Method and apparatus for manufacture of dry powders

A kind of equipment, powder technology, used in the field of manufacturing dry powder and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

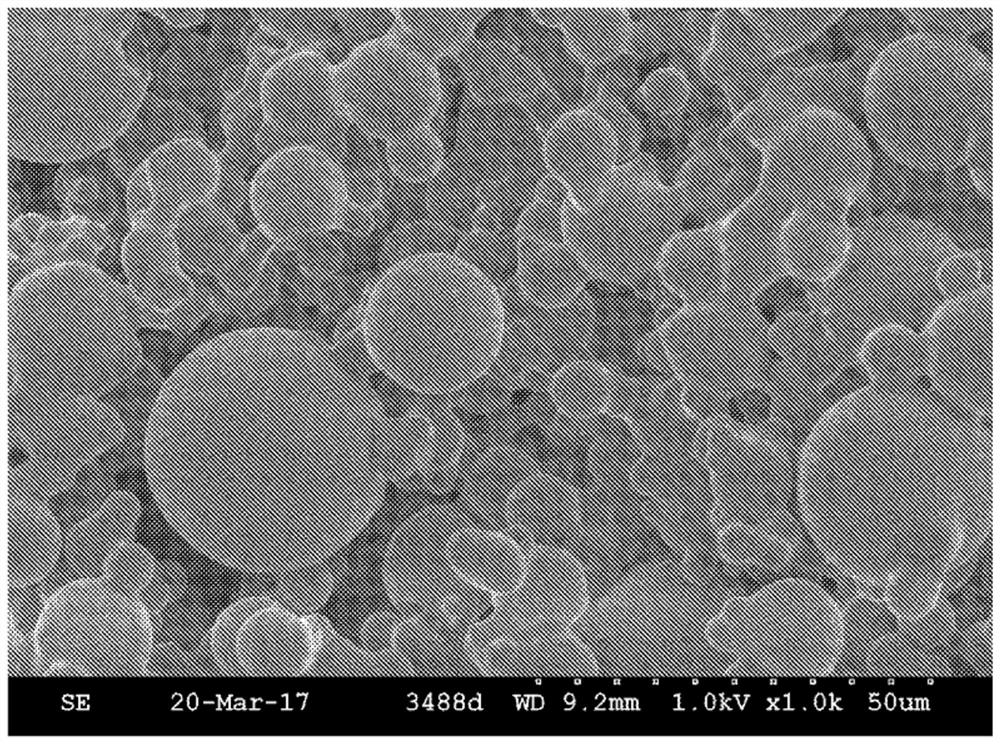

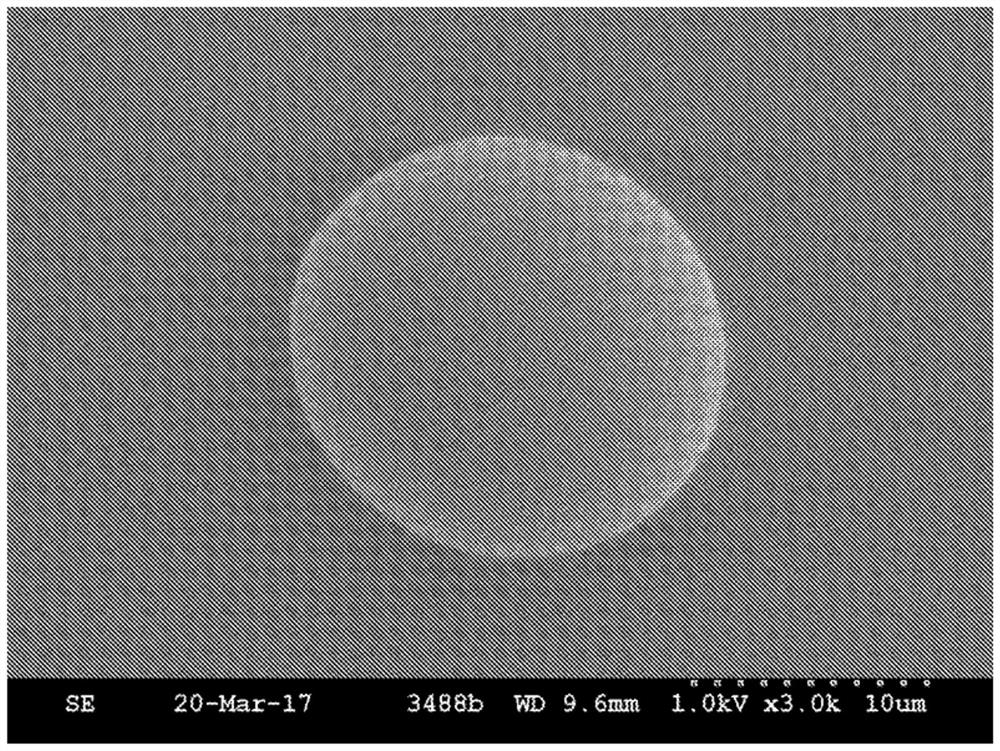

[0047] In the following examples, a homogeneous sugar-enriched product was formed from sugarcane products extracted from sugarcane using the methods described in Australian Provisional Patent Application No. 2017901576 and International Patent Application No. PCT / AU2018 / 050338, which The contents of each of the patent applications are hereby incorporated by reference in their entirety.

