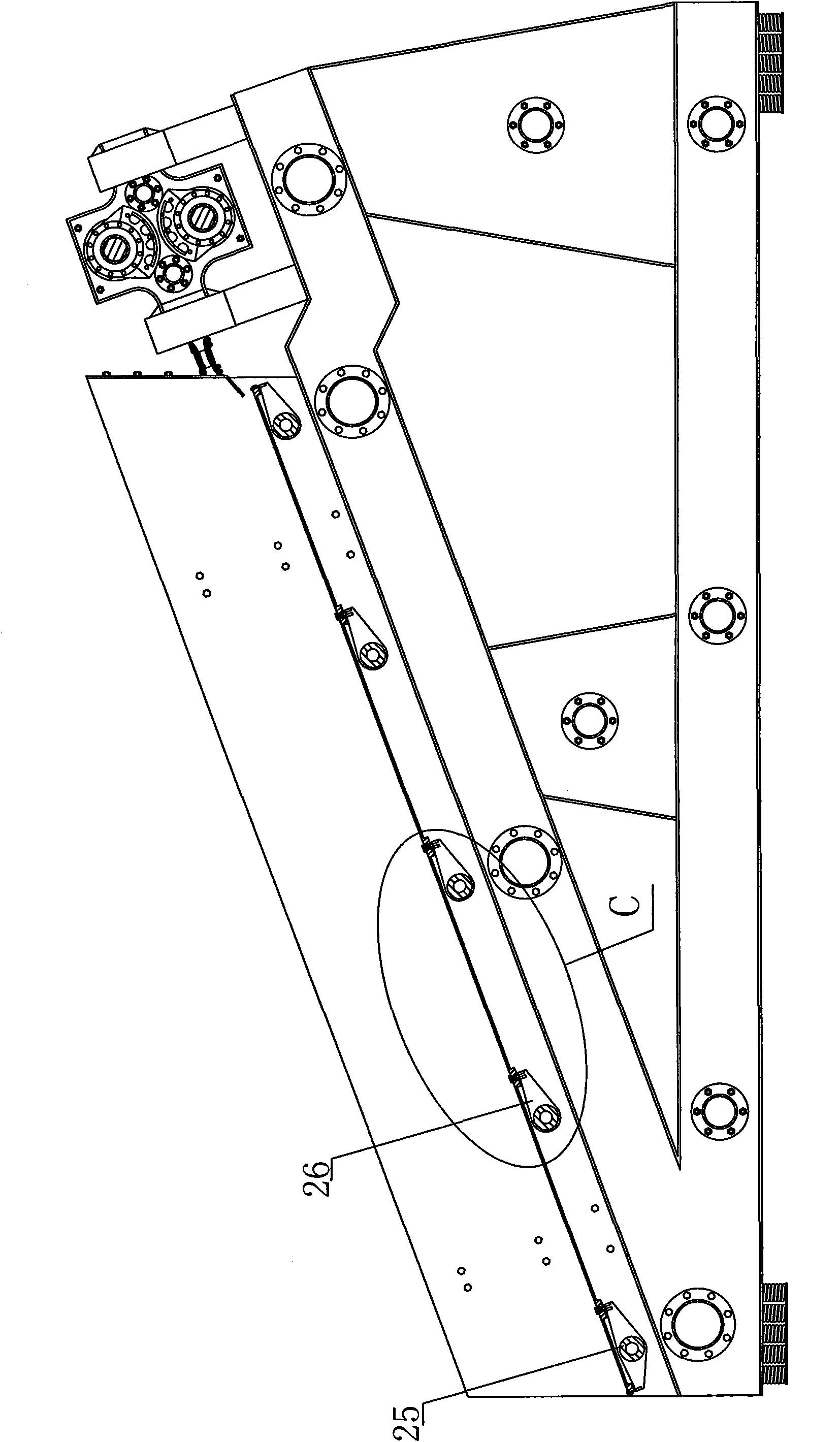

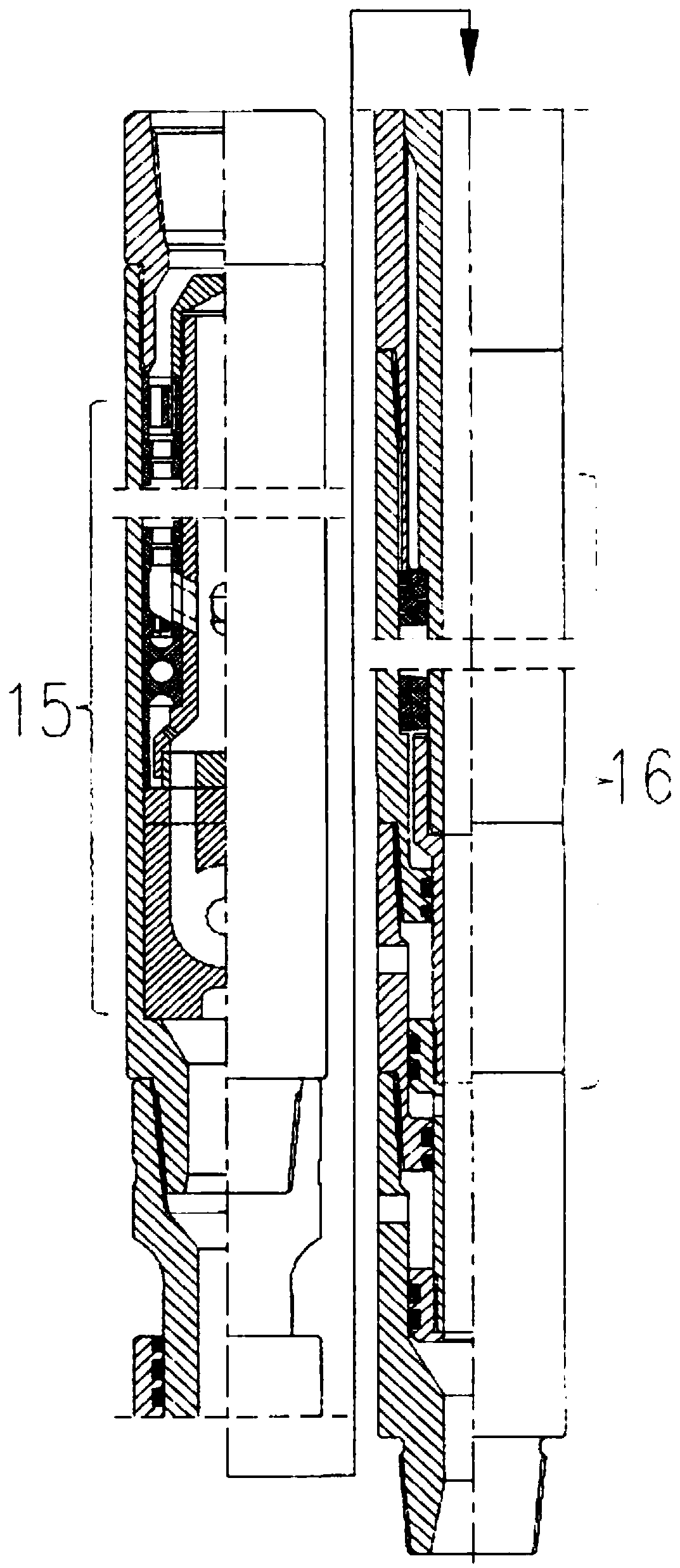

Low-pressure-loss underground tool for speeding up by vibration

ActiveCN106089025ALow pressure lossImprove the vibration effectBorehole drivesVibration drillingVibration amplitudeEngineering

The invention relates to a low-pressure-loss underground tool for speeding up by vibration. A technical scheme provided by the invention is as follows: the low-pressure-loss underground tool for speeding up by vibration consists of a pressure pulse generation tool and a vibration amplitude amplification tool, wherein a movable valve block is arranged in the pressure pulse generation tool and is driven by a turbine to rotate, and the rotation speed of the movable valve block is regulated by a speed reduction turbine; a U-shaped eddy vibration device is arranged at the lower part of a movable-fixed valve group; runners are continuously switched by the movable valve block, so that the fluid in a circular vortex chamber is switched between an eddy state and a non-eddy state; when the fluid in the vortex chamber is at the eddy state, the upper part of the pressure pulse generation tool is at a high pressure state, and when the fluid in the vortex chamber is at the non-eddy state, the upper part of the pressure pulse generation tool is at a low pressure state, so that a periodic pressure pulse is generated in the pressure pulse generation tool; the upper part or the lower part of the pressure pulse generation tool is connected with the vibration amplitude amplification tool, so that periodic axial vibration is generated by bottom hole assemblies, thereby effectively improving the friction resistance between a drill column and the wall of a well, and improving the drilling speed.

Owner:天津世纪华源地环科技有限公司

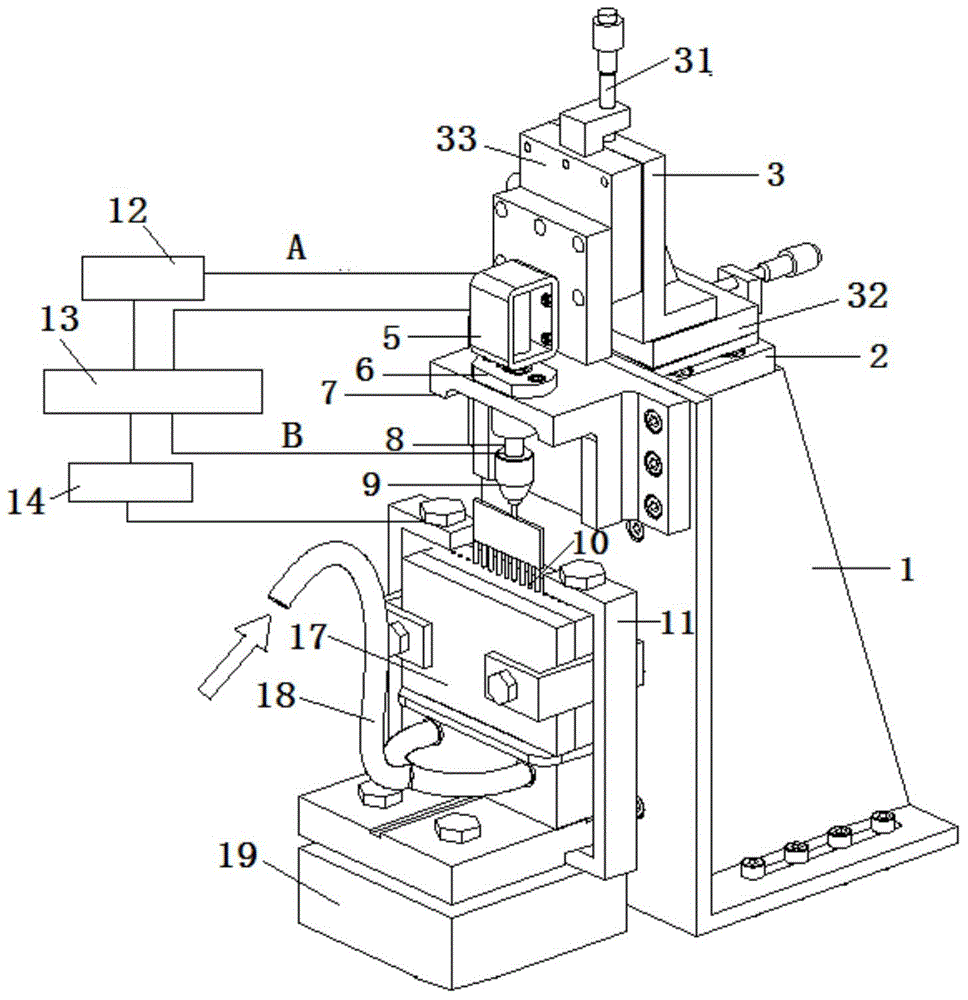

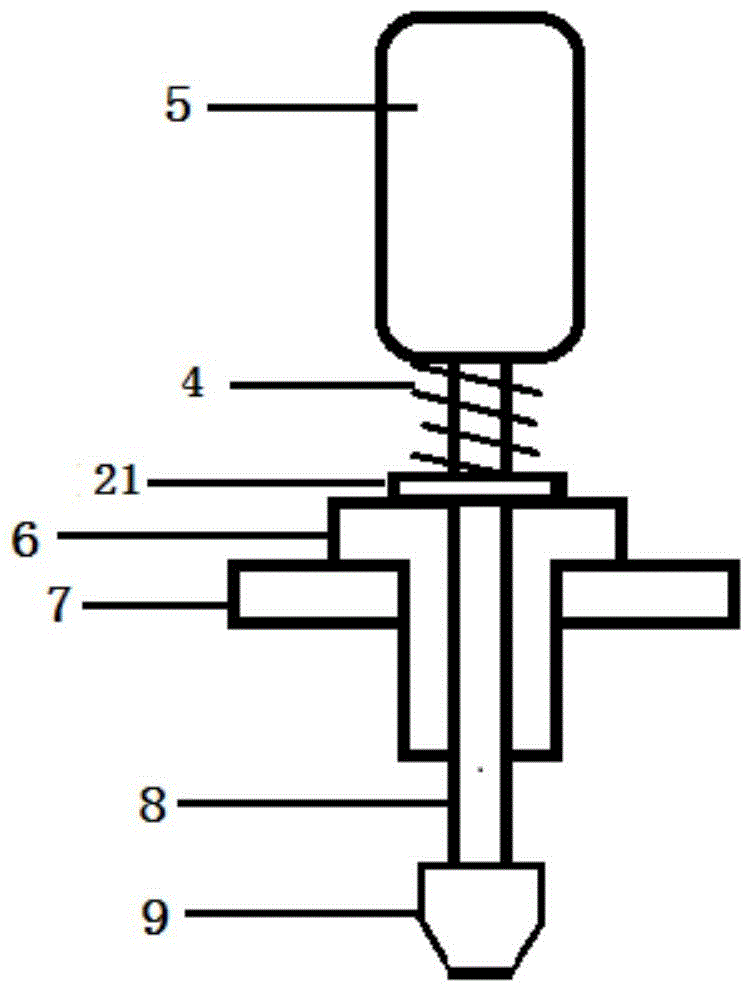

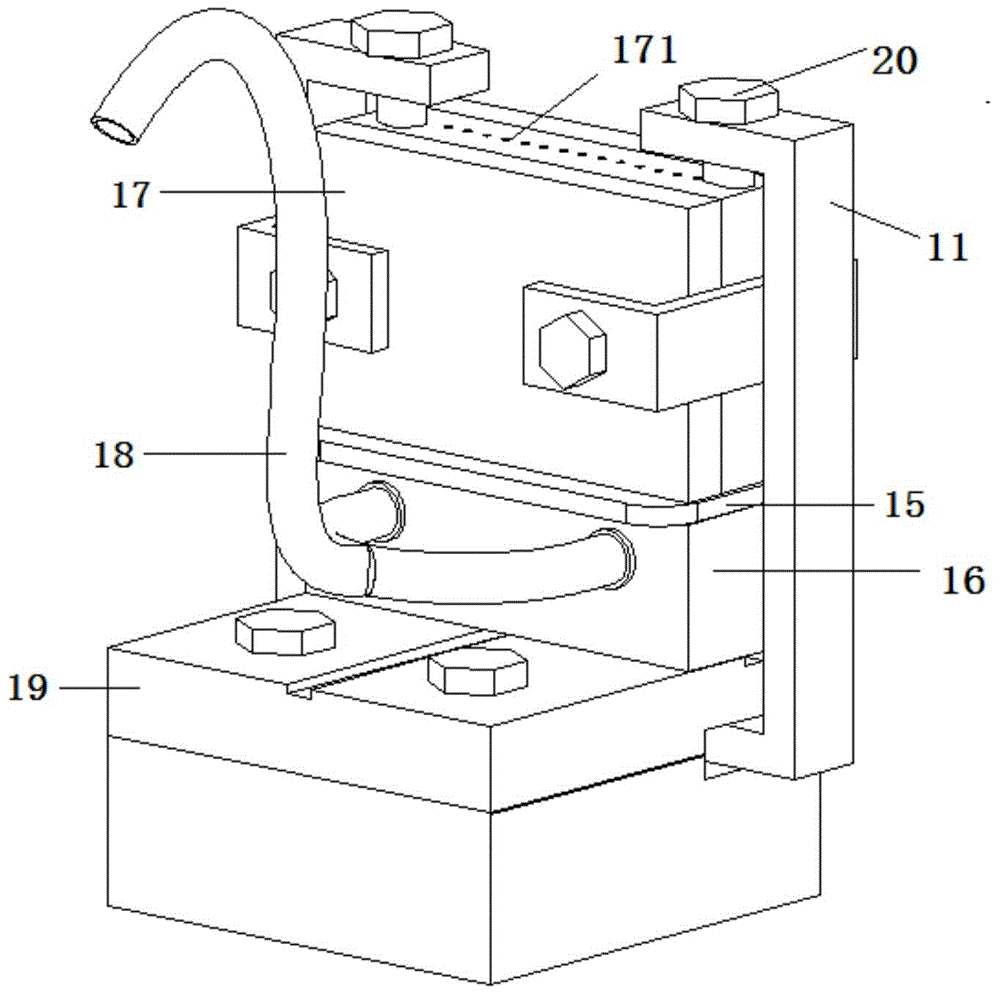

Low-frequency vibration and electrolytic machining device for tool electrodes

ActiveCN104827144AAdjustable electrode amplitudeAdjustable vibration frequencyMachining electric circuitsElectrical-based machining electrodesRubber ringElectrolysis

Provided is a low-frequency vibration and electrolytic machining device for tool electrodes. The top surface of a workpiece is provided with through holes, above which the tool electrodes are arranged. The tool electrodes are arranged on an adjusting rack. A horizontal adjusting plate of a displacement table is arranged on a base. A shell of an electromagnetic coil is fixed onto a vertical adjusting plate of the displacement table. An iron column of an electromagnet is wounded by a coil. The coil, a multi-loop time relay and a stabilized voltage supply are connected end to end to form a driving loop. The upper end of a vibrating shaft is inserted into the hollow iron column. The lower end of the vibrating shaft orderly penetrates through a support table and a linear bearing and then is connected with the tool electrodes via a universal chuck. A solution tank is arranged in a fixing seat of a fixing device. The workpiece is erected into the solution tank. The through holes of the workpiece are communicated with the solution tank via an outlet arranged in a rubber ring. A clamp is arranged on the fixing seat. The clamp and the vibrating shaft are made by conductive material. The clamp, the vibrating shaft, the multi-loop time relay and a machining power supply are connected end to end in order to form an electrolytic loop.

