Patents

Literature

71results about "Sugar drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

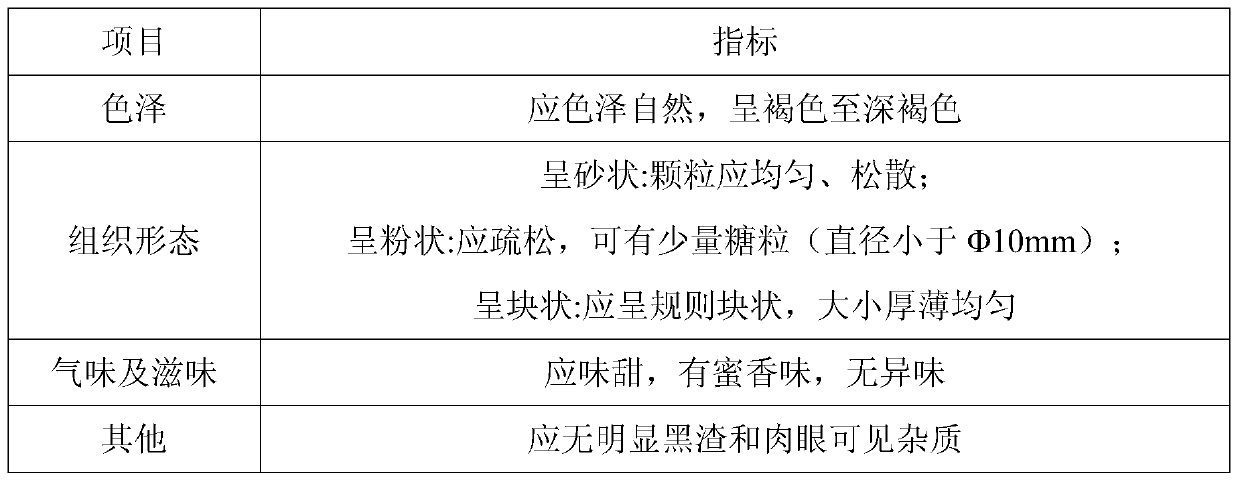

Originally ecological black sugar processing method

ActiveCN104805225ATroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsUltrafiltrationAdditive ingredient

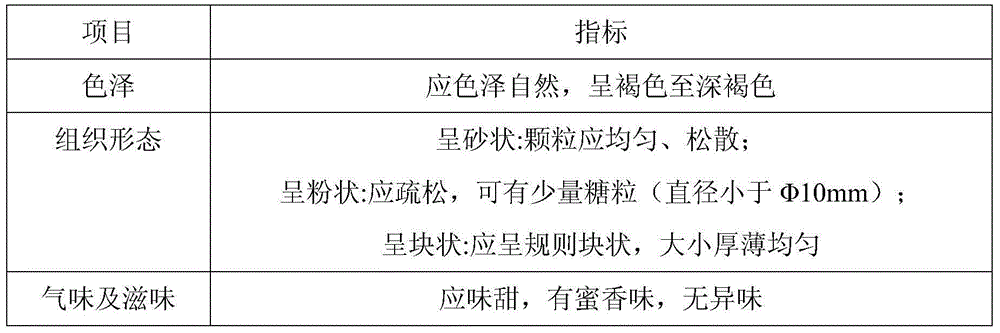

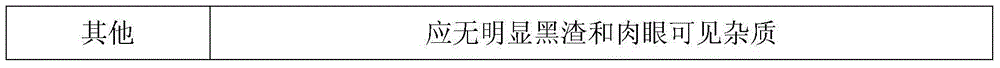

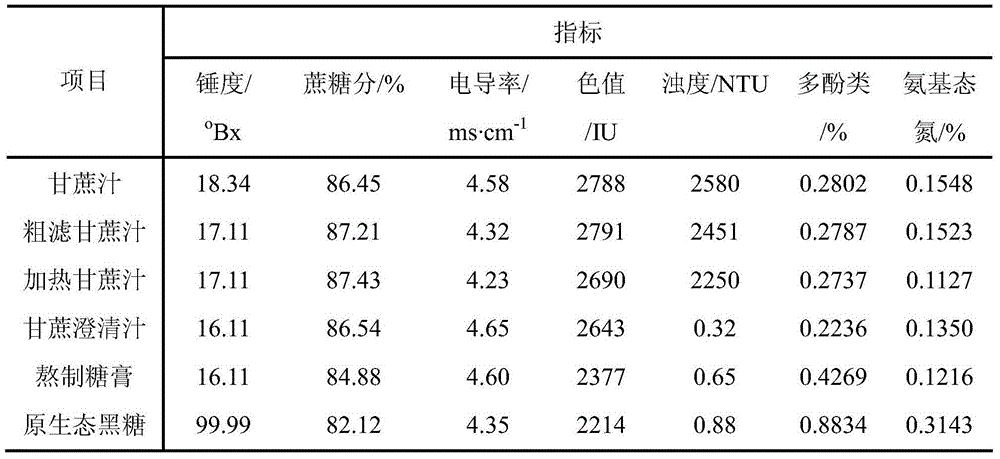

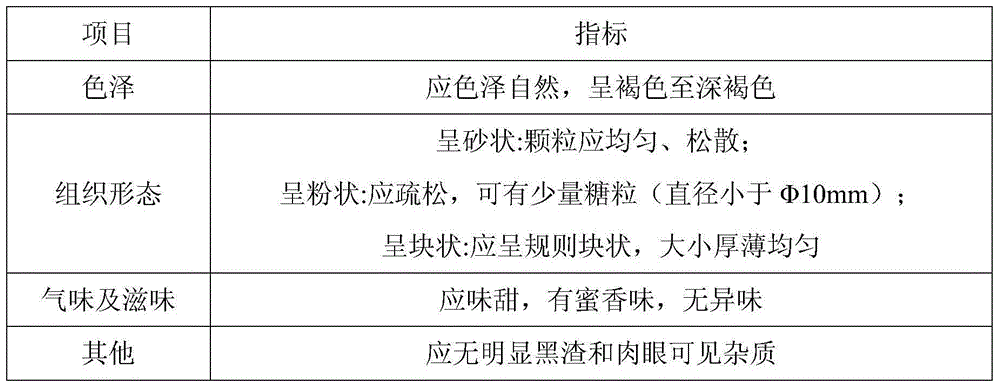

An originally ecological black sugar processing method comprises the following steps: after sugarcane is squeezed for extracting juice, carrying out rough filtration so as to obtain sugarcane juice; heating the sugarcane juice to 90-100 DEG C and keeping heat for 1-3 min so as to obtain heated sugarcane juice; conveying the heated sugarcane juice to a multistage ceramic membrane ultrafiltration device for ultrafiltration clarification so as to obtain clarified sugarcane juice; concentrating the clarified sugarcane juice into syrup; concentrating the syrup through a jacketed iron pot so as to obtain decocted massecuite; graining, cooling and forming so as to obtain originally ecological black sugar. The originally ecological black sugar prepared through the method provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that precipitates occur after the black sugar is dissolved for a long time is solved.

Owner:广西百桂堂食品科技有限公司

Method for producing original ecologic colored sugar product

ActiveCN103757142ARetain trace elementsClearing away heat and promoting body fluidSugar dryingPurification using alkaline earth metal compoundsBiotechnologyO-Phosphoric Acid

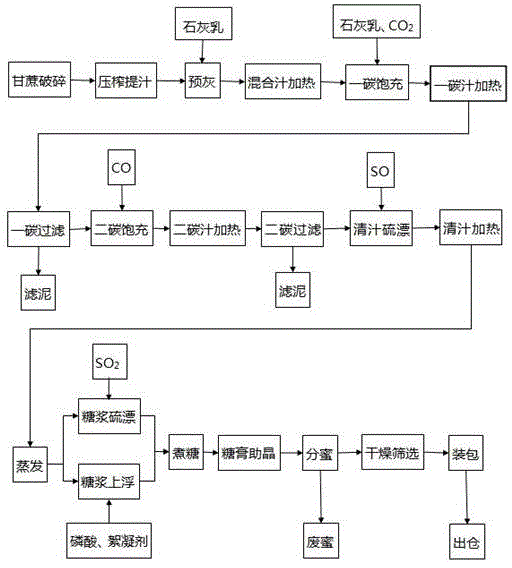

The invention discloses a method for producing an original ecologic colored sugar product. The method comprises the following steps: preliming a mixture juice obtained by extruding sugarcanes till the pH value is 7.0-7.2, adding 100-150PPM (Parts Per Million) of phosphoric acid, subsequently performing primary heating, further adding lime milk into the heated mixture juice till the pH value is 7.6-8.2, adding activated calcium carbonate to fulfill, further performing dreg-foam separation to obtain floating clear juice, adding phosphoric acid and lime milk into the floating clear juice till the pH value is 8.4-8.6, wherein the addition amount of the phosphoric acid is 50-100PPM, subsequently performing secondary heating to obtain a neutral juice, sinking the neutral juice to separate a clear juice and a mud juice, filtering the mud juice by using a filter to obtain a filtrate, combining the filtrate with the clear juice, heating for three times, evaporating, filtering in rotational flow, boiling the sugar to crystallize, prompting crystal, purging, drying, deironing and the like so as to obtain the original ecologic colored sugar product. The method is low in production cost and preserves activated sugarcane antioxidant substances to the maximum extent, and the sugar product is safe to eat, good in environment-friendly effect and has good population values and social and economic benefits.

Owner:GUANGXI DUAN YONGXIN SUGAR CO LTD

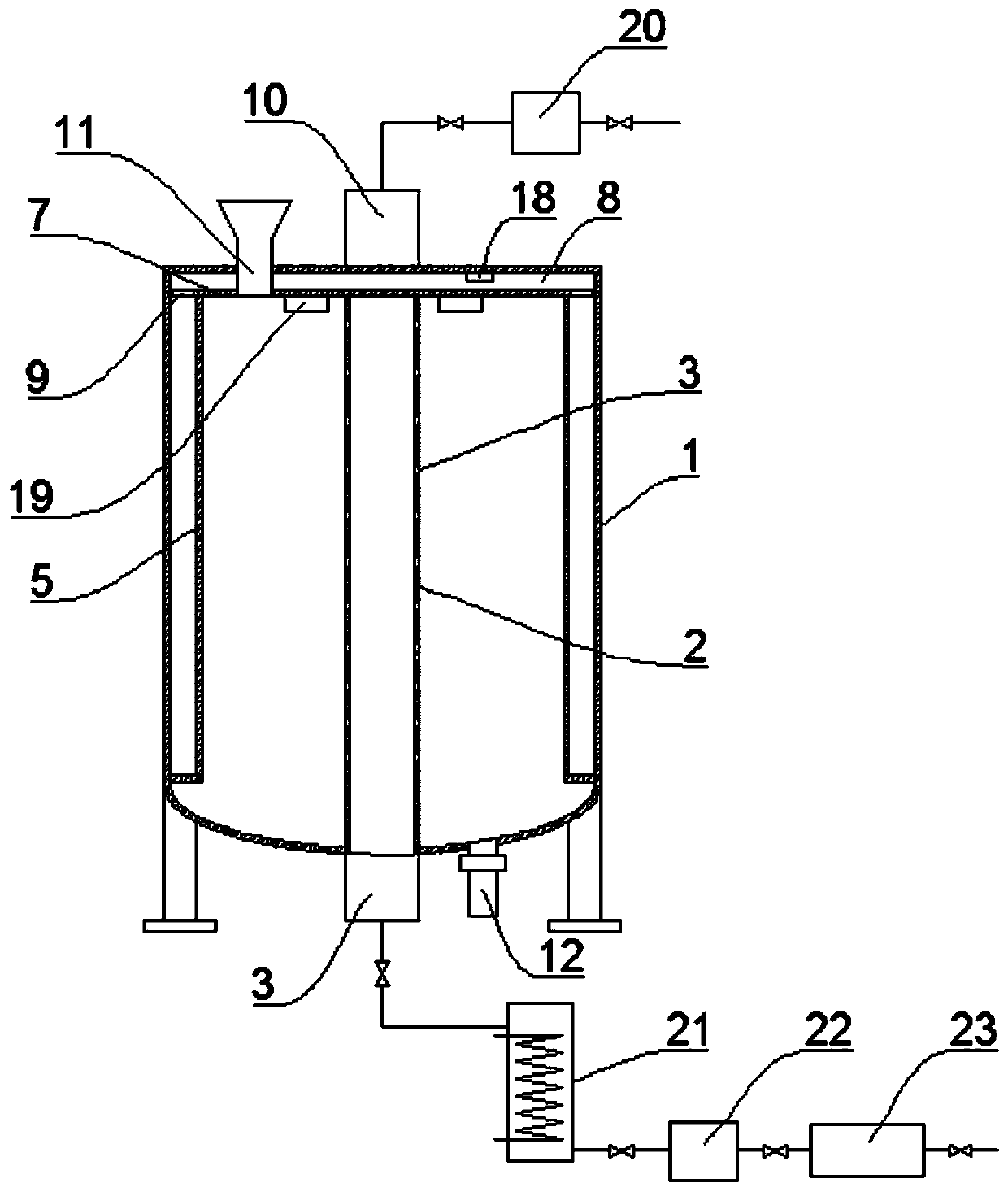

Method for preparing full-nutrient solid cane molasses

InactiveCN102321770AEasy to operateShorten drying timeSugar dryingSugar productsMoistureVacuum drying

The invention relates to a method for preparing full-nutrient solid cane molasses, namely the traditional liquid cane molasses is processed into full-nutrient solid cane molasses. The method comprises the following steps: putting liquid cane molasses without any pretreatment directly in a vacuum drying machine; removing moisture under the heating and vacuum condition; and smashing after cooling, thus powder full-nutrient solid cane molasses is obtained, wherein the drying temperature is controlled at 50-130 DEG C, and the vacuum degree is controlled within minus 0.05-minus 0.10 MPa. By adopting the method provided by the invention, the liquid cane molasses with 20-30% of water content can be converted into the full-nutrient solid cane molasses with 0.5-2.5% of water content, and the original nutrition components of the cane molasses can be preserved without influencing the using efficacy of the original cane molasses; the storage and transportation costs can be lowered; the cane molasses is convenient to use; the quality guarantee period of products is prolonged, and the application range of the products can be widened; and the method has less operation steps, has low production cost, and is easy to be industrialized.

Owner:广西轻工业科学技术研究院有限公司

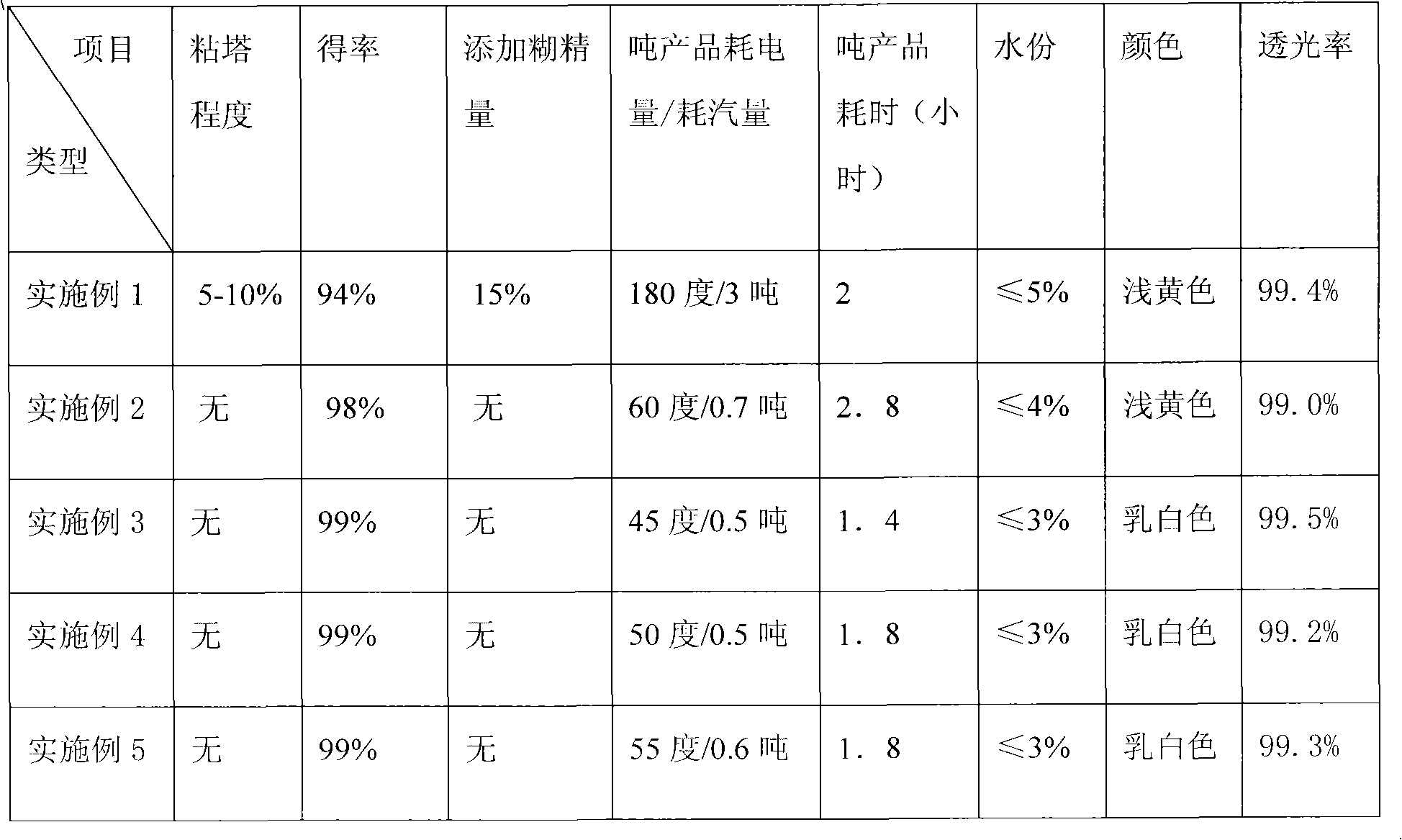

Dry preparation method of starch sugar

The invention relates to a dry preparation method of starch sugar, in particular to a method for preparing starch sugar powder by taking starch sugar syrup prepared by various techniques, belonging to the technical field of starch sugar powder preparation. The method comprises the following steps: (1) preparing starch sugar syrup; (2) vacuum drying; and (3) smashing. The invention has the beneficial effect: due to adopting a method of independent control by sections, the vacuum drying technique of starch sugar has high automation degree, easy realization of industrial production, high drying speed, energy saving, favourable product quality, favourable colour, low moisture content, easy storage and high sanitation cleanliness, production efficiency is improved, and probability in breeding bacteria is small.

