White granulated sugar drying machine with self-cleaning function

A white sugar, self-cleaning technology, applied in the direction of sugar drying, cleaning methods using tools, dryers, etc., can solve the problems of easy blockage of bag filter and affecting the quality of sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

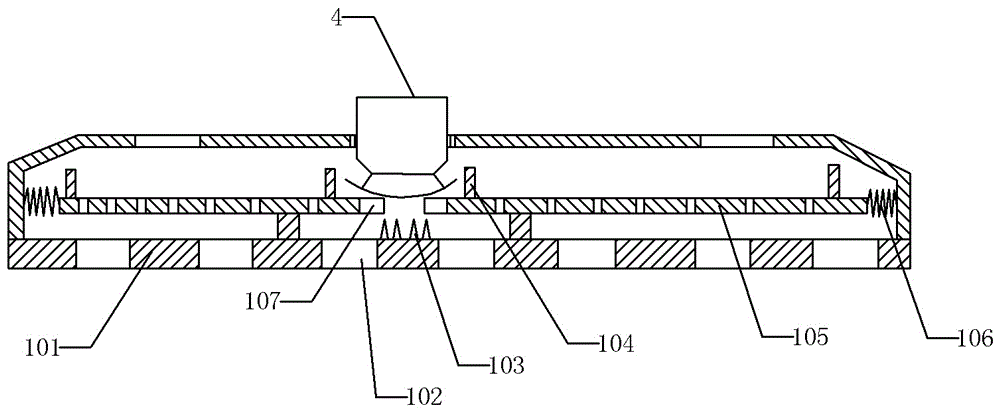

[0017] like figure 1 As shown, some structures in this embodiment are not in figure 1 As shown in , the white granulated sugar dryer with self-cleaning function of this embodiment includes a lower box and an upper box cover positioned at the upper part of the lower box and fastened with the lower box, and an air inlet is opened on the lower box, and the air inlet There are four, and the four air inlets are arranged on the same horizontal line, evenly arranged, and there is an air outlet on the upper box cover.

[0018] A vibrating plate 105 is arranged between the lower box body and the upper box cover. There are through holes for passing the wind on the vibrating plate 105, and the through holes are arranged in a matrix. The first vibrating motor is equipped with a material inlet and a material outlet on both sides of the upper box cover in the conveying direction.

[0019] An installation cylinder 4 is arranged in the air outlet, and the installation cylinder 4 is threaded...

Embodiment 2

[0031] The difference from Embodiment 1 is that in this embodiment, the installation cylinder is empty at the air outlet, and the gap between the installation cylinder and the air outlet is used to discharge exhaust gas. There is a retaining bar on the installation cylinder, an installation block on the upper part of the upper box cover, and an upper support block on the side of the installation block. The end of the support block is tapered, and the support block is elastic. When the installation cylinder is at a high position, the The retaining bar is supported on the upper support block to realize positioning.

[0032] The difference from the embodiment is that when the white sugar is dried, the airflow passing through the white sugar can be discharged from the gap between the installation cylinder and the air outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com