Sugarcane crusher

A crusher and sugarcane technology, applied in the direction of sugarcane tearing, etc., can solve the problems that affect the treatment of sugarcane residues, and the particle size of the liquid output rate has little relationship.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

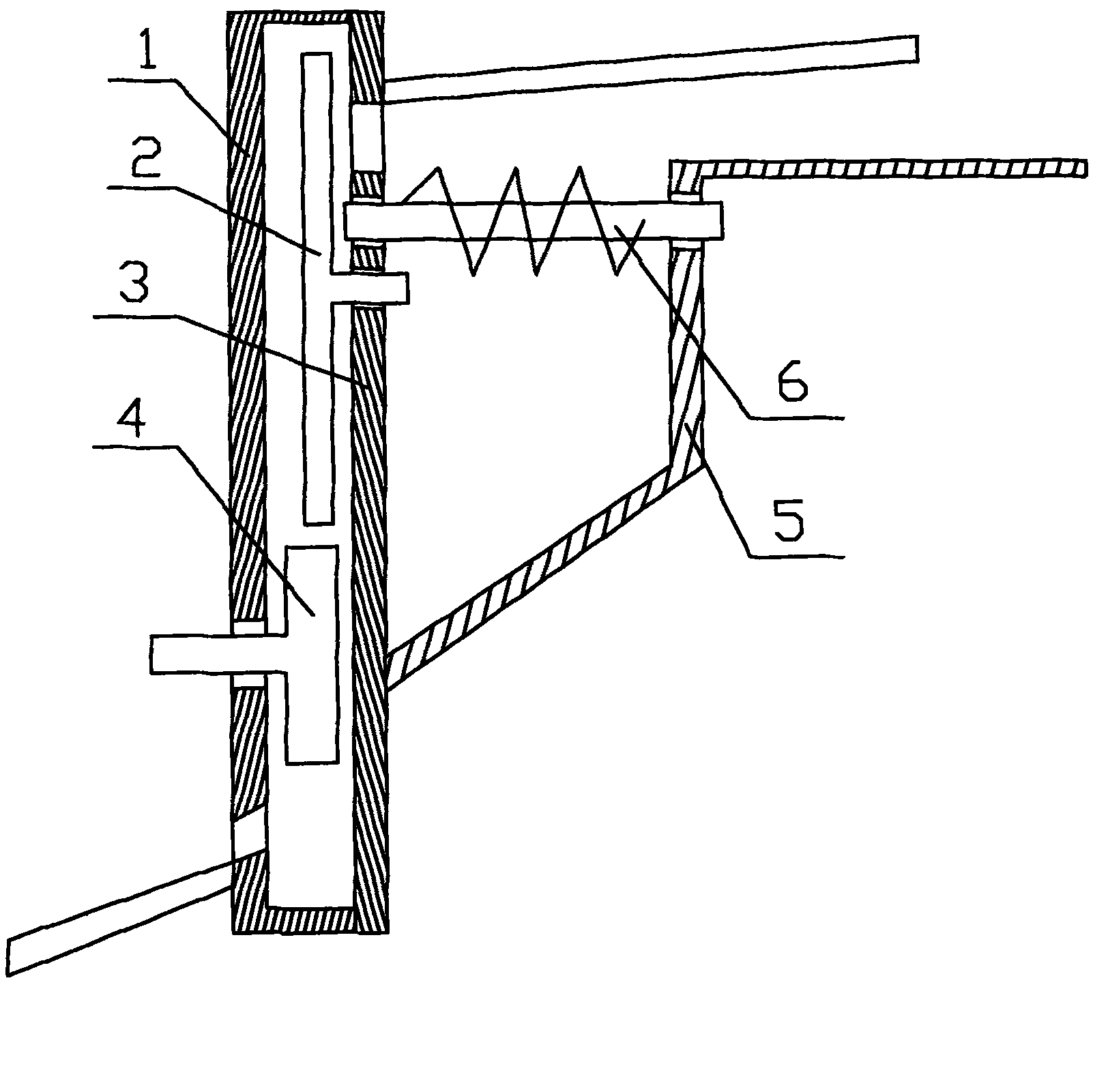

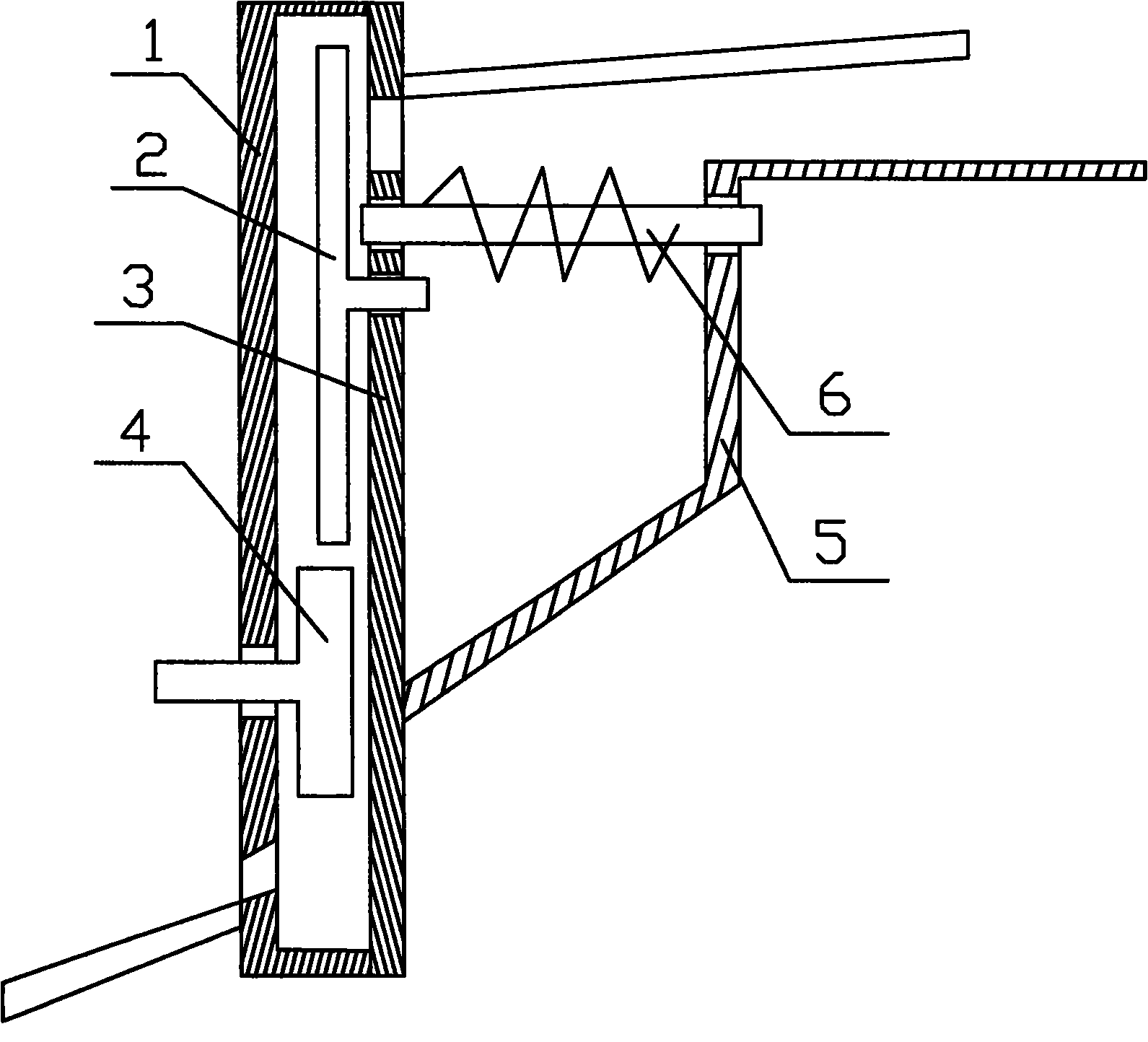

[0009] The accompanying drawing is an embodiment of the present invention, and this embodiment will be described in detail in conjunction with the accompanying drawings, including a left casing 1, a first crushing wheel 2, a right casing 3, a second crushing wheel 4, an outer support 5 and a screw propulsion device 6. The left casing 1 and the right casing 3 are set to form a closed cavity, the outer bracket 5 is set to be fixedly connected with the right casing 3, one end of the screw propulsion device 6 is set to be rotatably connected to the right casing 3, and the other end It is arranged to be rotatably coupled with the outer bracket 5, and a feed inlet is provided on the upper side of the screw propulsion device 6 on the right housing 3, and a cover plate fixedly connected with the right housing 3 is arranged on the upper side of the feed inlet, and on the left The closed cavity of the housing 1 and the right housing 3 is provided with a first pulverizing wheel 2 and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com