Owner:BAOLINGBAO BIOLOGY

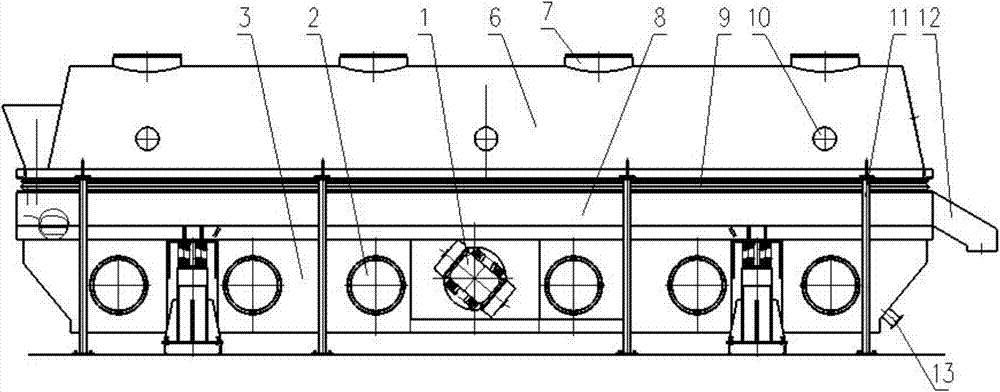

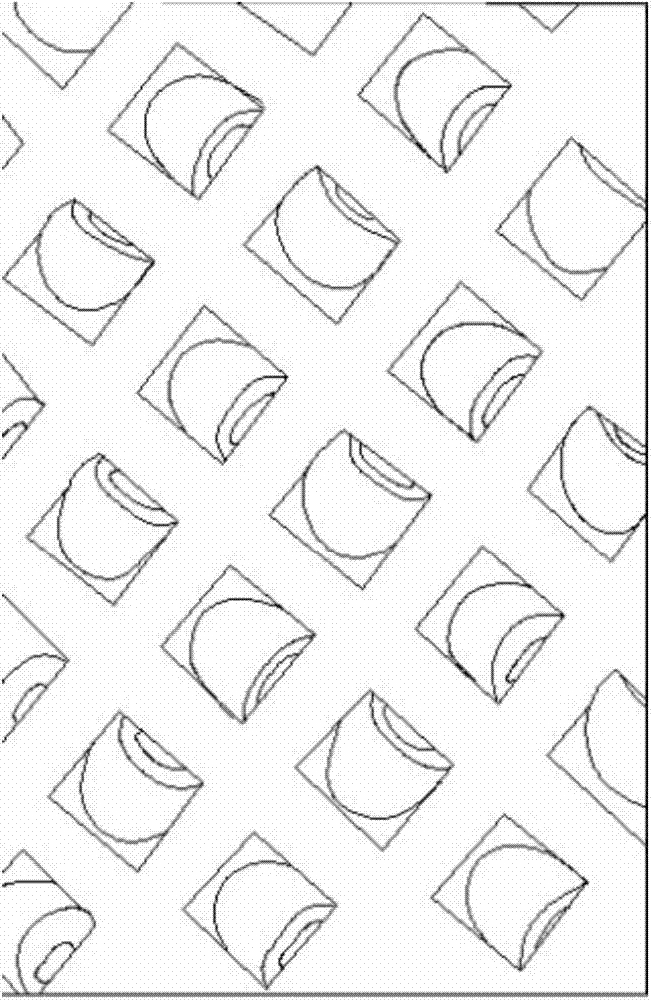

White granulated sugar vibrated fluidized bed

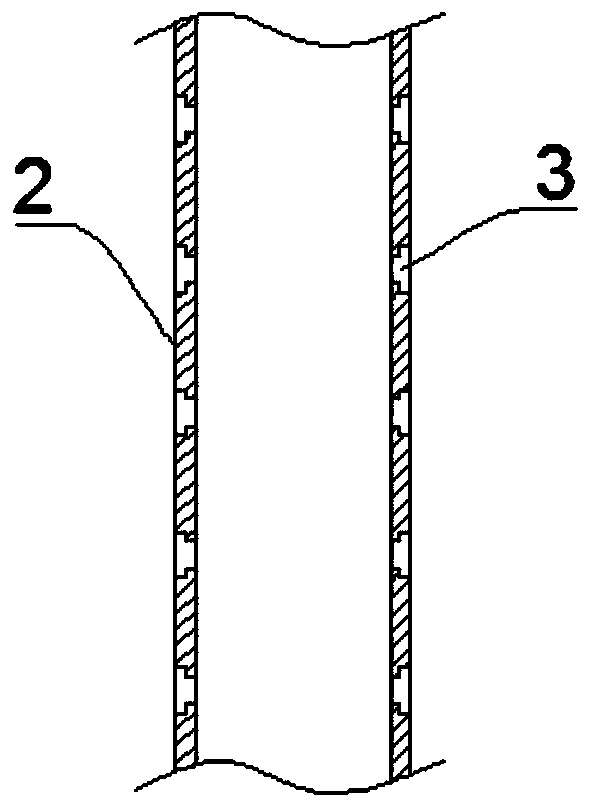

InactiveCN103571975AHigh strengthFluidized state is goodSugar dryingDrying solid materials with heatSeashellVibratory fluidized bed

The invention discloses a white granulated sugar vibrated fluidized bed. The white granulated sugar vibrated fluidized bed comprises a main machine box, a vibration motor and a macroporous plate and a seashell-type pore plate, wherein the main machine box is of a hollow structure with a ventilation cavity, and a vibration bed is arranged at the upper part of the main machine box; the vibration motor is used for driving the vibration bed to vibrate in an upper and down slant direction, and the slant direction is the white granulated sugar advancing direction; the macroporous plate is arranged on the vibration bed and vibrates along with the vibration bed under the driving of the vibration bed, and multiple straight-through holes are formed in the macroporous plate and are communicated with the ventilation cavity; the seashell-type pore plate is arranged on the macroporous plate, multiple seashell-shaped raised seashell through holes are formed in the seashell-type pore plate and are two groups of seashell-shaped through holes which are arranged in a staggering manner, and the opening directions of the seashell-shaped through holes are vertical to each other; white granulated sugar to be fluidized is fed into the seashell-type pore plate. Materials in the white granulated sugar vibrated fluidized bed are at good mixing and boiling state under the effect of wind power, and as vertical surfaces are not provided with openings, the materials are unlikely to block the openings and leak below the bed.

Owner:广西幸丰科技有限责任公司

Producing method of pharmaceutic adjuvant cane sugar by carbonic acid method process

InactiveCN104611473ALow equipment requirementsSimple processSugar dryingPurification using chemicalsSucroseImpurity

A producing method of a pharmaceutic adjuvant cane sugar by a carbonic acid method process is disclosed. The producing method directly adopts sugarcane as a raw material and obtains the pharmaceutic cane sugar by steps of smashing, squeezing, clearing, evaporating, sugar boiling, separating molasses and drying. A sulphur bleaching-floating combined step is added between the evaporating step and the sugar boiling step to further remove various impurities in the cane sugar and to improve the cleanliness level of the cane sugar, so that contents of sulfates, residues on ignition, calcium salts, heavy metals, and the like in the cane sugar meet the index requirements in the Chinese Pharmacopoeia of the 2010 edition. The carbonic acid method is low in equipment requirement and simple in process, and therefore the producing method is suitable for large-scale production of cane sugar, and overcomes the problem that cane sugar produced by traditional carbonic acid method processes cannot meet the standards of the pharmaceutic cane sugar and the problem that the pharmaceutic cane sugar is difficult in large-scale production.

