Patents

Literature

48results about "Sugarcane shredding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

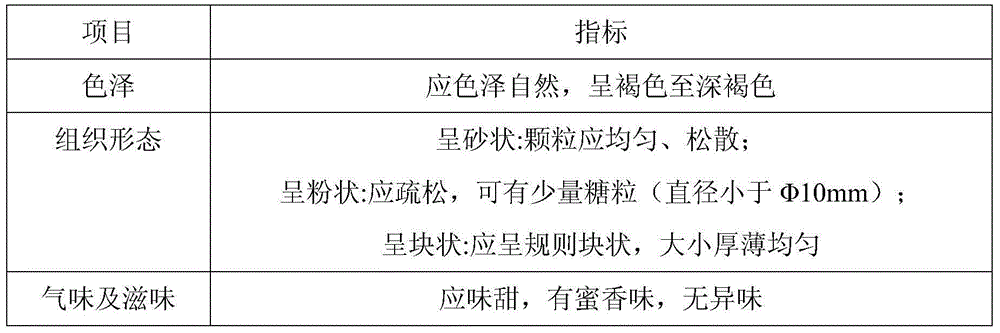

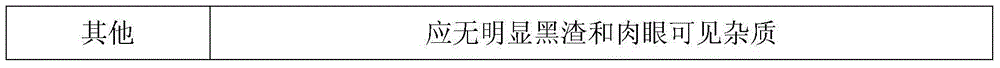

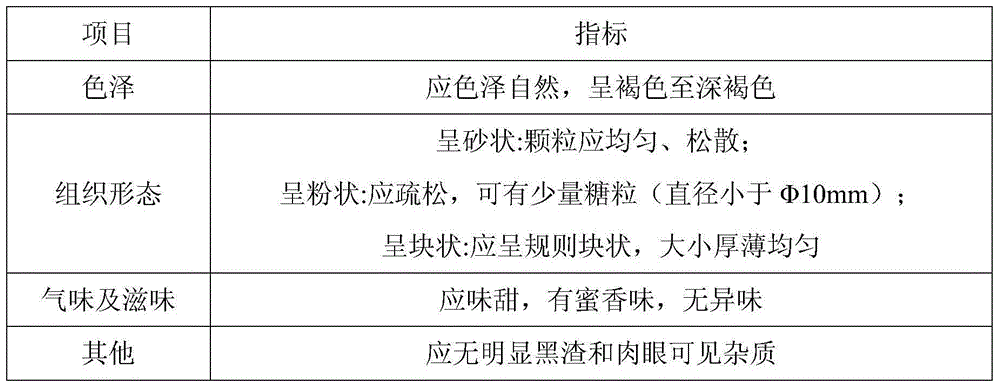

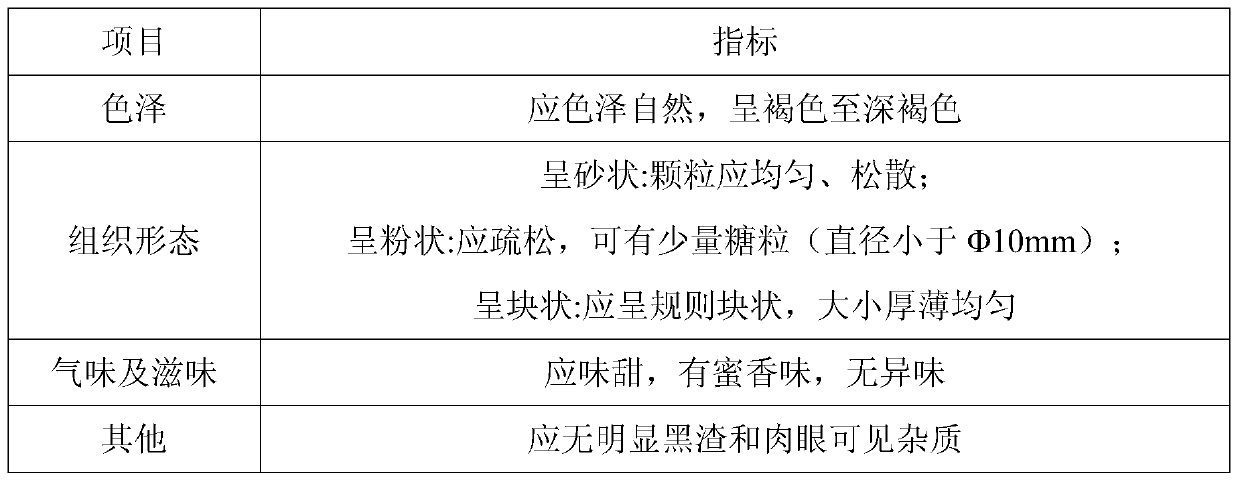

Originally ecological black sugar processing method

ActiveCN104805225ATroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsUltrafiltrationAdditive ingredient

An originally ecological black sugar processing method comprises the following steps: after sugarcane is squeezed for extracting juice, carrying out rough filtration so as to obtain sugarcane juice; heating the sugarcane juice to 90-100 DEG C and keeping heat for 1-3 min so as to obtain heated sugarcane juice; conveying the heated sugarcane juice to a multistage ceramic membrane ultrafiltration device for ultrafiltration clarification so as to obtain clarified sugarcane juice; concentrating the clarified sugarcane juice into syrup; concentrating the syrup through a jacketed iron pot so as to obtain decocted massecuite; graining, cooling and forming so as to obtain originally ecological black sugar. The originally ecological black sugar prepared through the method provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that precipitates occur after the black sugar is dissolved for a long time is solved.

Owner:广西百桂堂食品科技有限公司

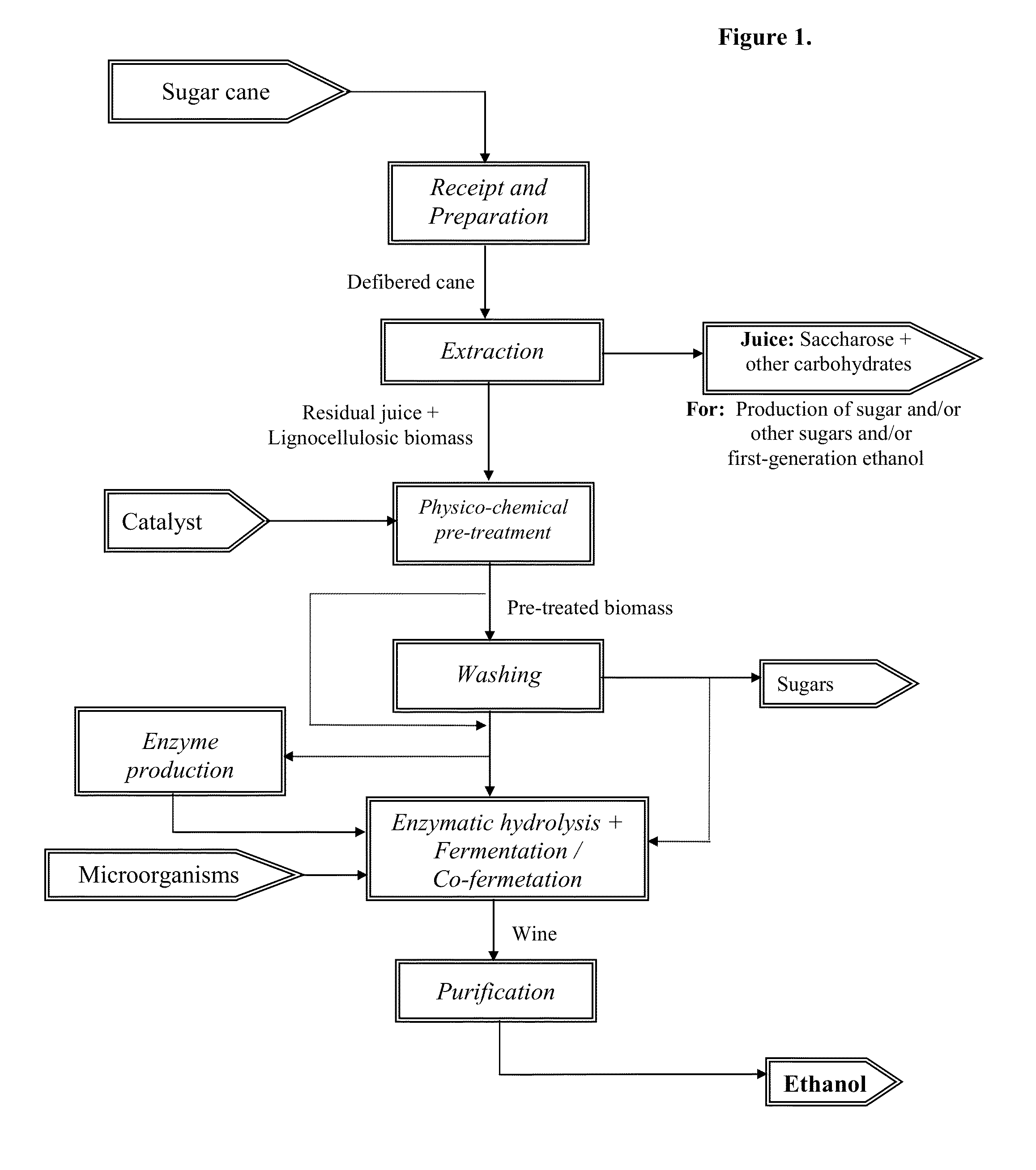

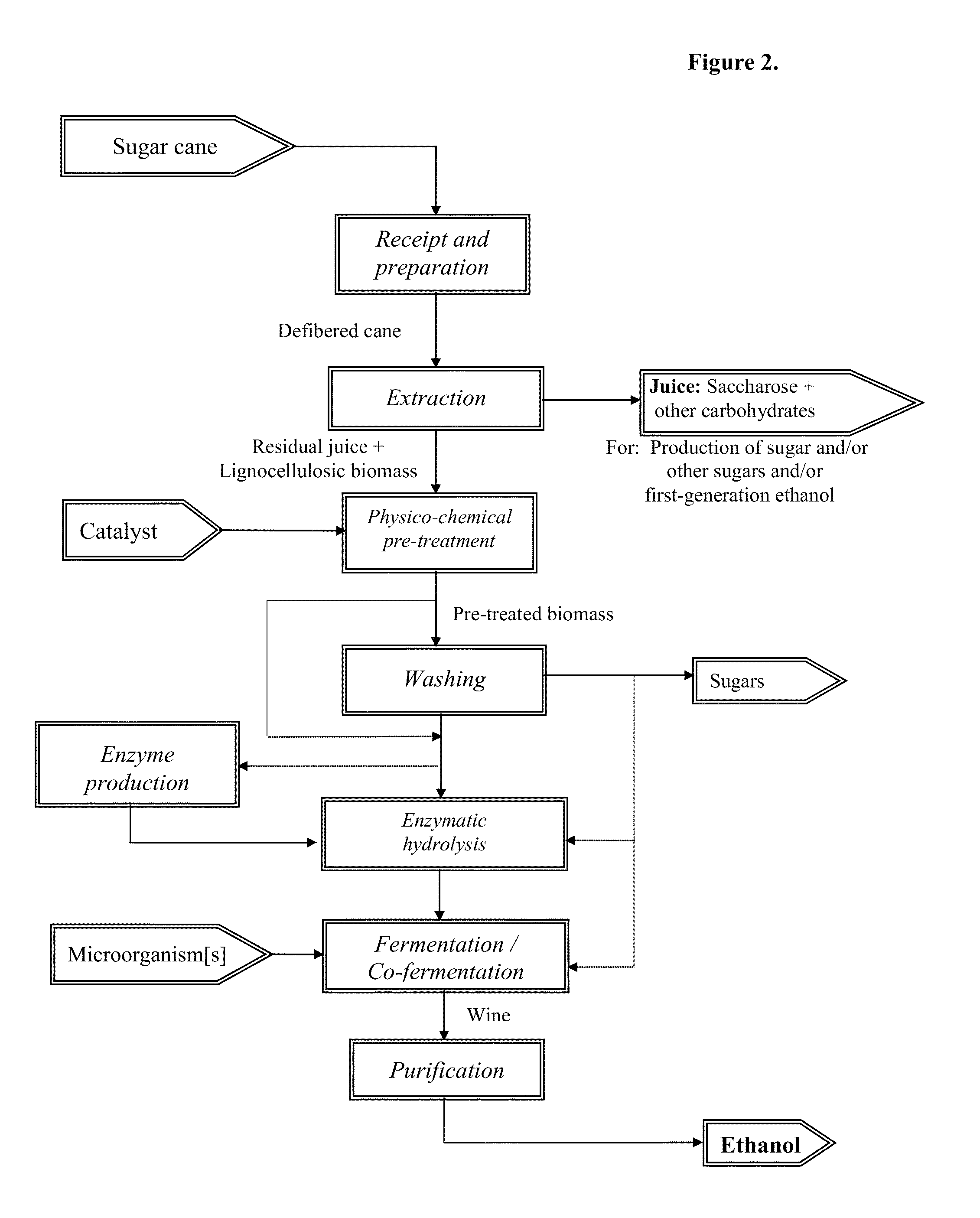

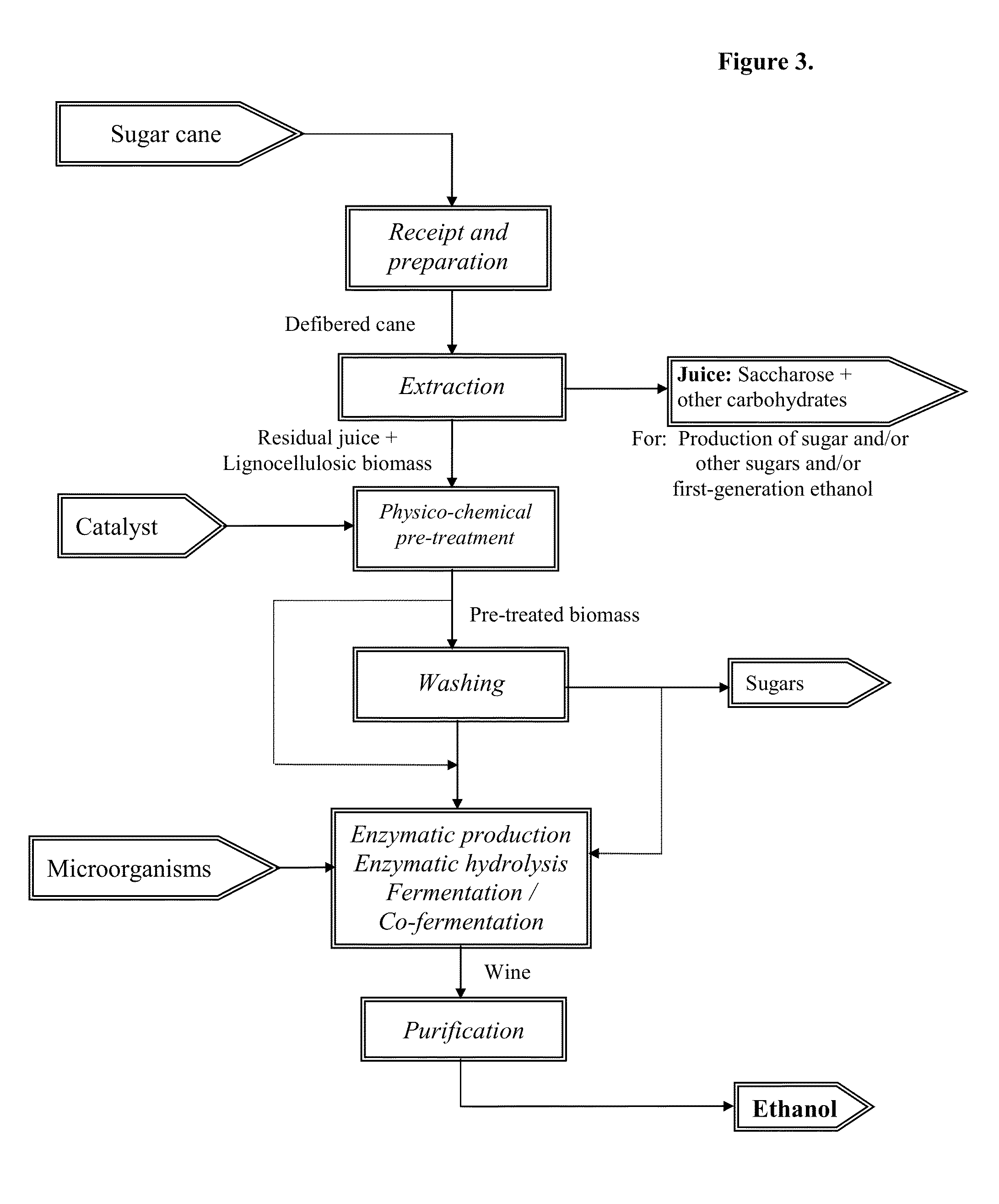

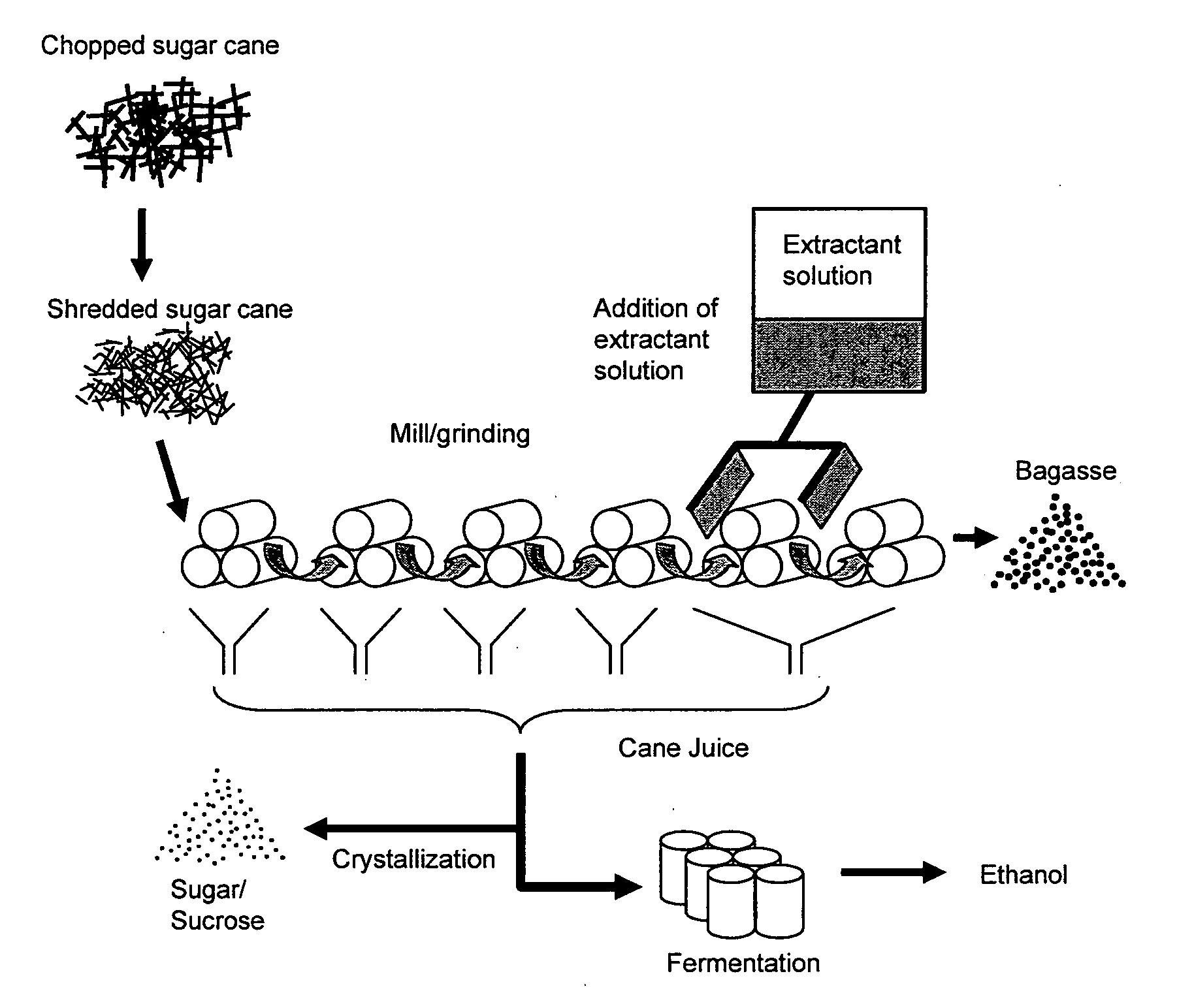

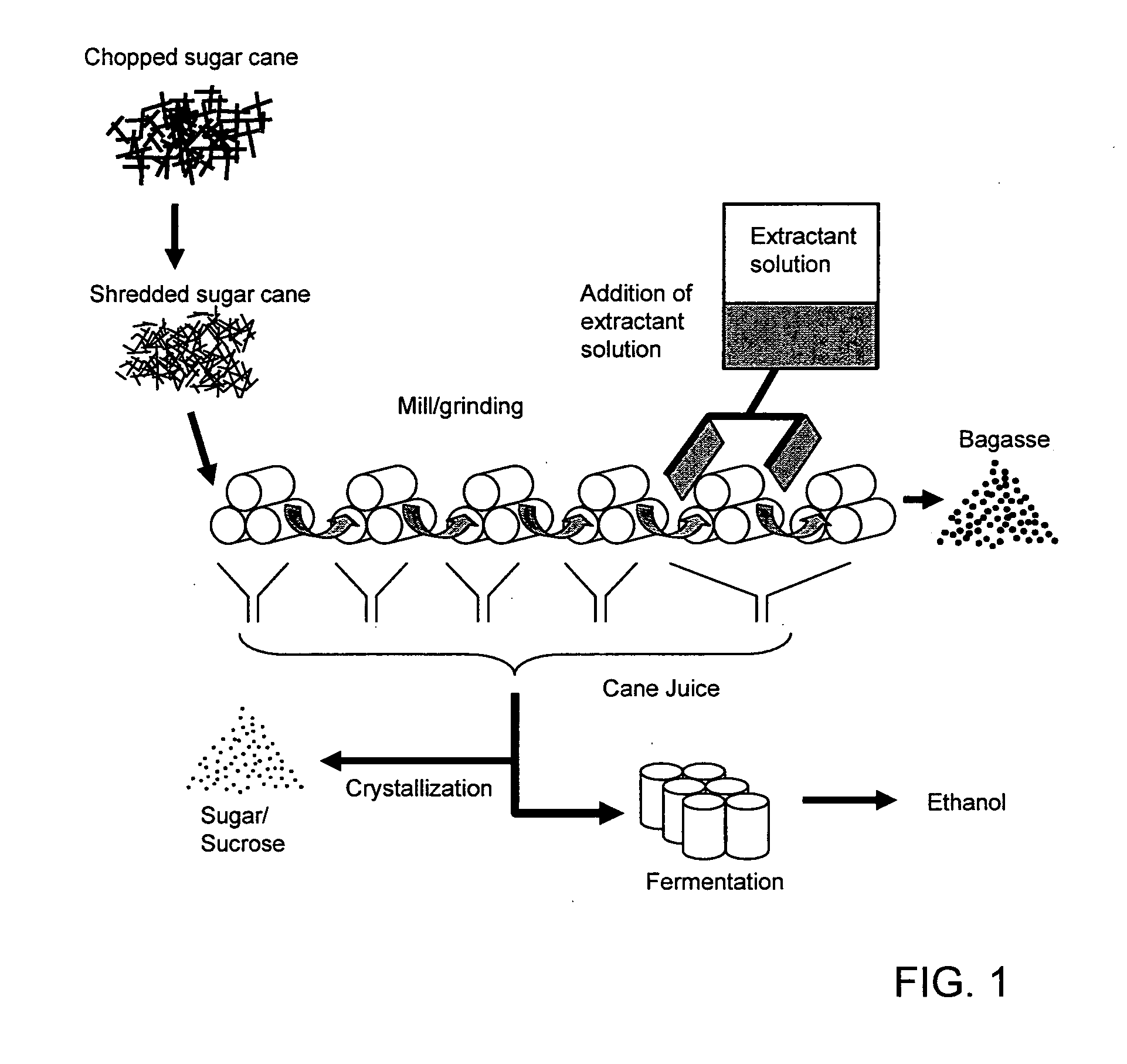

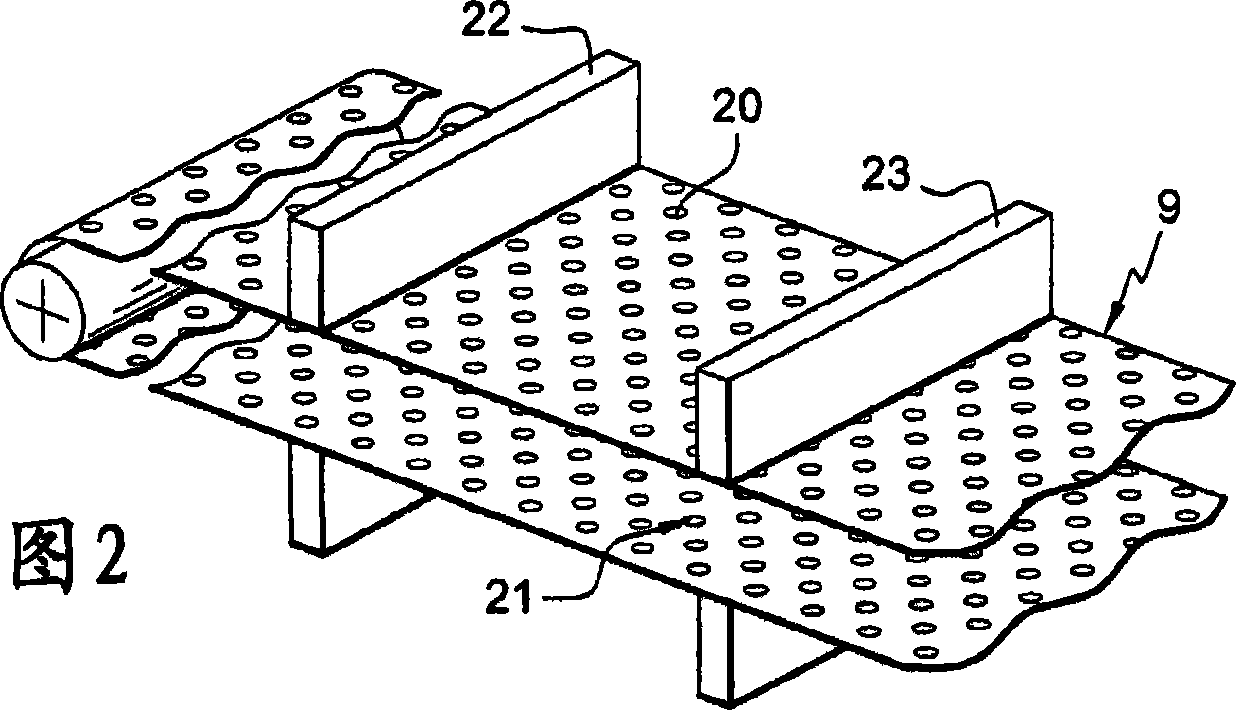

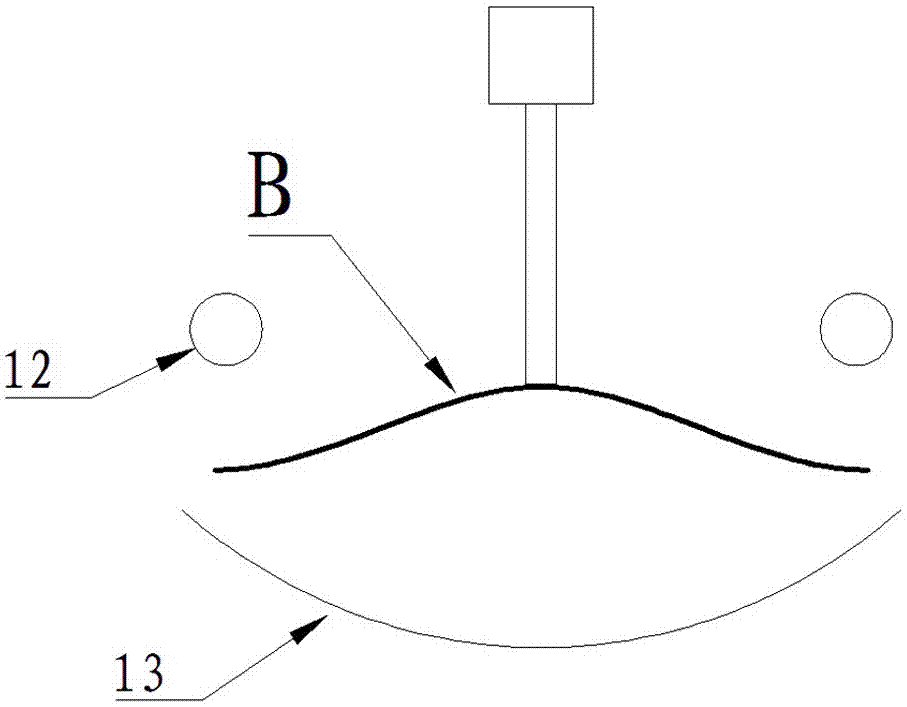

Method for processing vegetable biomass

The present invention relates to an energy-efficient process for the treatment of plant biomass, particularly sugar cane, for the production of carbohydrates and ethanol, using physico-chemical and extraction techniques, as well as very simple milling configurations, thereby minimizing energy consumption during extraction of the cane juice.The biomass treated and obtained through this process, when subjected to a fermentation process for the production of ethanol, increases the yield of the process in comparison with that of traditional sugar cane. It can also be used for the production of enzymes, animal feedstuffs, and other useful products.

