Method and device for producing granulated sugar and refined sugar by membrane method

A production method and technology for refining sugar, which is applied in sucrose production, sugar production, sugar juice purification, etc., can solve problems such as single industrial operation mode, weak ability to resist market risks, and failure to satisfy consumers, etc., and achieve a solution Effects of sugar safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

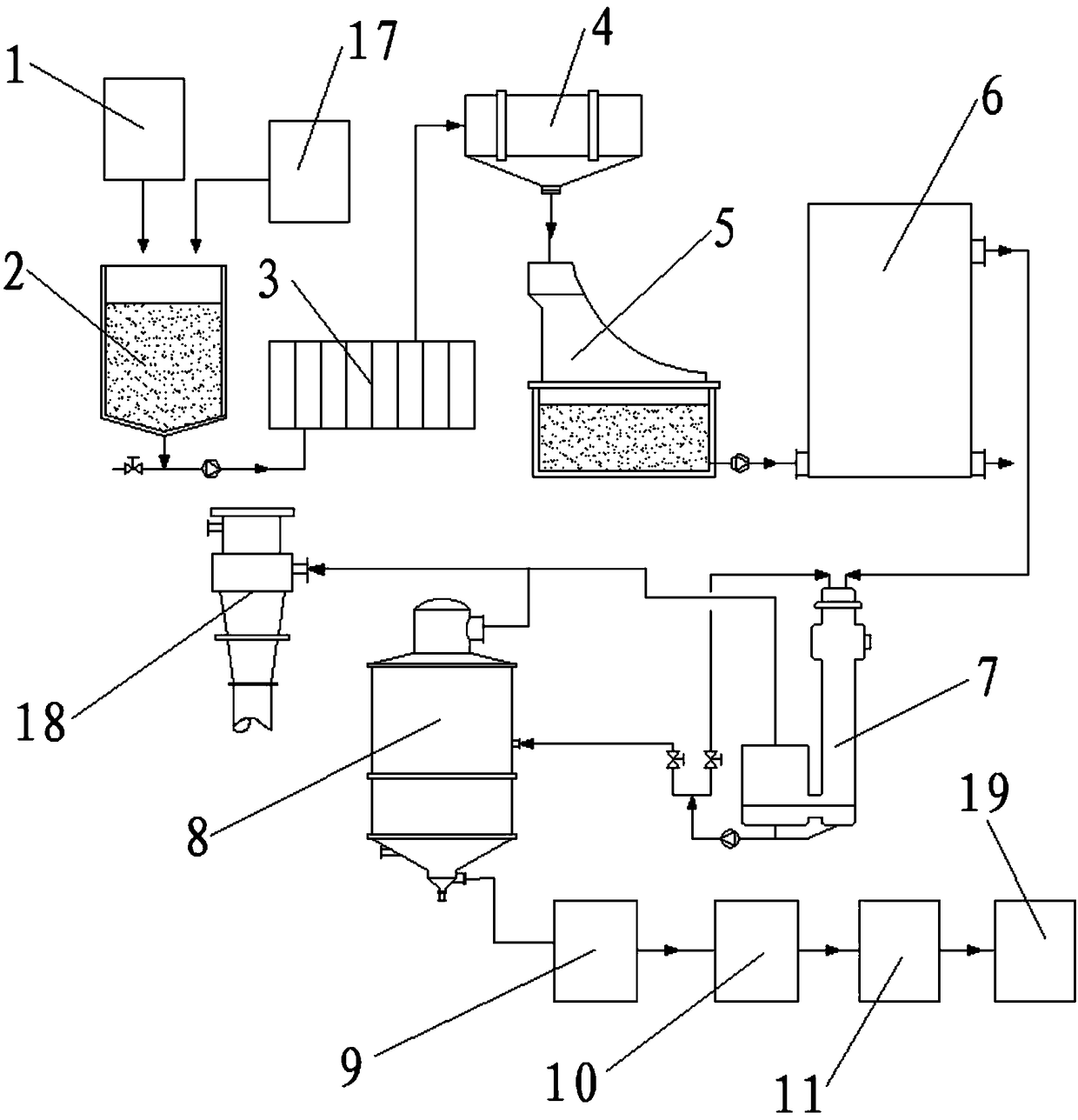

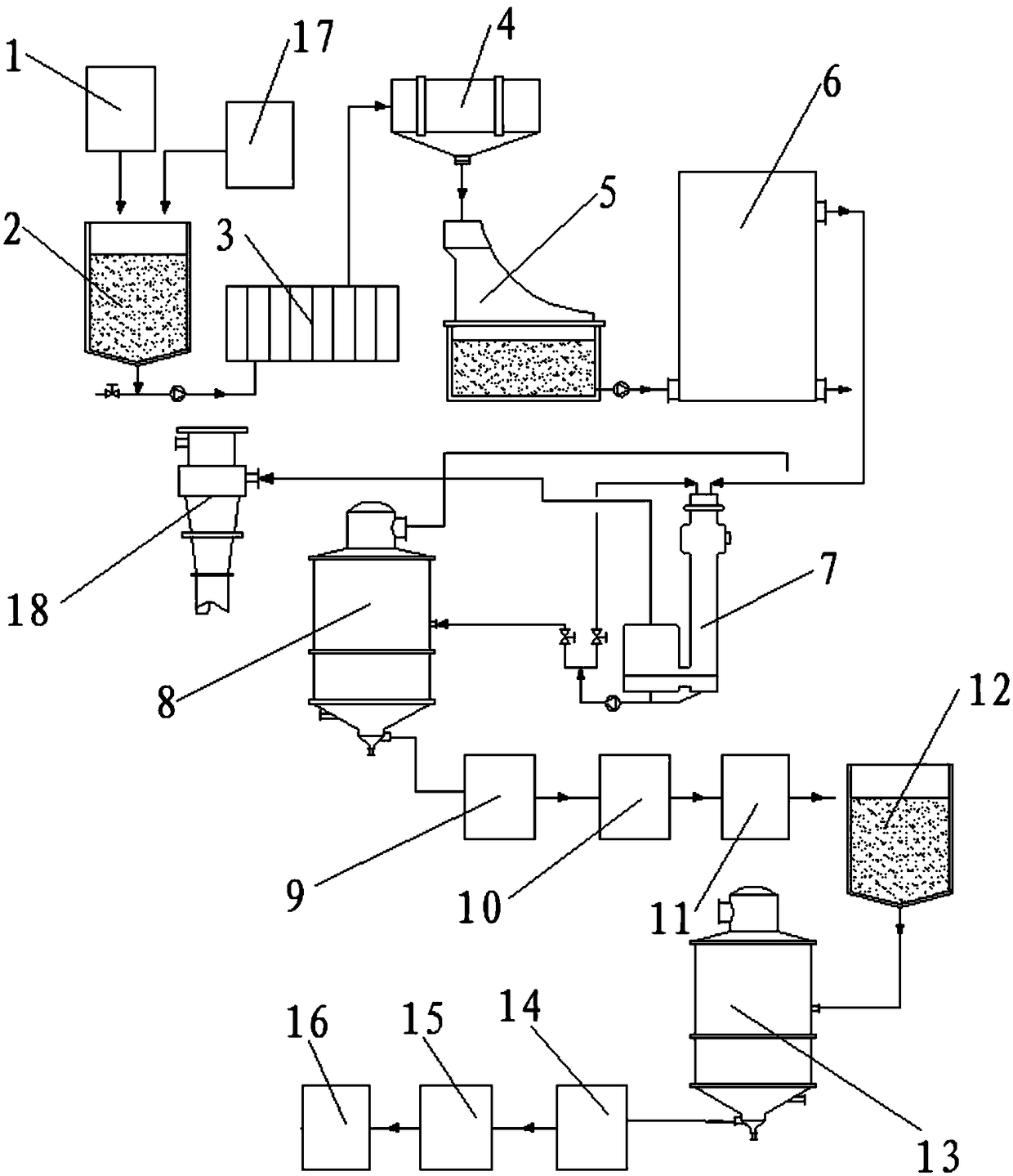

Image

Examples

Embodiment 1

[0030] A method for membrane production of granulated sugar and refined sugar, comprising the following steps:

[0031] (1) Liming: add lime milk to the sugarcane mixed juice to adjust the pH to 7.4, prevent the sucrose in the sugarcane juice from being converted and lost under slightly acidic conditions, and obtain the limed sugarcane juice;

[0032] (2) Heating: heating the ash-added sugarcane juice to 95°C to obtain heated sugarcane juice;

[0033] (3) Coarse filtration: the heated sugarcane juice is successively filtered through a 40-order linear sieve and an 80-order curved sieve to obtain coarsely filtered sugarcane juice;

[0034] (4) Inorganic membrane ultrafiltration: after the coarsely filtered sugarcane juice is ultrafiltered through an inorganic membrane with a pore size of 0.02 μm, clarified sugarcane juice is obtained;

[0035] (5) Evaporation and concentration: the sugarcane clarified juice is evaporated and concentrated to 60°Brix to obtain syrup;

[0036] (6...

Embodiment 2

[0039] A method for membrane production of granulated sugar and refined sugar, comprising the following steps:

[0040] (1) Liming: add lime milk to the sugarcane mixed juice to adjust the pH to 7.6, prevent the sucrose in the sugarcane juice from being converted and lost under slightly acidic conditions, and obtain limed sugarcane juice;