Owner:NANNING SUGAR INDUSTRY CO LTD

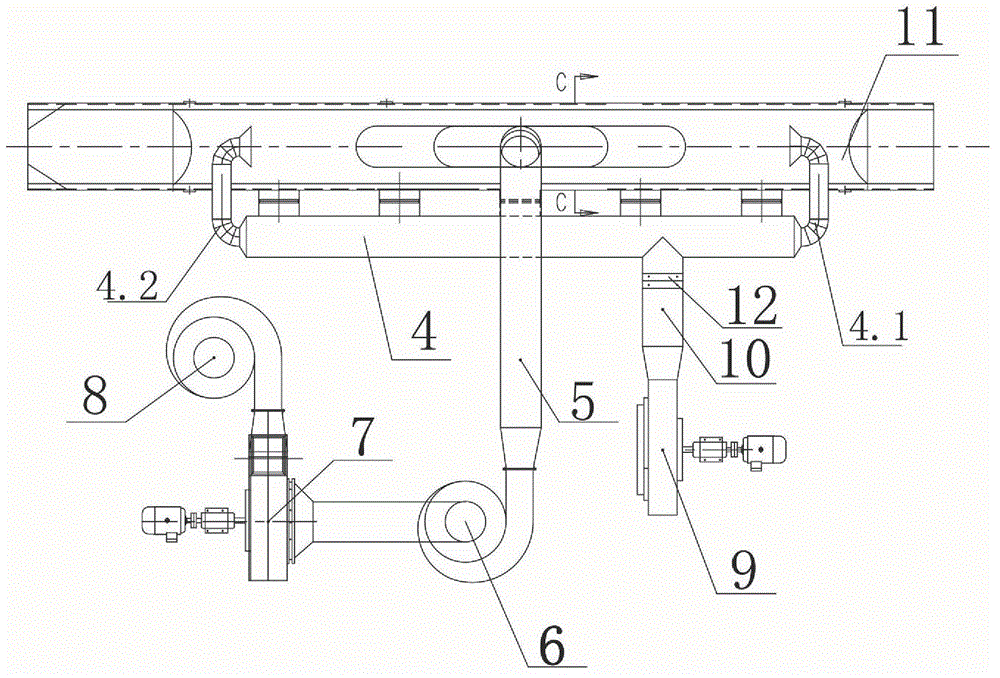

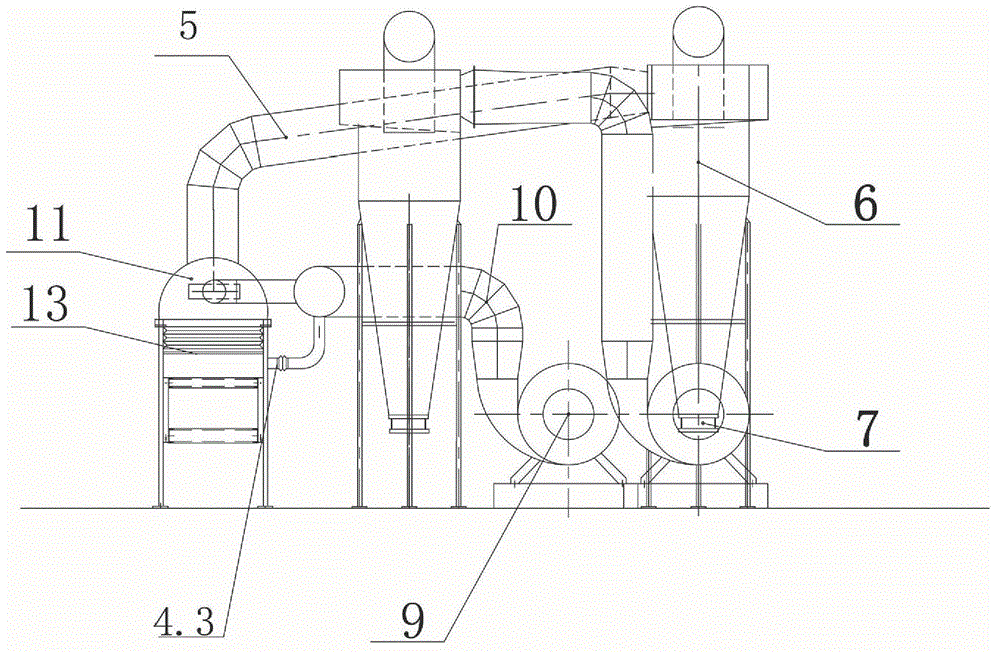

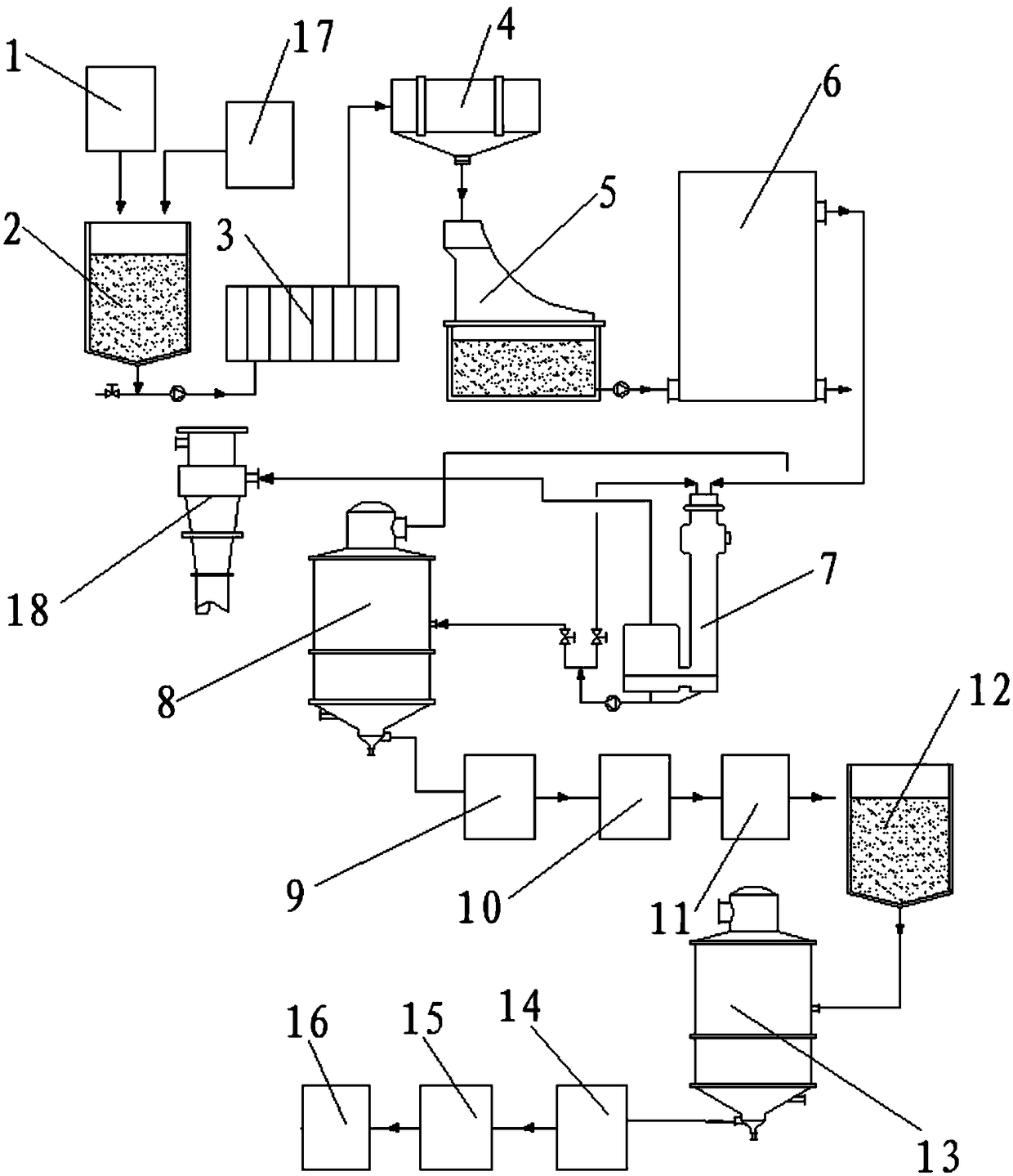

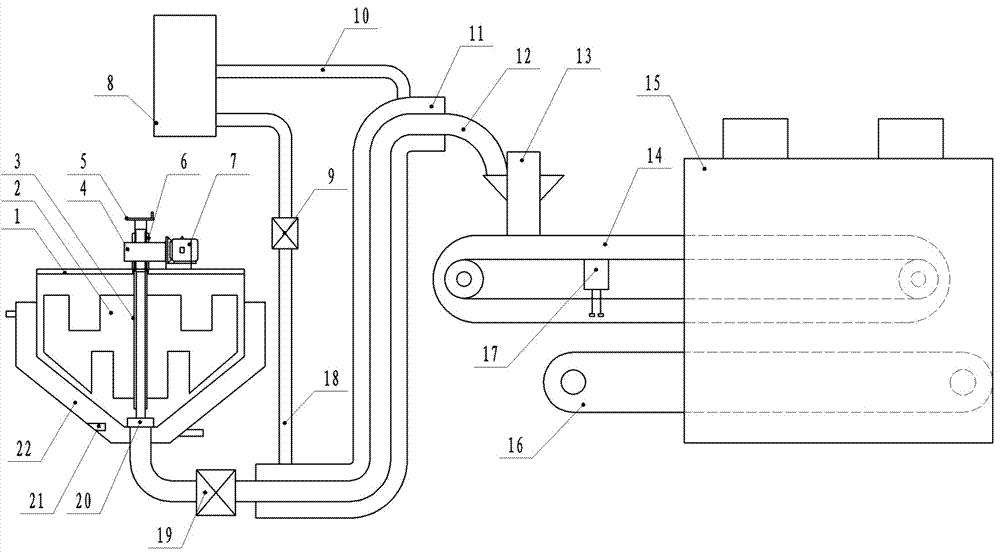

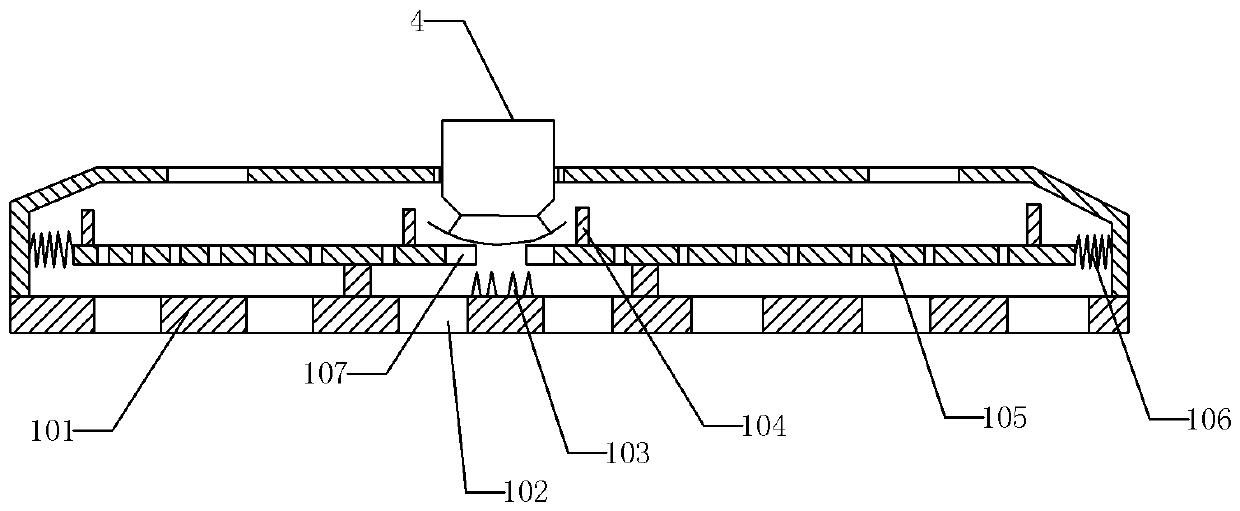

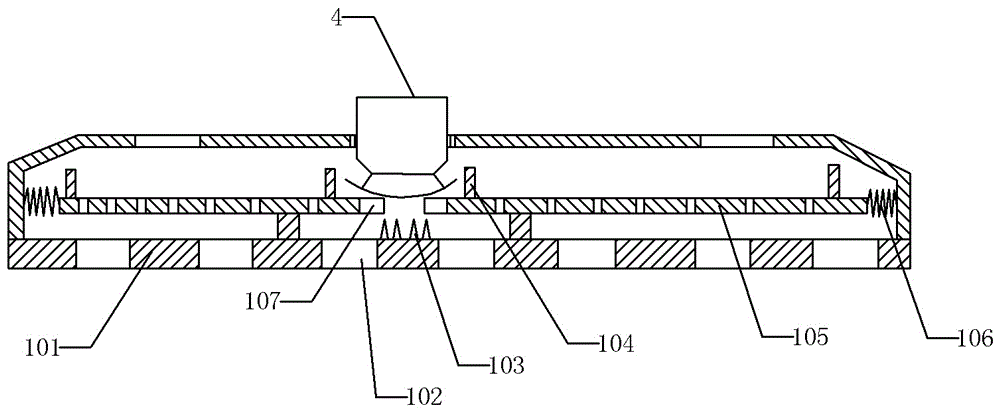

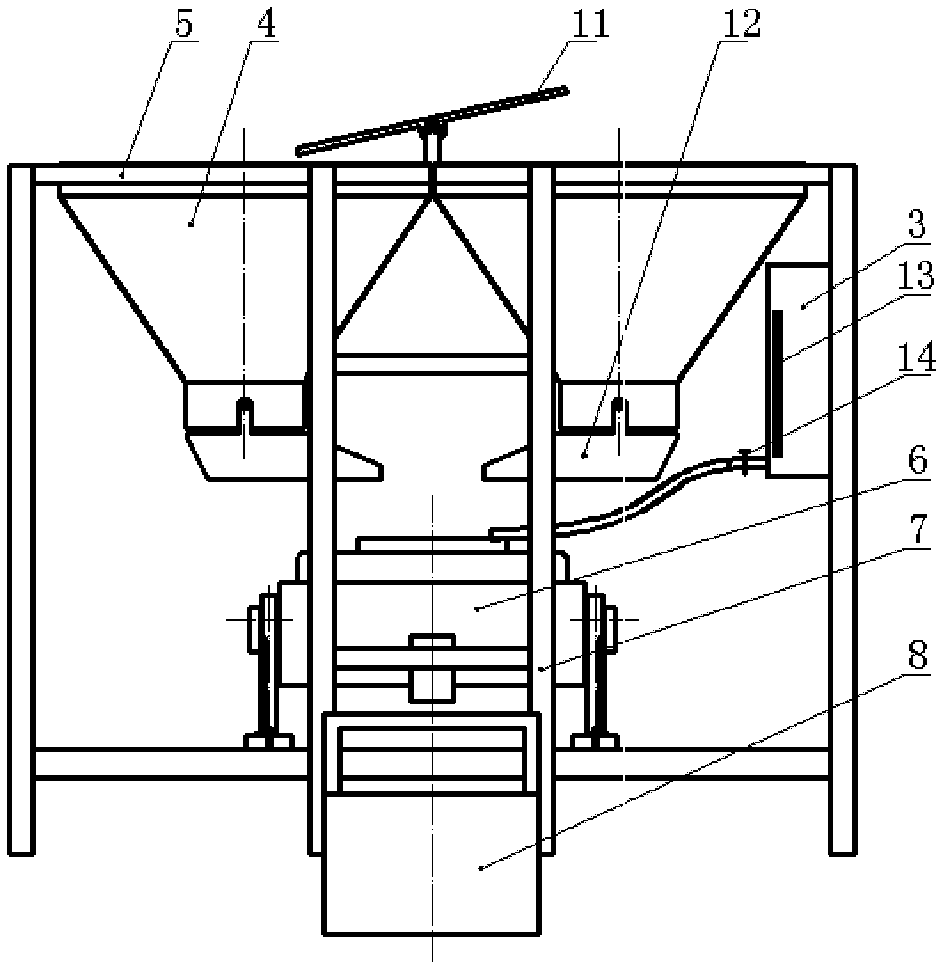

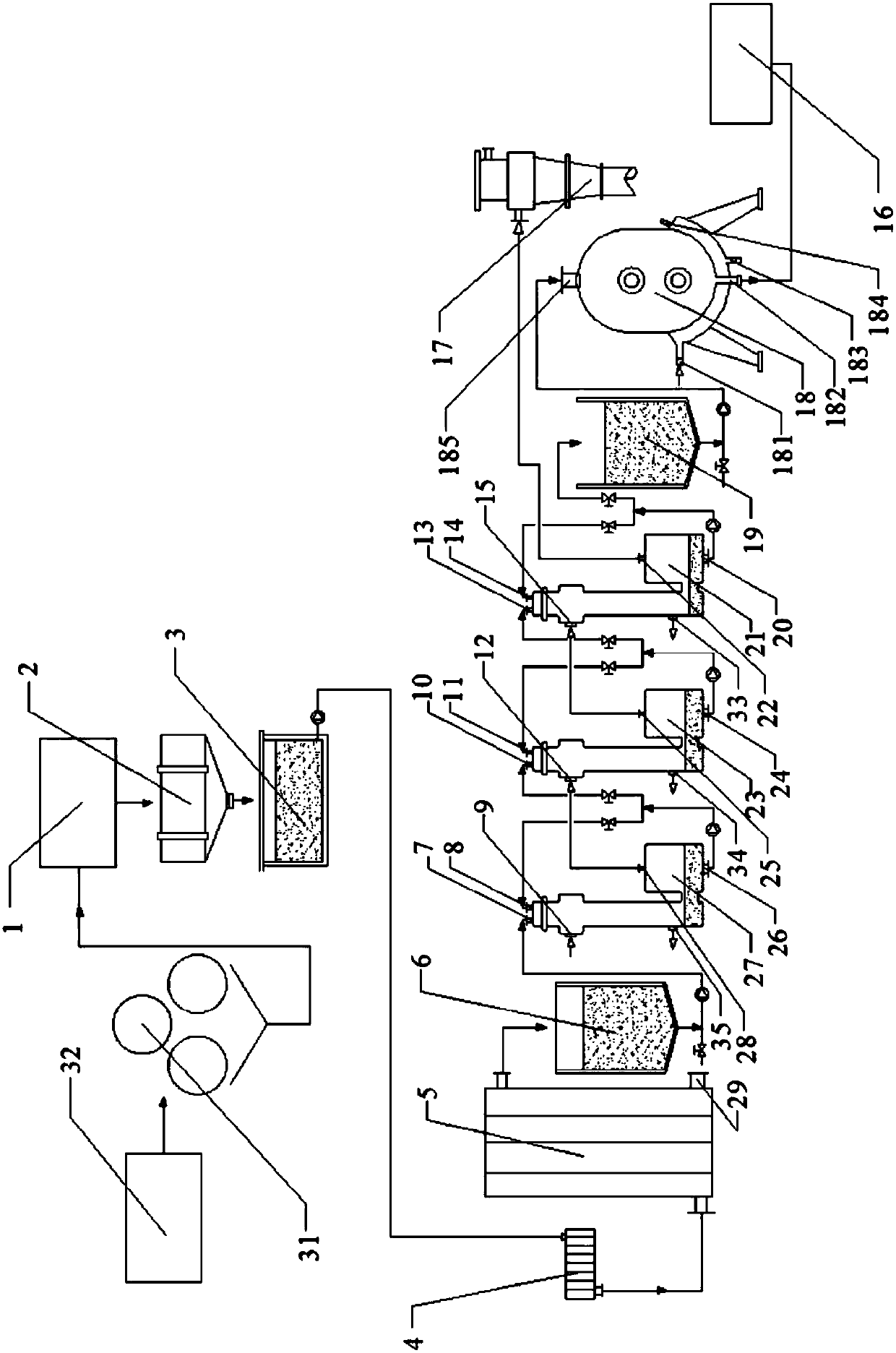

Originally ecological black sugar processing device

ActiveCN104805224ATroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsAdditive ingredientUltrafiltration

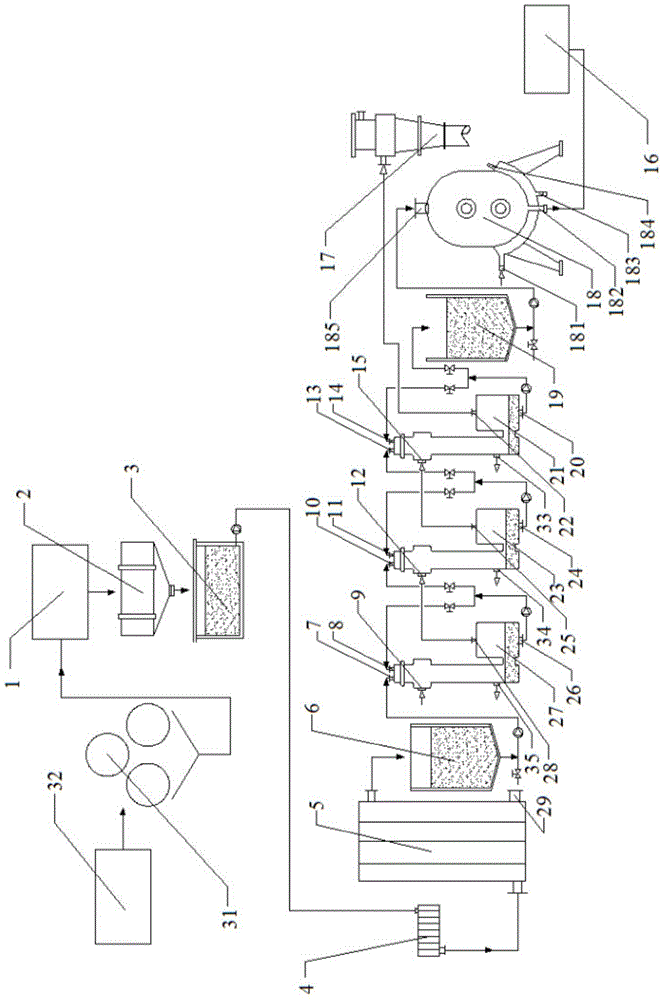

An originally ecological black sugar processing device comprises a squeezing rough-filtration device, a heat exchanger, a multistage ceramic membrane ultrafiltration device, a falling-film type three-effect vacuum evaporation system, a water jet condenser, a jacketed iron pot and a graining drying forming device, which are sequentially connected, wherein a clarified sugarcane juice box is connected between the multistage ceramic membrane ultrafiltration device and the three-effect vacuum evaporation device; a syrup box is connected between the falling-film type three-effect vacuum evaporation system and the jacketed iron pot. The black sugar prepared through the device provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, sweet, delicious, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that black residues exist after the black sugar is dissolved is solved and the quality of the black sugar is improved.

Owner:广西百桂堂食品科技有限公司

Preparation method of ancient-formula brown sugar applicable to pregnant women and postpartum women

InactiveCN106702030AIncrease heatNo side effectsSugar dryingSugar productsMiscarriageRadix Astragali seu Hedysari

The invention discloses a preparation method of ancient-formula brown sugar applicable to pregnant women and postpartum women. The preparation method comprises the following procedures: firstly, squeezing sugarcanes and filtering to remove dreg; adding a medicine package and continuously boiling with a boiler; scattering and filling into a mold; cooling and molding; drying with air, and bundling sugarcane leaves; drying with the air for a second time and the like. The medicine package is prepared from the following components in parts by weight: 1 to 15 parts of radix astragali seu hedysari, 1 to 15 parts of codonopsis pilosula, 1 to 15 parts of bighead atractylodes rhizome, 1 to 15 parts of radix scutellariae, 10 to 20 parts of folium artemisiae argyi and 10 to 20 parts of fructus jujubae. According to the preparation method, any chemical additive is not added; a plurality of nutrient substances including glucose, dark brown sugar, amino acid, nicotinic acid, carotene in the sugarcanes are naturally kept; the ancient-formula brown sugar has a natural and sweet taste and a rich sandy taste, is just melted in the mouth and has agreeable sweetness. The ancient-formula brown sugar can be used for tonifying qi and nourishing blood of human bodies and has a very high nutrient value for the female, especially the pregnant women and the postpartum women (the ancient-formula brown sugar has effects of preventing miscarriage, tonifying qi, nourishing blood and the like on the pregnant women, and helping the postpartum women to discharge lochia, tonify qi, nourish blood and restore energy).

Owner:于文侠

Method for preparing ancient-prescription brown sugar with menstruation regulating action

InactiveCN106399593ASweet tasteStrong sense of sandSugar dryingSugar productsFiltrationAdditive ingredient

The invention discloses a method for preparing ancient-prescription brown sugar with a menstruation regulating action. The method comprises the procedures of firstly, juicing sugar canes, carrying out filtration so as to remove bagasse, adding a drug bag into sugar-cane juice, carrying out series pot decocting, carrying out scattering, carrying out mold loading, carrying out cooling molding, carrying out air drying, carrying out bundling-up by sugarcane leaves, carrying out secondary air drying, and the like. The drug bag is prepared from the following ingredients in parts by weight: 1-10 parts of folium artemisiae argyi, 5-15 parts of herba leonuri, 1-10 parts of zingiber officinalis, 1-10 parts of Chinese angelica, 1-10 parts of prepared rehmannia roots, 1-10 parts of rhizoma chuanxiong, 5-15 parts of radix paeoniae alba and 5-15 parts of dried red dates. According to the method, series-pot manual decocting is used, the method is a pure physical method, no chemical additive is added, and normal-temperature natural crystallization is carried out, so that a variety of nutrients such as glucose, brown sugar, amino acids, nicotinic acid and carotene in the sugar canes are naturally reserved, the taste is naturally fragrant and sweet, the sandy feeling is rich, the ancient-prescription brown sugar is melted once the ancient-prescription brown sugar enters a mouth, and the ancient-prescription brown sugar is agreeable in sweetness. The ancient-prescription brown sugar has the effects of nourishing Yin and tonifying blood, removing heat from the liver, regulating and nourishing Qi and blood, activating blood circulation to dissipate blood stasis and promoting circulation of Qi to relieve pain and is good in effect and high in effect taking speed.

Owner:于文侠

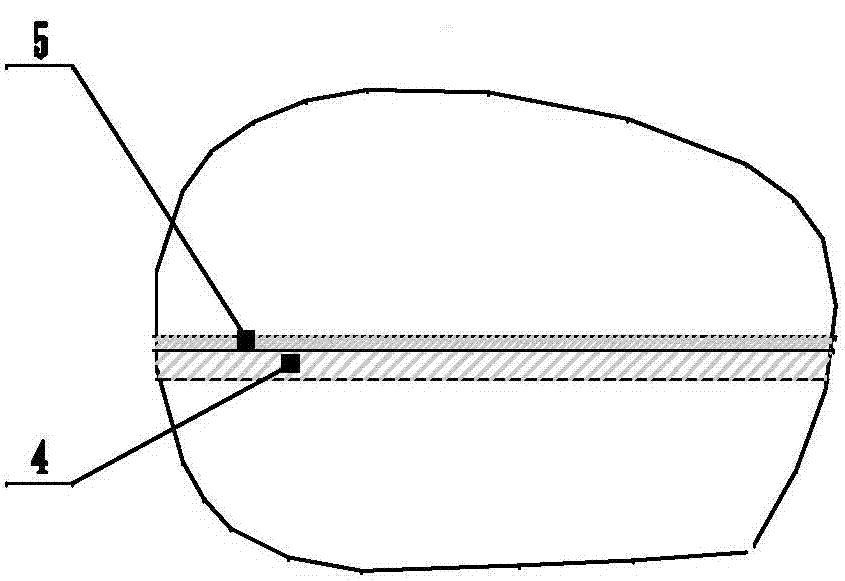

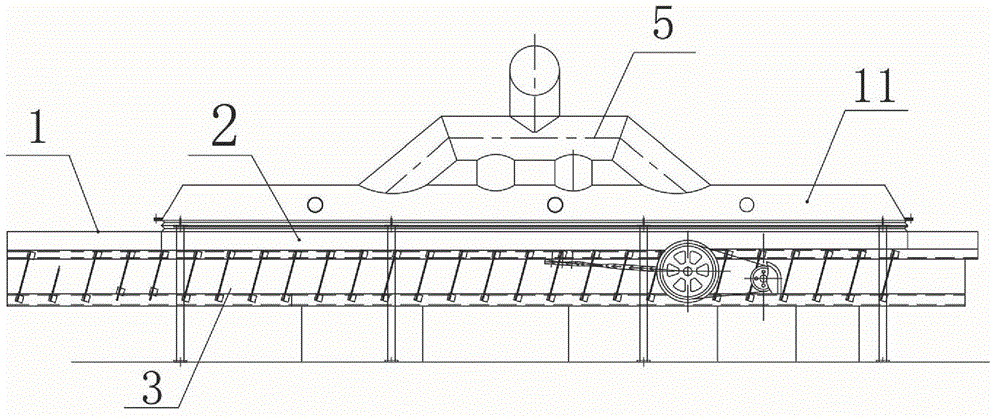

Cooling and drying equipment for white granulated sugar

InactiveCN102912042AImprove efficiencyGood dehumidification and drying effectSugar dryingAir volumeEngineering

The invention discloses cooling and drying equipment for white granulated sugar, which comprises a vibrating conveyor, wherein the vibrating conveyor comprises a housing (1), a conveyor belt (3) and a vibrating trough (2); the conveyor belt (3) and the vibrating trough (2) are arranged in the housing (1); and the vibrating trough (2) is arranged at the upper part of the conveyor belt (3). The cooling and drying equipment is characterized in that a sealing cover (11) is arranged at the top of the housing (1) and connected with the vibrating trough (2) to form a cavity; the top of the sealing cover (11) is connected with an exhaust system; and the vibrating trough (2) is internally provided with a double-layer screen (13). According to the cooling and drying equipment, with the adoption of the double-layer screen mesh, the blast volume of a blast system is reduced, so that the air volume suffered by the white granulated sugar in the dehumidification process is reduced, the amount of the white granulated sugar blown into the exhaust system is reduced, and finally the blown air passes through two layers of meshes to form a relatively gentle air flow and accomplish dehumidification and drying of the white granulated sugar.

Owner:DAYUAN ENVIRONMENTAL PROTECTION ENG NANNING CITY

Method for producing soft white sugar

The invention belongs to the food industry, and particularly relates to a method for producing soft white sugar, in particular, the method is as follows: beet or sugar cane is processed to obtain diffusion juice, the diffusion juice is filtered to obtain high-purity sugar juice, the high-purity sugar juice is heated in a container evaporating tank for evaporating water, after sugar juice concentration reaches 70-rix, the sugar juice is sent to a crystallization step; concentration is continued to until sugar crystals are precipitated, and solid-liquid separation and cleaning are performed in aseparator; the separated sugar crystals are placed in a screw conveyor, fructose syrup is added, a dryer is used for drying to obtain the soft white sugar, and the drying time is about 7-8 minutes. The method adopts the fructose syrup as invert sugar in the production to improve the production quality of the soft white sugar while reducing the production cost, and brings huge market benefits to aproduction enterprise.