Owner:CTC CENT DE TECHA CANAVIEIRA

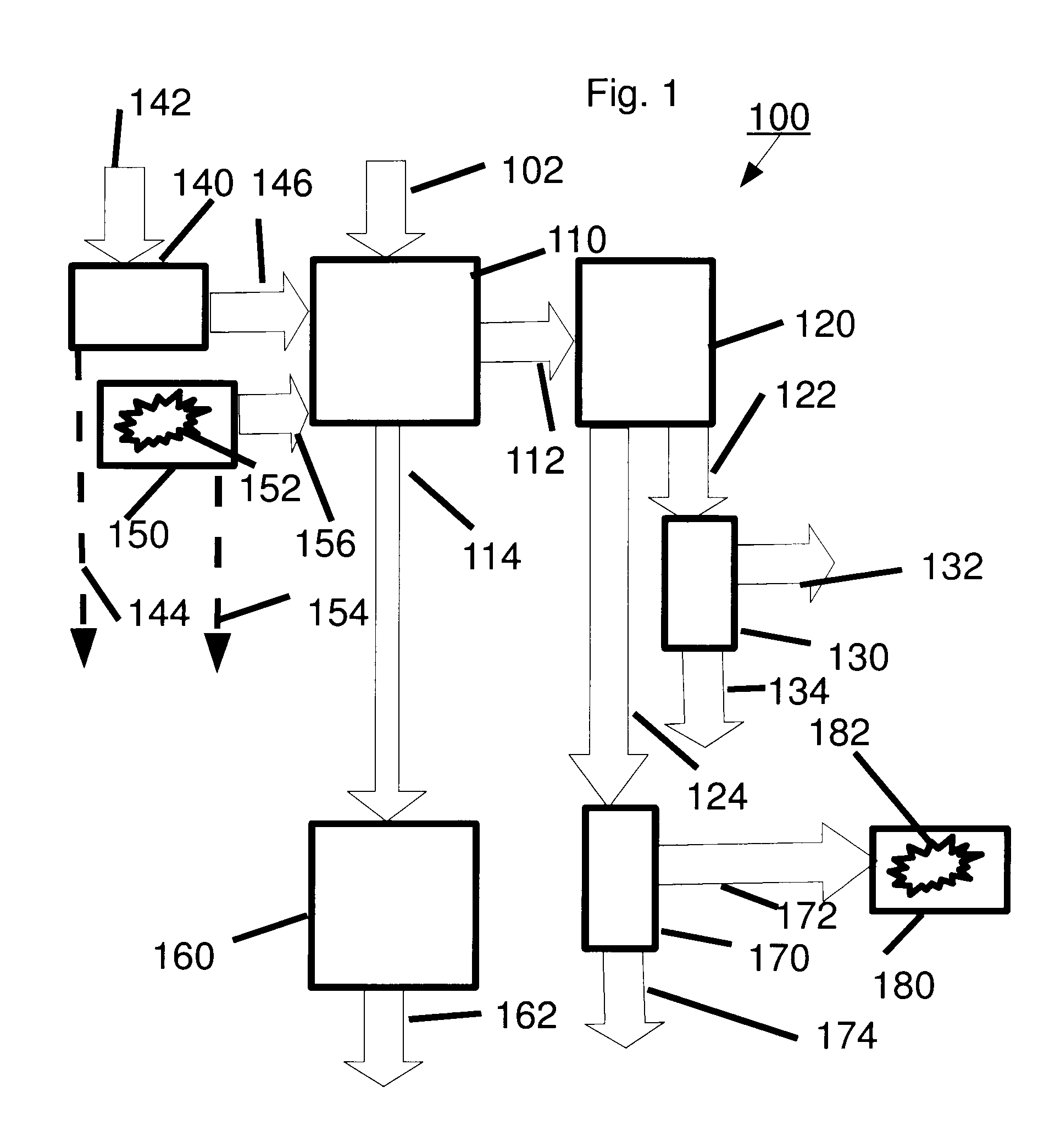

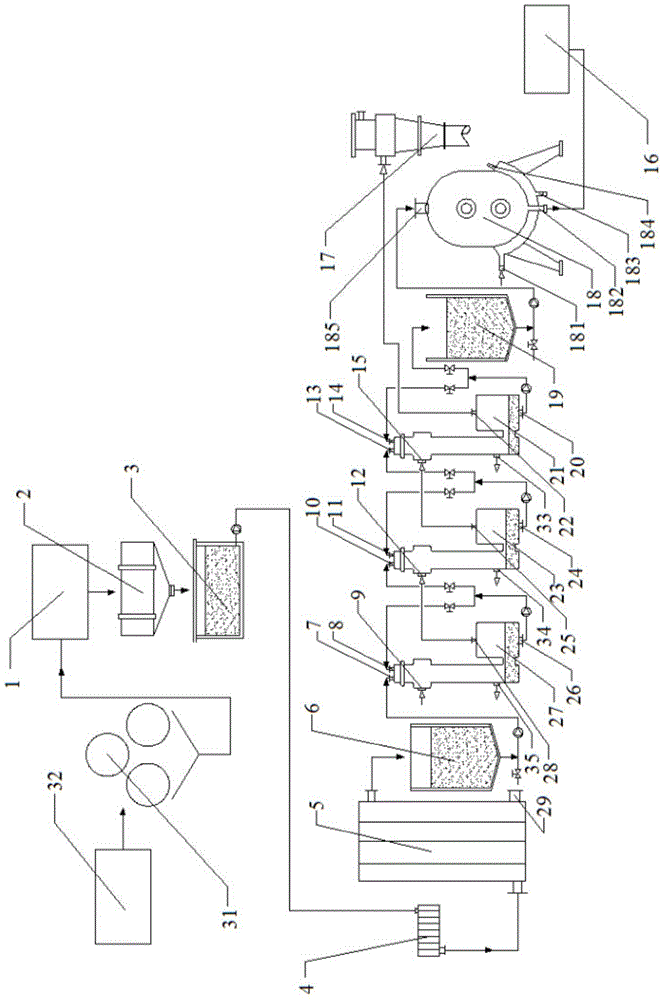

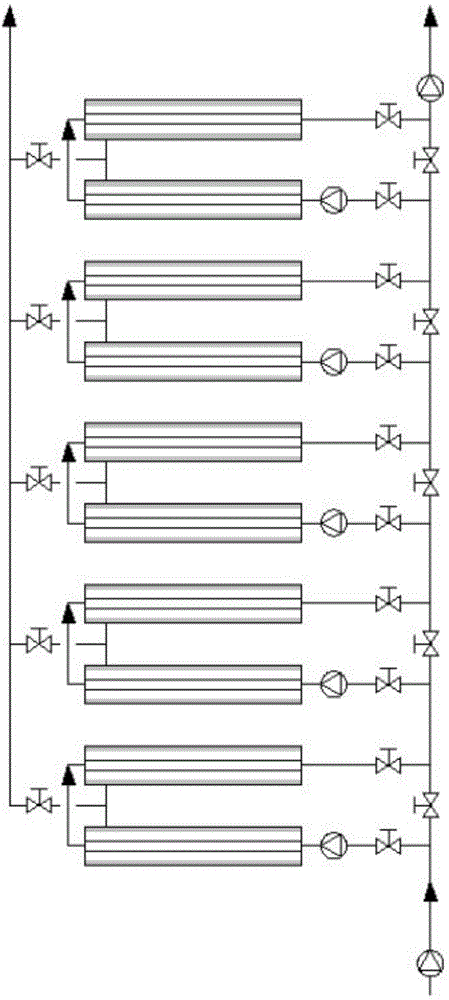

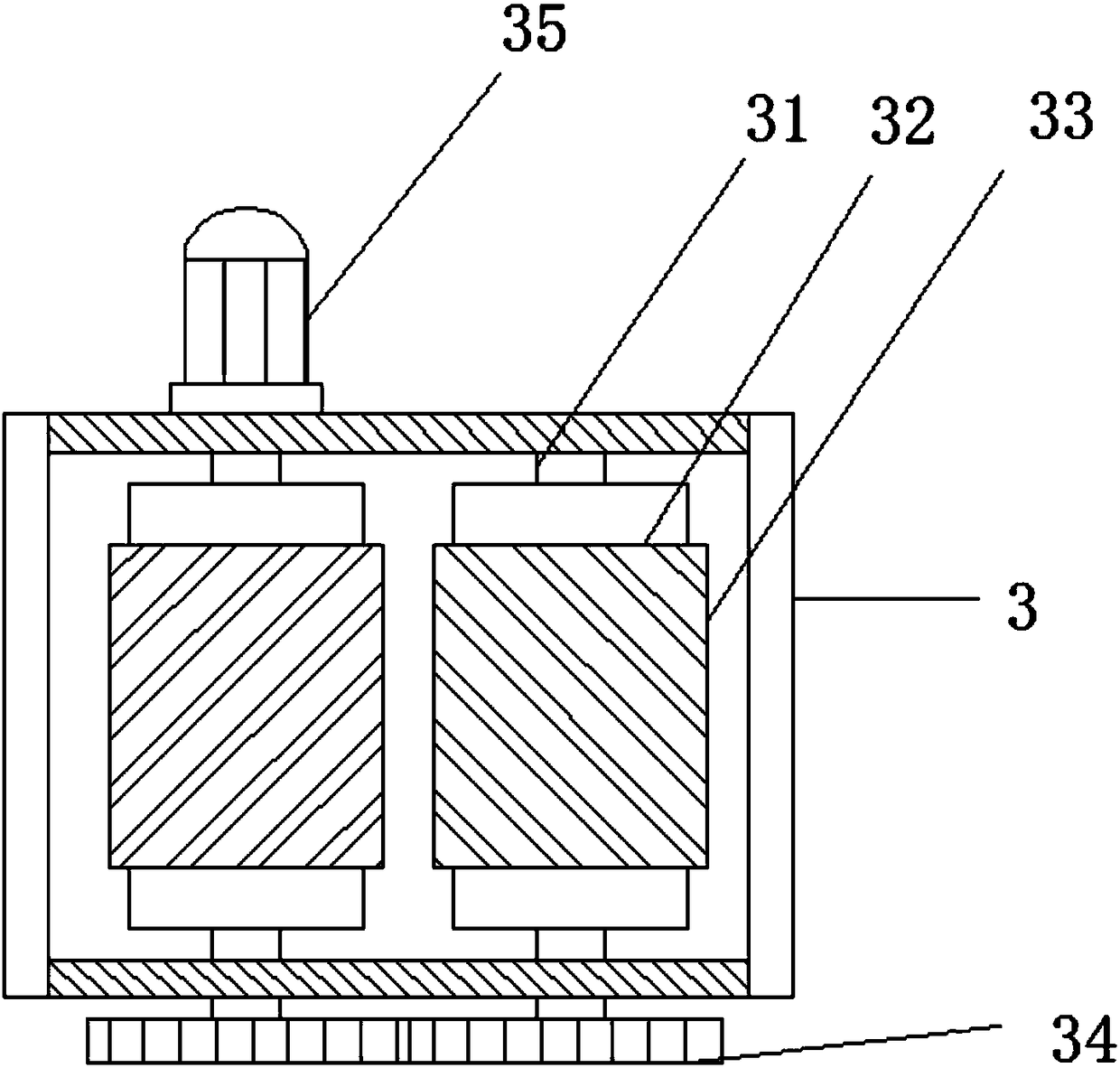

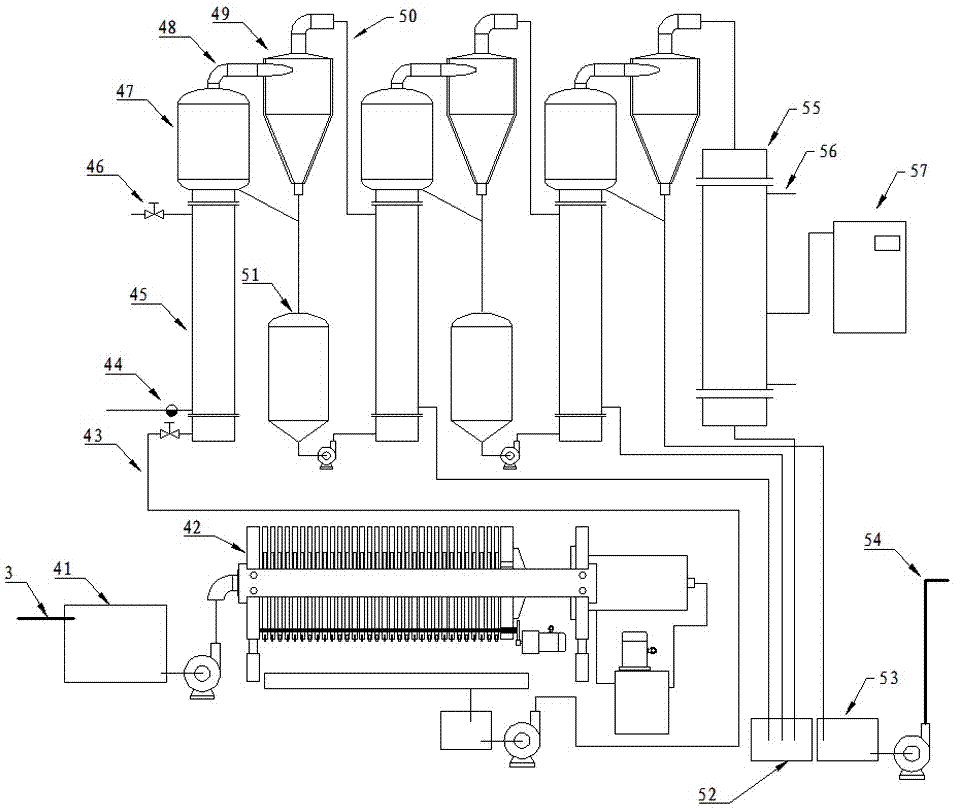

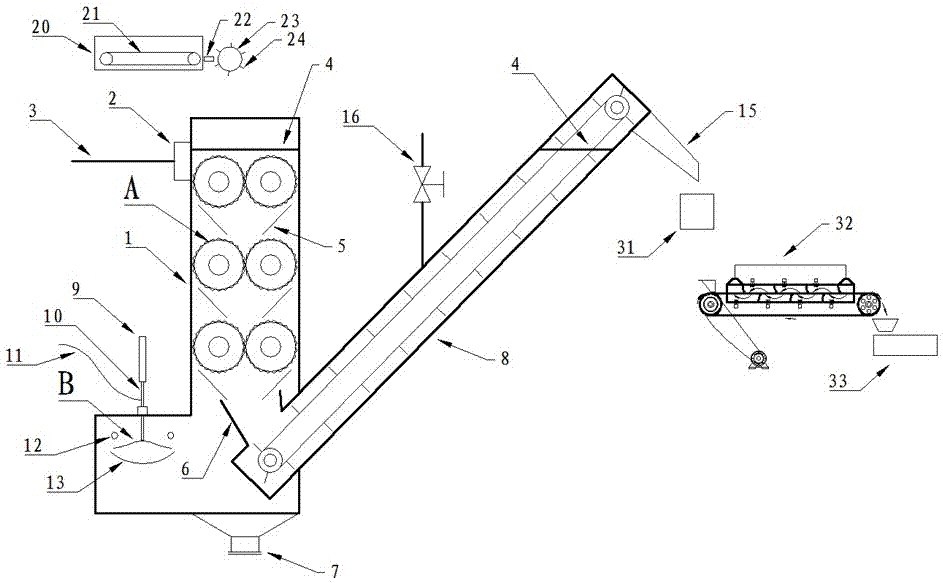

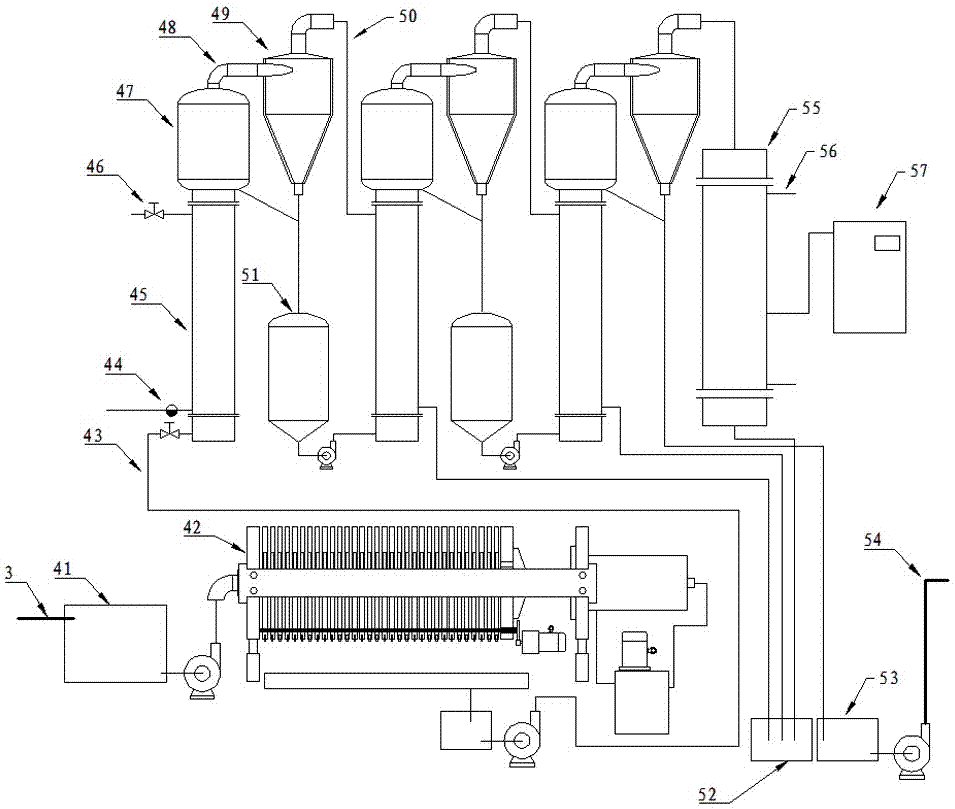

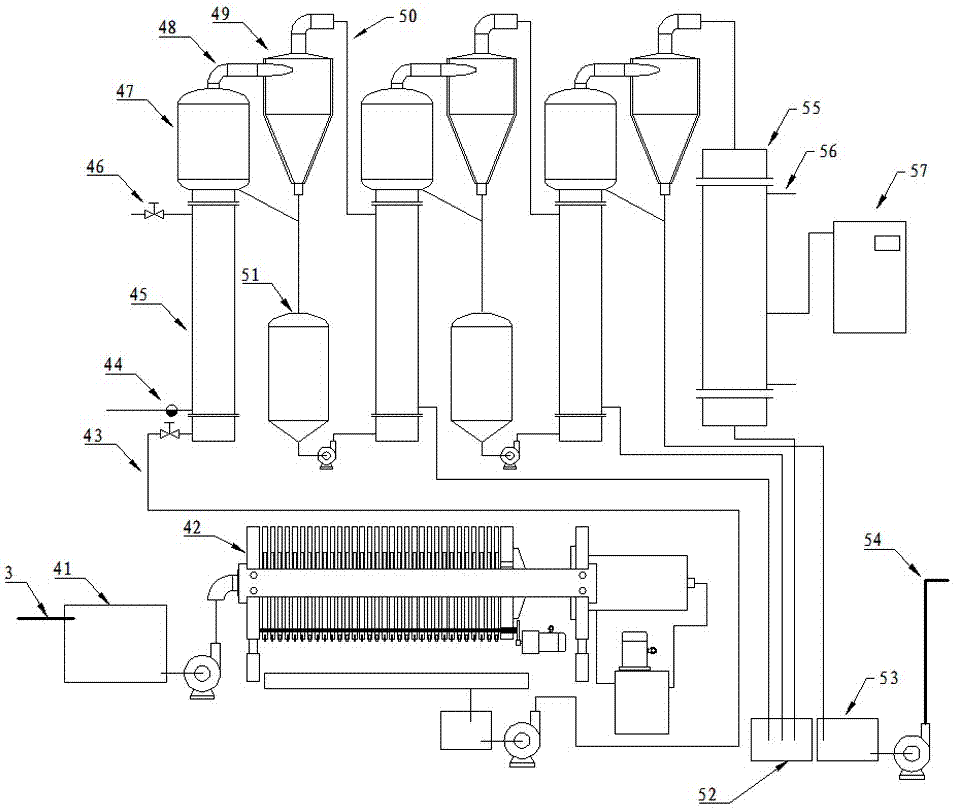

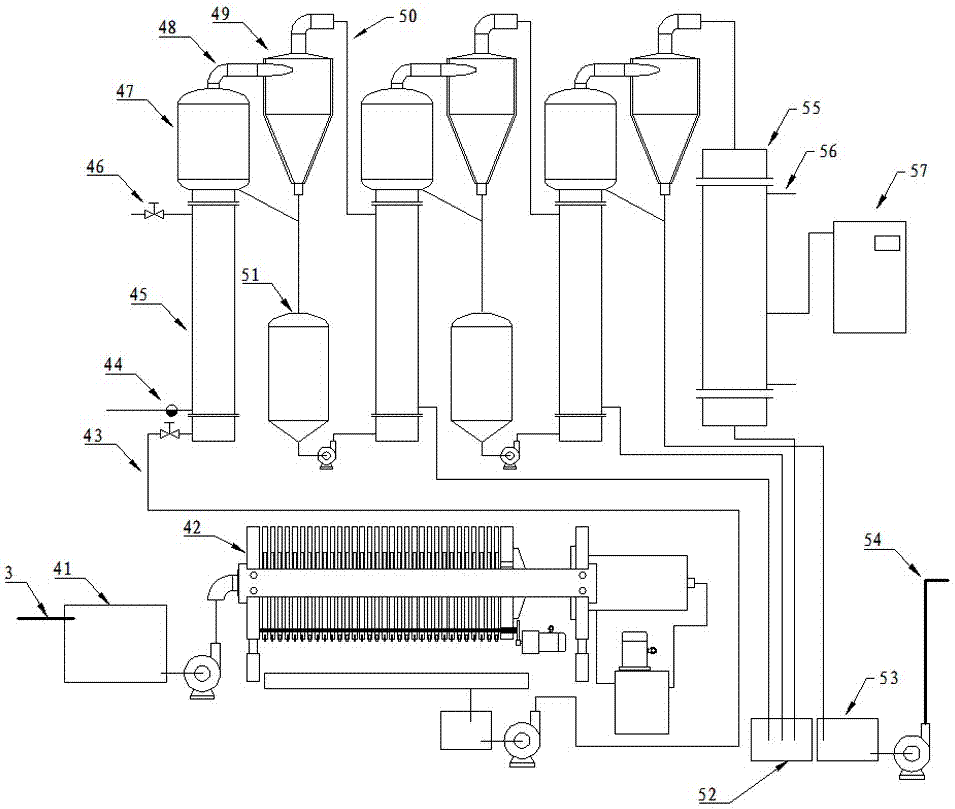

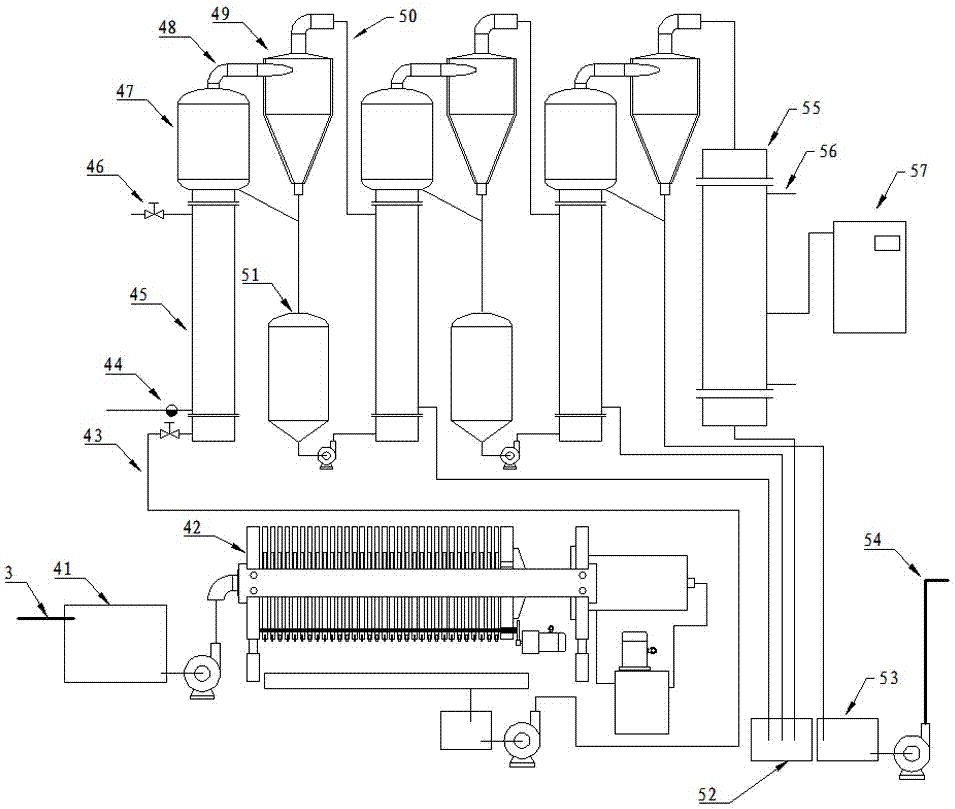

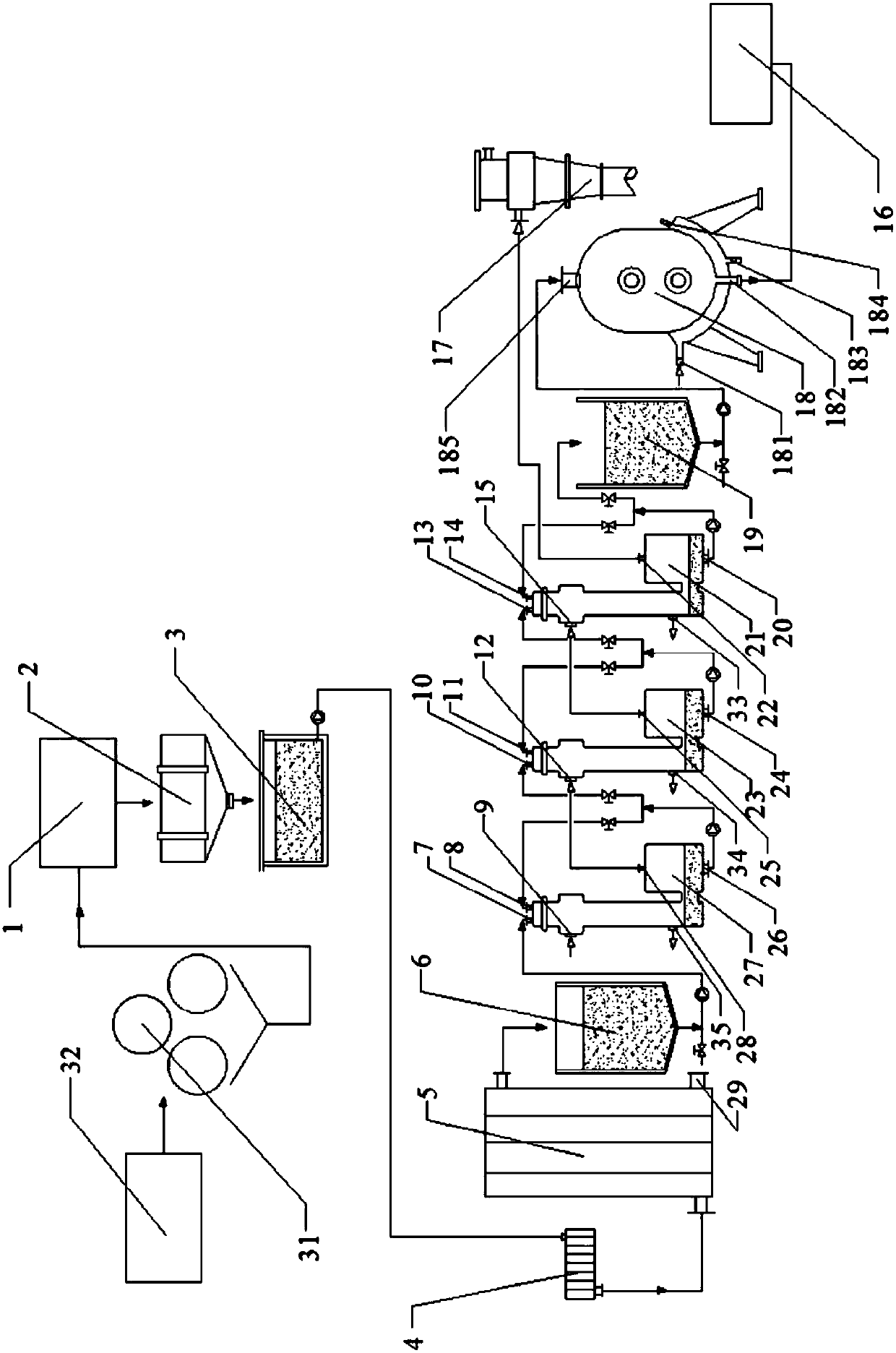

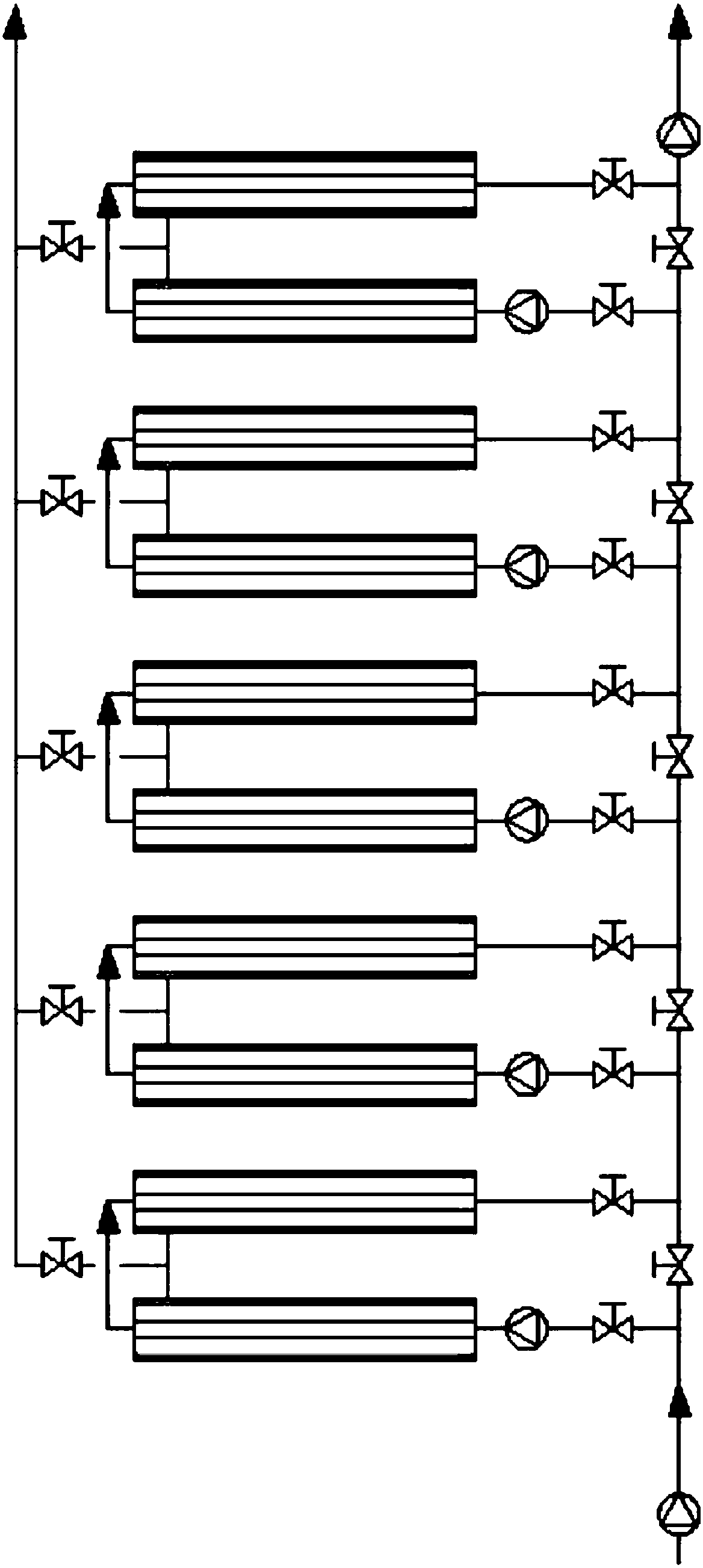

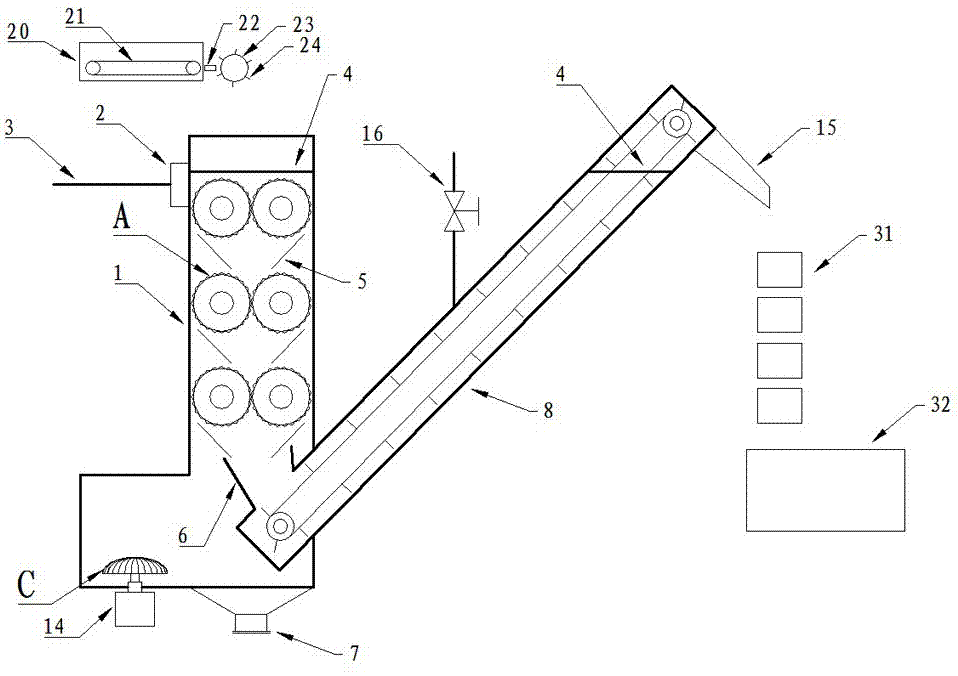

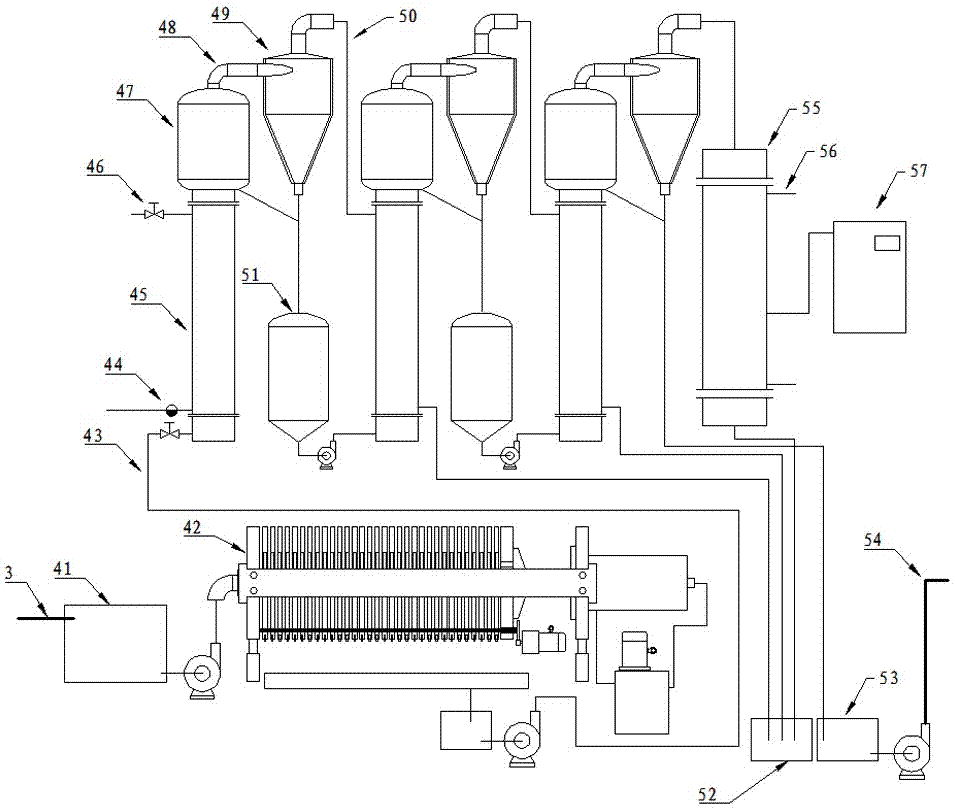

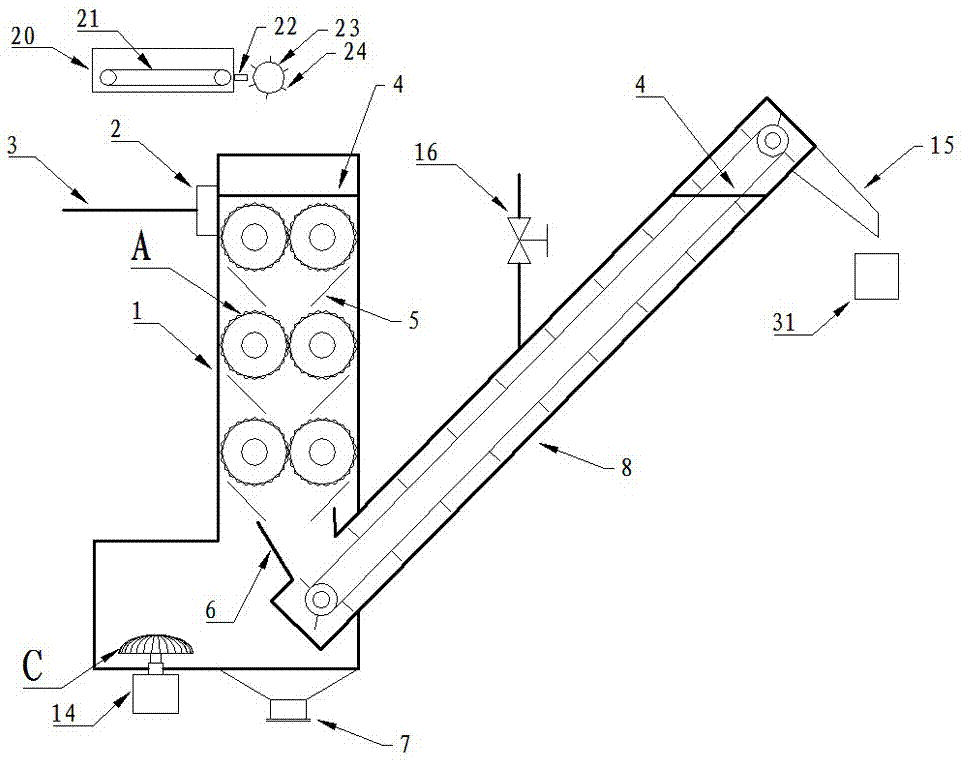

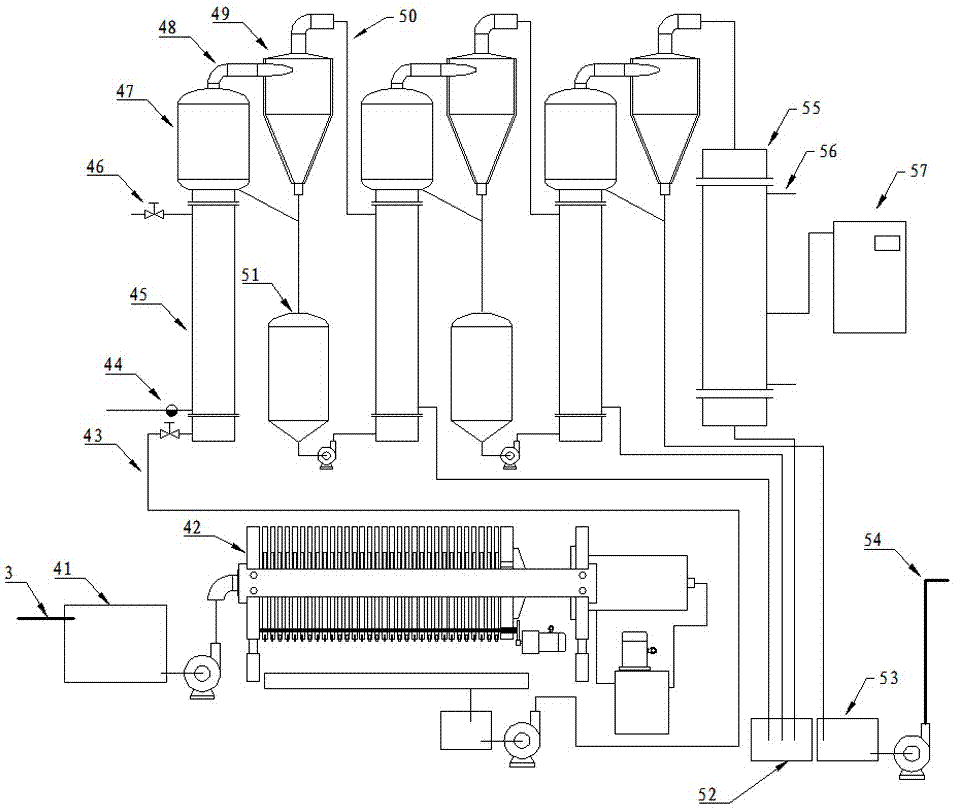

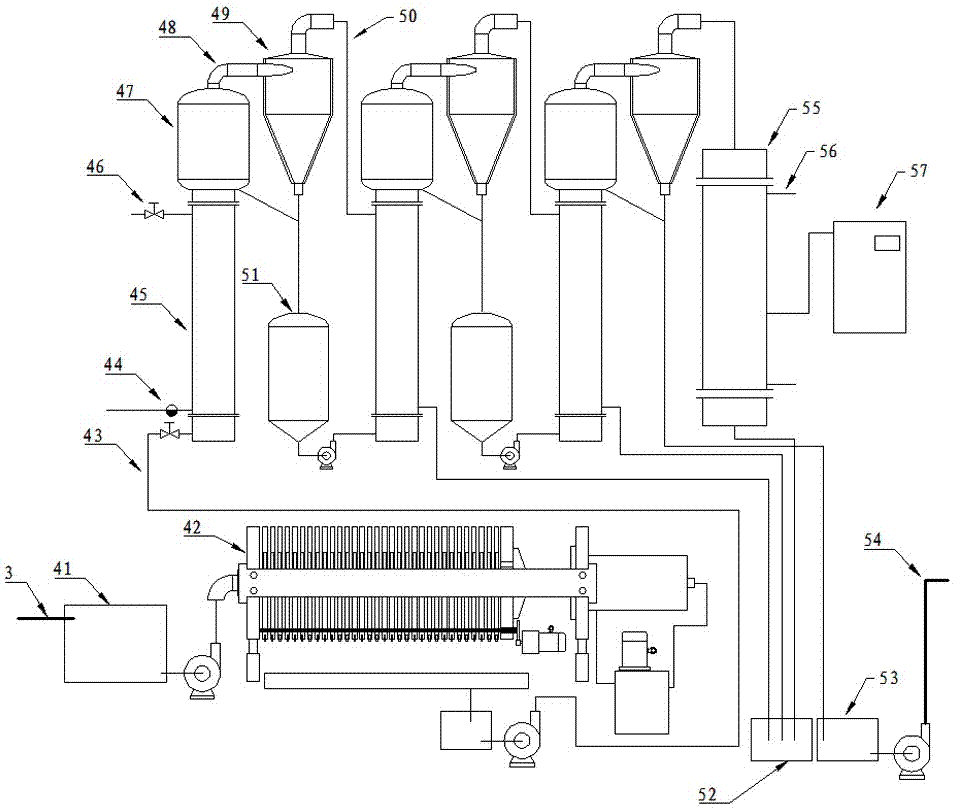

Originally ecological black sugar processing device

ActiveCN104805224ATroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsAdditive ingredientUltrafiltration

An originally ecological black sugar processing device comprises a squeezing rough-filtration device, a heat exchanger, a multistage ceramic membrane ultrafiltration device, a falling-film type three-effect vacuum evaporation system, a water jet condenser, a jacketed iron pot and a graining drying forming device, which are sequentially connected, wherein a clarified sugarcane juice box is connected between the multistage ceramic membrane