Forming device and method for aluminum alloy structure refining

A forming device and aluminum alloy technology, which is applied in the field of aluminum alloy forming technology, can solve the problems of difficult industrial mass production, high equipment maintenance costs, expensive electromagnetic stirring equipment, etc., and achieve the effect of improving structure and increasing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

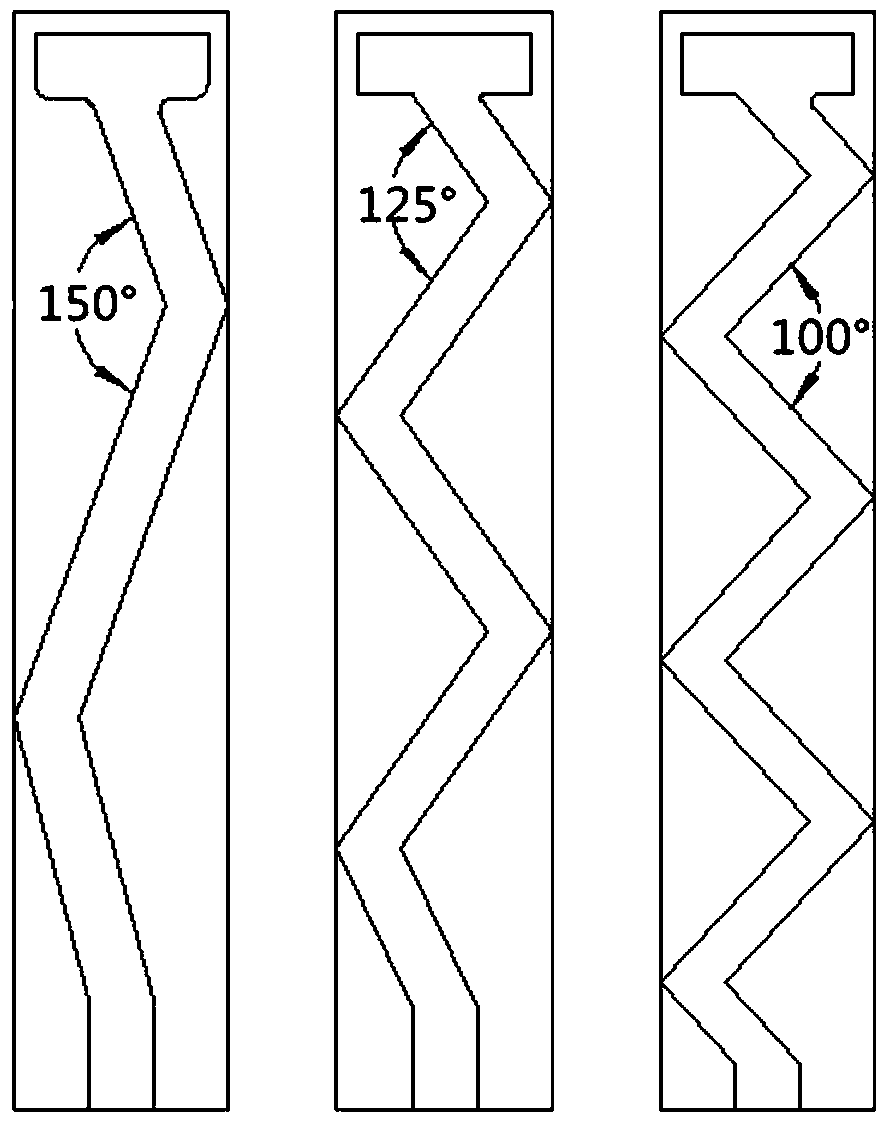

[0053] The alloy system used in this comparative example is still 20%Mg2Si / A356-1.5%Fe alloy. First select a slope serpentine channel with 6 curves, the angle of the curve is 100°, the angle of the slope is 40°, the straight line length of the slope serpentine channel is 1000 mm, and the frequency of the vibration platform is set to 200 Hz. The alloy smelting process is the same as that of Comparative Example 1. After slag removal and refining, the alloy melt is poured into a feeding hopper preheated at 200°C. flow, and finally fall into a metal mold preheated at 200°C, and the alloy melt is solidified and cooled to obtain an ingot.

[0054] Samples were taken from the ingot for scanning electron microscope (SEM) structure observation, the morphology of the alloy phase was analyzed, its size was measured, and tensile mechanical properties were tested. The SEM organization of this comparative example gained is as Figure 7 It can be seen from the figure that its organization ...

Embodiment 2

[0058] The alloy system used in this comparative example is still 20%Mg2Si / A356-1.5%Fe alloy. First select a slope serpentine channel with 4 curves, the angle of the curve is 125°, the angle of the slope is 50°, the straight line length of the slope serpentine channel is 1000 mm, and the frequency of the vibration platform is set to 180 Hz. The alloy smelting process is the same as that of Comparative Example 1. After slag removal and refining, the alloy melt is poured into a feeding hopper preheated at 200°C. flow, and finally fall into a metal mold preheated at 200°C, and the alloy melt is solidified and cooled to obtain an ingot.

[0059]Samples were taken from the ingot for scanning electron microscope (SEM) structure observation, the morphology of the alloy phase was analyzed, its size was measured, and tensile mechanical properties were tested. The SEM structure obtained in this comparative example is similar to that of Example 1. Randomly select 100 primary Mg 2 Si a...

Embodiment 3

[0062] The alloy system used in this comparative example is still 20%Mg2Si / A356-1.5%Fe alloy. First select a slope serpentine channel with 6 curves, the angle of the curve is 100°, the angle of the slope is 50°, the straight line length of the slope serpentine channel is 1000 mm, and the frequency of the vibration platform is set to 160 Hz. The alloy smelting process is the same as that of Comparative Example 1. After slag removal and refining, the alloy melt is poured into a feeding hopper preheated at 200°C. flow, and finally fall into a metal mold preheated at 200°C, and the alloy melt is solidified and cooled to obtain an ingot.

[0063] Samples were taken from the ingot for scanning electron microscope (SEM) structure observation, the morphology of the alloy phase was analyzed, its size was measured, and tensile mechanical properties were tested. The SEM structure obtained in this comparative example is similar to that of Example 1. Randomly select 100 primary Mg 2 Si ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com