Contrarotating-roller huperzine-A leaching-extracting device with feeding machine and extruding dewatering machine

A technology of extrusion dehydrator and huperzine A, applied in the directions of organic chemistry, solvent extraction, countercurrent extraction, etc., can solve the problems of difficult separation and extraction of effective components, low leaching efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

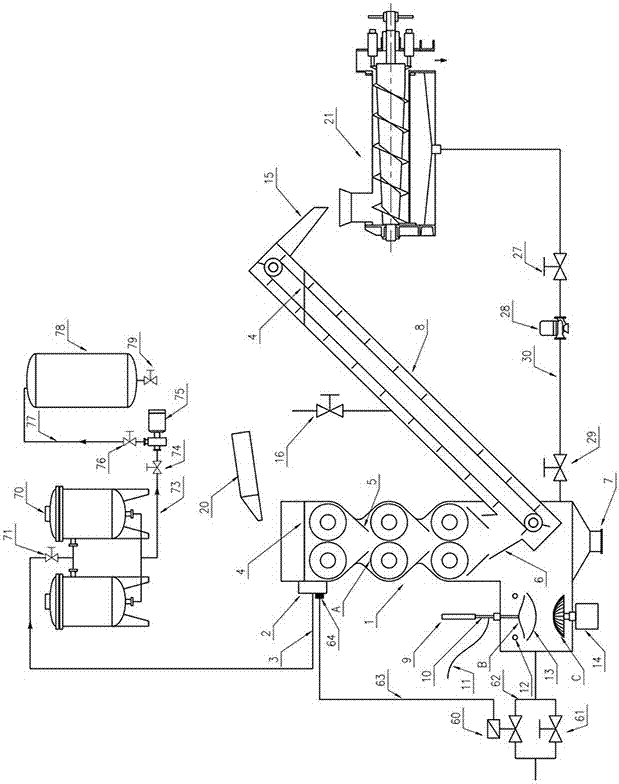

[0033] Now in conjunction with accompanying drawing, the present invention is described in further detail.

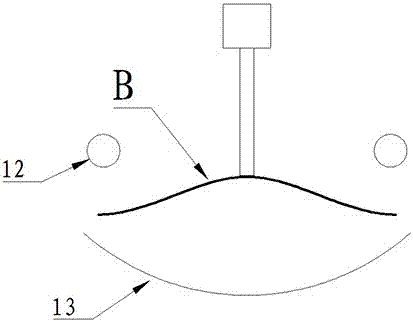

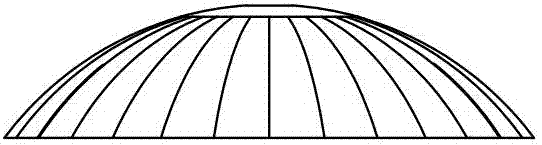

[0034] Such as Figure 1-Figure 7The shown counter-rotating roller huperzine A leaching device with a feeder and a squeeze dehydrator includes a body 1, which is characterized in that: a feeder 20 is arranged above the body 1, and three stages are arranged inside the body 1. Counter-rotating rollers A, counter-rotating rollers A are cylindrical, each stage of counter-rotating rollers A is provided with a Melaleuca tower guide groove 5, and the last stage guide groove 5 is connected to the hopper 6 of the Melaleuca tower hoist 8, The outlet trough 15 of the hoist 8 is connected to the screw extrusion dehydrator 21; the hoist 8 is provided with a liquid inlet valve 16, and the upper part of the body 1 is provided with a filter 2 and a liquid outlet pipe 3, and the liquid outlet pipe 3 is filtered through the liquid inlet valve 71 communicates with the inlet of duplex fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com