Cooling and drying equipment for white granulated sugar

A technology of cooling and drying white sugar, which is applied in sugar drying, sucrose production, sugar production, etc., can solve the problems of slow drying efficiency of white sugar, easy generation of dust, and large equipment volume, so as to achieve easy application and promotion, and reduce Dust, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

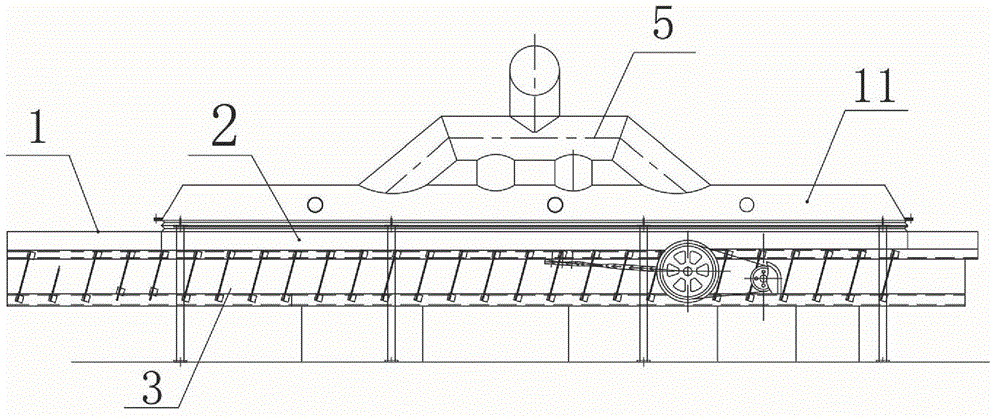

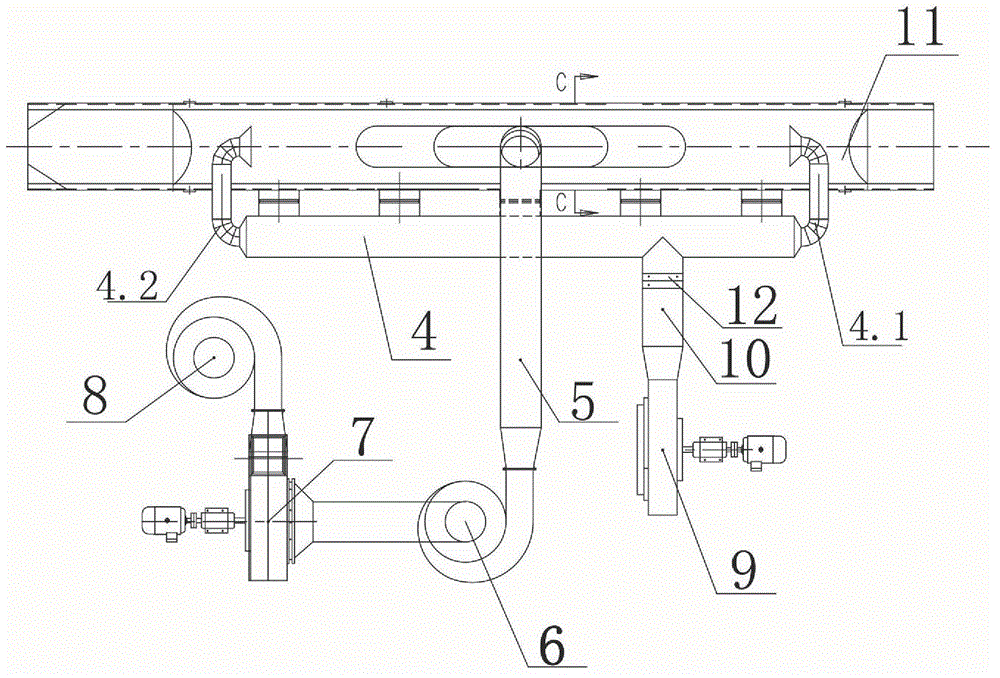

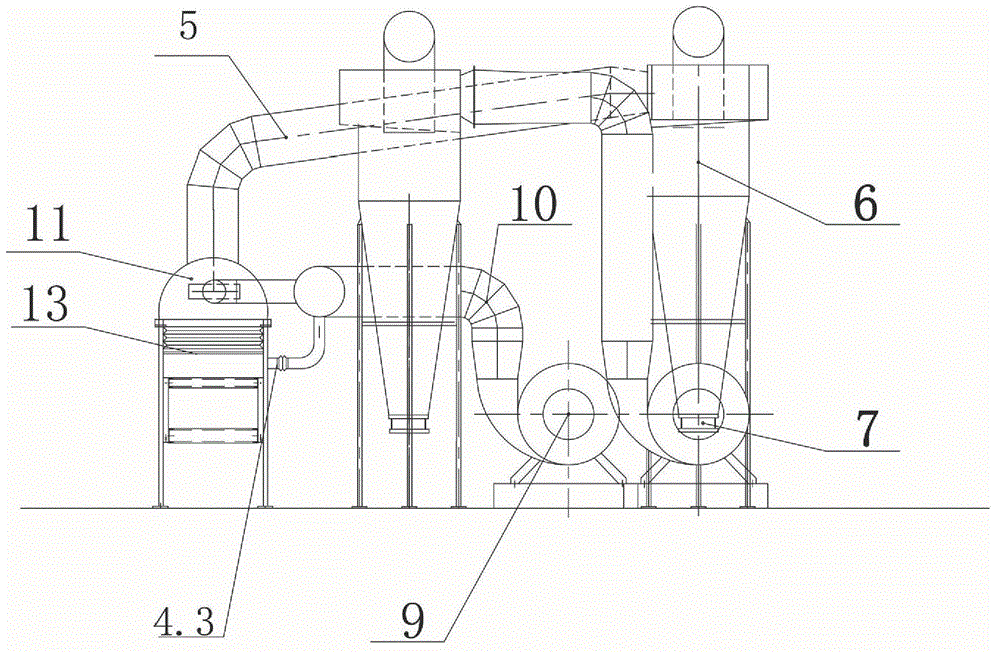

[0033]According to the above-mentioned position connection relationship, in the present embodiment, the aperture size of the upper screen is 0.3mm, the aperture of the lower screen is 4mm, and the upper screen and the lower screen are closely connected. During operation, start the equipment, conveyor belt 3 and The vibrating tank 2 starts to work, driving the white granulated sugar on the double-layer sieve to jump and drive, the blast pipe 10 blows the wind into the blast pipe 10, and after being filtered by the air filter 12, the wet and cold dry air flows from the air inlet 4.1 and the air inlet respectively. 4.2 blows into the upper cavity A1, and the air inlet 4.3 blows the wind into the lower cavity A2, the wet and cold dry air exchanges heat with the white sugar to form hot and humid air, and the exhaust fan 7 blows the hot and humid air from the air duct 5 Extraction makes the airflow formed between the blower system and the exhaust system, and the white granulated suga...

Embodiment 2

[0035] In this embodiment, the aperture size of the upper screen is 2.0mm, the aperture of the lower screen is 6mm, and the distance between the upper screen and the lower screen is 2cm, and the rest of the working principles are the same as in Embodiment 1.

Embodiment 3

[0037] In this embodiment, the aperture size of the upper screen is 1 mm, the aperture of the lower screen is 5 mm, and the distance between the upper screen and the lower screen is 4 cm, and the rest of the working principles are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com