ultrafiltration device and the three-effect vacuum evaporation device; a syrup box is connected between the falling-film type three-effect vacuum evaporation system and the jacketed iron pot. The black sugar prepared through the device provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, sweet, delicious, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that black residues exist after the black sugar is dissolved is solved and the quality of the black sugar is improved.

Owner:广西百桂堂食品科技有限公司

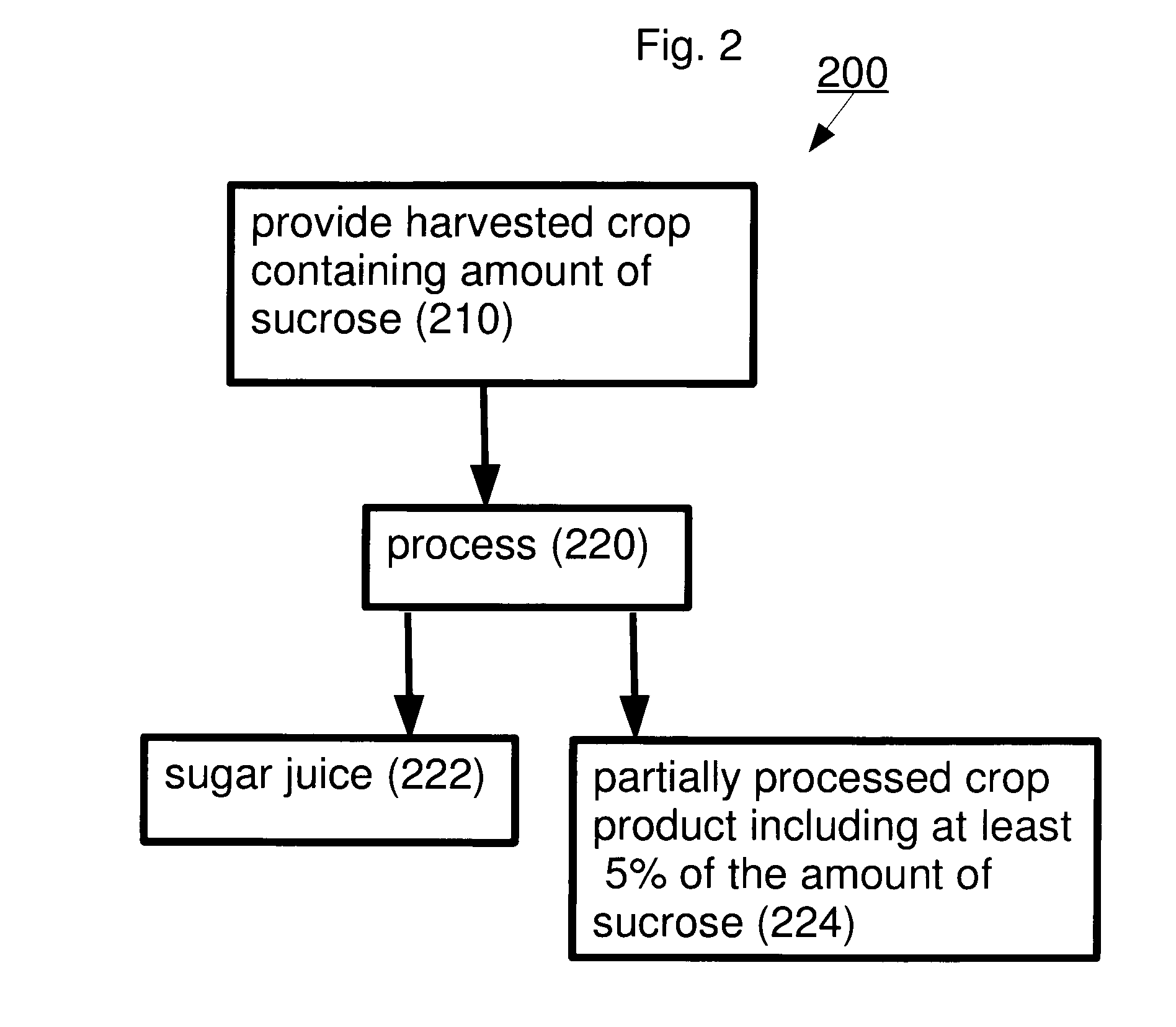

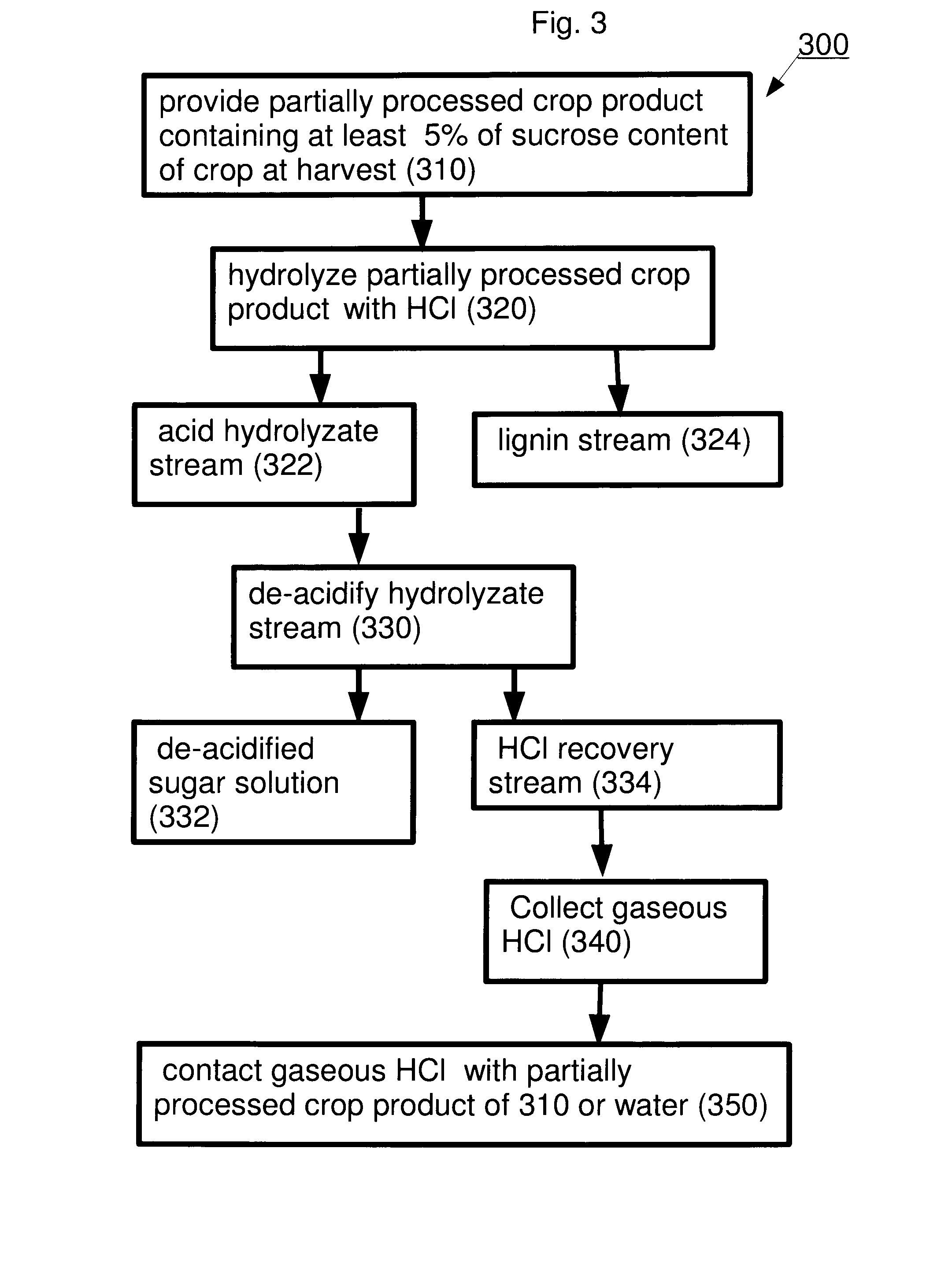

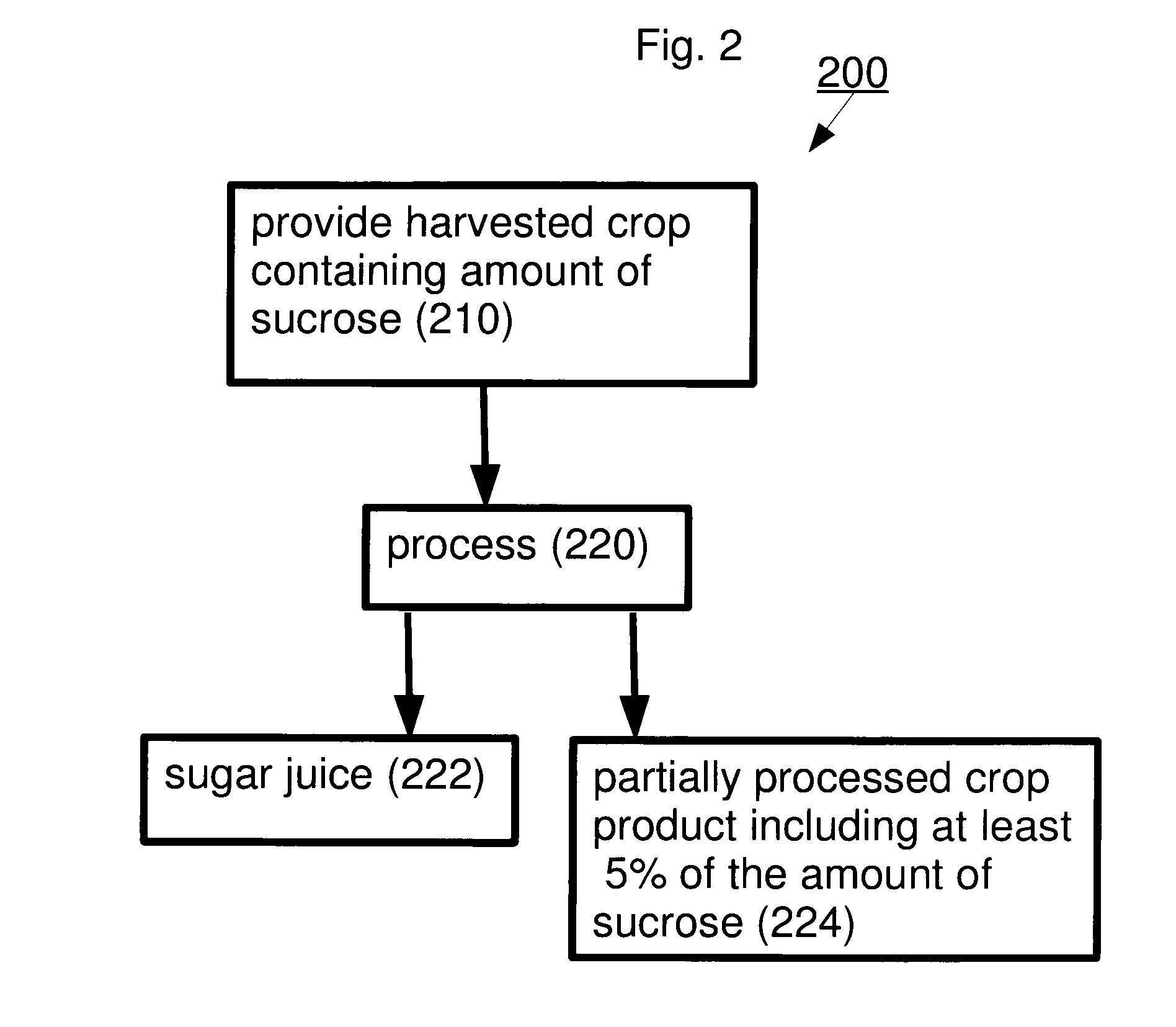

Methods and systems for processing a sucrose crop and sugar mixtures

ActiveUS20140190470A1Reduce concentrationDecrease in price per unitPressurized chemical processSugar productsCelluloseSucrose

A method comprising: (a) providing a partially processed sucrose crop product containing at least 2% optionally at least 5% of the sucrose content of said crop at harvest on a dry solids basis, cellulose and lignin; (b) hydrolyzing said partially processed crop product with HCl to produce an acid hydrolyzate stream and a lignin stream; and (c) de-acidifying said hydrolyzate stream to produce a de-acidified sugar solution and an HCl recovery stream. Additional, methods, systems and sugar mixtures are also disclosed.