Owner:内蒙古佰惠生新农业科技股份有限公司 +1

Drying device of multicrystal rock sugar

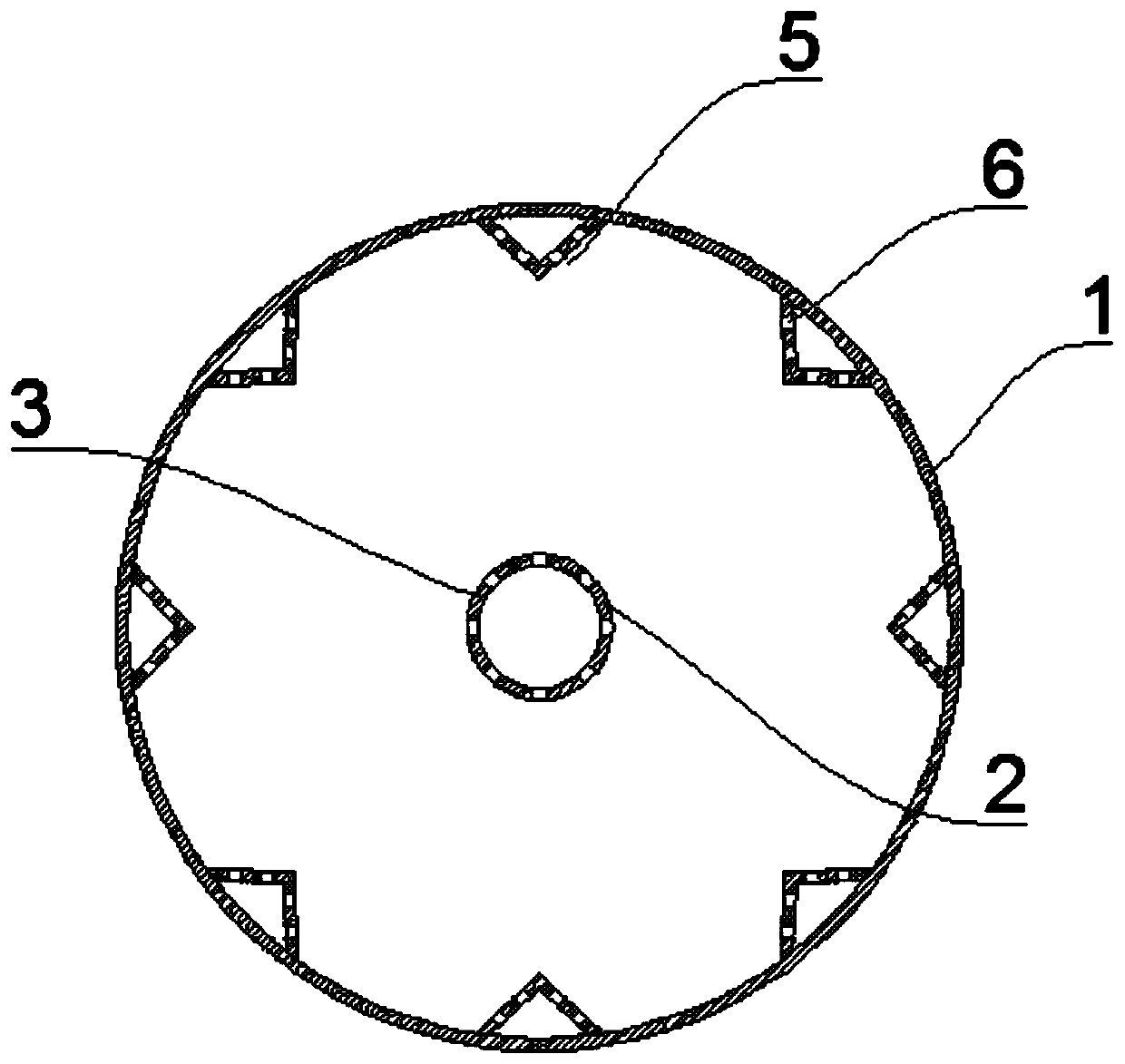

PendingCN110715526ADry evenlyImprove drying effectSugar dryingDrying gas arrangementsStructural engineeringSugar

The invention provides a drying device of multicrystal rock sugar. The drying device comprises a drying cylinder. An inner cylinder is arranged in the drying cylinder. The axis of the inner cylinder coincides with the axis of the drying cylinder. The side wall of the inner cylinder is provided with a plurality of first through holes. An air inlet pipe communicating with the inner cylinder is arranged at the bottom of the drying cylinder. The inner wall, on the periphery of the inner cylinder, of the drying cylinder is provided with a plurality of air outlet cylinders. The side walls of the airoutlet cylinders are provided with second through holes. An upper partition plate is arranged on the top in the drying cylinder. An air outlet cavity is formed between the upper partition plate and the top wall of the drying cylinder. Air outlets communicating with the air outlet cavity are formed in the tops of the air outlet cylinders. An air outlet pipe communicating with the air outlet cavityis arranged on the top of the drying cylinder. A feeding pipe is arranged on the top of the drying cylinder. The feeding pipe penetrates through an upper partition plate. A discharging pipe is arranged at the bottom of the drying cylinder. The rock sugar drying efficiency is high, and the drying effect is good.

Owner:南京甘汁园股份有限公司

Cane sugar manufacturing method capable of reducing pigment generation

InactiveCN109530290AImprove cleaning efficiencyImprove cleanlinessSugar dryingPurification using alkaline earth metal compoundsPhosphoric acidEvaporation

The invention provides a cane sugar manufacturing method capable of reducing pigment generation. The cane sugar manufacturing method capable of reducing the pigment generation comprises the followingsteps of 1) introducing ozone into sugarcane juice, and filtering to obtain sugarcane dregs and sugarcane filtered juice; 2) spraying ethanol solution to the surface of the mixture of the sugarcane dregs and sugarcane residues, and squeezing and filtering again to obtain ethanol extract; 3) dropping an acetic acid-chitosan solution into the ethanol extract, adjusting the pH value to 7.0, and filtering to obtain filtrate; 4) introducing nitrogen into the sugarcane filtered juice, heating, adding phosphoric acid while stirring, uniformly mixing, adding lime milk to adjust the pH value to 6.5, and obtaining supernatant liquid after separation and sedimentation; 5) dropping the acetic acid-chitosan solution into mixed solution of the supernatant liquid and the filtrate, adjusting the pH value,adding nano ferroferric oxide powder, carrying out magnetic field separation, introducing nitrogen into clear juice until the clear juice is saturated and carrying out negative pressure evaporation and concentration to obtain fine syrup; and 6) carrying out sugar boiling, honey separation and drying on the fine syrup to obtain finished sugar. According to the cane sugar manufacturing method capable of reducing the pigment generation, the product has the characteristics of low sugar color value, high quality and the like.

Owner:合浦县工业和信息化局

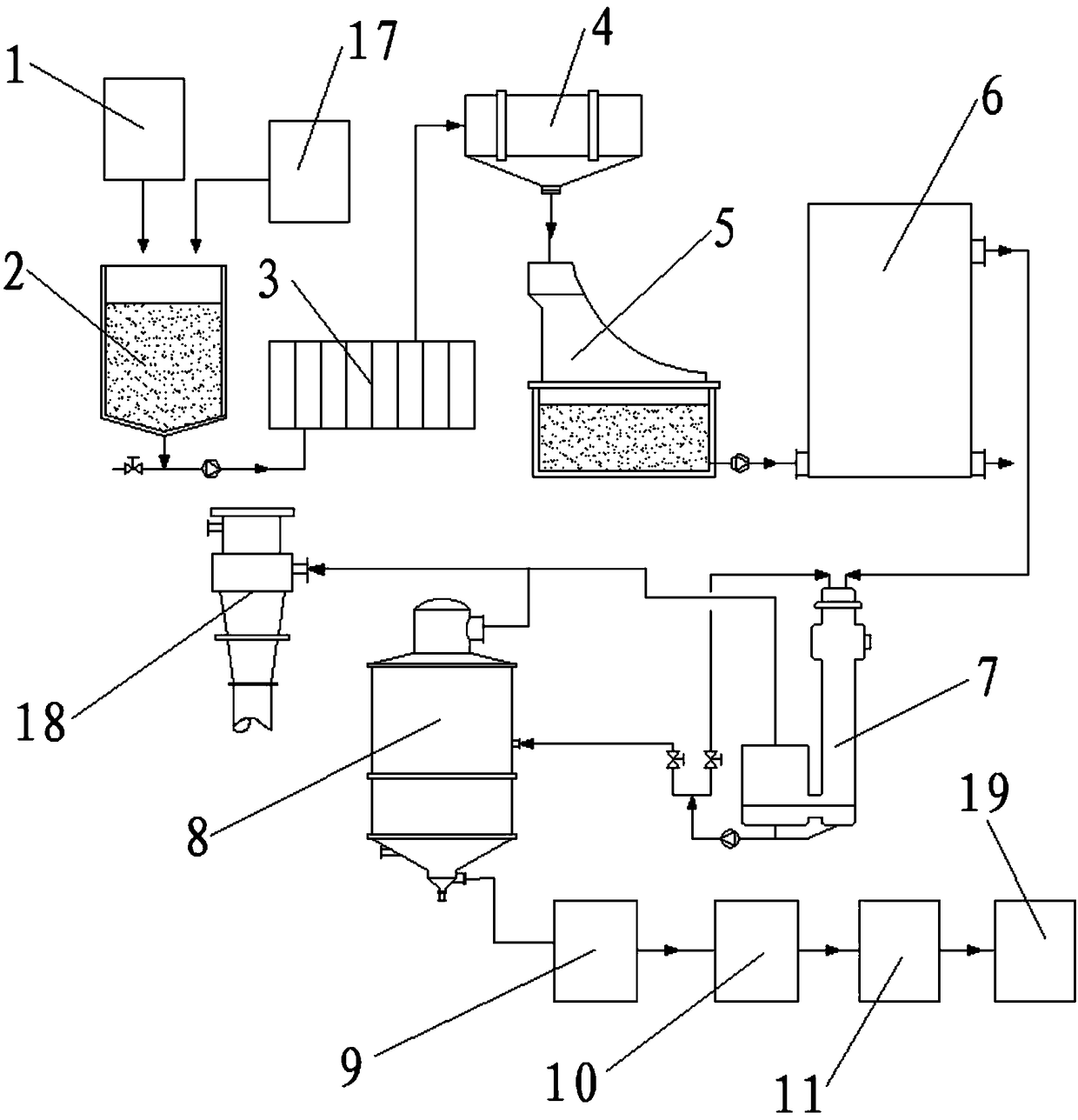

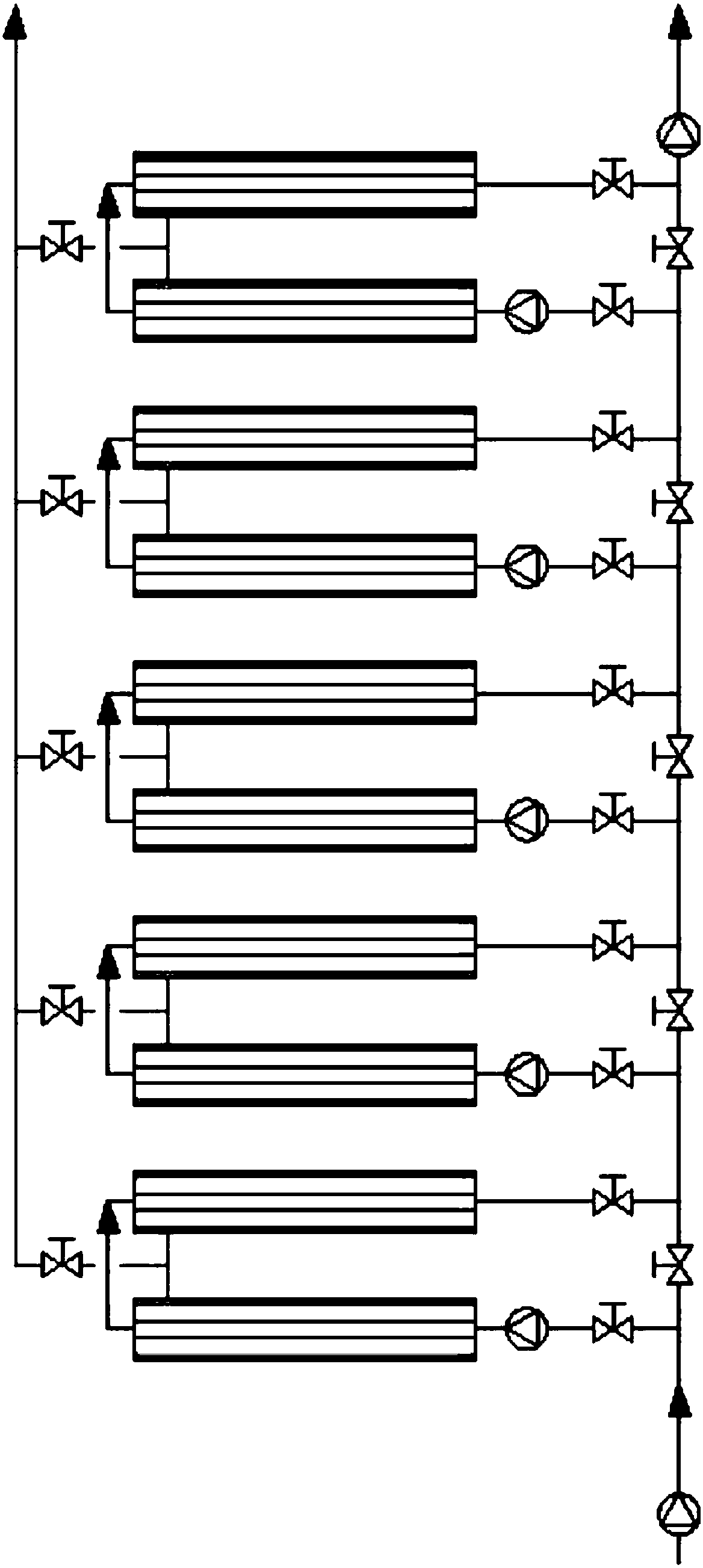

Method and device for producing granulated sugar and refined sugar by membrane method

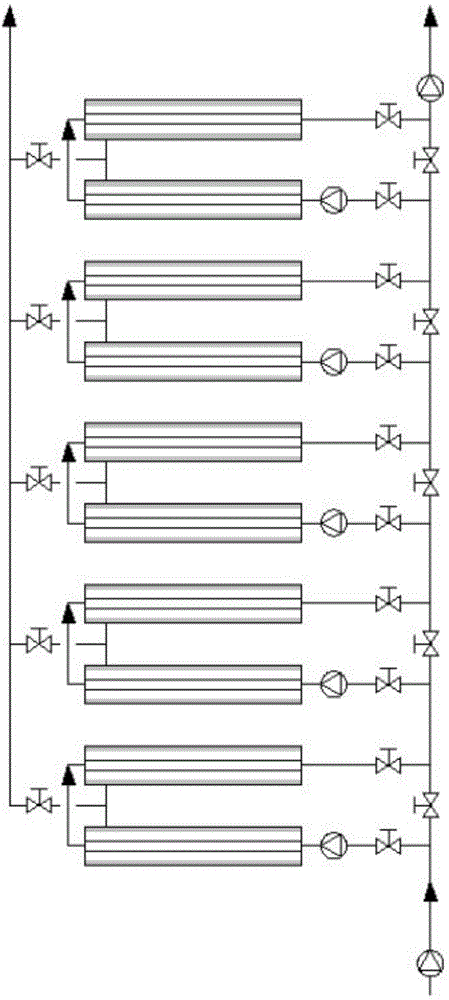

PendingCN108251563AAddressing the hidden dangers of sugar safetyEasy to upgradeSugar dryingPurification using alkaline earth metal compoundsMembrane methodFiltration

The invention provides a method for producing granulated sugar and refined sugar by a membrane method. The method comprises the following steps: adding ash, heating, carrying out coarse filtration, carrying out ultra-filtration by utilizing an inorganic membrane with the pore diameter of 0.02 to 0.2mu m, separating molasses and drying and recrystallizing to obtain membrane-method refined sugar. Adevice for producing the granulated sugar and the refined sugar by the membrane method comprises a sugarcane mixed juice source, an ash adding stirring tank, a heat exchanger, a linear sieve with thesize of 40 to 60 meshes, a bent sieve with the size of 80 to 100 meshes, inorganic membrane ultra-filtration equipment with the pore diameter of 0.02 to 0.2mu m, evaporation and concentration equipment, a first sugar boiling tank, a first crystallization-assisting box, first centrifuging and molasses separating equipment and first frying equipment, which are connected in sequence. In a granulatedsugar production process, less lime cream is used and any chemical auxiliary agent is not added, so that the problem of hidden dangers of sugar safety is solved.

