Patents

Literature

131results about How to "Good secondary crushing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contra-rotating roller type huperzine-A leaching device with cleaning machine and drying machine

InactiveCN107308683AContinuous and reliable biteExtrusion compression ratio is largeOrganic chemistryCounter-current extractionSlagInlet valve

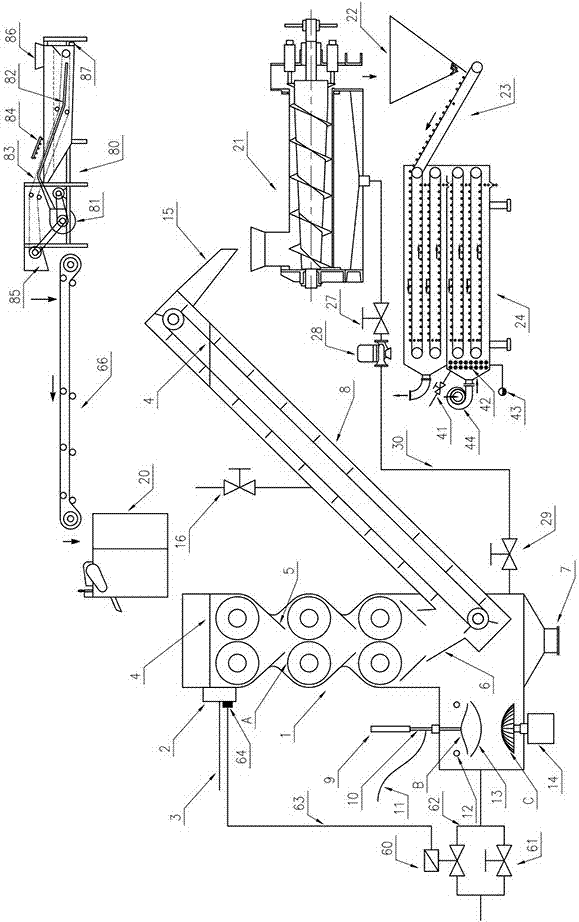

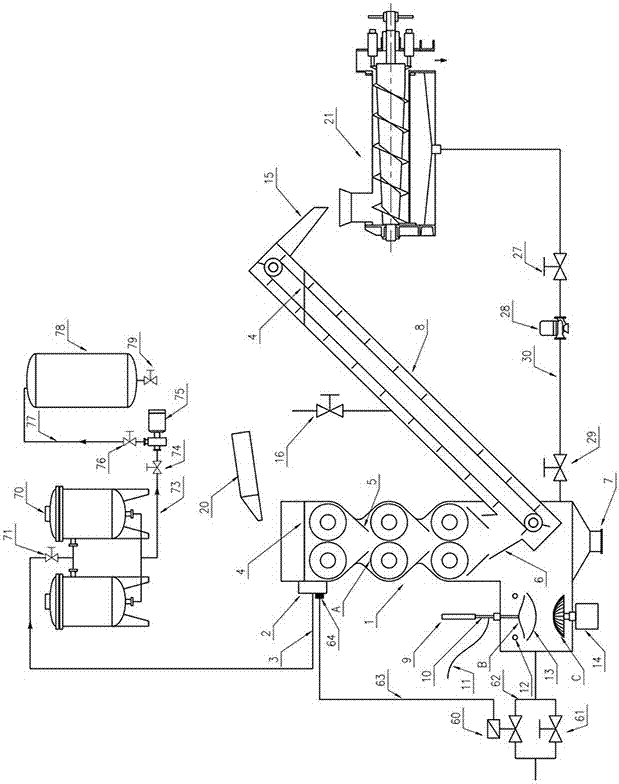

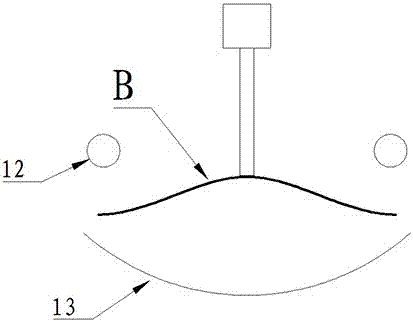

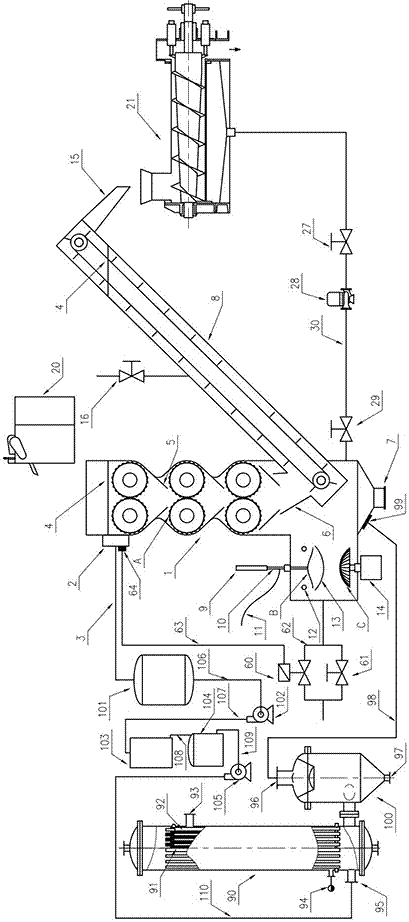

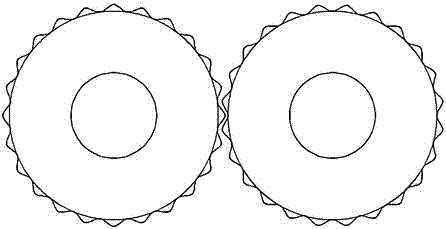

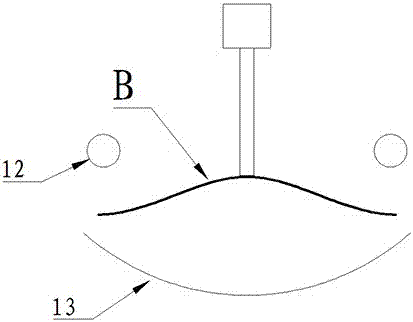

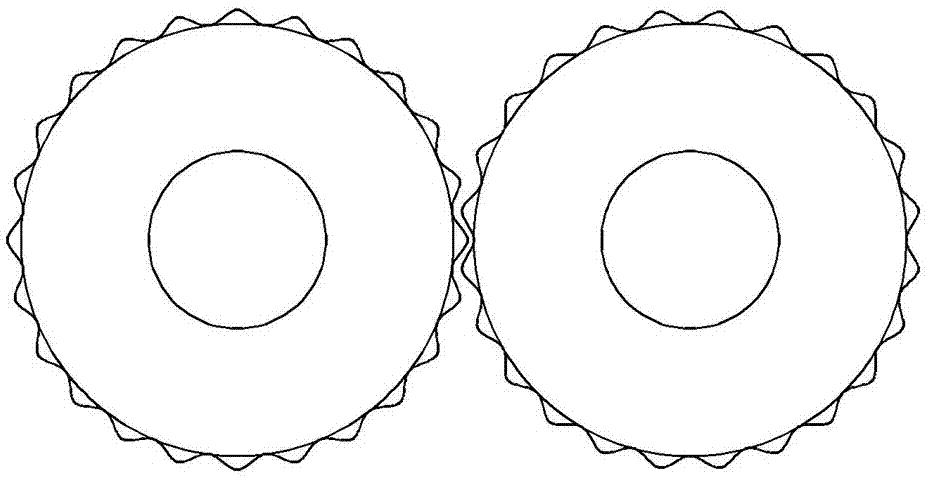

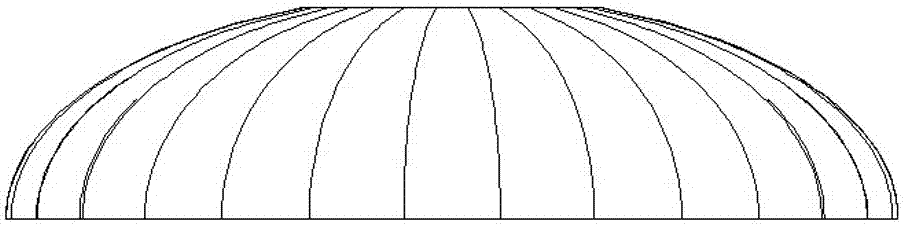

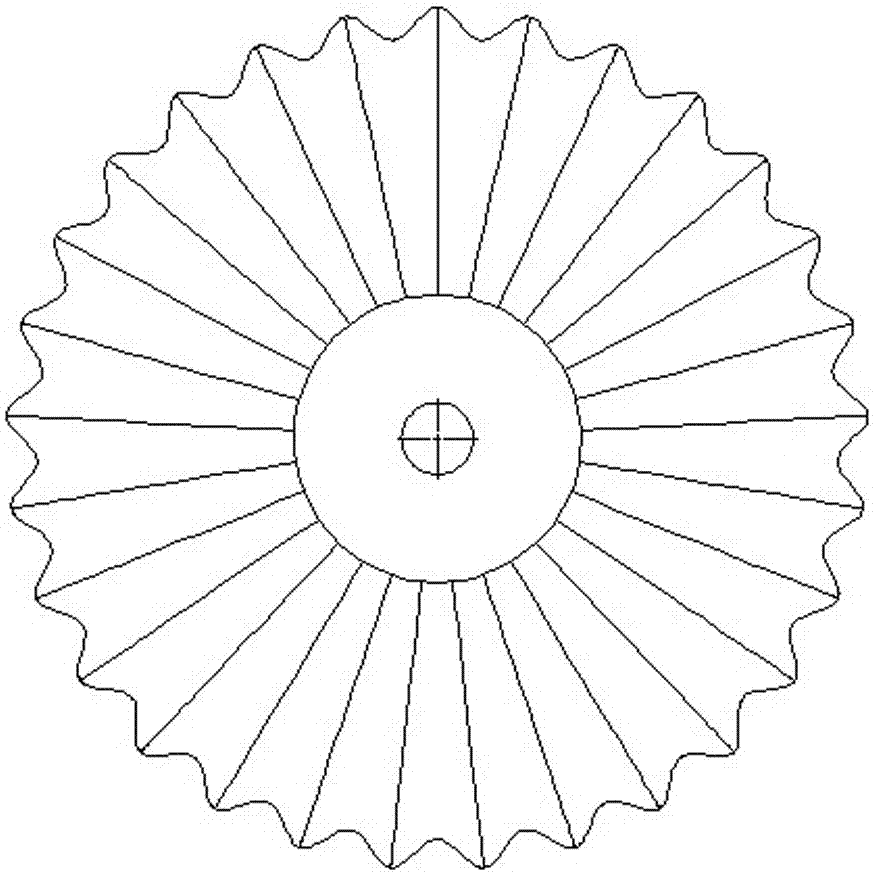

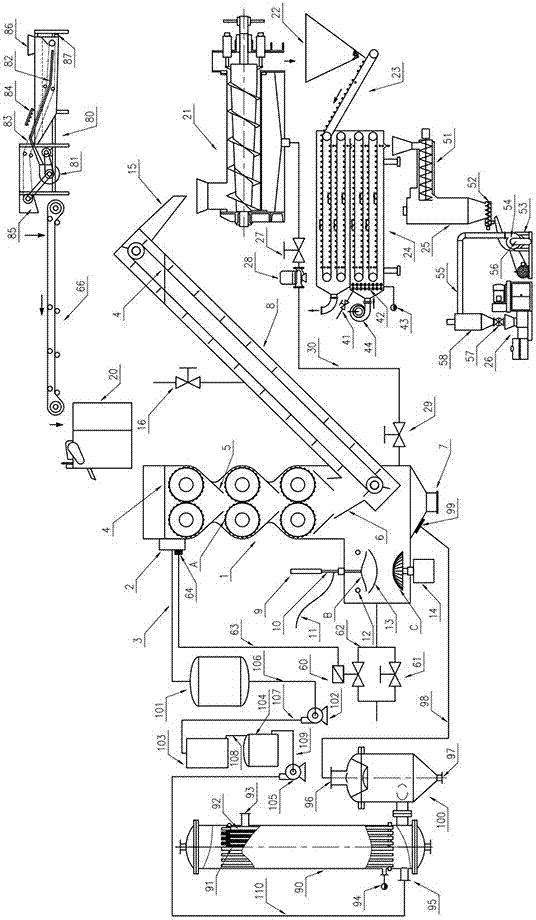

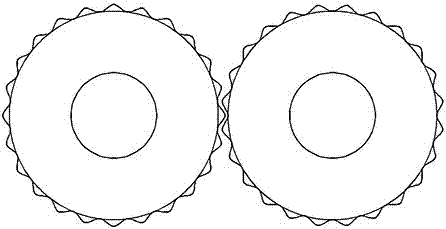

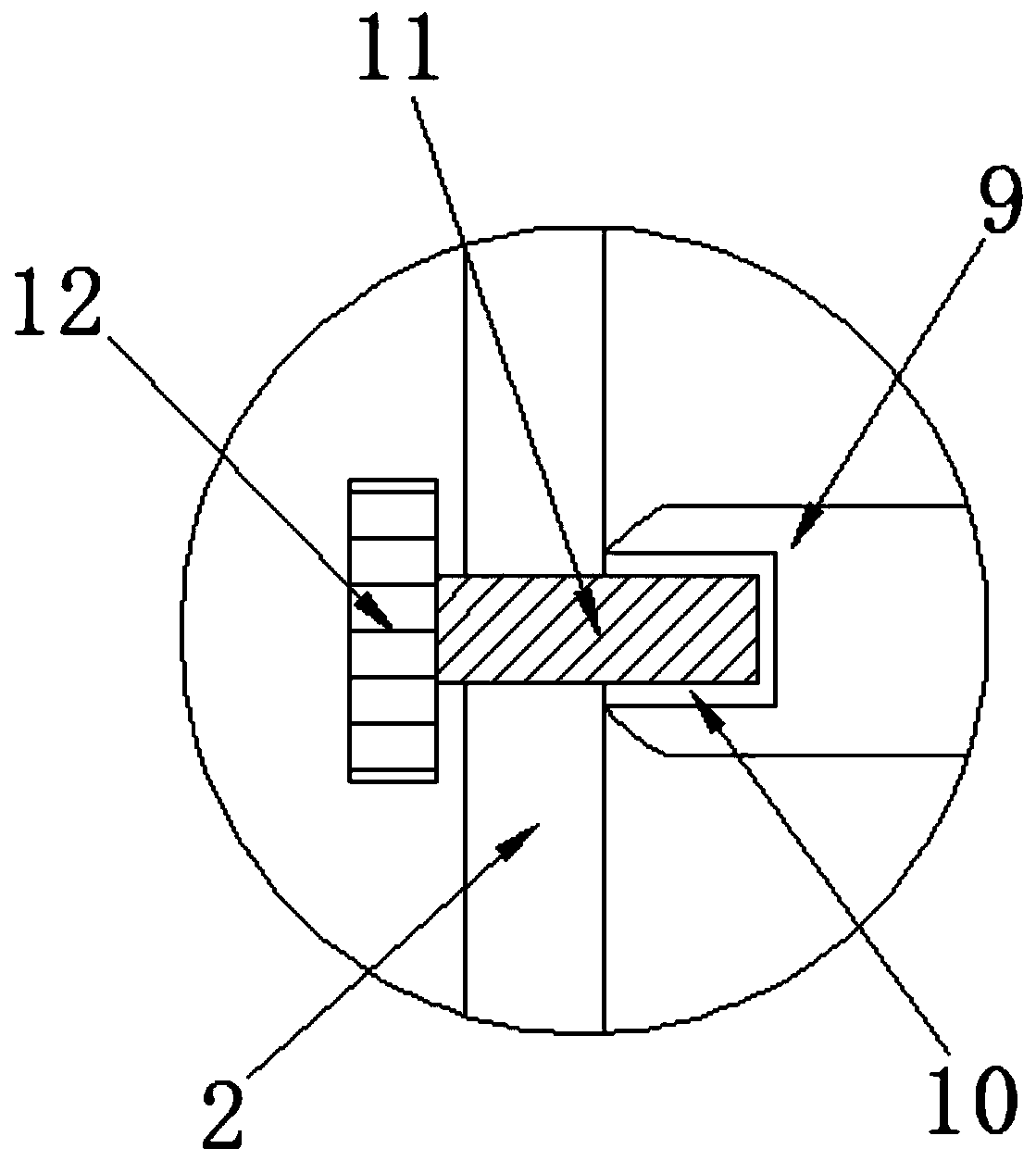

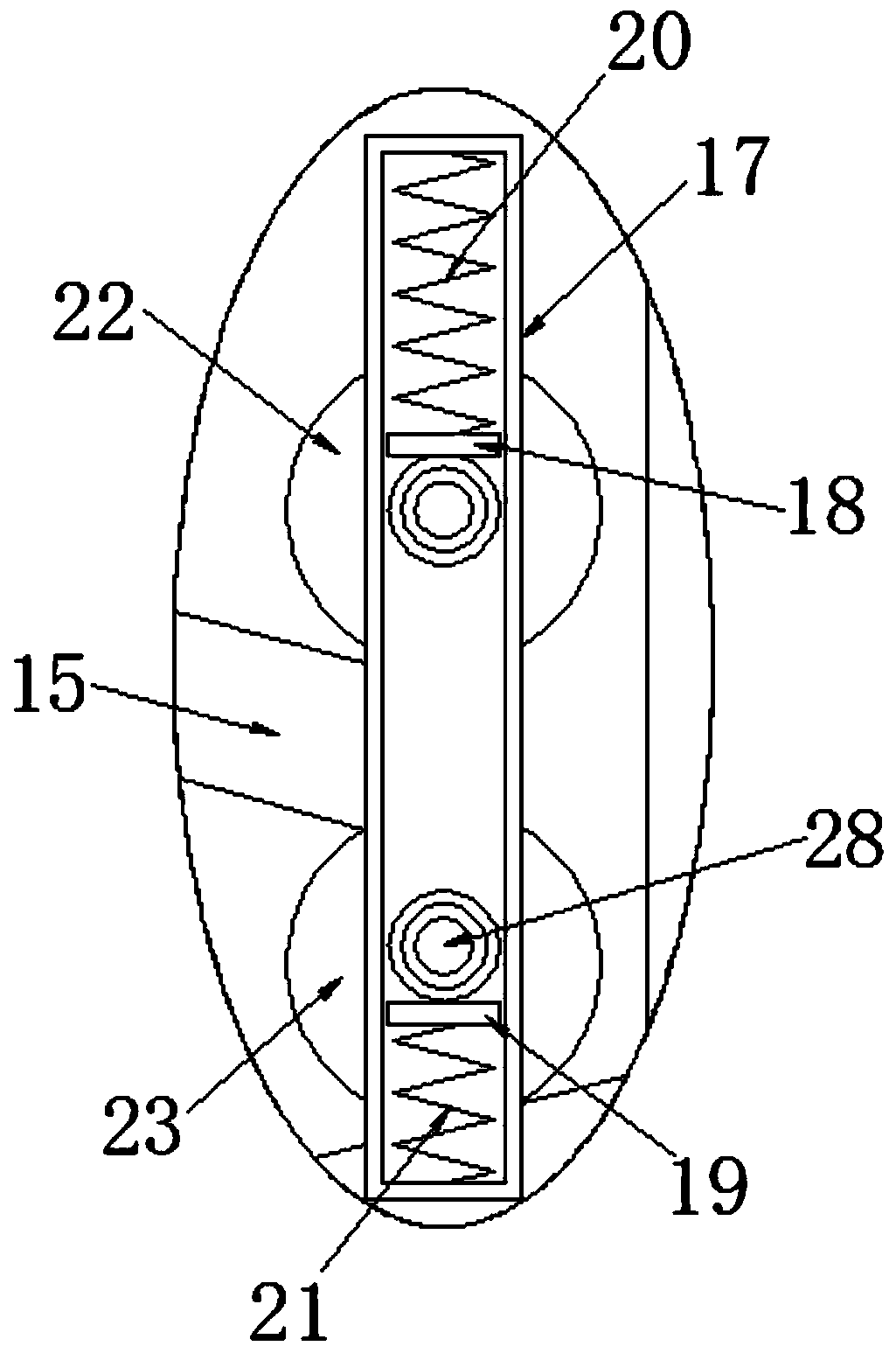

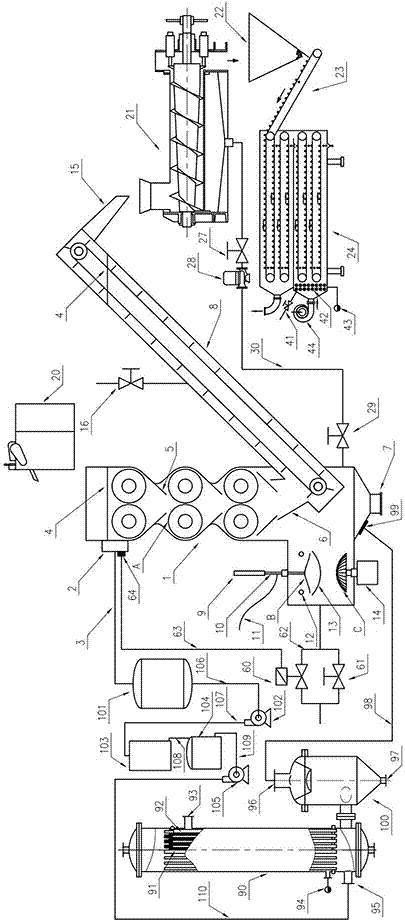

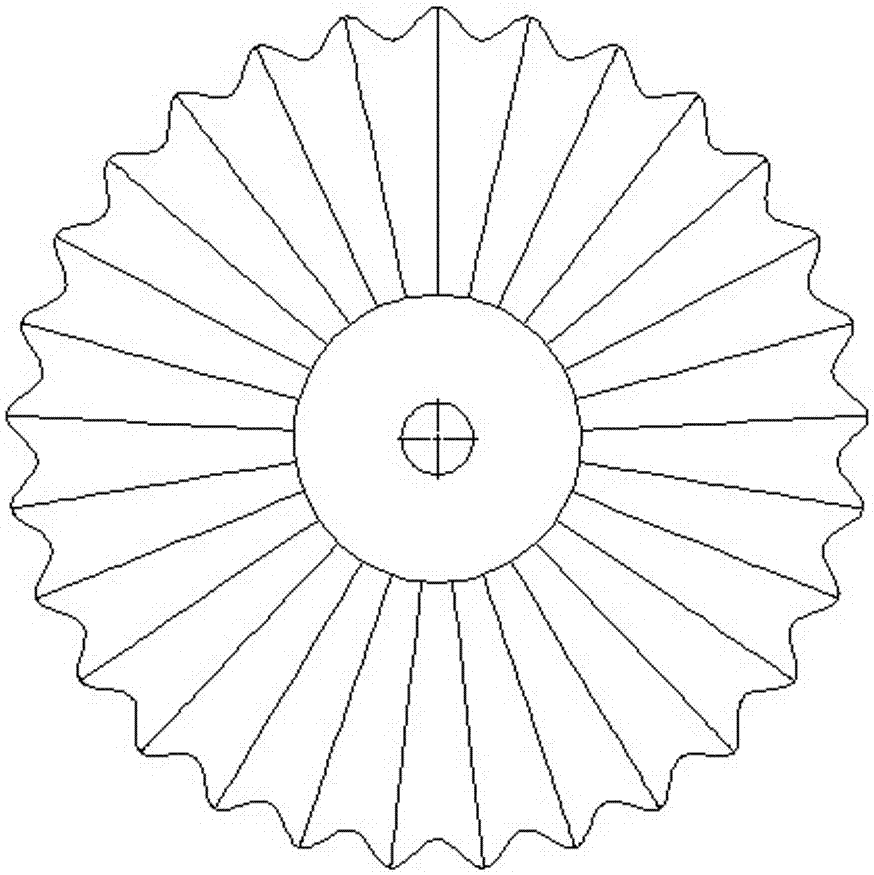

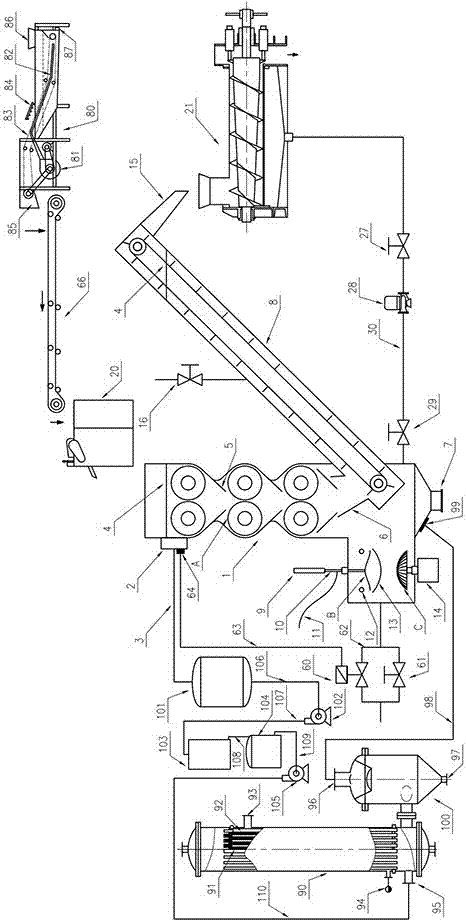

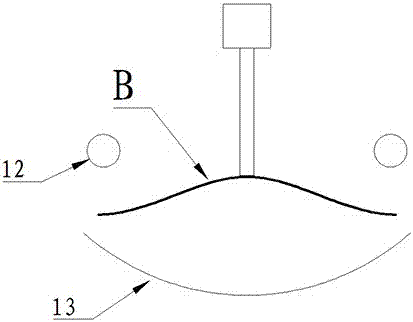

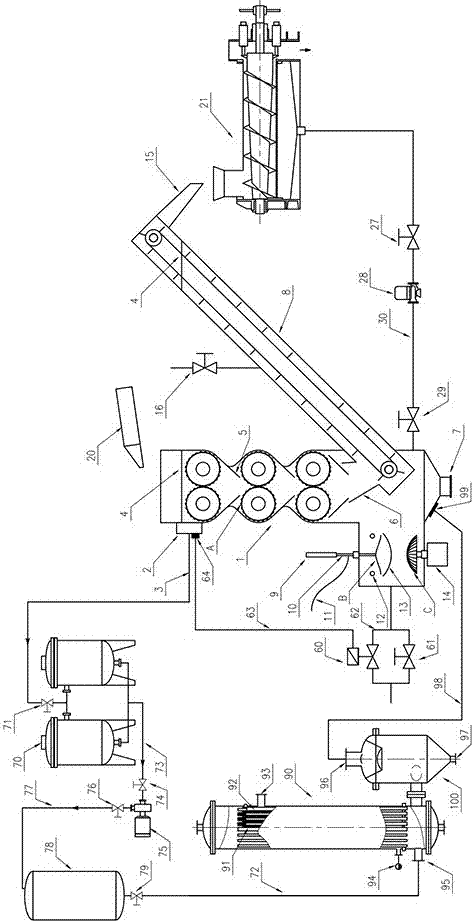

