Frequency variable hydraulic vibration exciter

A vibration-exciting device and hydraulic technology, which is applied in the direction of fluid, solid separation, and filter screens using vibration, can solve the problem that the vibration parameters of excitation force, amplitude, and frequency cannot be adjusted, cannot meet multi-working conditions, and the bearing bears a large load and other problems, to achieve the effect of light weight, simple structure, and small vibration mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

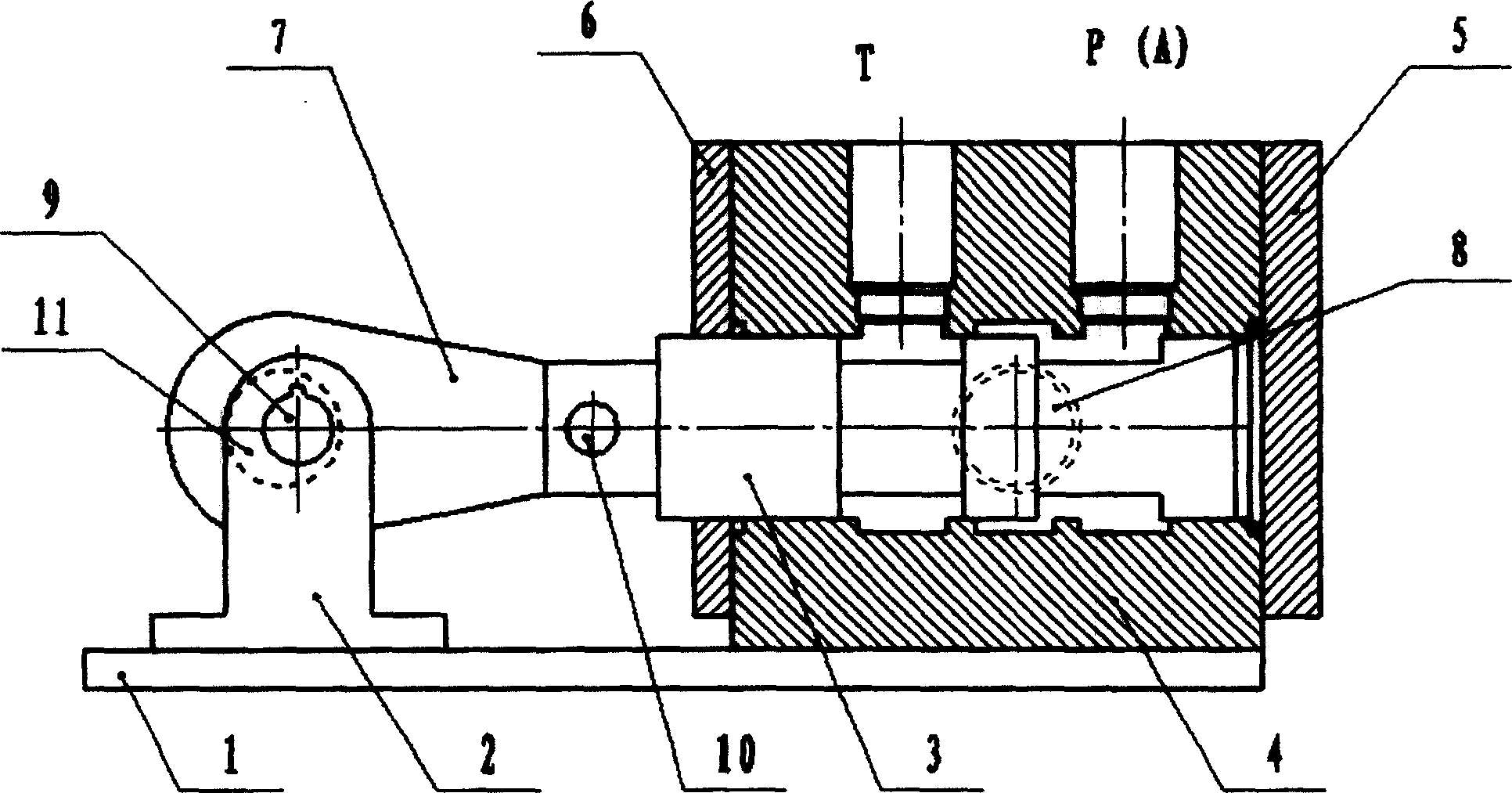

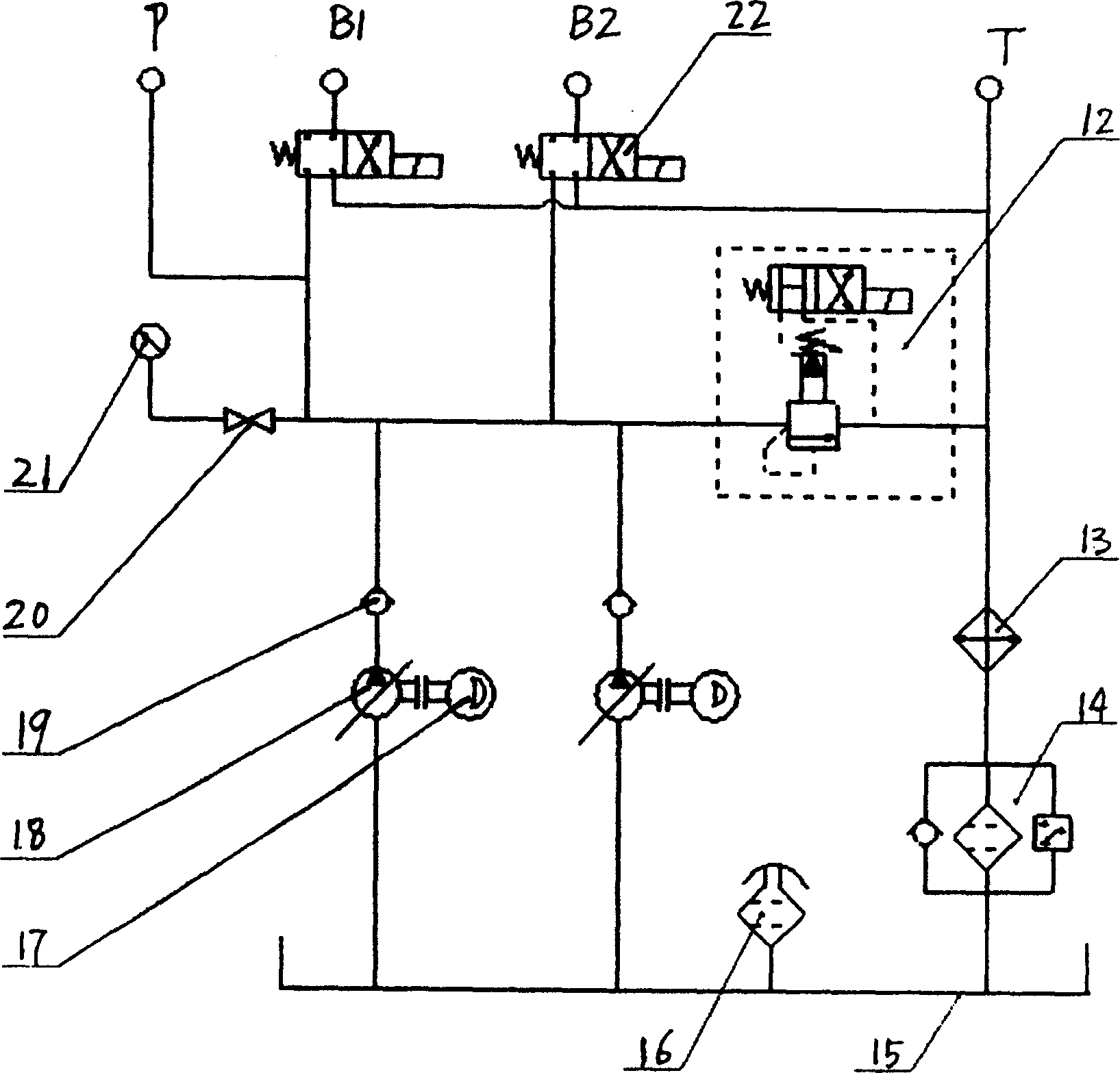

[0011] The main motor adopts a three-phase asynchronous motor, which is fixedly connected to the frame 1 by bolts. The shock wave device is a high-frequency reversing device, which affects the vibration frequency of the system. The shock wave shaft core 3 realizes the reversing through reciprocating linear motion. The shock wave motor adopts a low-power four-stage three-phase asynchronous motor and is connected in Y shape. The shock wave motor is connected with the shock wave shaft core 3 through the eccentric wheel 11, the connecting rod 7, and the pin shaft 10. Both the shock wave motor and the valve body 4 are connected to the frame 1 through bolts. The hydraulic cylinder adopts a differential cylinder, and the two ends are connected by earrings. The end of the rod is connected to the support seat of the vibrating screen body through a pin shaft, and the other end is connected to the foundation support seat through a pin shaft. The electromagnetic overflow valve 12 adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com