Owner:ZHEJIANG UNIV OF TECH

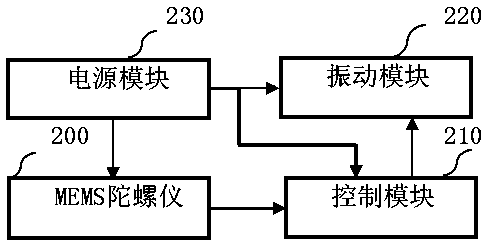

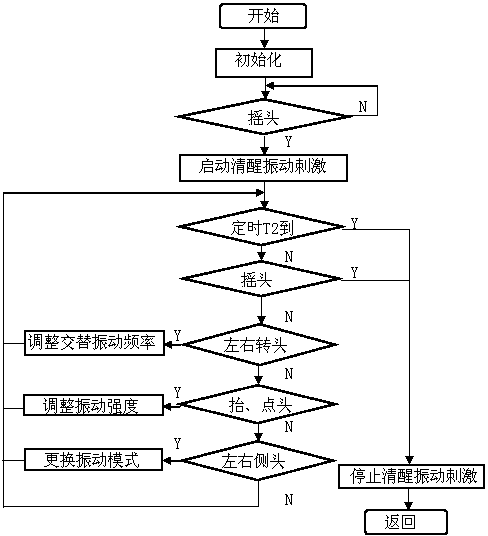

Lucidity maintaining device

ActiveCN103432677AIncreased sobrietyAdjustable stimulation vibration patternDiagnostic recording/measuringSensorsGyroscopeAngular velocity

The invention discloses a lucidity maintaining device. The lucidity maintaining device is a head-mounted device and consists of a sensing controller and a head-mounted carrier which is sleeved at the head, wherein the sensing controller and the head-mounted carrier are mechanically fixed and electrically connected into a whole; the sensing controller comprises a micro-electromechanical system (MEMS) gyroscope, a control module and a power supply module; the head-mounted carrier comprises a vibration module and a wearable carrier for bearing the vibration module; the MEMS gyroscope performs real-time data acquisition and data processing on triaxial angular velocity signals; the control module is used for calculating and identifying the class of the head action of a person and executing instruction operation corresponding to the head action; the vibration module is used for providing consciousness vibration stimulation to the person. The lucidity maintaining device can realize consciousness vibration stimulation conveniently and timely, can select vibration modes and adjust vibration strength and frequency, achieves an obvious and continuous stimulation effect, is favorable for maintaining excellent lucidity of the person, and has wide application occasions.

Owner:顶能科技有限公司

Linear motor

ActiveUS20170288524A1Adjustable vibration frequencyMiniaturizationWindingsSupports/enclosures/casingsEngineeringMagnetic shield

The present invention provides a linear motor, wherein, a coil is fastened on a mass block that is suspended inside a housing, and a magnet is fastened on the housing and thus does not move during use. In the linear motor of the present invention, the design route that utilizes coil motion to drive mass block motion is different from the traditional route that utilizes magnet motion to drive mass block motion, thereby the traditional “moving-magnet type” is changed into “moving-coil type” of the present invention. When the linear motor provided by the present invention is used in a highly magnetic environment, even if magnetic shield plates for shielding external magnetic induction lines are glued on both outer sides of the housing, because the magnet is fixed stationary itself, no vertical deviation of the magnet due to influence of the shield plates like in the prior art occurs. Meanwhile, even if the magnetic shield plates exert vertical forces on the coil, because such forces exerted by the shield plates on the coil are very small, they are hardly able to drive the coil to move in the vertical direction, and thus no vertical deviation of the coil is caused, so that vibration noise is avoided.

Owner:JINLONG MACHINERY & ELECTRONICS CO LTD

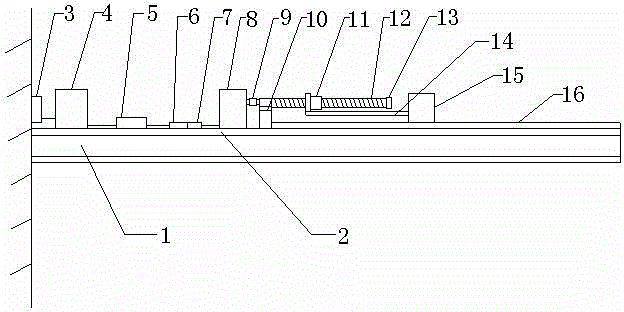

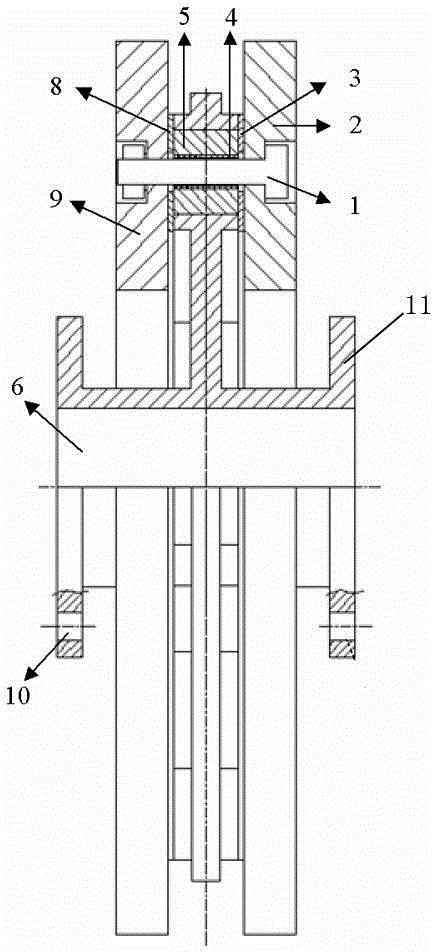

Piezoelectric energy collecting system

InactiveCN103986367AAdjustable vibration frequencyHigh energyPiezoelectric/electrostriction/magnetostriction machinesMotor driveEngineering

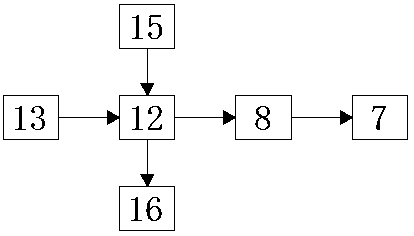

A piezoelectric energy collecting system comprises a piezoelectric cantilever beam, piezoelectric pieces, a first vibration frequency sensor, a micro capacitor, a second vibration frequency sensor, a single chip microcomputer, a motor drive chip, a micro motor, a coupler, a supporting frame, a ball nut, a ball screw rod, a screw cap, a connection rod, a mass block and a sliding channel. The piezoelectric cantilever beam is installed on a vibration structure body, the front face and the back face of the piezoelectric cantilever beam are covered with the piezoelectric pieces, the first vibration frequency sensor is installed on the vibration structure body and is respectively connected with the micro capacitor and the single chip microcomputer through wires, the micro capacitor, the second vibration frequency sensor, the single chip microcomputer, the motor drive chip and the micro motor are all arranged on the piezoelectric piece on the front face of the piezoelectric cantilever beam, the micro capacitor is connected with the second vibration frequency sensor through a wire, and the second vibration frequency sensor is connected with the single chip microcomputer through a wire. Vibration frequency of a piezoelectric vibrator is adjustable.

Owner:ZHEJIANG OCEAN UNIV

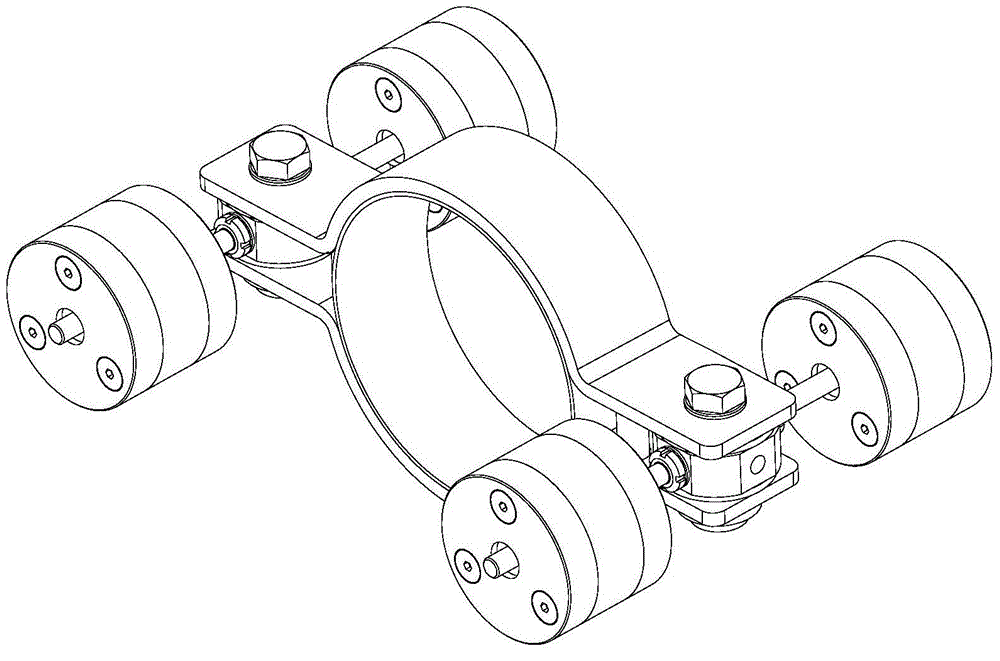

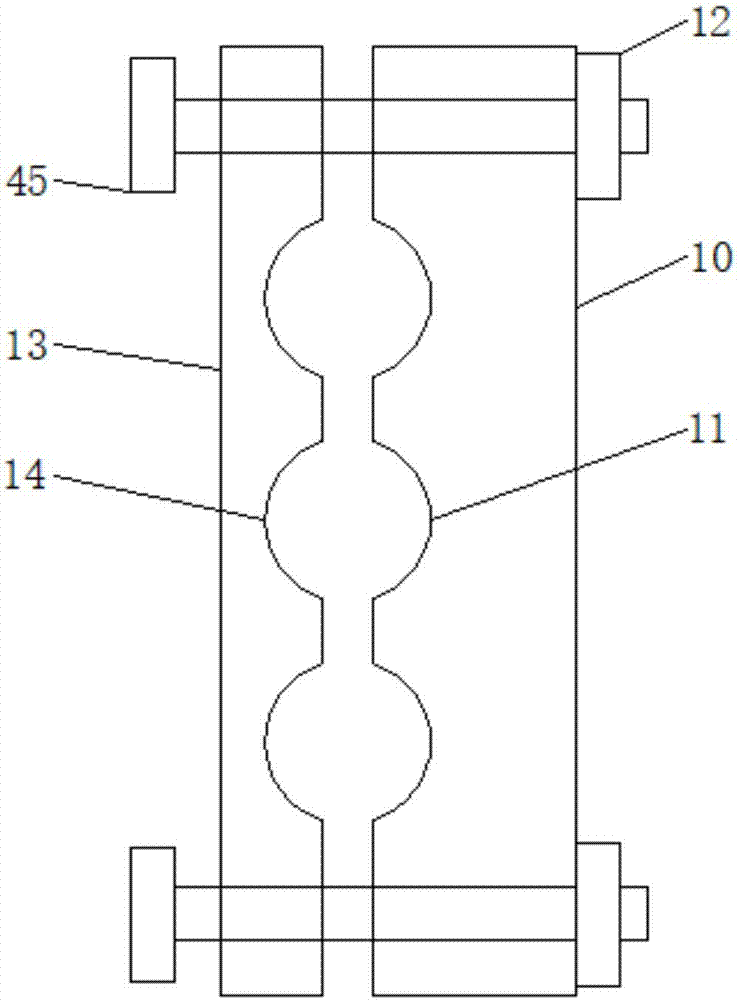

Pipeline vibration-absorption clamping hoop with adjustable direction

InactiveCN104989882AMaximum fixedPrevent slidingPipe supportsPipe elementsNoise controlVibration absorption

The invention provides a pipeline vibration-absorption clamping hoop with an adjustable direction, and belongs to the technical field of vibration noise control. The pipeline vibration-absorption clamping hoop with the adjustable direction comprises a clamping hoop assembly and vibration absorption assemblies. The clamping hoop assembly comprises an upper clamping ring, a rubber gasket, a lower clamping ring and conversion connecting blocks. The upper clamping ring and the lower clamping ring are installed on the external circumference surface of the rubber gasket in a sleeving mode after the upper clamping ring and the lower clamping ring are connected in a butting mode. The two conversion connecting blocks are arranged between the upper clamping ring and the lower clamping ring, and the two ends of each conversion connecting block are connected with the upper clamping ring and the lower clamping ring respectively. Each vibration absorption assembly comprises a cantilever rod, mass component end blocks and a mass component middle block, wherein the mass component middle block and the cantilever rod are connected through threads, and the mass component end blocks penetrate through the cantilever rod and then are fixed to the two ends of the mass component middle block. The vibration absorption assemblies are fixedly arranged in threaded holes of the conversion connecting blocks of the clamping hoop assembly through the cantilever rods respectively. The pipeline vibration-absorption clamping hoop is compact in structure and adjustable in vibration absorption direction, can effectively restrain pipeline spectrum vibration of ships, and is low in demand of the installation space and convenient to disassemble, assemble and maintain.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