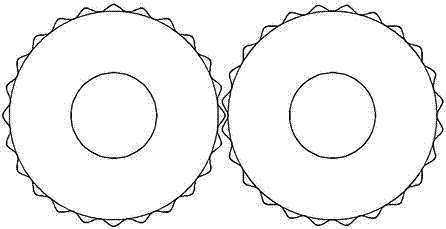

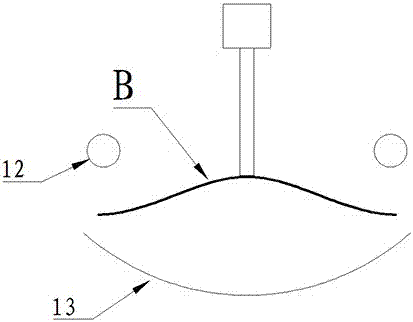

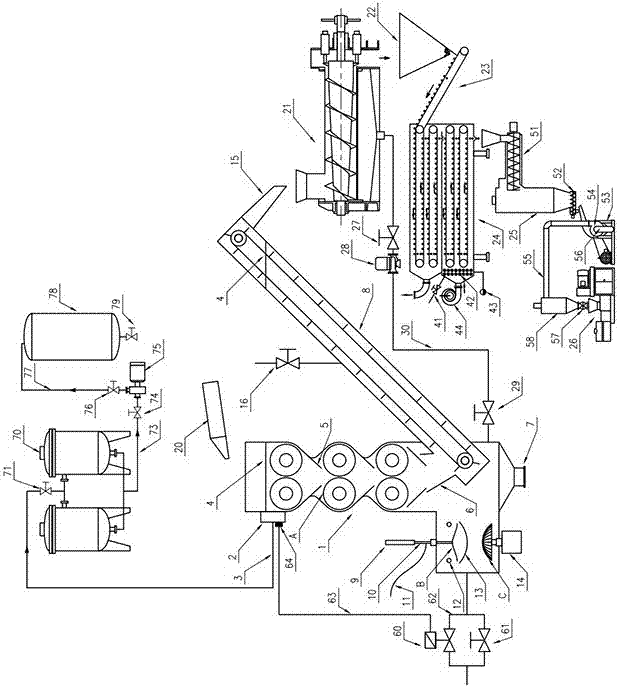

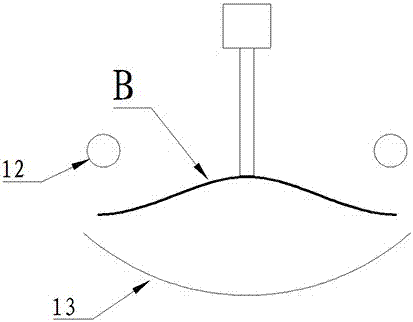

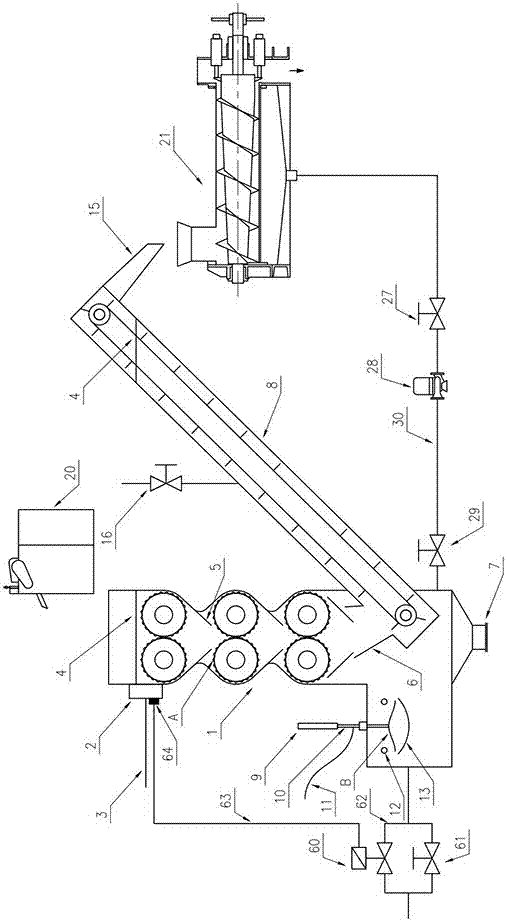

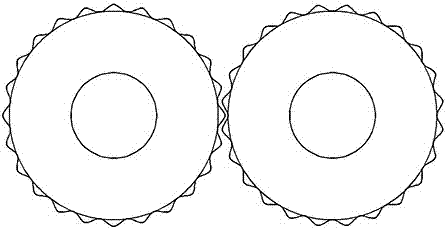

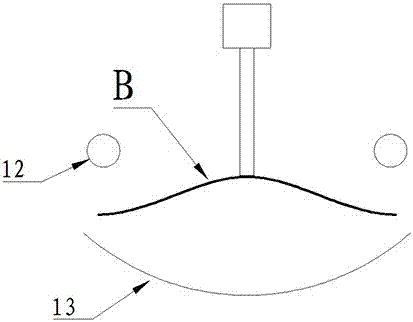

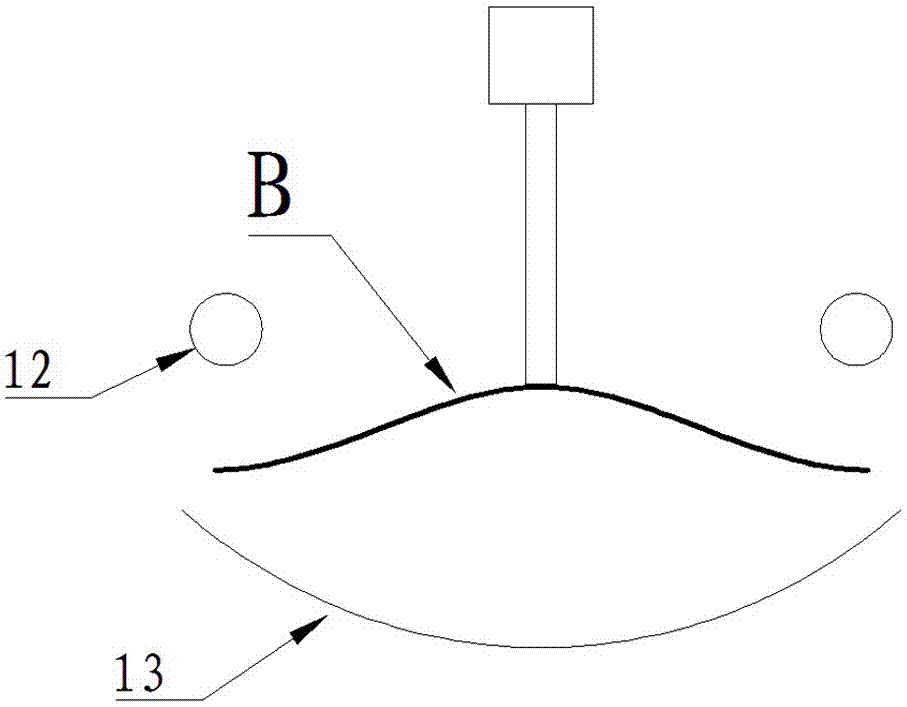

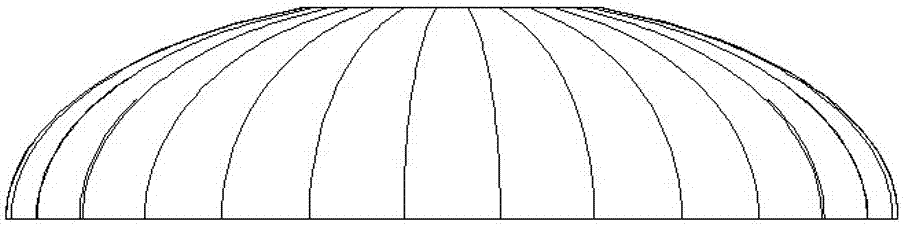

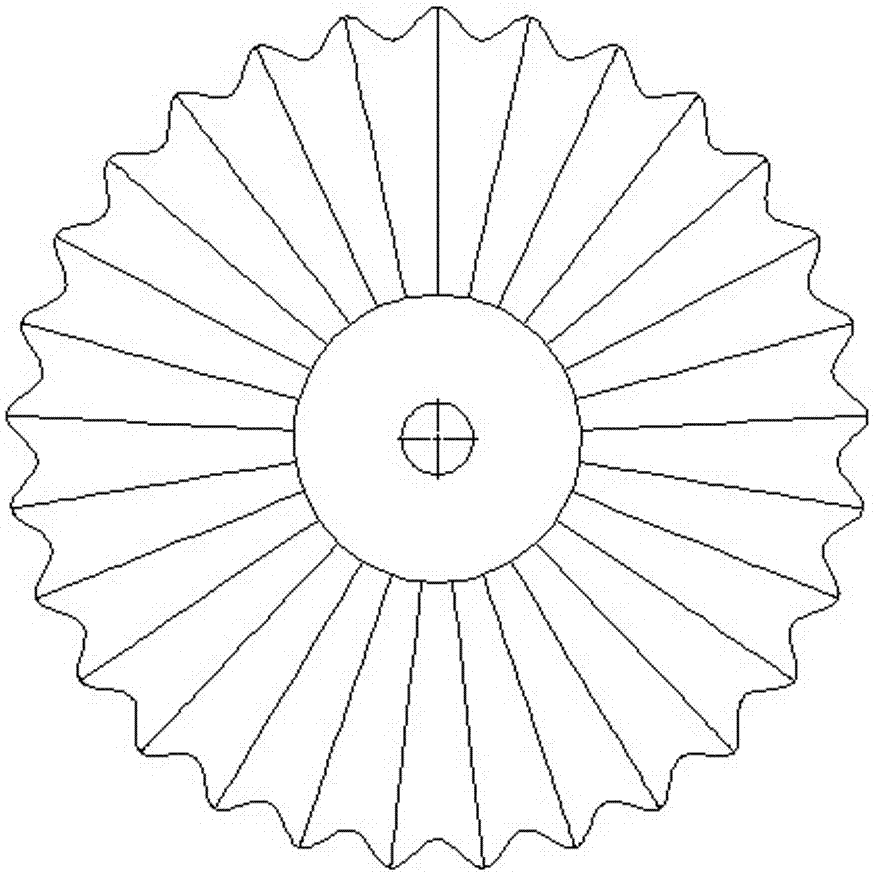

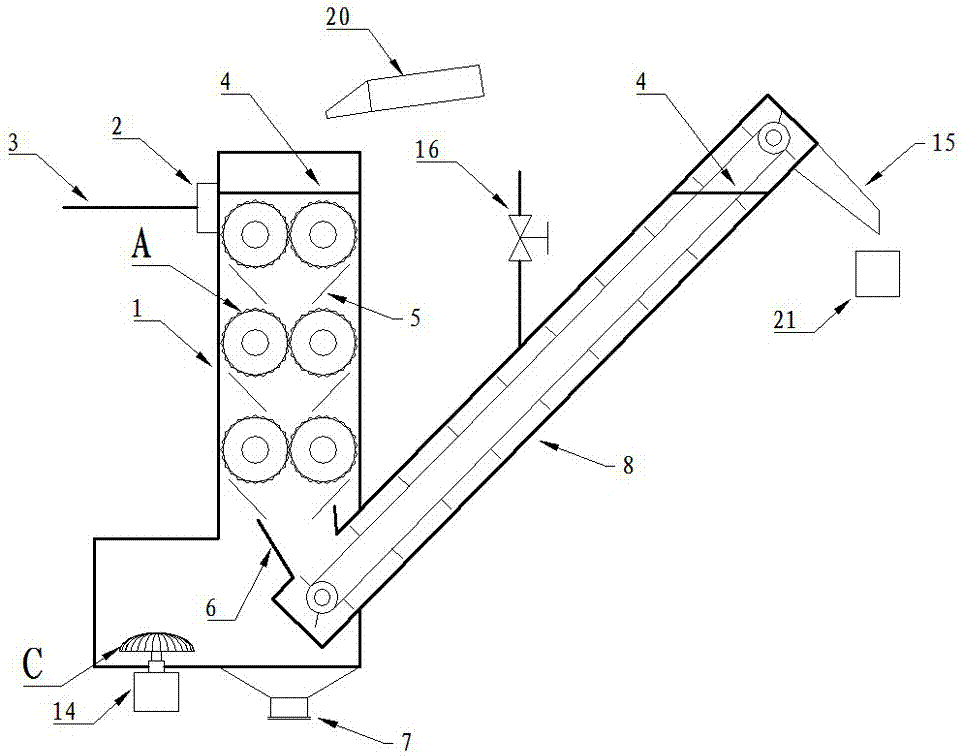

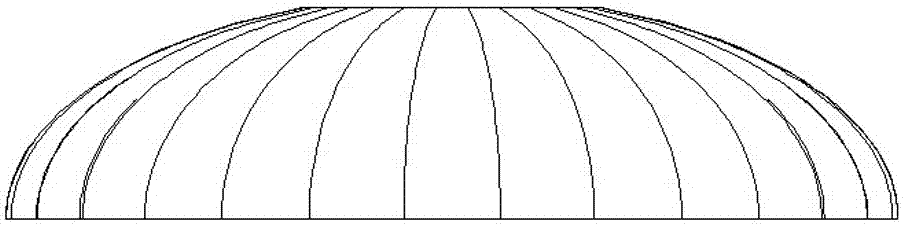

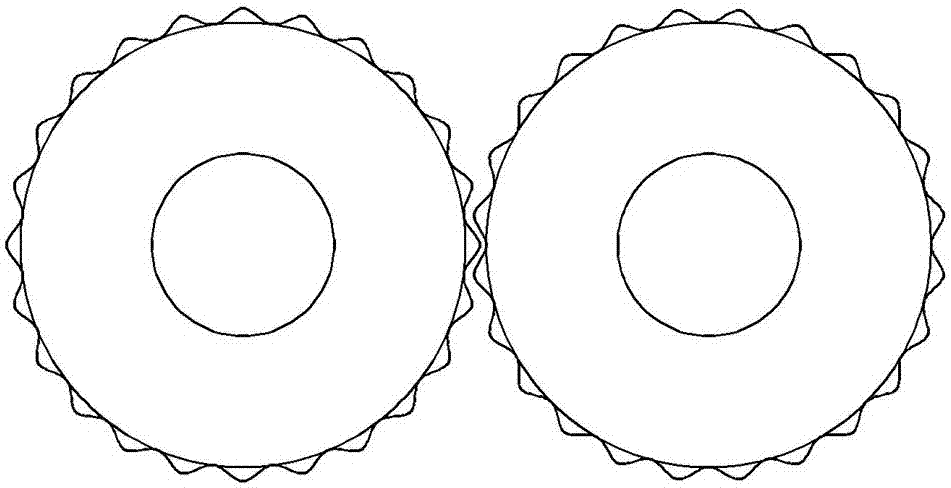

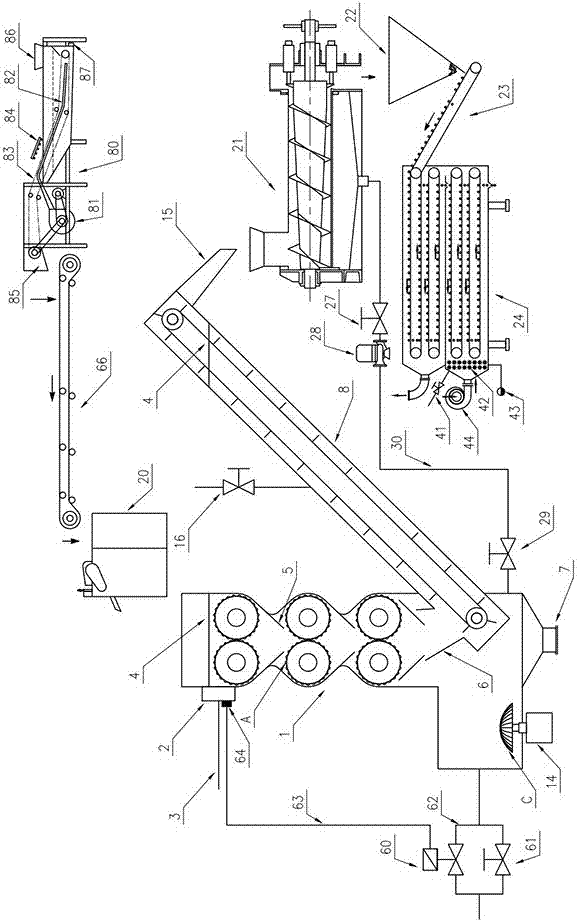

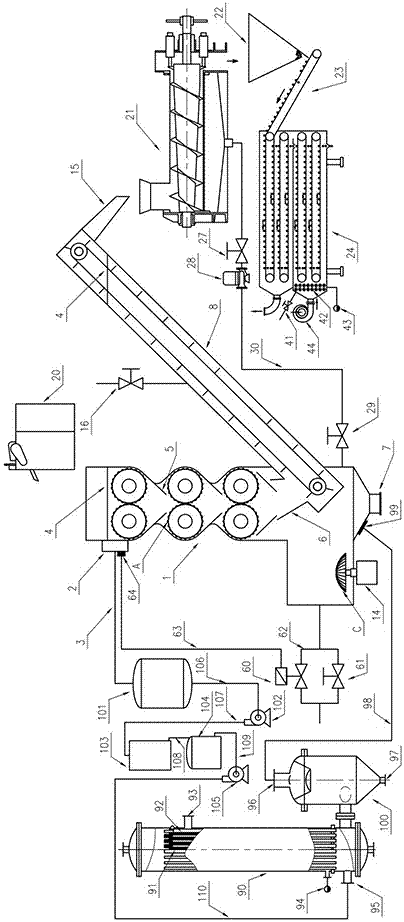

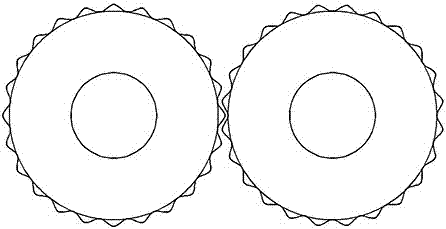

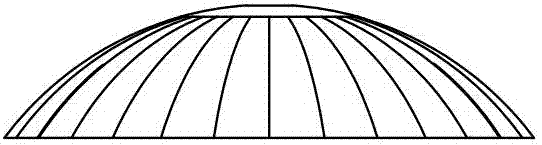

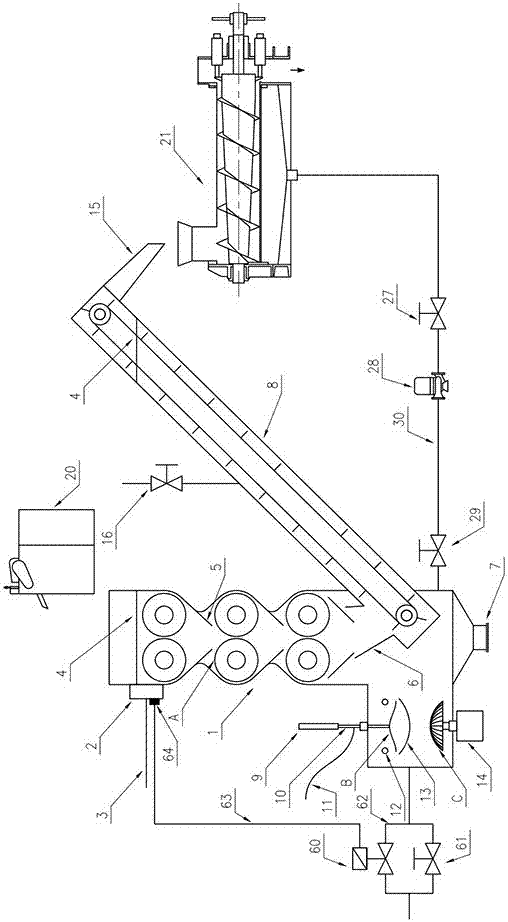

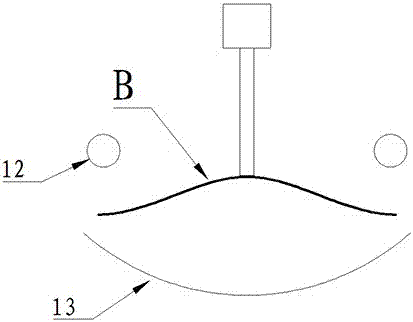

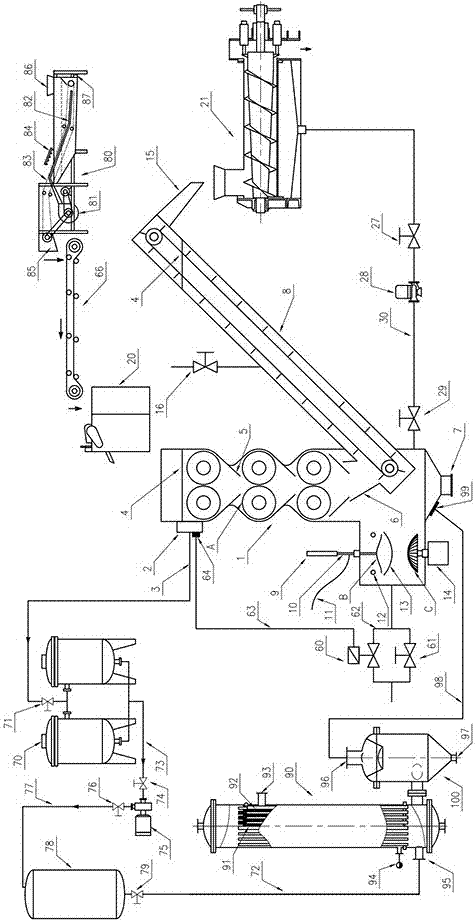

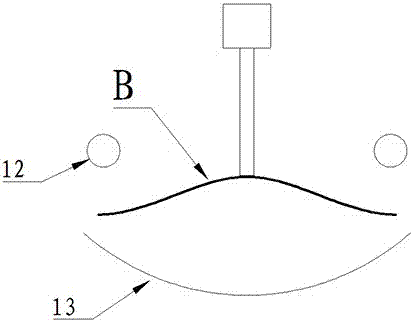

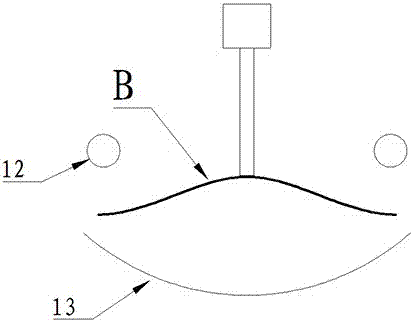

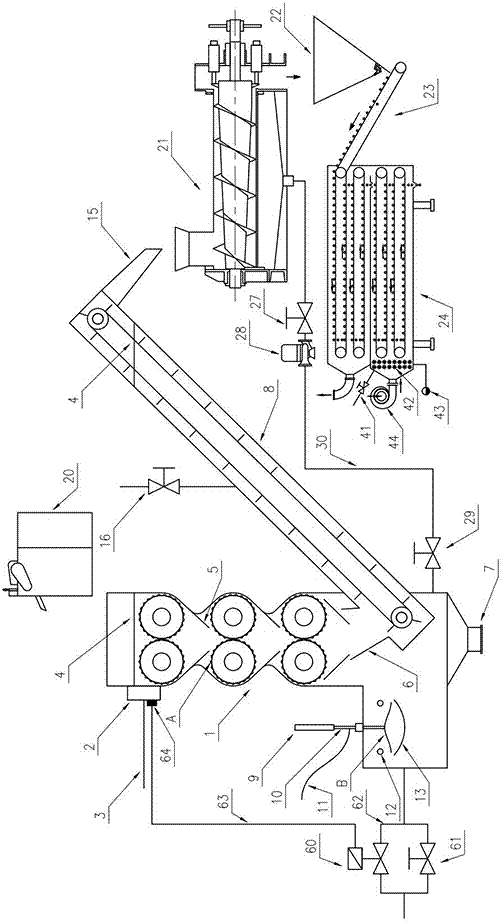

The invention discloses a counter-rotating drum type huperzine A leaching device with a cleaning machine and a drying machine. The bubble cleaning machine is sequentially connected with a Melaleuca tower conveyor, a shredder and a body. Rotating rollers, counter-rotating rollers are cylindrical, each stage of counter-rotating rollers is equipped with a Melaleuca tower guide groove, the last stage guide groove is connected to the hopper of the Melaleuca tower hoist, and the discharge chute of the hoist is passed through the spiral The squeeze dehydrator and the slag hopper are connected to the dryer; there is a liquid inlet valve on the elevator, a filter and a liquid outlet pipe on the upper part of the body; a spline curve rubber disc pulse explosion device is installed in the body, and a mechanical The ultrasonic exciter, the three-stage counter-rotating roller, the spline curve rubber disk pulse explosion device and the mechanical ultrasonic exciter of the present invention all have distinctive features, and can synergistically promote the leaching and extraction of huperzine A. The working principles and technical effects that are difficult for personnel to predict have strong practical application value.