Owner:VIRDIA

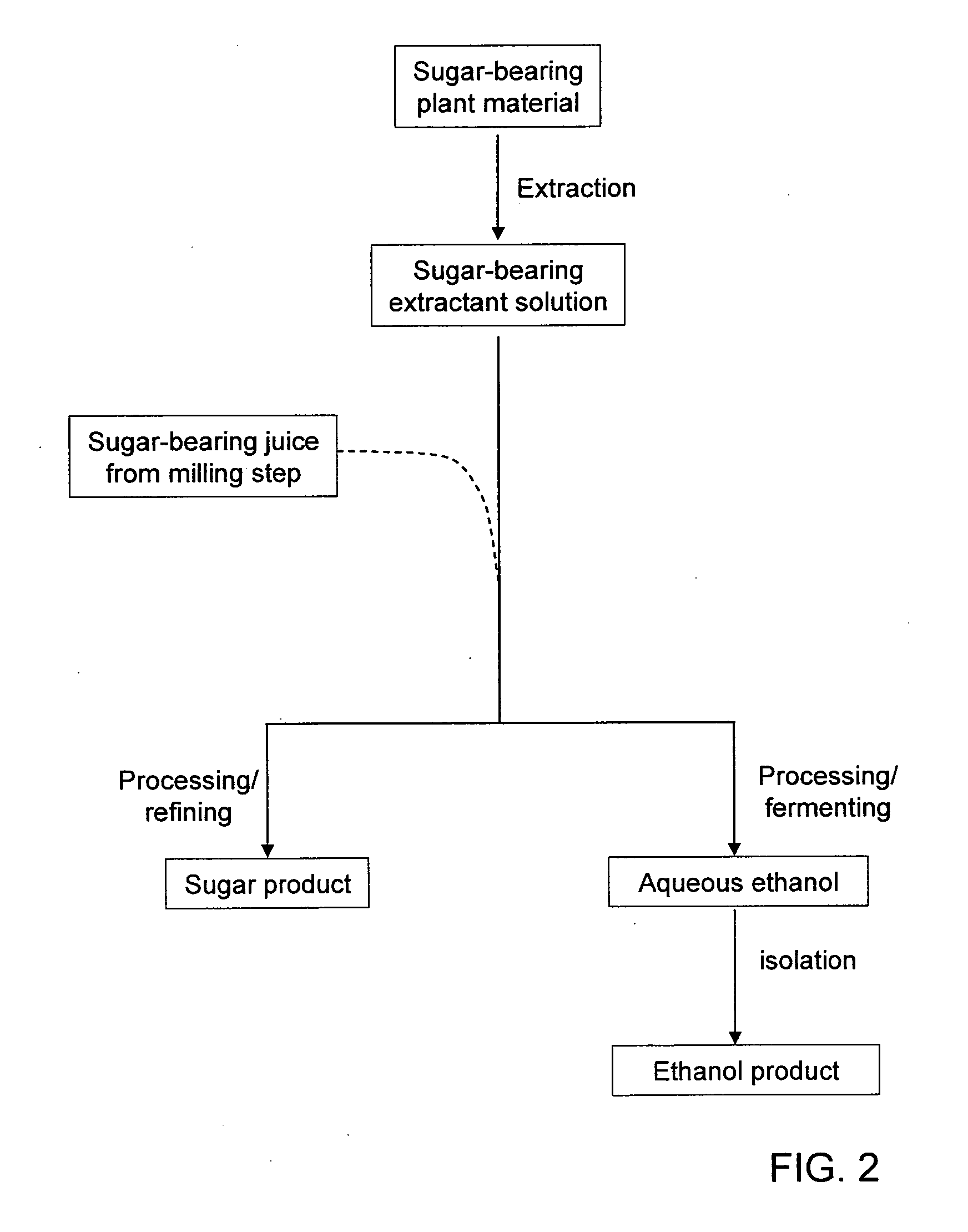

Processes for Extraction of Sugar From Sugar-Bearing Plant Material

The invention provides processes for the extraction of sugar from sugar-bearing plant material such as sugar cane. Accordingly, in one aspect of the invention, a process for extracting sugar from sugar-bearing plant material comprises contacting the sugar-bearing plant material with an extractant solution comprising water and a surfactant; and separating the extractant solution from the sugar-bearing plant material. One example of a suitable surfactant is a poly(alkylene oxide) polymer such as a poly(propylene oxide) polymer, a poly(ethylene oxide) polymer, or a poly(propylene oxide) / (ethylene oxide) copolymer.

Owner:DOW BRASIL SUDESTE IND

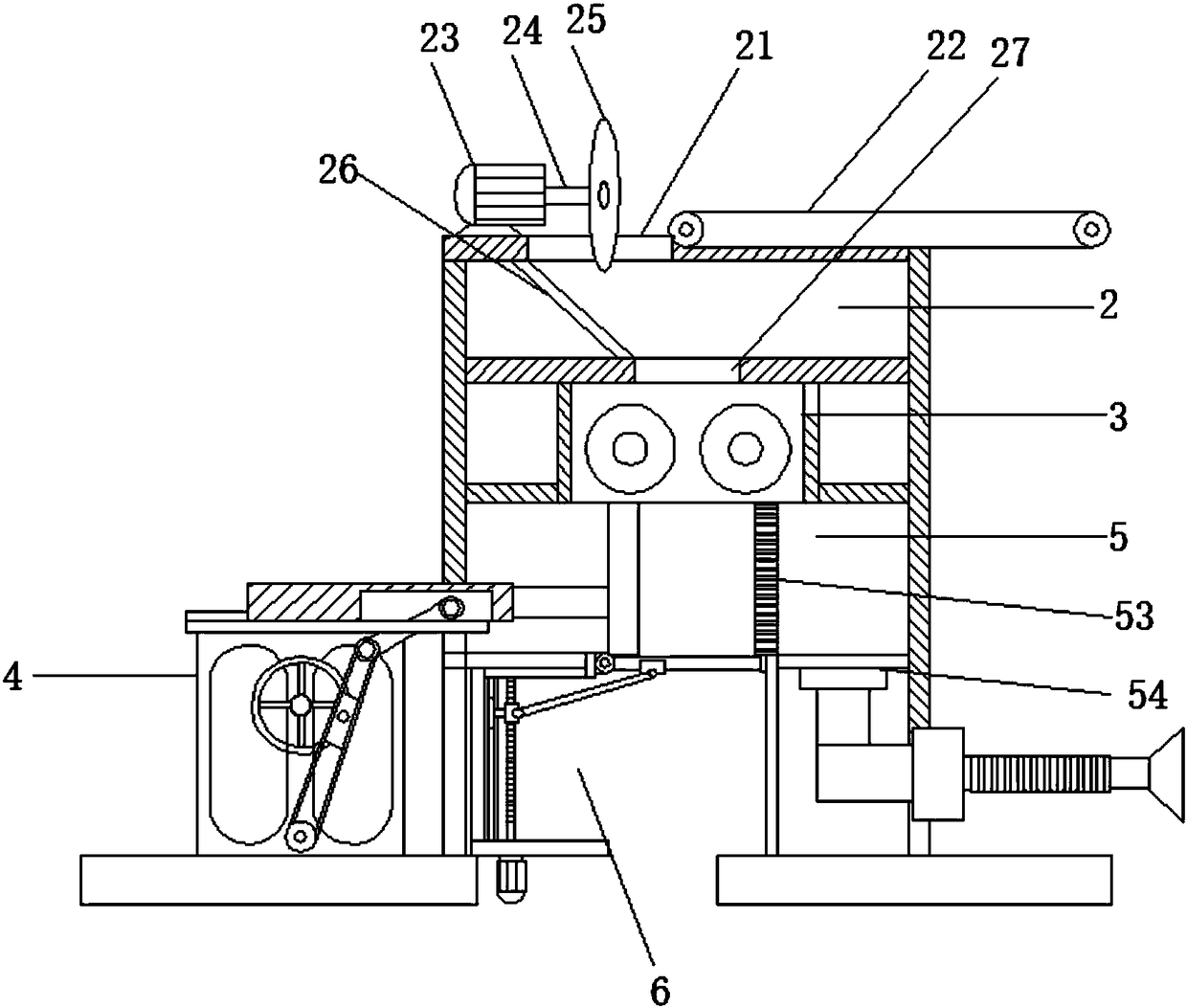

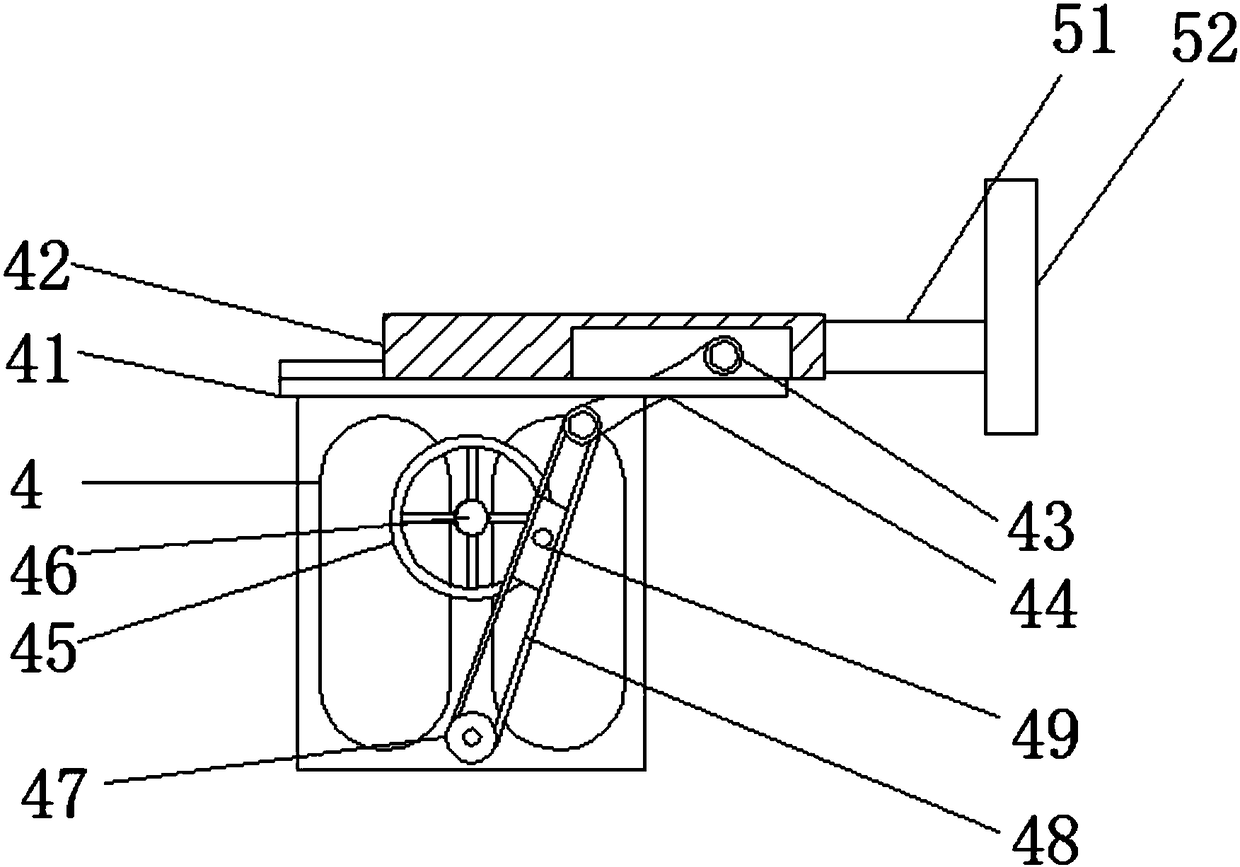

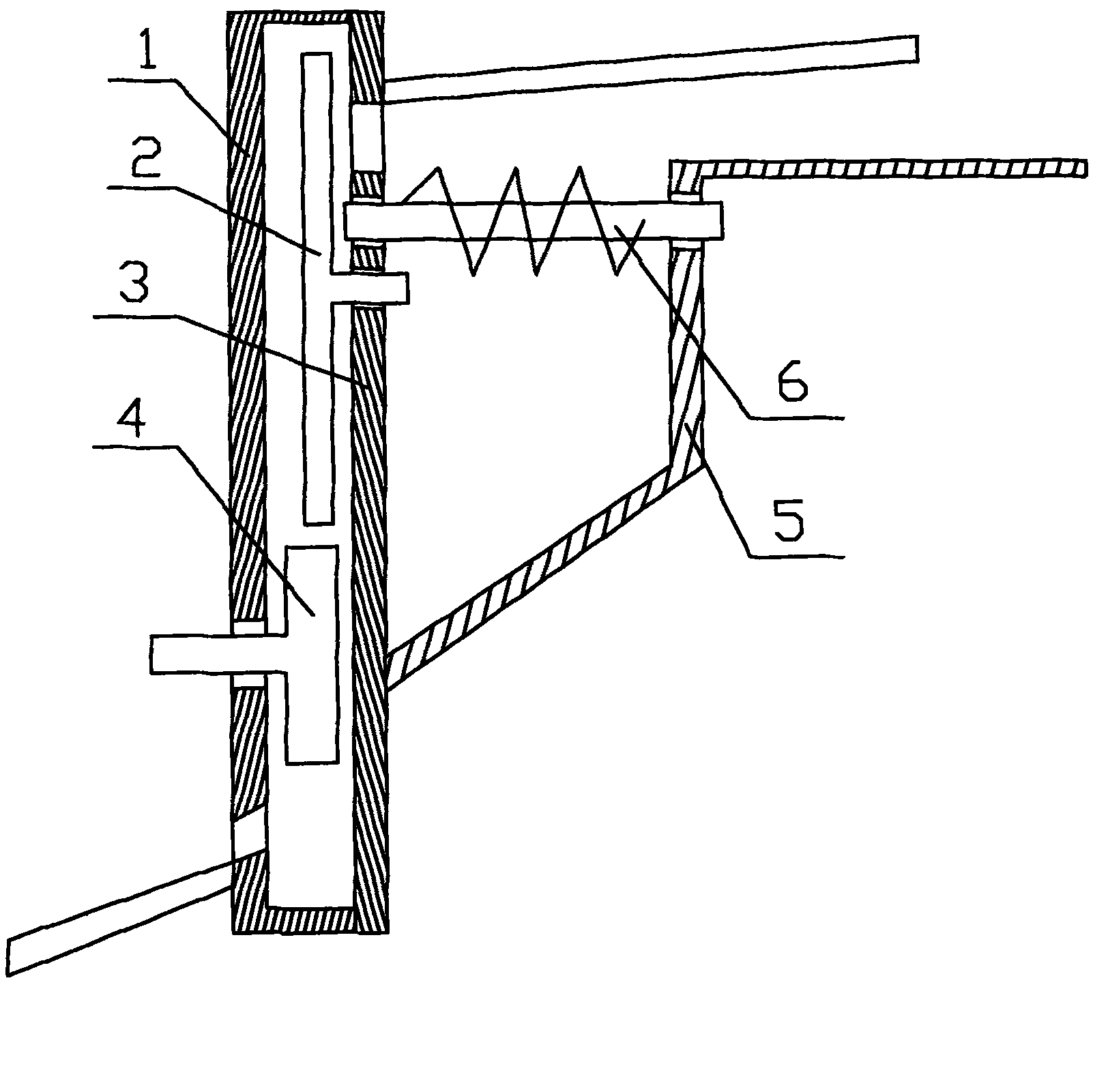

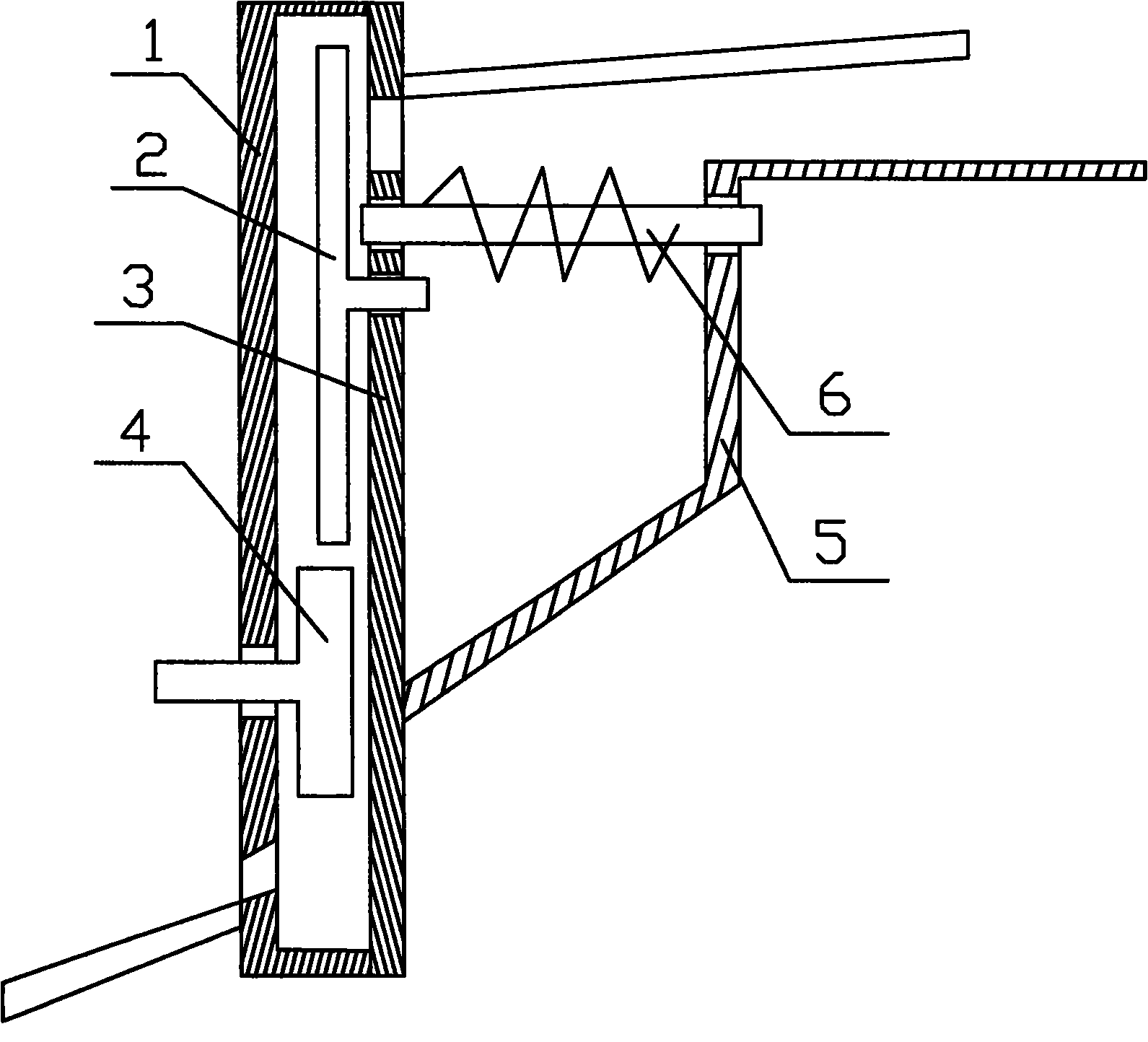

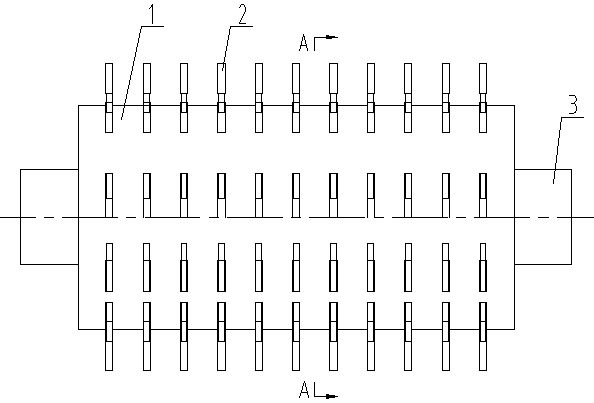

Extrusion juice squeezing device for sugarcane

PendingCN108546787AEfficient dischargeEasy to handleSugarcane cuttingSugarcane shreddingEngineeringMechanical engineering

The invention discloses an extrusion juice squeezing device for sugarcane. The extrusion juice squeezing device comprises a machine frame, wherein a material conveying cavity, a crushing cavity, an extrusion cavity and a material discharging cavity are formed in the machine frame; a transmission frame is arranged at the back side of the machine frame; a slide groove is formed in a top plate of thetransmission frame; a movable plate is arranged on the slide groove; a movable shaft is transversely arranged in an inner cavity of the movable plate; a transmission block is arranged on the movableshaft; the middle position of the transmission frame is provided with a transmission disc through a rotating shaft; the bottom end of the transmission frame is provided with a fixed shaft bolt; a slide rail is connected between the tail end of the transmission block and the fixed shaft bolt; a slide block is arranged in the slide rail; the slide block is connected with an outer disc of a transmission disc through a locking bolt; a push rod is arranged at the front end of the movable plate; the push rod extends into the extrusion cavity; the front end of the push rod is provided with an extrusion plate. The operation stroke of a crank connecting rod mechanism is shorter than the return stroke, so that the high-impact force during the extrusion in each time is maintained; the extrusion juicesqueezing effect is ensured.

Owner:孙明

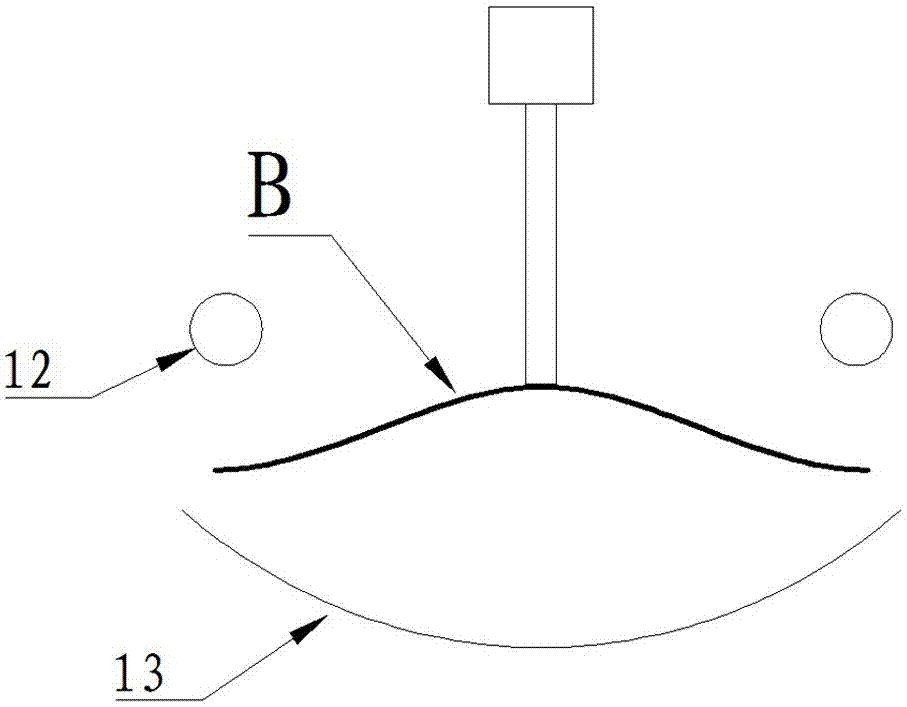

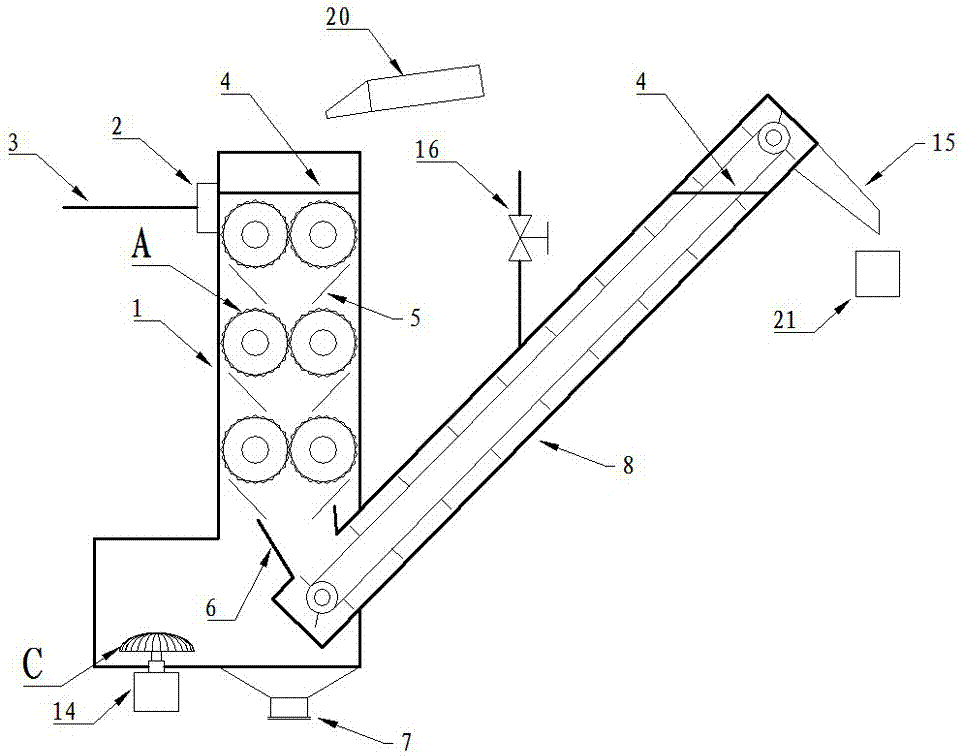

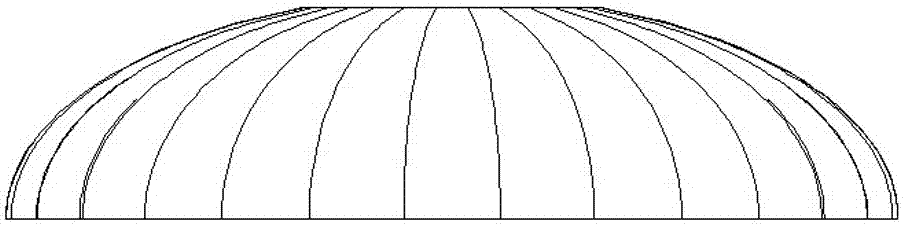

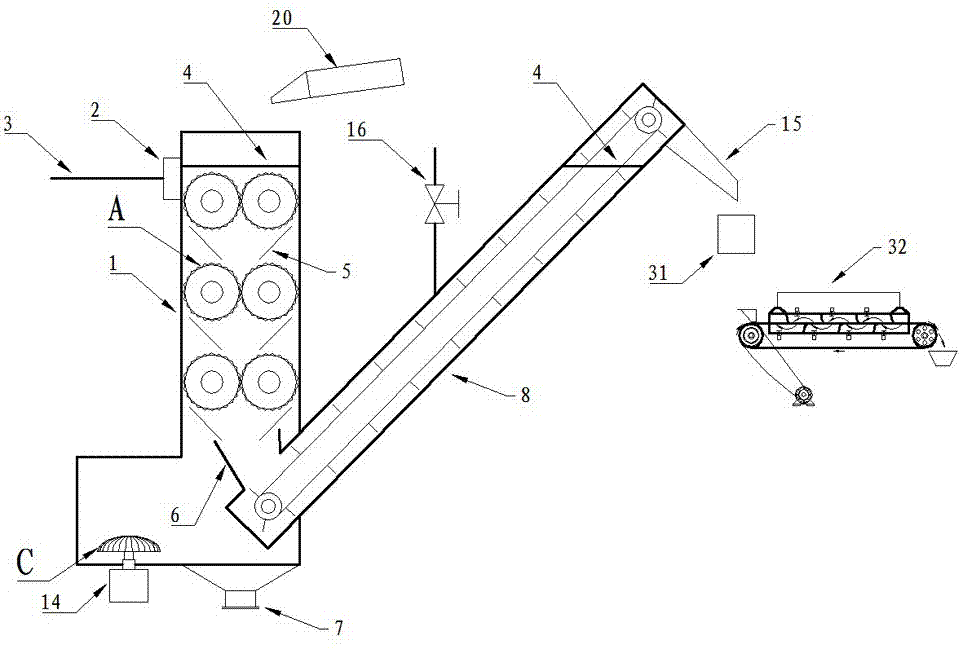

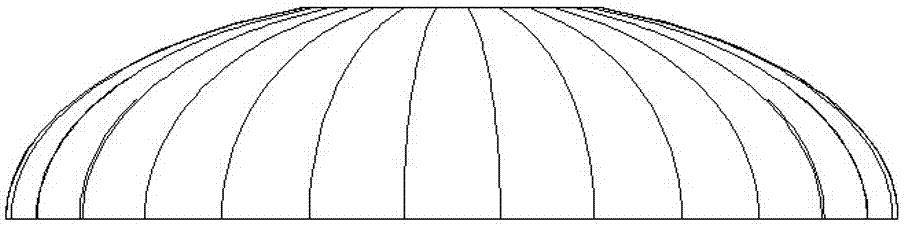

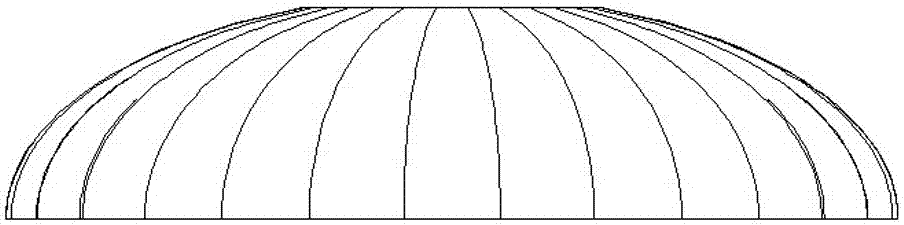

Sugarcane bagasse treatment device with straw cutting machine and carbon-making molding machine