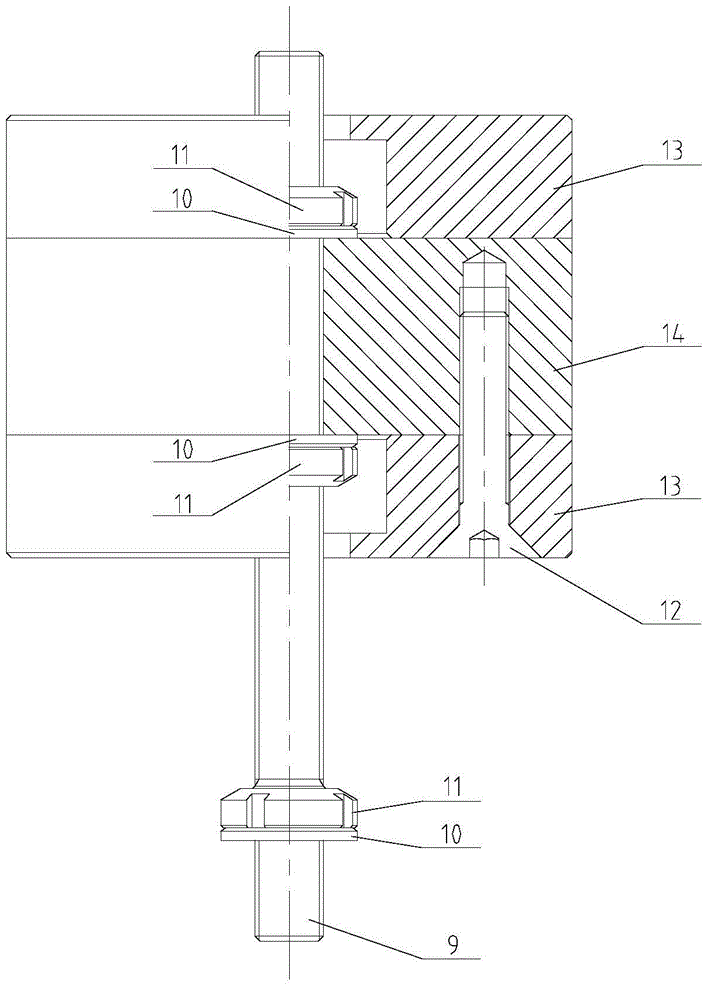

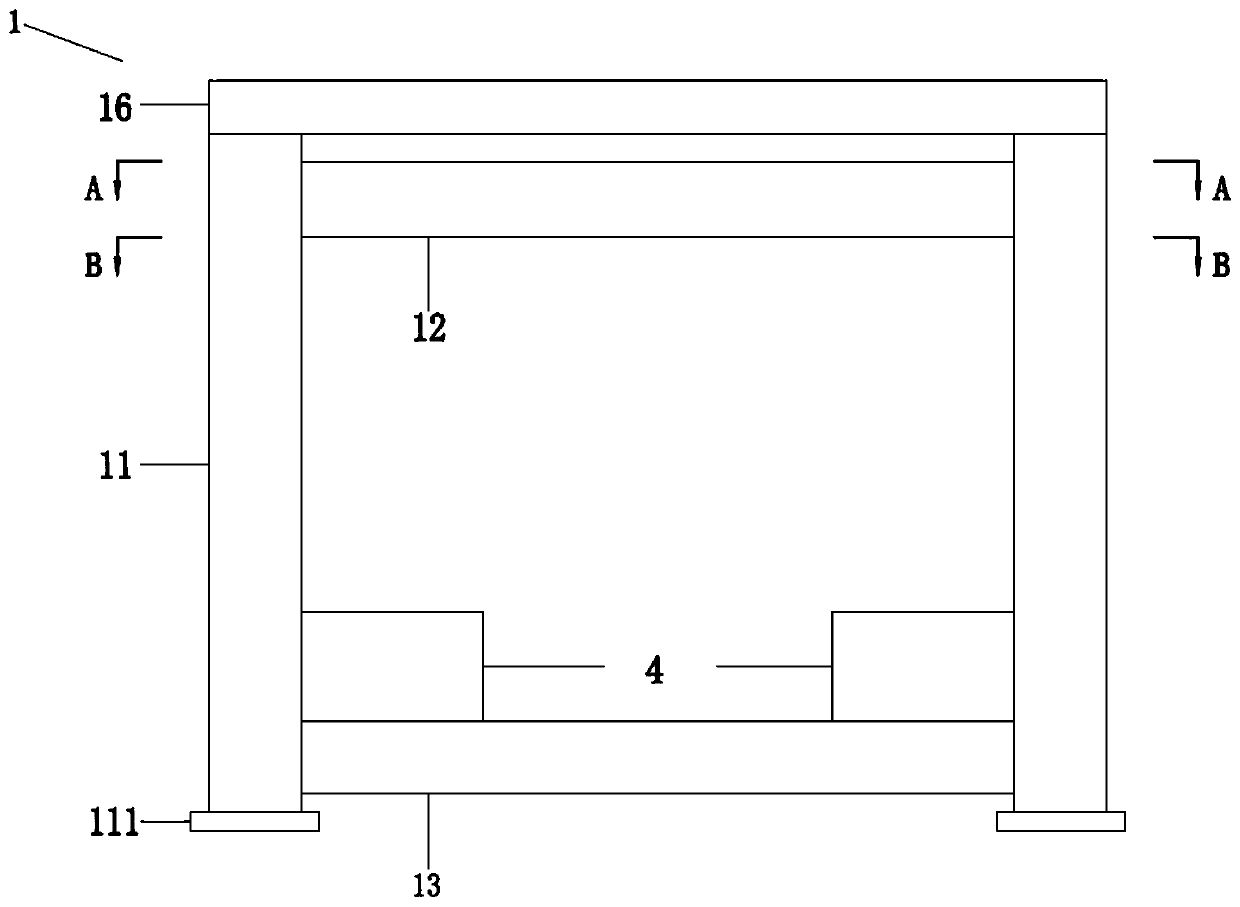

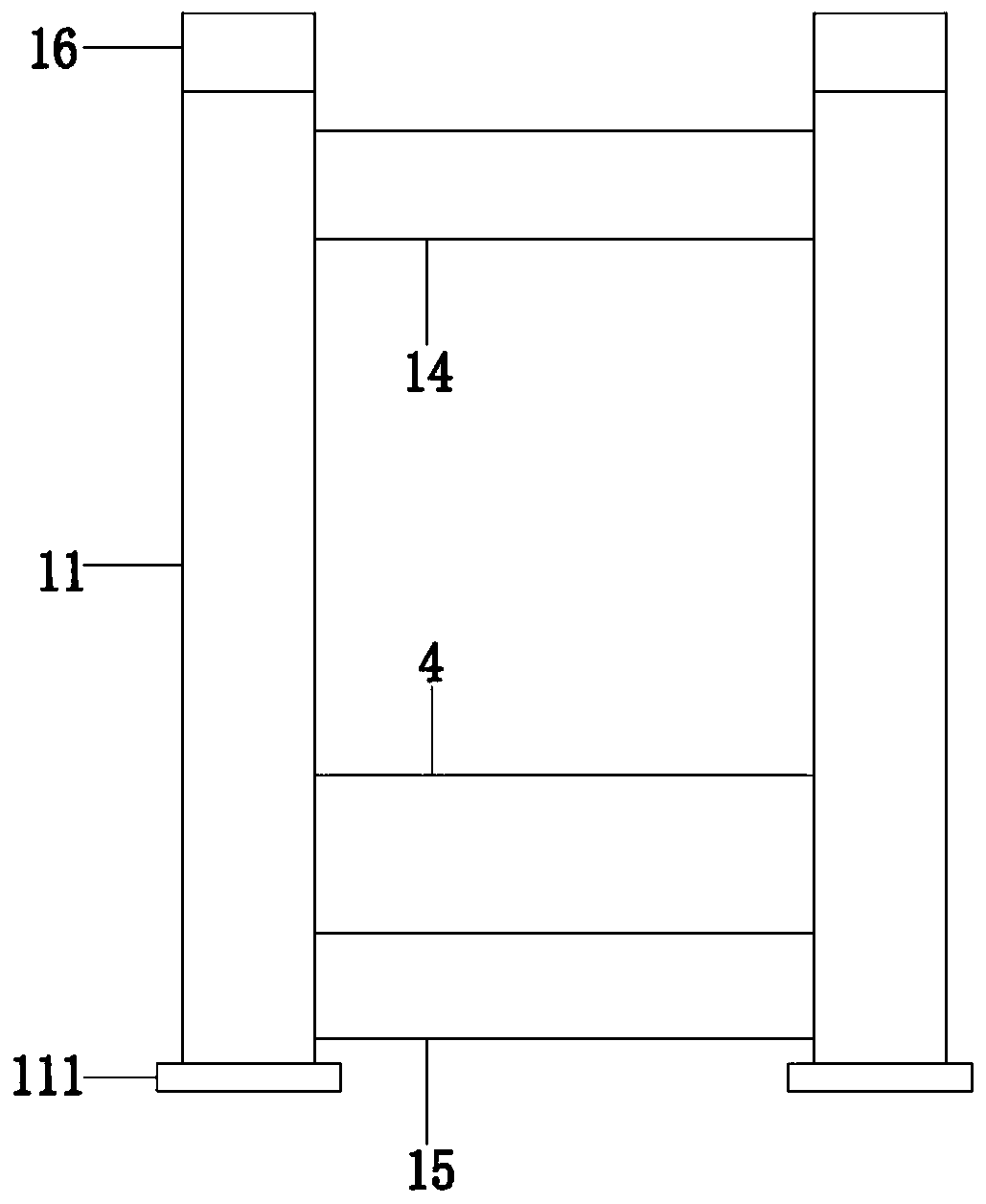

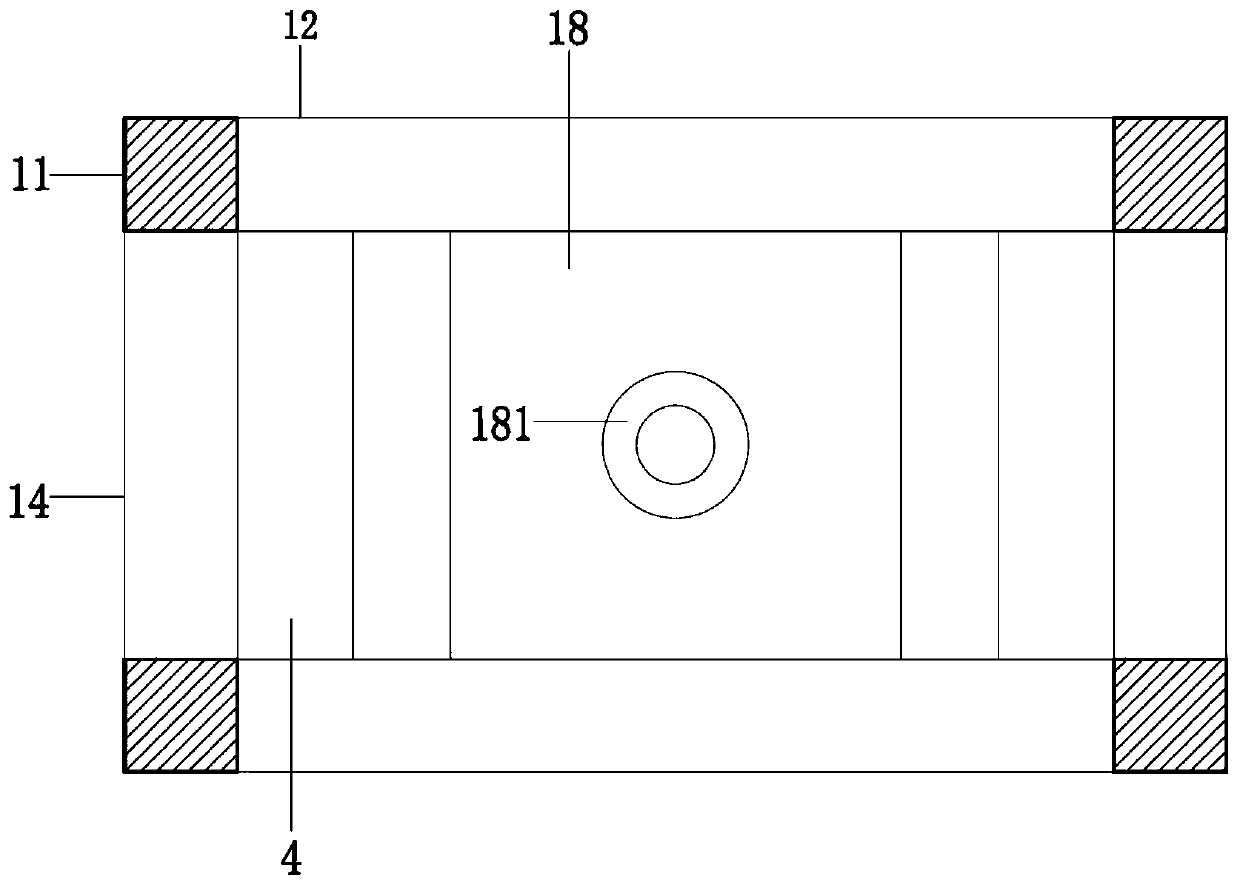

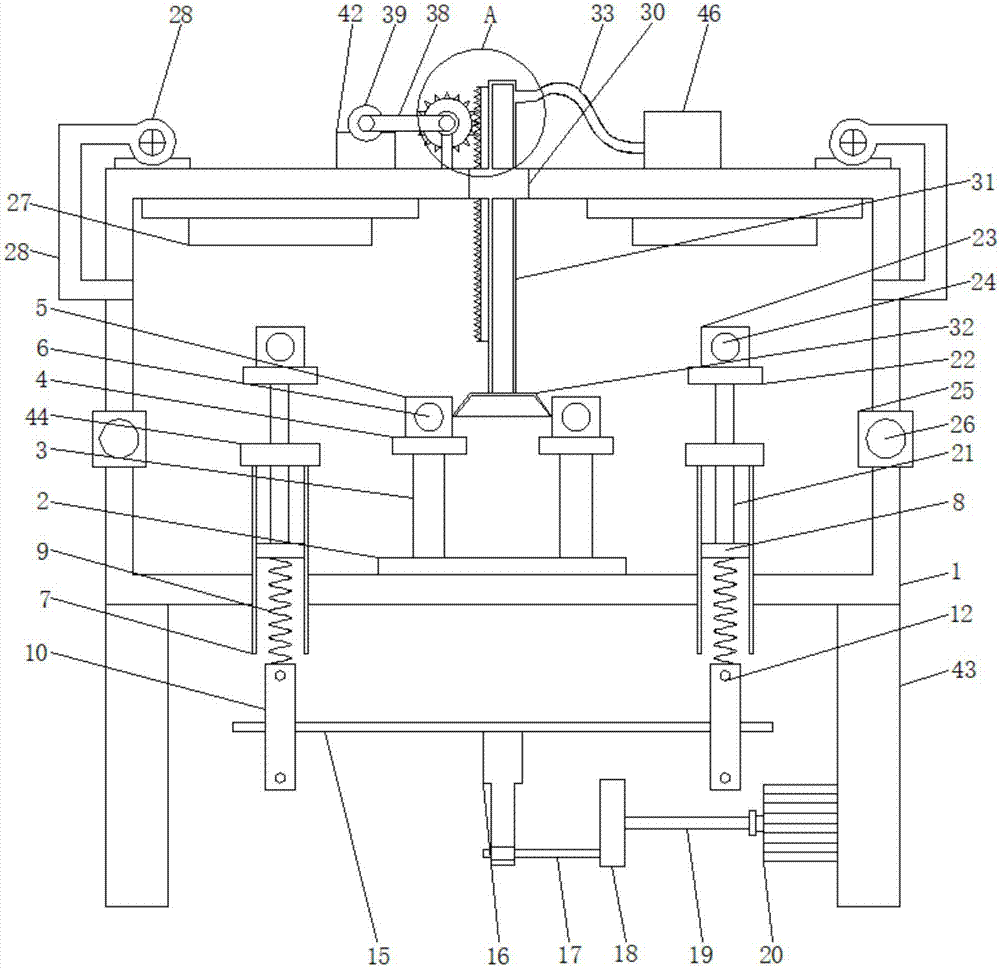

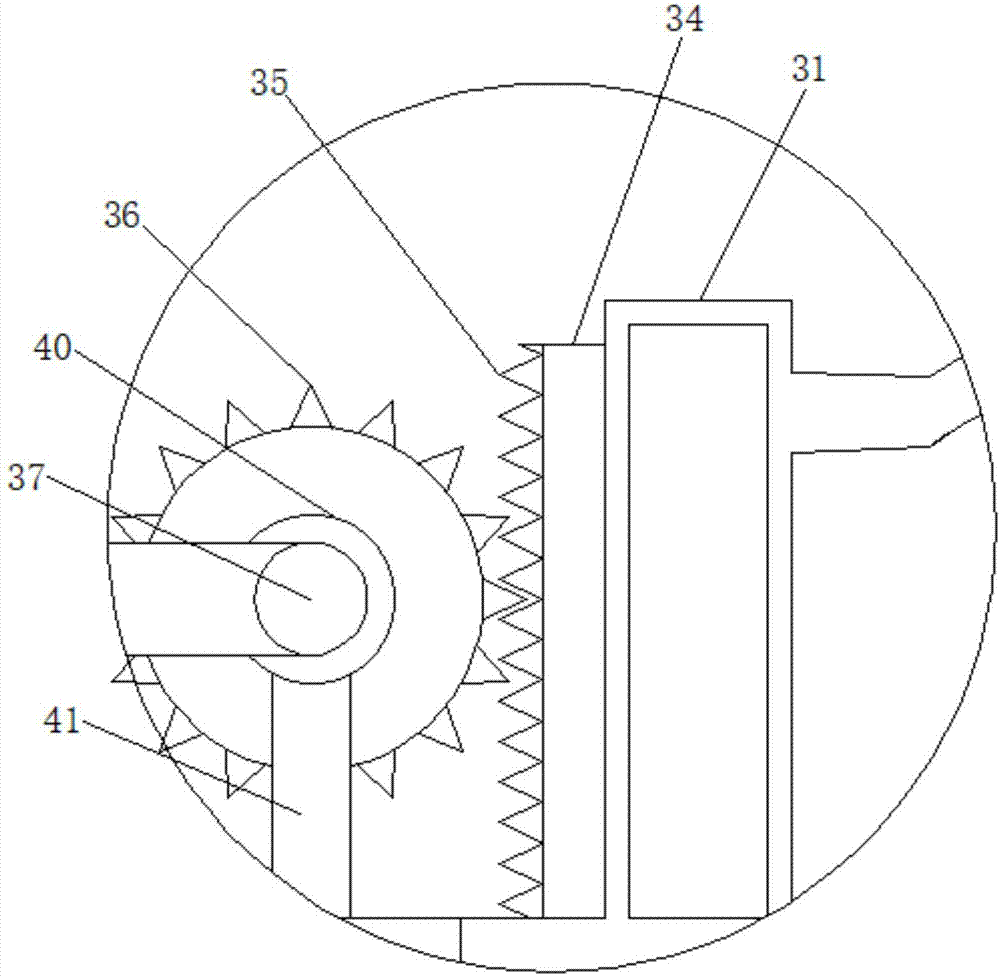

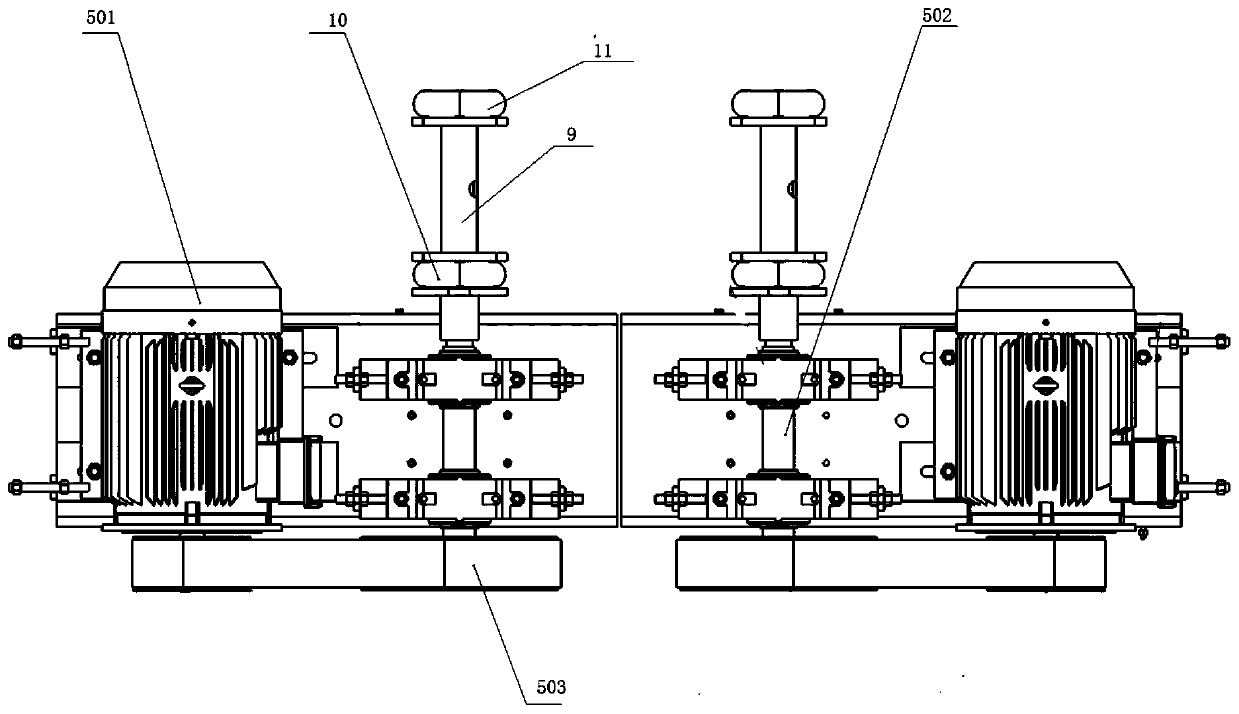

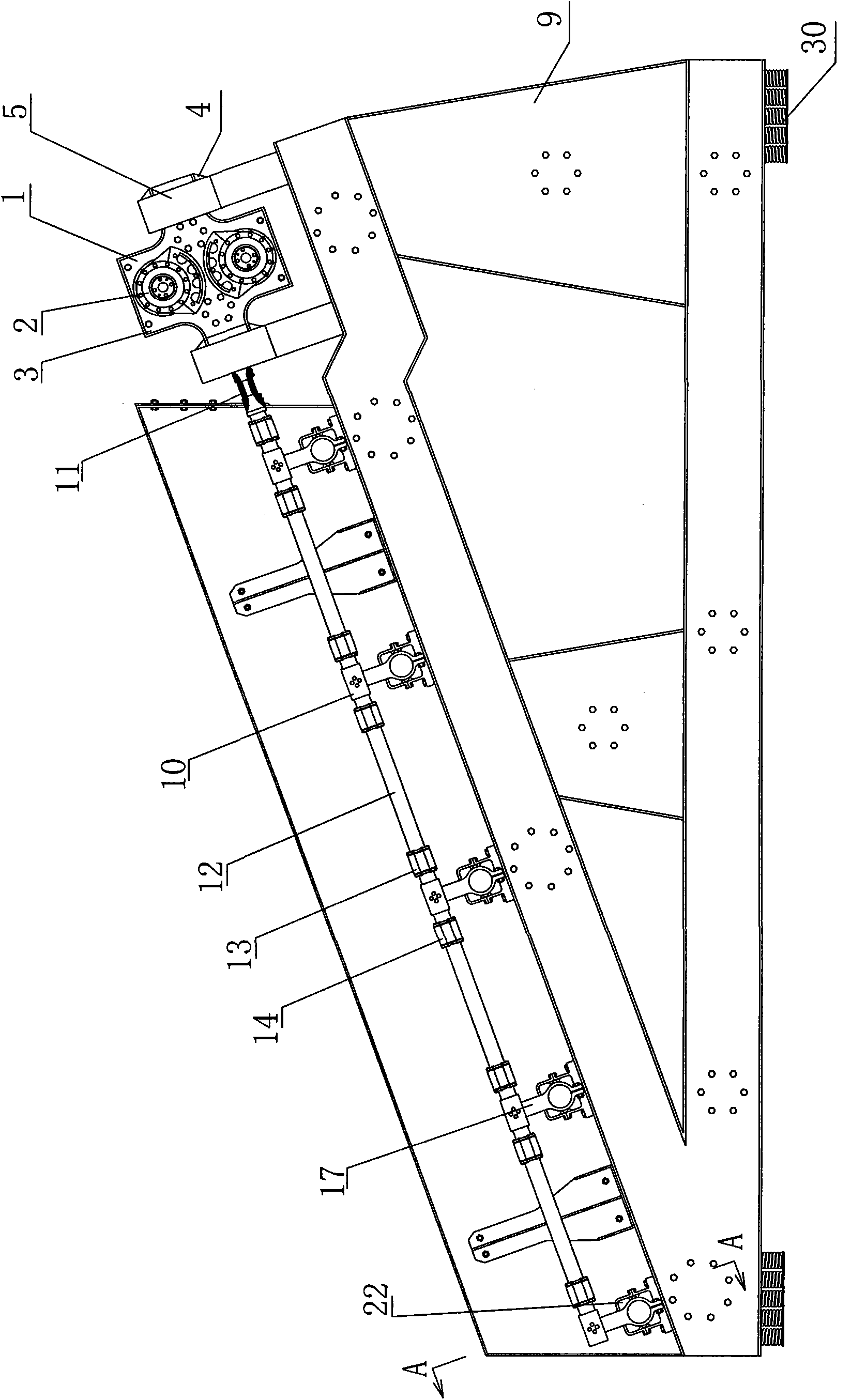

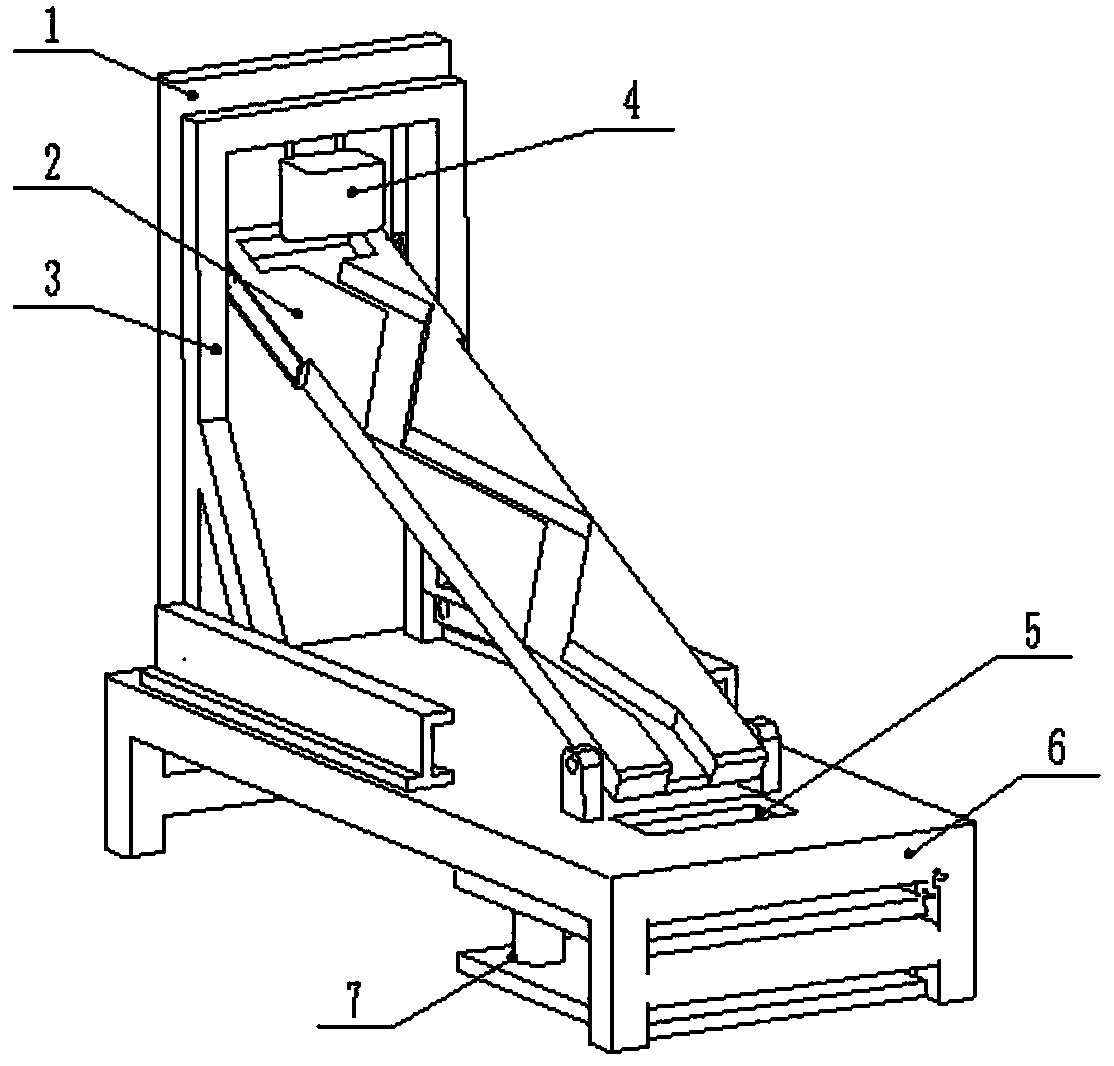

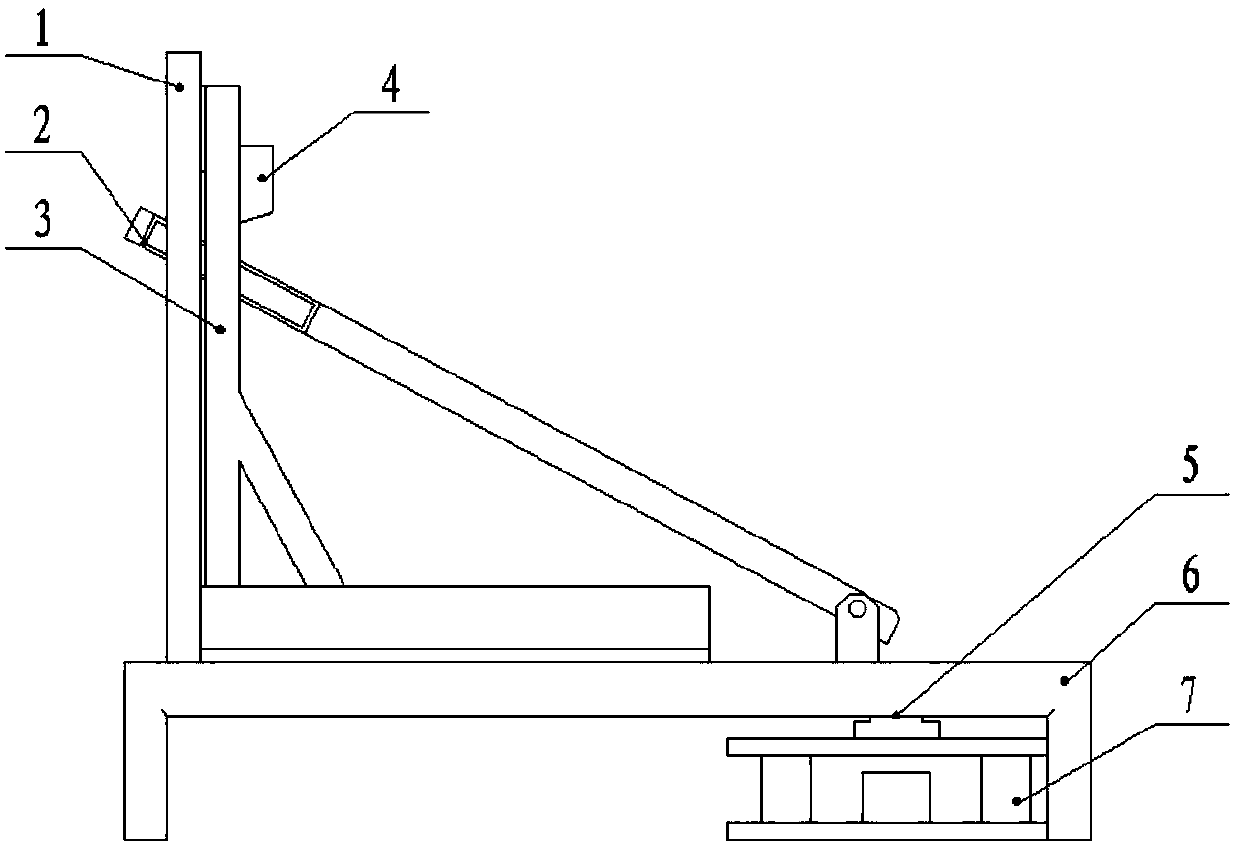

Horizontal unidirectional vibration table with adjustable amplitude and frequency

ActiveCN110987341AAdjust the amplitudeEasy to adjustVibration testingVibration amplitudeElectric machinery

The invention discloses a horizontal unidirectional vibration table with adjustable amplitude and frequency, which relates to the technical field of vibration test equipment. The vibration table comprises a bracket, a vibration table board and a driving mechanism, wherein the vibration table board and a test piece fixed to the table board are driven by means of the driving mechanism to vibrate horizontally on the bracket in a reciprocating mode; the driving mechanism comprises a variable frequency motor capable of adjusting a rotating speed to control the vibration frequency, a reduction gearbox and an eccentric adjusting mechanism for controlling the amplitude; the eccentric adjusting mechanism comprises a Pi-shaped sliding groove fixed to the lower portion of the table board, a U-shapedsliding groove connected with an output shaft of the reduction gearbox and an eccentric shaft; the eccentric shaft comprises an eccentric shaft sliding block and an eccentric shaft pin arranged aboveone end of the eccentric shaft sliding block; the eccentric shaft sliding block can slide and be locked in the U-shaped sliding groove so as to adjust an eccentric distance of the eccentric shaft pin;the eccentric shaft pin is inserted into the Pi-shaped sliding groove; and the eccentric shaft pin does circular motion in the horizontal plane and drives the Pi-shaped sliding groove and the vibration table board to vibrate horizontally in a reciprocating mode in the rotating process of the eccentric shaft.