Owner:向英

Contrarotating-roller huperzine-A leaching-extracting device with feeding machine and extruding dewatering machine

InactiveCN107321003AContinuous and reliable biteExtrusion compression ratio is largeOrganic chemistryCounter-current extractionInlet valveEngineering

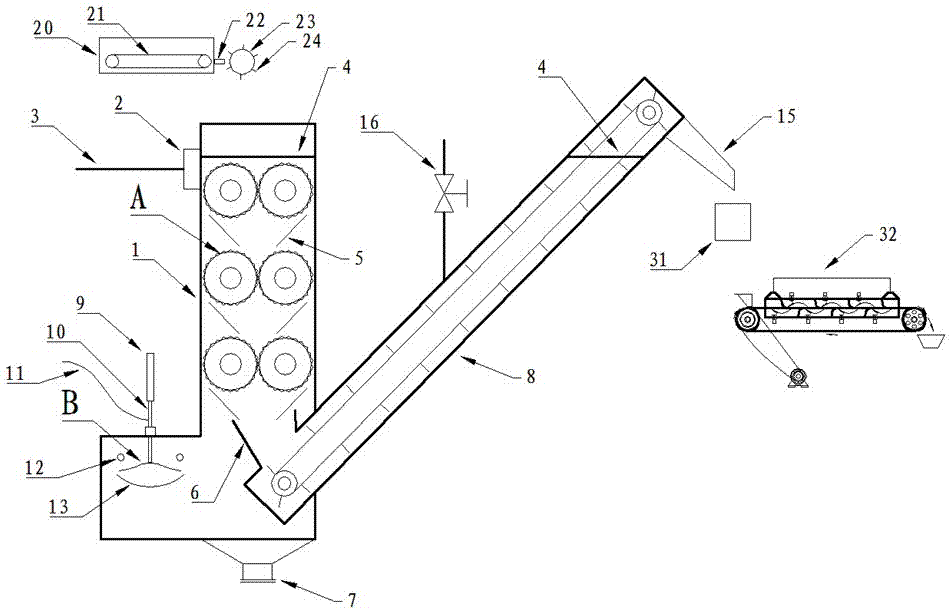

The invention discloses a counter-rotating roller type huperzine A leaching device with a feeder and a squeeze dehydrator. A feeder is arranged above the body, and three stages of counter-rotating rollers are arranged inside the body. Melaleuca tower guide grooves are provided under the counter-rotating rollers, the last level of guide grooves is connected to the hopper of the Melaleuca tower hoist, and the discharge chute of the hoist is connected to the screw extrusion dehydrator; the hoist is equipped with a liquid inlet valve, and the machine body The upper part is provided with a filter and a liquid outlet pipe. The liquid outlet pipe is connected to the duplex filter through the filter liquid inlet valve. The duplex filter passes through the first filtrate pipe, the filtrate valve, the filtrate pump, the pump outlet valve, the second filtrate pipe and the The liquid storage tank is connected; the body is provided with a spline curve rubber disc pulse explosion device, and the lower left corner of the body is provided with a mechanical ultrasonic vibrator, the three-stage counter-rotating roller of the present invention, the spline curve rubber disc pulse explosion device and Mechanical ultrasonic exciters have distinctive features, can synergistically promote the leaching and extraction of huperzine A, and have strong practical application value.

Owner:向英

Fluid licorice extract extracting device provided with chopping machine and spiral squeezing dewatering machine

InactiveCN107485886AContinuous and reliable biteExtrusion compression ratio is largeEvaporator accessoriesCounter-current extractionAutomatic controlThree stage

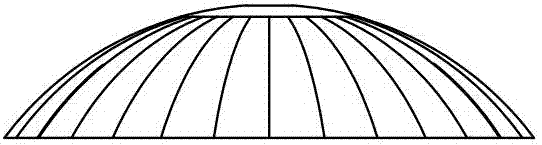

The invention discloses a licorice liquid extract extraction device with a chopper and a screw extrusion dehydrator. A chopper is arranged above the body, and a three-stage counter-rotating spline curve roller is arranged inside the body. The surface of the curved roller is a continuous spline surface, and there is a licorice guide groove under each stage of the counter-rotating spline curved roller. The last stage of the guide groove is connected to the hopper of the licorice elevator, and the discharge chute of the elevator is connected to the spiral extrusion dehydration machine; there is a liquid inlet valve on the elevator, a filter and a liquid outlet pipe on the upper part of the body, and the liquid outlet pipe is connected to the lifting film evaporator; a spline curve rubber disk pulse explosion device is installed in the body, and a The mechanical ultrasonic exciter, one side of the machine body is connected with the steam valve to automatically control the steam valve, the three-stage counter-rotating spline curve roller, the spline curve rubber plate pulse explosion device and the mechanical ultrasonic exciter of the present invention all have distinctive features , can synergistically promote the leaching and extraction of active ingredients of licorice, and has strong practical application value.

Owner:杨保生

Mechanical ultrasonic radix puerariae utilization device with cutter and radix puerariae centrifuge

InactiveCN107307433AContinuous and reliable biteExtrusion compression ratio is largeJuice extractionSolid solvent extractionFiberDietary fiber

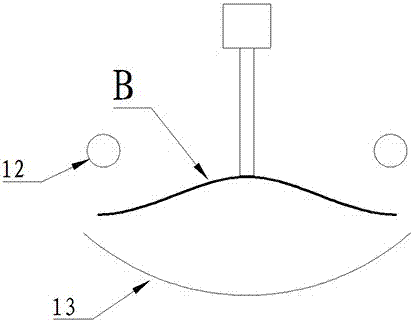

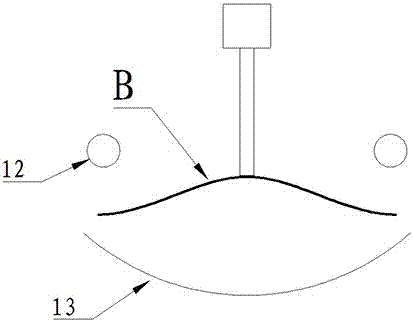

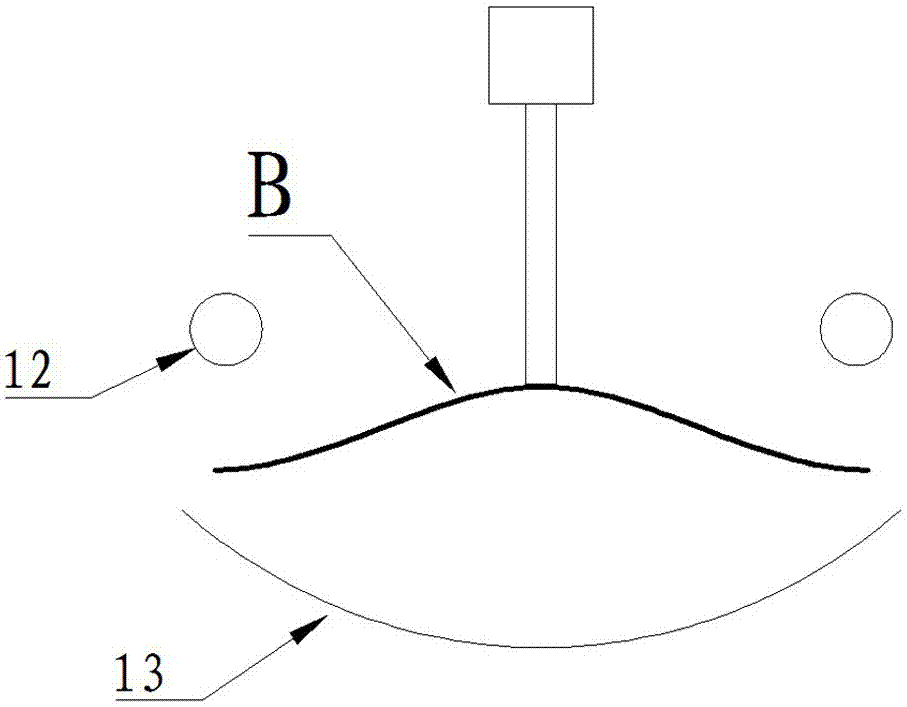

The invention discloses a mechanical ultrasonic kudzu root utilization device with a segment cutting machine and an kudzu powder centrifuge. A powder rubbing machine is arranged above a water washing tank. The powder rubbing machine is connected to a hoist through a chute, and a horizontal centrifuge is sequentially arranged above the hoist , Counter-rotating cosine drum and feed shaking trough; the feeding shaking trough is conveyed by the cutting machine to convey kudzu root to the counter-rotating cosine drum for pressing, and the bottom is equipped with inclined screen and trough; the liquid phase discharge end of the horizontal centrifuge is set There is a discharge pipe output; the washing tank is equipped with a mechanical ultrasonic vibrator; the washing tank is equipped with an overflow pipe to output dietary fiber, and the discharge end of the draining screen is connected to a dehydration centrifuge. Both the counter-rotating cosine drum and the mechanical ultrasonic exciter of the present invention have distinctive features, and can synergistically promote kudzu root juice extraction and subsequent efficient separation of fibers and starch. practical application value.

Owner:李跃华

Extractum glycyrrhizae liquidum extraction device provided with cleaning machine and charcoal molding machine

InactiveCN107496495AIncrease evaporation rateIncrease the concentration ratioSolid solvent extractionCleaning using liquidsPulverizerCarbonization

The invention discloses a licorice fluid extract extraction device with a cleaning machine and a charcoal forming machine. The bubble cleaning machine is connected with a licorice conveyor, a shredder and a body in sequence, and a three-stage counter-rotating spline curve roller is arranged inside the body. , there is a licorice guide groove under each counter-rotating spline curve roller, and the last level of guide groove is connected to the hopper of the licorice elevator. The machine is connected to the carbonization furnace, the pulverizer and the rod making machine in turn; there is a liquid inlet valve on the elevator, a filter and a liquid outlet pipe on the upper part of the body, and the liquid outlet pipe is connected to the lifting film evaporator; a spline curve glue is installed inside the body. Disc pulse explosion device, with a mechanical ultrasonic exciter in the lower left corner of the machine body, the three-stage counter-rotating spline curve roller, spline curve rubber disk pulse explosion device and mechanical ultrasonic exciter of the present invention have distinctive features, It can synergistically promote the leaching and extraction of active ingredients of licorice, and has strong practical application value.

Owner:杨保生

Crusher for producing waterborne polyurethane resin raw material

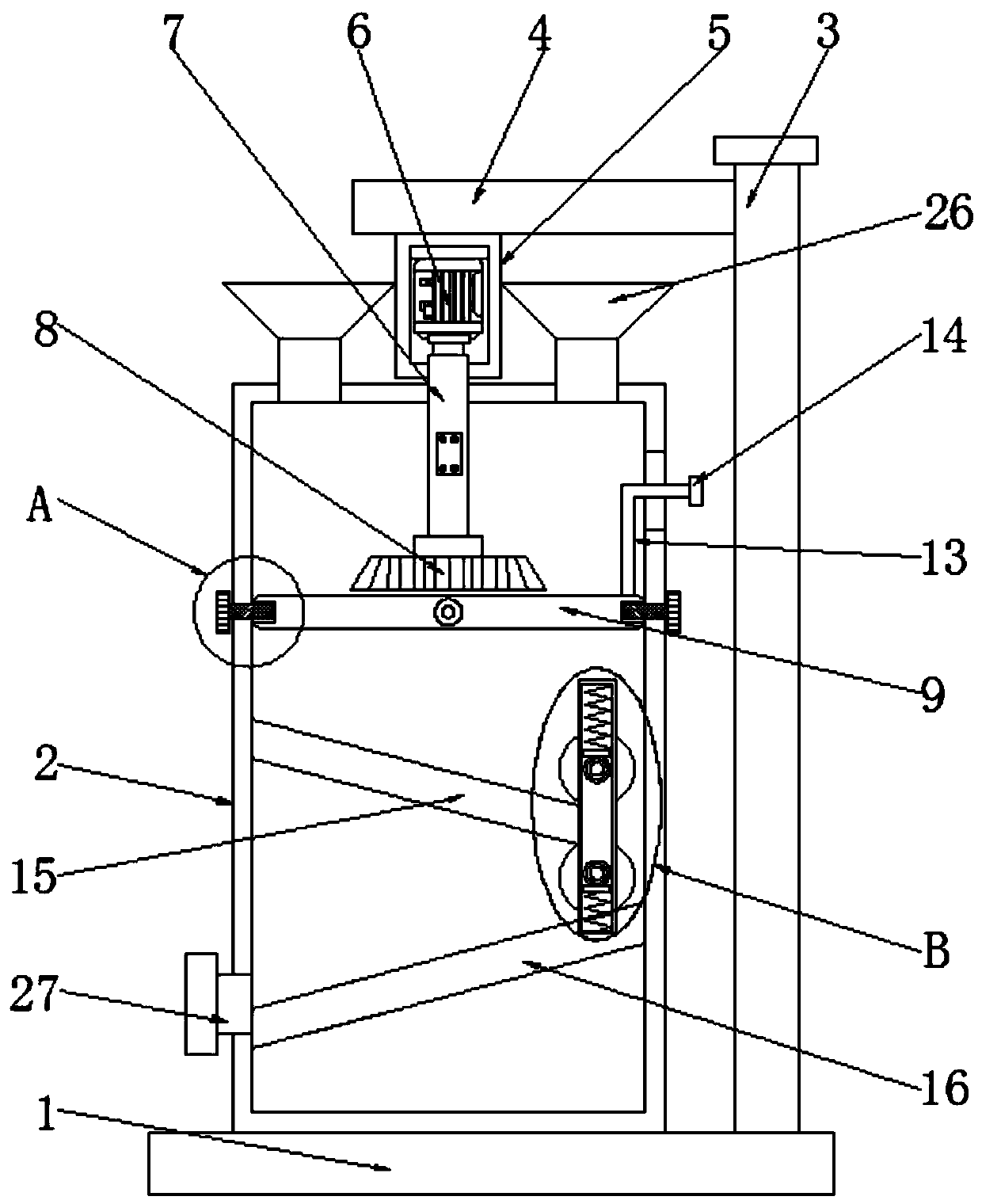

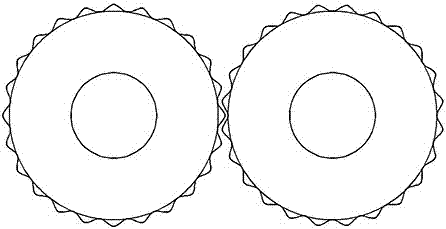

InactiveCN111421700AImprove primary processing capabilitiesImprove secondary crushing capacityCocoaGrain treatmentsManufacturing engineeringCrusher

The invention discloses a crusher for producing a waterborne polyurethane resin raw material. The crusher comprises a horizontal stable bottom plate, wherein the top of the horizontal stable bottom plate is fixedly connected with a crushing working box; the right side of the top of the horizontal stable bottom plate is fixedly connected with a vertical rod; the left side of the surface of the vertical rod is fixedly connected with a horizontal top plate; the middle of the bottom of the horizontal top plate is fixedly connected with a rotary motor box; the top of the inner wall of the rotary motor box is fixedly connected with a rotary motor through a motor base; and a thread clamping rod penetrates through one side of the surface of the crushing working box. The invention relates to the technical field of crushers. According to the crusher for producing the waterborne polyurethane resin raw material, disclosed by the invention, when the crusher is used for carrying out primary crushing, materials can be stably crushed at the top and the stability of the primary crushing is improved; and a swinging rod and a swinging handle are arranged so that a worker can conveniently swing an adjusting plate when the materials are subjected to secondary crushing, and furthermore, the materials at the top of the adjusting plate are released.

Owner:尚福平

Counter-rotating roller type extractum glycyrrhizae liquidum extraction device with chopper and drying machine

InactiveCN107376413AIncrease evaporation rateIncrease the concentration ratioCounter-current extractionSolid solvent extractionAutomatic controlThree stage

The invention discloses a counter-rotating roller type licorice fluid extract extraction device with a chopper and a dryer. A chopper is arranged above the body, and three-stage counter-rotating rollers are arranged inside the body. The counter-rotating rollers are Cylindrical, there is a licorice guide groove under each stage of counter-rotating rollers. The last stage of guide groove is connected to the hopper of the licorice elevator. There is a liquid inlet valve, a filter and a liquid outlet pipe are installed on the upper part of the body, and the liquid outlet pipe is connected to the lifting film evaporator; a spline curve rubber plate pulse explosion device is installed in the body, and a mechanical ultrasonic vibration is installed in the lower left corner of the body. One side of the machine body is connected to the automatic control steam valve and the manual steam valve through a steam pipeline. The three-stage counter-rotating rollers, the spline curve rubber disc pulse explosion device and the mechanical ultrasonic exciter of the present invention all have distinctive features and can cooperate with each other. Promoting the leaching and extraction of active ingredients of licorice has strong practical application value.

Owner:王佳希

Mechanical ultrasonic-type utilizing device of the root of kudzu vine with cutting machine and drying machine of the root of kudzu vine

InactiveCN107319579AIngeniously generate strong cavitation effectContinuous and reliable biteJuice extractionSolid solvent extractionDietary fiberSieve

The invention discloses a mechanical ultrasonic kudzu root utilization device with a section cutting machine and an kudzu powder dryer. A powder rubbing machine is arranged above a water washing tank. The powder rubbing machine is connected to a hoist through a chute, and a horizontal centrifuge is arranged above the hoist in turn. , Counter-rotating cosine drum and feed shaking trough; the feeding shaking trough is conveyed by the cutting machine to convey kudzu root to the counter-rotating cosine drum for pressing, and the bottom is equipped with inclined screen and trough; the liquid phase discharge end of the horizontal centrifuge is set There is a discharge pipe output; the washing tank is equipped with a mechanical ultrasonic vibrator; the washing tank is equipped with an overflow pipe to output dietary fiber, and the discharge end of the draining screen is connected to a dehydration centrifuge. Both the counter-rotating cosine drum and the mechanical ultrasonic exciter of the present invention have distinctive features, and can synergistically promote kudzu root juice extraction and subsequent efficient separation of fibers and starch. practical application value.