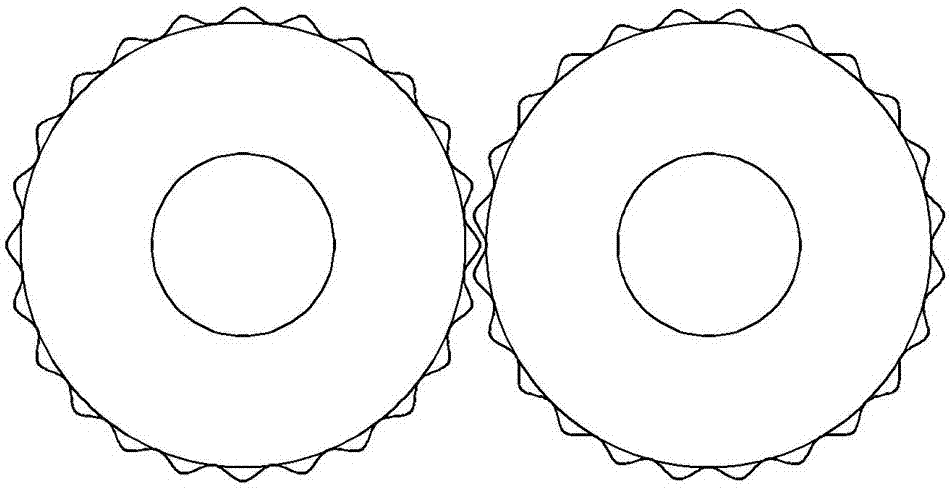

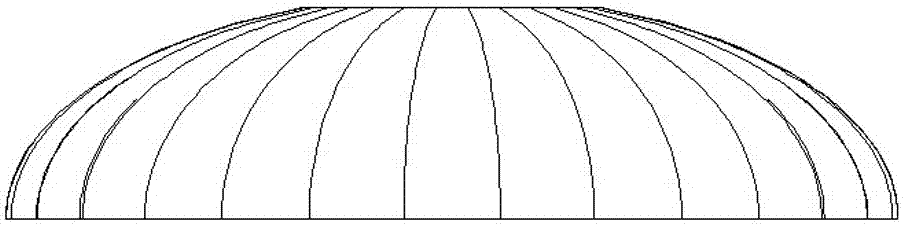

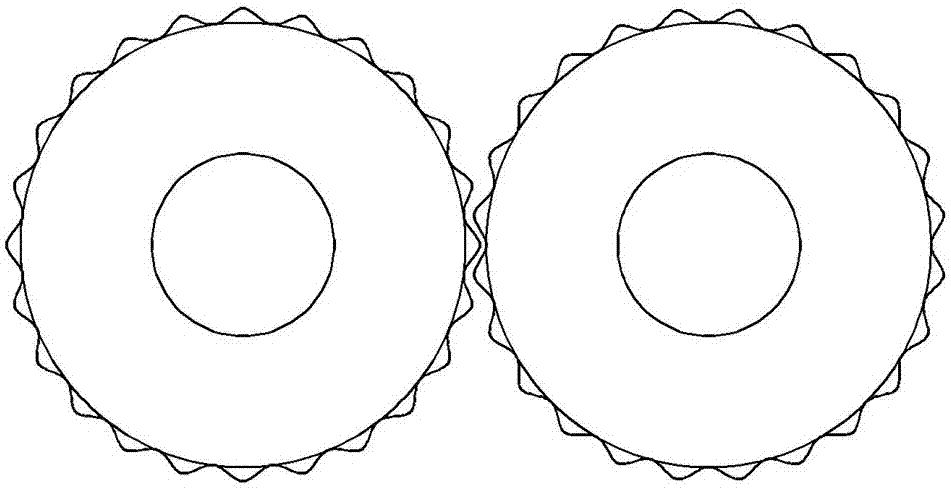

InactiveCN107299161AContinuous and reliable biteExtrusion compression ratio is largeSolid waste disposalTransportation and packagingThree levelMolding machine

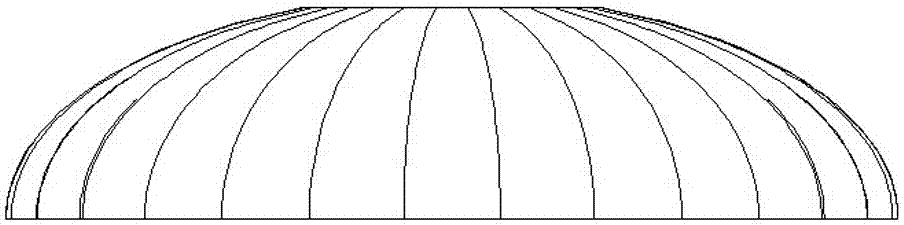

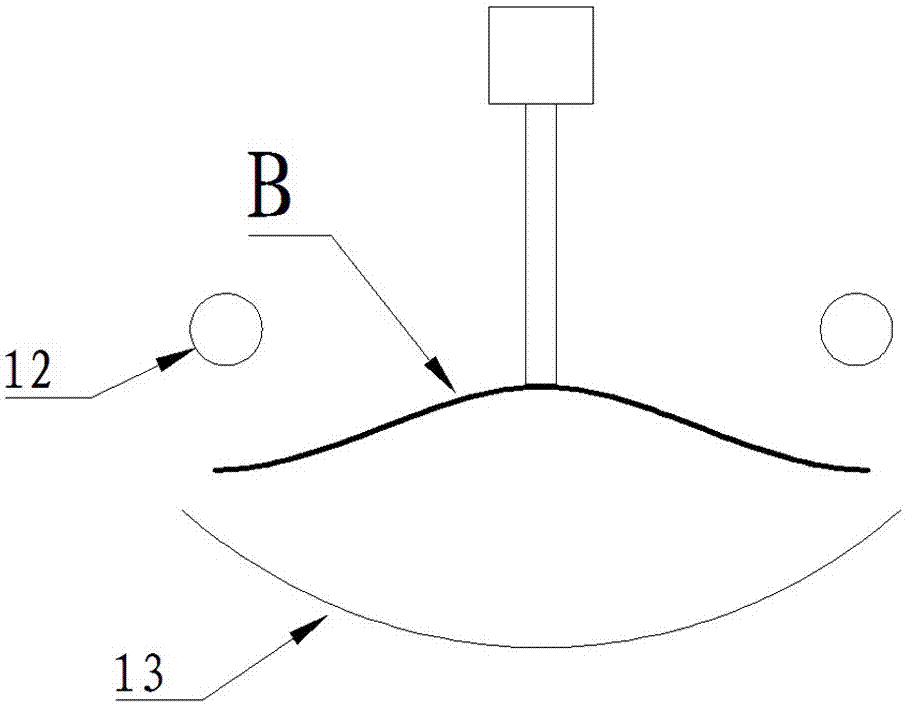

The invention discloses a sugarcane bagasse treatment device with a straw cutting machine and a carbon-making molding machine. The straw cutting machine is arranged above a device body; three levels of counter-rotation cosine rollers are arranged inside the device body, and surfaces of the counter-rotation cosine rollers are continuous cosine curved surfaces; sugarcane bagasse guiding slots are formed in lower parts of the three levels of counter-rotation cosine rollers; the last level of guiding slot is connected with a hopper of a sugarcane bagasse lifting machine; a discharging groove of the lifting machine is connected with a dryer through a centrifugal machine; a discharging end of the dryer is connected with a mechanized carbon-making molding machine; the lifting machine is provided with a water inlet valve; an upper part of the device body is provided with a filter and a liquid outlet pipe; the liquid outlet pipe is connected with a triple-effect long-tube rising-film evaporation concentration device; a cosine gel tray pulse aeration device is arranged in the device body; a mechanical ultrasonic vibration exciter is arranged at a left lower corner of the device body. The three levels of counter-rotation cosine rollers, the cosine gel tray pulse aeration device and the mechanical ultrasonic vibration exciter of the sugarcane bagasse treatment device disclosed by the invention all have distinctive characteristics; the leaching extraction of sugars can be promoted in a cooperation manner; the device has a working principle and a technical effect which are difficultly predicted by technicians in the field, and has a stronger practical application value.

Owner:熊小媚

Cosine roller type bagasse processing device provided with cutter and made carbon former

InactiveCN107312877AContinuous and reliable biteExtrusion compression ratio is largeTransportation and packagingSolid waste disposalThree stageInlet valve

The invention discloses a cosine roller type bagasse processing device provided with a cutter and a made carbon former. The bagasse cutter is arranged above the body of the processing device; three-stage counter rotating cosine rollers are arranged in the body, the surface of every counter rotating cosine roller is a continuous cosine curved surface, a bagasse guiding chute is arranged below every stage counter rotating cosine roller, the last stage guiding chute is connected with the hopper of a bagasse elevator, the discharging chute of the elevator is connected with a drying machine through a centrifuge, and the discharging end of the drying machine is connected with the machine-made carbon former; the elevator is provided with a water inlet valve, the upper part of the body is provided with a filter and a liquid discharging tube, and the liquid discharging tube is connected with a triple-effect long tube rising membrane evaporation concentrator; and a cosine plastic plate pulse aerator is arranged in the body. The three-stage counter rotating cosine rollers and the cosine plastic plate pulse aerator have distinct characteristics, and can cooperatively promote the leaching extraction of sugar, and the device has a working principle and technical effects which cannot be foreseen by technical personnel in the field, and has high practical application values.

Owner:段少海

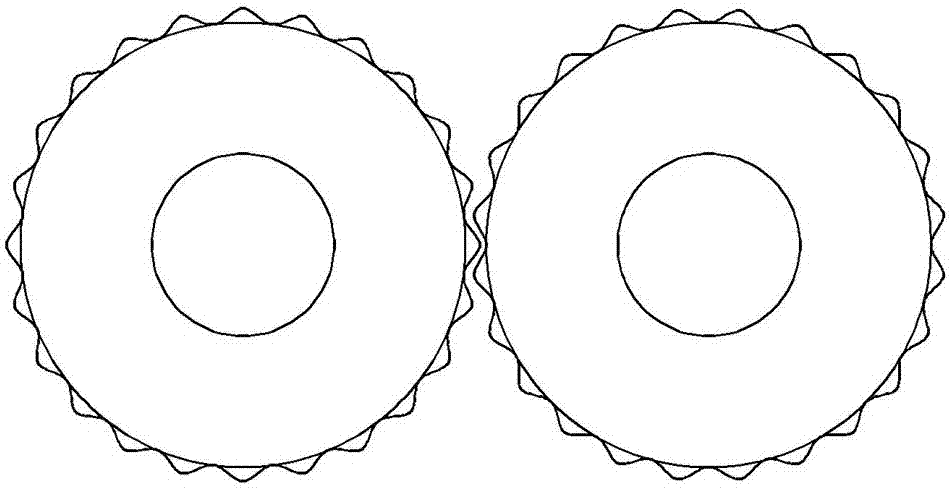

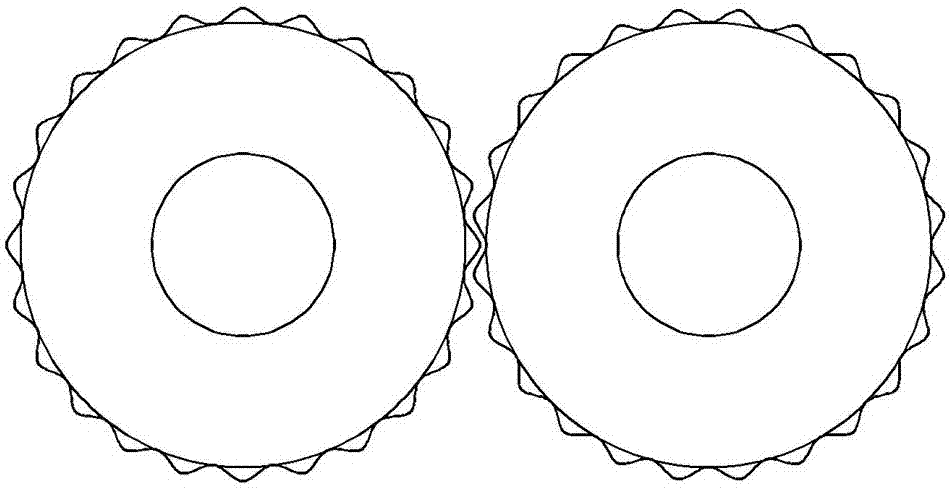

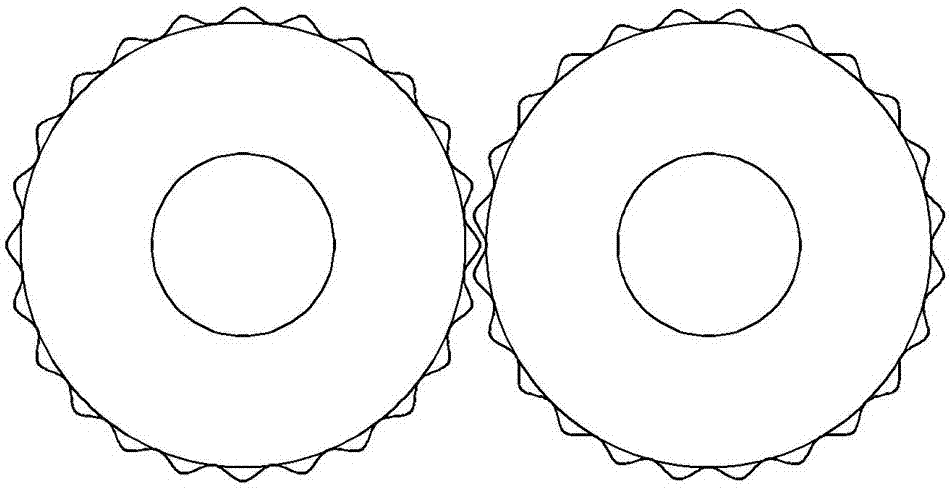

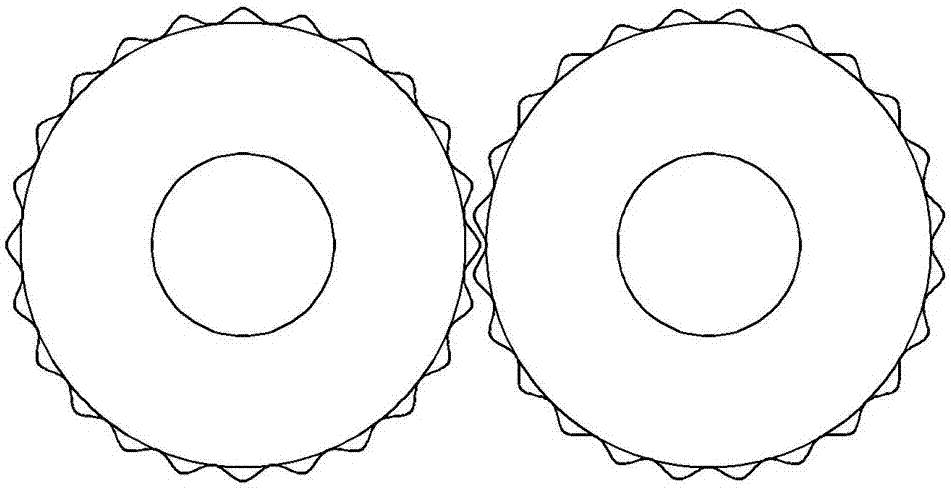

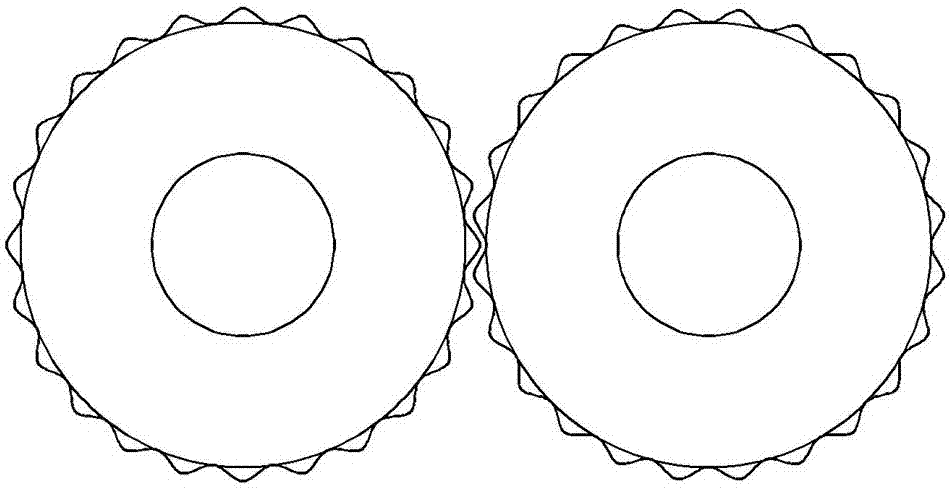

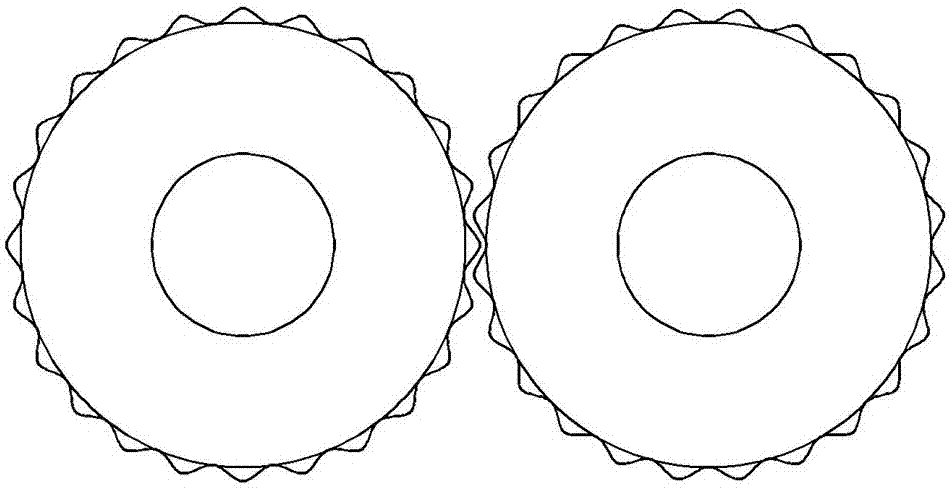

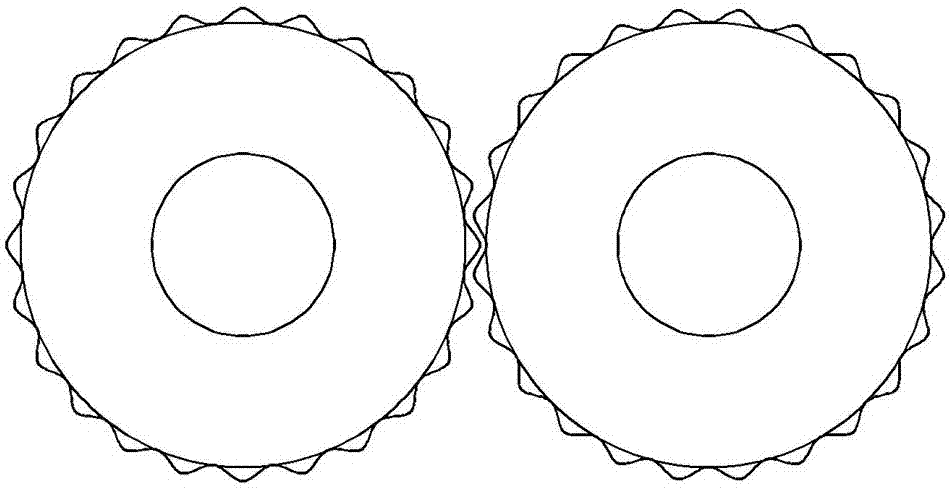

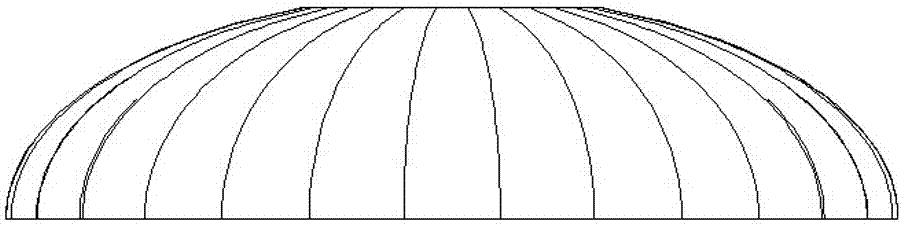

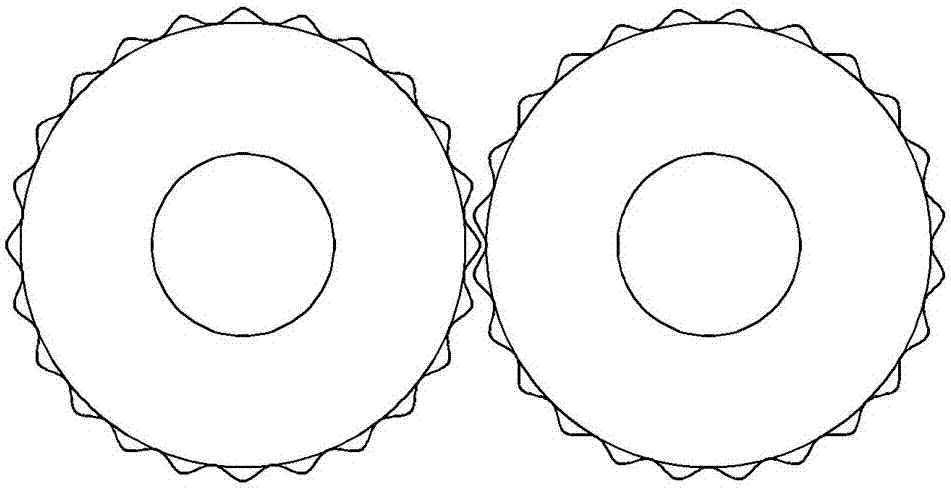

Sugarcane crusher

The invention discloses a sugarcane crusher. The sugarcane crusher comprises a left shell (1), a first crushing wheel (2), a right shell (3), a second crushing wheel (4) and a feeding device, wherein the left shell (1) and the right shell (3) are arranged to form a closed cavity; the first crushing wheel (2) and the second crushing wheel (4) are arranged in the closed cavity of the left shell (1) and the right shell (3); the first crushing wheel (2) is arranged in rotatable linkage with the right shell (3); the feeding direction of the feeding device is set to be the same as the axial direction of the first crushing wheel (2); the second crushing wheel (4) is arranged on the lower side of the first crushing wheel (2) and arranged in rotatable linkage with the left shell (1); and input shafts of the first crushing wheel (2), the second crushing wheel (4) and the feeding device are connected with an output shaft of a power source respectively. Therefore, a sugarcane stem can be formed into blocks well and sugarcane residues are convenient to treat.

Owner:张琳

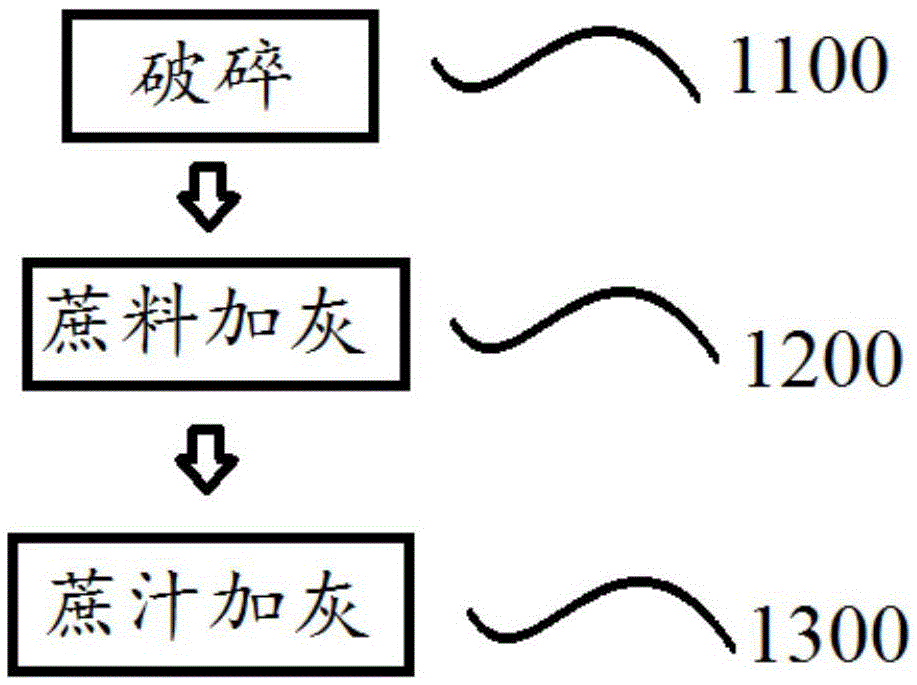

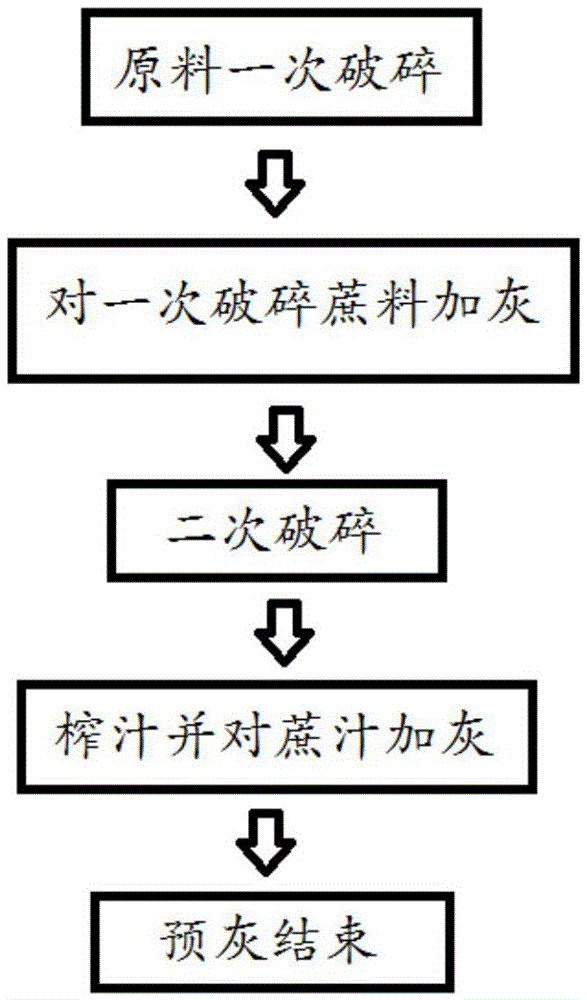

Sugar cane preliming pressing technique

ActiveCN105567878AClarification is goodExtended pre-ashing processPurification by physical meansSugarcane shreddingMicrobial transformationSugar

The invention provides a sugar cane preliming pressing technique which comprises the following steps: a) crushing: crushing the sugar cane raw material to obtain a crushed sugar cane material; b) sugar cane material liming: spraying lime milk into the crushed sugar cane material to regulate the pH value of the sugar cane material, and uniformly mixing to obtain a lime-milk-mixed crushed sugar cane material, wherein the quantity of the lime milk sprayed into the crushed sugar cane material enables the pH value of the initially pressed juice to be 8-8.5; and c) cane juice liming: pressing the lime-milk-mixed crushed sugar cane material to obtain juice, and adding lime milk into the cane juice to regulate the pH value to 10.5-11. The progressive liming technique can enhance the pressing liming reaction effect, and also gives consideration to the disinfection and sterilization in the pressing stage. The technique promotes the improvement of the product quality, lowers the microbial transformation loss, and enhances the recovery of sugar.

