Drying device of multicrystal rock sugar

A polycrystalline rock sugar and drying device technology, which is applied in drying, drying machines, sugar drying, etc., can solve the problems of slow drying speed, uneven drying, and single function of rock sugar, so as to reduce the burden and improve the drying effect , Improve the effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

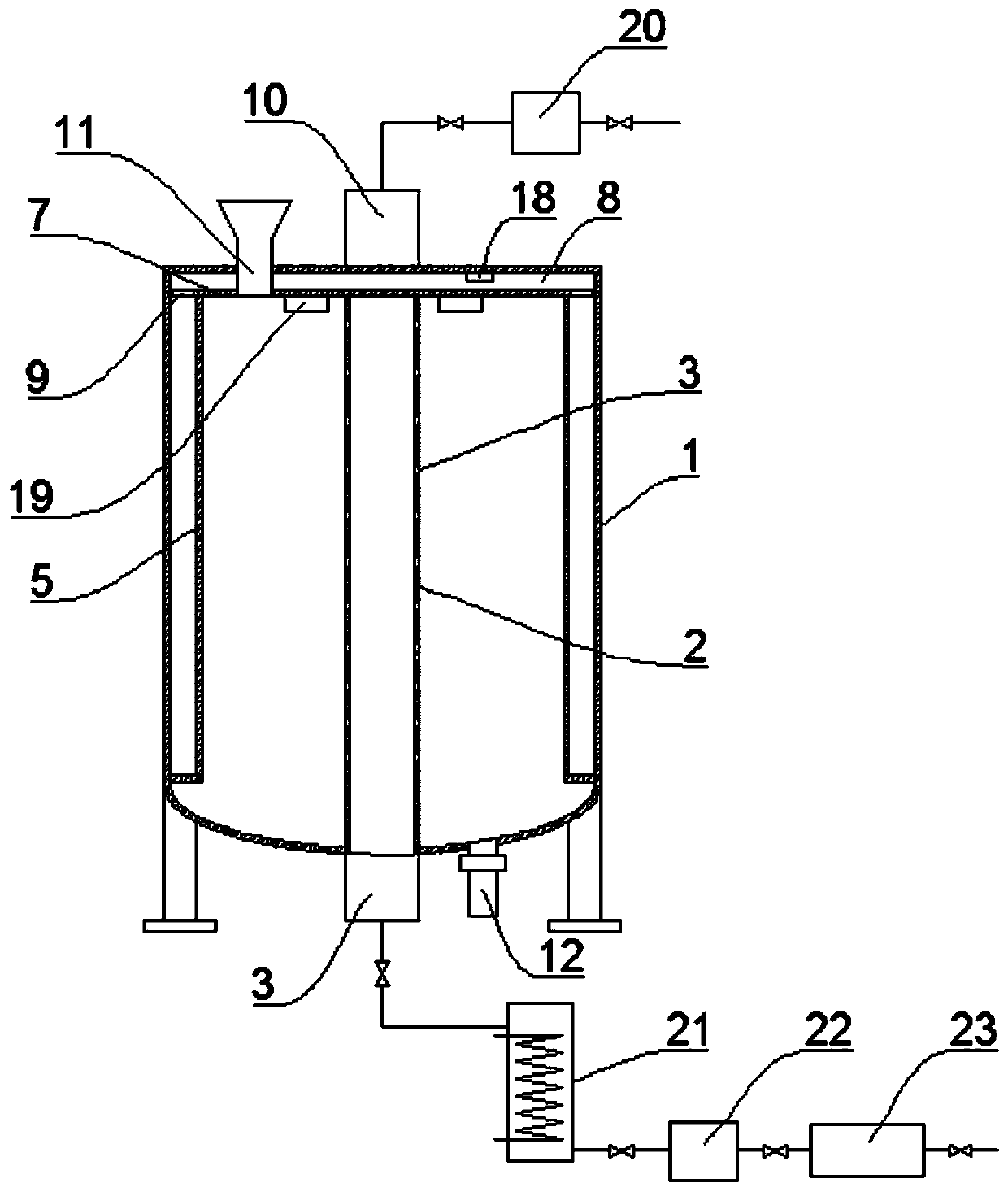

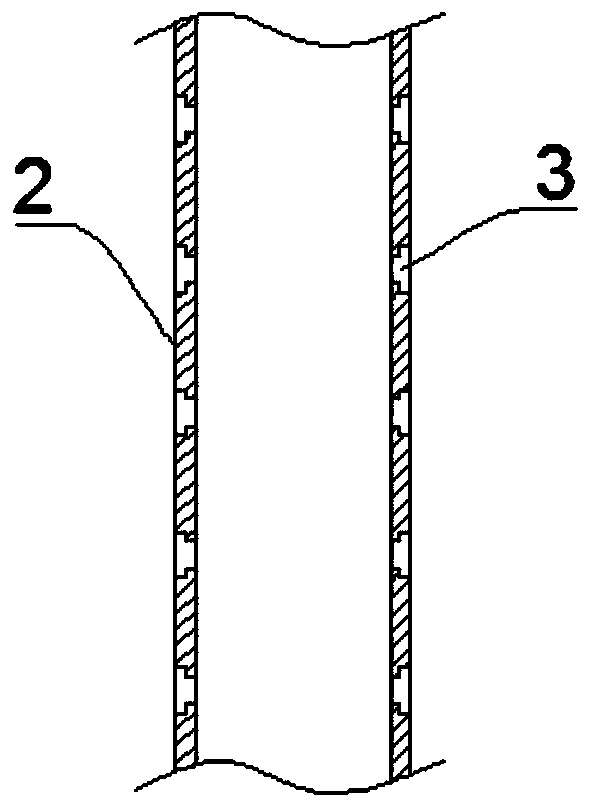

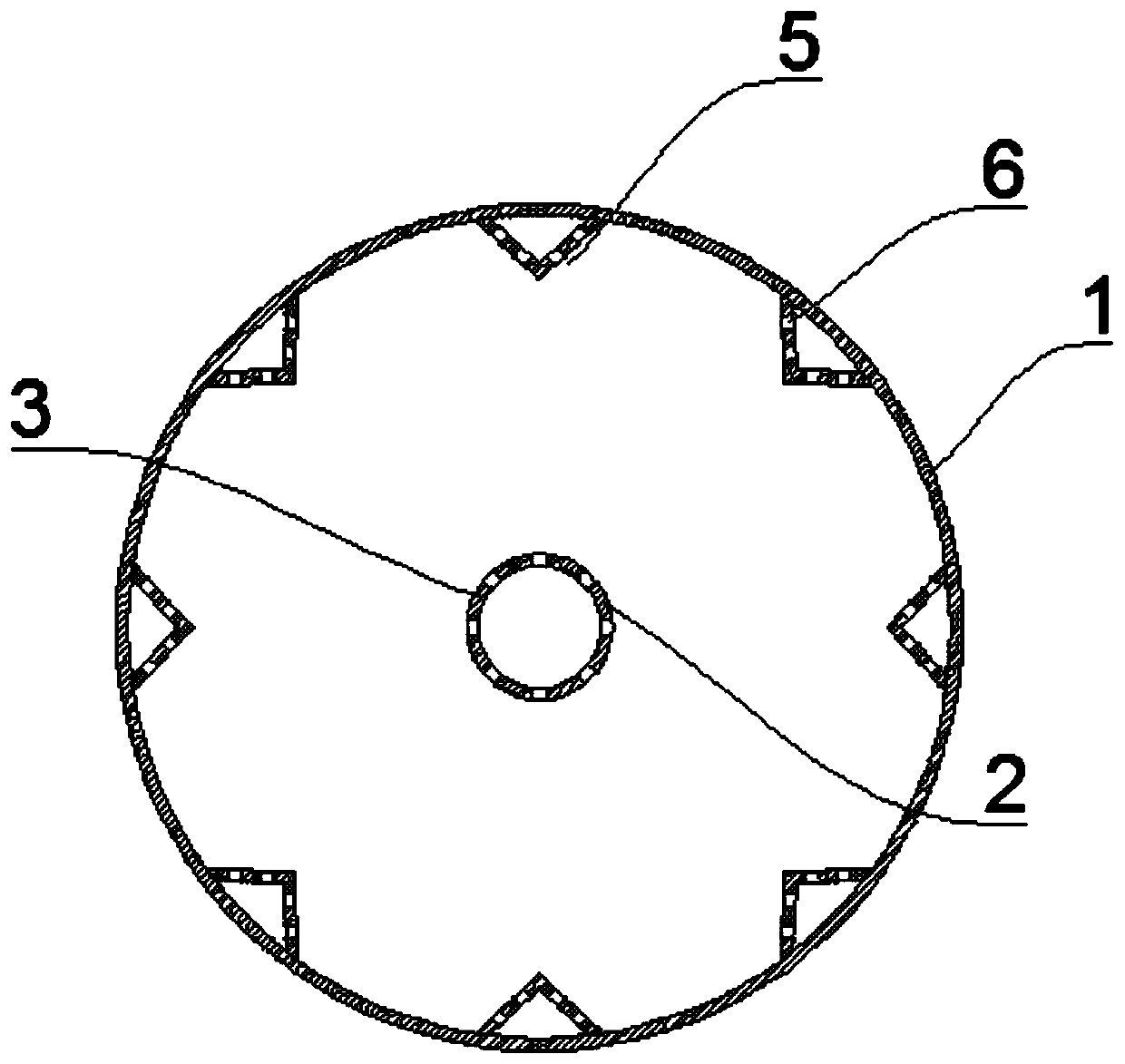

[0024] like Figure 1 to Figure 4 As shown, a drying device for polycrystalline rock sugar includes a drying cylinder 1, an inner cylinder 2 is arranged inside the drying cylinder 1, and the axis of the inner cylinder 2 coincides with the axis of the drying cylinder 1 , the side wall of the inner cylinder 2 is provided with a number of first through holes 3, the first through holes 3 are stepped holes with a convex cross section, and the distribution density of the first through holes 3 is along the axial direction of the inner cylinder 2. It gradually decreases from bottom to top, and an air inlet pipe 4 communicating with the inner cylinder 2 is also provided at the bottom of the drying cylinder 1 .

[0025] The inner wall of the drying cylinder 1 around the inner cylinder 2 is provided with a number of outlet cylinders 5, the cross section of the outlet cylinder 5 is angled or arc-shaped, the side wall of the outlet cylinder 5 is provided with a second through hole 6, and t...

Embodiment 2

[0029] like Figure 5 As shown, a drying device for polycrystalline rock sugar, on the basis of Embodiment 1, the inside of the drying cylinder 1 is also provided with a lower partition 13, the lower partition 13 is located below the outlet tube 5, and the lower partition 13 is There are several filter holes 14, the upper partition 7 and the lower partition 13 form a drying chamber 15, the lower partition 13 and the bottom wall of the drying cylinder 1 form a drainage chamber 16, the discharge pipe 12 and the drying chamber 15 In communication, the bottom of the drying cylinder 1 is also provided with a drain pipe 17 , and the drain pipe 17 communicates with the drain chamber 16 .

[0030] The present embodiment is also provided with a lower dividing plate 13, and the lower dividing plate 13 is provided with a filter hole 14. Before utilizing the hot air to dry the rock sugar, part of the water can be allowed to flow into the drainage cavity 16 by standing still, and then be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com