White granulated sugar vibration fluidized bed with air volume adjusting structure

A vibrating fluidized bed and air volume adjustment technology, applied in sugar drying, hearth furnace, sucrose production, etc., can solve the problems of easy agglomeration, easy melting of white sugar, loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below by specific embodiments:

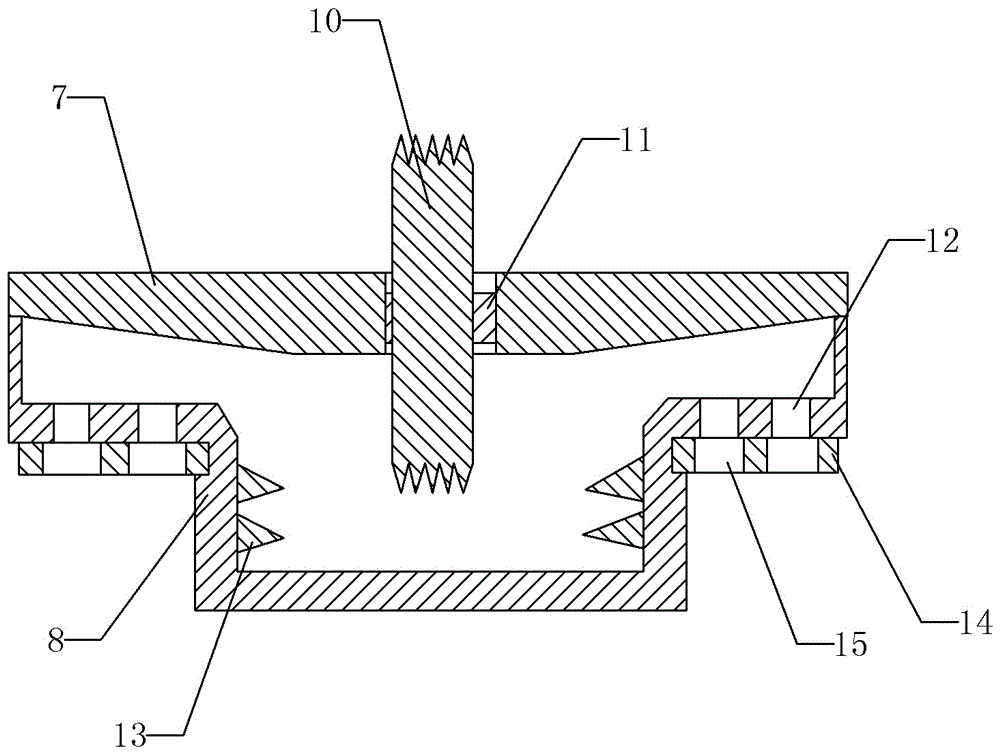

[0015] Reference numerals in the accompanying drawings include: wind deflector 7 , fluidization groove 8 , runner 10 , support shaft 11 , first air passage 12 , scraping teeth 13 , air regulating plate 14 , second air passage 15 .

[0016] The white granulated sugar vibrating fluidized bed with an air volume adjustment structure includes a bellows arranged at the lower part, and an air inlet is opened on the bellows. There are two air inlets in this embodiment, and a fluidization groove is arranged above the bellows. A feeding hopper is provided on one side of the fluidization tank, and a discharging pipe is provided on the other side of the fluidization tank. An upper cover is arranged above the fluidization tank, and an air outlet is opened on the upper part of the upper cover. There are two air outlets in this embodiment, and a vibration motor is arranged at the lower part of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com