Owner:云南西双版纳英茂糖业有限公司

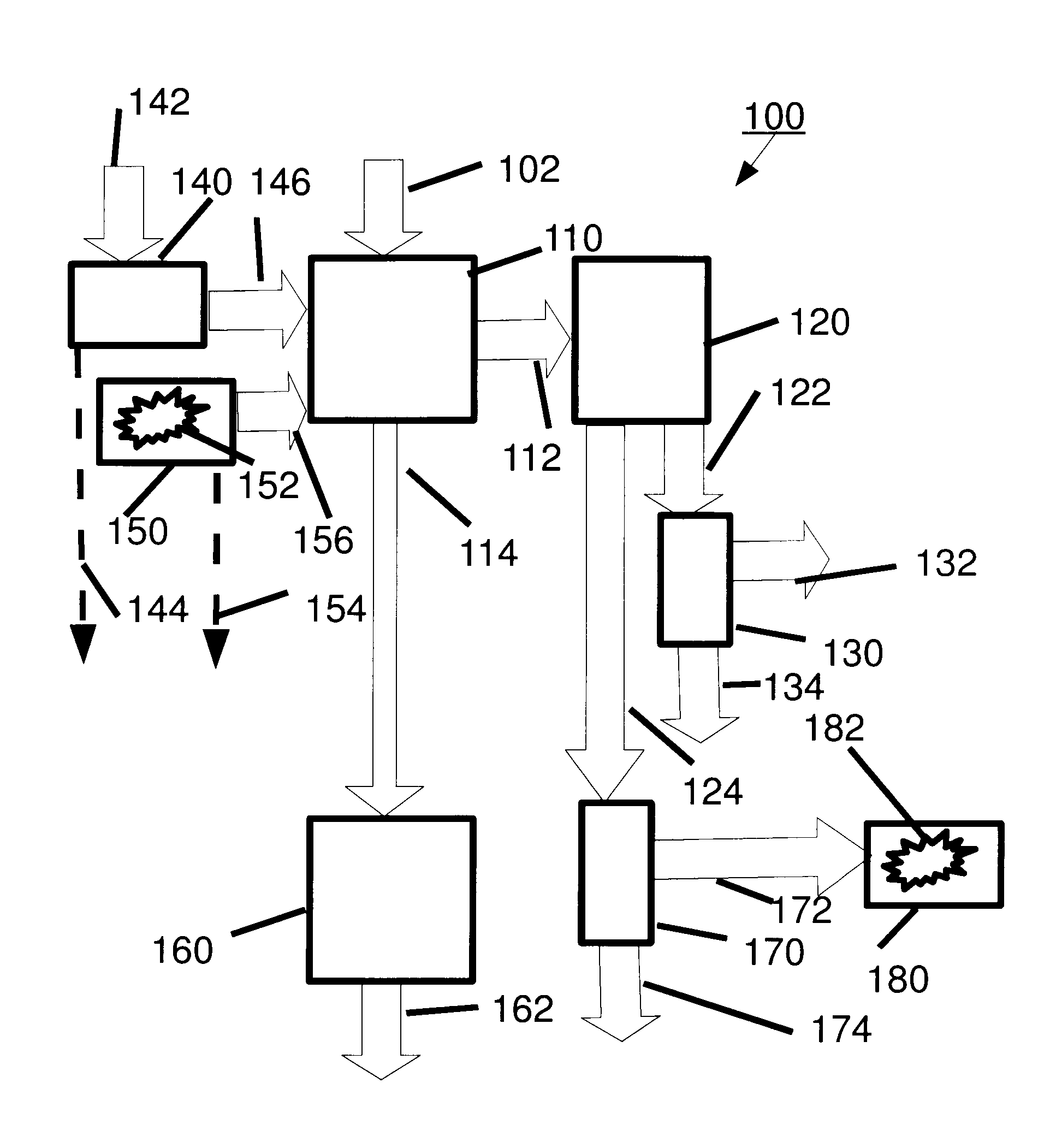

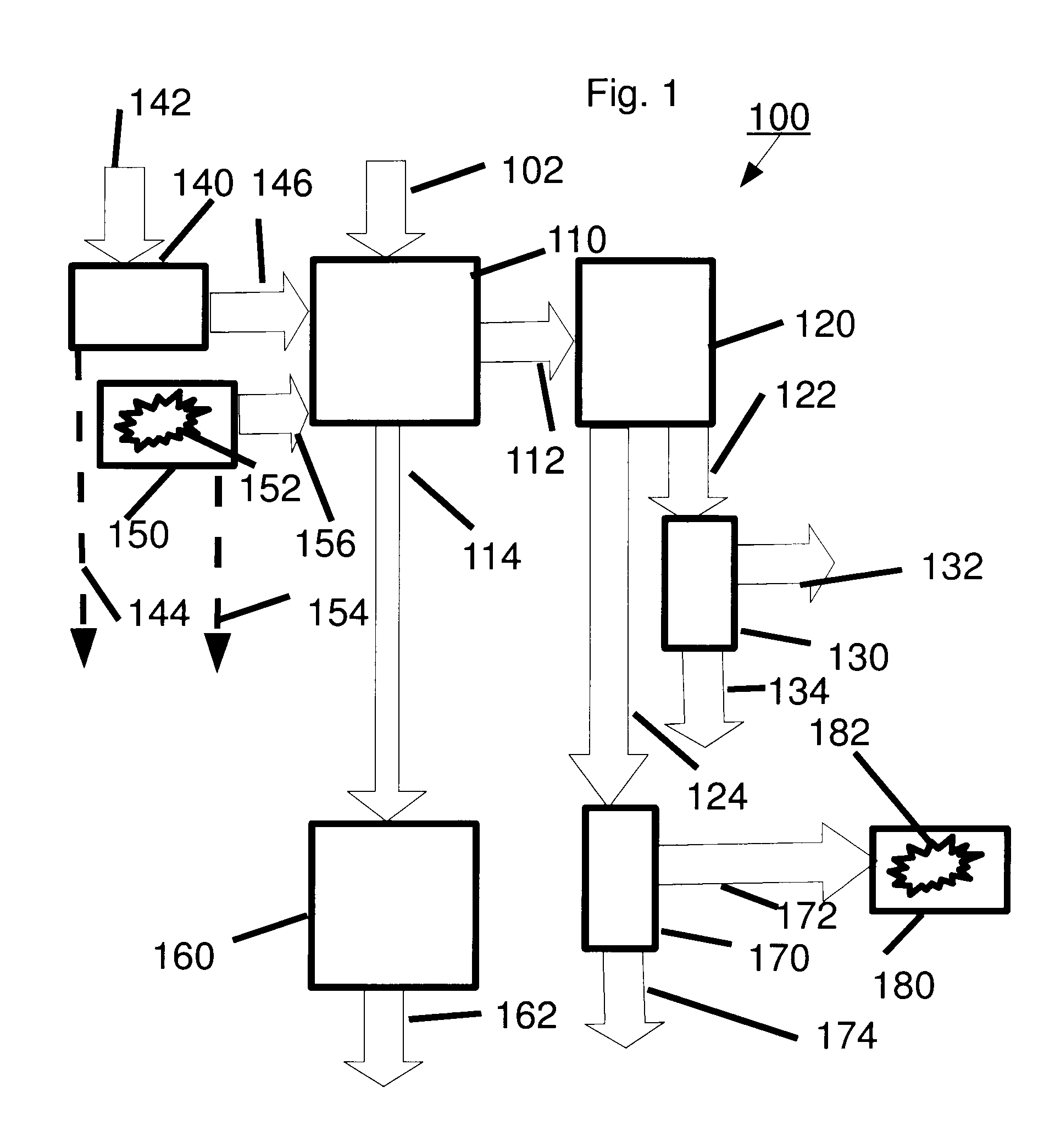

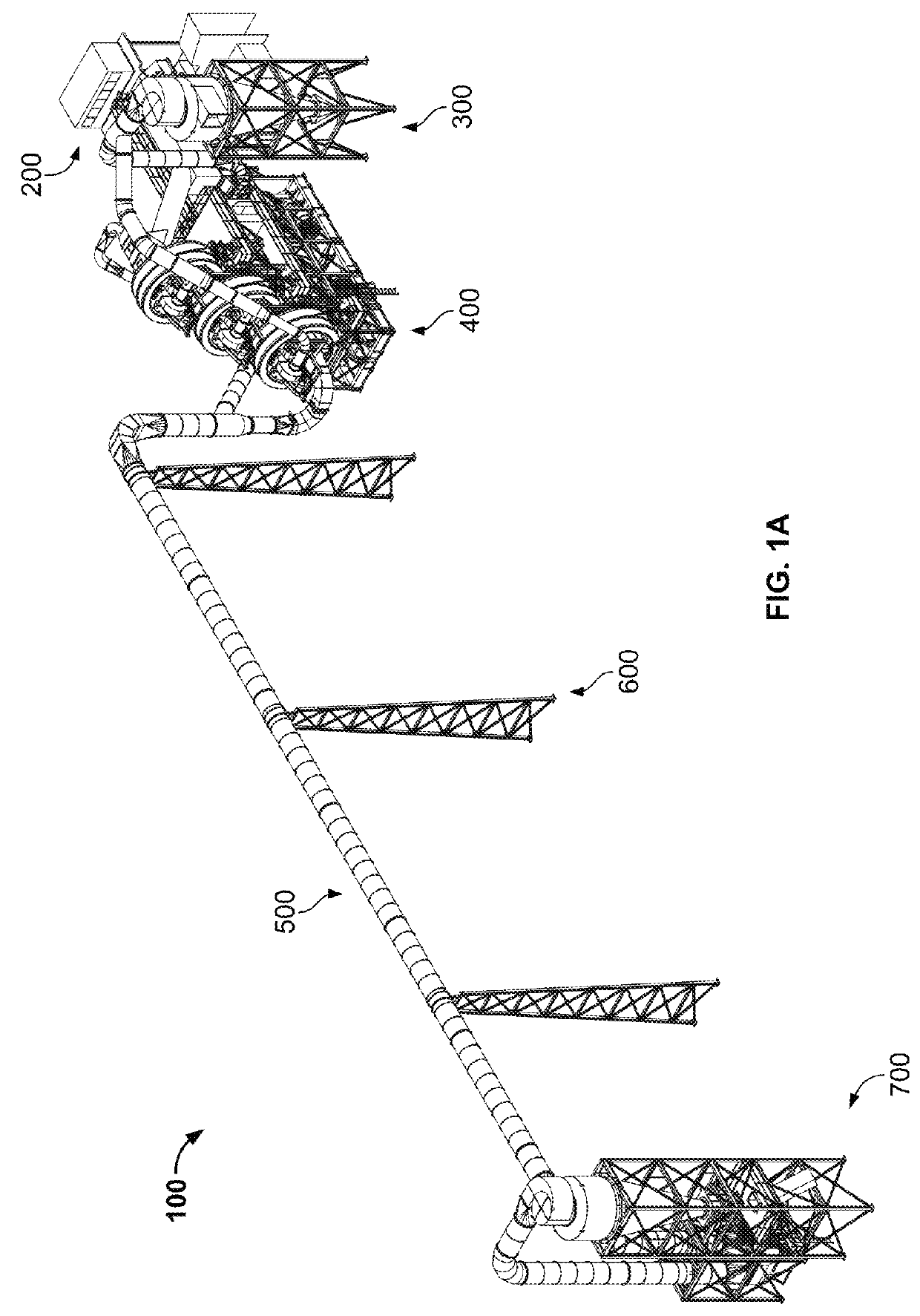

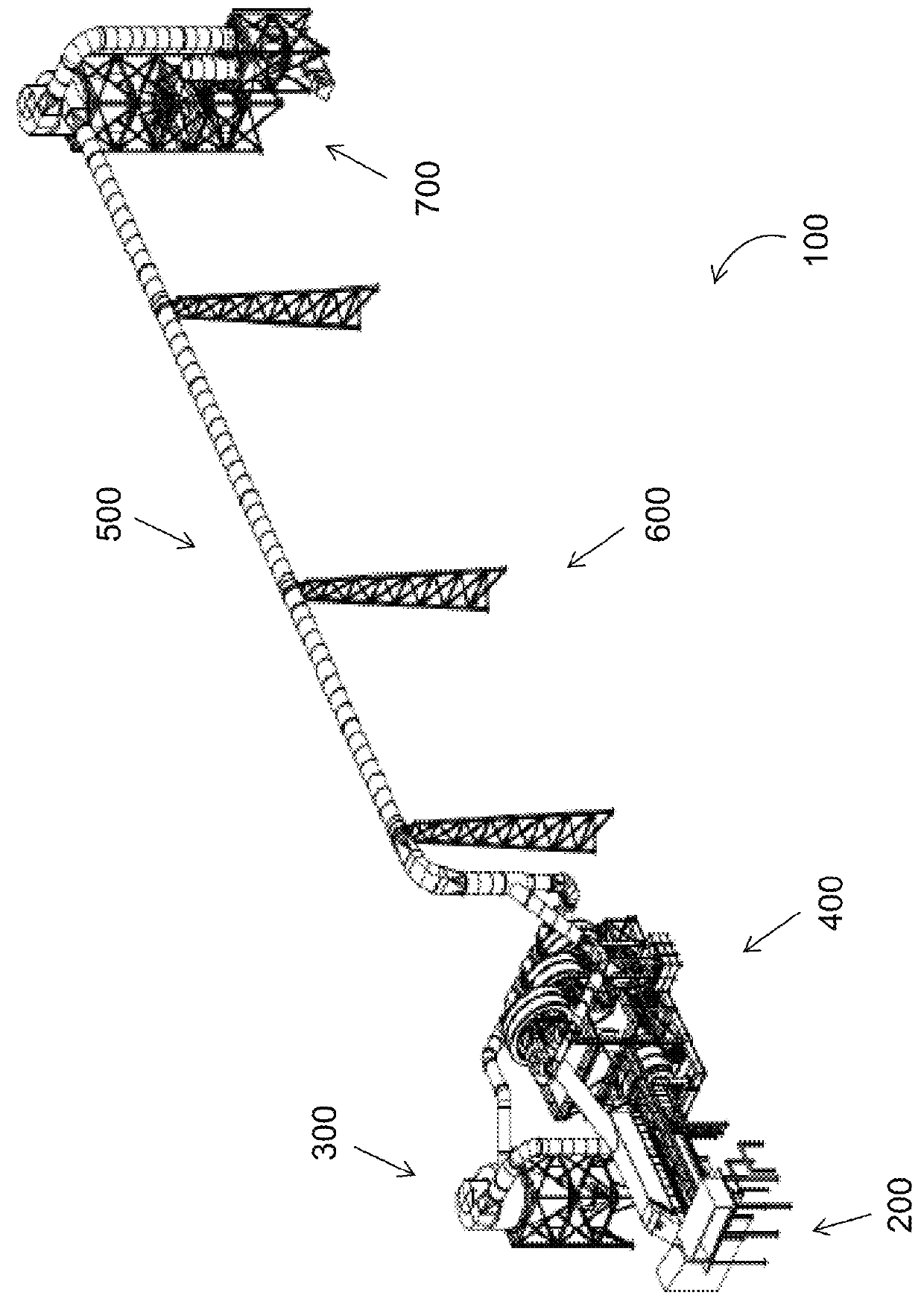

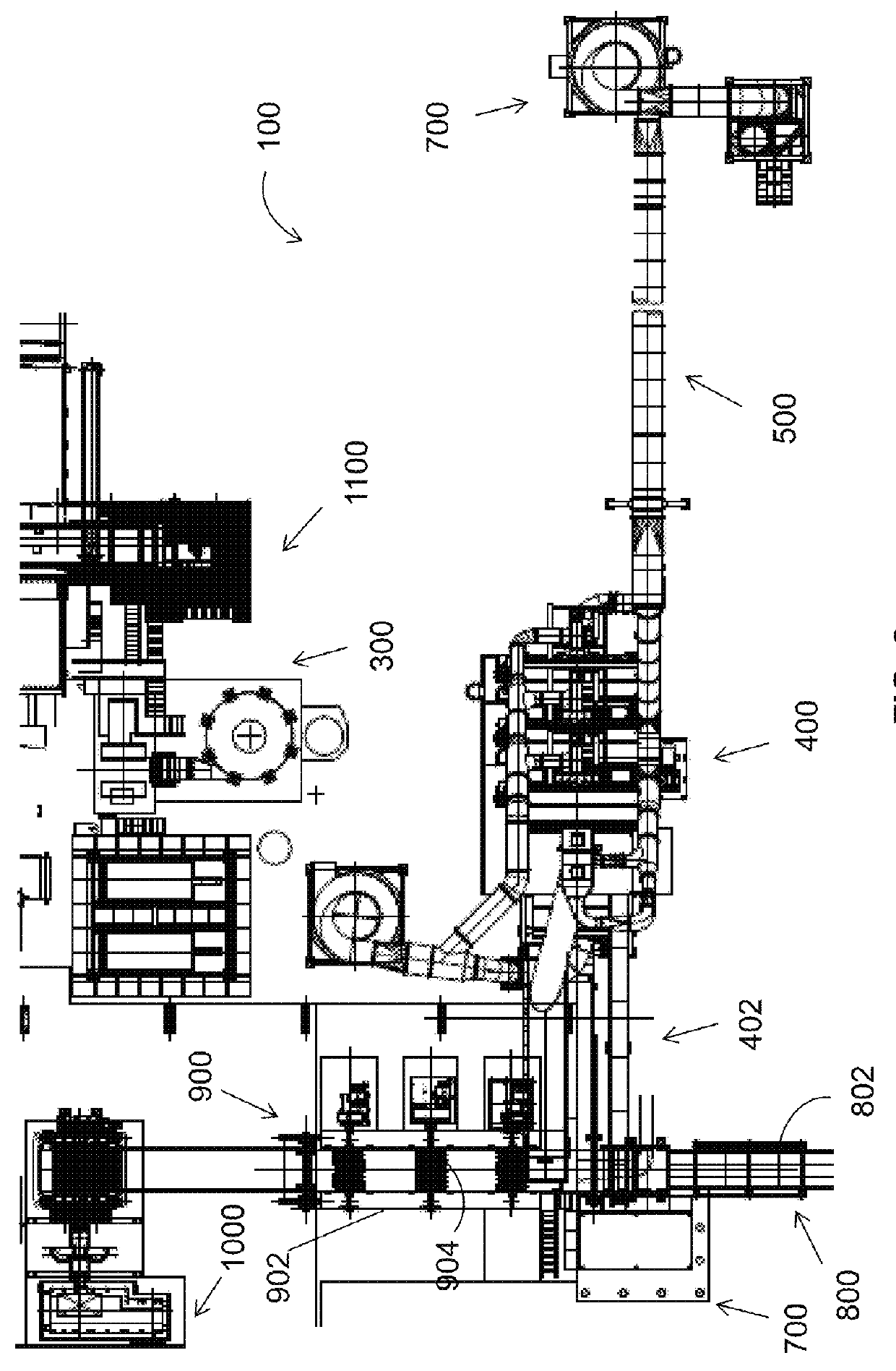

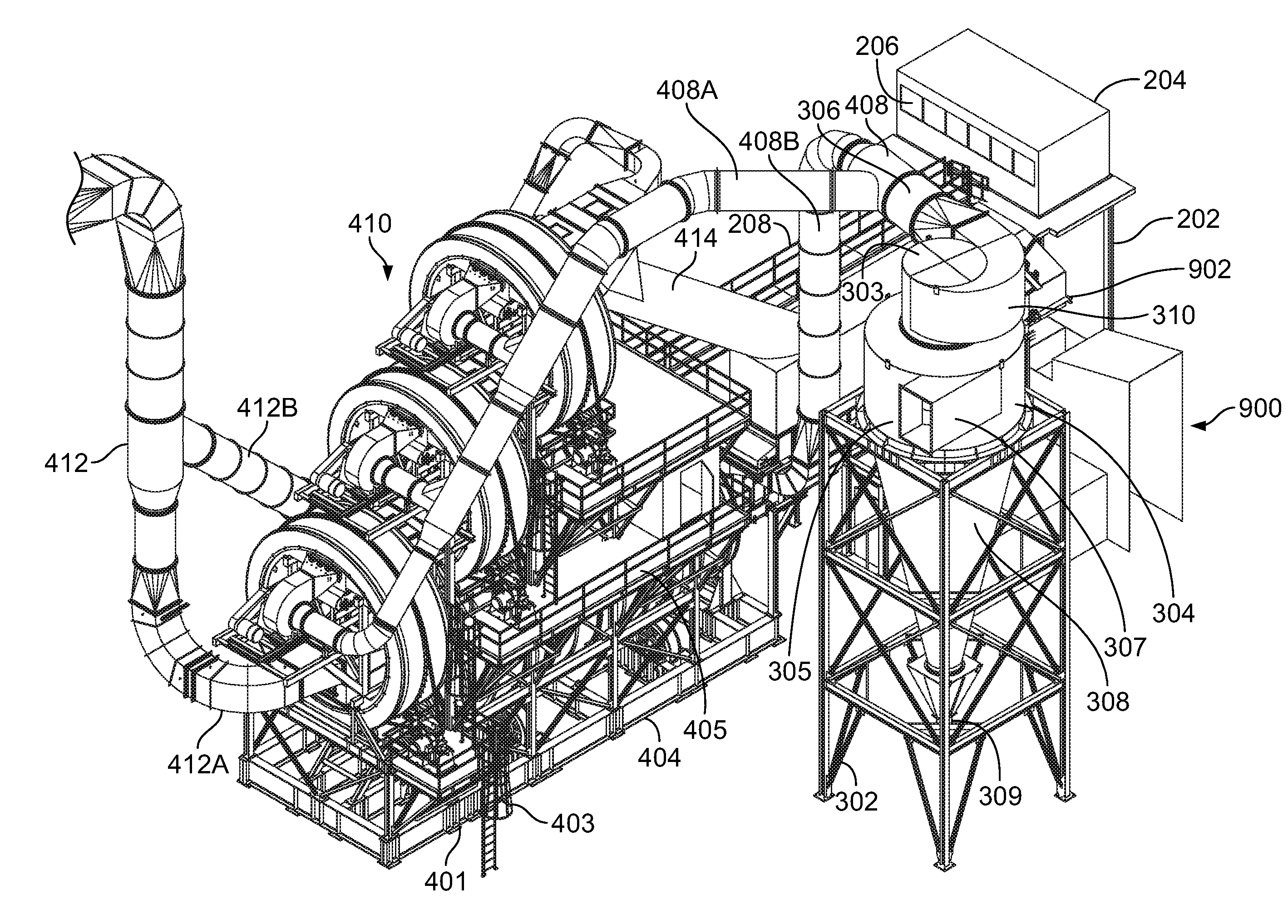

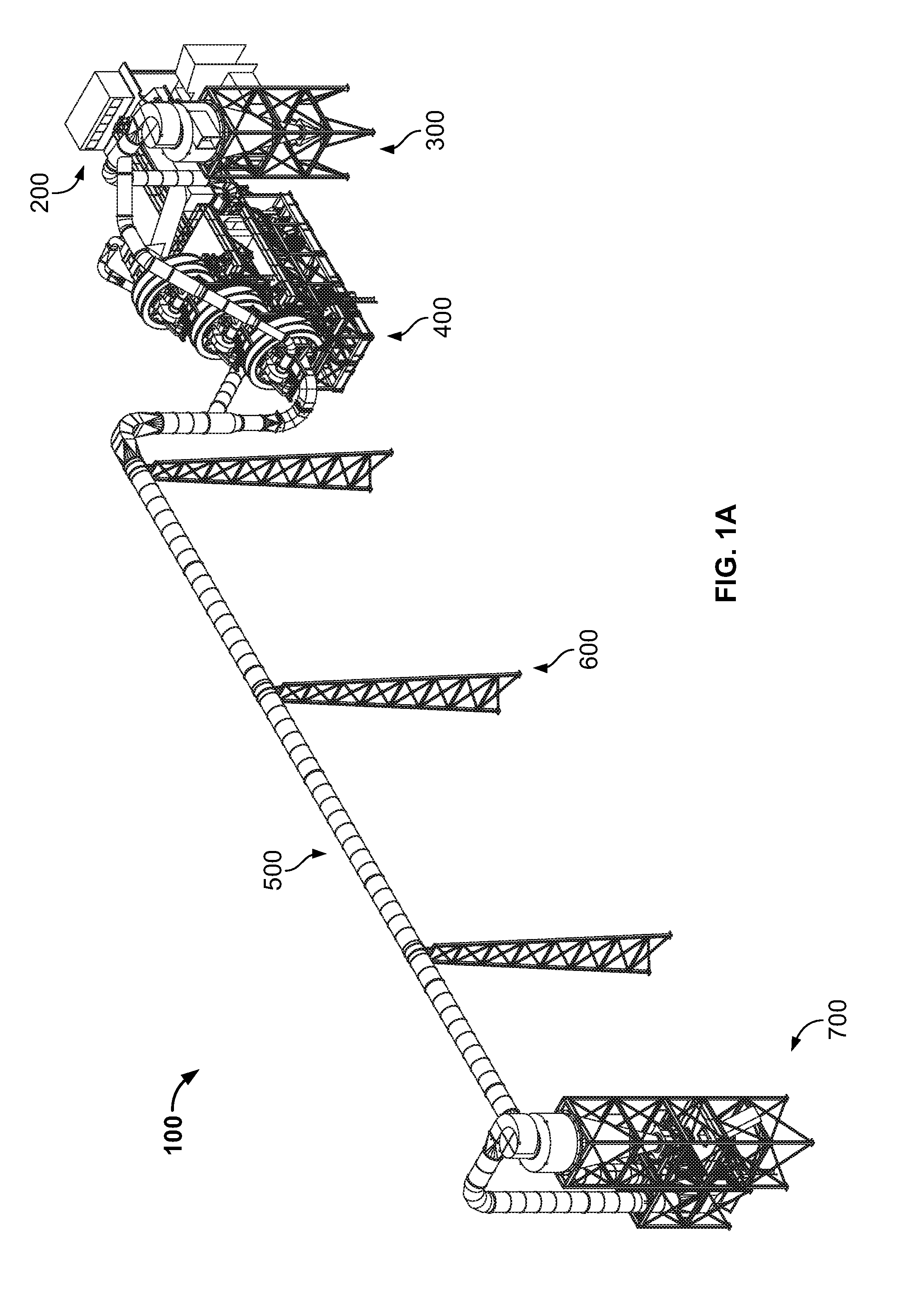

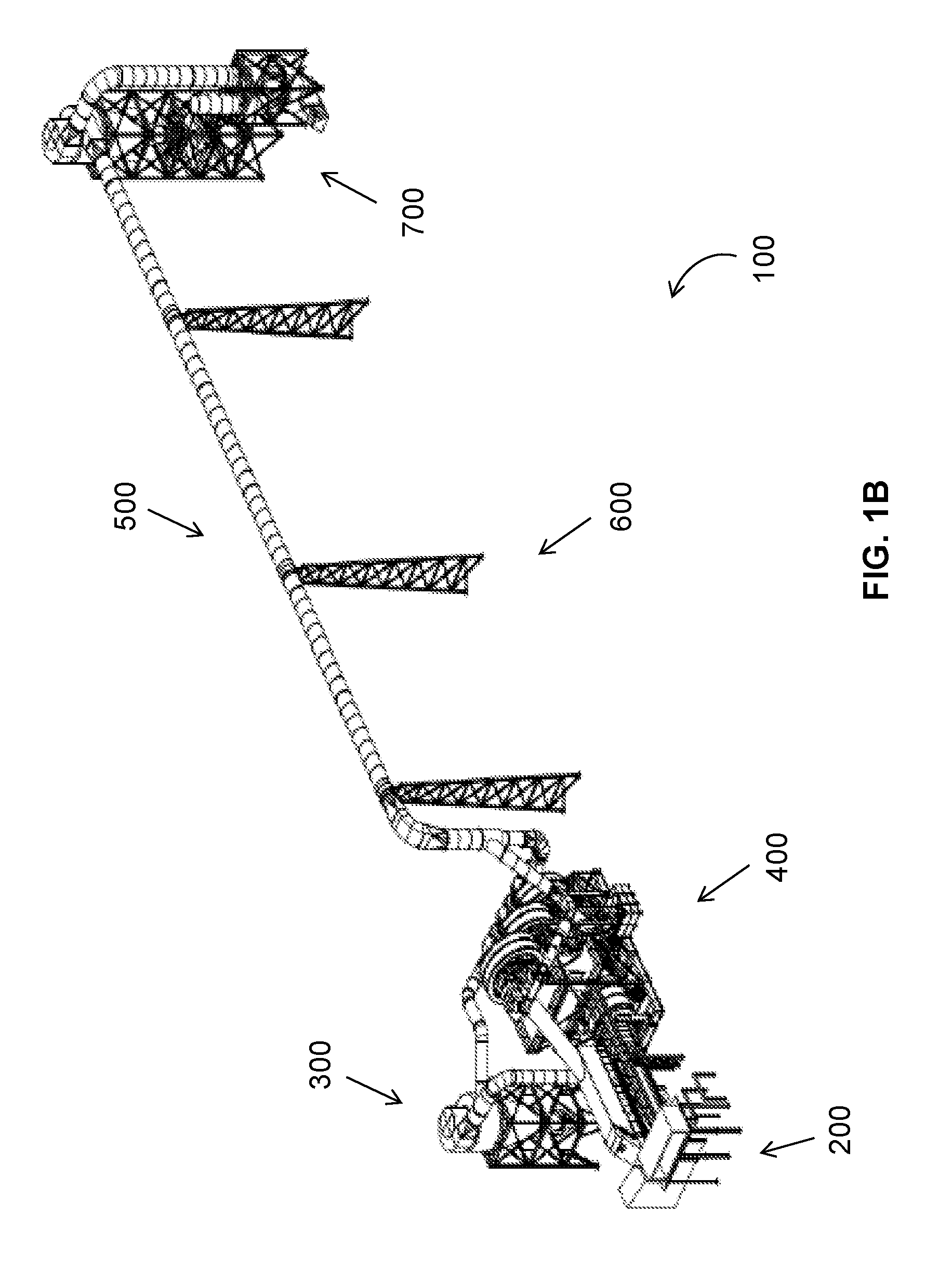

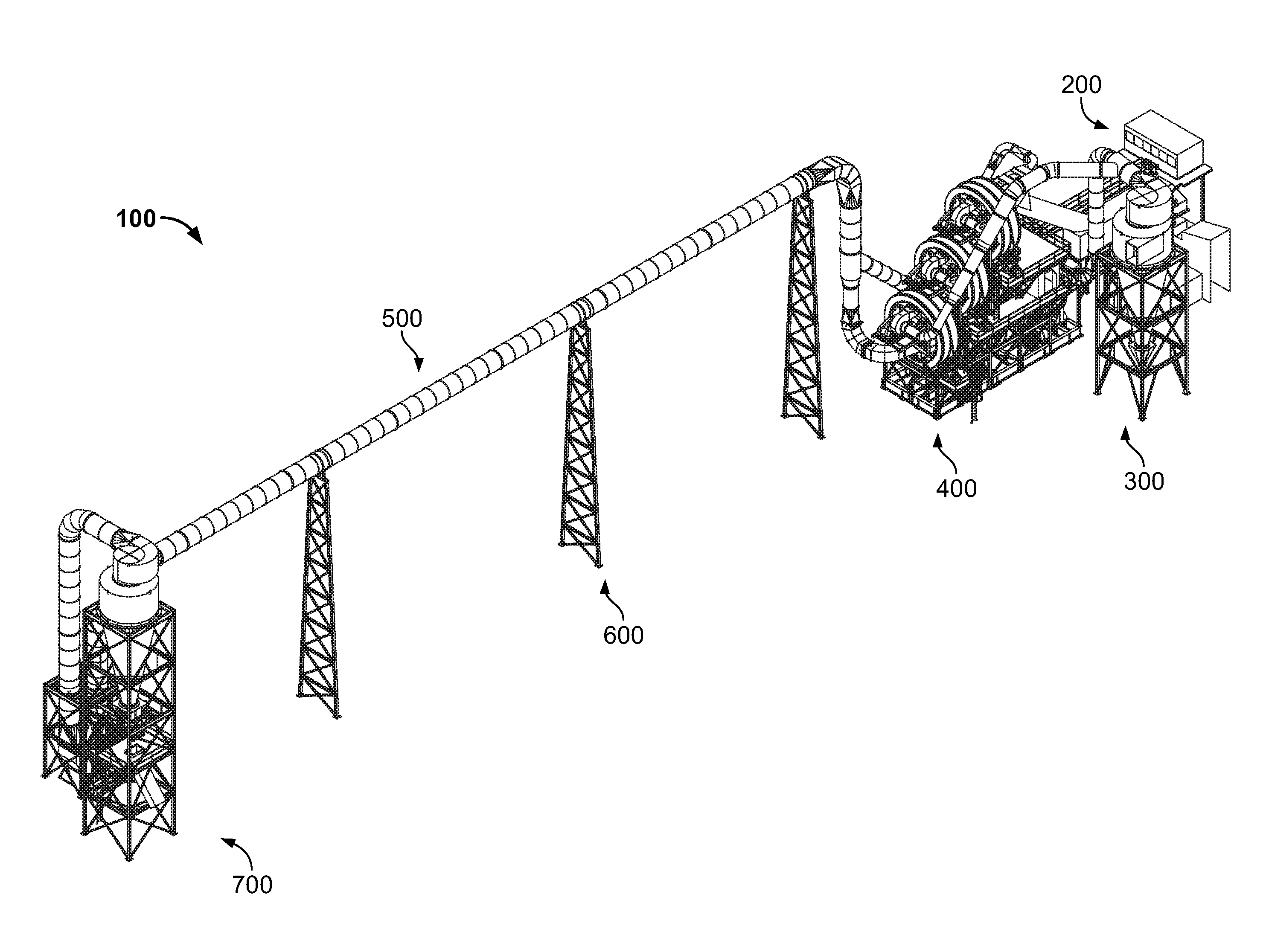

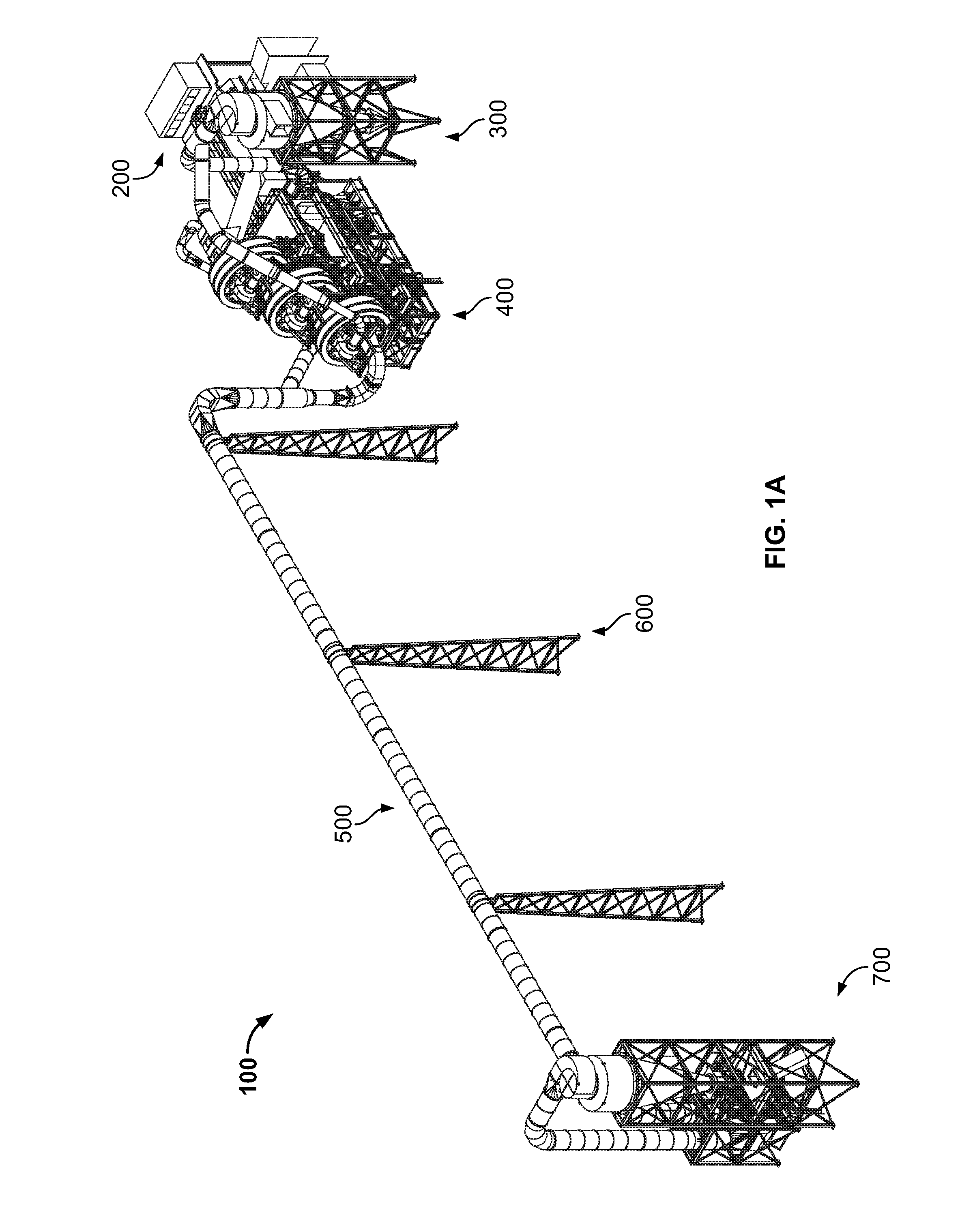

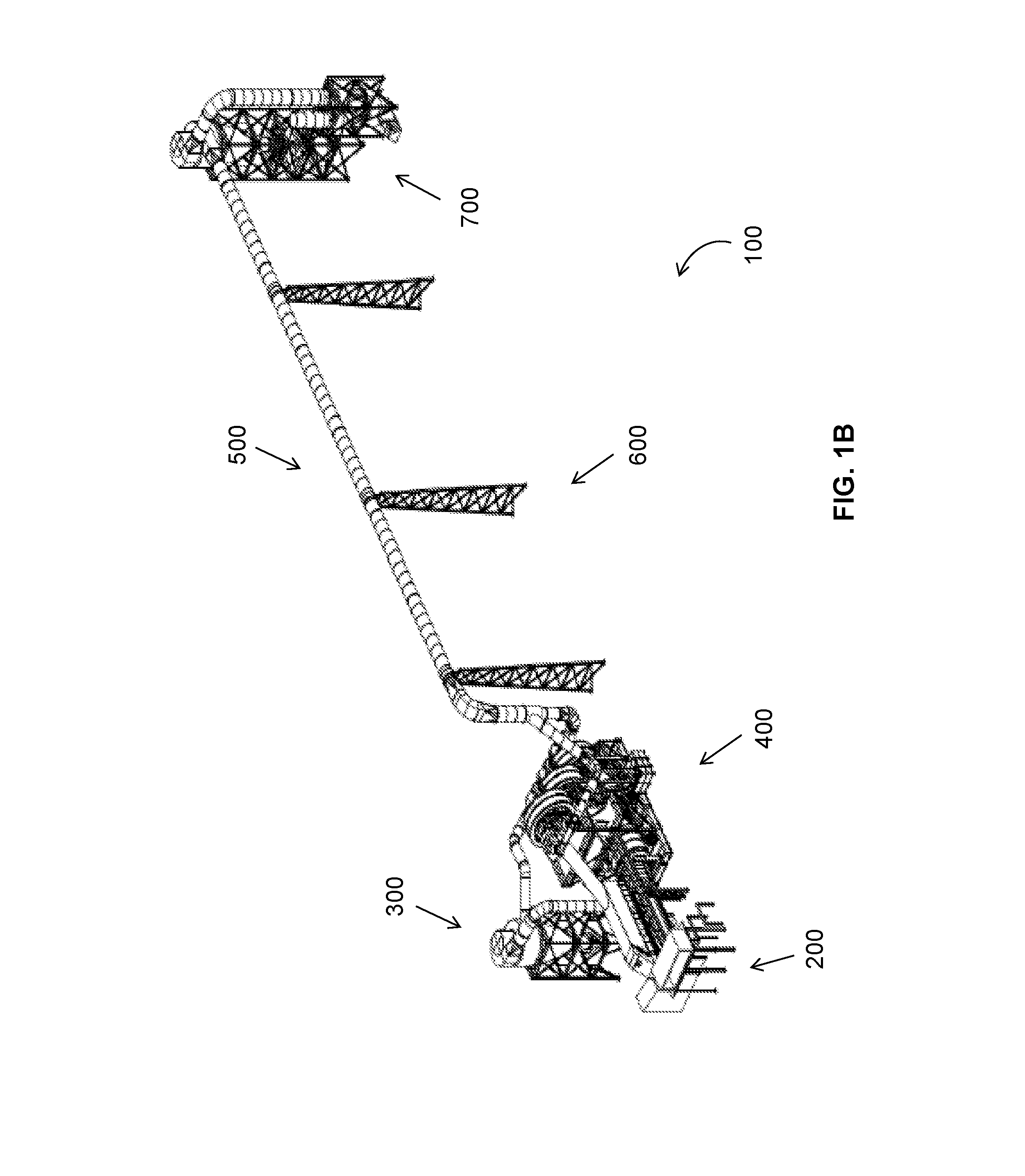

Technologies for material separation

A technology for material separation is provided. The technology enables an output of a first material from a rotary lifter. The technology enables a direction of a fluid stream onto the first material in flight based on the output of the first material such that the first material is separated into at least a second material and a third material. The technology enables a conveyance of the second material away from the rotary lifter. The technology enables a removal of the third material via a vacuum port.

Owner:AMERICAN BIOCARBON

Technologies for cyclonic material separation

A technology for material separation is provided. The technology enables an output of a first material from a rotary lifter. The technology enables a direction of a fluid stream onto the first material in flight based on the output of the first material such that the first material is separated into at least a second material and a third material. The technology enables a conveyance of the second material away from the rotary lifter. The technology enables a removal of the third material via a vacuum port.

Owner:AMERICAN BIOCARBON

Mechanical ultrasonic type sugarcane bagasse leaching device with feeding slot

InactiveCN107299160AContinuous and reliable biteExtrusion compression ratio is largeSolid waste disposalTransportation and packagingThree levelInlet valve

The invention discloses a mechanical ultrasonic type sugarcane bagasse leaching device with a feeding slot. A sugarcane bagasse feeding slot is formed in an upper part of a device body of the leaching device; three levels of counter-rotation cosine rollers are arranged inside the device body; surfaces of the counter-rotation cosine rollers are continuous cosine curved surfaces; sugarcane bagasse guiding slots are formed in lower parts of the three levels of counter-rotation cosine rollers; the last level of guiding slot is connected with a hopper of a sugarcane bagasse lifting machine; a discharging groove of the lifting machine is connected with a sugarcane bagasse temporary storage groove; the lifting machine is provided with a water inlet valve; an upper part of the device body is provided with a filter and a liquid outlet pipe; a mechanical ultrasonic vibration exciter is arranged at a left lower corner of the device body. The three levels of counter-rotation cosine rollers and the mechanical ultrasonic vibration exciter of the mechanical ultrasonic type sugarcane bagasse leaching device disclosed by the invention both have distinctive characteristics; the leaching extraction of sugars can be promoted in a cooperation manner; the device has a working principle and a technical effect which are difficultly predicted by technicians in the field, and has a stronger practical application value.

Owner:蒋霞

Mechanical ultrasonic type sugarcane bagasse treatment device with straw cutting machine and centrifugal machine

InactiveCN107299158AContinuous and reliable biteExtrusion compression ratio is largeTransportation and packagingSolid waste disposalThree levelInlet valve

The invention discloses a mechanical ultrasonic type sugarcane bagasse treatment device with a straw cutting machine and a centrifugal machine. A sugarcane bagasse straw cutting machine is arranged above a device body of a leaching device; three levels of counter-rotation cosine rollers are arranged inside the device body, and surfaces of the counter-rotation cosine rollers are continuous cosine curved surfaces; sugarcane bagasse guiding slots are formed in lower parts of the three levels of counter-rotation cosine rollers; the last level of guiding slot is connected with a hopper of a sugarcane bagasse lifting machine; a discharging groove of the lifting machine is connected with the centrifugal machine; the lifting machine is provided with a water inlet valve; an upper part of the device body is provided with a filter and a liquid outlet pipe; the liquid outlet pipe is connected with a triple-effect long-tube rising-film evaporation concentration device; a mechanical ultrasonic vibration exciter is arranged at a left lower corner of the device body. The three levels of counter-rotation cosine rollers and the mechanical ultrasonic vibration exciter of the mechanical ultrasonic type sugarcane bagasse treatment device disclosed by the invention both have distinctive characteristics; the leaching extraction of sugars can be promoted in a cooperation manner; the device has a working principle and a technical effect which are difficultly predicted by technicians in the field, and has a stronger practical application value.

Owner:李小兰

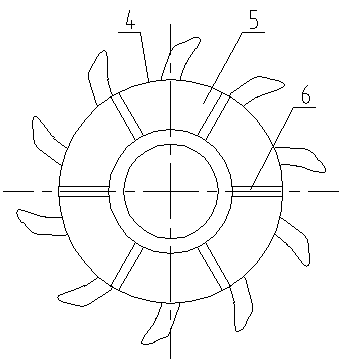

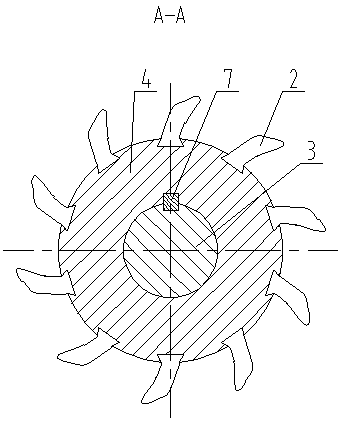

Squeezing and tearing cutter for sugarcane in sugar refinery, and manufacturing process thereof

