Mechanical ultrasonic-type utilizing device of the root of kudzu vine with cutting machine and drying machine of the root of kudzu vine

A technology of drying machine and segment cutting machine, applied in application, chemical instrument and method, juice extraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Now in conjunction with accompanying drawing, the present invention is described in further detail.

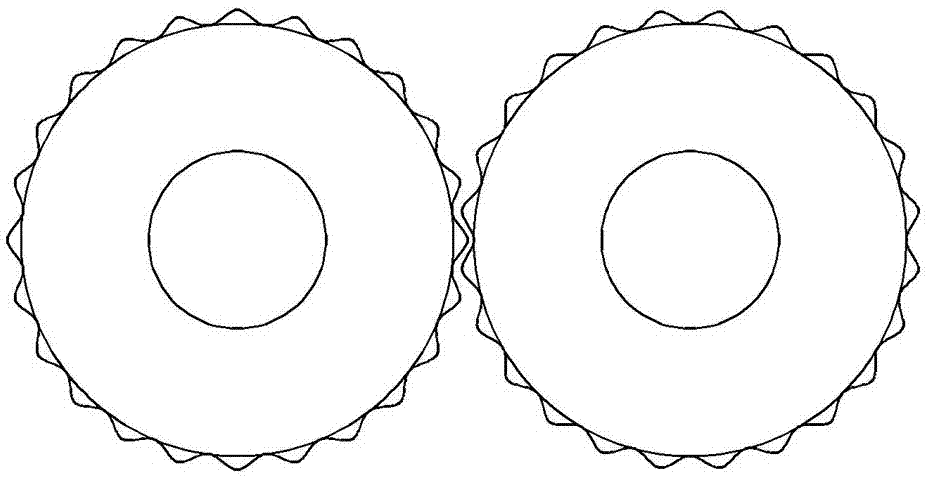

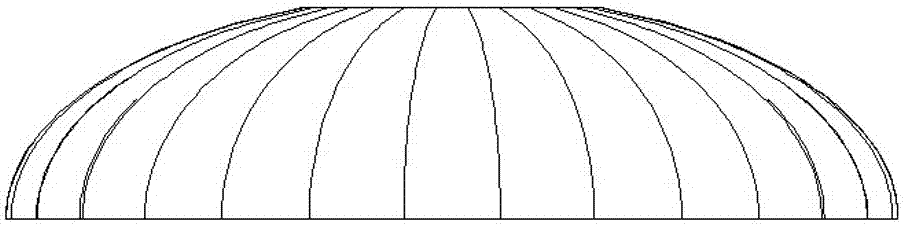

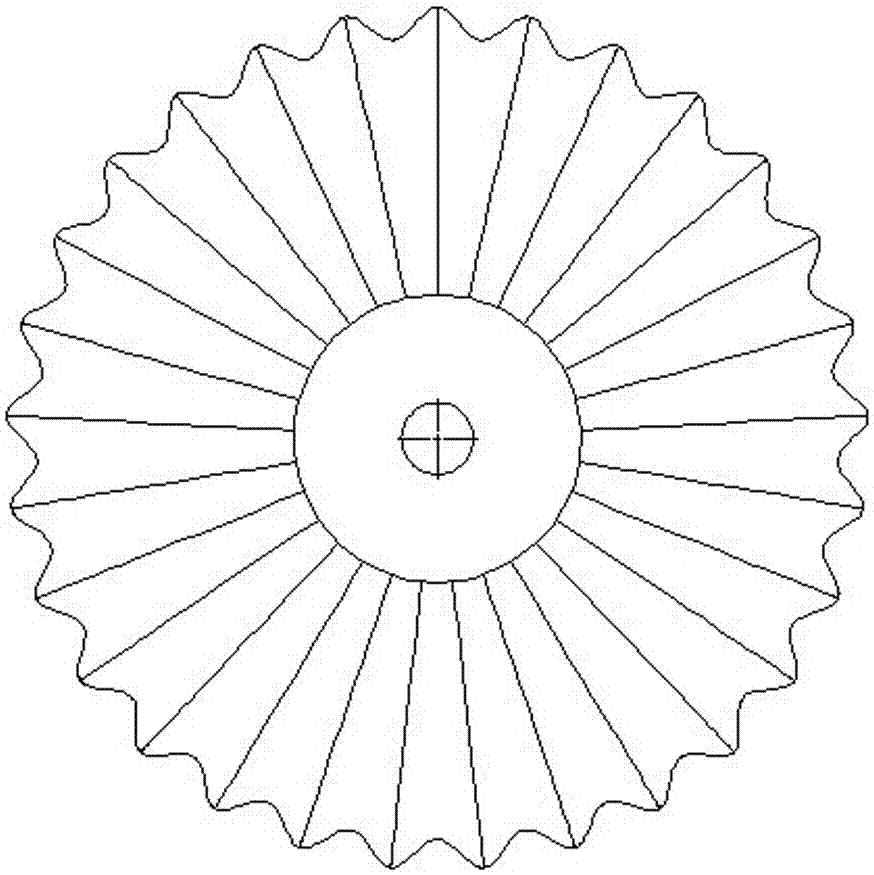

[0035] Such as Figure 1-Figure 10 As shown in the mechanical ultrasonic kudzu root utilization device with section cutting machine and kudzu powder dryer, a powder rubbing machine D is arranged above the washing tank 15, and the powder rubbing machine D is connected to the discharge end of the hoist 10 through a chute, and the feed of the hoist 10 is A horizontal centrifuge 6, a counter-rotating cosine roller barrel A, and a feed shaking tank 1 are successively arranged above the end; the feeding shaking tank 1 conveys kudzu root to the counter-rotating cosine roller barrel A through a cutting machine for squeezing, and the cosine roller barrel A surface It is a continuous cosine surface, with an inclined screen 3 and a launder 2 below, the inclined screen 3 is connected to the feed end of the hoist 10 through the chute, the launder 2 is connected to the horizontal cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com