Mechanical ultrasonic bagasse leaching device provided with feeding chute, centrifuge and drying machine

A sugarcane bagasse and dryer technology, applied in dryer combination, sugarcane tearing, transportation and packaging, etc., to achieve continuous and reliable bite, good effect, and large extrusion compression ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

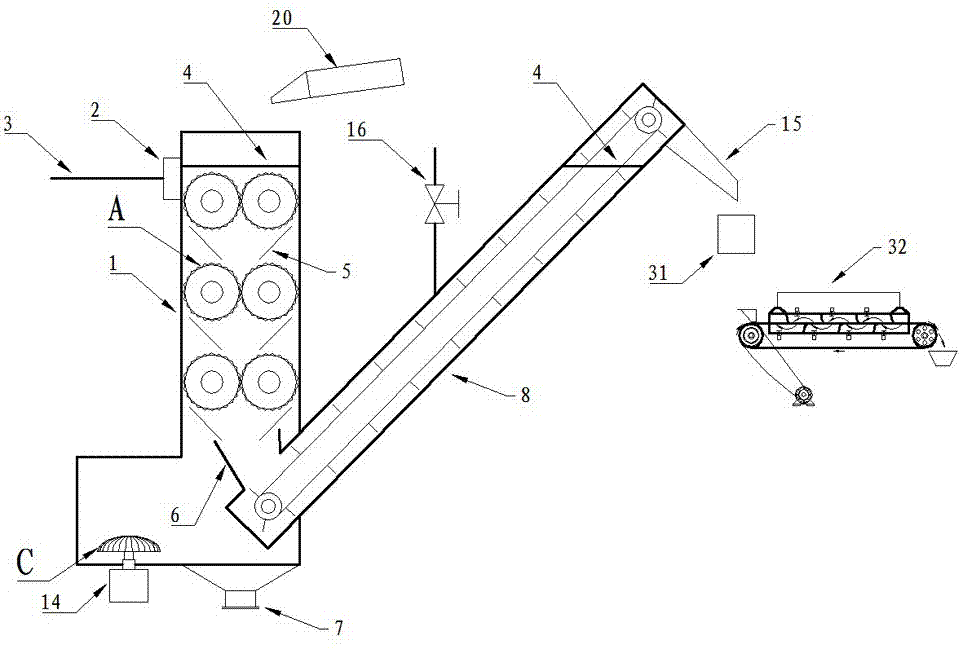

[0027] Now in conjunction with accompanying drawing, the present invention is described in further detail.

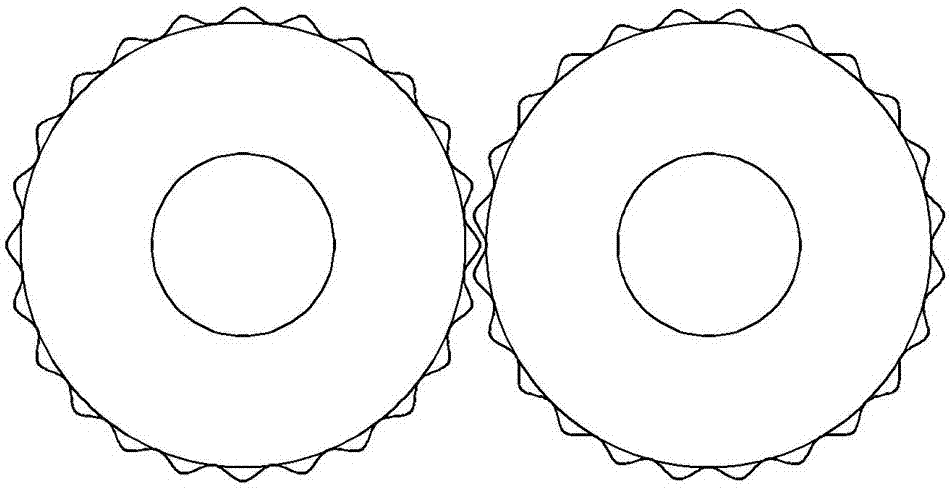

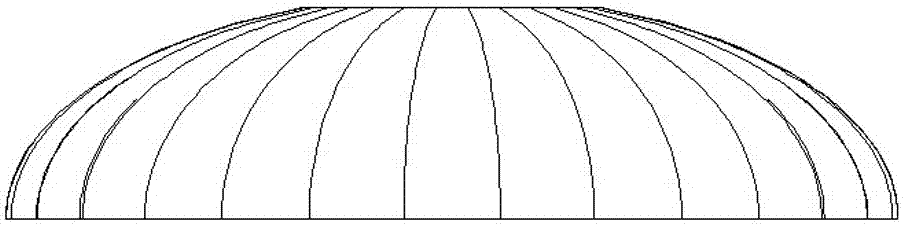

[0028] Such as Figure 1-Figure 7 The shown mechanical ultrasonic bagasse leaching device with a feeding tank, a centrifuge and a dryer includes a body 1, a bagasse feeding tank 20 is arranged above the body 1; a three-stage counter-rotating cosine drum A is arranged inside the body, The surface of the counter-rotating cosine drum is a continuous cosine surface, and there is a bagasse guide groove 5 under each counter-rotating cosine drum, and the last-level guide groove is connected to the hopper 6 of the bagasse hoist 8, and the discharge trough 15 of the hoist The dehydration centrifuge 31 is connected to the dryer 32; the hoist is equipped with a water inlet valve 16, and the upper part of the body is equipped with a filter 2 and a liquid outlet pipe 3; the lower left corner of the body is equipped with a mechanical ultrasonic vibration exciter C, driven by a power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com