Owner:GUANGXI UNIV

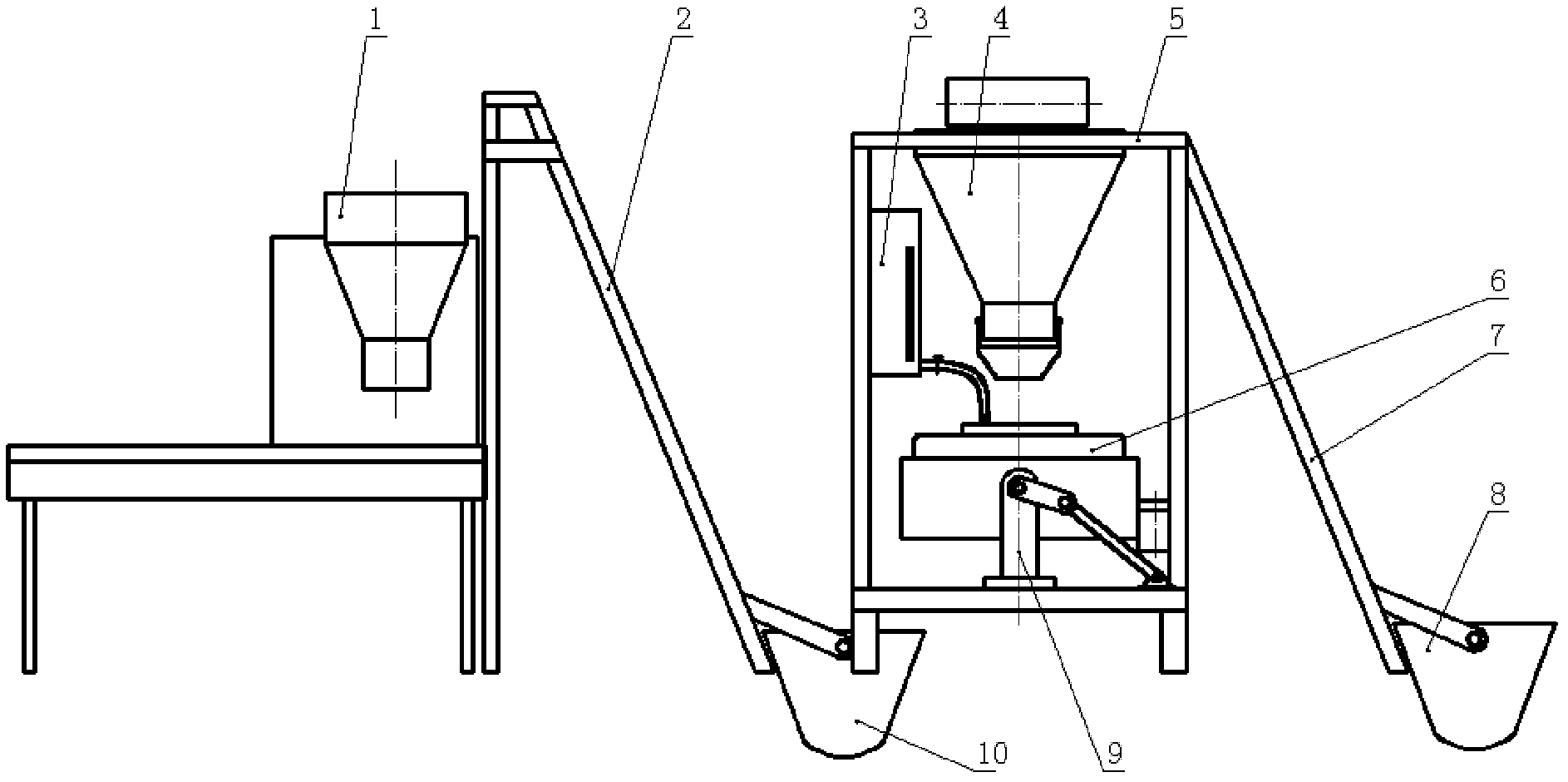

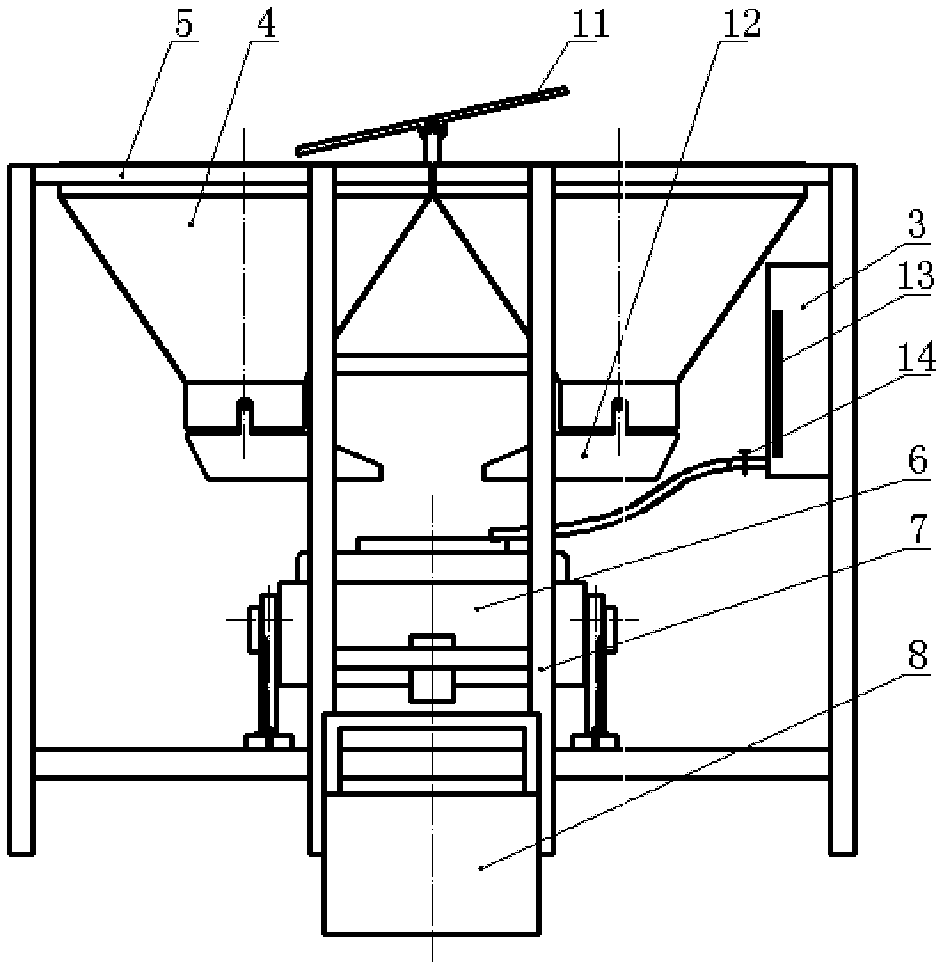

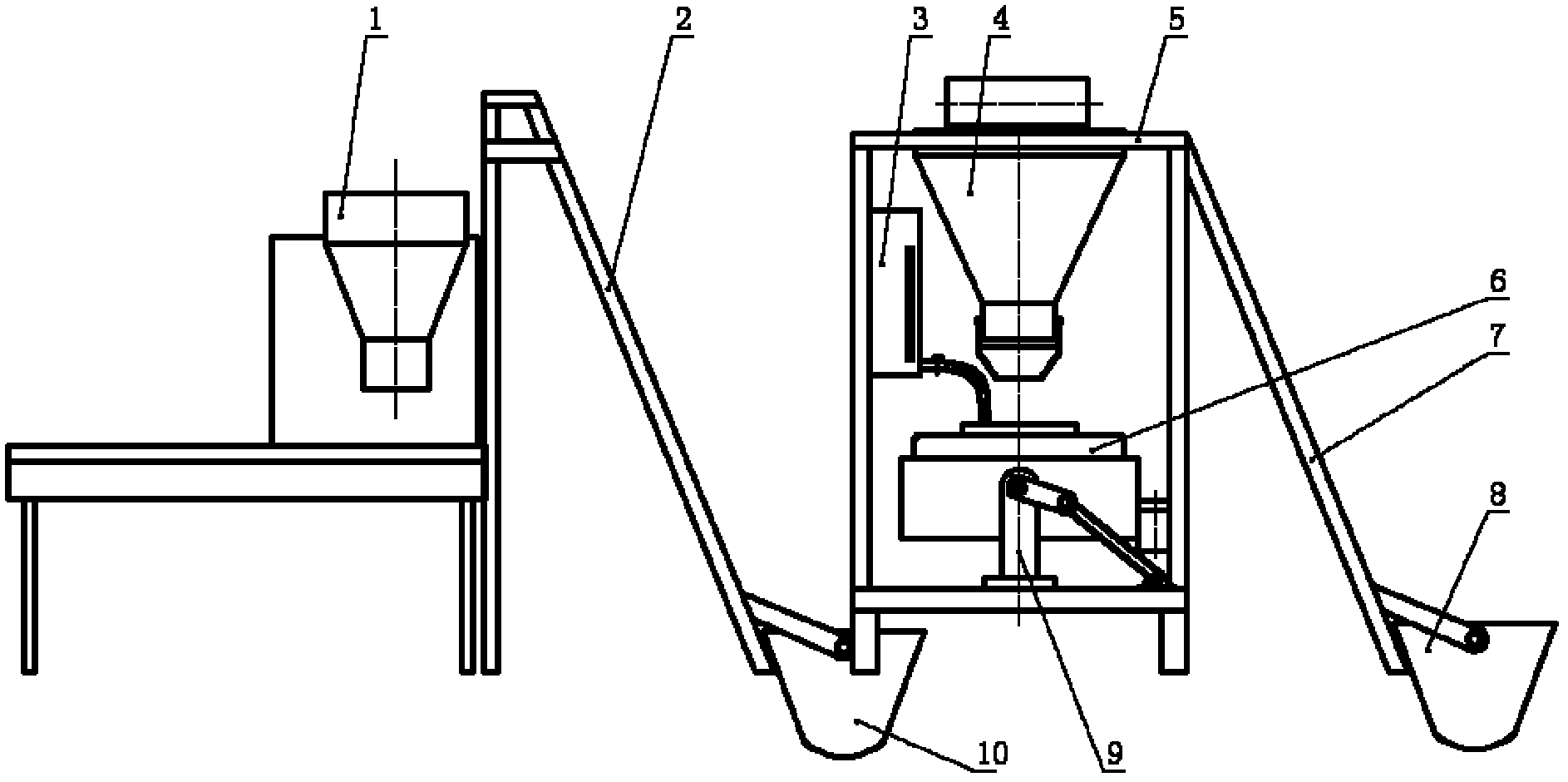

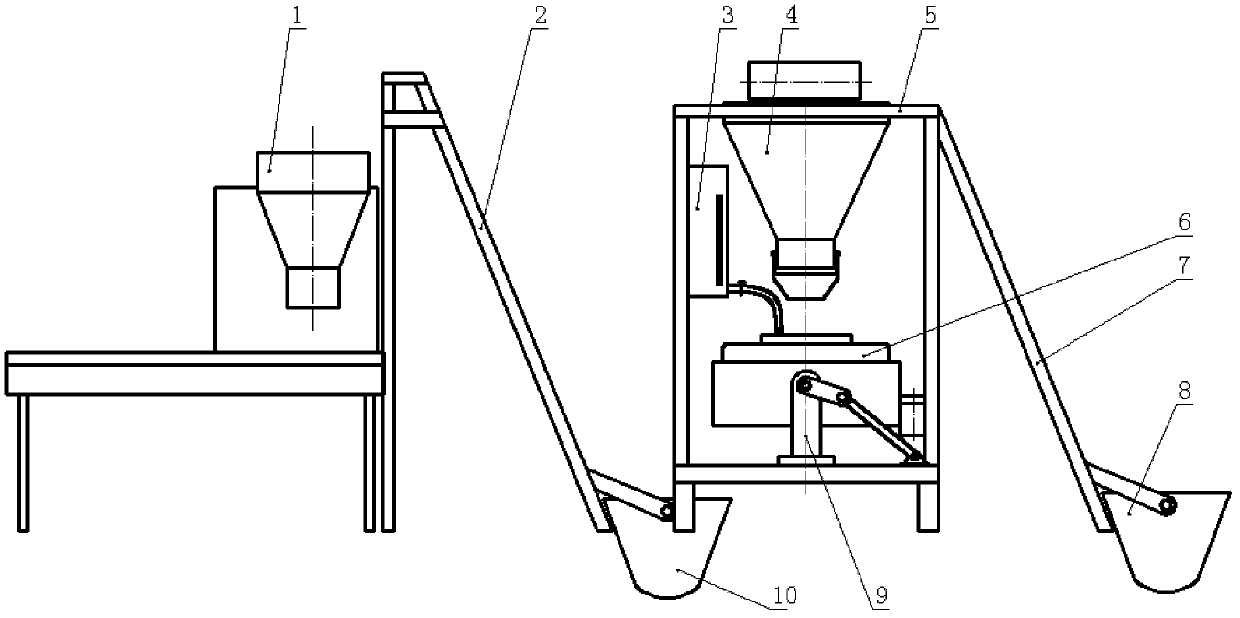

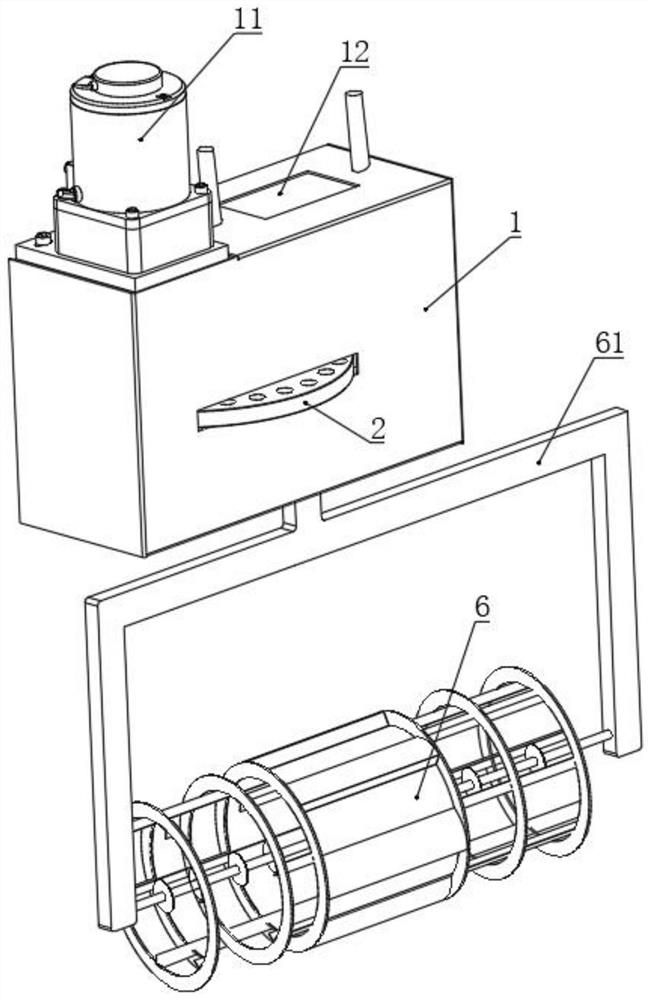

Automatic dehydration and sub-packaging system of monocrystal rock sugar

The invention relates to an automatic dehydration and sub-packaging system of monocrystal rock sugar, and the system provided by the invention comprises a loading device, a loading hopper, a dehydrator, a feeding device and a quantitative packaging machine, wherein the loading hopper is fixedly arranged at the upper part of a three-dimensional framework, the dehydrator is fixedly arranged below a discharge port corresponding to the loading hopper, the dehydrator is hinged on the three-dimensional framework through turnover arms arranged on the two sides of the dehydrator, the loading device and the feeding device are respectively mounted at the front end and back end of the three-dimensional framework, the quantitative packaging machine is arranged at the back end of the feeding device, a loading overturning skip of the loading device is used for upwards supplying materials to the loading hopper, a feeding overturning skip of the feeding device is used for supplying the materials to the quantitative packaging machine, a spraying device is fixedly arranged on the three-dimensional framework in the vicinity of the dehydrator, and a water pipe of the spraying device is communicated with the dehydrator. The automatic dehydration and sub-packaging system is scientific and reasonable in design, simple in structure, easy to operate, clean, sanitary, energy-efficient and environmentally-friendly and can be used for effectively saving manpower, reducing the labor intensity of operation staff, further saving water, significantly improving the production efficiency and ensuring the product quality.

Owner:TIANJIN HONGLU FOODS

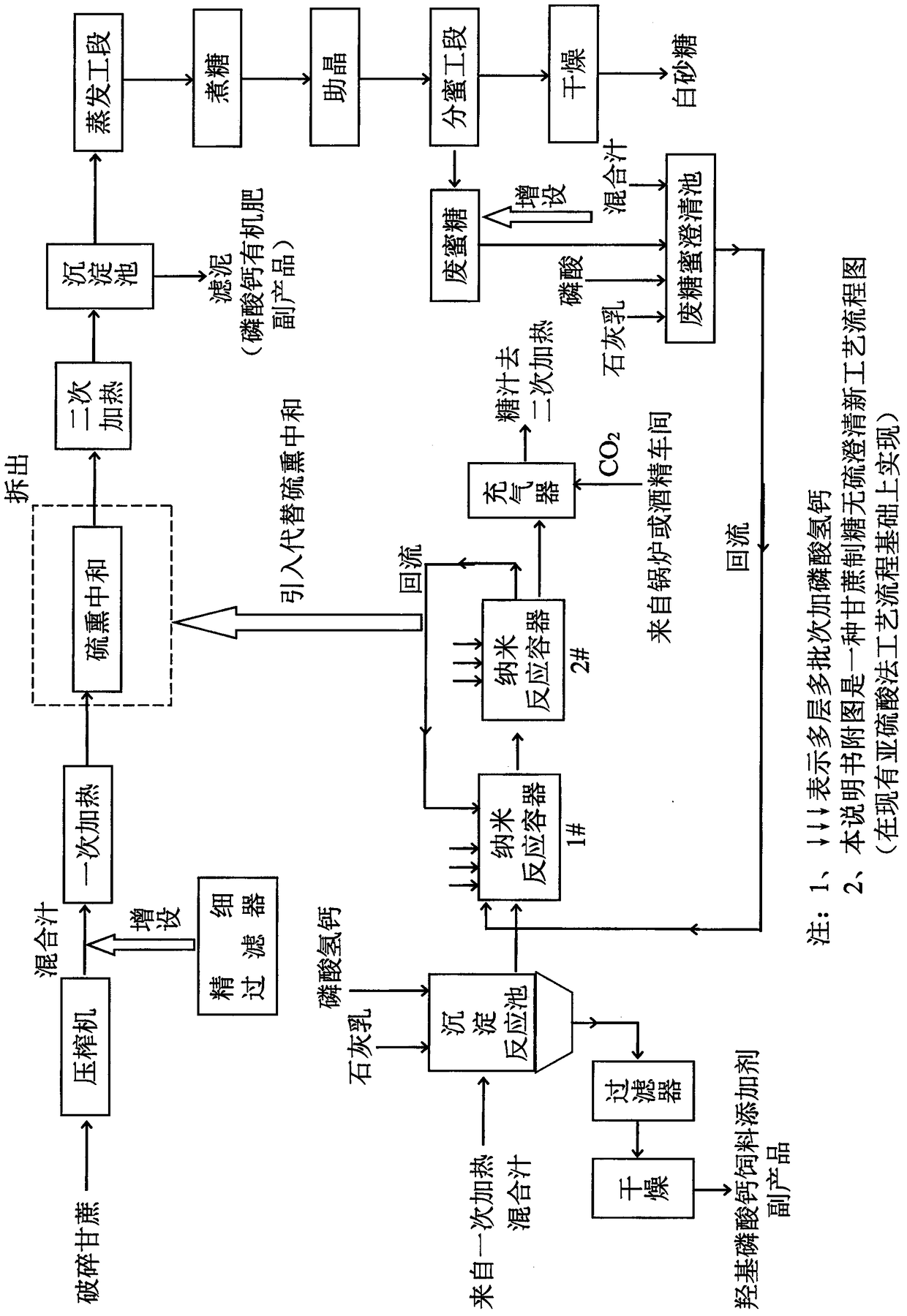

Novel cane sugar manufacturing sulfur-free clarification process

InactiveCN108315501AReduce investmentImprove product qualitySugar dryingPurification by physical meansCalcium biphosphateProcess equipment

The invention discloses a novel cane sugar manufacturing sulfur-free clarification process. According to the process, on the basis of conventional sulfurous method process equipment, sulfur renuetralization facilities after primary heating before secondary heating are all dismounted, and sulfur-free clarification production equipment which is capable of replacing the facilities and preparing nanohydroxy calcium phosphate is introduced. The novel production process further comprises a fine mixed juice filter at a squeezing section and partial discard molasse clarification backflow equipment. The novel cane sugar manufacturing sulfur-free clarification process has the characteristics that the additional equipment can be manufactured by a producer self, a low investment is needed, multiple byproducts can be produced, the main product, namely white sugar, is free of sulfur, the sugar yield can be increased by 0.2-0.45%, the quality of a white sugar product can be remarkably improved, andthe economic benefits of sugar making companies can be greatly increased.

