A raw material batching station with stable batching function

A functional and raw material technology, applied in the field of cement production equipment, can solve the problems of high stability coefficient of raw material entering the kiln, unstable strength of clinker exiting the kiln, and adverse effects of kiln calcination, so as to achieve low labor intensity and reduce personnel The effect of labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

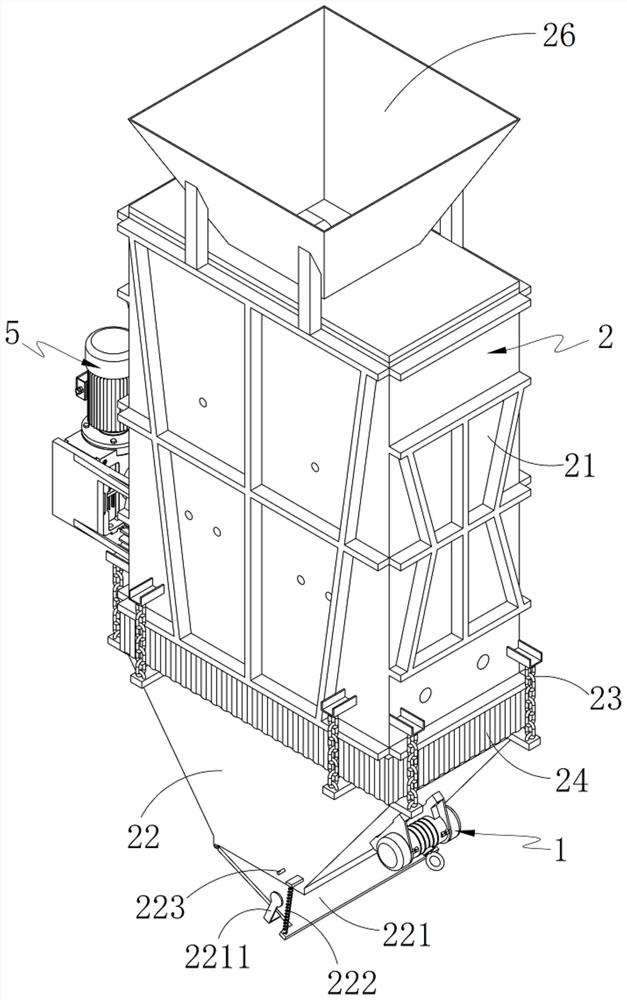

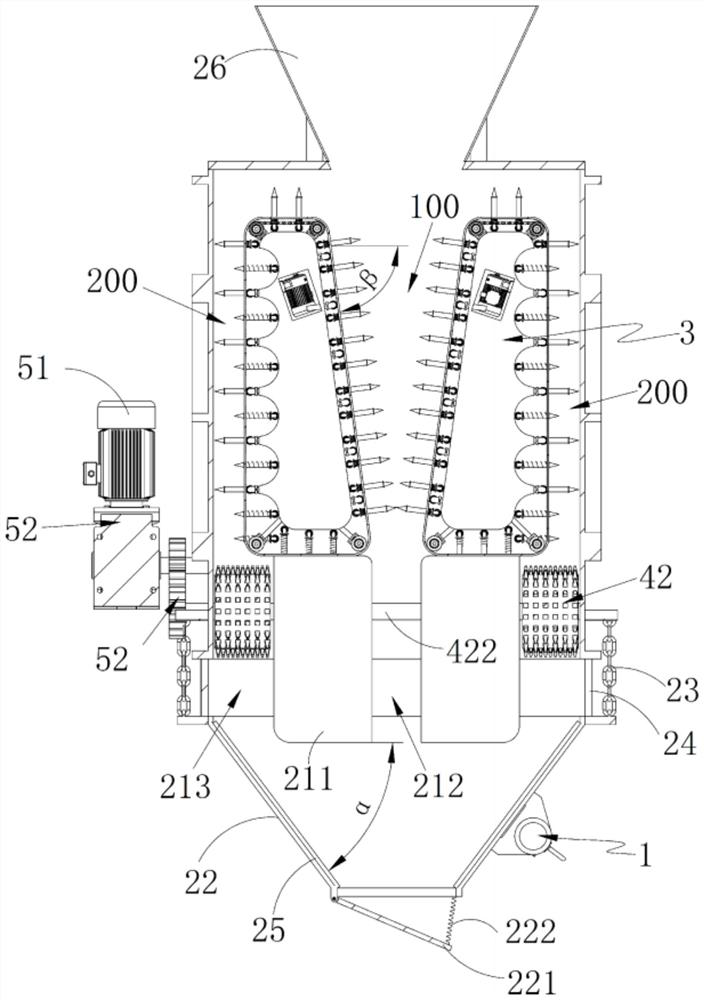

[0051] Such as figure 1 , 14 As shown, a raw material batching station with stable batching function, including:

[0052] Hopper unit 2; the hopper unit 2 is an upper and lower split structure, which includes an upper hopper 21 and a lower hopper 22; the lower hopper 