Sugar-free brown sugar preparation method for removing saccharose in brown sugar by nanofiltration and application thereof

A brown sugar and nanofiltration technology, applied in the field of medicine, can solve problems such as difficulty in brown sugar, and achieve the effects of maintaining the taste, preventing the rise of blood sugar, and maintaining the curative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

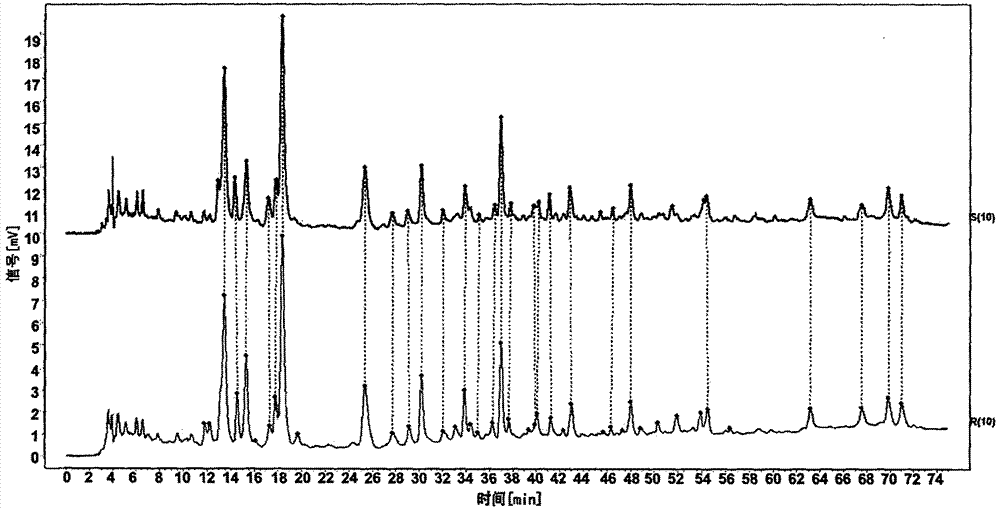

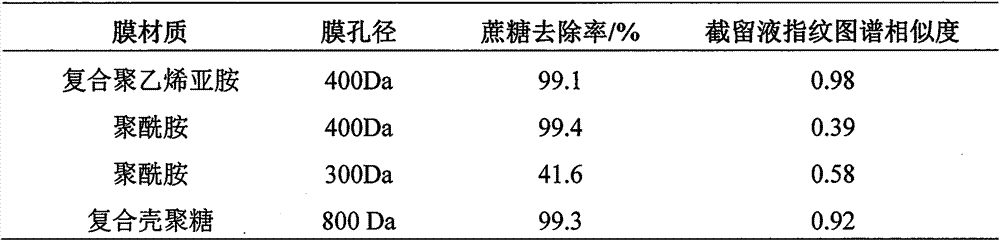

[0018] Embodiment 1: the influence of nanofiltration membrane material on the removal rate of sucrose in brown sugar

[0019] 1. Materials and Methods

[0020] 1) 400Da nanofiltration membrane material: composite polyethyleneimine, polyamide

[0021] 300Da Nanofiltration Membrane Material: Polyamide

[0022] 800Da Nanofiltration Membrane Material: Composite Chitosan

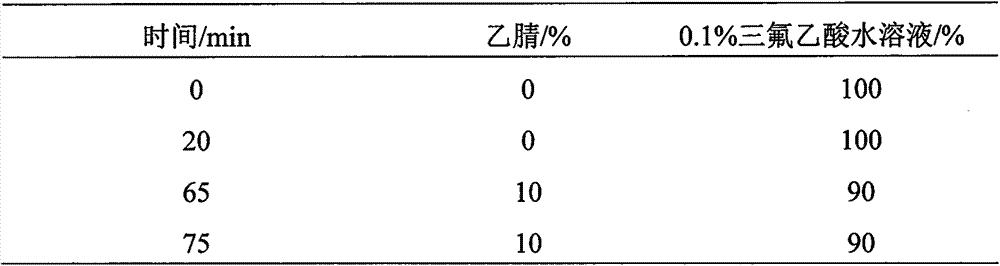

[0023] 2) Take 3.0kg of brown sugar, dissolve it in purified water to 15L, and filter it with a 0.45μm microporous membrane. The filtrate is divided into three parts of about 5L each, and the nanofiltration materials made of composite polyethyleneimine, cellulose, and composite polyamide are used respectively. Membrane desugaring, operating pressure 1.0Mpa, operating at room temperature, collecting nanofiltration concentrate and when the volume of the concentrate reaches 1L, make up the volume to 5L, repeat the operation 3 times, and when the concentrate is enriched to a specific gravity of 1.05-1.10, respectiv...

Embodiment 2

[0027] Embodiment 2: the preparation of sugar-free brown sugar

[0028] Take 2.0kg of brown sugar thick paste boiled after sugarcane pressing and clarification, dissolve in purified water to 5L, and filter through a 0.45 μm microporous membrane. Sugar, operating pressure 1.0 Mpa, operating at room temperature, collecting the nanofiltration concentrate and when the volume of the concentrate reaches 1L, make up the volume to 5L, repeat the operation 3 times, and when the concentrate is enriched to a specific gravity of 1.05-1.10, add 0.95kg wood The sugar alcohol is crystallized, stirred evenly, dried and crystallized at a low temperature of 40°C, and sugar-free brown sugar is obtained.

Embodiment 3

[0029] Embodiment 3: the preparation of sugar-free brown sugar

[0030] Take 1.0 kg of brown sugar, dissolve it in purified water to 5 L, and filter it through a 0.45 μm microporous membrane. Filter the concentrated solution and when the volume of the concentrated solution reaches 1L, make up the volume to 5L, and repeat the operation 3 times. When the concentrated solution is enriched to a specific gravity of 1.05-1.10, add 0.95kg of xylitol crystals, stir evenly, and dry at a low temperature of 40°C. Crystallize to get sugar-free brown sugar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com