[0048] Concentrated sugarcane juice (Description 1 (Version 1))

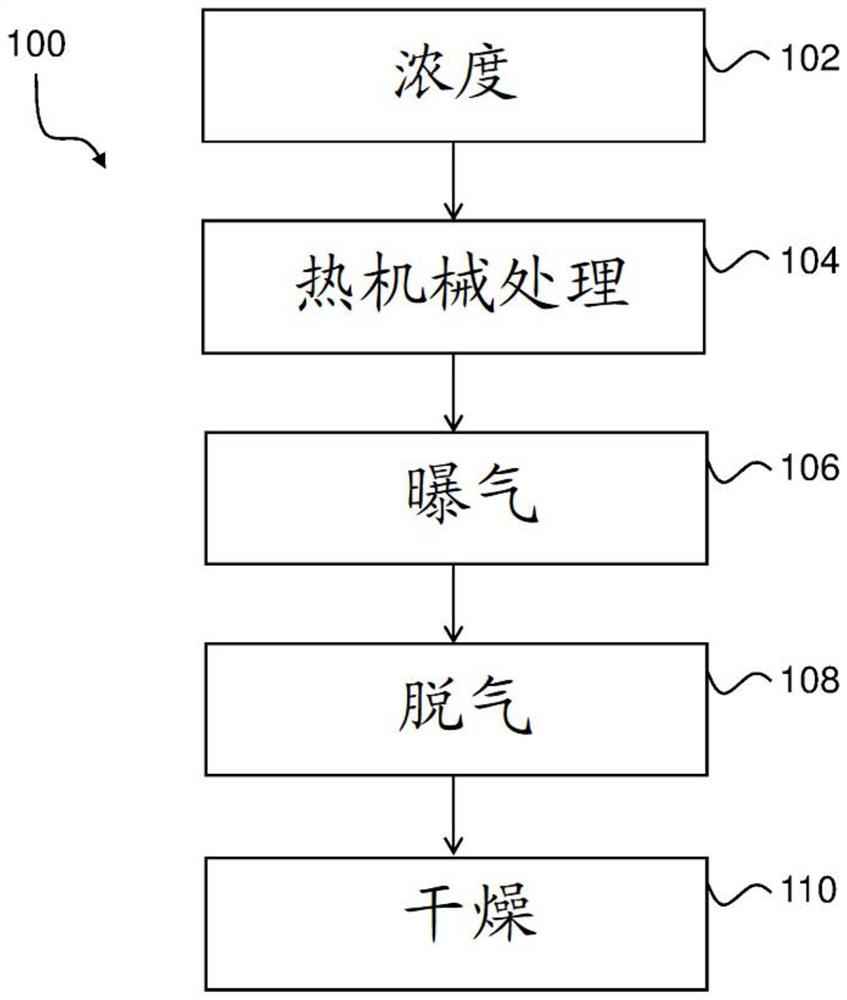

[0049] In the following example, carbon dioxide is passed into the viscous sugarcane solution having a specific gravity of 1.4 after the concentration in step 102 and before the thermomechanical treatment in step 104, so that after aeration in step 106, its specific gravity is reduced to below 0.4 . The processing details of the sugarcane solution are as follows.

[0050] Starting product:

[0051] Total solids (TS) 70%

[0052] Specific gravity: 0.4

[0053] Amount of gas injected:

[0054] Greater than 10nl·kg -1 mn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com