Owner:CHINA UNIV OF MINING & TECH

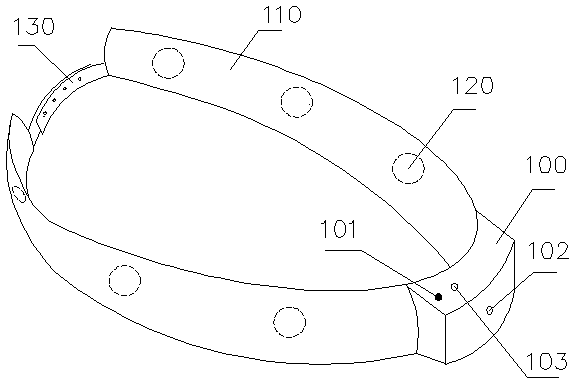

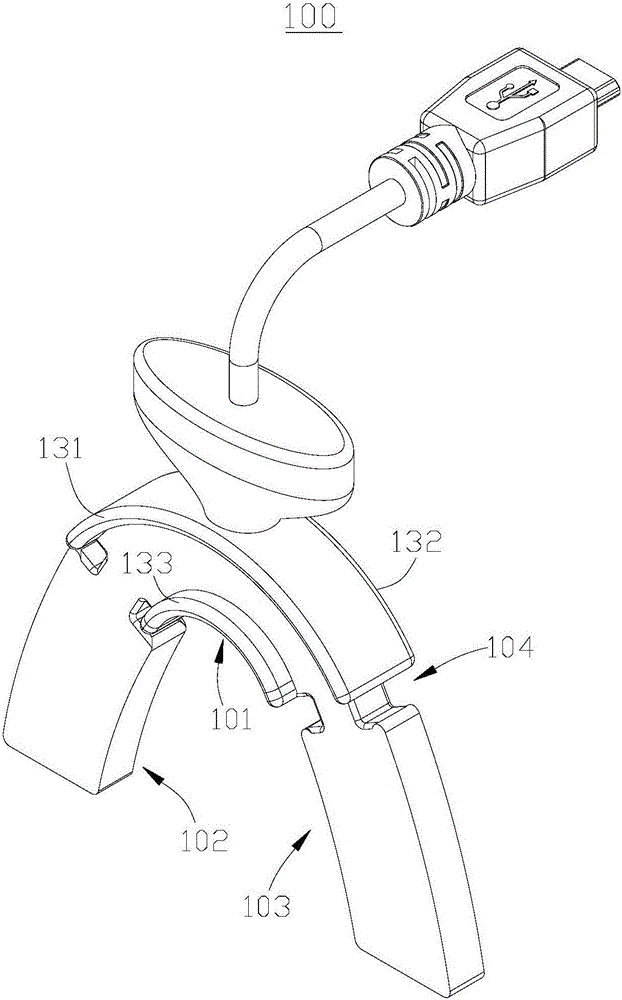

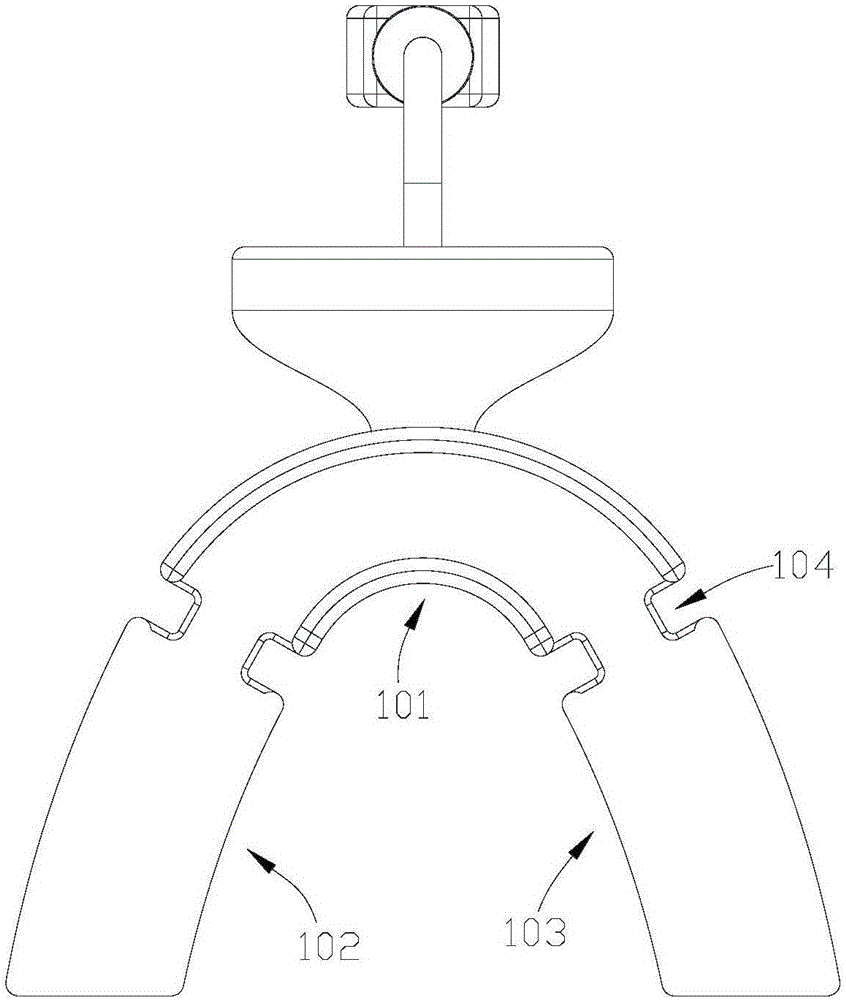

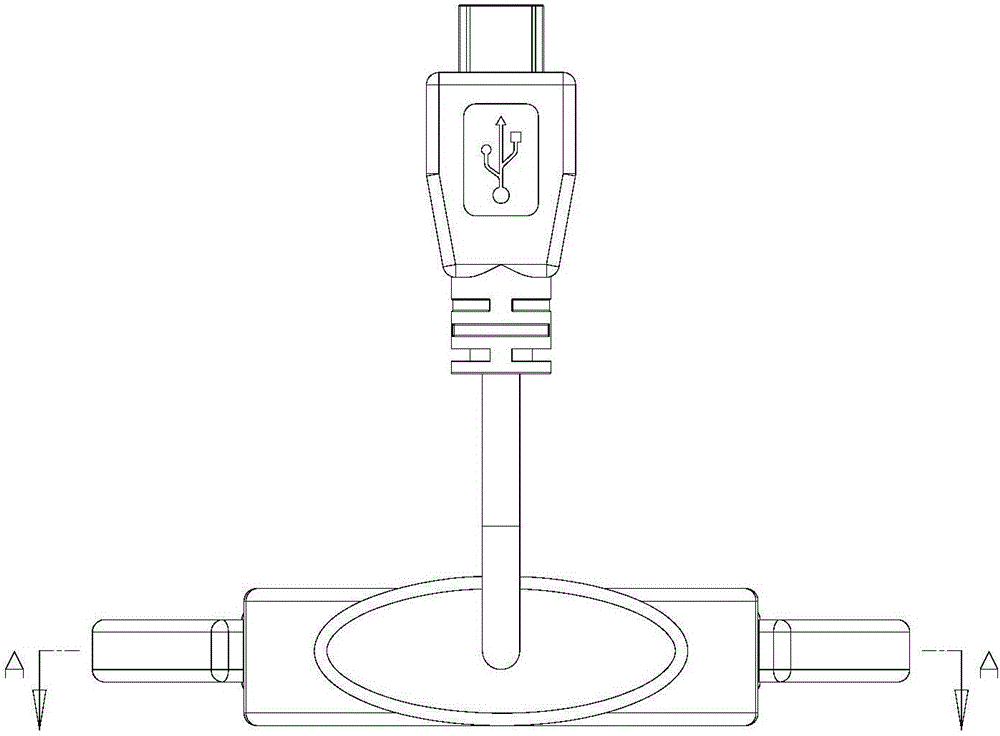

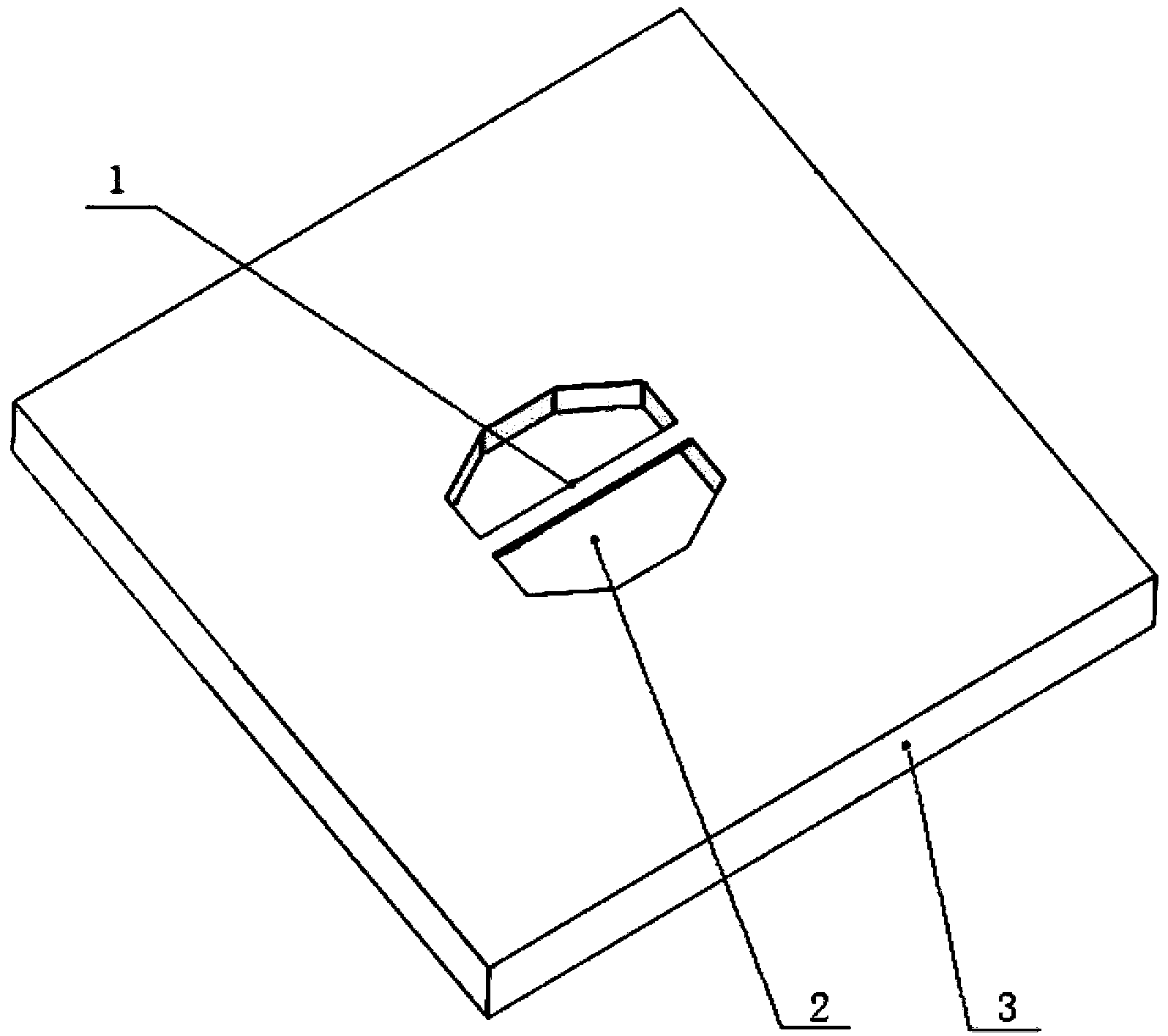

Sectional-type differential vibrating biteplate and sectional-type differential dentognathic orthopedic device

The invention relates to the field of dentognathic orthopedic techniques, and provides a sectional-type differential vibrating biteplate and a sectional-type differential dentognathic orthopedic device. Such a sectional-type differential vibrating biteplate comprises an anterior tooth vibrating unit, a left posterior tooth vibrating unit and a right posterior tooth vibrating unit, wherein the anterior tooth vibrating unit is corresponding to the position of an anterior tooth; the left posterior tooth vibrating unit is corresponding to the position of a left posterior tooth; the right posterior vibrating unit is corresponding to the position of a right posterior tooth; independent vibrating mechanisms are mounted in the anterior tooth vibrating unit, the left posterior tooth vibrating unit and the right posterior tooth vibrating unit respectively; elastic connecting units used for weakening vibration transmission are connected both between the anterior tooth vibrating unit and the left posterior tooth vibrating unit and between the anterior tooth vibrating unit and the right posterior tooth vibrating unit. The sectional-type differential dentognathic orthopedic device comprises the sectional-type differential vibrating biteplate and an extra-oral machine. The three vibrating units of the sectional-type differential biteplate can independently generate vibration; therefore, the directional vibration can be applied to a tooth; the movement of a local tooth is promoted; the personalized movement of the tooth at a specific segment is carried out.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Processing method of silicon micro resonator

InactiveCN103439032ASimple and efficient operationHigh pressure resistance effect and stabilityForce measurement by measuring frquency variationsFluid pressure measurement by electric/magnetic elementsSilicon chipIon

The invention discloses a processing method of a silicon micro resonator, belongs to the field of sensors, and aims at solving the problems in an existing method for manufacturing a resonator. The method provided by the invention comprises the following steps: 1, performing thermal oxidation treatment on an N-type (111) silicon wafer (with the resistivity of 3Omega.cm-10Omega.cm) selected as a to-be-processed silicon wafer so as to obtain a thermal oxidation treatment type silicon wafer; 2, etching a resonance beam structure diagram on the upper surface of the thermal oxidation treatment type silicon wafer by adopting a photoetching technology; removing oxidation layers in areas at two sides of a resonance beam; meanwhile, forming two deep grooves symmetrically in the two sides of the resonance beam by utilizing a deep reaction ion etching technology; 3, covering passivation layers on side walls of the resonance beam; 4, etching passivation layers on the bottoms of the two deep grooves; 5, re-etching the bottoms of the two deep grooves again continuously by a certain depth; 6, corroding the silicon wafer by a TMAH (tetramethylammonium hydroxide) solution, and releasing the resonance beam; communicating the two deep grooves in two sides of the resonance beam to form a vibration chamber, and processing the silicon micro resonator.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

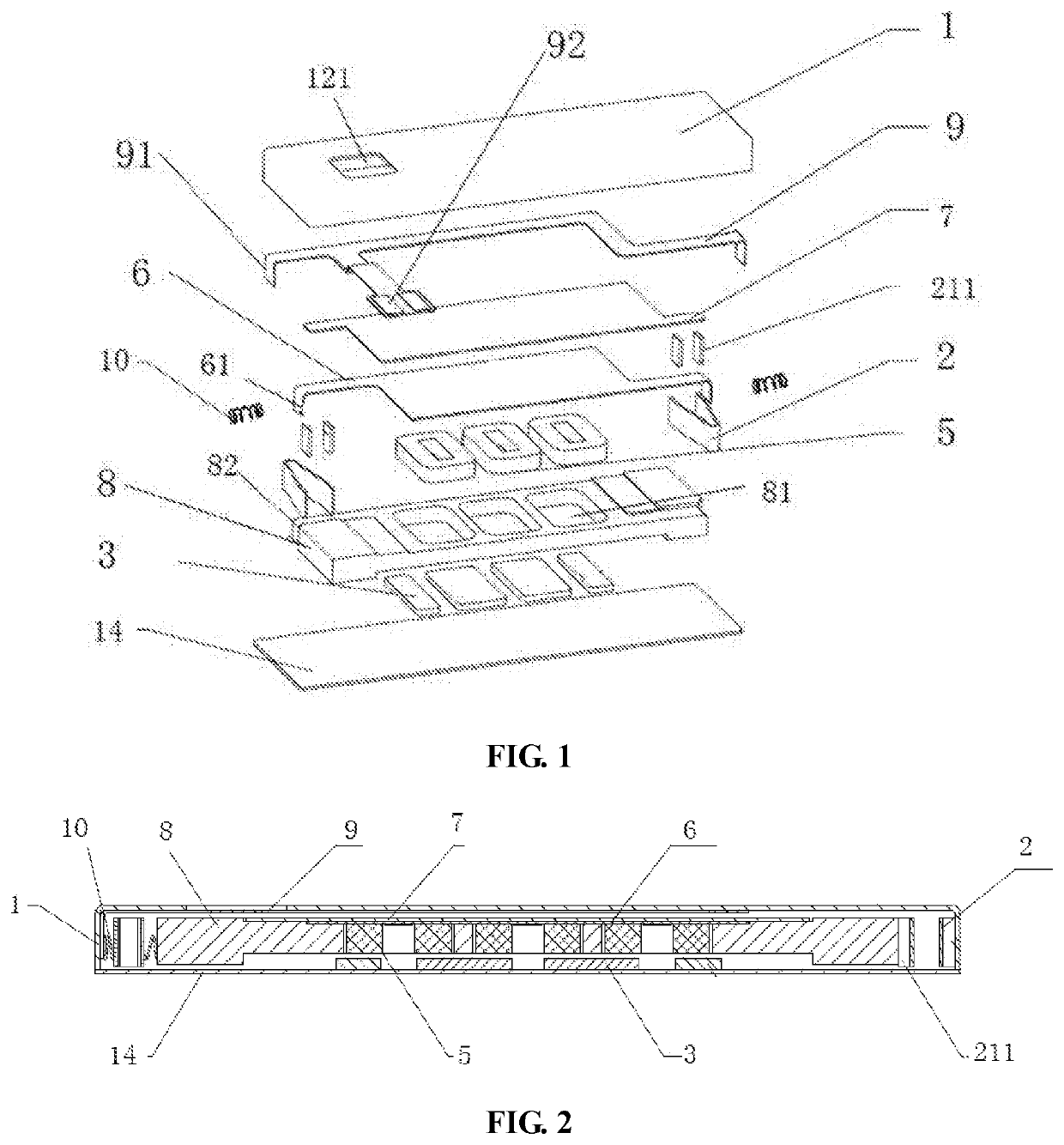

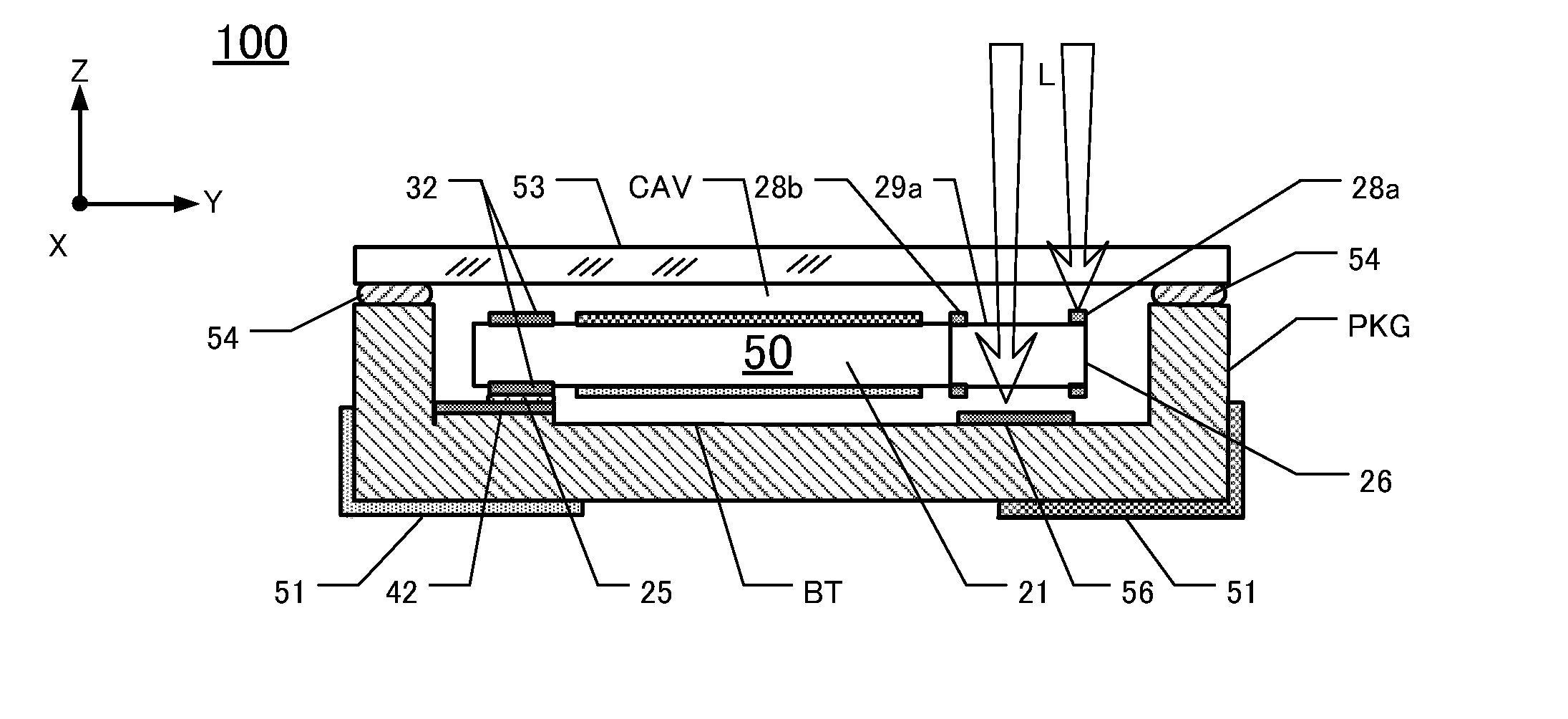

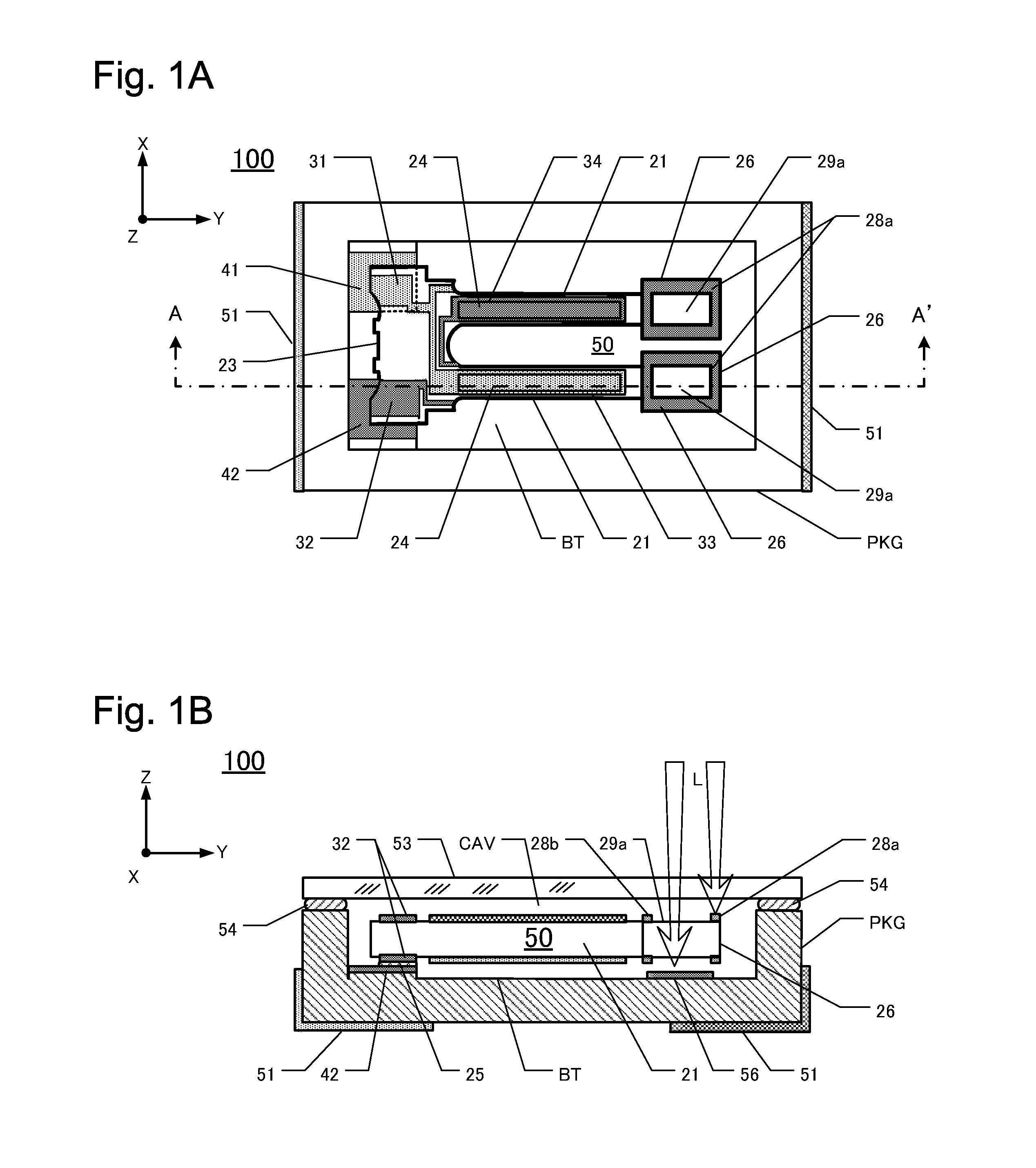

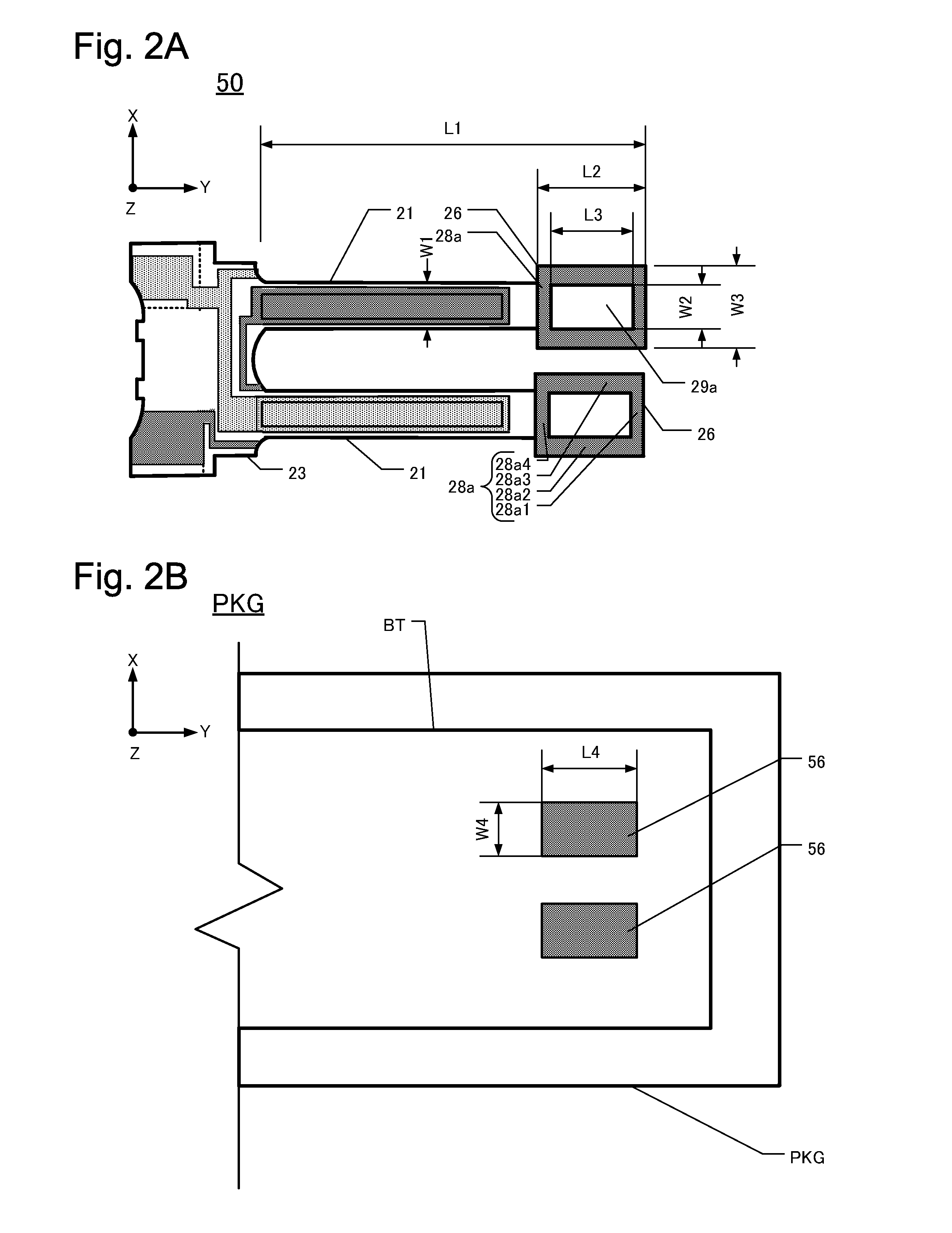

Piezoelectric devices including frequency-adjustment units

InactiveUS20110291524A1Reduce manufacturing defectsAdjustable vibration frequencyPiezoelectric/electrostriction/magnetostriction machinesImpedence networksTuning forkLight beam