Owner:白教法

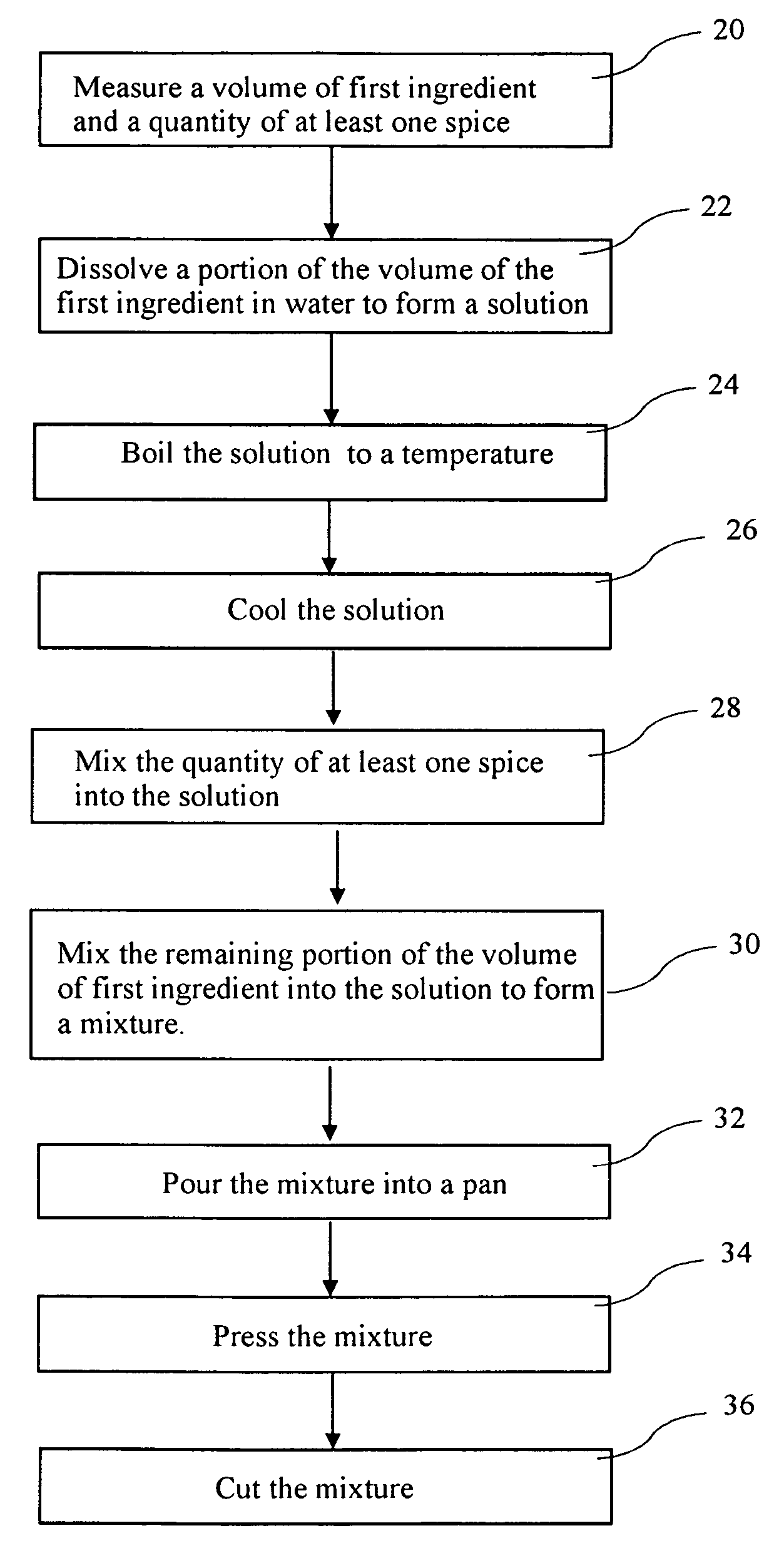

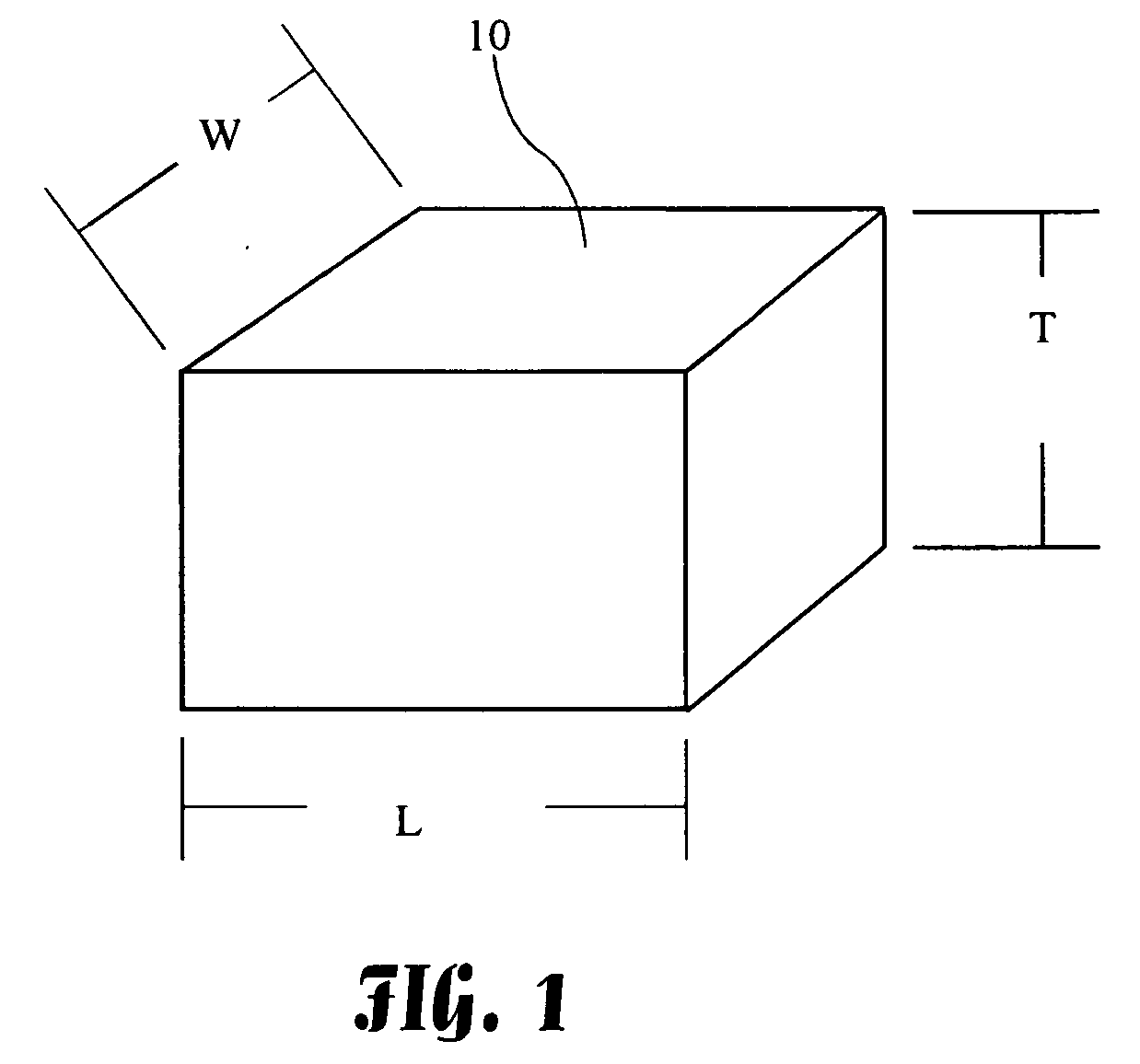

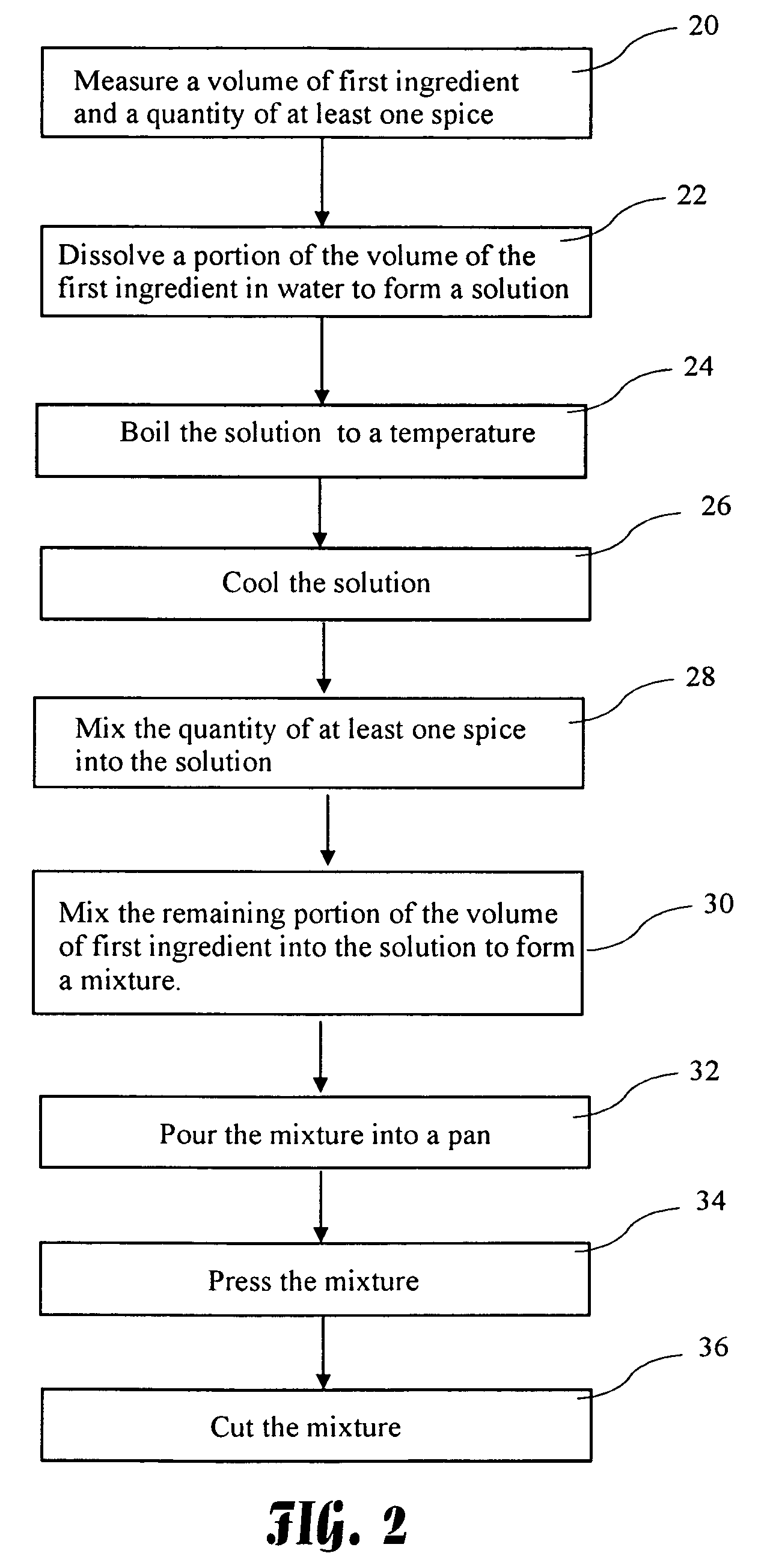

Method for making a spice sugar cube

A method for making a high quality spice sugar cube. The spice sugar cube consists essentially of sugar or a sugar substitute and at least one spice. A quantity of spice and a volume of sugar are measured. A first portion of about one third of the volume of sugar is dissolved in water to create a sugar water solution. The sugar water solution is heated until the solution reaches a temperature between 215 and 235 degrees Fahrenheit resulting in an amount of the water evaporating (e.g., boiling out) from the solution. The solution is than allowed to cool to between 80 and 120 degrees Fahrenheit. The quantity of spice is then mixed into the solution, and then the remaining portion of the volume of sugar is mixed into the solution to form a mixture. The mixture is then poured into a flat pan and pressed to remove any voids and cut into cubes.

Owner:MASIHI ANDRANIK V

Production method of lumpy brown sugar with donkey-hide gelatin

ActiveCN107058635ASimple production methodIncrease productivitySugar dryingSugar productsWater contentChemistry

A production method of lumpy brown sugar with donkey-hide gelatin comprises the steps of (1) adding precipitated filtered fresh sugarcane juice and brown sugar powder into a brown sugar boiling container of a lumpy brown sugar boiling former, and heating through heat transfer oil; (2) stirring the materials in the brown sugar boiling container nonstop, and stopping heating after 40-50 min when the water content of syrup is 8-12%; (3) after heating is stopped, adding donkey-hide gelatin, Chinese date power and wolfberry fruit powder accounting for 1-3%, 2-3% and 1-3% of the weight of the syrup into the syrup, and mixing well; (4) injecting the syrup into a lumpy brown sugar forming mold through a syrup injection unit, conveying the lumpy brown sugar forming mold into an air cooling box for air cooling so that the syrup solidifies into lumpy brown sugar; (5) removing the lumpy brown sugar from the lumpy brown sugar forming mold, and conveying the lumpy brown sugar into the air cooling box to blow-dry surface water by air cooling; (6) aseptically packaging the lumpy brown sugar to obtain the finished lumpy brown sugar with donkey-hide gelatin. The production method is simple, high in production efficiency and low in equipment investment cost.