The invention discloses a squeezing and tearing cutter for sugarcane in a sugar refinery. The cutter comprises a rotating shaft and a knife roll assembly mounted on the rotating shaft, wherein the surface of the knife roll assembly is further provided with at least 10 knives. The cutter is characterized in that the knife roller assembly comprises a rotating roller and covers mounted on the front and rear end faces of the rotating roller, and the outer surfaces of the covers are provided with reinforcing ribs; each knife comprises a knife body and a knife head arranged on the knife body, and the outer surface of the knife head is provided with at least two cladding layers prepared by using a plasma cladding process; the front corner of each knife head is provided with a main front rake angle and an auxiliary front rake angle from knife edge down; the back rake angle of each knife head is successively provided with a main back rake angle and an auxiliary back rake angle from knife edge down; an arc-shaped knife point chamfered edge is arranged between the front rake angle and the back rake angle of each knife head; and an auxiliary back rake angle fillet is arranged at the joint of each auxiliary back rake angle and the corresponding knife body. The cutter provided by the invention has the characteristics of stable product quality, high strength, reasonable structure, good durability, extensive adaptability, etc.

Owner:广西隆成机械设备制造有限公司

Technologies for material separation

A technology for material separation is provided. The technology enables an output of a first material from a rotary lifter. The technology enables a direction of a fluid stream onto the first material in flight based on the output of the first material such that the first material is separated into at least a second material and a third material. The technology enables a conveyance of the second material away from the rotary lifter. The technology enables a removal of the third material via a vacuum port.

Owner:AMERICAN BIOCARBON

Bagasse treatment device with feeding trough, centrifugal machine and drying machine

InactiveCN107312886AContinuous and reliable biteExtrusion compression ratio is largeTransportation and packagingSolid waste disposalThree stageInlet valve

The invention discloses a bagasse treatment device with a feeding trough, a centrifugal machine and a drying machine. The bagasse feeding trough is arranged above a body of a leaching device; three stages of contra-rotating cosine rollers are arranged in the body; surfaces of the contra-rotating cosine rollers are continuous cosine curved surfaces; a bagasse guide groove is formed below each stage of contra-rotating cosine roller; the final stage of guide groove is connected with a hopper of a bagasse elevator; a discharging groove of the elevator is connected with the drying machine via the dewatering centrifugal machine; a water inlet valve is arranged on the elevator; a filter and a liquid outlet tube are arranged on the upper part of the body; the liquid outlet tube is connected with a three-effect long-tube climbing-film evaporating and concentrating device; a cosine plastic plate pulse aeration device is arranged in the body; and a mechanical ultrasonic exciter is arranged at the left lower corner of the body. The three stages of contra-rotating cosine rollers, the cosine plastic plate pulse aeration device and the mechanical ultrasonic exciter have distinct characteristics, and can cooperatively facilitate leaching and extracting of sugar, and the bagasse treatment device has working principles and technical effects which are difficultly predicted by those skilled in the art, and has high actual application value.

Owner:熊小媚

Mechanical ultrasonic bagasse leaching device provided with feeding chute, centrifuge and drying machine

InactiveCN107312880AContinuous and reliable biteExtrusion compression ratio is largeSolid waste disposalTransportation and packagingThree stageInlet valve

The invention discloses a mechanical ultrasonic bagasse leaching device provided with a feeding chute, a centrifuge and a drying machine. The bagasse feeding chute is arranged above the body of the leaching device; three-stage counter rotating cosine rollers are arranged in the body, the surface of every counter rotating cosine roller is a continuous cosine curved surface, a bagasse guiding chute is arranged below every stage counter rotating cosine roller, the last stage guiding chute is connected with the hopper of a bagasse elevator, and the discharging chute of the elevator is connected with the drying machine through the dehydration centrifuge; the elevator is provided with a water inlet valve, and the upper part of the body is provided with a filter and a liquid discharging tube; and the bottom left corner of the body is provided with a mechanical ultrasonic vibration exciter. The three-stage counter rotating cosine rollers and the mechanical ultrasonic vibration exciter have distinct characteristics, and can cooperatively promote the leaching extraction of sugar, and the device has a working principle and technical effects which cannot be foreseen by technical personnel in the field, and has high practical application values.

