Vibrating screen

A technology of vibrating screens and vibrating rods, which is applied in the direction of filter screens, mobile filter element filters, grilles, etc., which can solve the problems of large foundation vibration force, large screen box structure, screen vibration, etc., and achieve small vibration quality, There are many adjustable parameters and the effect of uniform vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

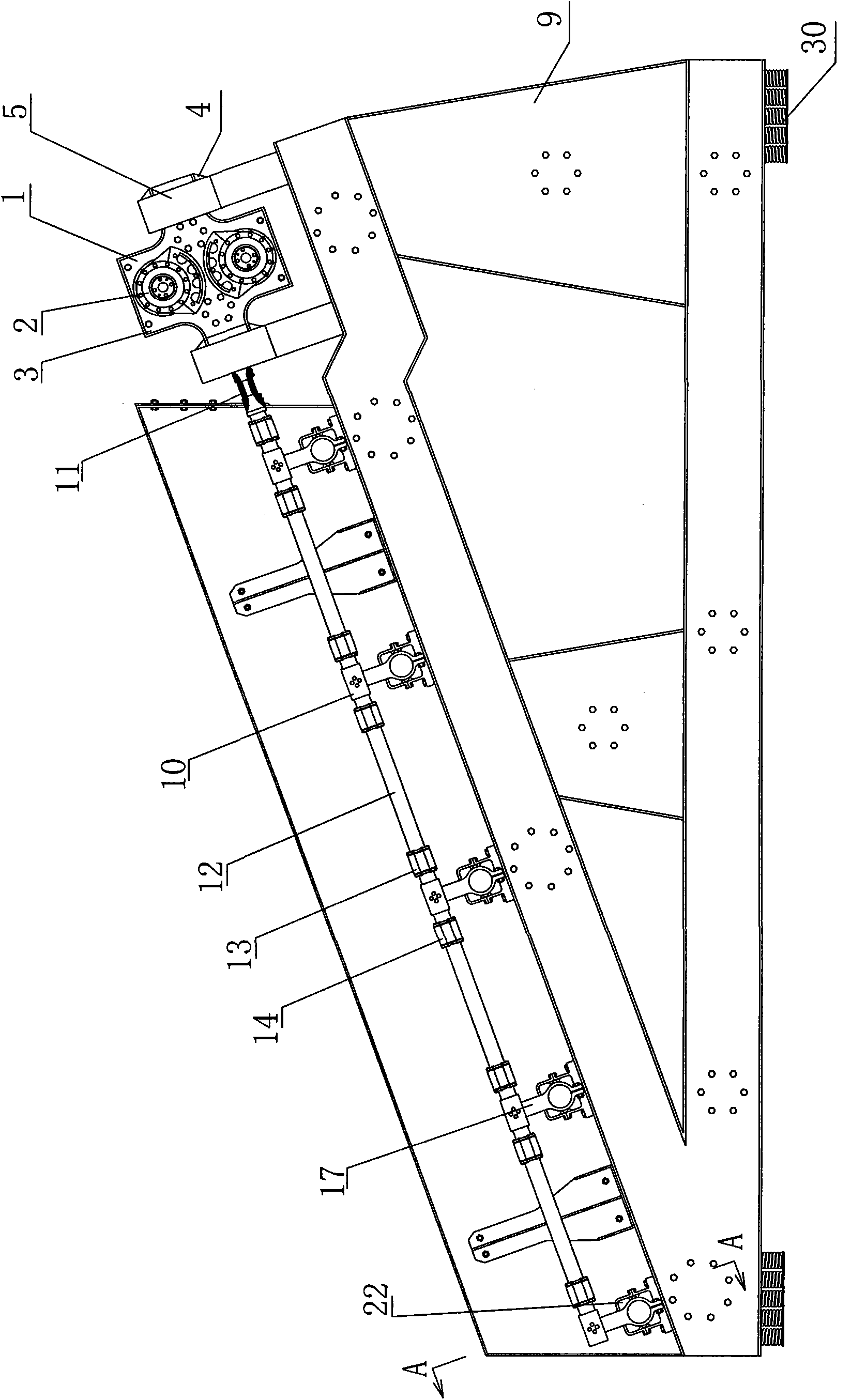

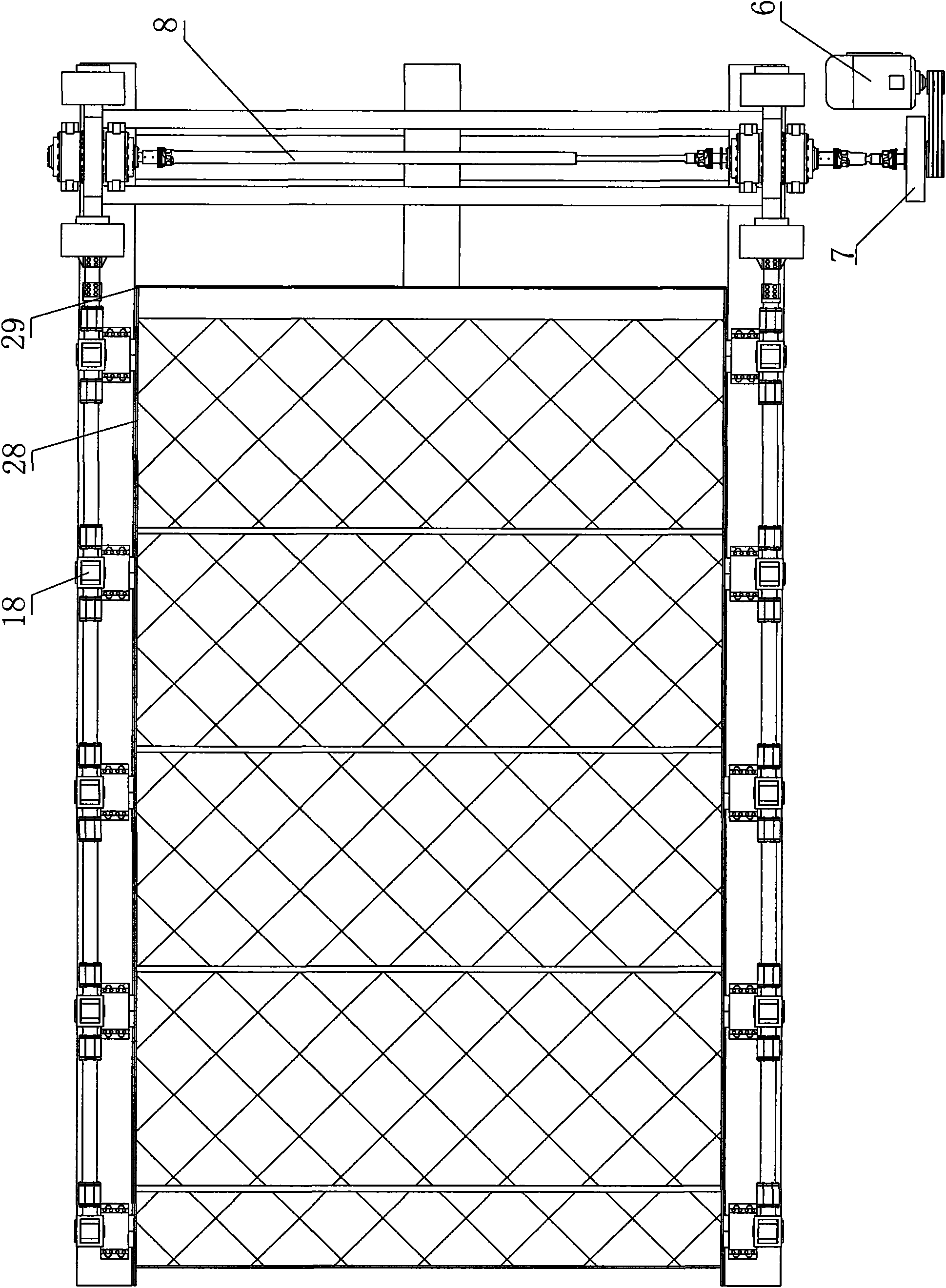

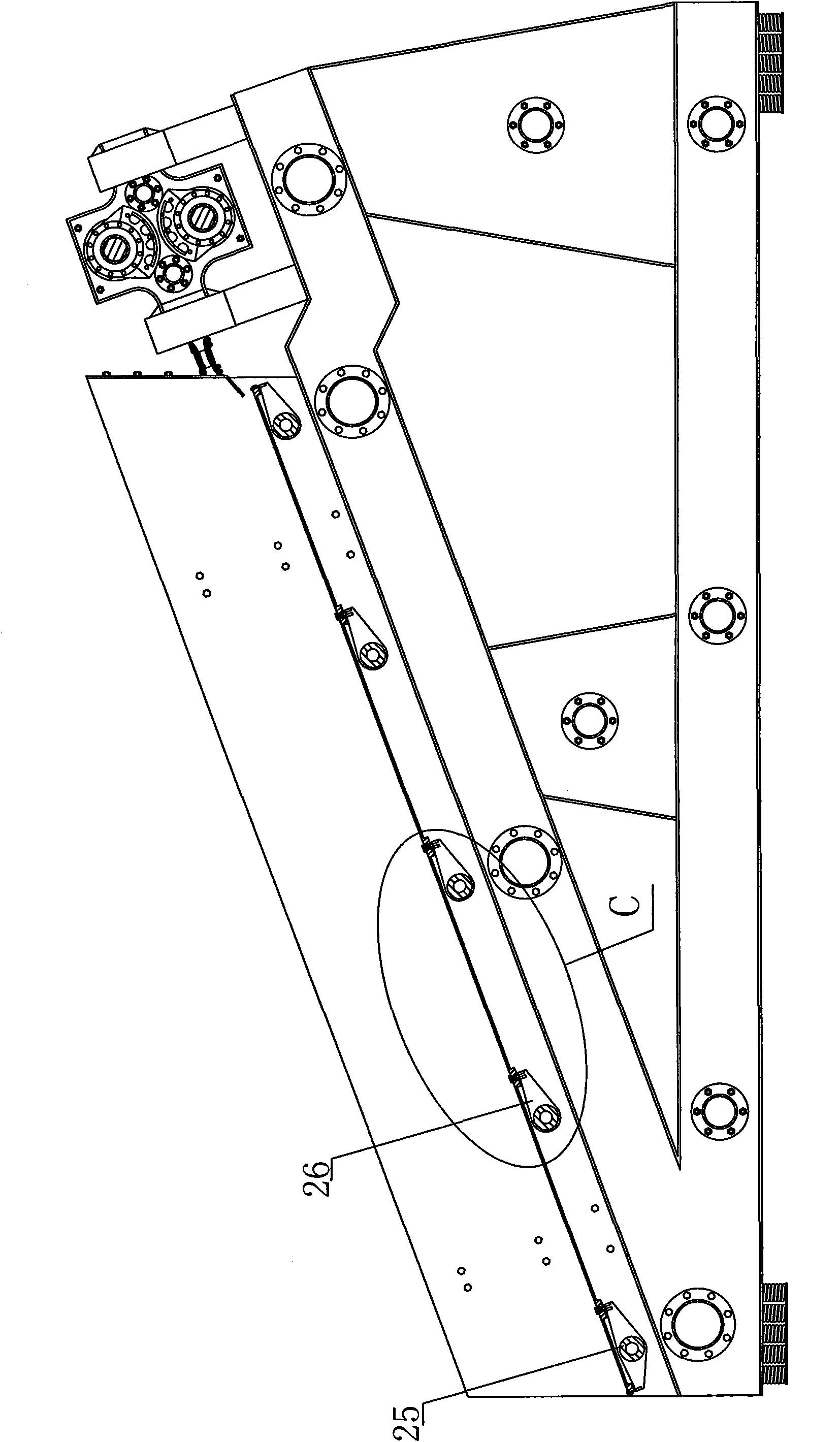

[0024] Example 1, such as Figure 1 to Figure 4 As shown, the vibration excitation device 1 is fixed on the tail of the frame 9, the vibration exciter 2 is installed on the vibration exciter seat 3, the vibration exciter seat 3 is installed in the exciter frame 5 through the spring 4, and the vibration