Owner:李跃华

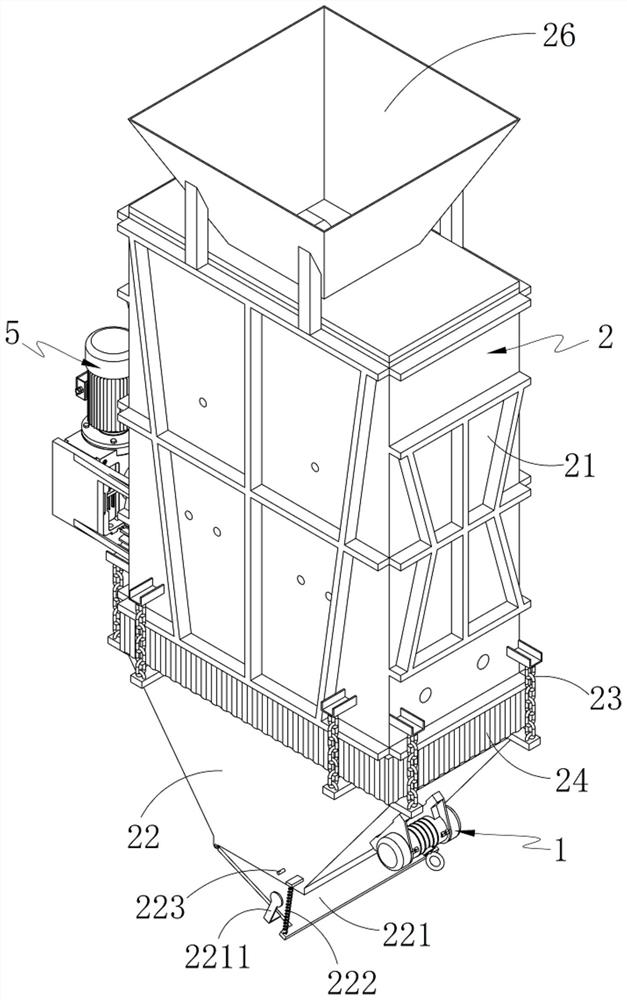

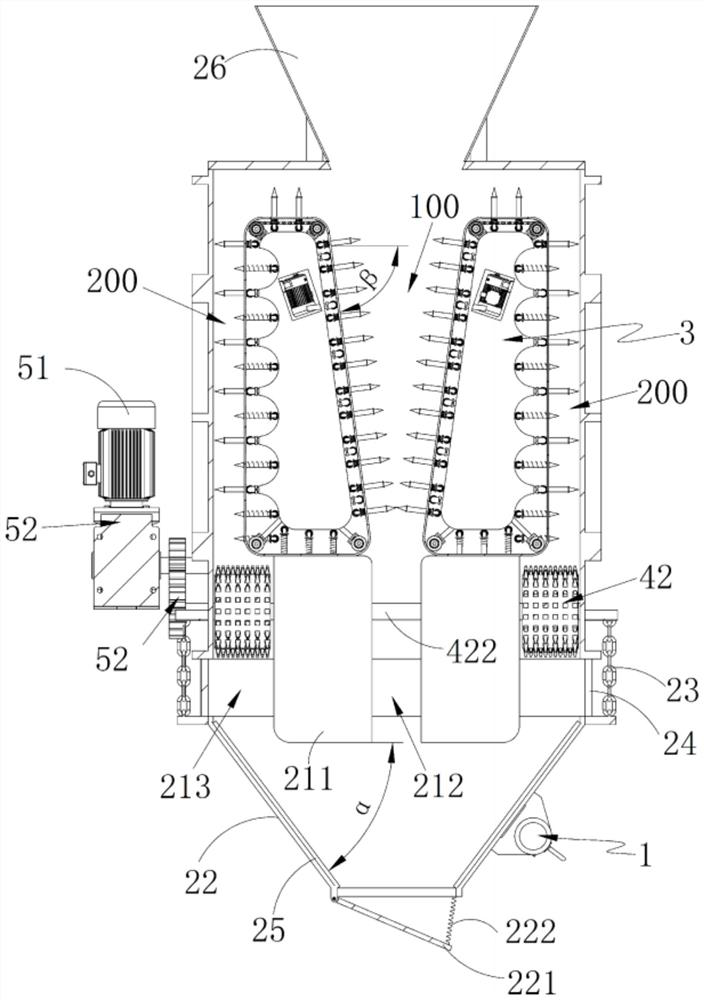

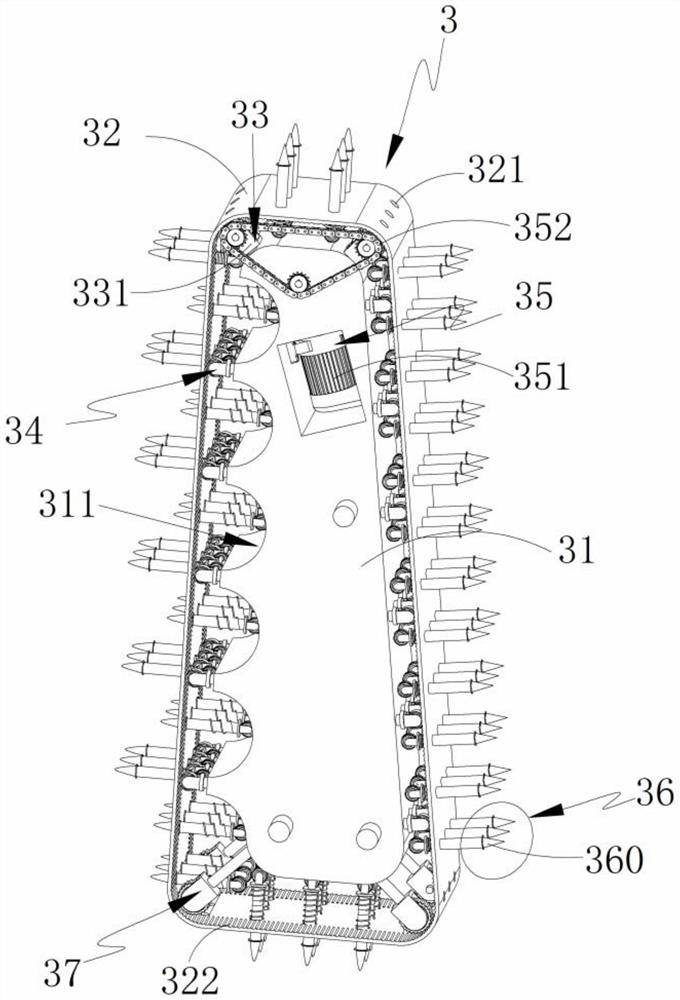

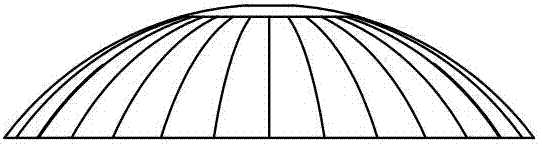

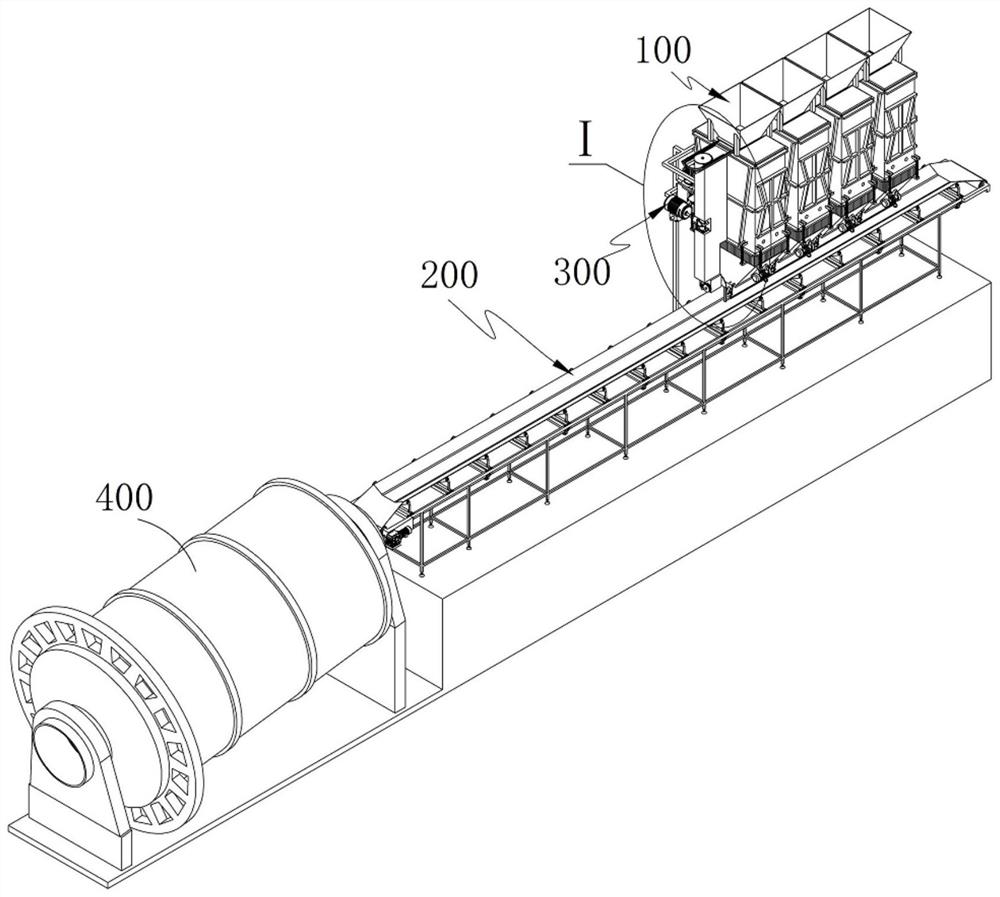

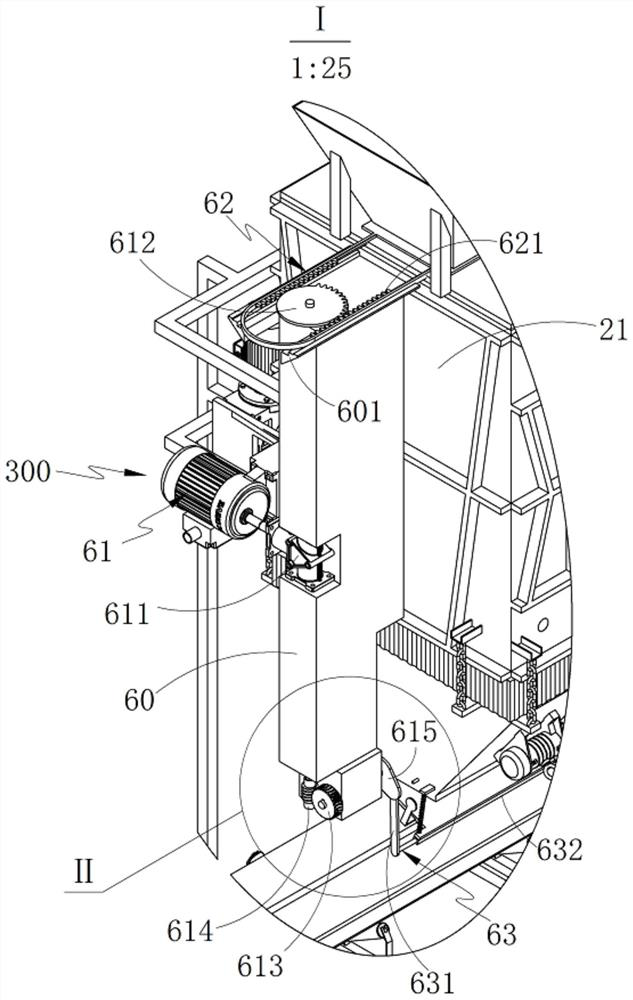

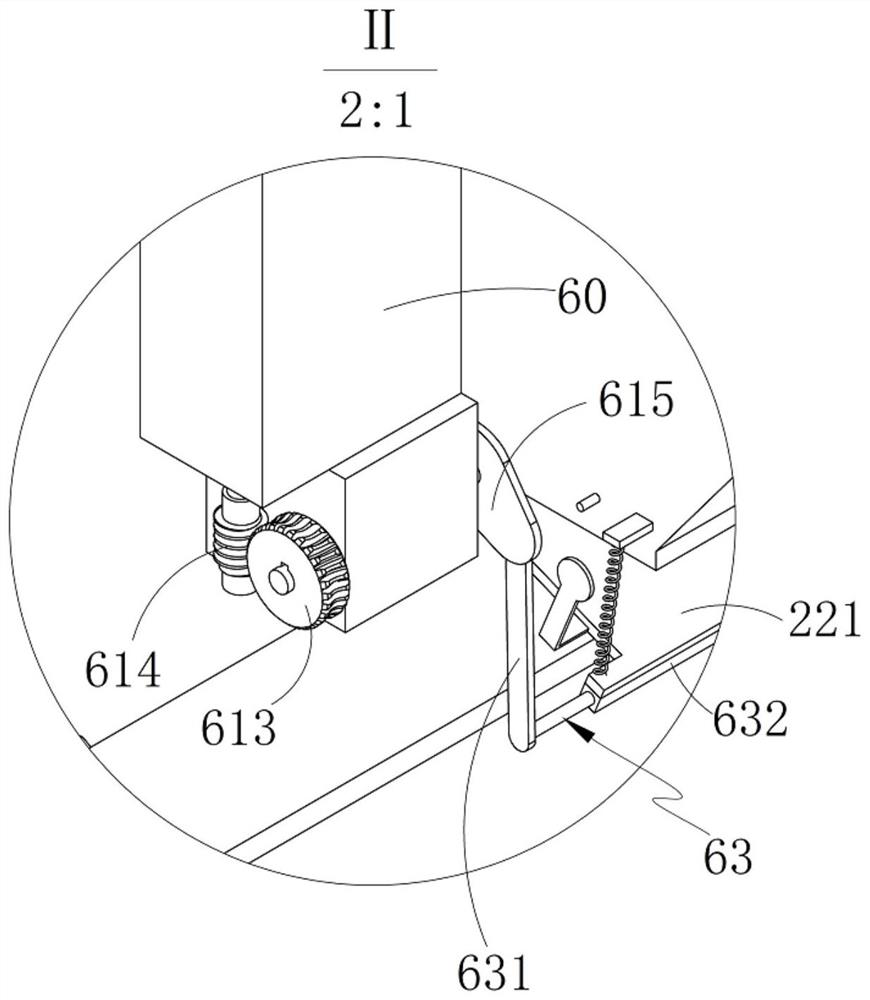

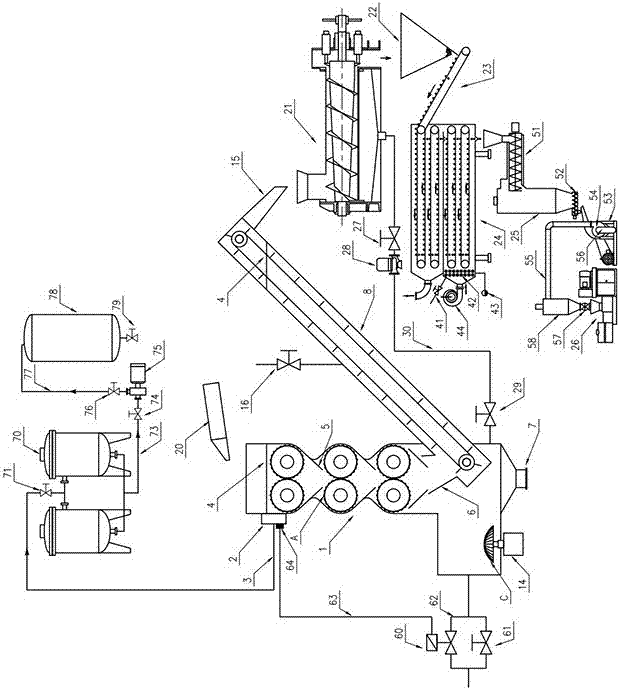

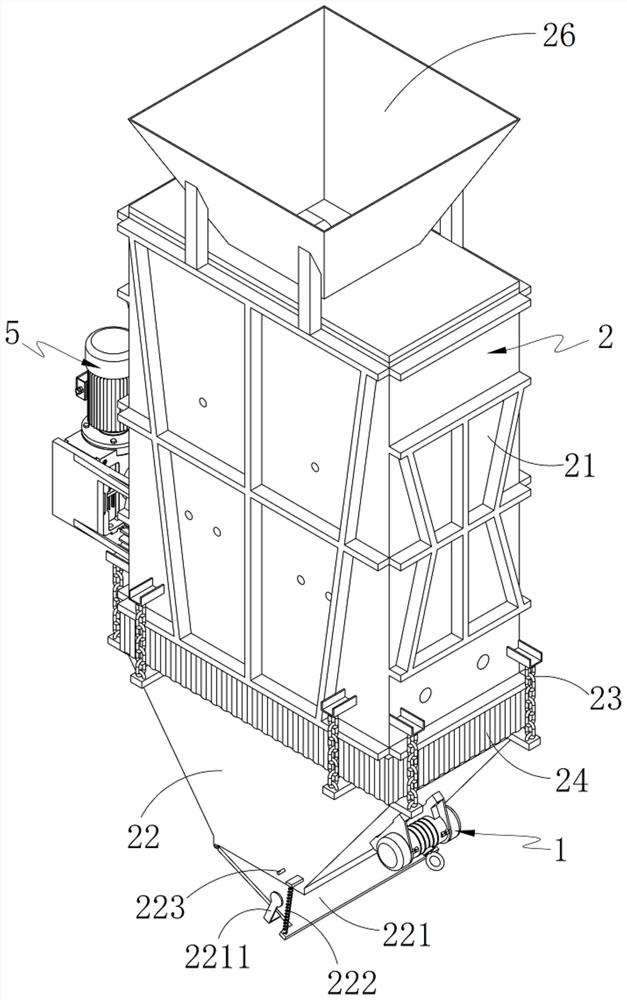

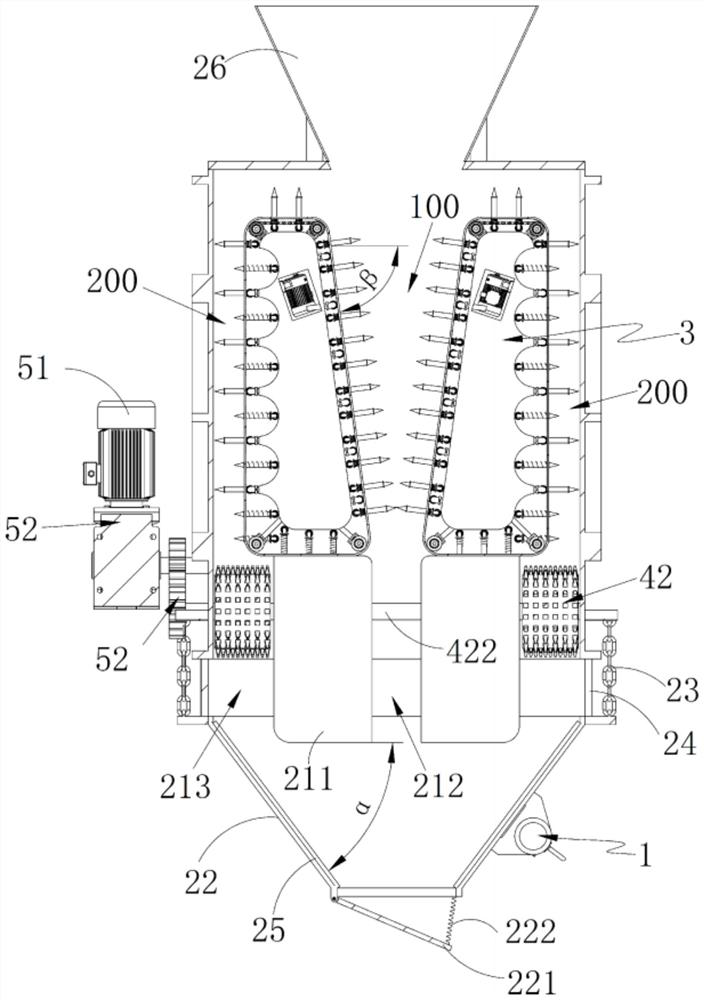

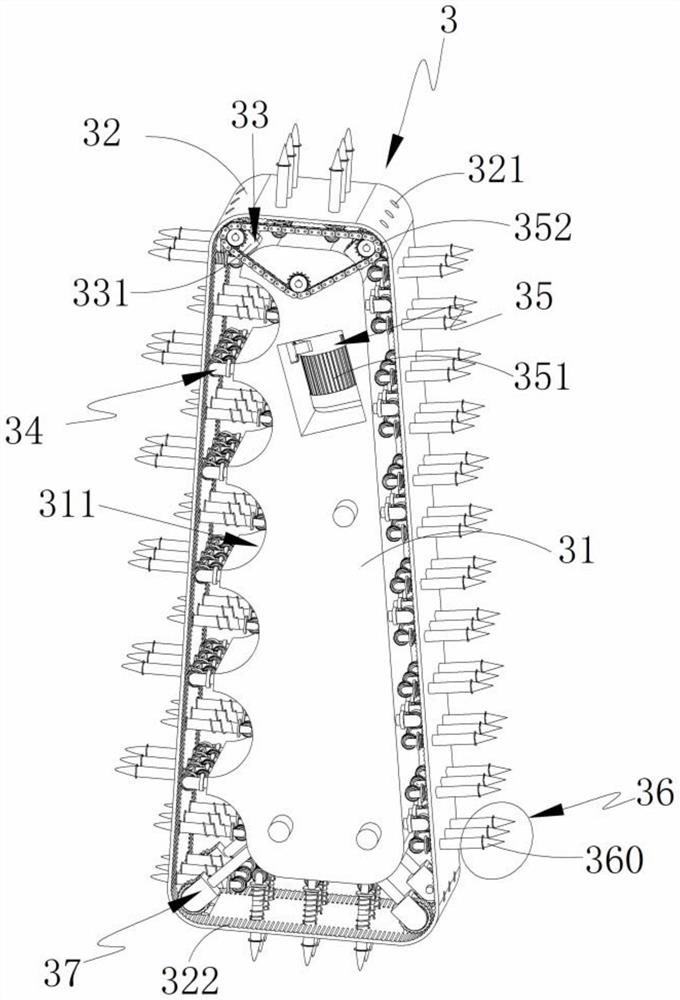

Raw material batching station with stable batching function

ActiveCN112275360AUniform sizeReduced weight differenceGrain treatmentsElectric machineryProcess engineering

The invention provides a raw material batching station with a stable batching function. The raw material batching station comprises a hopper unit, pre-crushing units and secondary crushing assemblies.When materials are located in a primary screening and crushing space, the screening and pre-crushing units are used for lifting and screening the materials, so that the primary crushing effect is achieved; and when the materials are conveyed to secondary crushing spaces, the secondary crushing assemblies are used in cooperation with concave-convex tracks arranged on screening mounting frames in the descending process, large materials are subjected to secondary crushing multiple times, crushing units arranged below the secondary crushing spaces are used for crushing the materials which are notcrushed in a tertiary mode, and it is guaranteed that the particle size of the flowing-out material is uniform and consistent. Due to the split design of the hopper unit and a vibration motor on oneside of the hopper, the problem of material accumulation is effectively solved, it is guaranteed that the mass of the materials falling per unit area is equal during continuous discharging, thus, it is guaranteed that the final proportion meets the technological requirement, the yield of cement clinker is increased, and the production efficiency is improved.

Owner:广德独山南方水泥有限公司

Mechanical ultrasonic type huperzine A leaching device with cutting machine and drying machine

InactiveCN107362574AContinuous and reliable biteExtrusion compression ratio is largeOrganic chemistryCounter-current extractionAutomatic controlThree stage

The invention discloses a mechanical ultrasonic type huperzine A leaching device with a cutting machine and a drying machine. The cutting machine is arranged above a machine body, the machine body is internally provided with three stages of contrarotating spline rollers, a contrarotating spline roller surface is a continuous spline plane, a huperzine serrate guiding slot is formed below each stage of contrarotating spline roller, the final stage of guiding slot is connected to a hopper of a huperzine serrate elevator, and a discharging slot of the elevator is connected to the drying machine through a spiral extrusion dehydrating machine and a slag hopper; the elevator is provided with a liquid inlet valve, and the upper part of the machine body is provided with a filter and a liquid discharge pipe; a mechanical ultrasonic vibration exciter is arranged at the left lower corner of the machine body; and one side of the machine body is connected to an automatic control steam valve and a manual steam valve through steam pipelines. The three stages of contrarotating spline rollers and the mechanical ultrasonic vibration exciter are of distinct characteristics respectively, leaching and extraction of huperzine A can be promoted cooperatively, the device has working principles and technical effects hardly unforeseeable for technical persons in the field, and the device has relatively high practical application values.

Owner:田兴云

Counter rotating roller type sucrose crystallization device with large crystal sorting machine

InactiveCN107326116AEasy to produceContinuous and reliable biteVibration crystallizationSugar crystallisationPlate heat exchangerSucrose

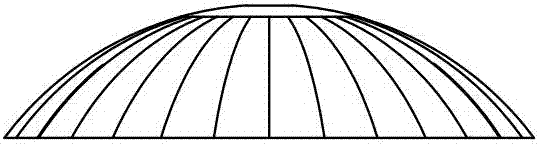

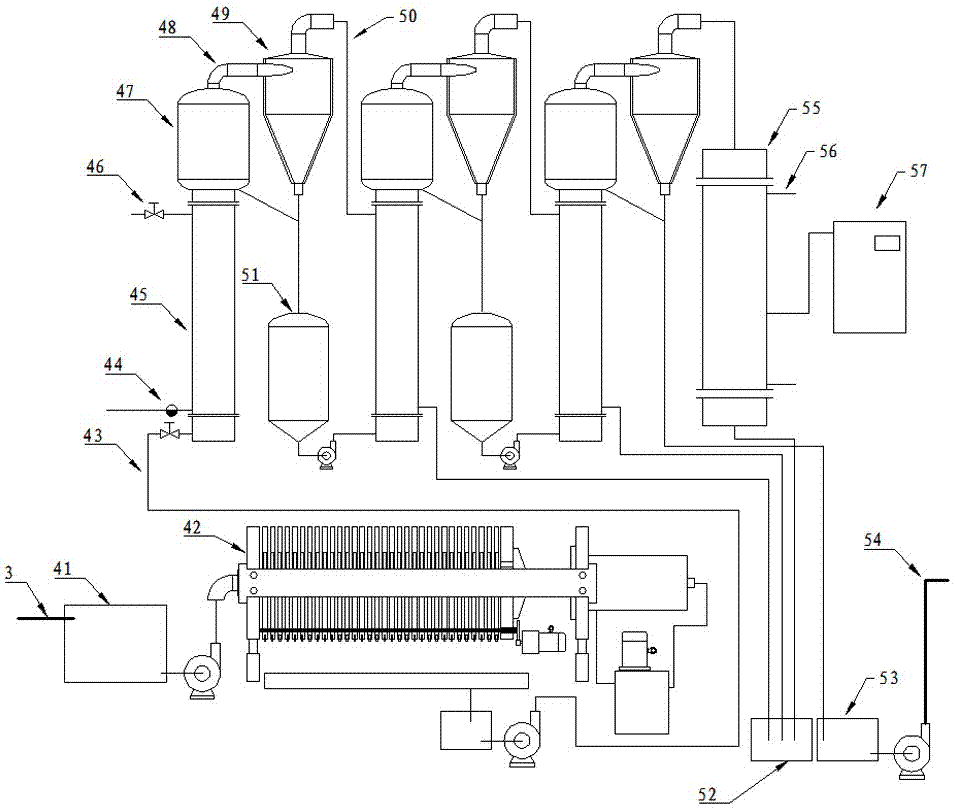

The invention discloses a counter-rotating drum type sucrose crystallization device with a large crystal sorting machine. The crystallizer is connected to a condensing vacuum machine system through a dilute liquid pipe and a concentrator; After the crystallizer, it enters the lower part of the crystallizer; the body of the crystallizer is a spiral surface, and the spiral surface is connected to the elevator hopper through a slope transition, and the hopper is connected to the large crystal sorting machine through the chute, washing centrifuge, and dryer; inside the feeder on the thin liquid pipe There are counter-rotating rubber rollers; the cosine rubber disk pulse explosion device and mechanical ultrasonic exciter are installed in the crystallizer body. The counter-rotating rubber drum, the cosine rubber disk pulse explosion device and the mechanical ultrasonic exciter of the present invention all have distinctive features, which can reliably and cooperatively promote the gradual downward movement of sugar crystals on the helical surface of the device and realize the reverse flow of liquid flow and crystal movement Mass transfer crystallization has working principles and technical effects that are difficult for those skilled in the art to foresee, and has strong practical application value.

Owner:袁香桃

Contra-rotating roller type bagasse treatment device with feeding trough, centrifugal machine and drying machine

InactiveCN107312888AContinuous and reliable biteExtrusion compression ratio is largeTransportation and packagingSolid waste disposalEngineeringThree stage

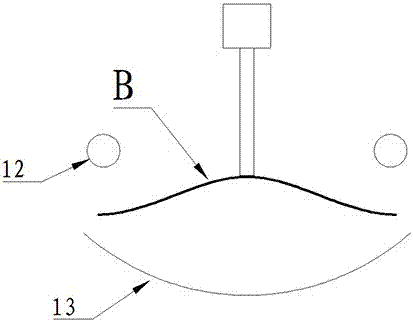