Piezoelectric devices are disclosed that allow outside-in adjustment of vibration frequency produced by the devices. I.e., the vibration frequency can be increased or reduced. An exemplary piezoelectric device includes a tuning-fork type piezoelectric vibrating piece mounted inside a package. The vibrating piece has a base fabricated of a piezoelectric material, a pair of vibrating arms extending parallel from the base in a predetermined direction, and a frequency-adjustment unit situated on the distal ends of the vibrating arms. The package includes first metal films disposed on the inner main surface of the package at a location where a beam from an external laser can be irradiated. The frequency adjustment unit includes a transparent region that extends in a predetermined direction for allowing the laser beam, passing through the lid of the package, to be incident on second metal films by passing through the transparent regions. The laser beam also can be incident on first metal films without also being incident on the second metal films, by passing through the lid but not through the transparent regions.

Owner:NIHON DEMPA KOGYO CO LTD

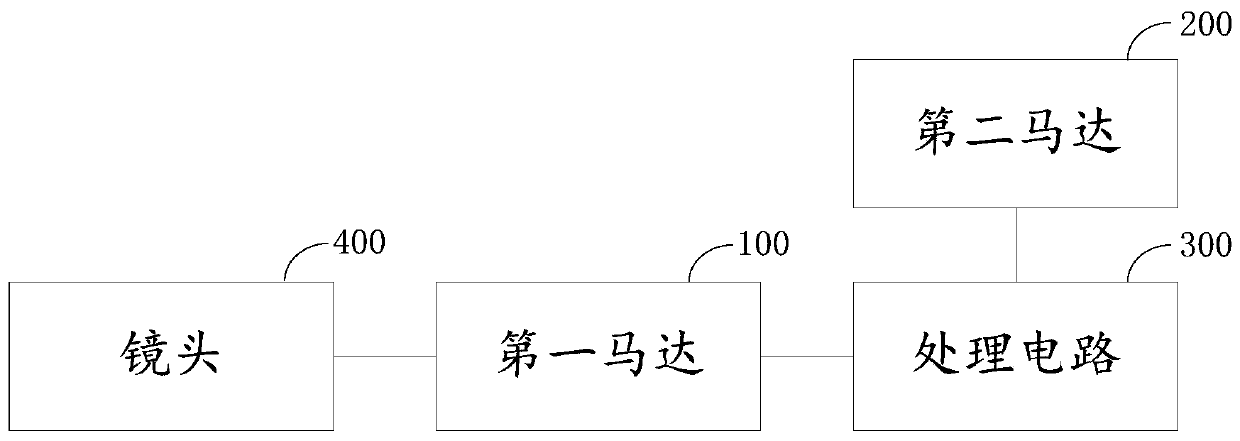

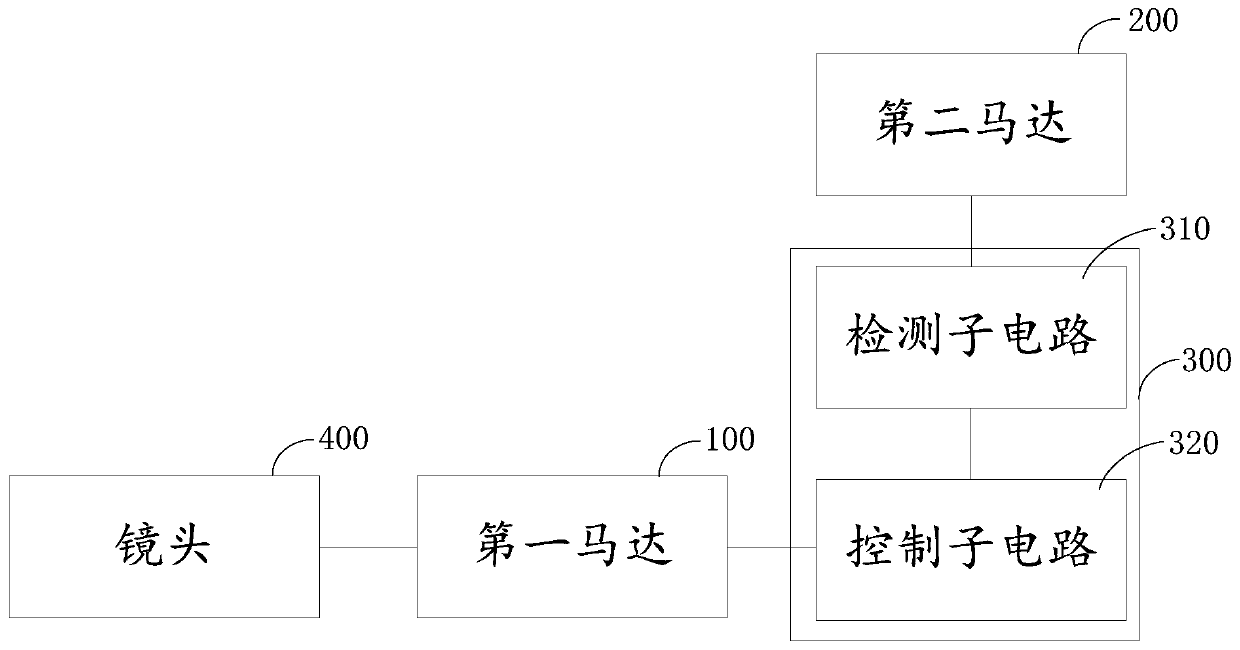

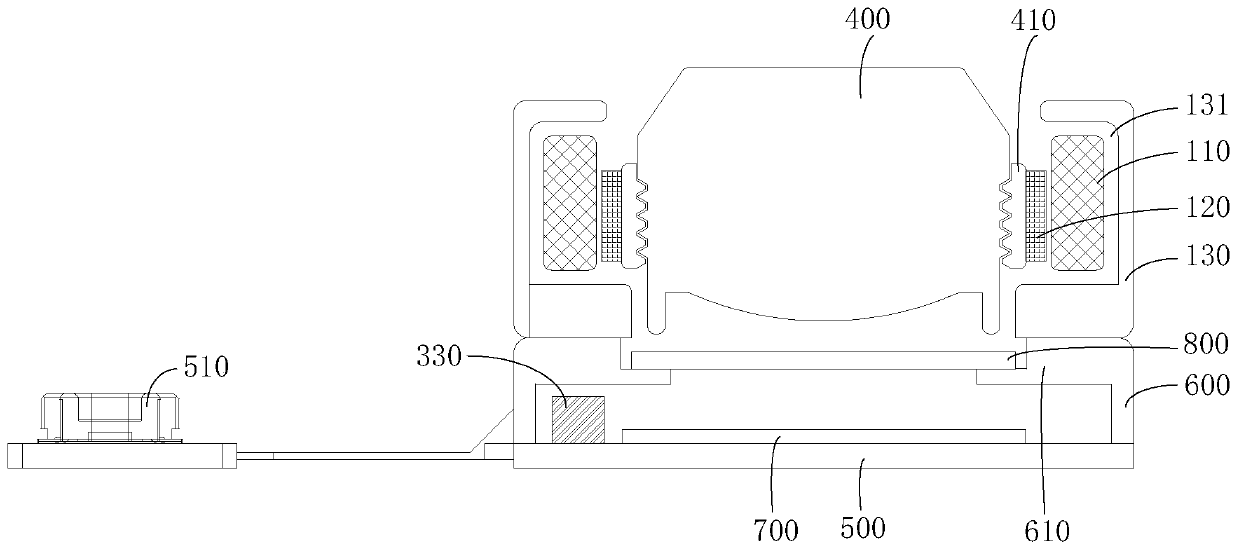

Terminal device and control method of terminal device

ActiveCN109862243AVibration frequency increases or decreasesAdjustable vibration frequencyTelevision system detailsColor television detailsTerminal equipment

The invention discloses terminal equipment. The terminal equipment includes a first motor, a second motor, a lens and a processing circuit. The first motor is connected with the lens and drives the lens to zoom. The processing circuit is connected with the first motor and the second motor, when the processing circuit determines that the vibration frequency of the second motor is the target frequency, the vibration frequency of the second motor is increased or decreased, and when the second motor vibrates at the target frequency, the first motor resonates. The invention further discloses a control method of the terminal device. According to the scheme, the problem of focusing failure caused by resonance of the first motor and the second motor in the current terminal equipment can be solved.

Owner:VIVO MOBILE COMM CO LTD

Vibrating-type anti-blocking printer spray head assembly

InactiveCN104802404AAdjustable vibration frequencyAdjust vibration intensityAdditive manufacturing apparatusResonanceEngineering

The invention discloses a vibrating-type anti-blocking printer spray head assembly which comprises a spray head, a feed venturi tube, a heater and a threaded mechanism, and further comprises a vibrator, wherein a feed opening in the spray head is communicated with a discharge opening in the feed venturi tube; the heater is arranged outside the spray head and in tight contact with the heated area in the spray head; the spray head, the feed venturi tube and the heater are all connected fixedly through the threaded mechanism; an anti-leakage step is arranged the joint of the spray head and the feed venturi tube; the threaded mechanism used for fixedly connecting the spray head with the feed venturi tube is arranged in the inner wall of a cavity at the upper part of the spray head; a reverse threaded mechanism is correspondingly arranged on the outer wall of the feed venturi tube; a thread in the reverse threaded mechanism extends out of the feed opening in the spray head; the vibrator is arranged on the outer wall of the feed venturi tube, and drives a wire material to be separated from the feed venturi tube wall by triggering resonance of the feed venturi tube wall. The vibrating-type anti-blocking printer spray head assembly is high in anti-leakage and anti-blocking properties, solid and durable.

Owner:NANNING LIHAN INSTR EQUIP CO LTD

Small vibrating table for precast block

InactiveCN108145829AAdjustable vibration frequencySolve the problem of not being able to achieve a good vibration effectCeramic shaping apparatusElectric machineryEngineering

The invention discloses a small vibrating table for a precast block. The small vibrating table comprises a working table, wherein supporting legs are welded to the two sides of the bottom of the working table respectively, and a stabilizing rod is welded between the supporting legs; guide rods are connected to the two sides of the top of the working table through bolts respectively, and springs are arranged on the surfaces of the guide rods in a sleeving mode; the tops of the guide rods are connected to a vibrating table body through bolts, and the two ends of each spring are fixedly connectedto the surface of the working table and the surface of the vibrating table body respectively; and a motor is fixedly arranged on the front side of the working table, a power regulator is fixedly arranged at the bottom of the motor, the power regulator is fixedly connected to the top of the stabilizing rod, and the output end of the motor is connected with a first cam in a clamped mode. Accordingto the small vibrating table for the precast block, the motor, the power regulator, the first cam, a second cam, a fixing bolt and a control box are matched, so that the problem that the amplitude andthe frequency of vibration of an existing vibrating table cannot be adjusted, so a good vibrating effect cannot be achieved is solved.

Owner:吴燕梅

Wirelessly controlled vibrating capsule and in vitro portable controller

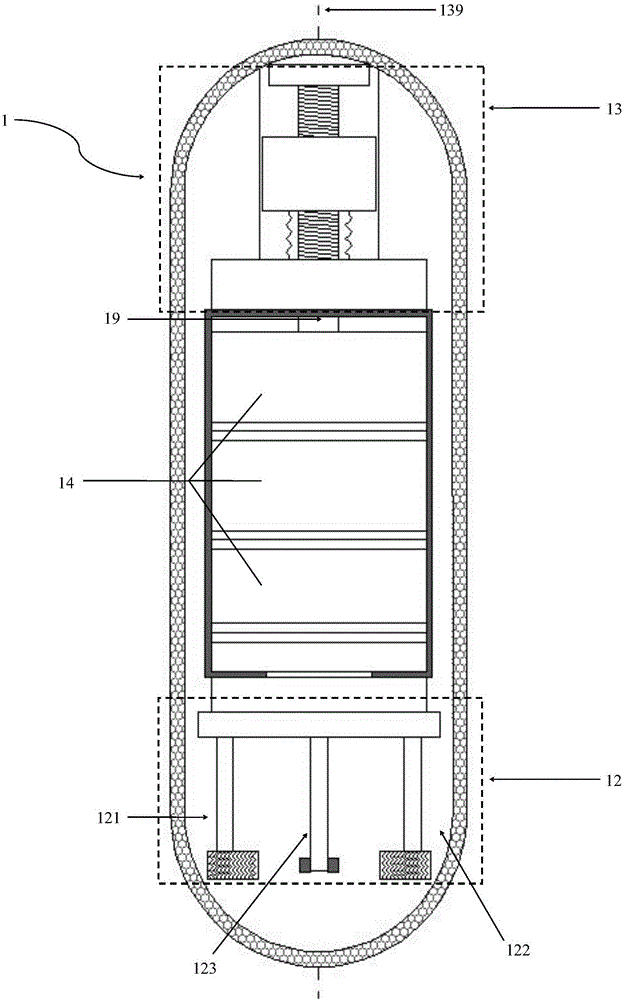

ActiveCN106333837AEffective stimulationEasy to moveCavity massageVibration massageEngineeringControl switch

The invention relates to a wirelessly controlled vibrating capsule and an in vitro portable controller. The wirelessly controlled vibrating capsule comprises a shell, a radial vibration module, an axial vibration module, a power source, a controller, a relay, a U-shaped connector, and a magnetically controlled switch. The axial vibration module comprises a motor, a screw, a spring, a hammer, a sliding cavity, and a stop piece. The wirelessly controlled vibrating capsule has the following advantages: (1) the radial vibration module and the axial vibration module are disposed in the vibrating capsule of the present invention to provide radial vibrations and axial vibrations, respectively, and the two types of vibrations of different modes may realize more effective stimulus on the wall of the gastrointestinal tract; (2) according to the present invention, the in vitro portable controller may be connected to the wireless vibrating capsule, such that a user can control the intensities of the radial vibrations and axial vibrations of the wireless vibrating capsule in the body in real time; and timing adjustment of the vibrating frequencies of the wireless vibrating capsule can be realized.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Waste silk clearing device for textile fabric processing

InactiveCN107354658AGuarantee product qualityAvoid removalHeating/cooling textile fabricsFloats removalPulp and paper industryPiston

The invention discloses a waste silk cleaning device for textile cloth processing, which includes a cleaning box, a first transmission roller connected between two first bearings, and a second transmission roller connected between two second bearings. The bottom of the piston plate is connected with a support spring, the middle part of the bottom of the movable rod is connected with a transmission rod, and the lower side of the transmission rod is inserted with a rotating rod, and the right side of the rotating rod is connected with a turntable. The end of the tube far away from the cleaning box is connected to the suction fan, and the middle part of the top of the cleaning box is provided with a port, the inside of the port is provided with a conduit, the bottom of the conduit is connected to a dust cover, and the left side of the adjustment plate A rack is connected, and the left side of the rack meshes with the transmission gear. The invention has the advantage of reducing the long time spent on removing waste silk from the textile cloth, and solves the problems that the waste silk removal on the textile cloth takes a long time and the poor removal effect of the waste silk will reduce the production quality of the textile cloth.

