Contra-rotating roller type bagasse leaching device with chopping machine and pulping machines

A sugarcane bagasse and pulping machine technology, which is applied in the direction of extracting juice from sugarcane and using physical methods to purify, etc., to achieve continuous and reliable bite, good effect, and large extrusion compression ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Now in conjunction with accompanying drawing, the present invention is described in further detail.

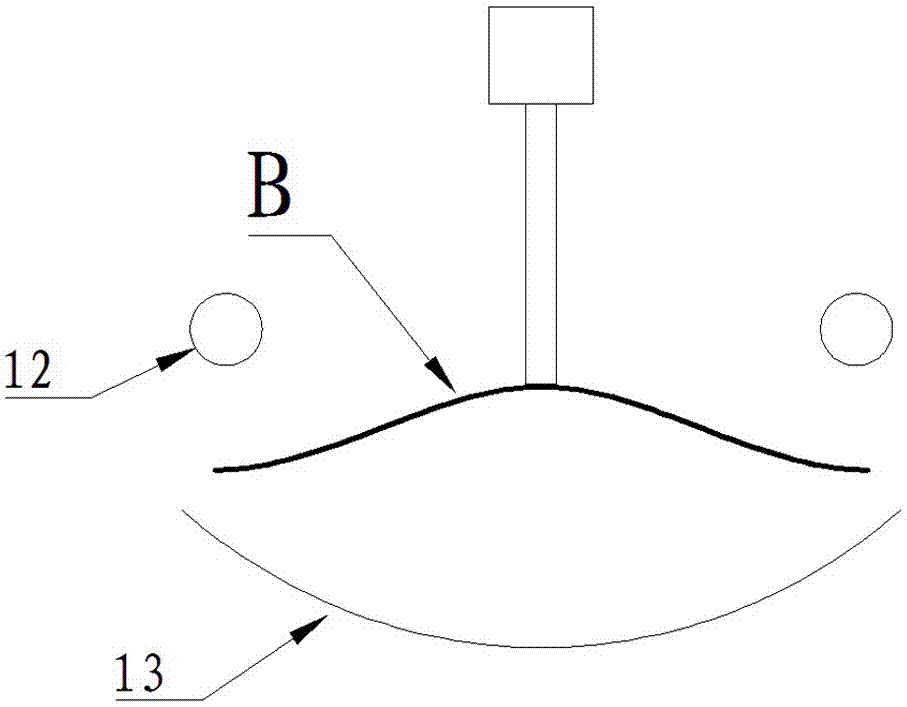

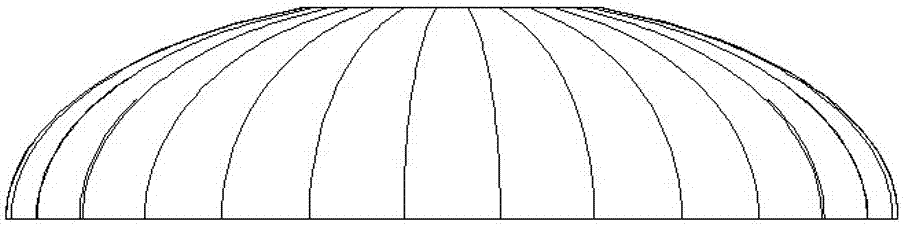

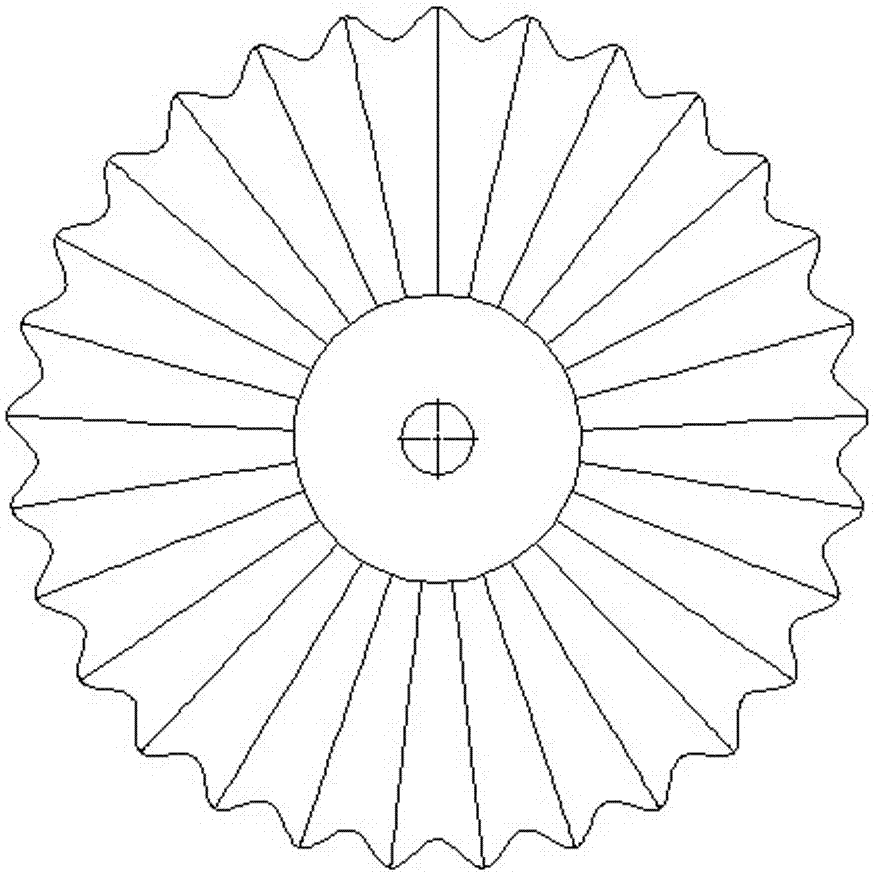

[0032] Such as Figure 1-Figure 7 The counter-rotating drum-type bagasse leaching device with a guillotine cutter and a pulping machine includes a body 1, and a guillotine cutter 20 is arranged above the body 1; a three-stage counter-rotating drum A is arranged inside the body, and a counter-rotating drum The barrel is cylindrical, and there is a bagasse guide groove 5 under each counter-rotating roller barrel. The last stage guide groove is connected to the hopper 6 of the bagasse elevator 8, and the discharge chute 15 of the elevator passes through the cascade pulper 31 Connect the temporary storage tank 32; the hoist is provided with a water inlet valve 16, the upper part of the body is provided with a filter 2 and a liquid outlet pipe 3; Disc B, cylinder 9, telescopic rod 10, compressed air pipe 11, retaining ring 12 and pot-shaped spherical disc 13, the cosine rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com