22 is hoisted below the upper hopper 21 through a flexible part 23; the upper hopper 21 The top is provided with a feed hopper 26; wherein the flexible member 23 can be selected from nylon belts, belts, chains, etc., preferably chains; Dust is prone to occur at the place and causes the problem of poor working environment on site; wherein the inner wall of the lower hopper 22 is provided with a polyethylene plate 25, which reduces the friction of the inner wall of the lower hopper, improves the smoothness of the passage of materials, and avoids the phenomenon of material blockage;

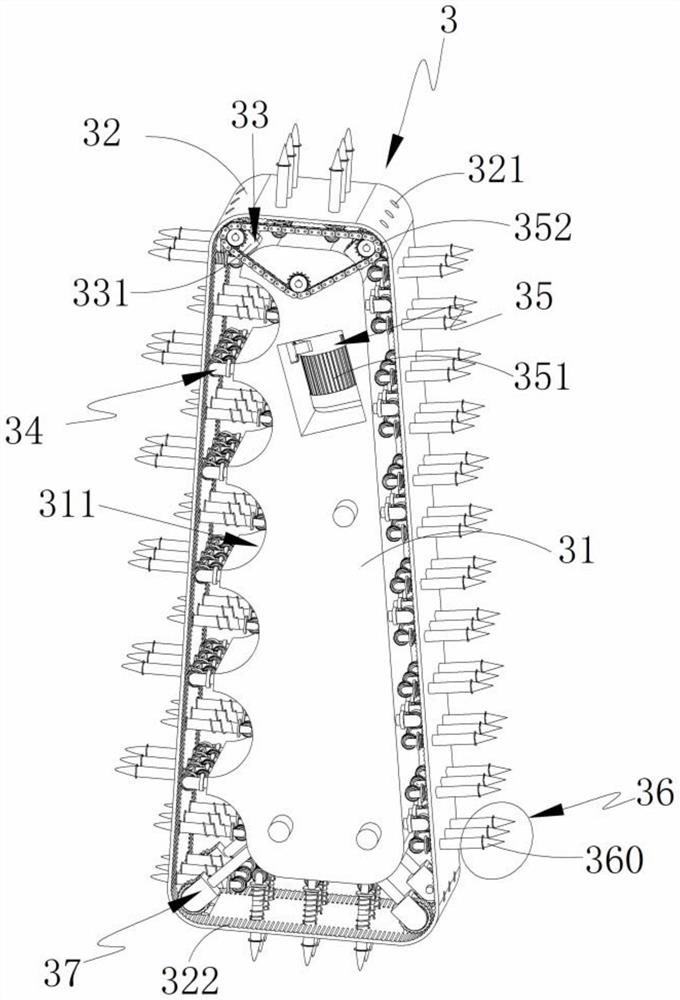

[0053] Two groups of screening pre-crushing units 3 symmetrically arranged in the upper hopper 21, such as image 3 , 4 A primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com