[0041] (2) Heating: heating the ash-added sugarcane juice to 100°C to obtain heated sugarcane juice;

[0042] (3) coarse filtration: the heated sugarcane juice is successively filtered through a 60-order linear sieve and a 100-order curved sieve to obtain coarsely filtered sugarcane juice;

[0043] (4) Inorganic membrane ultrafiltration: after the coarsely filtered sugarcane juice is ultrafiltered through an inorganic membrane with a pore size of 0.2 μm, clarified sugarcane juice is obtained;

[0044] (5) Evaporation and concentration: the sugarcane clarified juice is evaporated and concentrated to 65°Brix to obtain syrup;

[0045] (6) Bo...

Embodiment 3

[0049] A method for membrane production of granulated sugar and refined sugar, comprising the following steps:

[0050] (1) Liming: add lime milk to the sugarcane mixed juice to adjust the pH to 7.5, prevent the sucrose in the sugarcane juice from being converted and lost under slightly acidic conditions, and obtain the limed sugarcane juice;

[0051] (2) Heating: heating the ash-added sugarcane juice to 98°C to obtain heated sugarcane juice;

[0052] (3) Coarse filtration: the heated sugarcane juice is successively filtered through a 50-order linear sieve and a 90-order curved sieve to obtain coarsely filtered sugarcane juice;

[0053] (4) Inorganic membrane ultrafiltration: the coarsely filtered sugarcane juice is obtained after the inorganic membrane ultrafiltration with a pore size of 0.01 μm to obtain clarified sugarcane juice;

[0054] (5) Evaporation and concentration: sugarcane clarified juice is evaporated and concentrated to 62°Brix to obtain syrup;

[0055] (6) Boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com