A kind of calcium sulfate whisker airgel thermal insulation composite material and preparation method thereof

A calcium sulfate whisker and composite material technology, which is applied in the field of calcium sulfate whisker airgel thermal insulation composite material and its preparation, can solve the problems of high production cost and complicated preparation process, and achieve good block formation and high safety , the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

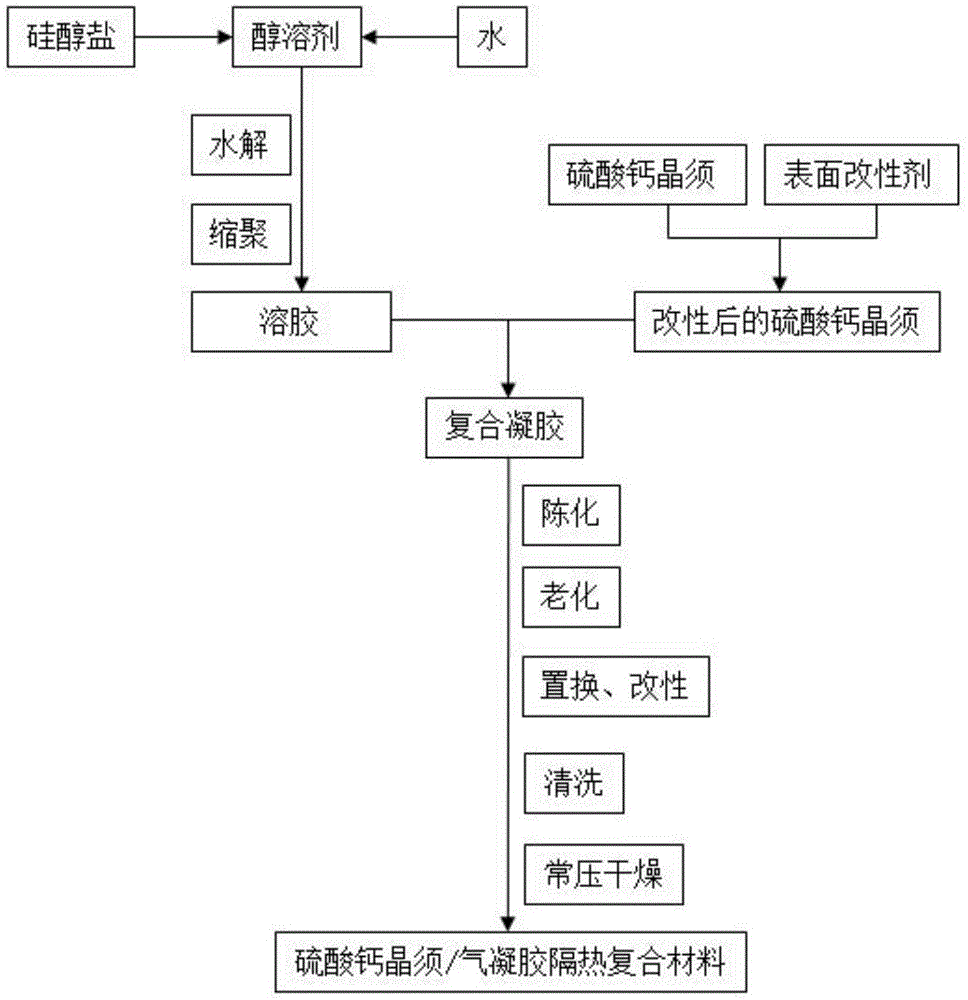

Method used

Image

Examples

Embodiment 1

[0039] According to the content of the present invention, the contriver makes calcium sulfate whisker / SiO 2 Airgel 1, the specific steps are as follows:

[0040] (1) Add stearic acid and calcium sulfate whiskers into absolute ethanol, stir for 0.5 hours at a temperature of 50°C and a stirring speed of 500 rpm, and then put it in a drying oven at 80°C for 8 hours , to obtain modified calcium sulfate whiskers;

[0041] (2) Add tetraethyl orthosilicate to absolute ethanol, and then add water and hydrochloric acid in turn under the conditions of temperature of 30°C and stirring speed of 200 rpm, so that the pH value is between 3, and a mixture is obtained. Solution A, the ratio of ethyl orthosilicate, absolute ethanol, water, and hydrochloric acid is 1:5:2:1×10 in molar ratio -5 ; The mixed solution A was left to stand at a temperature of 30°C for 0.1 hour, and then at a temperature of 30°C and a stirring speed of 600 rpm, DMF was added, and after stirring for 3 minutes, ammonia...

Embodiment 2

[0046] According to the content of the present invention, the contriver makes calcium sulfate whisker / SiO 2 Airgel 2, the specific steps are as follows:

[0047] (1) Add sodium lauryl sulfate and calcium sulfate whiskers into anhydrous methanol, stir for 1 hour at a temperature of 80°C and a stirring speed of 1000 rpm, and then put it into a drying oven at 120°C In 24 hours, obtain the modified calcium sulfate whisker;

[0048] (2) Water glass is added in anhydrous methanol, under the condition that the temperature is 60° C. and the stirring speed is 800 rpm, water and oxalic acid are added successively to make the pH value between 4 to obtain the mixed solution A, The ratio of the water glass, anhydrous methanol, water and oxalic acid is 1:40:10:5×10 in molar ratio -5 ; The mixed solution A was left to stand at a temperature of 80°C for 24 hours, and then at a temperature of 60°C and a stirring speed of 800 rpm, formamide was added, and after stirring for 3 minutes, sodium ...

Embodiment 3

[0053] According to the content of the present invention, the contriver makes calcium sulfate whisker / SiO 2 Airgel 3, the specific steps are as follows:

[0054] (1) Add Tween-80 and calcium sulfate whiskers to anhydrous isopropanol, stir for 0.8 hours at a temperature of 60°C and a stirring speed of 800 rpm, and then put it into a drying oven at 100°C Middle 12 hours, obtain the modified calcium sulfate whisker;

[0055] (2) Add diatomaceous earth to anhydrous isopropanol, under the condition of temperature of 50°C and stirring speed of 600 rpm, then add water and sulfuric acid in sequence to make the pH value between 3.5, and obtain a mixture Solution A, the molar ratio of diatomaceous earth, anhydrous isopropanol, water, and sulfuric acid is 1:20:8:3×10 -5 ; The mixed solution A was left to stand at a temperature of 60°C for 12 hours, and then at a temperature of 50°C and a stirring speed of 600 rpm, acetamide was added, and after stirring for 3 minutes, ammonium fluoride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com