Pipeline resonance fatigue test bench

A fatigue test and pipeline technology, applied in the field of testing machines, can solve problems that do not reflect the overall performance of components, test cycle, and even construction impact, uneven force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

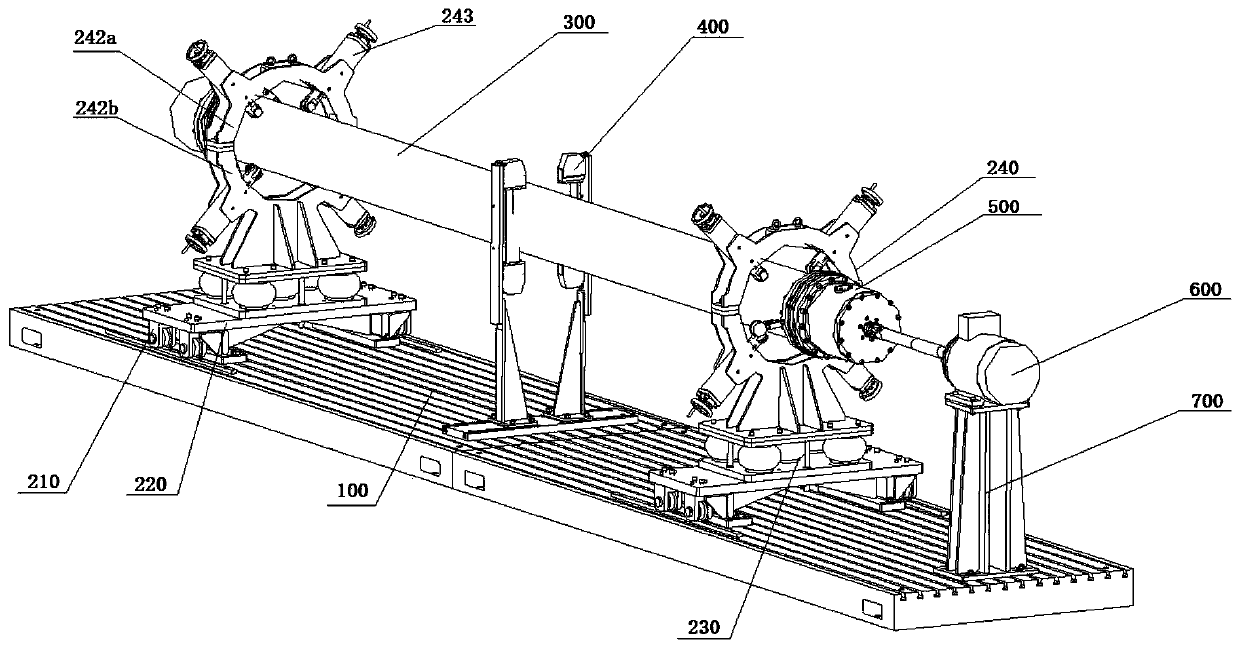

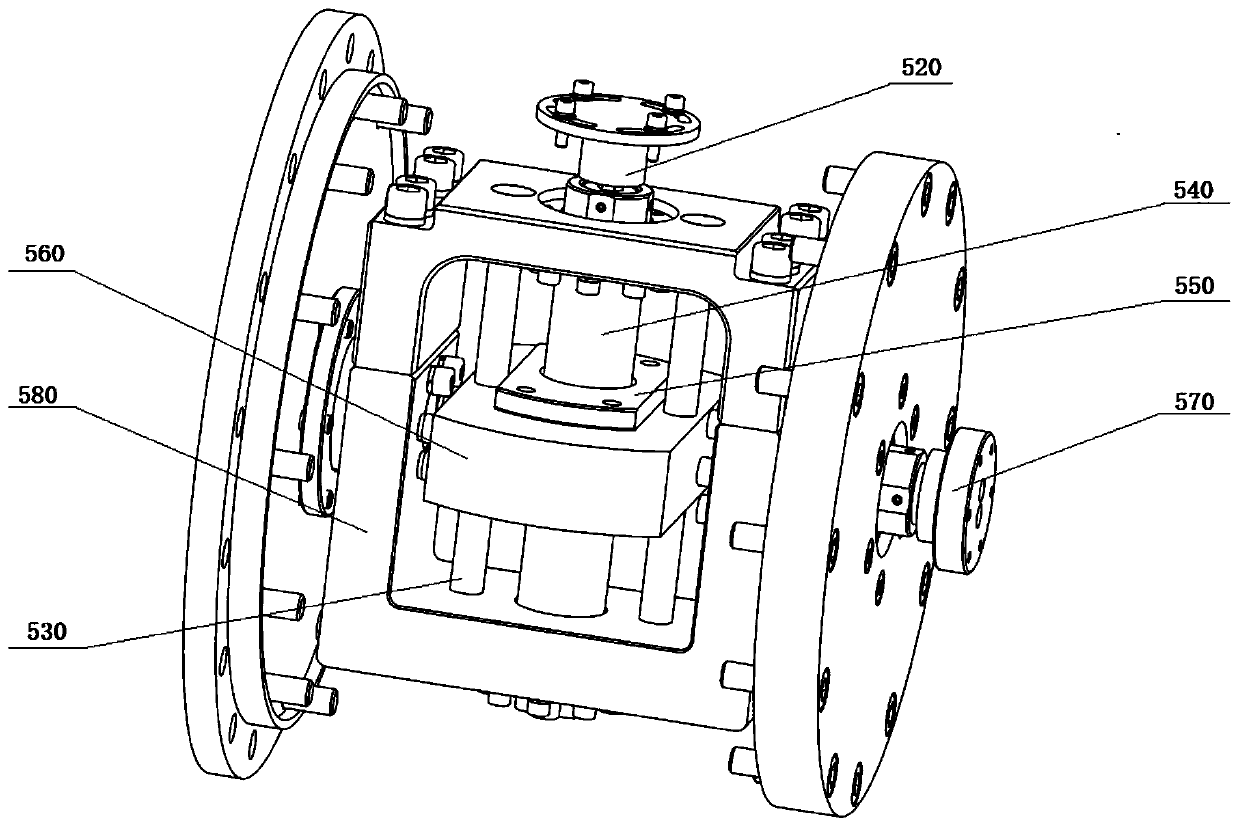

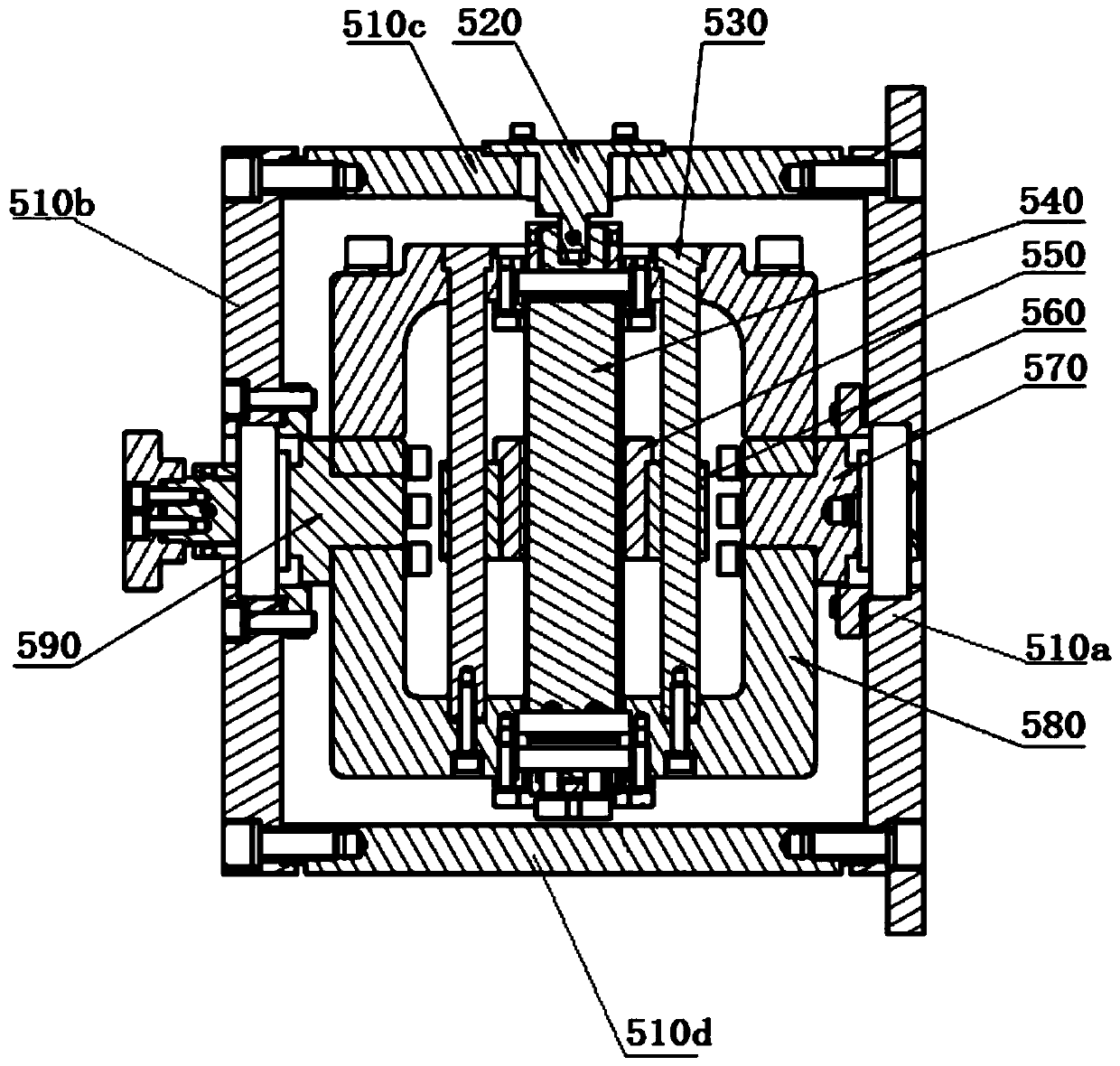

[0061] Such as Figure 1-6 As shown, the present invention provides a pipeline resonance fatigue test bench, including: a fixed plate 100, a support mechanism, a pipeline 300, a displacement measuring device 400, an eccentric vibrator 500, a driving motor 600 and a motor bracket 700.

[0062] Such as figure 1 As shown, the fixed plate 100 is a cuboid structure, placed horizontally on the ground, a plurality of T-shaped grooves are arranged on the top of the fixed plate 100, slide rails are arranged symmetrically on the top of the fixed plate 100, and the support mechanism is arranged on the slide rails It can move back and forth on the slide rail and adjust the position. Due to the characteristics of the pipeline, the number of supporting mechanisms should be at least two. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com