Owner:蒋霞

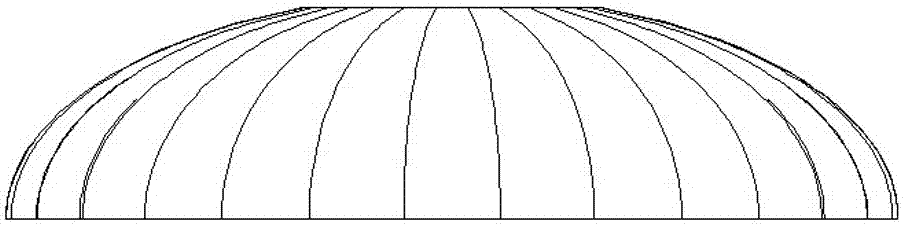

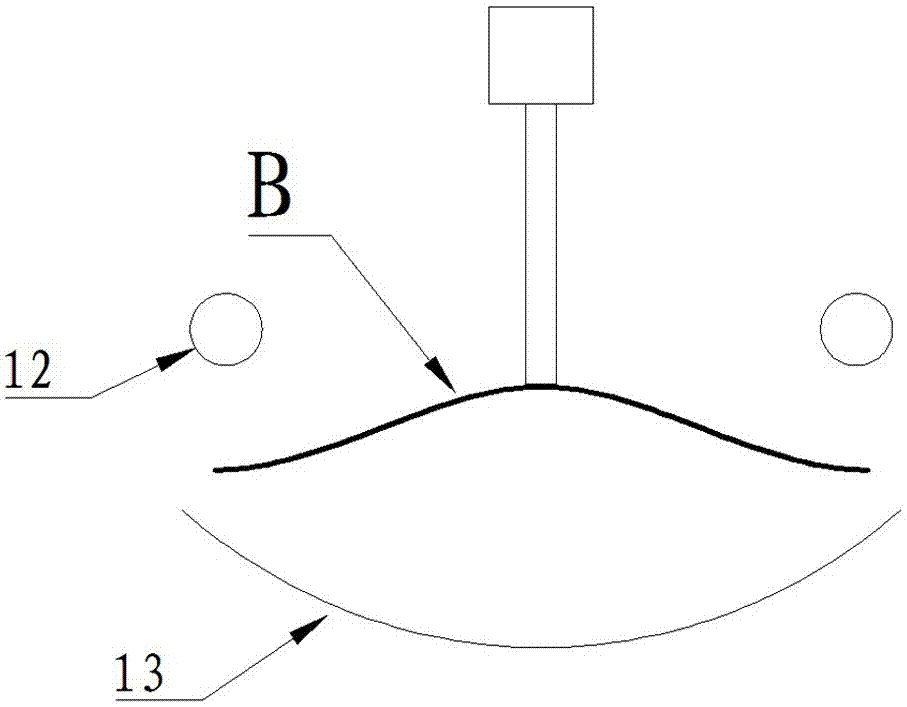

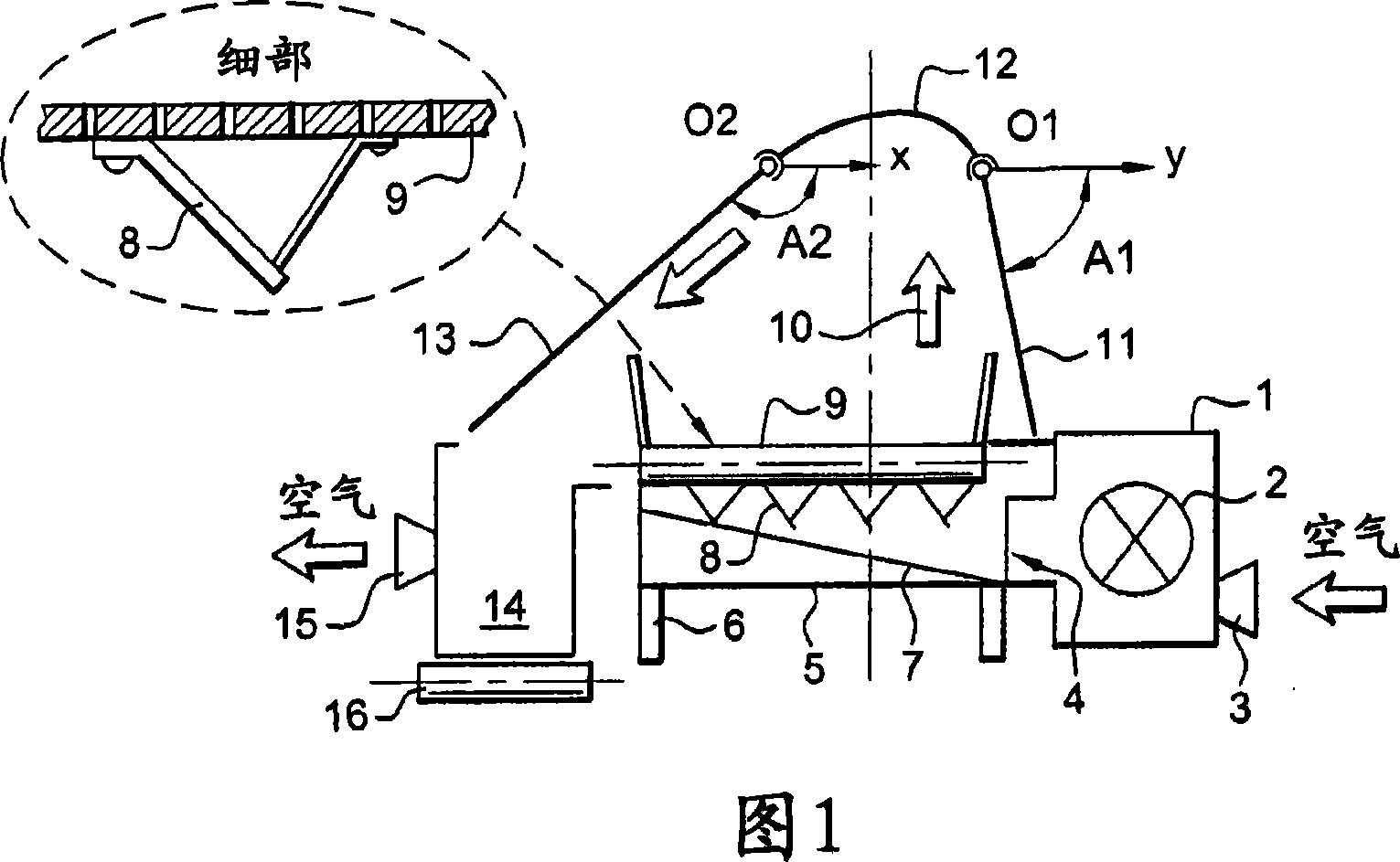

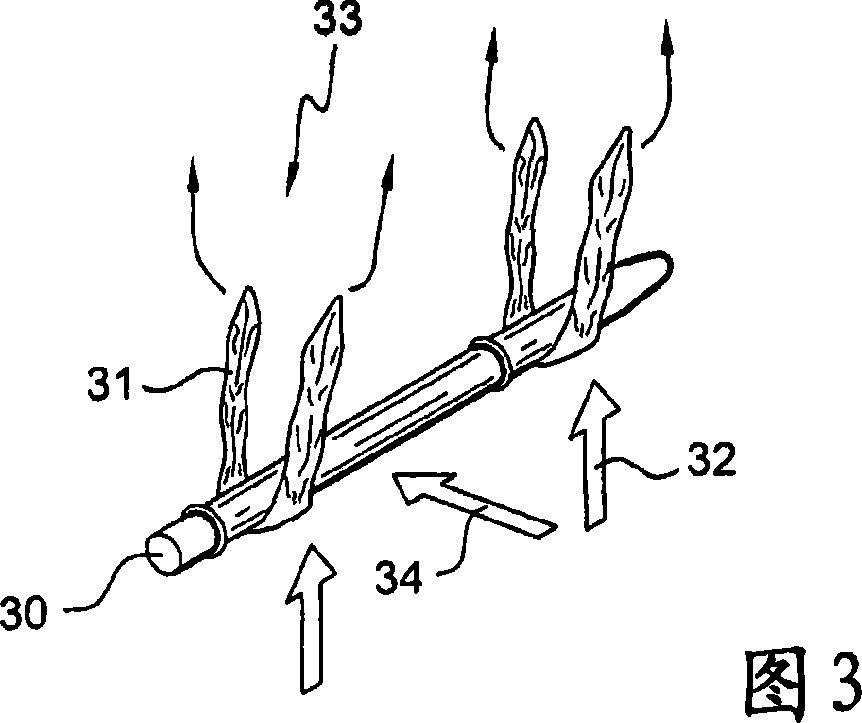

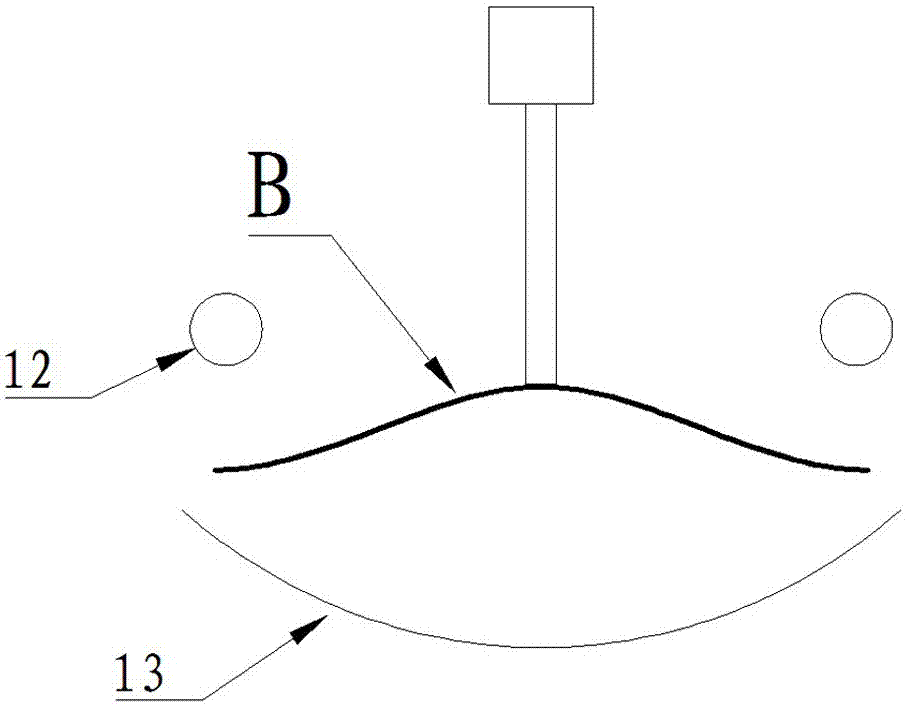

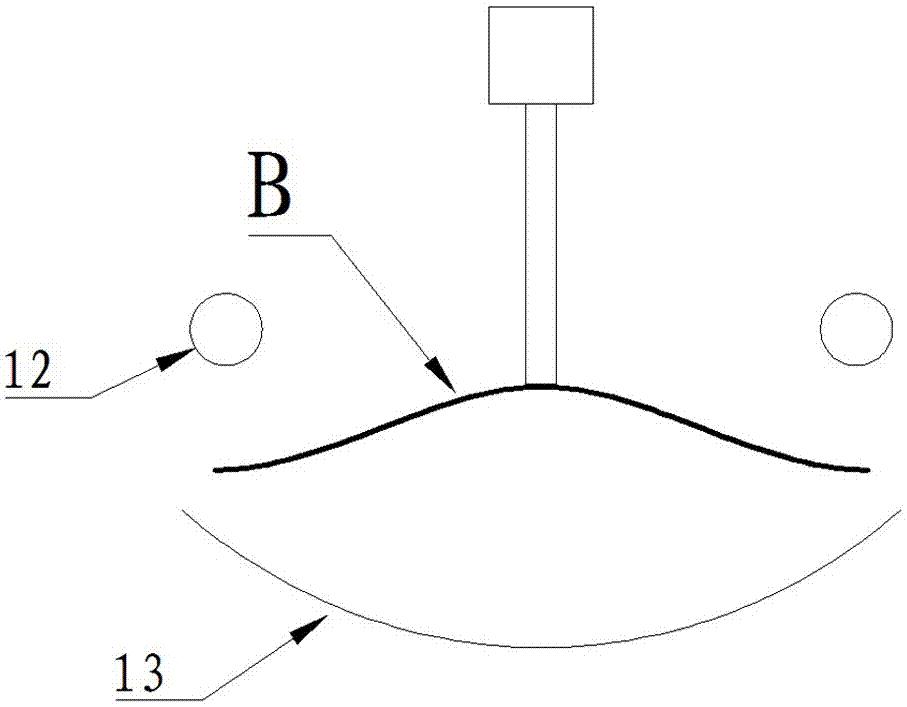

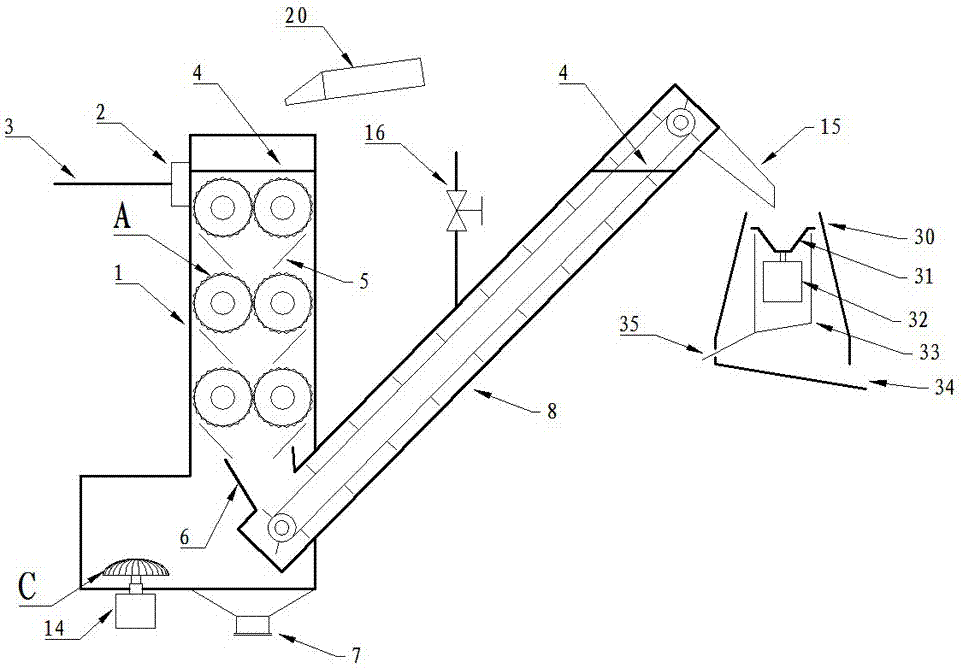

Method for removing straw from agriculture products and a straw removing device for carrying out said method

InactiveCN101080502AReduce volumeImprove overall processing efficiencyHarvestersSugarcane cuttingEngineeringSugar cane

The invention relates to a straw removing method, in particular for removing leaves and other vegetable wastes form agriculture products such as corn stalks or sugar canes. Said invention also relates to a straw removing device for carrying out said method. The inventive device comprises at least one transfer conveyor (9) carrying processable agriculture products, an air blow device (1, 2, 3) across the transfer conveyor and, finally, a ventilation bell (11, 12, 13) for orienting (10) an airflow and / or vegetable wastes transported thereby, for separating useless vegetable wastes (A2) as agriculture product leaves and to transfer said wastes to a receptacle area (14).

Owner:ODDEIS SA

Counter-rotation roller type sugarcane bagasse treatment device with feeding slot and carbon-making molding machine

InactiveCN107299162AContinuous and reliable biteExtrusion compression ratio is largeBiofuelsSolid fuelsThree levelMolding machine

The invention discloses a counter-rotation roller type sugarcane bagasse treatment device with a feeding slot and a carbon-making molding machine. A sugarcane bagasse feeding slot is formed in an upper part of a device body of a leaching device; three levels of counter-rotation rollers are arranged inside the device body, and the counter-rotation rollers are cylindrical; sugarcane bagasse guiding slots are formed in lower parts of the three levels of counter-rotation rollers; the last level of guiding slot is connected with a hopper of a sugarcane bagasse lifting machine; a discharging groove of the lifting machine is connected with a dryer through a centrifugal machine; a discharging end of the dryer is connected with the mechanized carbon-making molding machine; the lifting machine is provided with a water inlet valve; an upper part of the device body is provided with a filter and a liquid outlet pipe; the liquid outlet pipe is connected with a triple-effect long-tube climbing-film evaporation concentration device; a cosine gel tray pulse aeration device is arranged in the device body; a mechanical ultrasonic vibration exciter is arranged at a left lower corner of the device body. The three levels of counter-rotation rollers, the cosine gel tray pulse aeration device and the mechanical ultrasonic vibration exciter of the counter-rotation roller type sugarcane bagasse treatment device disclosed by the invention all have distinctive characteristics; the leaching extraction of sugars can be promoted in a cooperation manner; the device has a working principle and a technical effect which are difficultly predicted by technicians in the field, and has a stronger practical application value.

Owner:吴贻湖

A processing device for raw ecological brown sugar

ActiveCN104805224BTroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsAdditive ingredientUltrafiltration

An originally ecological black sugar processing device comprises a squeezing rough-filtration device, a heat exchanger, a multistage ceramic membrane ultrafiltration device, a falling-film type three-effect vacuum evaporation system, a water jet condenser, a jacketed iron pot and a graining drying forming device, which are sequentially connected, wherein a clarified sugarcane juice box is connected between the multistage ceramic membrane ultrafiltration device and the three-effect vacuum evaporation device; a syrup box is connected between the falling-film type three-effect vacuum evaporation system and the jacketed iron pot. The black sugar prepared through the device provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, sweet, delicious, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that black residues exist after the black sugar is dissolved is solved and the quality of the black sugar is improved.

Owner:广西百桂堂食品科技有限公司

Preparation method of brown sugar tablets

InactiveCN107760803ASimple preparation processEasy to implementSugar productsPurification by physical meansBoiling processAdditive ingredient

A preparation method of brown sugar tablets. Specifically, sugar cane is pressed to extract sugar cane juice, which is then filtered and boiled into syrup. Use quicklime as a coagulant, and add a coagulant during the boiling process of sugarcane juice. The sugarcane juice is concentrated into syrup through boiling, and then the syrup is cooled and formed. Finally, it is divided into flakes and packed according to the amount to obtain the finished product. . By implementing the present invention, the whole production process of the brown sugar slice finished product only needs about two hours before and after. The produced brown sugar tablet product almost retains all the ingredients in cane juice. In addition to the function of sugar, it also contains vitamins and trace elements, such as iron, zinc, manganese, chromium, etc., and its nutritional content is much higher than that of brown sugar and white sugar. . Simultaneously, the brown sugar tablet made by implementing the present invention adopts physical method completely, does not add any chemicals, and the sugar product is very healthy. In addition, the production cost of the product is low, and the market prospect is very broad.

Owner:黄秀英

Bagasse leaching device with feeding trough and pulper

InactiveCN107312885AContinuous and reliable biteExtrusion compression ratio is largeTransportation and packagingSolid waste disposalThree stageInlet valve

The invention discloses a bagasse leaching device with a feeding trough and a pulper. The bagasse feeding trough is arranged above a body of a leaching device; three stages of contra-rotating cosine rollers are arranged in the body; surfaces of the contra-rotating cosine rollers are continuous cosine curved surfaces; a bagasse guide groove is formed below each stage of contra-rotating cosine roller; the final stage of guide groove is connected with a hopper of a bagasse elevator; a discharging groove of the elevator is connected with a temporary storage groove via a cascaded pulper; a water inlet valve is arranged on the elevator; a filter and a liquid outlet tube are arranged on the upper part of the body; a cosine plastic plate pulse aeration device is arranged in the body; and a mechanical ultrasonic exciter is arranged at the left lower corner of the body. The three stages of contra-rotating cosine rollers, the cosine plastic plate pulse aeration device and the mechanical ultrasonic exciter have distinct characteristics, and can cooperatively facilitate leaching and extracting of sugar, and the bagasse leaching device has working principles and technical effects which are difficultly predicted by those skilled in the art, and has high actual application value.

Owner:谢瑶

Mechanical ultrasonic bagasse leaching device provided with cutter and pulper

InactiveCN107312883AFor smooth cuttingEasy to disassemble and maintainTransportation and packagingSolid waste disposalThree stageInlet valve

The invention discloses a mechanical ultrasonic bagasse leaching device provided with a cutter and a pulper. The bagasse cutter is arranged above the body of the leaching device; three-stage counter rotating cosine rollers are arranged in the body, the surface of every counter rotating cosine roller is a continuous cosine curved surface, a bagasse guiding chute is arranged below every stage counter rotating cosine roller, the last stage guiding chute is connected with the hopper of a bagasse elevator, and the discharging chute of the elevator is connected with a bagasse temporary storage tank; the elevator is provided with a water inlet valve, and the upper part of the body is provided with a filter and a liquid discharging tube; and the bottom left corner of the body is provided with a mechanical ultrasonic vibration exciter. The three-stage counter rotating cosine rollers and the mechanical ultrasonic vibration exciter have distinct characteristics, and can cooperatively promote the leaching extraction of sugar, and the device has a working principle and technical effects which cannot be foreseen by technical personnel in the field, and has high practical application values.

Owner:蒋霞

Counter-rotation roller type sugarcane bagasse treatment device with straw cutting machine and carbon-making molding machine

InactiveCN107299166AContinuous and reliable biteExtrusion compression ratio is largeTransportation and packagingSolid waste disposalThree levelMolding machine

The invention discloses a counter-rotation roller type sugarcane bagasse treatment device with a straw cutting machine and a carbon-making molding machine. The straw cutting machine is arranged above a device body of a leaching device; three levels of counter-rotation rollers are arranged inside the device body, and the counter-rotation rollers are cylindrical; sugarcane bagasse guiding slots are formed in lower parts of the three levels of counter-rotation rollers; the last level of guiding slot is connected with a hopper of a sugarcane bagasse lifting machine; a discharging groove of the lifting machine is connected with a dryer through a centrifugal machine; a discharging end of the dryer is connected with a mechanized carbon-making molding machine; the lifting machine is provided with a water inlet valve; an upper part of the device body is provided with a filter and a liquid outlet pipe; the liquid outlet pipe is connected with a triple-effect long-tube rising-film evaporation concentration device; a cosine gel tray pulse aeration device is arranged in the device body; a mechanical ultrasonic vibration exciter is arranged at a left lower corner of the device body. The three levels of counter-rotation rollers, the cosine gel tray pulse aeration device and the mechanical ultrasonic vibration exciter of the counter-rotation roller type sugarcane bagasse treatment device disclosed by the invention all have distinctive characteristics; the leaching extraction of sugars can be promoted in a cooperation manner; the device has a working principle and a technical effect which are difficultly predicted by technicians in the field, and has a stronger practical application value.

Owner:吴贻湖

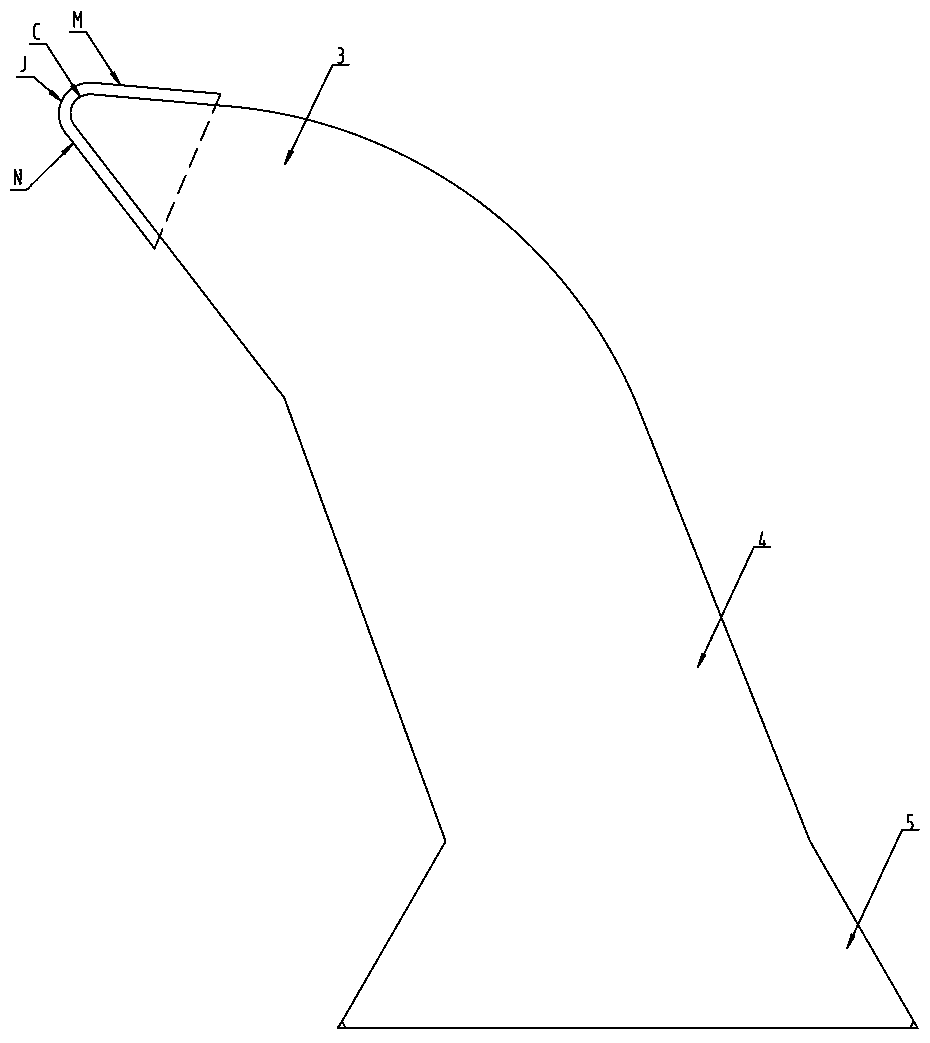

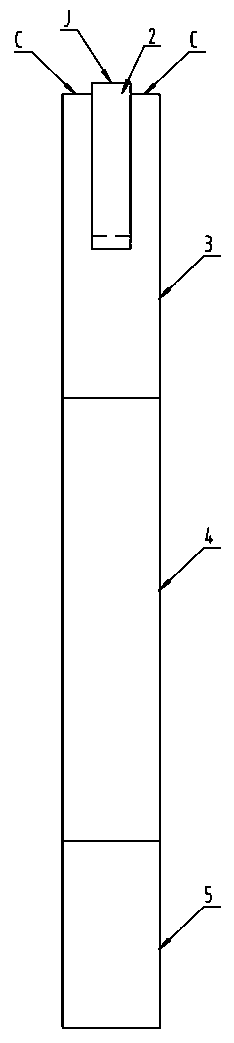

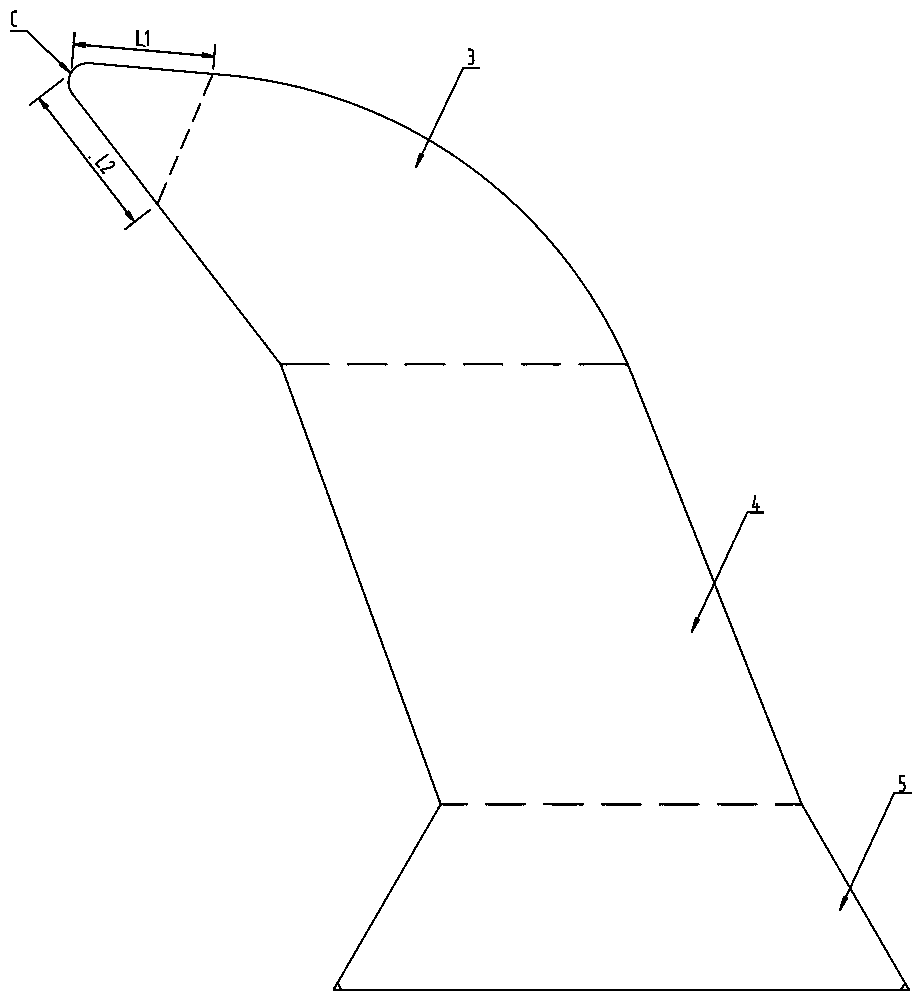

Sugarcane tearing machine cutter

InactiveCN110283946AImprove stress stabilityHigh bonding strengthSugar raw material preprocessing knivesSugarcane shreddingWear resistantButt joint

The invention relates to the technical field of sugar industry, and provides a sugarcane tearing machine cutter. The cutter comprises a cutter head, a matrix and a forked tail portion which are siamesed, whose thicknesses are the same, and whose end portions are in flush butt joint, wherein the side face of the matrix is an oblique quadrangle with substantially-equal opposite sides; the cutter head is gradually narrowed, and the arc of the tail portion, far away from the matrix, of the cutter head forms an arc end face through transition; particularly, the middle of the tail portion of the cutter head is longitudinally provided with a slotting; the slotting is internally embedded with a wear-resistant alloy block; the width of the slotting is 1 / 3 to 5 / 6 of the thickness of the cutter head; the distance from the midpoint of the arc end face to the slotting end is greater than the thickness of the cutter head; the thickness of the alloy block is adapted to the slotting; the bottom face of the alloy block directly faces the bottom slot face of the slotting, and the side connecting faces of the alloy block are respectively abut to the side slot faces of the slotting; the other faces of the alloy block are crushing working surfaces which are 0 to 10 mm higher than the surface of the corresponding position of the cutter head; optimally, an auxiliary working surface, on the outer side of the slotting, of the cutter head is firmly adhered to a wear-resistant alloy layer with the thickness of less than 2 mm. The cutter provided by the invention has the characteristics of good wear resistance and impact resistance, and the service life of the tearing machine cutter can be prolonged.

Owner:GUANGDONG PROVINCIAL BIOENGINEERING INST (GUANGZHOU SUGARCANE IND RES INST)

Mechanical ultrasonic bagasse processing device provided with cutter

InactiveCN107312884AFor smooth cuttingEasy to disassemble and maintainTransportation and packagingSolid waste disposalThree stageInlet valve

The invention discloses a mechanical ultrasonic bagasse processing device provided with a cutter. The bagasse cutter is arranged above the body of the processing device; three-stage counter rotating cosine rollers are arranged in the body, the surface of every counter rotating cosine roller is a continuous cosine curved surface, a bagasse guiding chute is arranged below every stage counter rotating cosine roller, the last stage guiding chute is connected with the hopper of a bagasse elevator, and the discharging chute of the elevator is connected with a bagasse temporary storage tank; the elevator is provided with a water inlet valve, the upper part of the body is provided with a filter and a liquid discharging tube, and the liquid discharging tube is connected with a triple-effect long tube rising membrane evaporation concentrator; and the bottom left corner of the body is provided with a mechanical ultrasonic vibration exciter. The three-stage counter rotating cosine rollers and the mechanical ultrasonic vibration exciter have distinct characteristics, and can cooperatively promote the processing extraction of sugar, and the device has a working principle and technical effects which cannot be foreseen by technical personnel in the field, and has high practical application values.

Owner:李小兰

Contrarotating-roller bagasse treating device with feeding trough and centrifugal machine

InactiveCN107326112AContinuous and reliable biteExtrusion compression ratio is largePurification by physical meansSugarcane shreddingEvaporationEngineering

The invention discloses a counter-rotating drum-type bagasse treatment device with a feeding tank and a centrifuge. A bagasse feeding tank is arranged above the body of the leaching device; The drum is cylindrical, and there is a bagasse guide groove under each stage of counter-rotating rollers. The guide groove of the last stage is connected to the hopper of the bagasse elevator, and the discharge chute of the elevator is connected to the centrifuge; the elevator is equipped with a water inlet Valve, the upper part of the body is equipped with a filter and a liquid outlet pipe, and the liquid outlet pipe is connected to a three-effect long tube rising film evaporation concentration device; a cosine rubber disk pulse explosion device is installed in the body, and a mechanical ultrasonic exciter is installed in the lower left corner of the body. The three-stage counter-rotating drum, cosine rubber disk pulse explosion device and mechanical ultrasonic exciter of the present invention all have distinctive features, can synergistically promote the leaching and extraction of sugar, and have working principles and technical effects that are difficult for those skilled in the art to foresee. It has strong practical application value.

Owner:吴贻湖

Mechanical ultrasonic type sugarcane bagasse leaching device with feeding slot and centrifugal machine

InactiveCN107299159AContinuous and reliable biteExtrusion compression ratio is largeTransportation and packagingSolid waste disposalThree levelInlet valve

The invention discloses a mechanical ultrasonic type sugarcane bagasse leaching device with a feeding slot and a centrifugal machine. A sugarcane bagasse feeding slot is formed in an upper part of a device body of the leaching device; three levels of counter-rotation cosine rollers are arranged inside the device body; surfaces of the counter-rotation cosine rollers are continuous cosine curved surfaces; sugarcane bagasse guiding slots are formed in lower parts of the three levels of counter-rotation cosine rollers; the last level of guiding slot is connected with a hopper of a sugarcane bagasse lifting machine; a discharging groove of the lifting machine is connected with the centrifugal machine; the lifting machine is provided with a water inlet valve; an upper part of the device body is provided with a filter and a liquid outlet pipe; a mechanical ultrasonic vibration exciter is arranged at a left lower corner of the device body. The three levels of counter-rotation cosine rollers and the mechanical ultrasonic vibration exciter of the mechanical ultrasonic type sugarcane bagasse leaching device disclosed by the invention both have distinctive characteristics; the leaching extraction of sugars can be promoted in a cooperation manner; the device has a working principle and a technical effect which are difficultly predicted by technicians in the field, and has a stronger practical application value.

Owner:蒋霞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com