A kind of preparation method of graphene-silica airgel

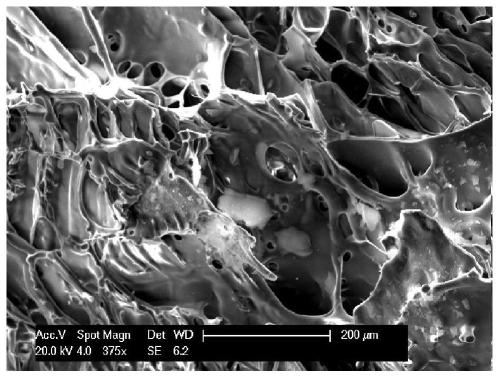

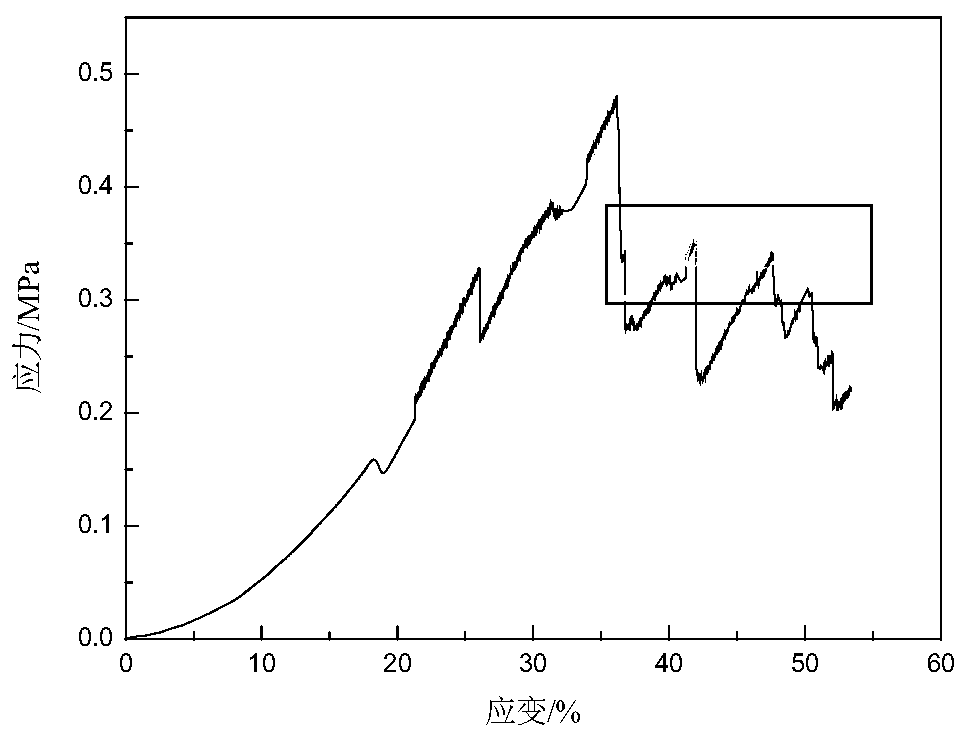

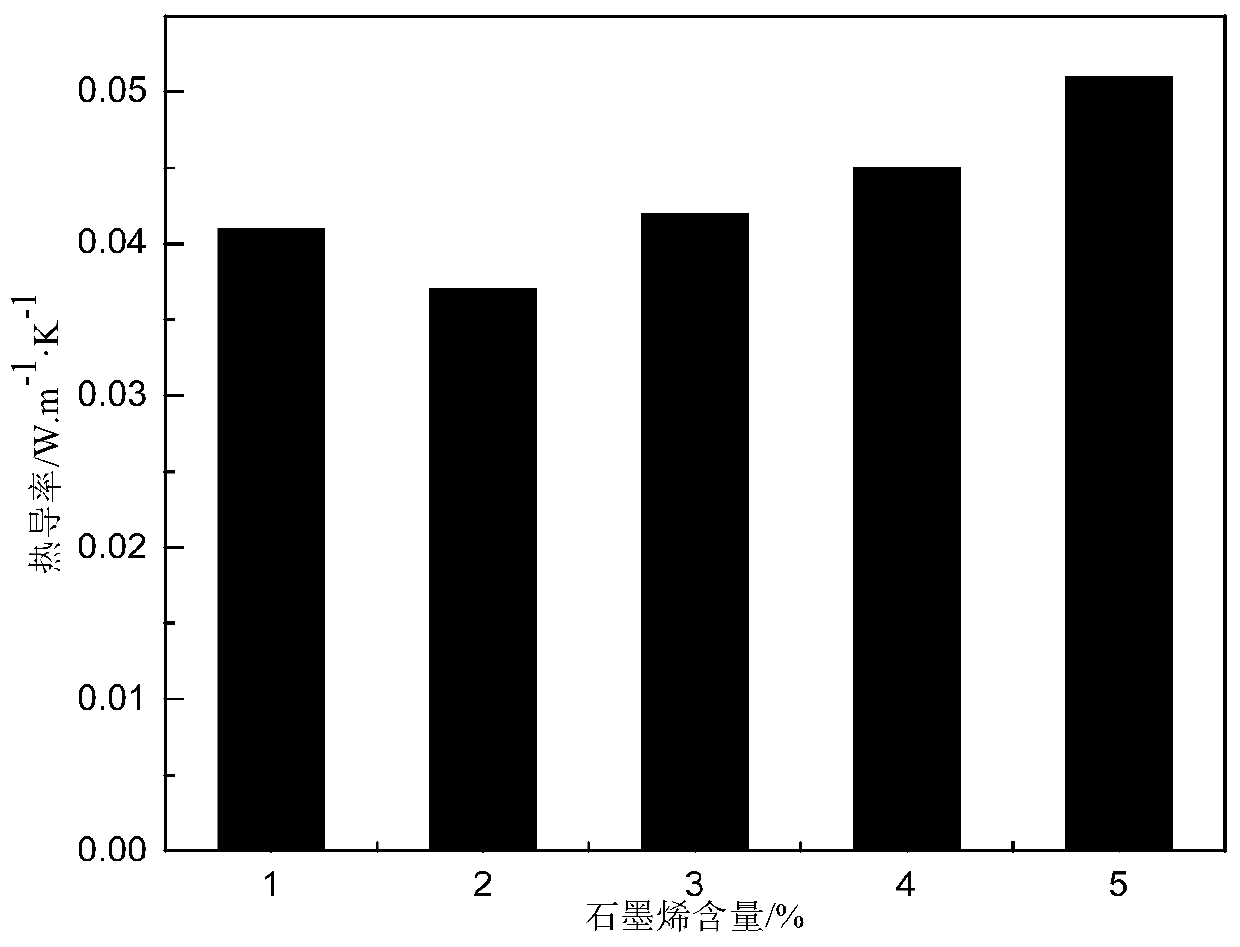

A silica and graphene technology, applied in graphene, ceramic products, other household appliances, etc., can solve the problems of poor mechanical properties and high brittleness of silica aerogel, and achieve good mechanical properties and good skeleton structure. , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] a. Synthesis of graphite oxide

[0034] In an ice-water bath, pour 21ml of 98% concentrated sulfuric acid into the flask, then pour 1g of natural graphite and 0.5g of sodium nitrate into a 250ml round-bottomed flask with ultrasonic stirring for 45min; magnetically stir for 30min, and weigh 3g of high Potassium manganate was slowly added to the flask, and stirring was continued for 45 minutes. Transfer the flask to another water bath, raise the temperature to 35°C, continue stirring for 30 minutes, measure 23ml of distilled water and slowly add it to the flask, then transfer to an oil bath at 98°C and continue stirring for 15 minutes, and finally add 140ml of distilled water and 20mL 30% hydrogen peroxide. The final mixture was bright yellow. The product was centrifuged and washed with 500 mL of 5% hydrochloric acid and distilled water until nearly neutral. The final product was dried in a vacuum oven at 60 °C for 24 h, and the obtained brown flake product was graphit...

Embodiment 2

[0048] a. Synthesis of graphite oxide

