Squeezing and tearing cutter for sugarcane in sugar refinery, and manufacturing process thereof

A knife and sugarcane technology, applied in the direction of sugarcane tearing, etc., can solve the problems of increasing the distance between sugarcane knife and conveyor belt, poor durability of sugarcane knife, unstable pressing quality, etc., to achieve enhanced blade strength, excellent corrosion resistance Effect of oxidation performance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

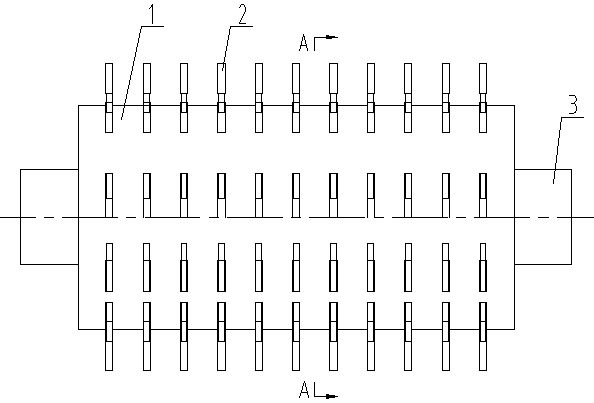

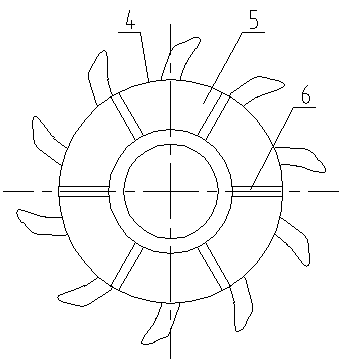

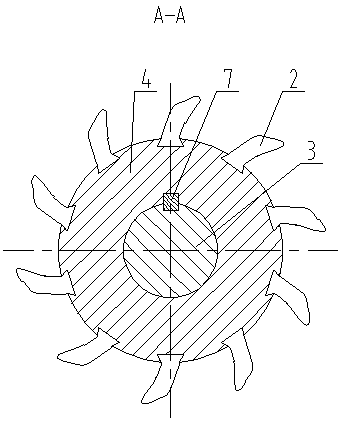

[0057] as attached Figure 1 to Figure 6 Shown, sugar factory sugarcane pressing tearing cutter of the present invention comprises cutter roll assembly 1, cutter 2, rotating shaft 3, rotating roller 4, cover 5, reinforcing rib 6, key 7, cutter head 8, cutter body 9, melting Cladding 10, main rake angle γ 1 , auxiliary rake angle γ 2 , main relief angle α 1 , auxiliary relief angle α 2 , Knife tip chamfer R 1 and sub relief corner rounding R 2 , the cutter roller assembly 1 is installed on the rotating shaft 3 through the key 7, 66 cutters 2 are installed on the surface of the cutter roller assembly 1, and the front and rear ends of the rotary roller 4 are provided with a cover 5, the seal Reinforcing ribs 6 are provided on each outer surface of the cover 5; the cutter 2 includes a cutter body 9 and a cutter head 8 arranged on the cutter body 9, and four layers of cladding are arranged on the outer surface of the cutter head 8 Layer 10, the cladding layer 10 adopts plasma...

Embodiment 2

[0073] as attached Figure 4 ~ Figure 8 Shown, sugar factory sugarcane pressing tearing cutter of the present invention comprises cutter roll assembly 1, cutter 2, rotating shaft 3, rotating roller 4, cover 5, reinforcing rib 6, key 7, cutter head 8, cutter body 9, melting Cladding 10, main rake angle γ 1 , auxiliary rake angle γ 2 , main relief angle α 1 , auxiliary relief angle α 2 , Knife tip chamfer R 1 and sub relief corner rounding R 2, the cutter roller assembly 1 is installed on the rotating shaft 3 through the key 7, 48 cutters 2 are installed on the surface of the cutter roller assembly 1, and the front and rear ends of the rotating roller 4 are provided with a cover 5, the seal Reinforcing ribs 6 are provided on each outer surface of the cover 5; the cutter 2 includes a cutter body 9 and a cutter head 8 arranged on the cutter body 9, and five layers of cladding are arranged on the outer surface of the cutter head 8 Layer 10, the cladding layer 10 adopts plasma...

Embodiment 3

[0089] as attached Figure 1 to Figure 6 Shown, sugar factory sugarcane pressing tearing cutter of the present invention comprises cutter roll assembly 1, cutter 2, rotating shaft 3, rotating roller 4, cover 5, reinforcing rib 6, key 7, cutter head 8, cutter body 9, melting Cladding 10, main rake angle γ 1 , auxiliary rake angle γ 2 , main relief angle α 1 , auxiliary relief angle α 2 , Knife tip chamfer R 1 and sub relief corner rounding R 2 , the cutter roller assembly 1 is installed on the rotating shaft 3 through the key 7, 66 cutters 2 are also installed on the surface of the cutter roller assembly 1, and the front and rear ends of the rotating roller 4 are provided with a cover 5, the seal Reinforcing ribs 6 are provided on each outer surface of the cover 5; the cutter 2 includes a cutter body 9 and a cutter head 8 arranged on the cutter body 9, and six layers of cladding are arranged on the outer surface of the cutter head 8 Layer 10, the cladding layer 10 adopts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com