Owner:广西怡神糖业有限公司

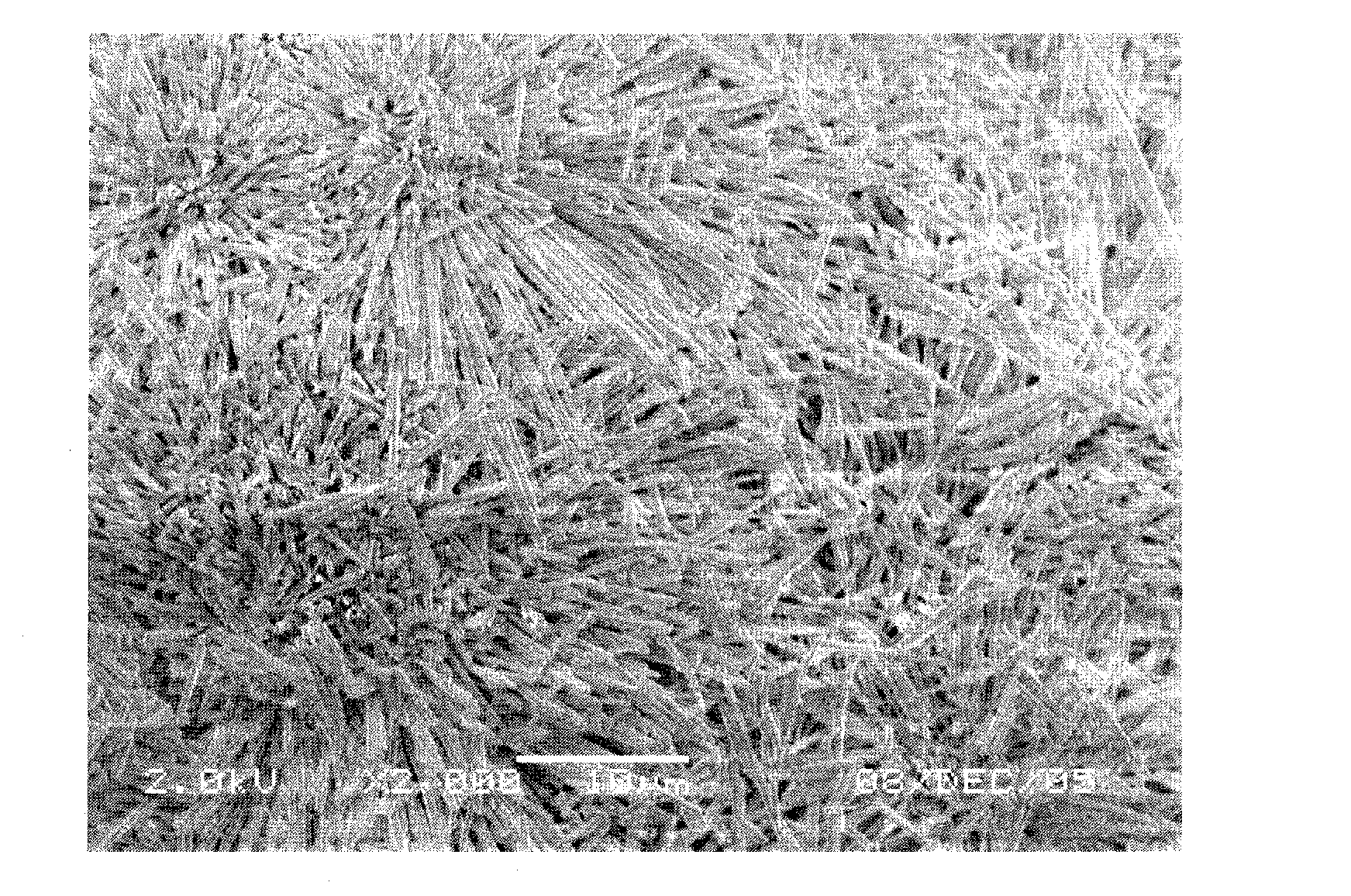

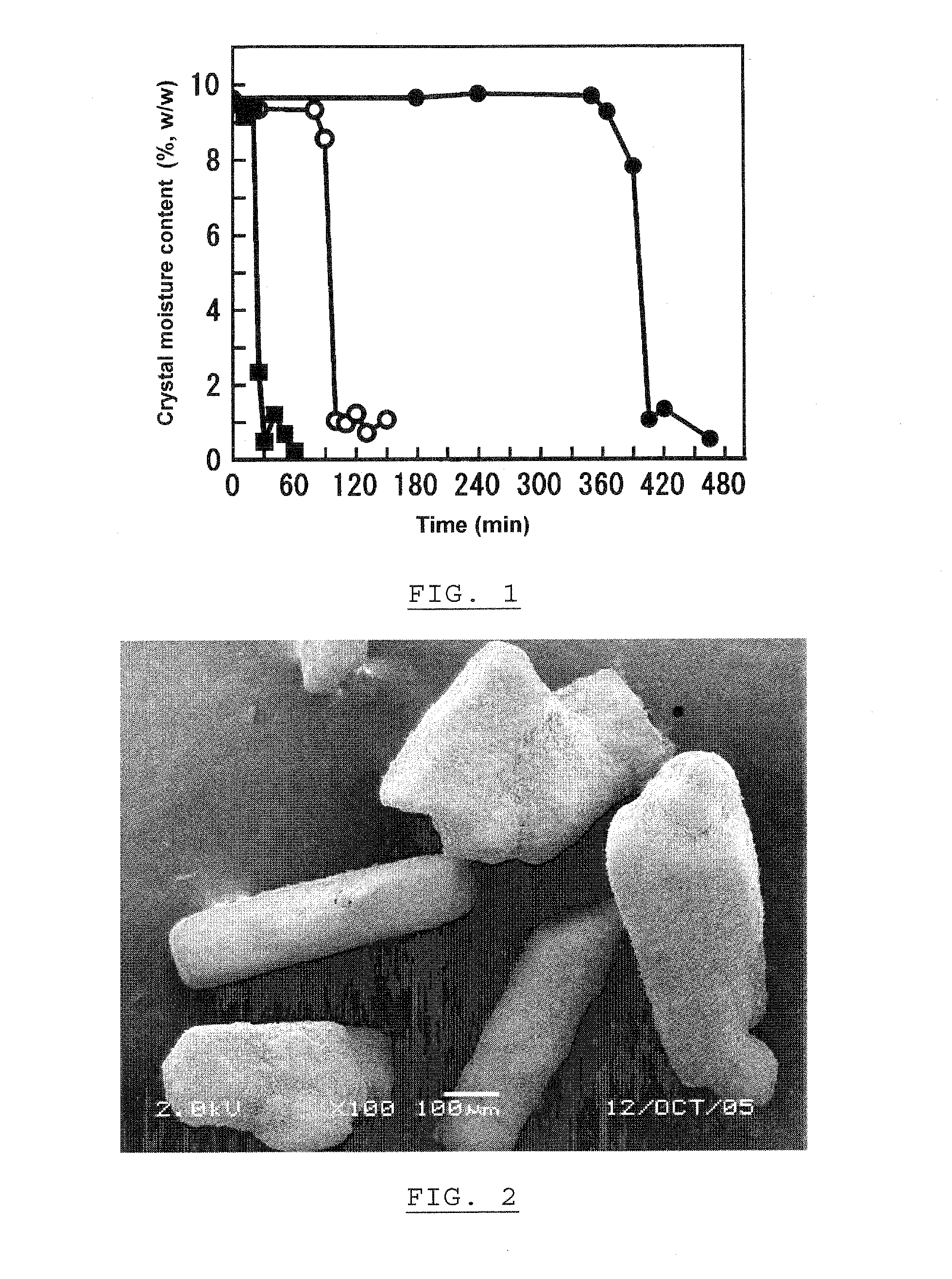

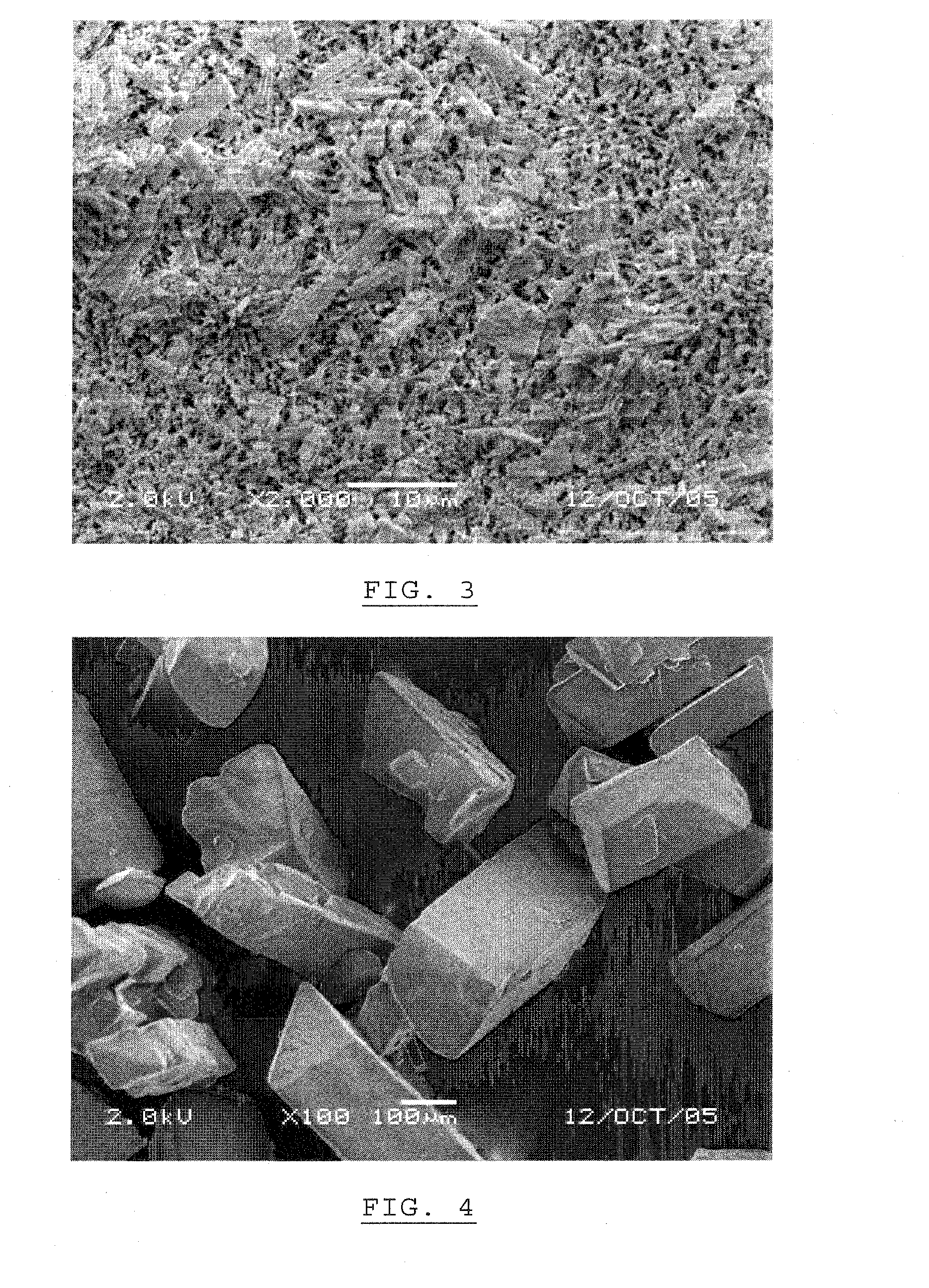

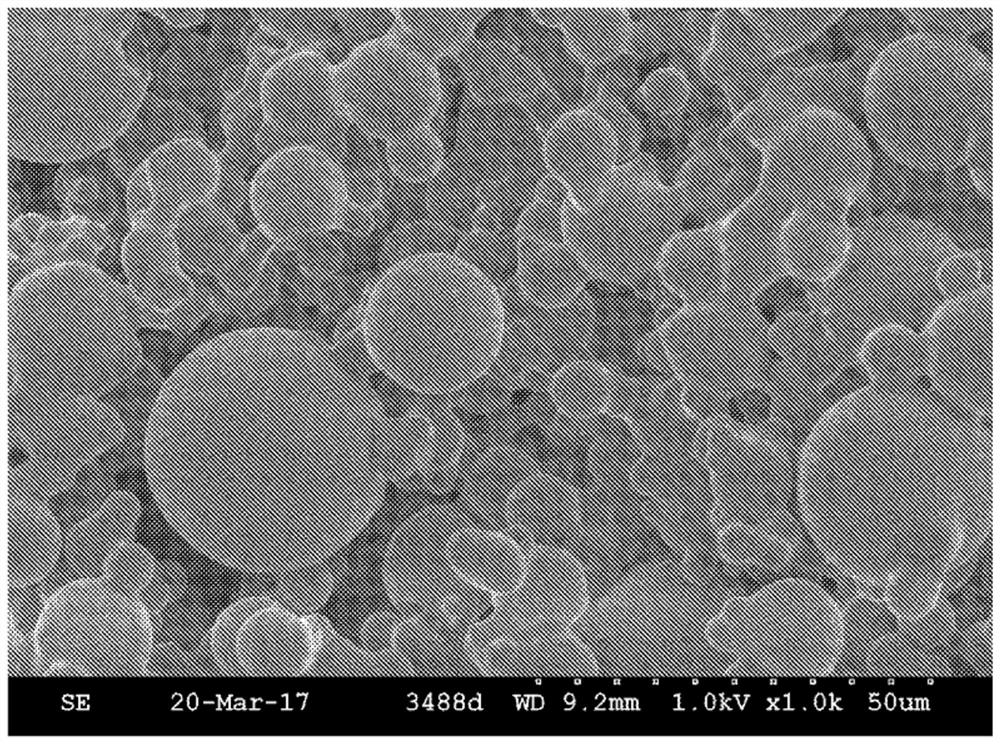

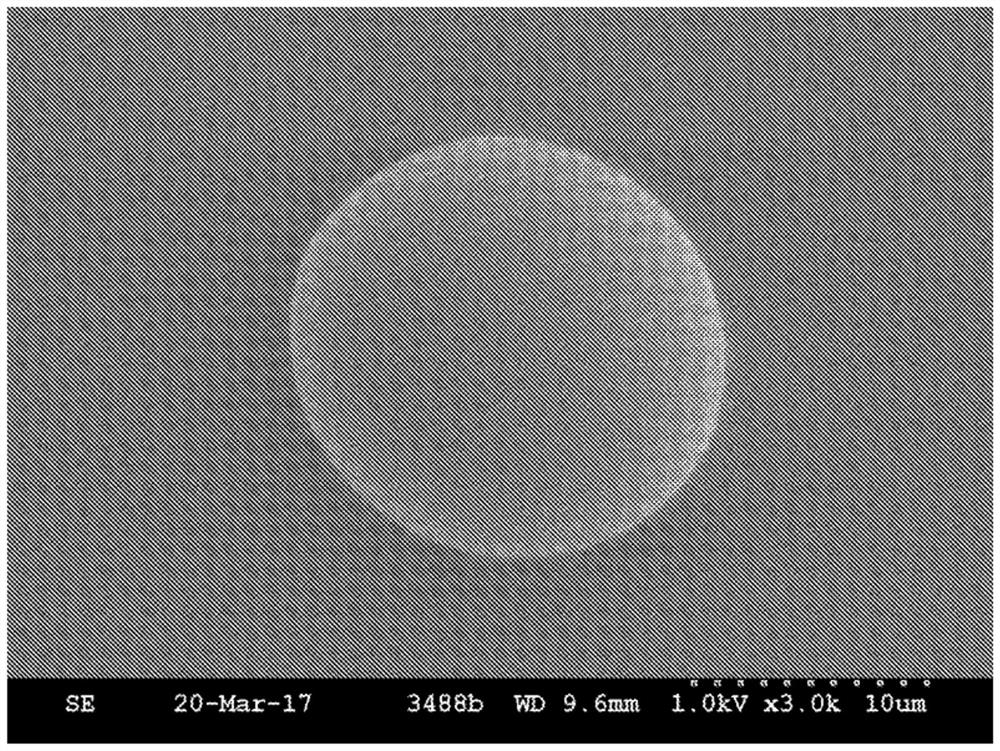

Porous crystalline saccharide, its preparation and uses

ActiveUS20100222569A1Improve solubilityEasy to useSugar dryingSugar productsOrganic solventPhysical property

An object of the present invention is to provide a crystalline saccharide having novel physical properties, a preparation and uses thereof. The present invention solves the above objects by providing a porous crystalline saccharide having a number of pores, a process for producing the same, comprising the step of keeping hydrous crystalline saccharide at an ambient temperature or higher in an organic solvent for the dehydration, and the use thereof.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

How to clean the sugar dryer

Owner:CHONGQING YU NIU FOOD CO LTD

White granulated sugar drying machine with self-cleaning function

Disclosed is a white granulated sugar drying machine with a self-cleaning function. The white granulated sugar drying machine with the self-cleaning function comprises a lower box body and an upper box cover. An air outlet is formed in the upper box cover, a mounting cylinder is arranged in the air outlet, and an adhesion plate is arranged below the mounting cylinder. A vibrating plate is arranged between the lower box body and the upper box cover. An air through plate is further arranged between the upper box cover and the lower box body and located below the vibrating plate, air through holes are formed in the air through plate, brush bristles are arranged on the top of the air through plate, and a second vibrating motor is arranged on the lower portion of the air through plate. The vibrating plate comprises two divided plates, wherein the divided plates are arranged in the white granulated sugar conveying direction, a compressed spring is arranged at one end of each divided plate, and the compressed springs force the divided plates to combine. Supporting blocks are further arranged on the top of the air through plate, the other end of each divided plate is arranged on the corresponding supporting block in a supported mode. U-shaped grooves are formed in the face-to-face ends of the divided plates, groove openings of the U-shaped grooves are formed in a face-to-face mode, and the U-shaped grooves are located exactly above the brush bristles. The mounting cylinder can vertically move, and the adhesion plate can push the combined divided plates to be opened and make contact with the brush bristles after the mounting cylinder moves downwards.

Owner:徐州宇之阳市场营销策划有限公司

Organic brown sugar

InactiveCN107083451ASimple preparation processEasy to operateSugar dryingSugar productsIcing sugarSide effect

The invention discloses an organic brown sugar. The organic brown sugar is prepared from the following raw materials by weight: 98 to 102 parts of powdered sugar, 0.05 to 0.5 part of an anti-oxidant and 0.01 to 0.05 part of a bacteriostatic agent. A preparation method for the organic brown sugar provided by the invention is simple in process and convenient to operate; physical means are employed in the whole process of preparation; and the prepared organic brown sugar is healthy, contains a plurality of vitamins and trace elements like iron, zinc, manganese and chromium, can nourish and tonify blood, improves the immunity of people and is free any toxic and side effect.

Owner:SHANGHAI TAOHONG CHEM TECH

Solid Molasses Composition

The present disclosure relates to a solid molasses product having a low water content. The solid molasses product retains the physical and palatable properties of untreated / hydrated molasses while having a prolonged shelf-life. It can be advantageously used to sweeten beverages (such as hot beverages) and in the manufacture of pharmaceutical compositions, confectionery as well as animal feed.

Owner:IAF SCI HLDG

White granulated sugar vibration fluidized bed with air volume adjusting structure

The invention discloses a white granulated sugar vibration fluidized bed with an air volume adjusting structure. The white granulated sugar vibration fluidized bed comprises a fluidized tank, wherein the fluidized tank is driven by a vibration motor. The white granulated sugar vibration fluidized bed is characterized in that the fluidized tank comprises a middle groove and step parts; the groove is used for conveying white granulated sugar; the step parts are arranged at both sides of the groove; each step part comprises a horizontal section and a vertical section; a plurality of first air through holes are formed in each horizontal section, and an air adjusting plate is arranged under each horizontal section and is moved along the width direction of the fluidized tank; a plurality of second air through holes are formed in each air adjusting plate, and the number of the second air through holes is the same with the number of the first air through holes; the second air through holes and the first air through holes are moved in a relative staggering way to adjust the size of an air passage formed by the first air through holes and the second air through holes; an air blocking plate is arranged above the fluidized tank, an air outlet hole is formed in the middle part of the air blocking plate, and the upper surface of each vertical section is overlapped with the lower surface of the air blocking plate.

Owner:CHONGQING YU NIU FOOD CO LTD

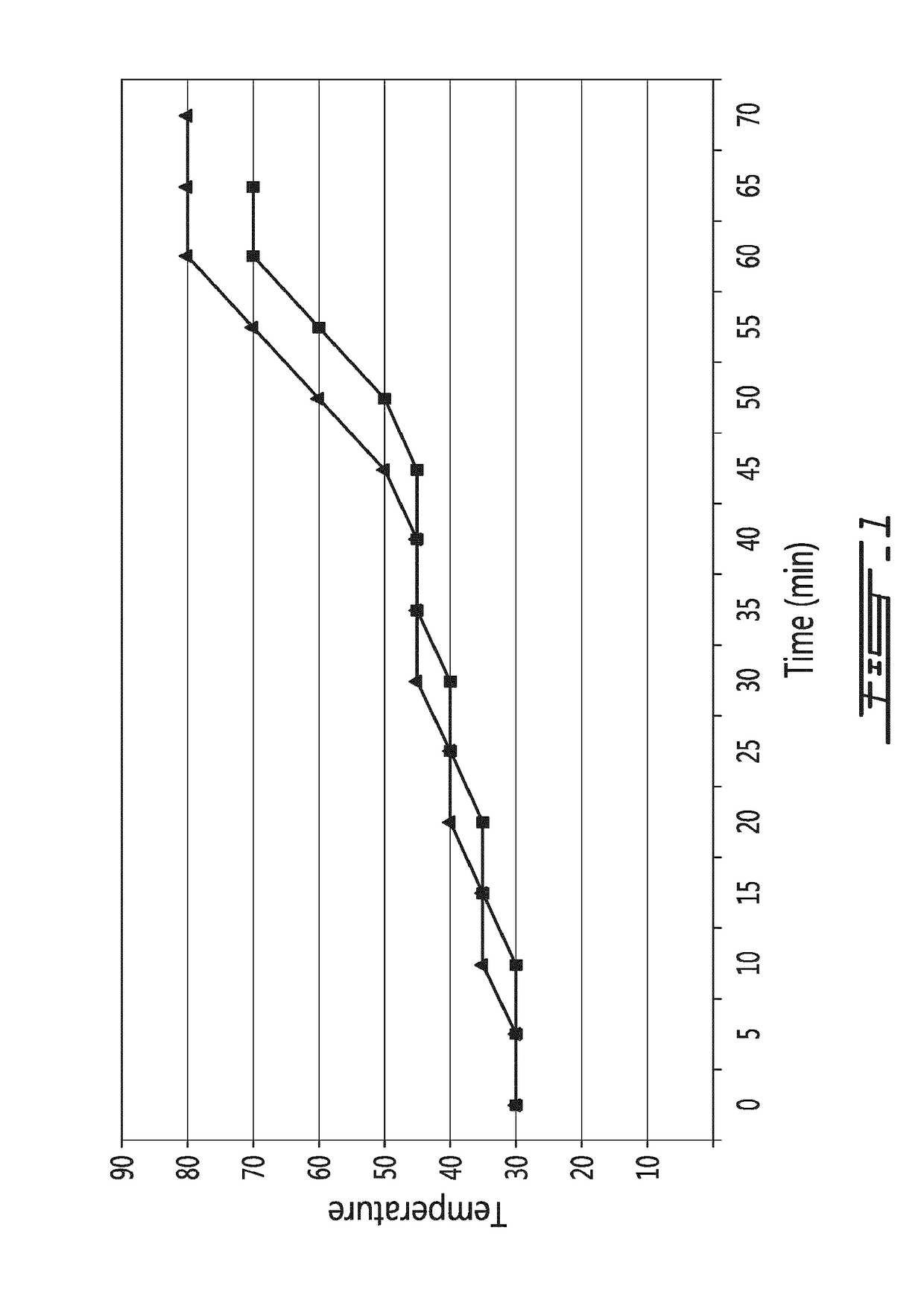

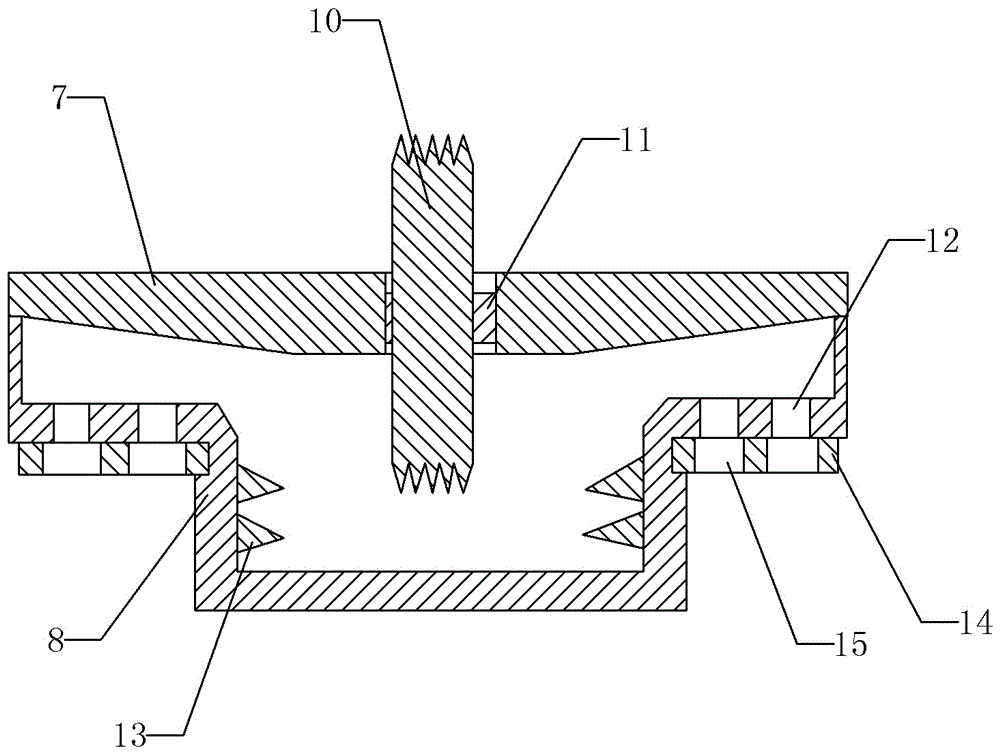

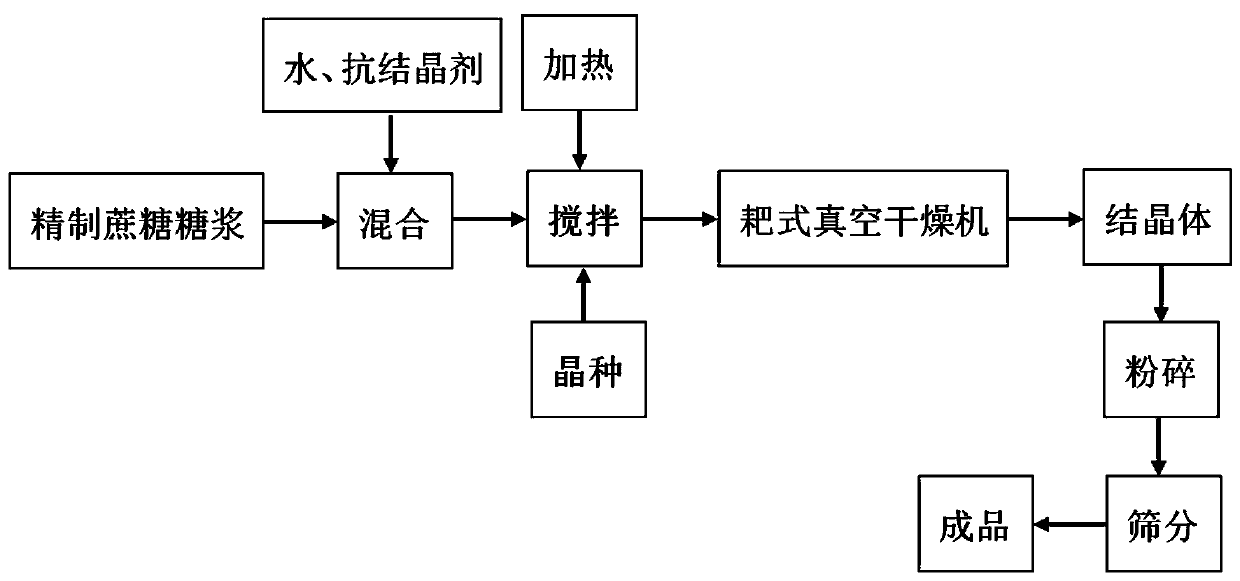

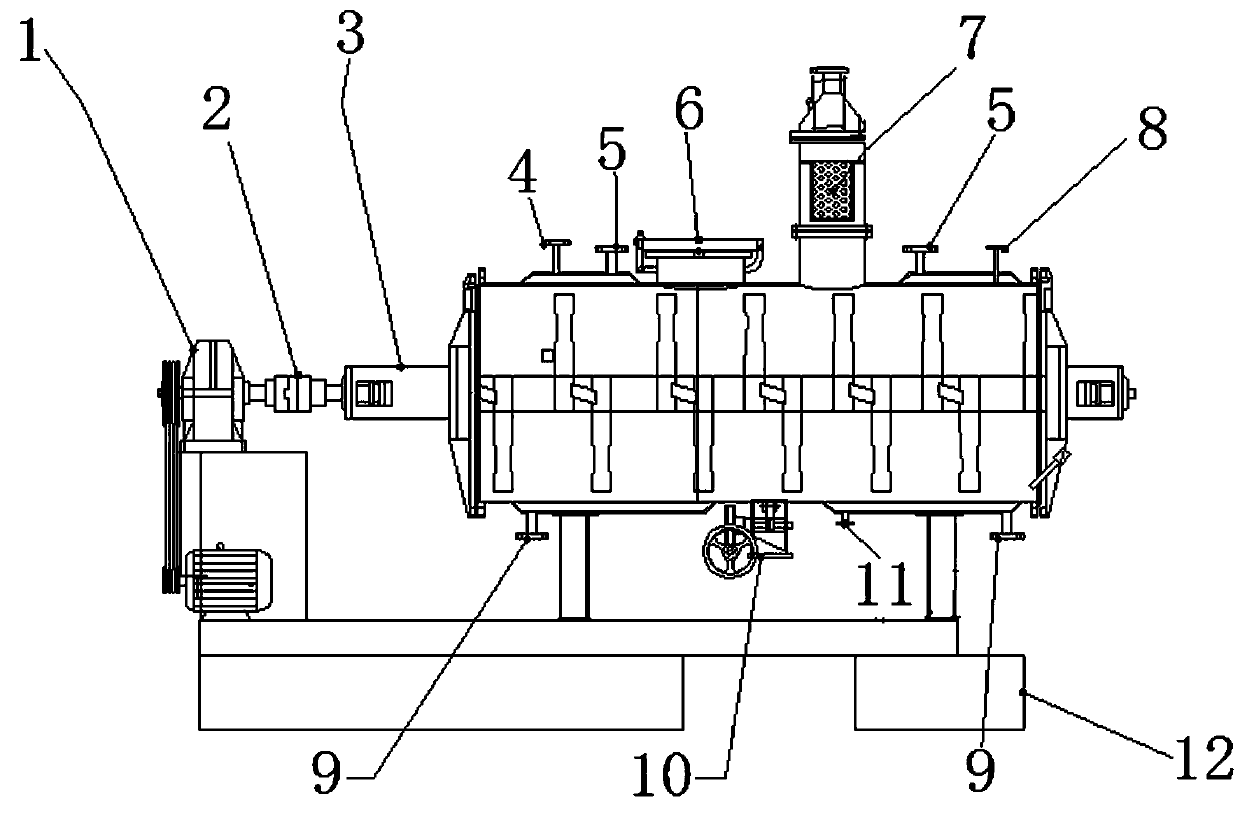

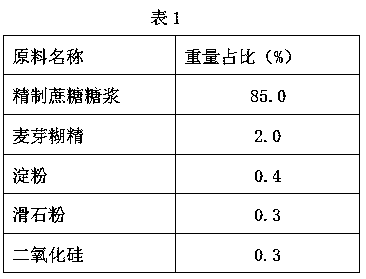

Method for preparing compressible cane sugar from cane sugar syrup

The invention belongs to the technical field of cane sugar processing, and particularly relates to a method for preparing compressible cane sugar from cane sugar syrup. The method uses the following raw materials in percentage by weight: 85-98% of refined cane sugar syrup and 1-5% of an anti-crystallization agent, with the balance being water. The method comprises the following steps: mixing the refined sucrose syrup with the anti-crystallization agent and water in proportion, further adding a compressible sugar seed crystal, carrying out mixing, then performing crystallizing and drying in a rake type vacuum drier, and carrying out crushing and screening to obtain a finished compressible cane sugar product. With the method provided by the invention, the process of cane sugar dissolving orpre-crushing is omitted; the adopted rake type vacuum drier is high in drying efficiency, saves time and reduces energy consumption and equipment investment; the integral process is greatly simplified; the raw materials, the anti-crystallization agent and the water are fully stirred in the dissolving process and then are mixed and crystallized, so the prepared compressible cane sugar product is small in particle density, low in particle strength, uniform in particle size and better in flowability and compression formability.