Owner:姚飞

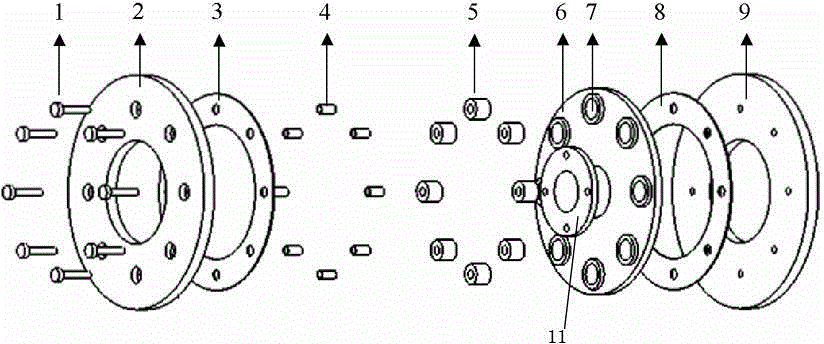

Power disc, torsion damper using power disc, transmission system and automobile

ActiveCN104791415APrevent excessive deformationSimple structureInertia force compensationShock absorbersEngineeringMechanical engineering

The invention relates to a power disc, a torsion damper using the power disc, a transmission system and an automobile. The power disc comprises a disc body of which the axis extends in the left-right direction. At least two rubber mounting holes which are throughout the disc body in the left-right direction are formed in the disc body in the circumferential direction. Damping rubber sleeves are arranged in the rubber mounting holes. The damping rubber sleeves are provided with inner rubber holes allowing corresponding connecting pieces to penetrate in the axial direction, and walls of the holes are in force transmission fit with the connecting pieces in the radial direction. The power disc in the torsion damper drives a rotational inertia disc to rotate through the damping rubber sleeves and the connecting pieces arranged in the inner rubber holes of the damping rubber sleeves, and the damping frequency of the damper can be adjusted by changing the number of the connecting pieces. Meanwhile, as the connecting pieces are arranged in the inner rubber holes of the damping rubber sleeves, the connecting pieces play a role in driving the rotational inertia disc to rotate and also play a role in preventing the damping rubber sleeves from deforming excessively; besides, there is no need to additionally arrange centering and limiting elements, so the structure is simple.

Owner:ZHENGZHOU YUTONG BUS CO LTD

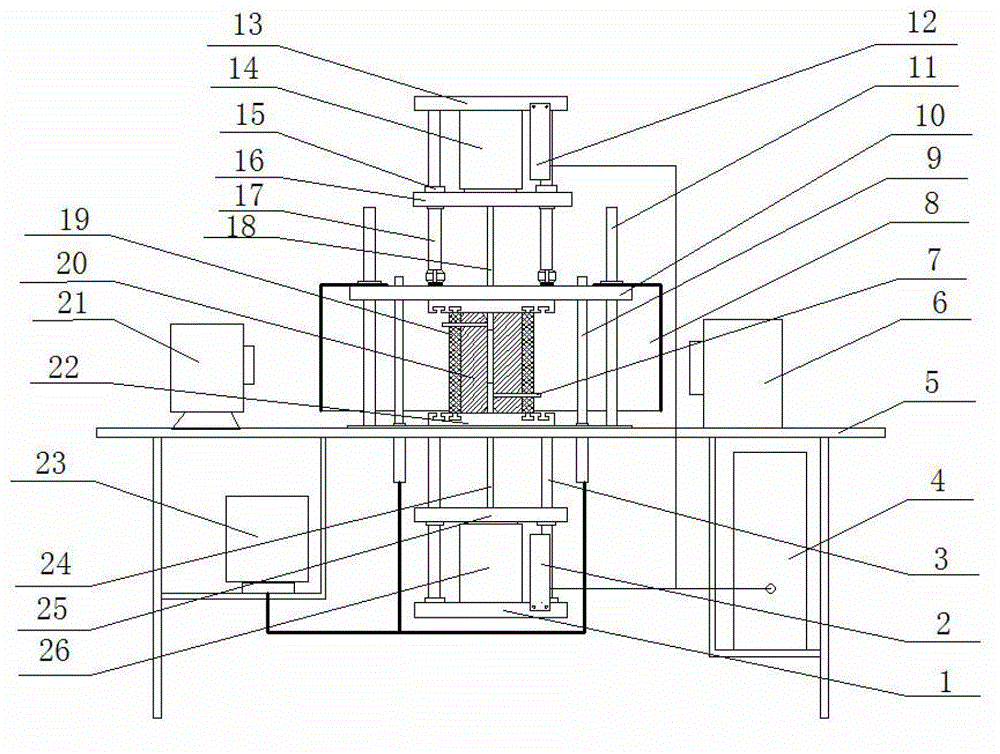

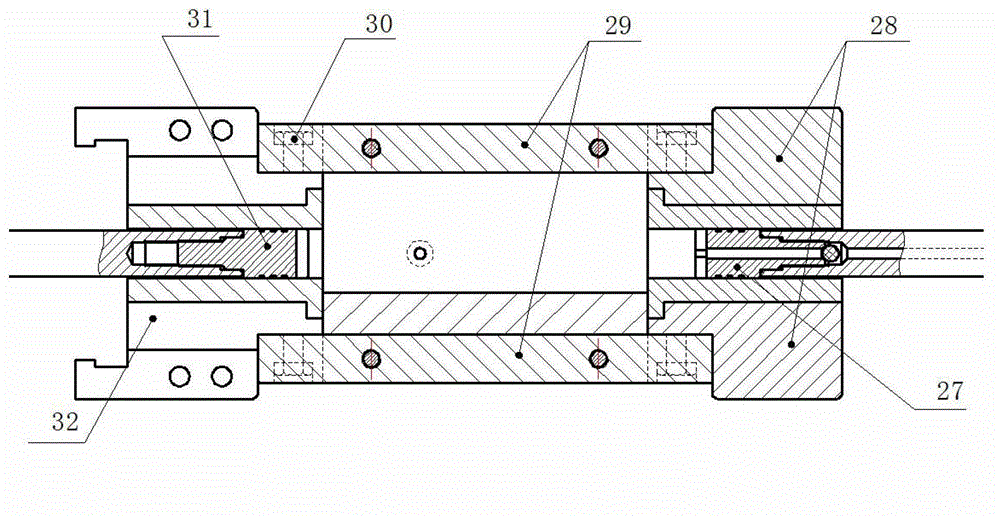

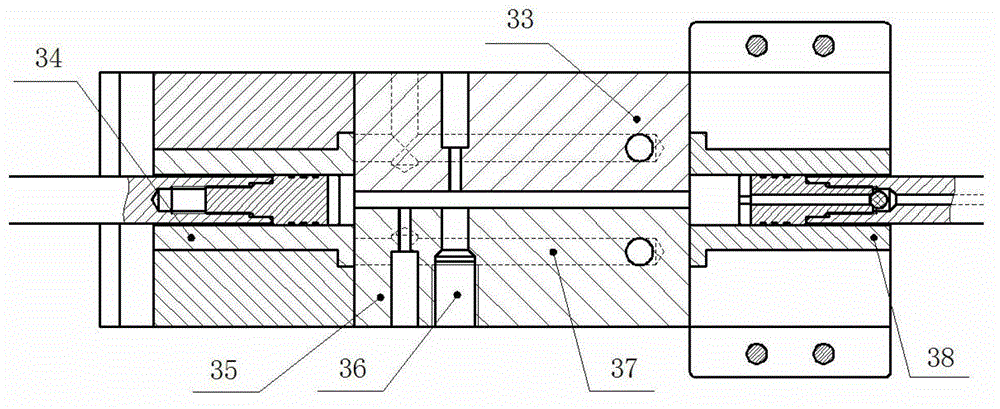

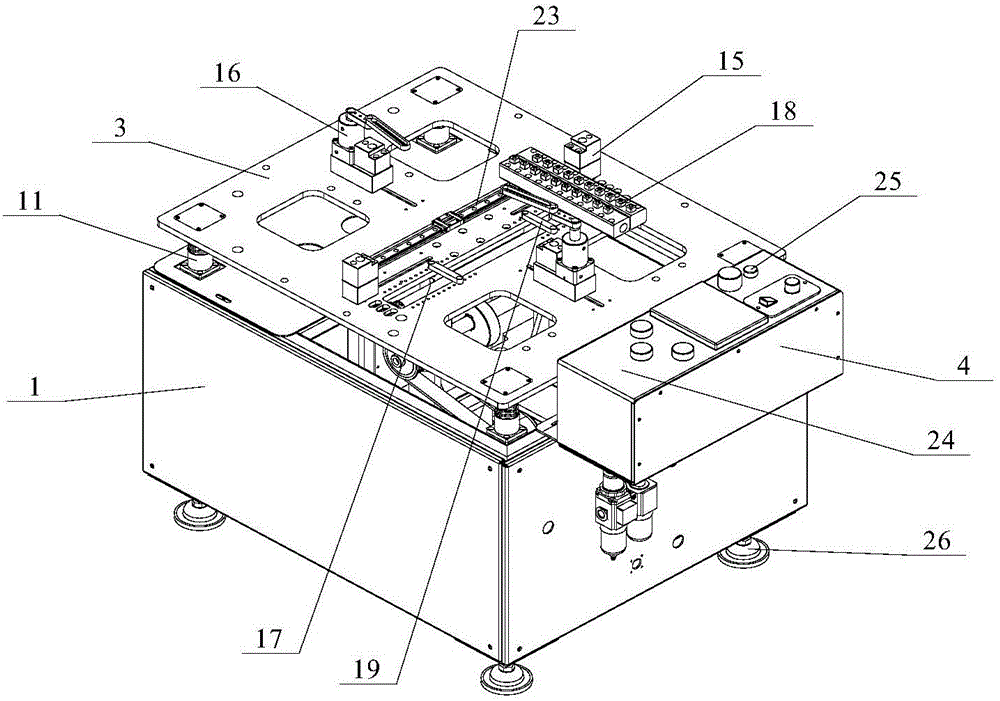

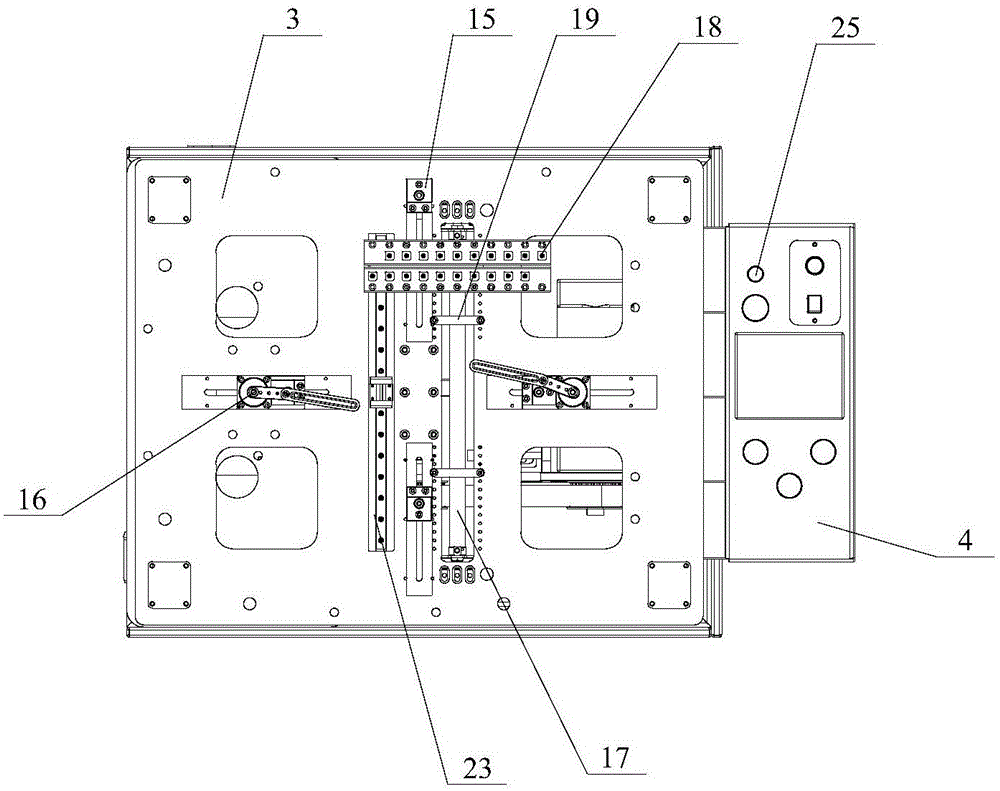

Plastic vibration processing and sample molding integration test equipment and method

The invention discloses plastic vibration processing and sample molding integration test equipment and a method. The equipment comprises a hydraulic power system, a vibration power driving system, a test platform, a piston assembly, a central mould, a visualization device, a controlling system and the like. The equipment and the method combine vibration field quantity with mould sample molding, combine cutting, pressing, vibration and sample processing molding function into a whole, are different from rheological property research limited by polymer of a traditional rheometer, avoid form change of plastic mixture structures when materials in a test cavity are taken out, monitor a microstructure online directly or directly mold and obtain detecting samples. The plastic vibration processing and sample molding integration test equipment and the method can not only achieve the rheological property test of moving state and steady state of the polymer, but also be used for microstructure form research of a plurality of polymer systems under multi-element field quantity and influence rule research between processing performance and technological conditions. The plastic vibration processing and sample molding integration test equipment and the method can be widely applied to industries of material, chemistry, pharmacy, coating, food, building and the like.

Owner:ZHEJIANG UNIV +1

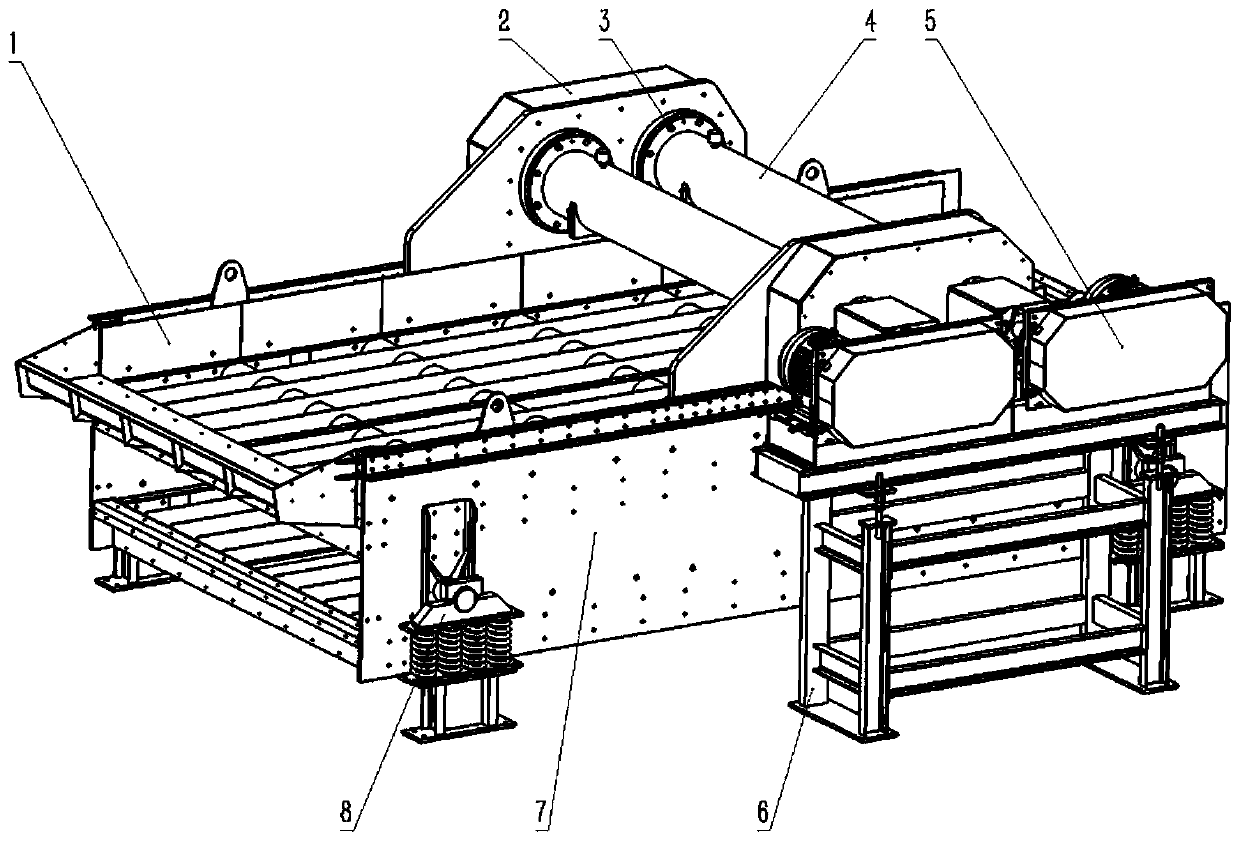

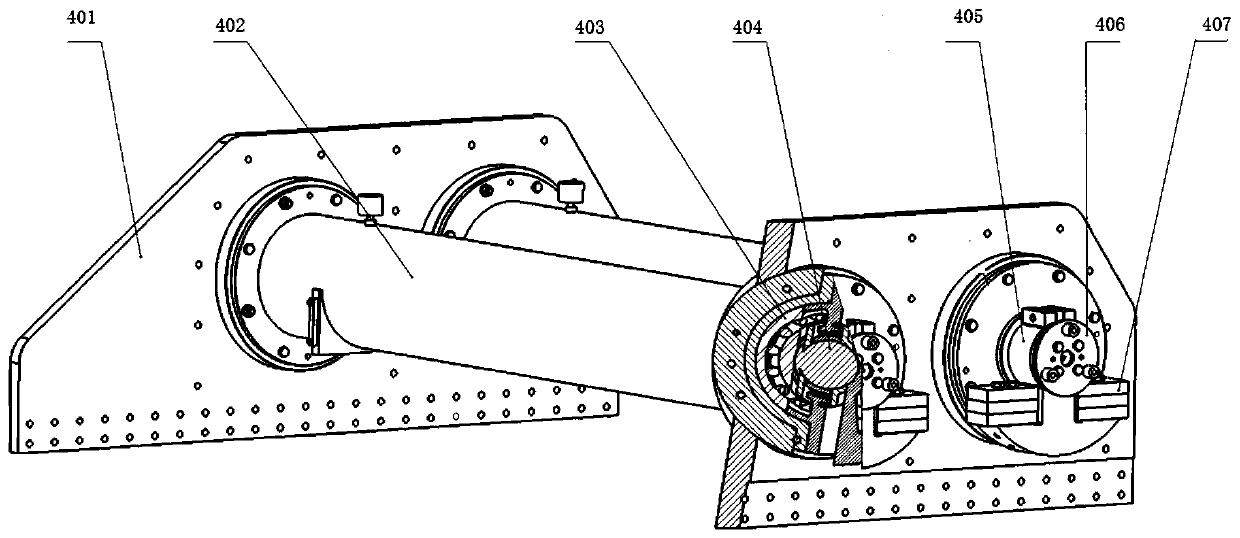

Flexible horizontal vibrating sieve

PendingCN110404766AEasy to adaptPlay a role of buffer protectionSievingScreeningEngineeringVibration exciter

The invention relates to a vibrating sieve, in particular to a flexible horizontal vibrating sieve. Balancing weights are arranged on an eccentric shaft, the eccentric mass change of the eccentric shaft is achieved, the vibrating form is flexible, and the amplitude is more flexible and changeable. The balancing weights with different masses can be selected to vibrate according to the type of ore,and thus the motion track can be switched between the straight line and the oval. Vibration exciters are arranged in different places on a sieve box, thus amplitude of the device at different positions can be adjusted slightly, and thus the device is applicable to different use occasions. The installing angle of the horizontal vibrating sieve is between -10 DEG C and +10 DEG C, the installing angle of the device is more flexible, and the suitable installing angle is selected according to the needed ore falling speed. The horizontal vibrating device is simple in structure, easy to assemble anddisassemble, convenient to debug and maintain, and capable of adapting to different working conditions.