The invention discloses a contra-rotating roller type bagasse treatment device with a feeding trough, a centrifugal machine and a drying machine. The bagasse feeding trough is arranged above a body of a leaching device; three stages of contra-rotating rollers are arranged in the body and are cylindrical; a bagasse guide groove is formed below each stage of contra-rotating roller; the final guide groove is connected with a hopper of a bagasse elevator; a discharging groove of the elevator is connected with the drying machine via the dewatering centrifugal machine; a water inlet valve is arranged on the elevator; a filter and a liquid outlet tube are arranged on the upper part of the body; the liquid outlet tube is connected with a three-effect long-tube climbing-film evaporating and concentrating device; a cosine plastic plate pulse aeration device is arranged in the body; and a mechanical ultrasonic exciter is arranged at the left lower corner of the body. The three stages of contra-rotating rollers, the cosine plastic plate pulse aeration device and the mechanical ultrasonic exciter have distinct characteristics, and can cooperatively facilitate leaching and extracting of sugar, and the contra-rotating roller type bagasse treatment device has working principles and technical effects which are difficultly predicted by those skilled in the art, and has high actual application value.

Owner:吴贻湖

Contra-rotating roller type licorice root fluid extract extraction device with cleaning machine and dehydrator

InactiveCN107469393AIncrease evaporation rateIncrease the concentration ratioCounter-current extractionSolid solvent extractionThree levelAdditive ingredient

The invention discloses a counter-rotating roller type licorice fluid extract extraction device with a cleaning machine and a dehydrator. The bubble cleaning machine is connected with a licorice conveyor, a shredder and a body in sequence, and three-stage counter-rotating rollers are arranged inside the body. , the counter-rotating rollers are cylindrical, and there is a licorice guide groove under each stage of the counter-rotating rollers. The last stage guide groove is connected to the hopper of the licorice hoist, and the discharge chute of the hoist is connected to the screw extrusion dehydrator; There is a liquid inlet valve on the machine, a filter and a liquid outlet pipe on the upper part of the body, and the liquid outlet pipe is connected to the lifting film evaporator; a spline curve rubber disk pulse explosion device is installed in the body, and a mechanical ultrasonic excitation device is installed in the lower left corner of the body. The vibrator, the three-stage counter-rotating roller, the spline curve rubber plate pulse explosion device and the mechanical ultrasonic vibrator of the present invention all have distinctive features, which can synergistically promote the leaching and extraction of the active ingredients of licorice, and have the characteristics that are difficult for those skilled in the art to foresee. The working principle and technical effect have strong practical application value.

Owner:王佳希

Fluid licorice extract extracting device provided with feeding machine and spiral squeezing dewatering machine

InactiveCN107485887AIncrease evaporation rateIncrease the concentration ratioEvaporator accessoriesCounter-current extractionAutomatic controlThree stage

The invention discloses a device for extracting licorice liquid extract with a feeder and a screw extrusion dehydrator. A feeder is arranged above the body, and three stages of counter-rotating spline curve rollers are arranged inside the body, and each stage counter-rotates. There are licorice guide grooves under the spline curve rollers, the last level of guide grooves is connected to the hopper of the licorice hoist, and the discharge chute of the hoist is connected to the screw extrusion dehydrator; there is a liquid inlet valve on the hoist, and a Filter and liquid outlet pipe, the liquid outlet pipe is connected to the lifting film evaporator; there is a spline curve rubber disk pulse explosion device in the body, a mechanical ultrasonic exciter is installed in the lower left corner of the body, and one side of the body is connected to the automatic Control the steam valve and manual steam valve, the three-stage counter-rotating spline curve roller, spline curve rubber plate pulse explosion device and mechanical ultrasonic vibrator of the present invention all have distinctive features, which can synergistically promote the leaching and extraction of active ingredients of licorice , has strong practical application value.

Owner:杨保生

Contra-rotating roller type huperzine-A infusion and extraction device with feeder and charcoal molding machine

InactiveCN107362577AContinuous and reliable biteExtrusion compression ratio is largeOrganic chemistryCounter-current extractionEngineeringLiquid storage tank

The invention discloses a contra-rotating roller type huperzine-A infusion and extraction device with a feeder and a charcoal molding machine. A feeder is arranged on a device body, the internal of the device body is provided with three-stage contra-rotating rollers, the lower of each stage of the contra-rotating roller is respectively provided with a serrate clubmoss herb guide groove, the last stage of the guide groove is connected with a hopper of a serrate clubmoss herb hoist, a discharging groove of the hoist is connected with a drier through a spiral extruding dehydrator and a residue hopper, and the drier is sequentially connected with a spiral feeding machine, a charcoal furnace, a spiral discharging machine, a crusher and a rod making machine; the hoist is provided with a liquid inlet valve, the upper part of the device body is provided with a filter and a liquid outlet pipe, and the liquid outlet pipe is sequentially connected with a duplex filter, a filtrate pump and a liquid storage tank through a pipeline; the internal of the device body is provided with a spline curve rubber plate pulse detonating device, and a mechanical ultrasonic vibration exciter is arranged at the lower left corner of the device body. The three-stage contra-rotating spline curve rollers, the spline curve rubber plate pulse detonating device and the mechanical ultrasonic vibration exciter provided by the invention all have distinct characteristics, which can synergistically promote the infusion and extraction of the huperzine-A, and have relatively strong practical application value.

