Manual raw material processing device and using method thereof

A processing device and raw material technology, which is applied in the field of manual raw material processing devices, can solve problems such as uneven quality of finished brown sugar powder, affecting the overall quality of finished brown sugar powder, and difficult control of syrup temperature, so as to ensure reliability, prevent loosening, shorten The effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

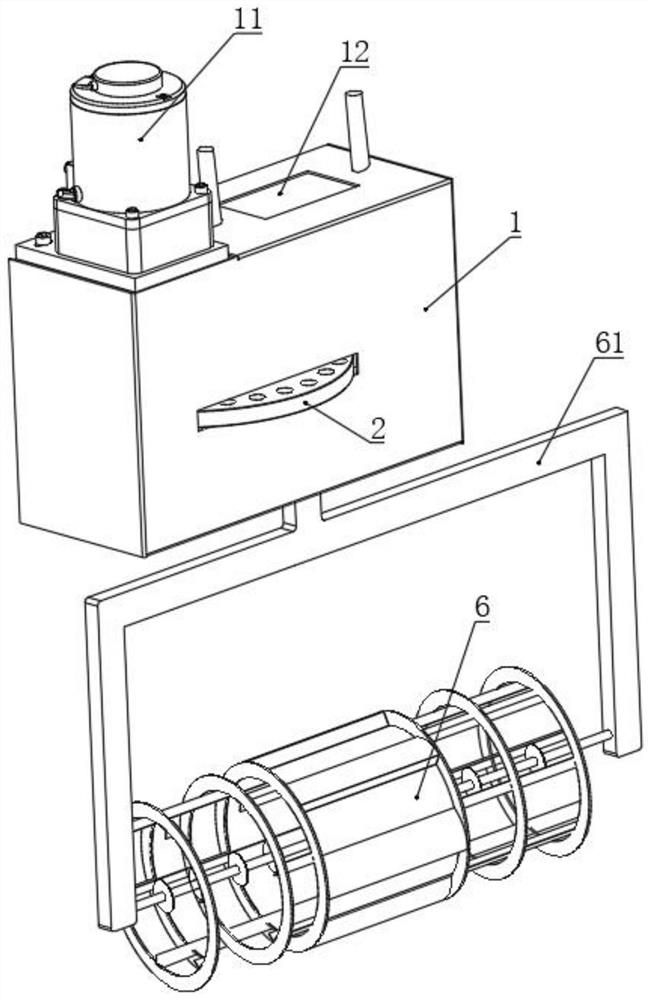

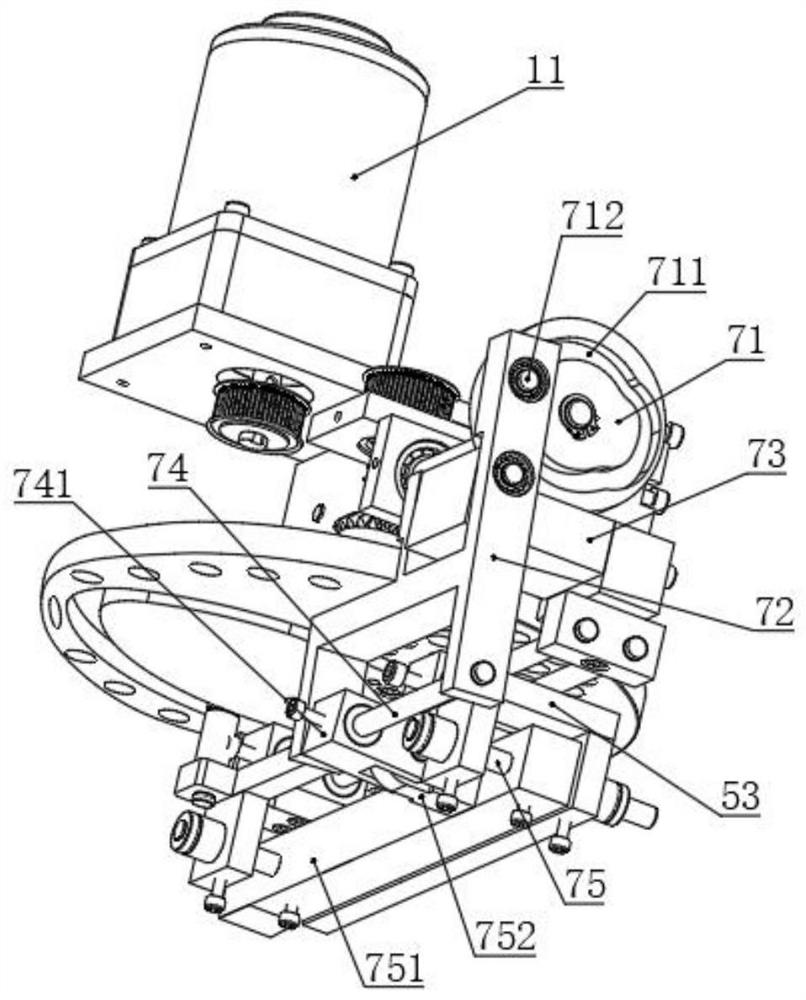

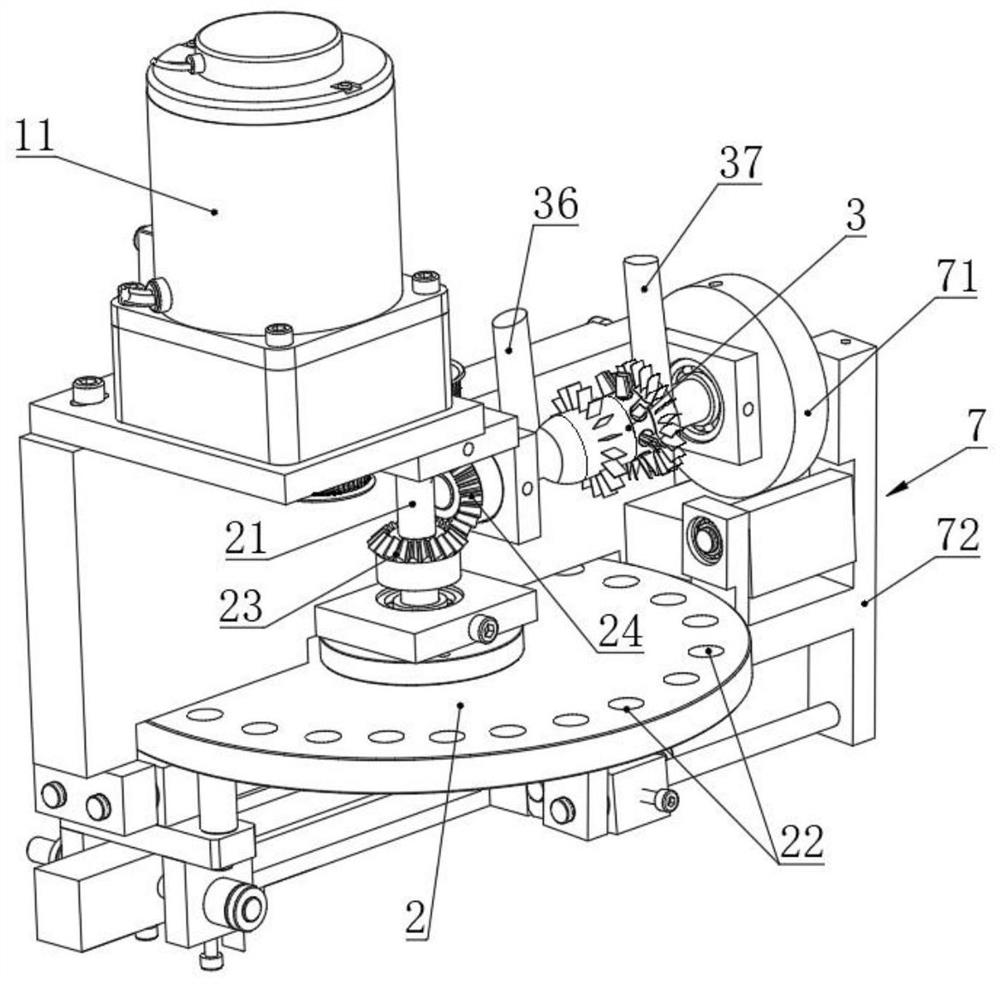

[0078] like Figure 1-11 As shown, a manual raw material processing device includes a housing 1, a drive motor 11 is provided on the housing 1, and a turntable 2 and a cooling fan 3 are also provided inside the housing 1;

[0079] A turntable shaft 21 is arranged in the middle of the turntable 2, and the turntable shaft 21 is connected to the output shaft of the drive motor 11. The turntable 2 is provided with several through holes 22 through the upper and lower surfaces;

[0080] The cooling fan 3 is above the turntable 2, and the rotating shaft 21 of the turntable is also provided with a driving bevel gear 23, the driving bevel gear 23 is gear-connected with a driven bevel gear 24, and the driven bevel gear 24 is connected with the cooling fan 3;

[0081] There is also a feed port 12 on the housing 1, and the feed port 12 is above the cooling fan 3;

[0082] The lower surface of the turntable 2 has a first chute 25, and the inside of the housing 1 is also provided with a fi...

Embodiment 2

[0107] This embodiment is a further improvement of the previous embodiment, such as Figure 1-11 As shown, a manual raw material processing device includes a housing 1, a drive motor 11 is provided on the housing 1, and a turntable 2 and a cooling fan 3 are also provided inside the housing 1;

[0108] A turntable shaft 21 is arranged in the middle of the turntable 2, and the turntable shaft 21 is connected to the output shaft of the drive motor 11. The turntable 2 is provided with several through holes 22 through the upper and lower surfaces;

[0109] The cooling fan 3 is above the turntable 2, and the rotating shaft 21 of the turntable is also provided with a driving bevel gear 23, the driving bevel gear 23 is gear-connected with a driven bevel gear 24, and the driven bevel gear 24 is connected with the cooling fan 3;

[0110] There is also a feed port 12 on the housing 1, and the feed port 12 is above the cooling fan 3;

[0111] The lower surface of the turntable 2 has a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com