Owner:广州市万瑞机械制造有限公司

Electronic product anti-vibration performance detection device

PendingCN110044564ARealize up and down vibration effectRealize shock resistance testingVibration testingReciprocating motionEngineering

The invention discloses an electronic product anti-vibration performance detection device and relates to the technical field of electronic product detection. The device comprises a base frame, whereina supporting plate is hinged on the base frame; longitudinal guide rods are vertically fixed on the supporting plate; a top plate is horizontally fixed on top ends of the longitudinal guide rods; a longitudinal adjustment mechanism in drive connection with a placement box is vertically set on the top plate; and a transverse adjustment mechanism in drive connection with a rack plate is horizontally set on a longitudinal guide rod. According to the device, through utilization of a set reciprocating mechanism, the rack plate is driven to carry out reciprocating motion, back and forth abutted drive between lower lugs and upper lugs is realized, an up and down vibration effect of the placement box is realized, and anti-vibration performance detection for an electronic product is realized; through utilization of the transverse adjustment mechanism, transverse movement speed of the rack plate can be adjusted, and a vibration frequency of the electronic product is adjusted; and through utilization of the set longitudinal adjustment mechanism, acting force between the lower lugs and the upper lugs is adjusted, and vibration stress of the electronic product is adjusted.

Owner:EAST CHINA UNIV OF TECH

Vibrating screen

InactiveCN101934270AParticipating mass is smallReduce energy consumptionSievingScreeningChemical industryEngineering

The invention discloses a vibrating screen with a vibrating screen surface and static screen box and aims to provide a vibrating screen which is low in energy consumption and foundation vibrating force and can be made in large size easily. The vibrating screen comprises a machine frame, a screen surface, a vibrating device and a transmission mechanism, wherein the transmission mechanism comprises a transmission rod, vibrating rods, rotating shafts, rotating shaft seats and a vibrating arm, wherein the vibrating device is connected with the transmission rods; the transmission rod is hinged with the vibrating rod, the vibrating rod is sleeved on the ends of the rotating shafts; the rotating shafts are arranged in the rotating shaft seats; at least two rotating shaft seats are arranged on each rotating shaft; the vibrating arms are arranged on the rotating shafts; the rotating shaft seats and the vibrating device are arranged on the machine frame; and the screen surface is fastened on the vibrating arms by bolts. The vibrating screen can be widely used in energy resource, metallurgical, ceramic, building material, chemical industries and other industries and mainly used for material grading and dehydration.

Owner:李卓

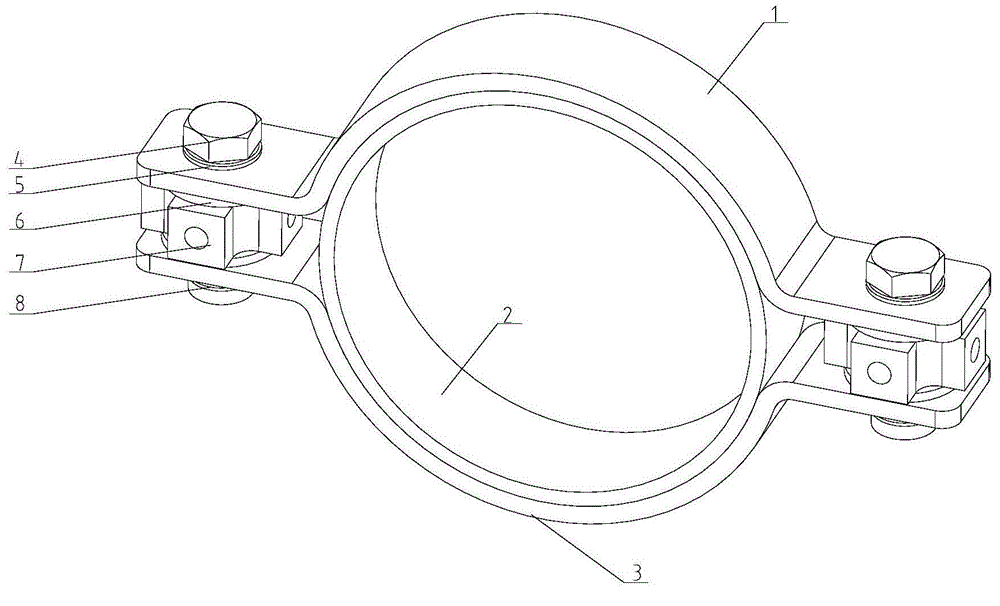

Pipeline resonance fatigue test bench

The present invention discloses a pipeline resonance fatigue test bench. The pipeline resonance fatigue test bench comprises: a fixing plate; at least two supporting mechanisms movably arranged on thefixing plate; a displacement measuring device; a first cover plate, one side of which is fixedly connected with the pipeline to be tested; a bearing pedestal, one side of which is rotatably supportedon the other side of the first cover plate; a screw shaft which passes through the centers of both sides of the bearing pedestal along the axial direction of the pipeline to be tested, is rotatably connected with the bearing pedestal and is provided with an external thread on the outer surface; a guide shaft arranged parallel to the screw shaft; an eccentric block with an internal thread passingthrough the guide shaft and appropriately sleeved on the external thread; and a driving motor, a power output end of which is connected with the other side of the bearing pedestal. Through the centrifugal vibration of the eccentric block, the vibration frequency is close to the frequency of the welded part of the pipeline and resonance is generated, then an overall fatigue performance test for circumferential weld of the pipeline and pipe fitting is realized.

Owner:中机试验装备股份有限公司 +1

Full-automatic vibrostand

ActiveCN106424022ARealize automatic controlAdjustable vibration frequencyCleaning using gasesProgramme control in sequence/logic controllersAutomatic controlEngineering

The invention provides a full-automatic vibrostand and relates to the technical field of vibration devices. A transmission device comprises a motor arranged on a first workbench, and the output end of the motor is connected with an eccentric wheel through a belt wheel assembly. A vibration device comprises a plurality of sets of elastic assemblies arranged between a second workbench and the top face of a box. A jacking assembly matched with the eccentric wheel to vibrate is arranged on the second workbench. A clamping device comprises two sets of workpiece bases arranged on the second workbench, and a corner air cylinder is arranged on one set of workpiece bases. An air-blowing assembly comprises a rodless air cylinder arranged on the second workbench, and a piston of the rodless air cylinder is connected with an air tap assembly. The full-automatic vibrostand further comprises a control device used for controlling the whole device to work. The full-automatic vibrostand achieves automatic control through cooperation work between the PLC system and an electric control system to adjust the vibration frequency, amplitude and the vibration time, and achieves final cleaning through air-blowing dust removing of the air-blowing device.

Owner:SHENZHEN WAVE TELECOMM TECH CO LTD

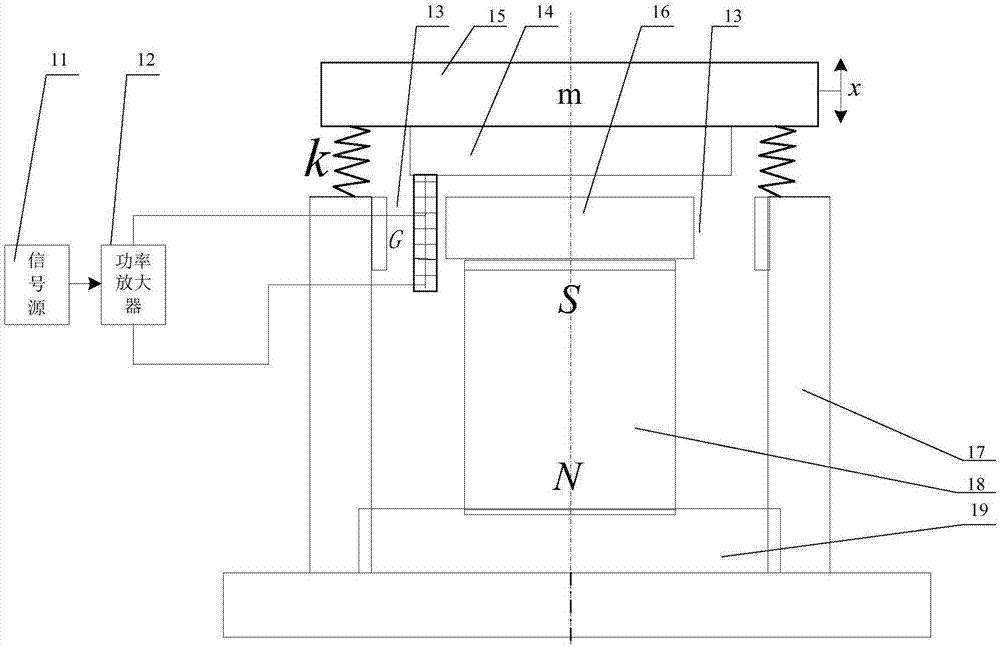

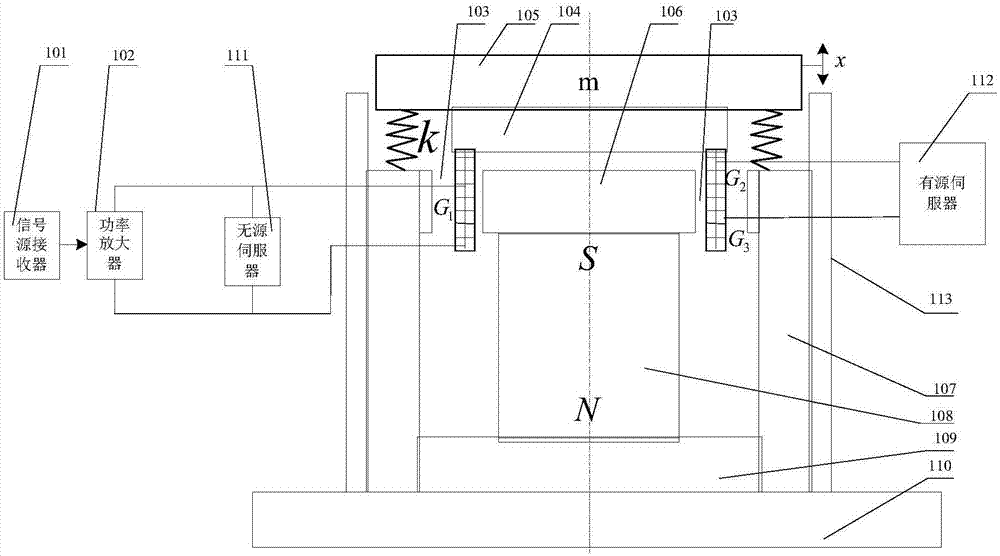

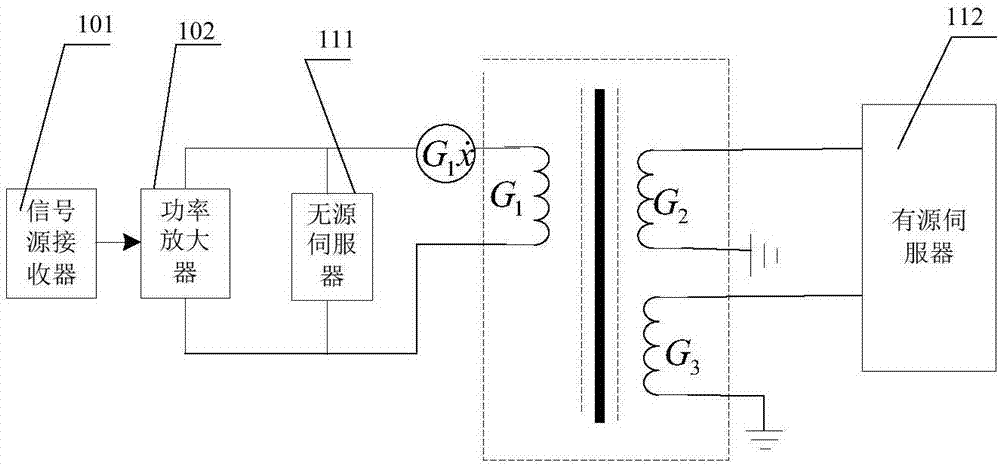

Servo shake table and control method thereof

PendingCN106959196ARealize frequency regulationHigh vibration frequencyVibration testingElectricityAudio power amplifier

The invention provides a servo shake table and a control method thereof, and relates to the shake table field; the servo shake table adds an active server on an original main body frame and a control circuit; a second coil and a third coil of the active server are respectively located in a magnetic slot, and respectively wind on a movable coil rack; the second coil, a servo amplifier, a feedback resistor and the third coil are electrically connected in sequence; in usage, the amplification multiple of the private server amplifier can be adjusted so as to adjust the shake table whole shaking frequency, thus adjusting the frequency.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION

Vibration device

InactiveCN1947864AEasy to useImprove vibration efficiencyMechanical vibrations separationEngineeringMechanical engineering

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Low pressure consumption downhole vibration speed-increasing tool

InactiveCN108643821ALow pressure lossImprove the vibration effectBorehole drivesVibration drillingWell drillingEngineering

The invention relates to a low pressure consumption downhole vibration speed-increasing tool. According to the technical scheme, the low pressure consumption downhole vibration speed-increasing tool is composed of a pressure pulse generating tool and an amplitude amplifying tool. The pressure pulse generating tool is internally provided with a moving valve plate, the moving valve plate is driven by turbines to rotate, and the rotating speed of the moving valve plate is adjusted by speed reducing turbines; and a U-shaped vortex vibration device is arranged on the lower part of a moving and stationary valve group, flow passages are continuously switched by the moving valve plate to enable fluid in a circular vortex chamber to switch between the vortex state and the non-vortex state, when thefluid in the vortex chamber is in the vortex state, the upper part of the pressure pulse generating tool is in a high pressure state, and when the fluid in the vortex chamber is in a non-vortex state, the upper part of the pressure pulse generating tool is in a low pressure state, so that periodic pressure pulse is generated in the pressure pulse generating tool. The amplitude amplifying tool isconnected to the upper part or the lower part of the pressure pulse generating tool, so that a bottom drilling assembly generates periodic axial vibrations, the frictional resistance between a drill stem and the wall of a well is effectively improved, and the well drilling speed is improved.

Owner:乌鲁木齐九品芝麻信息科技有限公司

Forming device and method for aluminum alloy structure refining

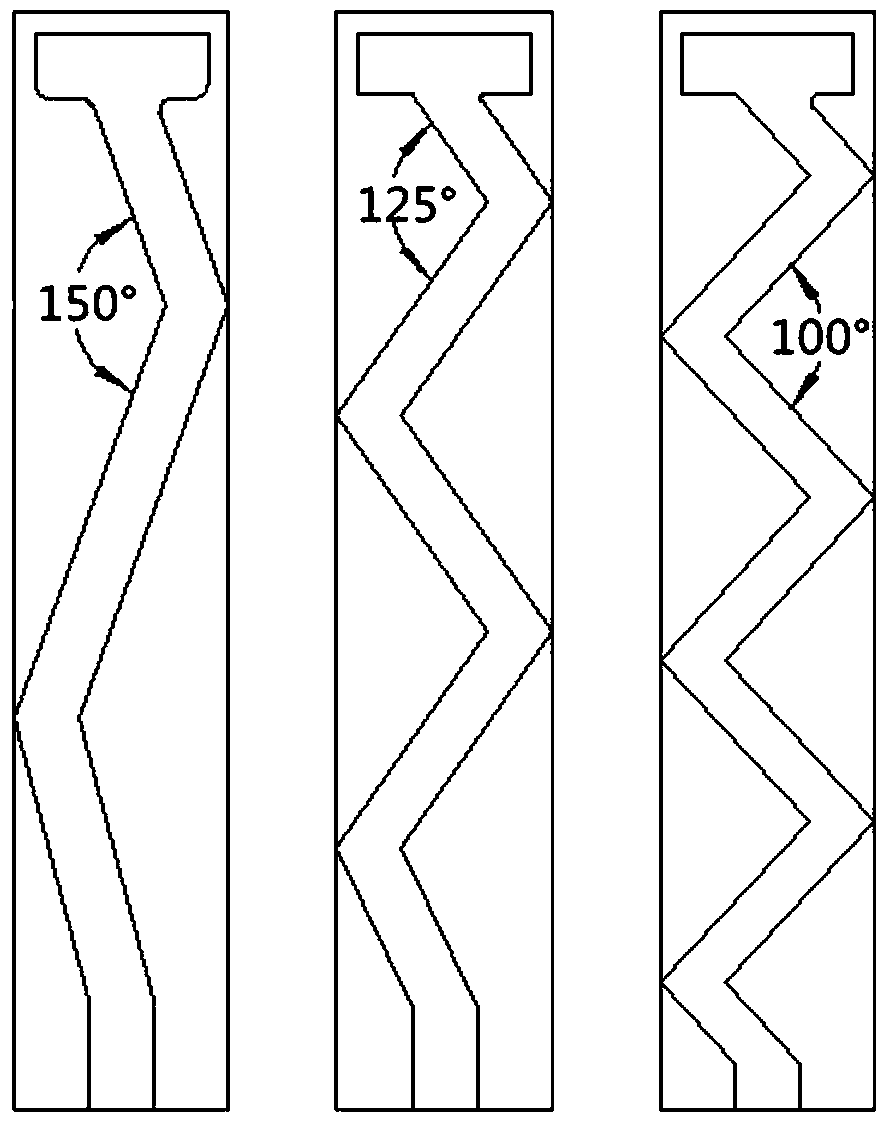

The invention discloses a forming device and method for aluminum alloy structure refining. The device comprises a slope serpentine channel, a feeding funnel, a vibration platform and a matched mold. The angle of the slope serpentine channel is 30-50 degrees, and the length of a slope is 1000mm. The number of bends is 2-6. The angle of each bend is 100-150 degrees, and the vibrational frequency is100-200Hz. According to the forming technology, the serpentine slope and the vibration technology are combined, and the aluminum alloy structure can be effectively refined. Aluminum alloy melt is poured into the feeding funnel after refining and drossing. The melt is poured into the metal mold connected with the vibration casting platform after passing through the slope serpentine channel with a certain tilted angle, and then is cooled, consolidated and formed at a certain vibrational frequency.

Owner:SOUTH CHINA UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com