Owner:向英

Spline curve roller type huperzine A leaching device with chopper and dehydrator

InactiveCN107497135AContinuous and reliable biteExtrusion compression ratio is largeOrganic chemistryCounter-current extractionAutomatic controlEngineering

The invention discloses a spline curve roller type huperzine A leaching device with a chopper and a dehydrator. A chopper is arranged above the body, and three-stage counter-rotating spline curve rollers are arranged inside the body. The surface of the counter-rotating spline curve roller is a continuous spline surface. There is a Melaleuca tower guide groove under each level of counter-rotating spline curve roller. The last level of guide groove is connected to the hopper of the Melaleuca tower elevator. The discharge trough is connected to the screw extrusion dehydrator; the elevator is equipped with a liquid inlet valve, and the upper part of the body is equipped with a filter and a liquid outlet pipe; the body is equipped with a spline curve rubber disc pulse explosion device, and one side of the body is connected by a steam pipeline Automatic control steam valve and manual steam valve, the three-stage counter-rotating spline curve roller and spline curve rubber disk pulse explosion device of the present invention all have distinctive features, can synergistically promote the leaching and extraction of huperzine A, and have the advantages in this field The working principles and technical effects that are difficult for technicians to foresee have strong practical application value.

Owner:祖慧楠

Contra-rotating roller type bagasse leaching device with chopping machine and pulping machines

InactiveCN107267680AContinuous and reliable biteExtrusion compression ratio is largePurification by physical meansJuice extraction from sugarcaneThree levelInlet valve

The invention discloses a counter-rotating drum type bagasse leaching device with a guillotine cutter and a pulping machine. A guillotine cutter is arranged above the body of the leaching device; The cylinder is cylindrical, and there is a bagasse guide groove under each counter-rotating roller cylinder. The last stage of the guide groove is connected to the hopper of the bagasse elevator, and the discharge groove of the elevator is connected to the temporary storage groove through the pulper; There is a water inlet valve, a filter and a liquid outlet pipe on the upper part of the body; a cosine rubber disc pulse explosion device is installed inside the body, and a mechanical ultrasonic exciter is installed at the lower left corner of the body. The three-stage counter-rotating drum, cosine rubber disk pulse explosion device and mechanical ultrasonic exciter of the present invention all have distinctive features, can synergistically promote the leaching and extraction of sugar, and have working principles and technical effects that are difficult for those skilled in the art to foresee. It has strong practical application value.

Owner:罗小英

Mechanical ultrasonic type sugarcane bagasse leaching device with feeding slot

InactiveCN107299160AContinuous and reliable biteExtrusion compression ratio is largeSolid waste disposalTransportation and packagingThree levelInlet valve

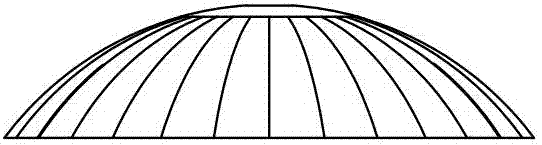

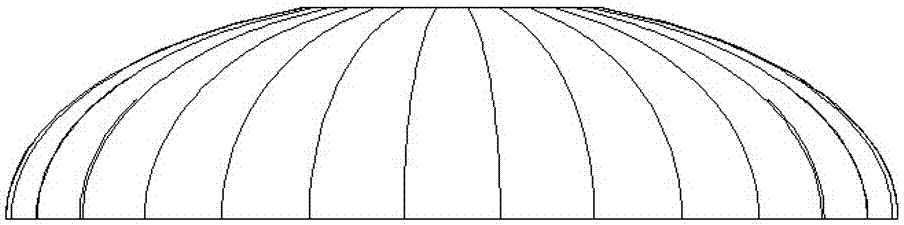

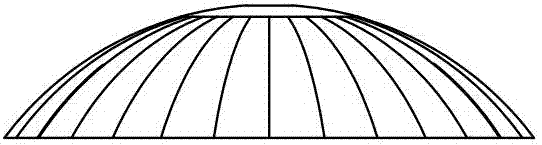

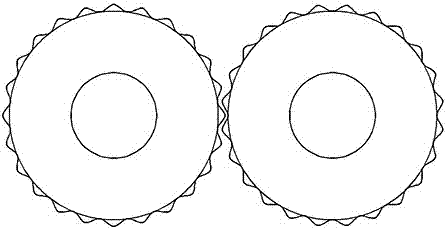

The invention discloses a mechanical ultrasonic type sugarcane bagasse leaching device with a feeding slot. A sugarcane bagasse feeding slot is formed in an upper part of a device body of the leaching device; three levels of counter-rotation cosine rollers are arranged inside the device body; surfaces of the counter-rotation cosine rollers are continuous cosine curved surfaces; sugarcane bagasse guiding slots are formed in lower parts of the three levels of counter-rotation cosine rollers; the last level of guiding slot is connected with a hopper of a sugarcane bagasse lifting machine; a discharging groove of the lifting machine is connected with a sugarcane bagasse temporary storage groove; the lifting machine is provided with a water inlet valve; an upper part of the device body is provided with a filter and a liquid outlet pipe; a mechanical ultrasonic vibration exciter is arranged at a left lower corner of the device body. The three levels of counter-rotation cosine rollers and the mechanical ultrasonic vibration exciter of the mechanical ultrasonic type sugarcane bagasse leaching device disclosed by the invention both have distinctive characteristics; the leaching extraction of sugars can be promoted in a cooperation manner; the device has a working principle and a technical effect which are difficultly predicted by technicians in the field, and has a stronger practical application value.

Owner:蒋霞

Mechanical ultrasonic type sugarcane bagasse treatment device with straw cutting machine and centrifugal machine

InactiveCN107299158AContinuous and reliable biteExtrusion compression ratio is largeTransportation and packagingSolid waste disposalThree levelInlet valve

The invention discloses a mechanical ultrasonic type sugarcane bagasse treatment device with a straw cutting machine and a centrifugal machine. A sugarcane bagasse straw cutting machine is arranged above a device body of a leaching device; three levels of counter-rotation cosine rollers are arranged inside the device body, and surfaces of the counter-rotation cosine rollers are continuous cosine curved surfaces; sugarcane bagasse guiding slots are formed in lower parts of the three levels of counter-rotation cosine rollers; the last level of guiding slot is connected with a hopper of a sugarcane bagasse lifting machine; a discharging groove of the lifting machine is connected with the centrifugal machine; the lifting machine is provided with a water inlet valve; an upper part of the device body is provided with a filter and a liquid outlet pipe; the liquid outlet pipe is connected with a triple-effect long-tube rising-film evaporation concentration device; a mechanical ultrasonic vibration exciter is arranged at a left lower corner of the device body. The three levels of counter-rotation cosine rollers and the mechanical ultrasonic vibration exciter of the mechanical ultrasonic type sugarcane bagasse treatment device disclosed by the invention both have distinctive characteristics; the leaching extraction of sugars can be promoted in a cooperation manner; the device has a working principle and a technical effect which are difficultly predicted by technicians in the field, and has a stronger practical application value.

Owner:李小兰

Cosine roller cylinder type bagasse treating device provided with chopping and cutting machine, centrifugal machine and drying machine

InactiveCN107321769AContinuous and reliable biteExtrusion compression ratio is largeSugar productsTransportation and packagingTriple effectThree level

The invention discloses a cosine roller cylinder type bagasse treating device provided with a chopping and cutting machine, a centrifugal machine and a drying machine. The bagasse chopping and cutting machine is arranged above a body of a leaching device. Three level counter rotating cosine roller cylinders are arranged in the body. The surface of each counter rotating roller cylinder is a continuous cosine curved surface. A bagasse guide groove is formed below each counter rotating cosine roller cylinder. The last level guide groove is connected with a hopper of a bagasse elevator. A discharging groove of the elevator is connected with the drying machine through the centrifugal machine. The elevator is provided with a water input valve. A filter and a liquid output pipe are arranged on the upper portion of the body. The liquid output pipe is connected with a triple-effect long pipe rising film evaporation and concentration device. A cosine plastic plate pulse detonating device is arranged in the body. According to the device, the three level counter rotating cosine roller cylinders and the cosine plastic plate pulse detonating device have distinct characteristics, and can collaboratively promote leaching extraction of sugar, and the device has the working principle and the technical effect difficult to foresee by technicians in the field and has high practical application value.

Owner:段少海

Mechanical ultrasonic huperzine A leaching device with cleaning machine and drying machine

InactiveCN107349627AContinuous and reliable biteExtrusion compression ratio is largeOrganic chemistryCounter-current extractionThree stageUltrasonic vibration

The invention discloses a mechanical ultrasonic type huperzine A leaching device with a cleaning machine and a drying machine. The air bubble cleaning machine is connected with a Melaleuca tower conveyor, a shredder and a body in sequence, and the body is equipped with three-stage counter-rotating samples. The surface of the counter-rotating spline curve roller is a continuous spline surface, and each level of counter-rotating spline curve roller is equipped with a Melaleuca tower guide groove. The hopper and the discharge trough of the elevator are connected to the dryer through the screw extrusion dehydrator and the slag hopper; the elevator is equipped with a liquid inlet valve, and the upper part of the body is equipped with a filter and a liquid outlet pipe; the lower left corner of the body is equipped with a mechanical ultrasonic exciter , the three-stage counter-rotating spline curve roller and mechanical ultrasonic vibrator of the present invention have distinctive features, can synergistically promote the leaching and extraction of huperzine A, have working principles and technical effects that are difficult for those skilled in the art to foresee, and have Strong practical application value.

Owner:田兴云

Mechanical ultrasonic liquorice root fluid extract extraction apparatus with chopper and dryer

InactiveCN107456778AContinuous and reliable biteExtrusion compression ratio is largeCounter-current extractionSolid solvent extractionThree levelAutomatic control

The invention discloses a mechanical ultrasonic licorice liquid extract extraction device with a chopper and a dryer. A chopper is arranged above the machine body, and three stages of counter-rotating spline curve rollers are arranged inside the body, and each stage counter-rotates There are licorice guide grooves under the spline curve rollers, and the last level of guide grooves is connected to the hopper of the licorice hoist, and the discharge chute of the hoist is connected to the dryer through the screw extrusion dehydrator and the slag hopper; there is a liquid inlet on the hoist. Valve, the upper part of the body is equipped with a filter and a liquid outlet pipe, and the liquid outlet pipe is connected to the lifting film evaporator; the lower left corner of the body is equipped with a mechanical ultrasonic vibrator, and one side of the body is connected to the automatic control steam valve and manual steam valve through a steam pipe. Both the three-stage counter-rotating spline curve roller and the mechanical ultrasonic exciter of the present invention have distinctive features, can synergistically promote the leaching and extraction of active ingredients of licorice, have working principles and technical effects that are difficult for those skilled in the art to foresee, and have strong practical application value.

Owner:王春鹏

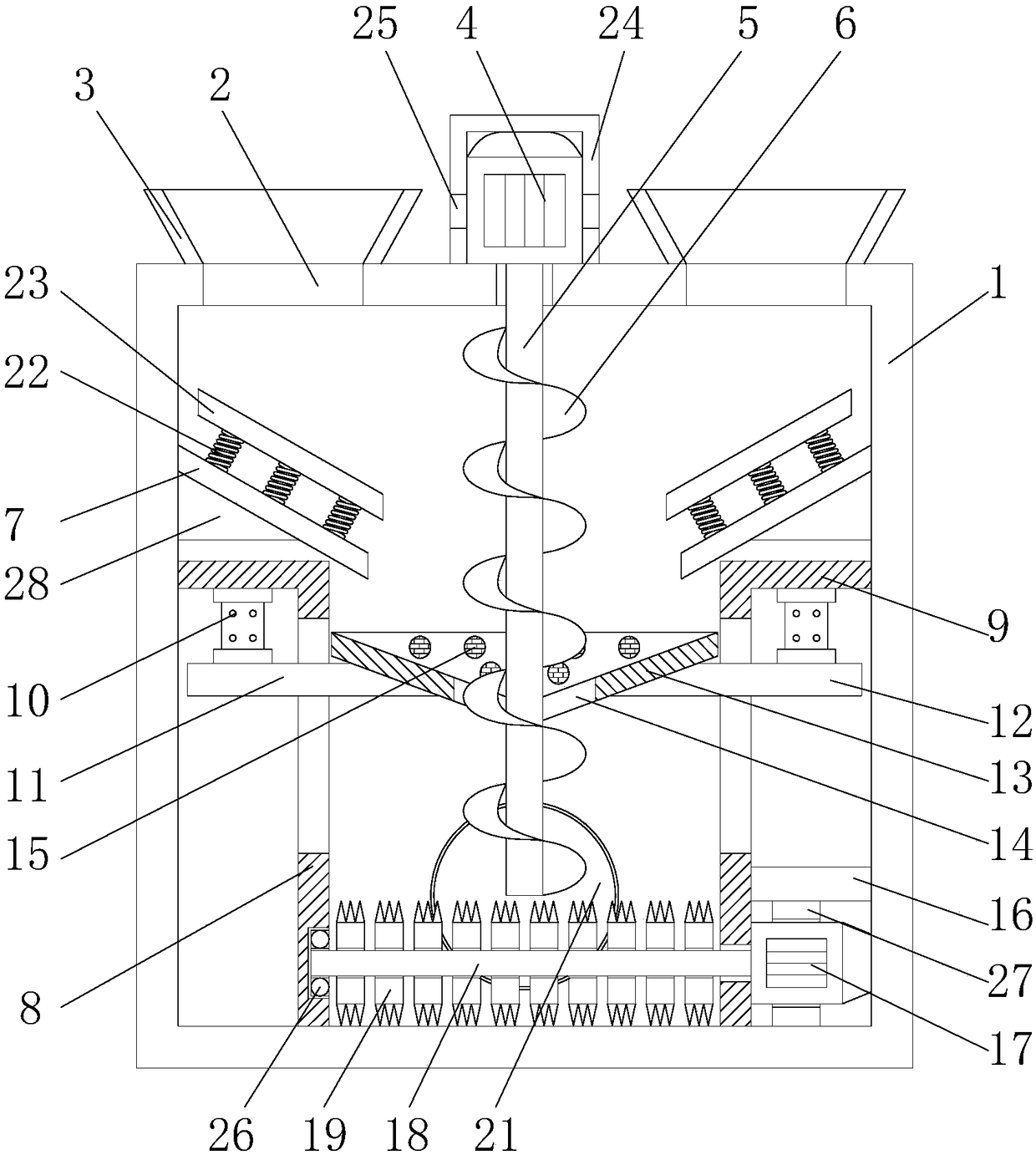

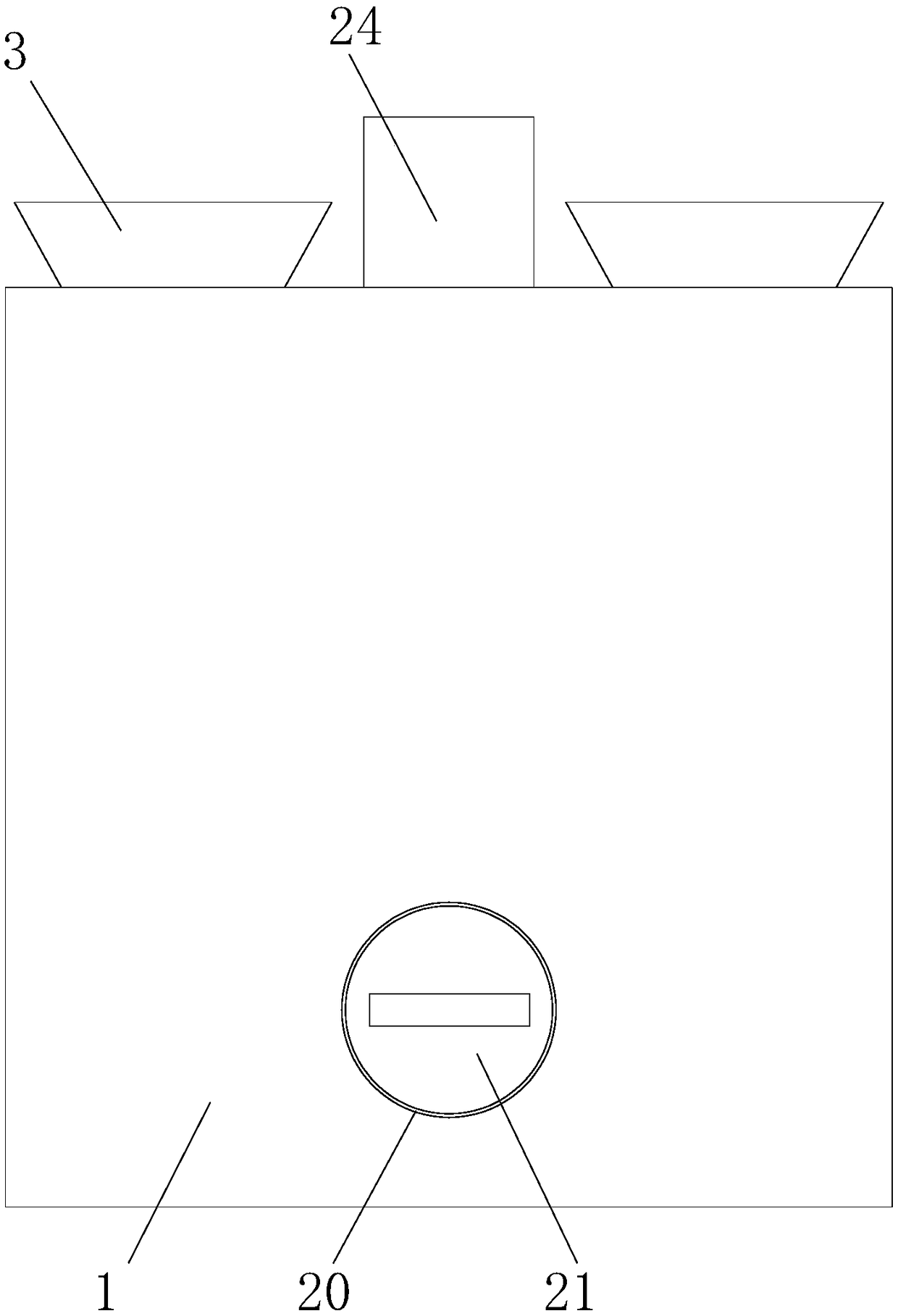

Solid waste treatment equipment

InactiveCN108543593AEasy to handleImprove crushing effectGrain treatmentsElectric machineryEngineering

The invention discloses solid waste treatment equipment which comprises a shell. Putting openings are formed in the two sides of the top of the inner wall of the shell, putting baffles are fixedly connected to the positions, corresponding to the putting openings, of the top of the shell, a first driving motor is fixedly connected to the central point of the top of the shell, a first driving rotating shaft is fixedly connected to an output shaft of the first driving motor, the bottom end of the first driving rotating shaft penetrates the shell and extends into the shell, a smashing packing auger is fixedly connected to the position, located inside the shell, of the surface of the first driving rotating shaft, guide inclined plates are fixedly connected to the positions, located below the putting openings, of the two sides of the inner wall of the shell, a first protection shell is fixedly connected to the left side of the bottom of the inner wall of the shell, and the left side of the first protection shell is fixedly connected with the left side of the inner wall of the shell. The solid waste treatment equipment is simple in structure and low in construction price, the full-automatic operation is achieved, the smashing effect is excellent, the safety performance is high, and a large quantity of solid waste can be treated.