[0049] In an ice-water bath, pour 22ml of 98% concentrated sulfuric acid into the flask, then pour 1g of natural graphite and 0.5g of sodium nitrate into a 250ml round bottom flask and stir ultrasonically for 50min; stir magnetically for 45min, and weigh 3g of high Potassium manganate was slowly added to the flask, and stirring was continued for 60 minutes. Transfer the flask to another water bath, raise the temperature to 35°C, continue stirring for 35 minutes, measure 25ml of distilled water and slowly add it to the flask, then transfer to an oil bath at 98°C and continue stirring for 15 minutes, and finally add 140ml of distilled water and 20mL 30% hydrogen peroxide, the product was centrifuged and washed with 500mL 3% dilute hydrochloric acid and distilled water until nearly neutral. The final product was dried in a vacuum oven at 60 °C for 24 h, and the obtained brown flake product was graphite oxide GO.

[0050] b Preparation of ...

Embodiment 3

[0063] a. Synthesis of graphite oxide

[0064] In an ice-water bath, pour 21ml of 98% concentrated sulfuric acid into the flask, then pour 1g of natural graphite and 0.5g of sodium nitrate into a 250ml round-bottomed flask with ultrasonic stirring for 45min; magnetically stir for 30min, and weigh 3g of high Potassium manganate was slowly added to the flask, and the stirring was continued for 45min-60min. Transfer the flask to another water bath, raise the temperature to 35°C, continue stirring for 30 minutes, measure 23ml of distilled water and slowly add it to the flask, then transfer to an oil bath at 98°C and continue stirring for 15 minutes, and finally add 140ml of distilled water and 20mL of 30 % hydrogen peroxide. The final mixture was bright yellow. The product was centrifuged and washed with 500 mL of 5% hydrochloric acid and distilled water until nearly neutral. The final product was dried in a vacuum oven at 60 °C for 24 h, and the obtained brown flake product wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com