screen on both sides The vibration excitation device 1 is connected by a universal coupling 8, a synchronizer 7 is set between the vibration excitation device 1 and the motor 6, the transmission mechanism 10 is connected with the vibration excitation device 1 through an elastic plate 11, and the transmission rod 12 is a multi-stage type , through the adjustment sleeve 13 and the connection sleeve 14 connected together, the upper end of the vibrating rod 17 is provided with an elastic connector 18, the lower end of the vibrating rod 17 is set on the end of the rotating shaft 25, each rotating shaft 25 is hinged by three elastic The support base 22 is installed on the frame 9, the...

Embodiment 2

[0031] Example 2, such as Figure 10 to Figure 13 As shown, the vibrating device 31 is fixed on the frame 36, the vibrator 33 is a forced synchronous vibrator, the vibrator 33 is installed in the vibrator frame 32 through a spring 34, and the motor 35 drives the vibrator 33 through a pulley , the transmission mechanism 37 is connected with the vibration excitation device 31, the transmission rod 38 is a two-stage type, an adjustment sleeve 39 and a connecting sleeve 40 are respectively installed on both sides of the vibration excitation device 31, and the upper end of the vibration rod 41 is provided with an elastic connector. The lower end of the vibrating rod 41 is sleeved on the end of the rotating shaft 43, each rotating shaft 43 is installed on the frame 36 through two bearing seats 42, the vibrating arms 44 are arranged on the rotating shaft 43, and the spring steel wire mesh 45 passes through the bolt Fastened on the vibrating arm 44, the frame 36 is provided with a sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com