Owner:安徽云帆科技咨询有限公司

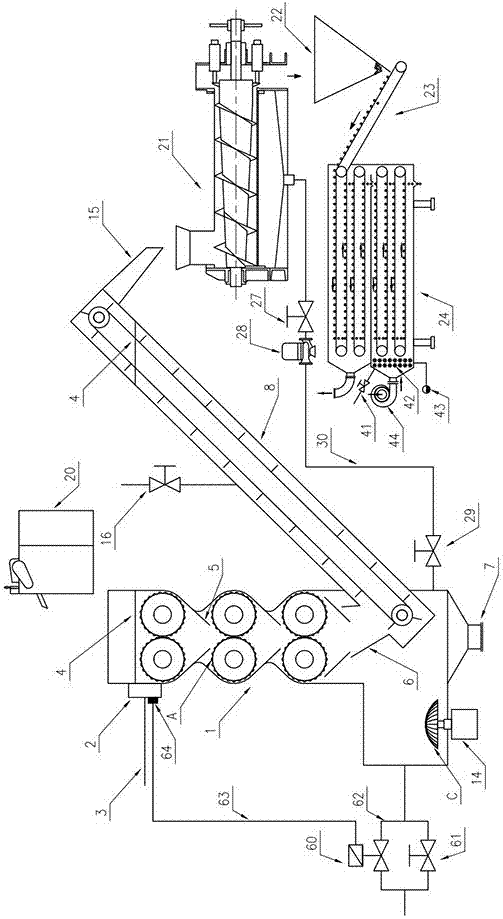

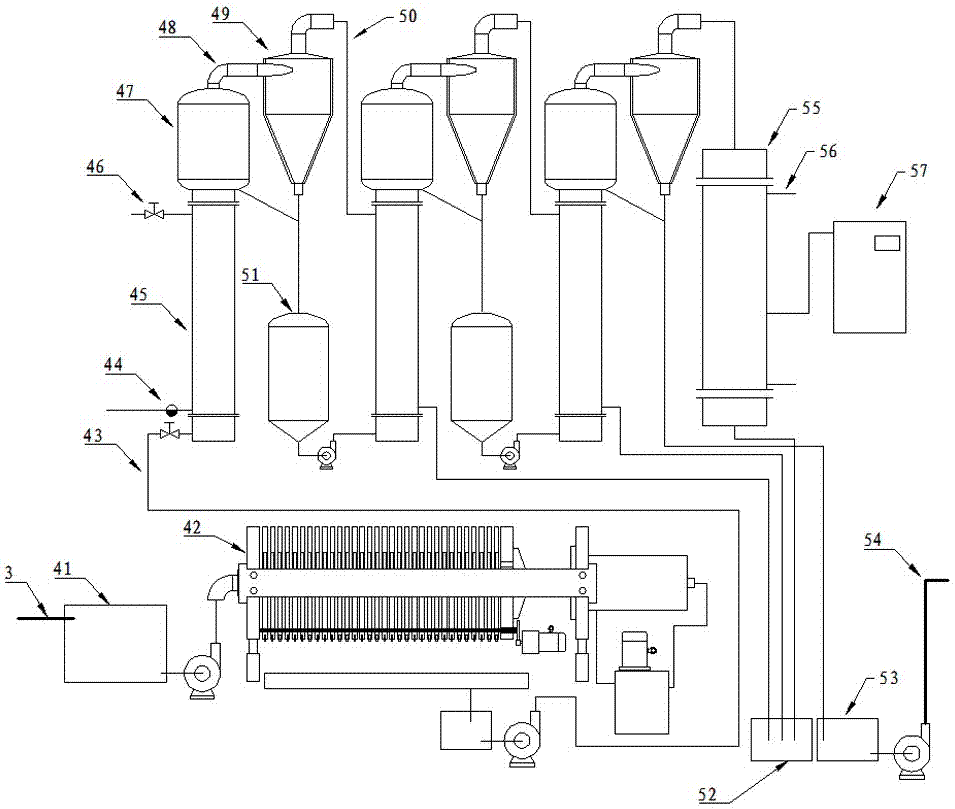

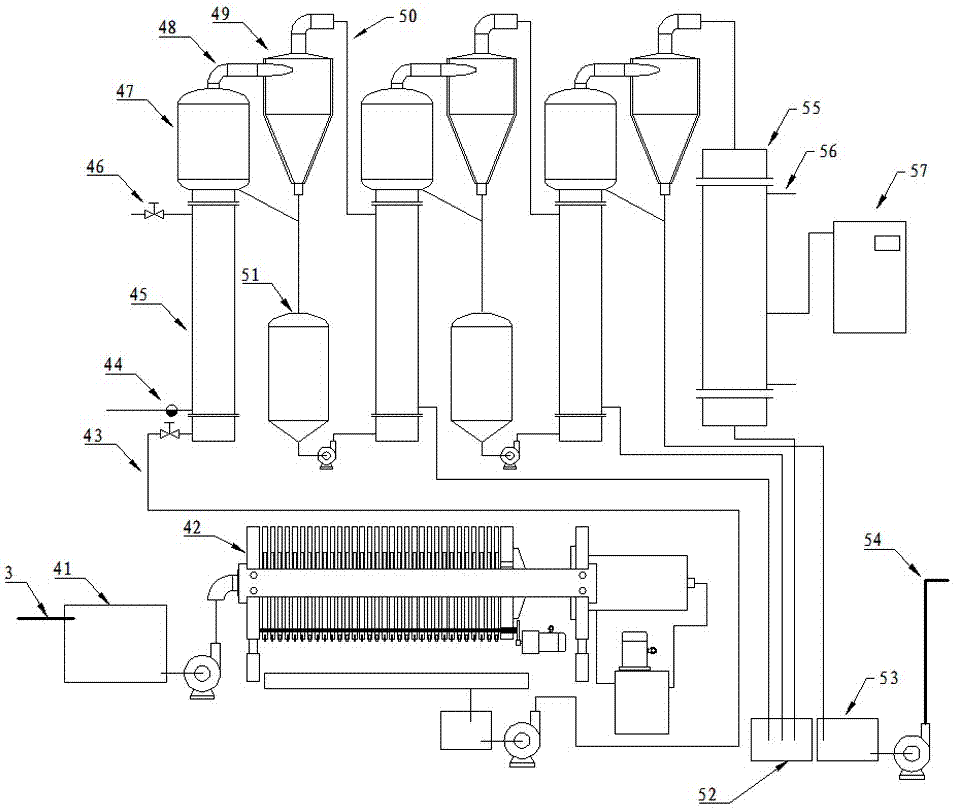

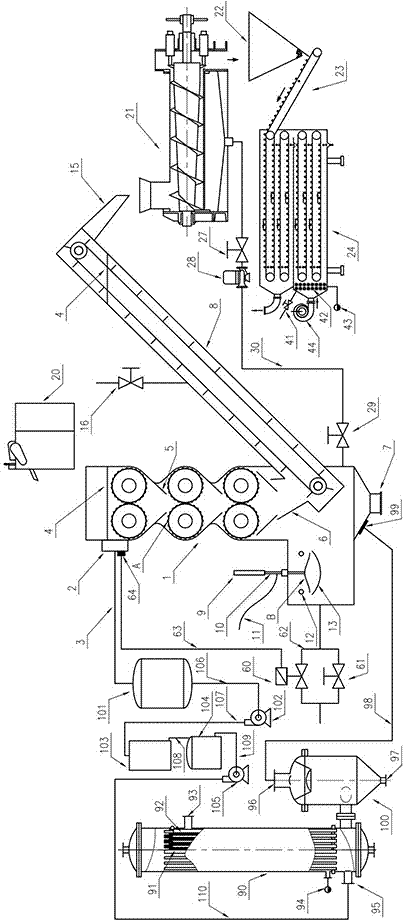

Continuous batching and feeding integrated system for cement production

ActiveCN112317095ASatisfied with the ratioThe ratio meets the process requirementsGrain treatmentsSynchronous controlElectric machinery

The invention provides a continuous batching and feeding integrated system for cement production. The continuous batching and feeding integrated system comprises a conveying unit, four raw material batching stations and a feeding control unit. The feeding control unit is used for synchronously controlling intermittent feeding and discharging of the four raw material batching stations, it is guaranteed that the crushing process of materials entering the raw material batching stations is smoothly carried out, and material blockage caused by material accumulation is avoided; a screening pre-crushing unit, a secondary crushing assembly and a crushing unit in the raw material batching stations are used for carrying out three-stage crushing on materials, so that the size consistency of particlesflowing out of the materials is improved, and it is guaranteed that the weights of the materials flowing out in unit time are equal; and by means of a hopper unit and a vibration motor which are designed in a split mode, materials are prevented from being accumulated on the inner surface of a discharging hopper, the discharging effect is prevented from being affected, it is guaranteed that the mass of the materials falling per unit area is equal during continuous discharging, and therefore it is guaranteed that the final proportion meets the technological requirement, the yield of cement clinker is increased, blocking is reduced, and production efficiency is improved.

Owner:广德独山南方水泥有限公司

Mechanical ultrasonic huperzine A leaching device with feeder and carbonizing molding machine

InactiveCN107497132AContinuous and reliable biteExtrusion compression ratio is largeOrganic chemistryCounter-current extractionThree stageMolding machine

The invention discloses a mechanical ultrasonic huperzine A leaching device with a feeder and a carbonizing molding machine. The mechanical ultrasonic huperzine A leaching device is characterized in that the feeder is arranged above a machine body, three stages of contra-rotating spline curve rollers are arranged inside the machine body, a thousand-storey tower guide groove is formed under each stage of contra-rotating spline curve roller, the last stage of guide groove is connected with a hopper of a thousand-storey tower elevator, and a discharging chute of the elevator is connected with a drier through a screw extrusion dehydrator and a slag hopper, and the drier is sequentially connected with a screw feeder, a carbonization furnace, a screw discharging machine, a pulverizer, a pulverizing fan and a rod making machine; a liquid inlet valve is arranged on the elevator; a filter and a liquid outlet tube are arranged at the upper part of the machine body; the liquid outlet tube is sequentially connected with a duplex filter, a filtrate pump and a liquid storage tank through a pipeline; and a mechanical ultrasonic vibration exciter is arranged at the left lower corner of the machine body. The mechanical ultrasonic huperzine A leaching device disclosed by the invention has the benefit that the three stages of contra-rotating spline curve rollers and the mechanical ultrasonic vibration exciter all have distinct characteristics and can synergistically promote the leaching and the extraction of huperzine A, and therefore, the practical application value is stronger.

Owner:田兴云

Contra-rotary roll cylinder huperzine A leaching device with cutting machine and dehydrator

InactiveCN107321002AContinuous and reliable biteExtrusion compression ratio is largeOrganic chemistryCounter-current extractionAutomatic controlInlet valve

The invention discloses a counter-rotating roller type huperzine A leaching device with a shredder and a dehydrator. A shredder is arranged above the body, and three-stage counter-rotating rollers are arranged inside the body. It is cylindrical, and there is a Melaleuca tower guide groove under each stage of counter-rotating rollers. The last stage guide groove is connected to the hopper of the Melaleuca tower hoist, and the discharge chute of the hoist is connected to the screw extrusion dehydrator; There is a liquid inlet valve, a filter and a liquid outlet pipe are installed on the upper part of the body; a spline curve rubber disk pulse explosion device is installed in the body, a mechanical ultrasonic exciter is installed in the lower left corner of the body, and one side of the body is connected to the automatic control by a steam pipeline The steam valve and the manual steam valve, the three-stage counter-rotating rollers, the spline curve rubber disc pulse explosion device and the mechanical ultrasonic vibrator of the present invention all have distinctive features, and can synergistically promote the leaching and extraction of huperzine A. The working principles and technical effects that are difficult for technicians in the field to foresee have strong practical application value.

Owner:向英

Counter-rotating roller type extractum glycyrrhizae liquidum extraction device with cleaning machine and extrusion dewatering machine

InactiveCN107376414AContinuous and reliable biteExtrusion compression ratio is largeCounter-current extractionSolid solvent extractionAutomatic controlThree stage

The invention discloses a counter-rotating roller type extractum glycyrrhizae liquidum extraction device with a cleaning machine and an extrusion dewatering machine. A bubble cleaning machine is connected with a glycyrrhiza conveyor, a chopper and a body in sequence, cylindrical counter-rotating rollers of three stages are arranged in the body, glycyrrhiza guide grooves are arranged under the counter-rotating rollers of three stages respectively, the guide groove of the last stage is connected with a hopper of a glycyrrhiza elevator, and a discharging chute of the elevator is connected with a screw extrusion dewatering machine. The elevator is provided with a liquid inlet valve, a filter and a liquid outlet pipe are arranged on the upper portion of the body, and the liquid outlet pipe is connected with a climbing-falling film evaporator. A spline rubber disc pulse air-blasting device is arranged in the body, a mechanical ultrasonic vibration exciter is arranged at the lower left corner of the body, and one side of the body is connected with an automatic-control steam valve and a manual steam valve through a steam pipeline. The counter-rotating rollers of three stages, the spline rubber disc pulse air-blasting device and the mechanical ultrasonic vibration exciter all have distinct characteristics and synergistically promote extraction of effective components of glycyrrhiza, and high practical application value is achieved.

Owner:王佳希

A raw material batching station with stable batching function

ActiveCN112275360BUniform particle sizeReduce weight differenceGrain treatmentsElectric machineryProcess engineering

The invention provides a raw material batching station with stable batching function, which includes a hopper unit, a pre-crushing unit and a secondary crushing component. Primary crushing effect: When the material is transferred to the secondary crushing space, the secondary crushing component is used to cooperate with the screening of the concave and convex tracks set on the mounting frame during the descending process, so that the bulk material is crushed by the secondary crushing multiple times. The crushing unit below the crushing space crushes the uncrushed material three times to ensure that the particle size of the outflowing material is uniform; the split-type hopper unit and the vibration motor on one side of the hopper effectively solve the problem of material accumulation. Ensure that the quality of materials falling per unit area is equal during continuous discharge, so as to ensure that the final ratio meets the process requirements, improve the yield of cement clinker, and improve production efficiency.

Owner:广德独山南方水泥有限公司

Spline roller type licorice root fluid extract extraction device with chopper and dryer

InactiveCN107469386AIncrease evaporation rateIncrease the concentration ratioCounter-current extractionSolid solvent extractionSlagAutomatic control

The invention discloses a spline curve roller type licorice fluid extract extraction device with a chopper and a dryer. A chopper is arranged above the body, and three-stage counter-rotating spline curve rollers are arranged inside the body. There are licorice guide grooves under the double-stage counter-rotating spline curve rollers, and the last-level guide grooves are connected to the hopper of the licorice elevator. There is a liquid inlet valve, a filter and a liquid outlet pipe are installed on the upper part of the body, and the liquid outlet pipe is connected to the lifting film evaporator; a spline curve rubber plate pulse explosion device is installed in the body, and one side of the body is connected to the steam pipe to automatically control the steam. Valve and manual steam valve, the three-stage counter-rotating spline curve roller and spline curve rubber plate pulse explosion device of the present invention all have distinctive features, which can synergistically promote the leaching and extraction of active ingredients of licorice, which is difficult for those skilled in the art to foresee. The working principle and technical effect have strong practical application value.

Owner:向澍予

Spline curve roller type huperzine A leaching device with shredding machine and drying machine

InactiveCN107349624AContinuous and reliable biteExtrusion compression ratio is largeOrganic chemistryCounter-current extractionThree stageEngineering

The invention discloses a spline curve roller type huperzine A leaching device with a chopper and a dryer. A chopper is arranged above the body, and three-stage counter-rotating spline curve rollers are arranged inside the body. The surface of the counter-rotating spline curve roller is a continuous spline surface. There is a Melaleuca tower guide groove under each level of counter-rotating spline curve roller. The last level of guide groove is connected to the hopper of the Melaleuca tower elevator. The discharge trough is connected to the dryer through a screw extruding dehydrator and a slag hopper; there is a liquid inlet valve on the hoist, a filter and a liquid outlet pipe on the upper part of the body; a spline curve rubber disk pulse explosion device is installed inside the body. The invented three-stage counter-rotating spline curve roller and spline curve rubber disk pulse explosion device have distinctive features, can synergistically promote the leaching and extraction of huperzine A, and have working principles and technical effects that are difficult for those skilled in the art to foresee , has strong practical application value.

Owner:祖慧楠

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com