Owner:广西南宁万宇科技有限公司 +1

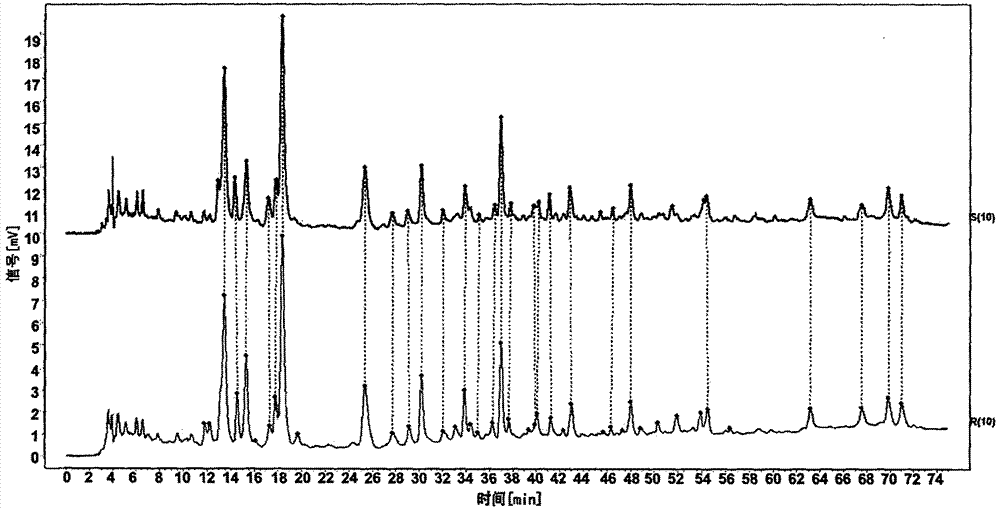

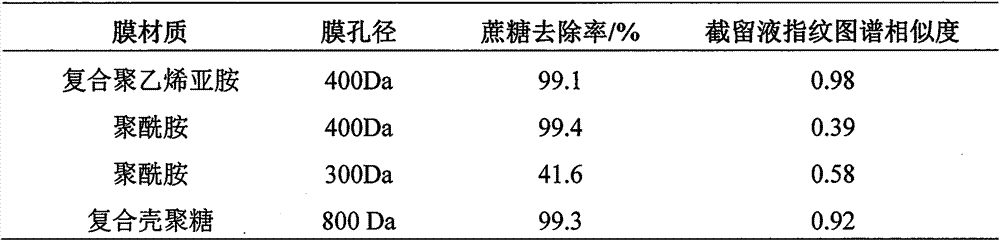

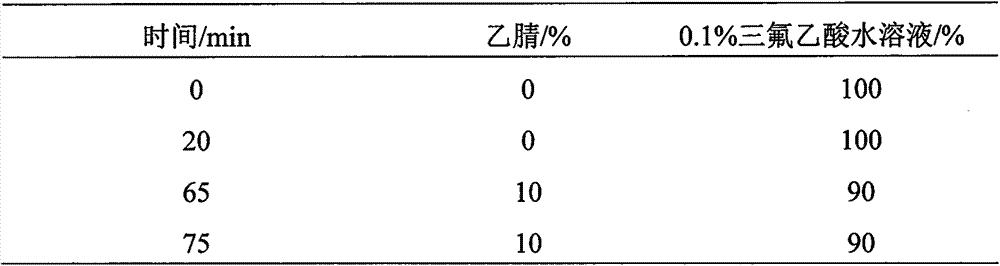

Sugar-free brown sugar preparation method for removing saccharose in brown sugar by nanofiltration and application thereof

InactiveCN107142336AKeep the tasteMaintain efficacySugar dryingSugar productsAcute hyperglycaemiaBlood sugar

The invention provides a nanofiltration preparation method for removing saccharose in brown sugar. Sugar-free brown sugar developed based on researches of industrial standard of pharmaceutic adjuvant for brown sugar is characterized by a nanofiltration technology. The whole process is free of chemical addition, health-care effective components of brown sugar are retained, and sugar-free brown sugar is prepared, so that the problem of body damage caused by administration of saccharide components for maintenance of diabetics, the aged with hypertension, hyperglycemia and hyperlipidemia or sugar-avoiding young women is solved. In the fields of beautifying and freckle removing, menstruation regulating and blood nourishing and postpartum recovery, the sugar-free brown sugar can replace brown sugar, maintains the taste and curative effect and avoids responses of blood sugar increase and the like induced by administration of sugar. The sugar-free brown sugar can replace common saccharide components as a seasoning for sweet components in kitchen, food and coffee beverages and the like. The quality is controlled by adopting a fingerprinting technology. The sugar-free brown sugar is commonly hard to copy and has a wide application prospect.

Owner:丁宁

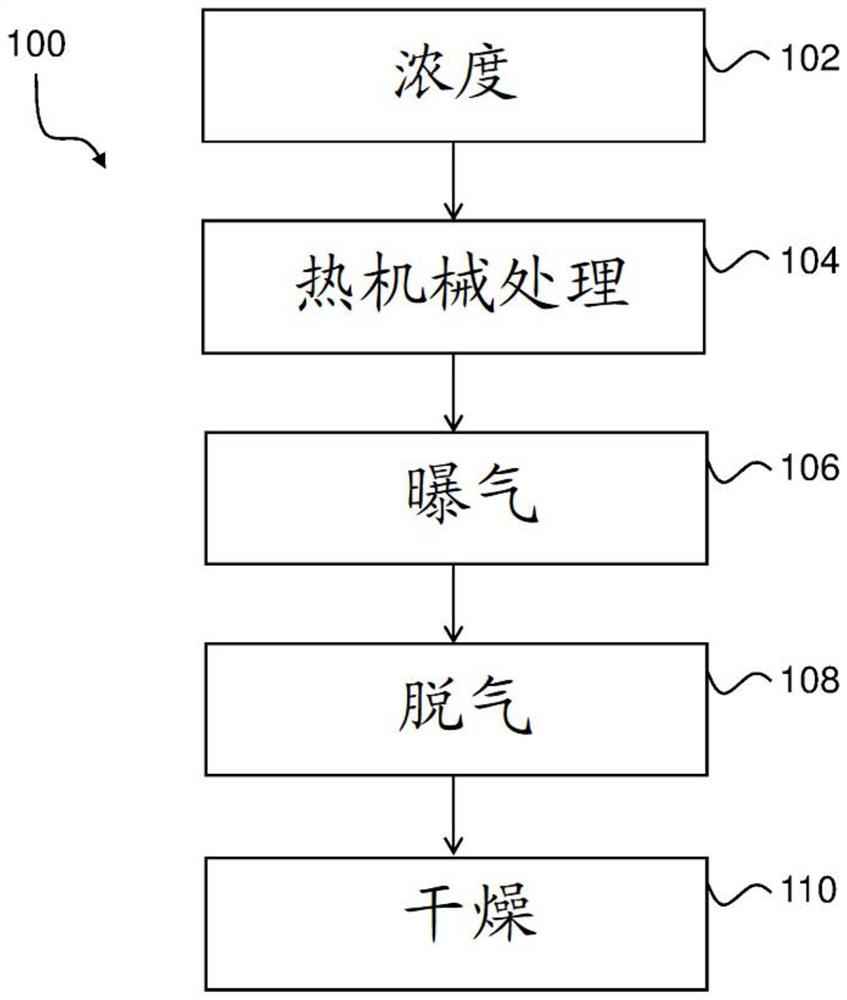

Method and apparatus for manufacture of dry powders

A method of production of a homogeneous powdered product from a starting product in a liquid state, the starting product having sugars as at least 60% of its total solids, the method comprising: in the absence of air: pressurizing the starting product to a pressure greater than 1 bar; injecting a gas into the starting product to form a mixture in which the starting product is substantially saturated by the gas; and degassing the mixture into a continuous stream of transport gas such that, on contact with the transport gas, water from the mixture evaporates to leave the homogeneous powdered product.

Owner:BIOMASS TECH PTY LTD

Automatic dehydration and sub-packaging system of monocrystal rock sugar

The invention relates to an automatic dehydration and sub-packaging system of monocrystal rock sugar, and the system provided by the invention comprises a loading device, a loading hopper, a dehydrator, a feeding device and a quantitative packaging machine, wherein the loading hopper is fixedly arranged at the upper part of a three-dimensional framework, the dehydrator is fixedly arranged below a discharge port corresponding to the loading hopper, the dehydrator is hinged on the three-dimensional framework through turnover arms arranged on the two sides of the dehydrator, the loading device and the feeding device are respectively mounted at the front end and back end of the three-dimensional framework, the quantitative packaging machine is arranged at the back end of the feeding device, a loading overturning skip of the loading device is used for upwards supplying materials to the loading hopper, a feeding overturning skip of the feeding device is used for supplying the materials to the quantitative packaging machine, a spraying device is fixedly arranged on the three-dimensional framework in the vicinity of the dehydrator, and a water pipe of the spraying device is communicated with the dehydrator. The automatic dehydration and sub-packaging system is scientific and reasonable in design, simple in structure, easy to operate, clean, sanitary, energy-efficient and environmentally-friendly and can be used for effectively saving manpower, reducing the labor intensity of operation staff, further saving water, significantly improving the production efficiency and ensuring the product quality.

Owner:TIANJIN HONGLU FOODS

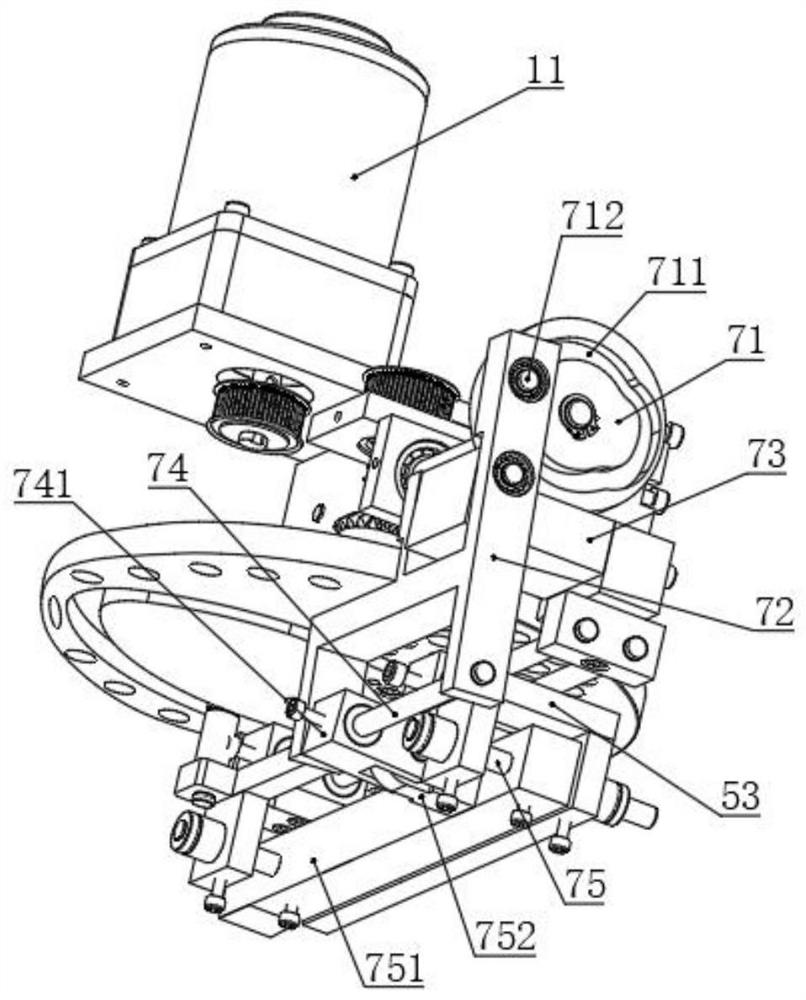

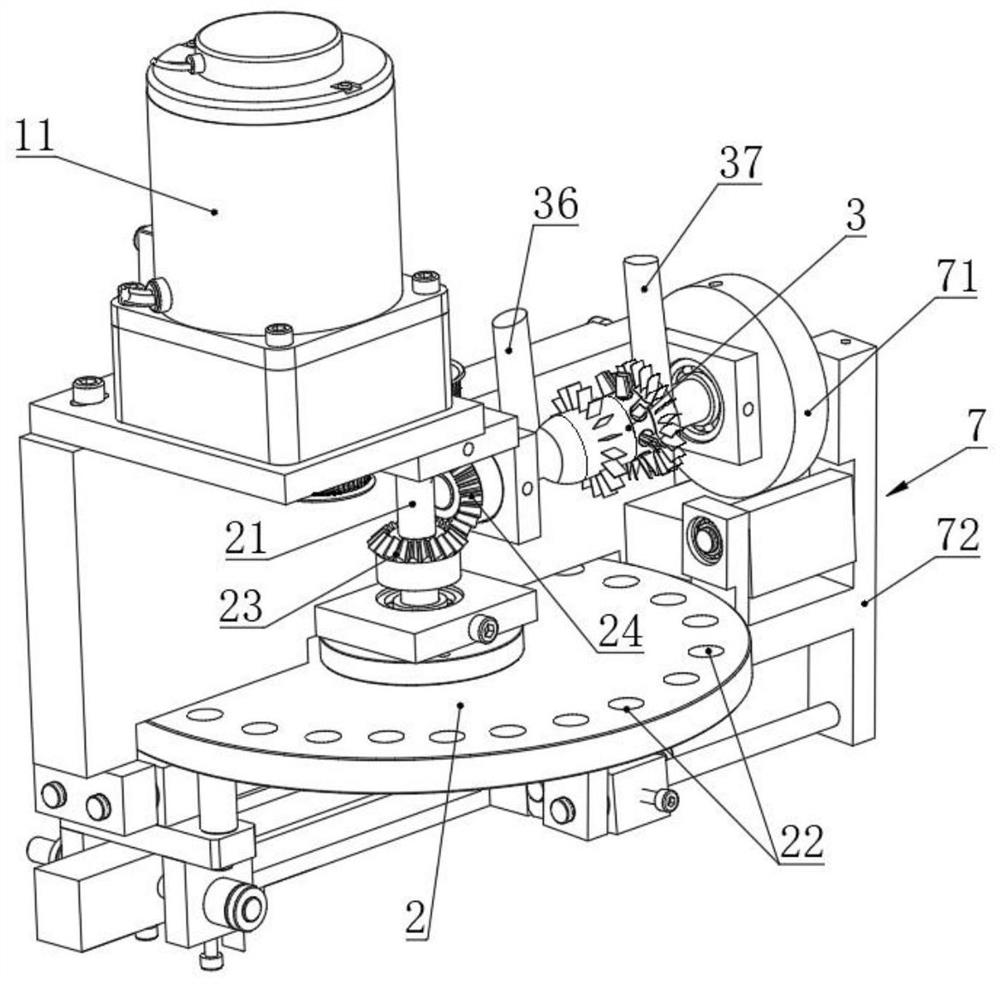

Manual raw material processing device and using method thereof

InactiveCN113201601AReduce processReduce work intensitySugar dryingSugar productsElectric machineryProcess engineering

The invention belongs to the technical field of brown sugar processing, and particularly relates to a manual raw material processing device. The manual raw material processing device comprises a shell and a driving motor arranged on the shell, wherein a rotating disc, a cooling fan and other structures are further arranged in the shell, and a sand rolling mechanism is further arranged on the lower portion of the shell. The invention further provides a using method of the device. The using method comprises the steps of power output, brown sugar syrup cooling, syrup rolling, milling and the like. According to the invention, a driving motor simultaneously drives the rotating disc and the cooling fan to rotate, the rotating disc drives a first sliding mechanism to move, the cooling fan drives a second sliding mechanism to move, and the first sliding mechanism and the second sliding mechanism simultaneously drive the sand rolling mechanism to move, so the movement of the sand rolling mechanism is similar to the action of manually pushing and rolling syrup back and forth; and meanwhile, the high-temperature syrup can be cooled many times through the rotating disc and the cooling fan, time for changing the syrup into brown sugar powder can be greatly shortened while it is guaranteed that the quality of the processed brown sugar powder is uniform, processing efficiency is improved, and the labor intensity of workers is reduced.

Owner:重庆披荆斩棘科技有限公司

A processing device for raw ecological brown sugar

ActiveCN104805224BTroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsAdditive ingredientUltrafiltration

An originally ecological black sugar processing device comprises a squeezing rough-filtration device, a heat exchanger, a multistage ceramic membrane ultrafiltration device, a falling-film type three-effect vacuum evaporation system, a water jet condenser, a jacketed iron pot and a graining drying forming device, which are sequentially connected, wherein a clarified sugarcane juice box is connected between the multistage ceramic membrane ultrafiltration device and the three-effect vacuum evaporation device; a syrup box is connected between the falling-film type three-effect vacuum evaporation system and the jacketed iron pot. The black sugar prepared through the device provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, sweet, delicious, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that black residues exist after the black sugar is dissolved is solved and the quality of the black sugar is improved.

Owner:广西百桂堂食品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com