Burning through point localization method suitable for updraft sintering machine and positioning system thereof

A positioning method and sintering machine technology, applied in the direction of thermometers using electric/magnetic elements that are directly sensitive to heat, using electrical devices, using electromagnetic means, etc., can solve problems such as large drift and difficulty in accurately locating the position of the burn-through point, etc. Achieve good effects of improving smelting quality, saving energy and reducing consumption, drum rate and desulfurization rate

Active Publication Date: 2011-01-05

华楚智能科技(湖南)有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the defect that the position of the burn-through point of the sintered material layer is difficult to accurately locate in the blast sintering machine and production, and to overcome the reality that the position of the burn-through point of the material layer in the actual operation drifts greatly among the nine bellows, the present invention aims to provide a method suitable for The burn-through point positioning method and its positioning system of the blast sintering machine make the positioning accuracy of the burn-through point much higher than the sinter point positioning of the suction sintering, and at the same time have a significant impact on the size of the sintered block, the drum rate and the desulfurization rate. To achieve a good effect, effectively improve the smelting quality of the blast furnace in the follow-up process and save energy and reduce consumption

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

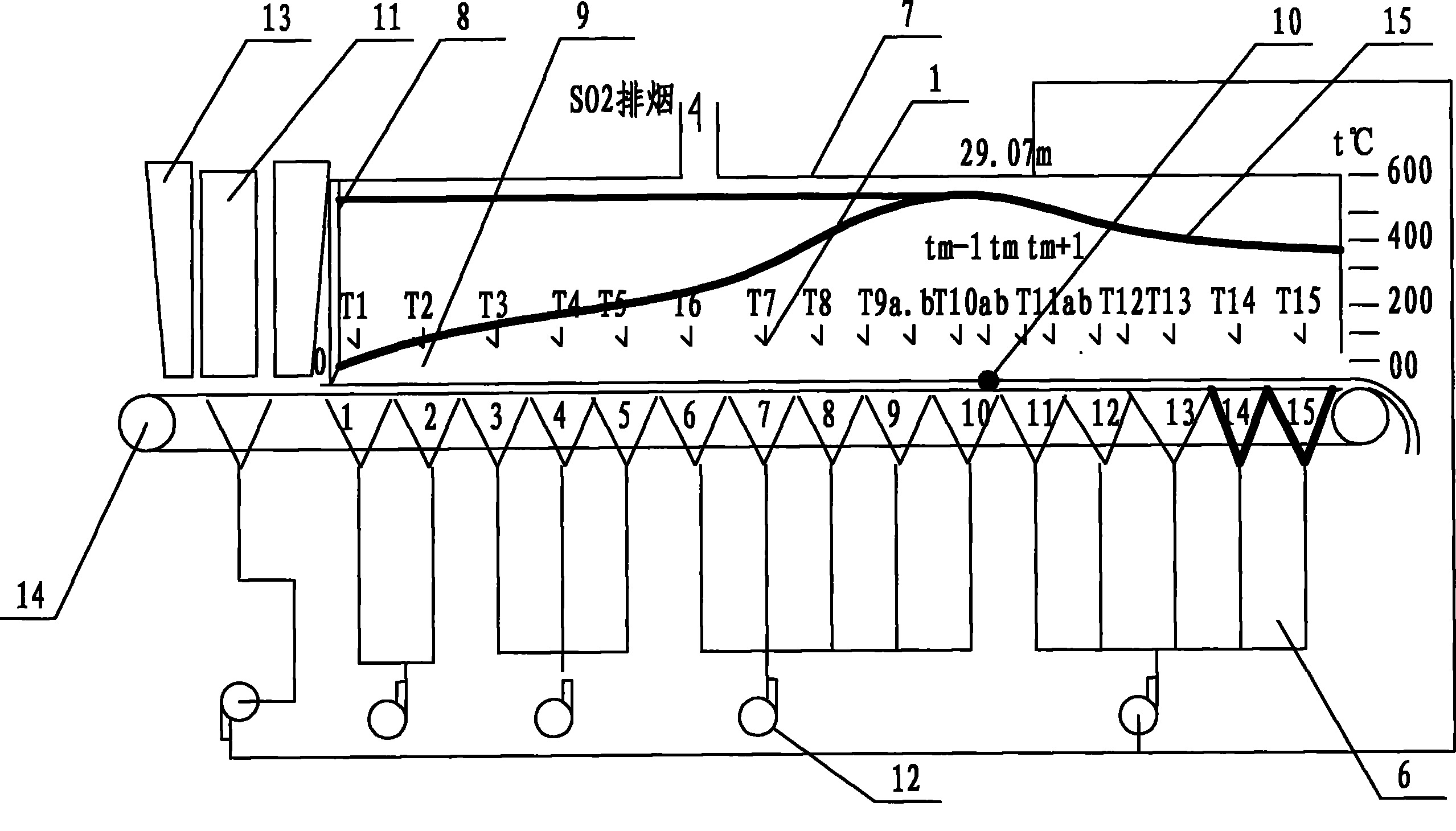

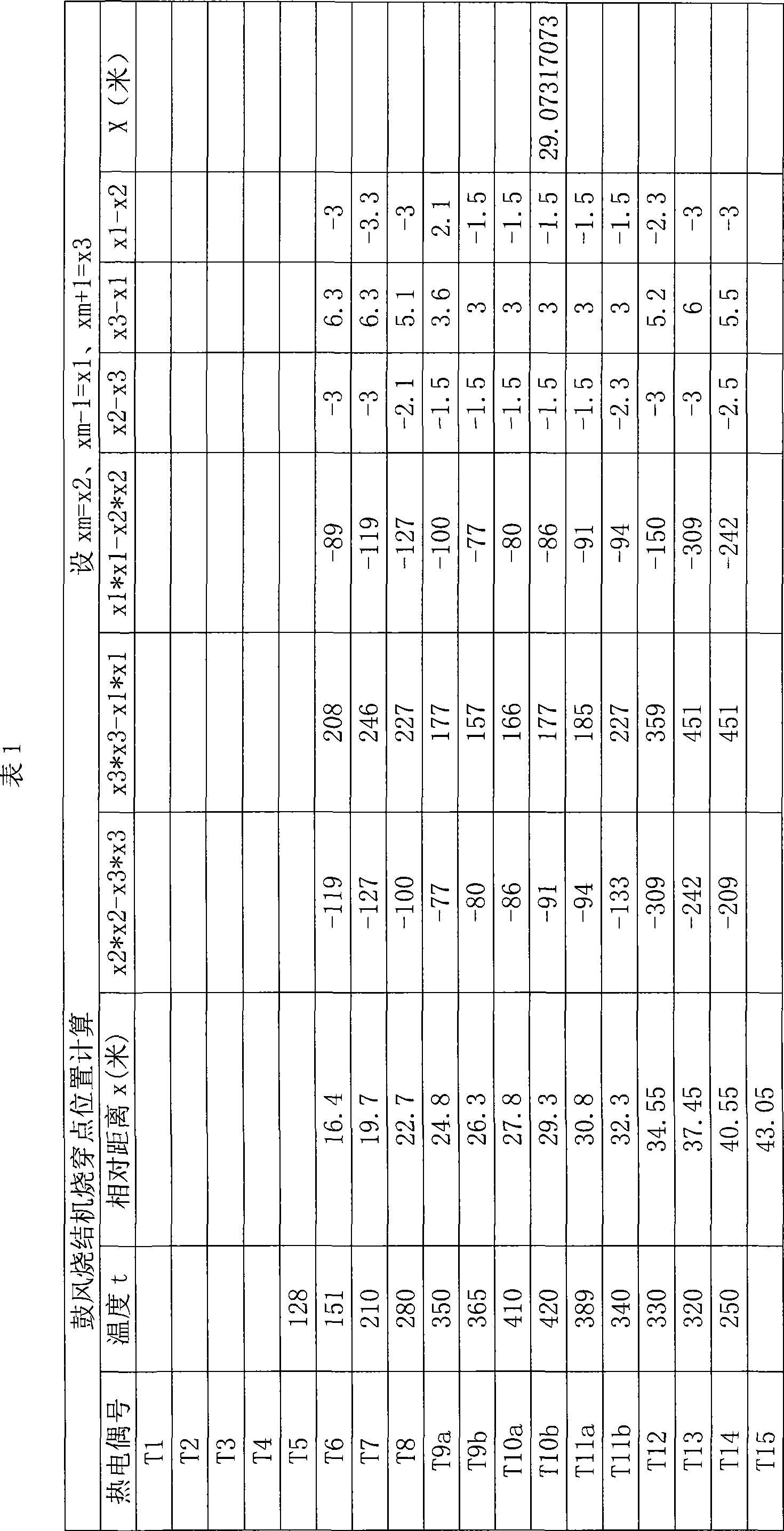

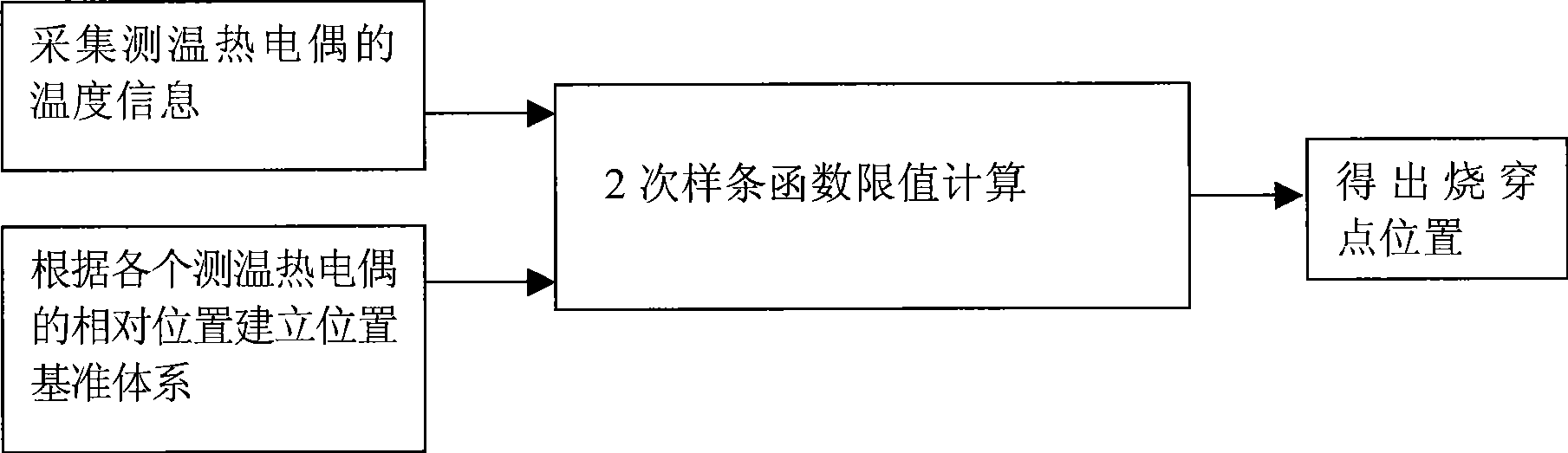

The invention discloses a burn-through point positioning method applicable for an updraft sintering machine and a positioning system thereof. Atmospheric temperature is detected by temperature thermocouples which are arranged on a petticoat pipe close to a batch layer, the temperature thermocouple with the highest temperature and two adjacent temperature thermocouples are found out, and the burn-through point position is calculated by utilizing the spline interpolation function according to reference positions of the three atmospheric temperatures. By using the positioning method and system, the burn-through point positioning is more precise than sinter point positioning of down-draft sintering. At the same time, the positioning method and system have good functions on the lumpiness of lump sinters, rolling drum rate and desulfurization rate, effectively improve smelting quality of blast furnaces in subsequent procedures, save energy and lower consumption.

Description

Burn-through point positioning method and positioning system suitable for blast sintering machine Technical field: The invention relates to a detection method in the ISP process, in particular to a positioning method and a positioning system for the burn-through point of the sintered layer of the blast sintering machine in the ISP closed blast furnace smelting process of non-ferrous metallurgy. Background technique: The measurement technology of the burn-through point position of the sintering machine is an important operation index for the qualification of the sintering block. At the burn-through temperature, travel a certain distance on the sintering belt, after cooling, fall from the tail of the machine, and pass through the crusher to form a qualified agglomerate with certain hardness, lumpiness and residual sulfur rate required by the blast furnace. Therefore, at a certain burn-through temperature, the burn-through point is at the location of the burn-through point design...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B21/00G01K7/02F27D21/00

Inventor 戈尔谷

Owner 华楚智能科技(湖南)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com